Page 1

GAS 210 ECO PRO

High efficiency Low NOX gas boiler

Types:

210-80

210-120

210-160

210-200

English

EN

Technical

information

114494-04

Page 2

Table of contents

GAS 210 ECO PRO

Table of contents

Preface 6

1. EC declaration 7

2. Introduction 8

2.1 Pictograms used 8

2.2 Important instructions 8

3. Safety 9

4. Installation 10

4.1 Scope of delivery and installation 10

4.2 Dimensions 11

4.3 Installation and service clearances 12

5. Water-side connections 13

5.1.1 Condensed water discharge 13

5.1.2 Water treatment 13

5.1.3 Pressure relief valve 14

5.1.4 Circulation pump 14

5.1.5 Water flow 14

6. Gas-side connections 15

6.1 Gas connection 15

6.2 Gas pressure 15

6.3 Gas/air ratio control 15

7. Connecting the flue gas discharge and air supply 16

7.1 General 16

7.2 Conventional open flue installation 16

7.2.1 Possible lengths for the flue gas discharge pipe 17

7.3 Room sealed installation 18

7.3.1 Possible lengths for the air supply and flue gas discharge 18

7.3.2 Discharge in different pressure areas 20

7.3.3 Connection of flue gas discharge and choice of material 21

7.3.4 Air supply connection and choice of material 21

7.3.5 Additional Directives 21

8. Control and electrical connections 22

8.1 General 22

8.1.1 Boiler control 22

8.1.2 Modulating controls general 22

8.1.3 Modulating room control 22

8.1.4 Modulating weather-compensated control rematic® 22

8.1.5 Modulating cascade controller MC4 23

8.2 Electrical specifications 23

8.2.1 Mains voltage 23

8.2.2 Control box 23

8.2.3 Fuse ratings 24

8.3 Electrical connection options 24

8.3.1 Connection options of standard control unit (PCU-01) 24

8.3.2 On/off control (OT) 24

8.3.3 Modulating controls (OT) 24

8.3.4 External interlock (BL) 24

8.3.5 Input release (RL) 25

8.3.6 Circulation pump (Pump) 25

8.3.7Connecting a PC 25

2

114494-03

Page 3

GAS 210 ECO PRO

Table of contents

8.3.8 Connection options for the PCB - SCU - X01 25

8.4 Connection options for the optional 0 - 10 V control PCB (IF-01) 26

8.4.1 Connection status (Nc) 26

8.4.2 OTm connection 26

8.4.3 Analogue input (0 - 10 V) 27

8.4.4 Analogue output (0 - 10 V) 27

8.5 Connection options of the optional expanded control/protection PCB (SCU-S01) 28

8.5.1 Flue gas damper control (FgV) 28

8.5.2 Hydraulic valve control (HdV) 28

8.5.3 External gas valve control (EgV) 28

8.5.4 Operation signal and failure signal (Nc / No) 28

8.5.5 Water pressure sensor (Wps) 28

8.5.6 Outside temperature sensor (Tout) 29

8.5.7 Minimum gas pressure switch (Gps) 29

8.5.8 Gas leakage control (VPS; only for 210- 160 and 210- 200 boilers) 29

8.5.9 Wiring diagram 30

9 Commissioning 31

9.1 Control panel 31

9.1.1 Normal start-up procedure 31

9.1.2 Fault during start-up procedure 32

9.1.3 Reading current values 33

9.1.3.1 Status and sub status 34

9.1.4 Adjusting the boiler to the system 34

9.1.5 Changing parameters at user level (without access code) 35

9.1.6 Changing parameters at service level (with access code) 35

9.1.7 Resetting factory settings 38

9.1.8 Setting manual operation ( symbol) 39

9.2 Commissioning 39

9.3 Taking the boiler out of operation 42

9.3.1 Boiler with frost protection, out of operation for a long time 42

9.3.2 Boiler without frost protection, out of operation for a long time 42

10. Inspection and maintenance 43

10.1 General 43

10.2 Combustion check of the boiler 43

10.2.1 Corrective maintenance 43

10.2.2 Cleaning the fan 44

10.2.3 Cleaning the heat exchanger (flue gas side) 46

10.2.4 Cleaning the burner 47

10.3 Cleaning the trap 48

10.4 Checking the ignition electrode 48

10.5 Checking for leaks 48

10.6 Checking water pressure 48

10.7 Putting boiler back into operation 48

11. Control stops and faults 49

11.1 General 49

11.2 Control stops and faults 49

11.3 Control stop codes 49

11.4 Fault codes 51

11.5 Control stop - and fault memory 54

11.5.1 Reading faults 55

11.5.2 Deleting control stops or faults 55

114494-03

3

Page 4

Table of contents

GAS 210 ECO PRO

12. Service parts 56

12.1 General 56

12.2 Exploded view 57

13. Regulations 58

13.1 General 58

13.2 Standards 58

13.3 Remeha factory test 58

13.4 Supplementary guidelines 59

14. Technical specifications 60

14.1 Technical data 60

15. Efficiency data and gas inspection labels 61

15.1 Unit usable efficiency (HR efficiency) 61

15.2 Water-side efficiency 61

15.3 Zero-load losses 61

15.4 Description of specifications 61

15.5 Accessories 62

15.6 Services 62

15.7 Type of unit 63

15.8 Operating principle 64

15.9 Boiler Control 64

15.9.1 Temperature control 64

15.9.2 Low water level protection 64

15.9.3 Maximum protection 65

15.9.4 Frost protection 65

16. Application data 66

16.1 General 66

16.2 Air and flue gas application options 66

16.3 Hydraulic application options 66

16.4 Cascade application 66

16.5 Control options 69

16.6 Gas application options 69

17. Checklists (records) 70

17.1 Checklist for commissioning (Commissioning record) 70

17.2 Checklist for annual inspection (inspection record) 70

17.3 Checklist for maintenance (maintenance record) 71

4

114494-03

Page 5

GAS 210 ECO PRO

Table of contents

114494-03

5

Page 6

Preface

Preface

GAS 210 ECO PRO

PREFACE

This technical information , which contains a lot of practical information about the Remeha Gas 210 ECO PRO, a High efficiency

central heating unit, is mainly intended for installers. It contains

important instructions for safe and trouble-free operation of the

boiler before commissioning and during operation.

Read these instructions carefully before putting the boiler into

operation, familiarise yourself with its control functions, operation

and strictly observe the instructions given. Failure to do so may

invalidate warranty or prevent the boiler from operating. The boiler

is available in the following types:

- Gas 210 ECO PRO 80 (3 sections; 87 kW)

- Gas 210 ECO PRO 120 (4 sections; 120 kW)

- Gas 210 ECO PRO 160 (5 sections; 166 kW)

- Gas 210 ECO PRO 200 (6 sections; 200 kW)

The installation, commissioning, inspection and servicing of the

boiler must be carried out by a competent Corgi registered engineer who holds valid A.C.S. certification and in accordance with

current gas safety (installation and use) regulations, the building

regulations and all other relevant codes of practice.

All electrical work must be carried out by a competent engineer

and to be installed in accordance with the current IEE regulations.

If you have any questions, require an engineer to call on site, or if

you need more information about specific subjects relating to this

boiler, or it's installation please do not hesitate to contact our technical help line 0118 978 3434.

When contacting Broag with a problem on the boiler, please have

available the boiler type, Serial No (located on the bottom of the

casing), and the symptoms or fault code (the fault code is a series

of flashing digits in the display panel).

The data published in these technical instructions is based on the

latest information (at date of publication) and may be subject to

revisions.

We reserve the right to continuous development in both design

and manufacture, therefore any changes to the materials or technology employed may not be retrospective nor may we be obliged

to adjust earlier supplies accordingly.

6

114494-03

Page 7

GAS 210 ECO PRO

1. EC declaration

EC - DECLARATION OF CONFORMITY

Manufacturer : Remeha B.V.

Address : Kanaal Zuid 110

City, Country : Postbus 32, NL-7300 AA Apeldoorn, Holland

- this is to declare that the following product(s) : Remeha Gas 210 ECO PRO

is/are in conformity with the following EEC-directives:

EEC- Directive: 90/396/EEC tested and examined to the following norms:

EN 656 A1

15240

92/42/EEC

73/23/EEC DIN EN 50165

DIN EN 60335-1

, EN 15417

(2006)

(2006)

(2006)

, EN 50165

(2001)

, EN 60335-1

(2003)

(1997 + A1: 2001)

07

(2002)

1. EC declaration

89/336/EEC EN 55014-1

EN 61000-3-2

(2000+A1:2001)

(2000+A2:2005)

97/23/EEC (article 3, sub 3)

Apeldoorn, aug. 2007

W.F. Tijhuis

Approval manager

, 55014-2

, 61000-3-3

(1997+A1:2001)

(1995+A1:2001)

114494-03

7

Page 8

2. Introduction

2. Introduction

2.1 Pictograms used

2.2 Important instructions

GAS 210 ECO PRO

The following pictograms are used in this document to emphasise

certain instructions. This is in order to increase your personal

safety and to safeguard the technical reliability of the boiler. The

pictograms used are:

Useful advice.

Important instruction for carrying out an action.

Possible risk of bodily injury or material damage to boiler,

building or environment.

Possible risk of electrical shocks. Serious bodily injury may

occur.

The boiler must be installed in a frost-free area.

Work on the boiler

Installation, commissioning, maintenance and repair work may

only be carried out by suitably qualified specialist installers in

accordance with the applicable national and local standards and

guidelines.Always disconnect the mains supply and close the main

gas cock when working on the boiler. Check the entire system for

leaks after maintenance and servicing work.

Casing panels may only be removed for maintenance and servicing purposes. Refit all panels on completion of maintenance and

servicing work.

Instruction and warning labels on the boiler must never be

removed or covered and must be clearly legible throughout the

entire service life of the boiler. Replace damaged or illegible

instruction and warning labels immediately. Generally applicable

safety instructions related to accident prevention must be consulted in addition to the information supplied in this technical documentation.

Boiler modifications

Modifications to the boiler require the written approval of Broag.

Keep this document near to the installation.

8

114494-03

Page 9

GAS 210 ECO PRO

3. Safety

3. Safety

Adhere strictly to the specific safety instructions.

Can you smell gas? Proceed as follows:

• do not smoke and avoid fire and sparks

• do not operate electrical switches.

• close the gas cock.

• open doors and windows.

• trace possible leaks and seal them off.

• if the leak is upstream of the gas meter, notify National Gas

Emergency Service tel: 0800 1110999.

Can you smell flue or combustion gases? Proceed as follows:

• isolate the mains power supply from the boiler.

• open doors and windows.

• trace possible leaks and seal them off.

114494-03

9

Page 10

4. Installation

4. Installation

4.1 Scope of delivery and installation

The boiler is supplied fully assembled and protected. The boiler

is placed on a pallet (70 x 130 cm, 145 cm high), which can be

transported with a pallet truck, hand truck, forklift truck or 4-wheel

transport boards. The packaging passes through all standard

doors (minimum width of 74.5 cm).

The boiler is installed as follows:

- Position the pallet with the boiler in the boiler room;

- Remove the fixing bands and all other packaging (some

components are packaged in the polystyrene cap);

- Lift the boiler from the pallet;

- Slide the boiler into the required position, using the recessed

handles in the boiler base;

- Cover the boiler and do not operate it whilst dust creating

construction processes or insulation to the pipe work etc. are

carried out in the plant room.

GAS 210 ECO PRO

10

114494-03

Page 11

GAS 210 ECO PRO

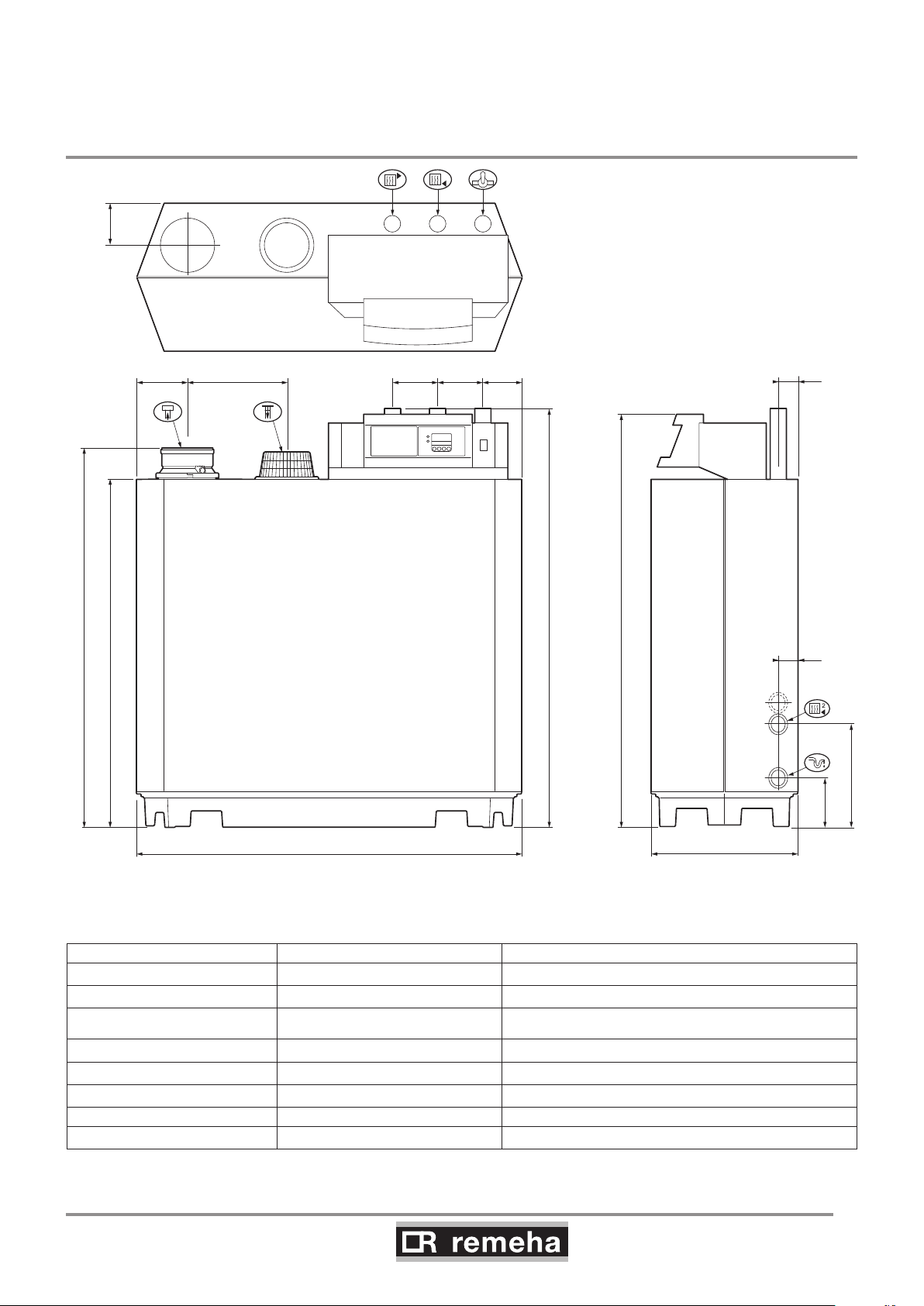

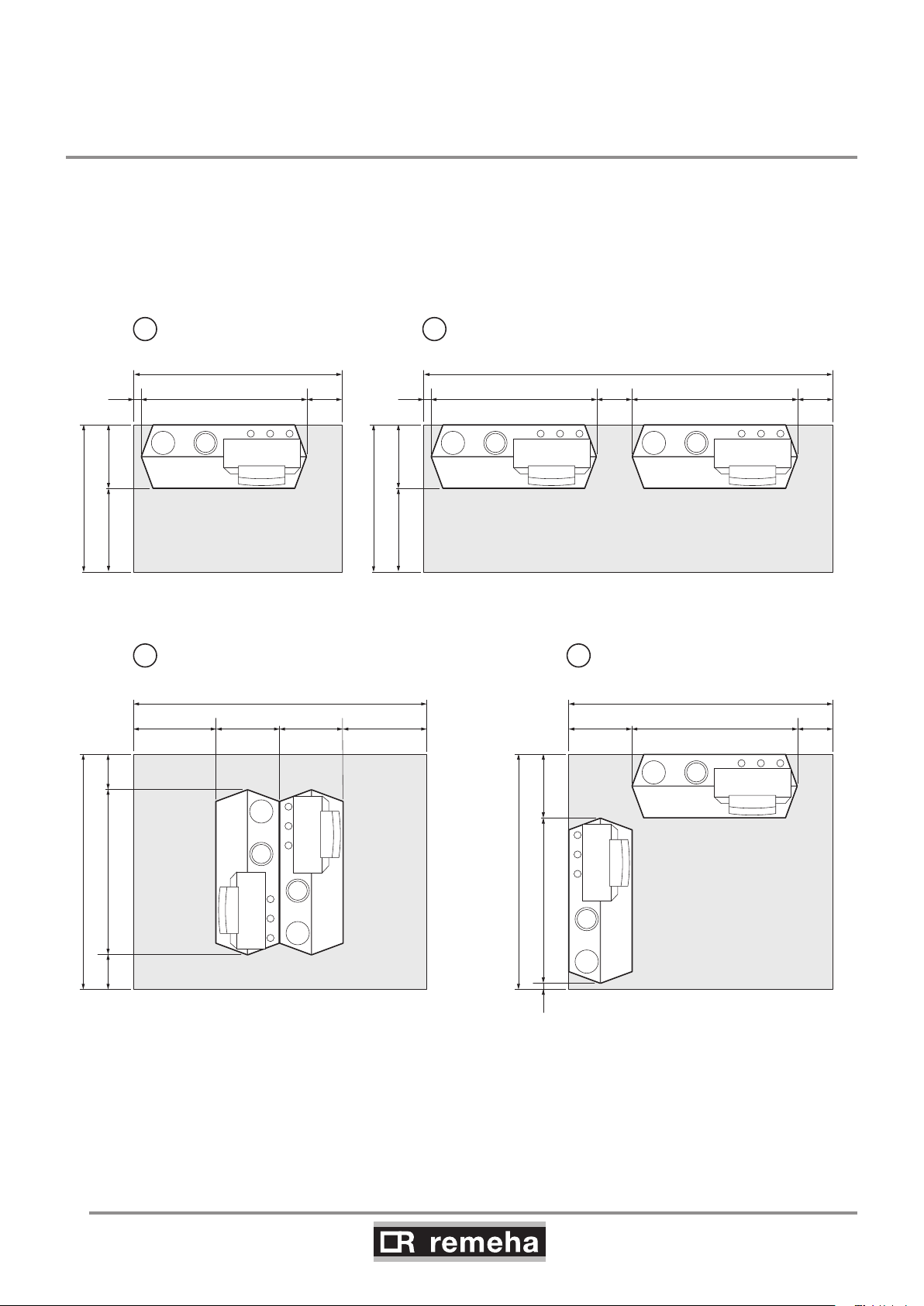

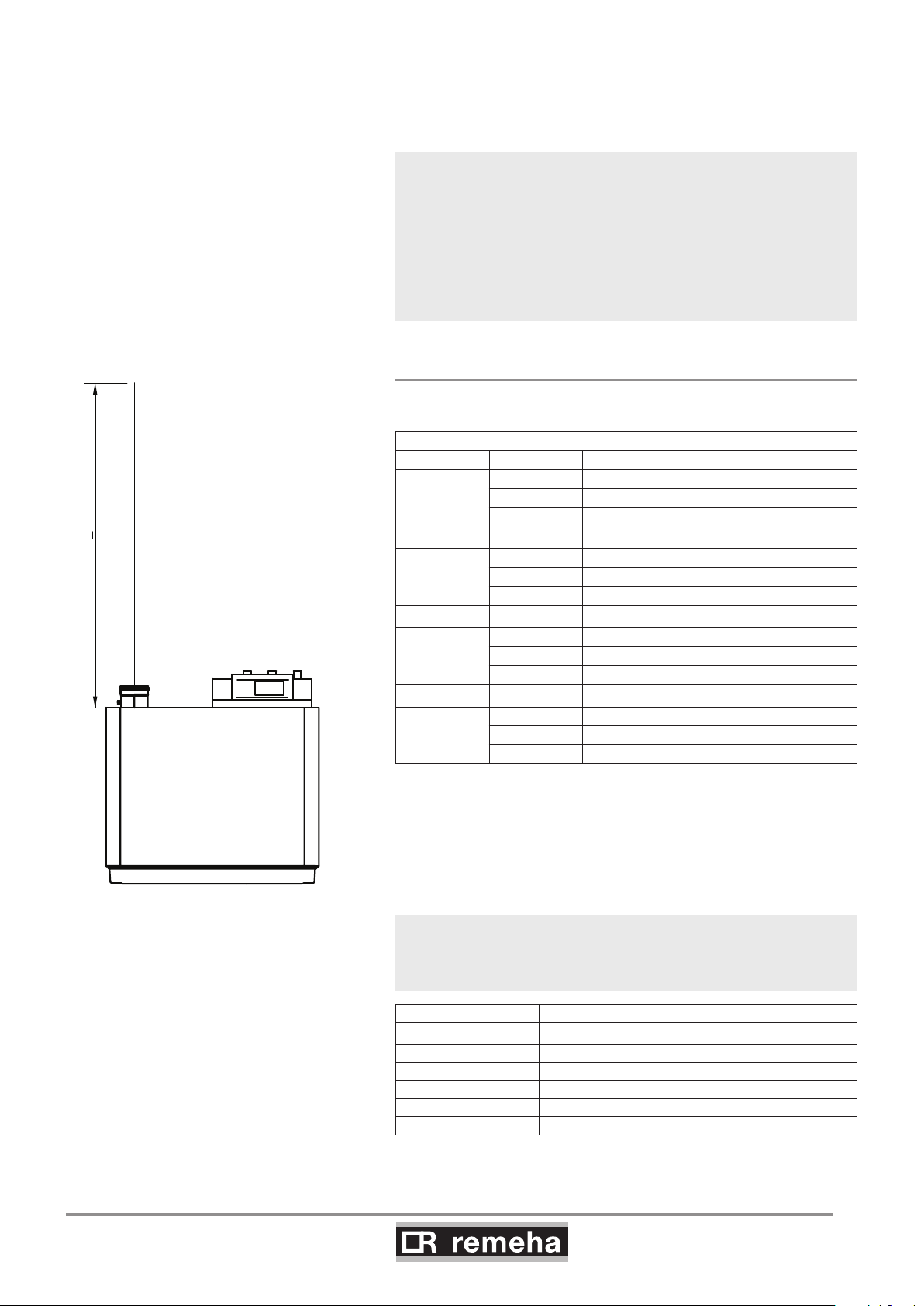

4.2 Dimensions

4. Installation

1200

1070 125

305160 140140 121

61

A

1272

61

316

152

1190

fig. 01 Elevation drawings

Connection Gas 210 ECO PRO 80/120/160 Gas 210 ECO PRO 200

É Flow

Ê Return

Gas connection

Ò Condensate drain

Ð Combustion air supply

Ñ Flue gas outlet

1¼” male thread 1½” male thread (fit supplied adapter 1¼” > 1½”)

1¼” male thread 1½” male thread (fit supplied adapter 1¼” > 1½”)

1¼” male thread 1¼” male thread

Ø 32 mm external Ø 32 mm external

Ø 150 mm Ø 150 mm

Ø 150 mm Ø 150 mm

Dimension “A” 1309 mm 1324 mm

Ì Second return (option)

1¼” male thread 1¼” male thread

114494-03

450

114492LTAL21H001b

11

Page 12

4. Installation

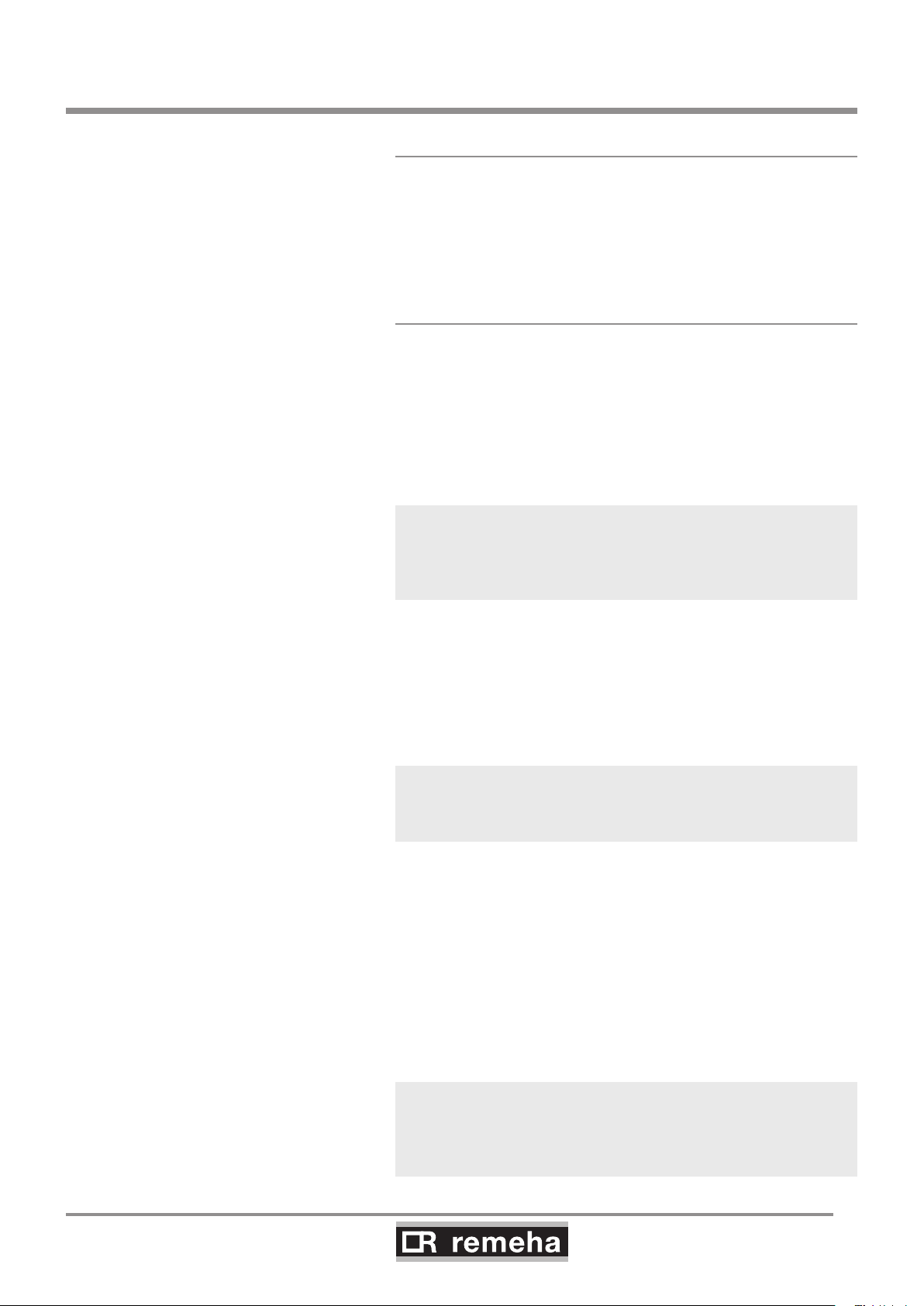

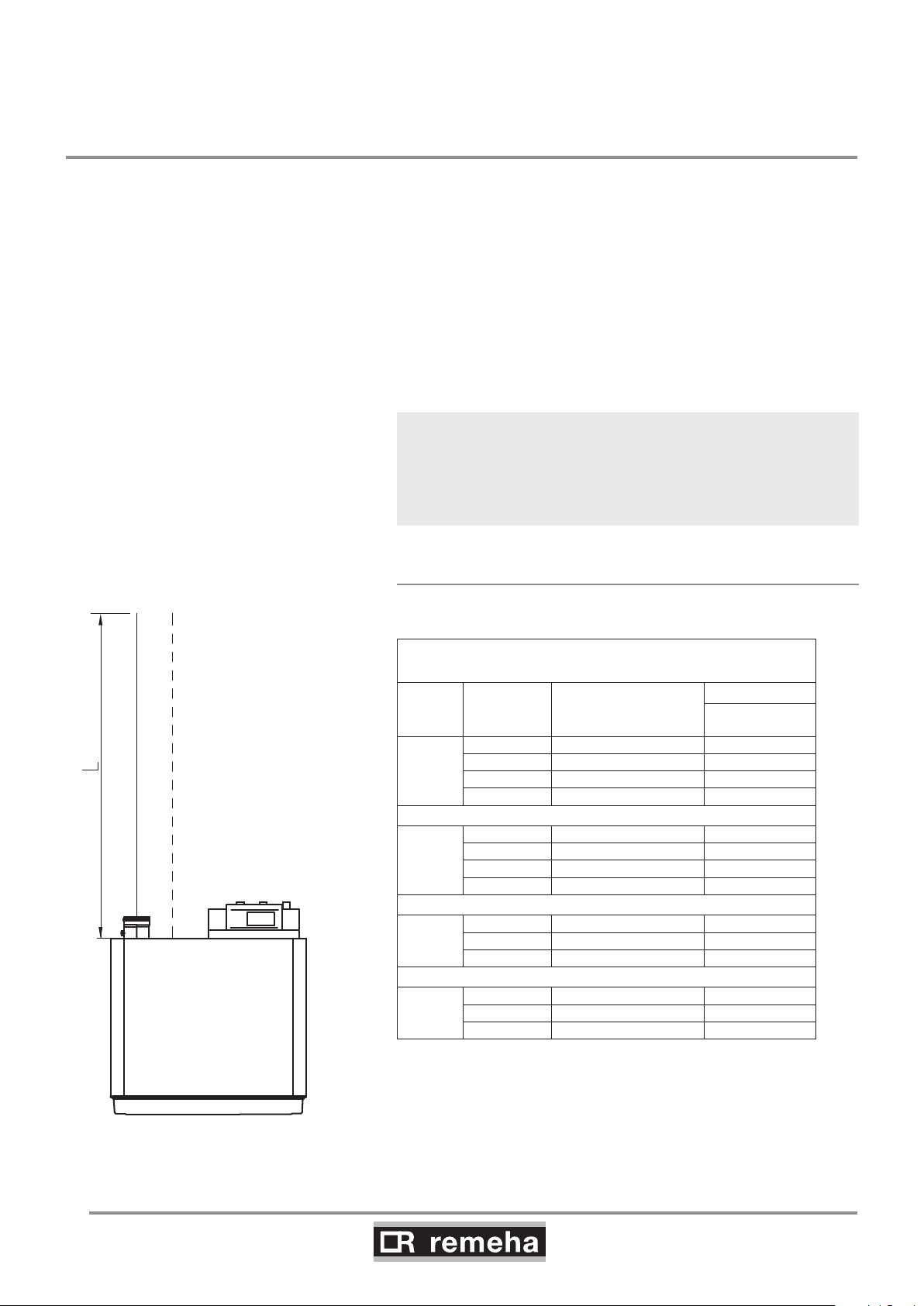

4.3 Installation and service clearances

Clearance of at least 60 cm is required at the front of the boiler.

However, we recommend a clearance of 1 m. We recommend a

clearance of at least 40 cm above the boiler control panel, at least

5 cm on the left side and at least 25 cm on the right side in connection with condensed water discharge. Install a gas cock in the

immediate vicinity of/above the boiler.

GAS 210 ECO PRO

1050

1

1490

250119050

450600

1050

2

450600

3 4

2100

600450 450600

2930

250119050 2501190

1890

2501190450

1690

1190

250 250

fig. 02 Boiler room installation options

12

4501190

1690

50

114492LTAL21H002a

114494-03

Page 13

GAS 210 ECO PRO

5. Water-side connections

5.1.1 Condensed water discharge

Discharge the condensed water directly into a foul water drain. In

view of the acidity level of condensate (pH between 3 and 5), only

use plastic material for the discharge pipe. After assembly, fill the

trap with clean water. Make an open connection with the drain. The

discharge pipe must slope down by at least 30 mm/m. Condensed

water must not be discharged into gutters or rain water down pipes.

5.1.2 Water treatment

• Use untreated tap water only to fill the CH system.

• The pH value of the system water must be between 7 and 9.

• Where inhibitors are being used, please refer to Broag recom-

mendations in this section and follow the manufactures instructions given.

If used correctly water treatment can improve the boilers efficiency

and increase the anticipated life expectancy of the boiler.

5. Water-side connections

For further information a special document “Remeha water quality

regulations” is available from Broag. The regulations mentioned in

this document must be followed.

As most systems contain a variety of metals, it is considered good

practice to provide some form of water treatment in order to prevent or reduce the following:

• Metallic corrosion

• Formation of scale and sludge

• Microbiological contamination

• Chemical changes in the untreated system water

All scale deposits, however small, will reduce the efficiency of the

boiler and should be prevented.

Suitable chemicals and their use should be discussed with a specialist water treatment company prior to carrying out any work

(environmental aspects, health aspects). The specification of the

system and manufacturers recommendations must be taken into

account, along with the age and condition of the system. New systems should be flushed thoroughly to BS 7593(1992) to remove

all traces of flux, debris, grease and metal swarf generated during installation. Care to be taken with old systems to ensure any

black metallic iron oxide sludge and other corrosive residues are

removed, again by power flushing, ensuring that the system is

drained completely from all low points.

114494-03

Please ensure that the new boiler plant is not in circuit when the

flushing takes place, especially if cleansing chemicals are used to

assist the process.

13

Page 14

5. Water-side connections

GAS 210 ECO PRO

It is important to check the inhibitor concentration after installation, system modifications, filling the system and every service in

accordance with these instructions.

For the correct dosage and the suitability of inhibitors for use with

our boilers and for further information on water treatment or system cleaning we advise direct contact with either of the following

companies:

‘Copal®’ manufactured by:

Fernox, Cookson Electronics

Forsyth Road

Sheerwater

Woking

Surrey GU21 5RZ

Tel No: 01483 793200

Fax No: 01483 793201

Email: sales@fernox.com

Website: www.fernox.com

or:

Sentinal ‘X100®’ manufactured by:

Sentinel Performance Solutions

The Heath Business & Technical

Park

Runcorn

Cheshire,

WA7 4QX

Tel No: 0800 389 4670

Fax No: 0800 389 4677

Email: info.uk@sentinel-solutions.net

Website: www.sentinel-solutions.net

5.1.3 Pressure relief valve

Install an pressure relief valve in the system, in accordance with

NEN 3028, between any valves and the boiler and in the flow pipe

within 0.5 m of the boiler.

5.1.4 Circulation pump

The boiler is equipped with a pump switch to connect an external

circulation pump. This pump is run once every 24 hours to prevent

sticking (24 hour pump operation). Only on/off pumps can be controlled. For connections, see Section 8.3.6.

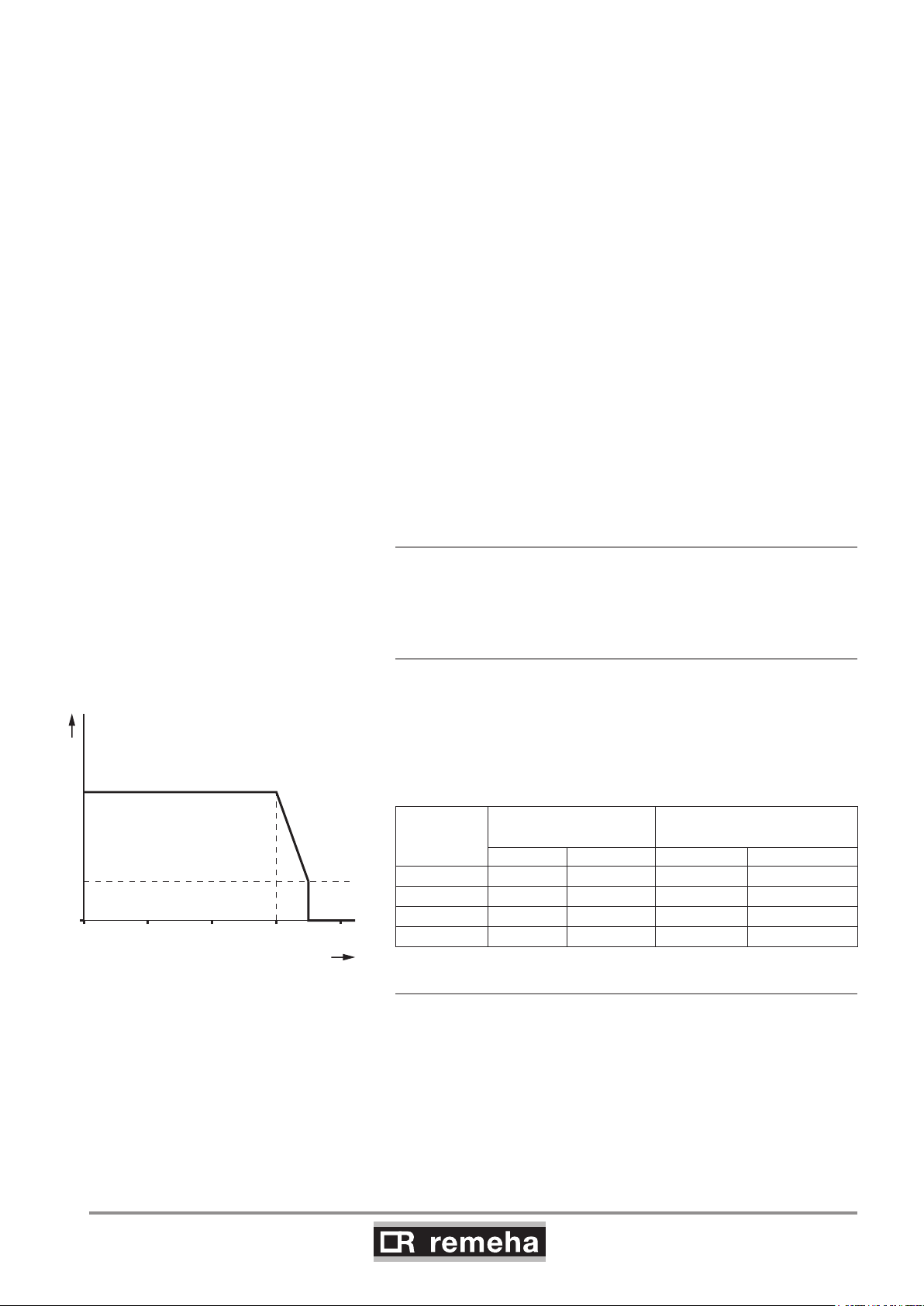

P (%)

V

D

0 10 20 30 40

35

∆T (°C)

114492LTAL21H031

fig. 03 Output control characteristic

V = full load P = heat output

D = part load ∆T = temperature difference

14

The hydraulic resistance for the various output options of the

boiler is as follows:

Boiler type

210-80

210-120

210-160

210-200

Hydraulic resistance at

a dT of 20°C

mbar kPa mbar kPa

165 16,5 545 54,5

135 13,5 446 44,6

170 17,0 562 56,2

180 18,0 595 59,5

Hydraulic resistance at a dT

of 10°C

5.1.5 Water flow

The maximum temperature difference between flow and return,

and the maximum rate of rise of the flow temperature and boiler

block temperature are limited by the boiler's modulating controls.

As a result, the boiler is virtually unaffected by low water flow.

However for a continuous supply of heat, the boiler requires a

minimum flow of 30 % of the nominal flow at the relevant design

temperatures.

114494-03

Page 15

GAS 210 ECO PRO

114492LTAL21H003a

6. Gas-side connections

6.1 Gas connection

The boiler is suitable for use with natural gas and propane* category II

department. All gas appliances must, by law, be installed by competent persons (e.g. Corgi). Failure to install appliances correctly

could lead to prosecution. It is in your own interest and that of

safety to ensure that the law is complied with.

The gas connection is at the top of the boiler. We recommend

installing a gas filter in the gas supply pipe to avoid pollution of the

gas multiblock. The gas filter's resistance must not be so high that

the minimum inlet gas pressure can no longer be achieved.

* Refer to Broag for using propane.

6.2 Gas pressure

6. Gas-side connections

. For other types of natural gas, consult our Technical

2H3P

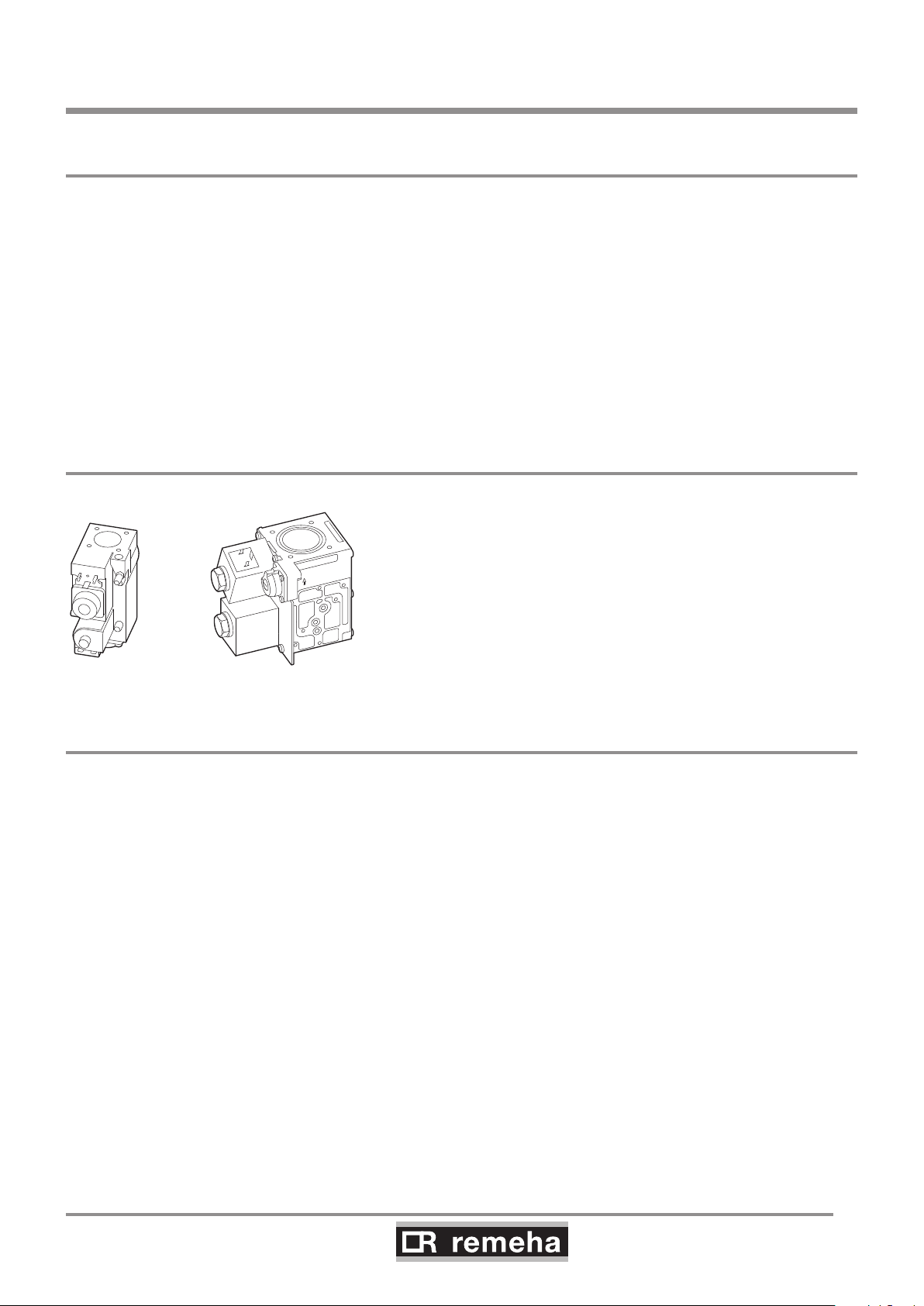

5+6 L3+4 L

fig. 04 Gas multiblocks

6.3 Gas/air ratio control

The boiler has been factory set and tested by Remeha to natural

gas (G20) - with an inlet pressure of 17 mbar.

The boiler is suitable for 17 - 30 mbar inlet gas pressure.

For propane (LPG), an inlet pressure of 37 - 50 mbar is required.

The boiler has a zero governor gas valve. This gas valve maintains the ratio between the gas and air quantities in the burner at

a constant level under variable loads. This ensures clean and reliable combustion and high efficiency across the entire load range.

114494-03

15

Page 16

7. Connecting the flue gas discharge and air supply

GAS 210 ECO PRO

7. Connecting the flue gas discharge and air supply

7.1 General

The Remeha Gas 210 PRO is suitable for conventional room ventilated or room sealed operation. Specify at the time of ordering if

the boiler is to be supplied for room sealed operation. In that case,

the boiler will be supplied with a purpose-designed room sealed

terminal, air supply connection and some accessories. The air

supply connection should rest on the heat exchanger underneath

the boiler casing after removing the standard perforated air inlet

cover. Horizontal components in the flue gas discharge system

should slope towards the boiler. Horizontal components in the air

supply system should slope towards the supply opening.

Room sealed terminals should comply with the national requirements for both horizontal and vertical outlet constructions.

Care should be taken when siting flue exit positions as a vapour

plume will be visible when the boiler is operational (flue gas temperature will be less than 80°C resulting in the water vapour condensing out on contact with the air).

Classification due to discharging flue gases

The boiler is approved according to CE with classification:

Type B23: Conventional room ventilated appliance without draft

diverter. Air supply from boiler room; flue gas discharge on roof.

Type B23P: Conventional room ventilated boiler without draft

diverter. Air supply from boiler room: flue gas discharge on roof,

metal flue gas discharge with CE symbol, meets pressure class P1.

Type C13: Room sealed boiler, connected to combined wall outlet.

Type C33: Room sealed appliance, connected to combined roof

outlet.

Type C43: Room sealed appliance in cascade configuration, connected via two ducts to a common duct system serving more than

one appliance.

Type C53: Room sealed appliance, connected to separate ducts

for the air supply and flue gas discharge, terminated in zones of

different pressure.

Type C63: Room sealed appliance, supplied without the terminal

or the air supply and flue gas discharge ducts.

Type C83: Room sealed appliance, connected to separate air

supply and flue gas discharge duct, with flue gas discharge duct

always in underpressure.

7.2 Conventional open flue installation

The open flue version extracts the necessary combustion air from

the plant room or compartment. A table showing the maximum discharge lengths can be found in Section 7.2.1.

16

114494-03

Page 17

GAS 210 ECO PRO

7. Connecting the flue gas discharge and air supply

• The air supply opening must stay open.

• The installation area or boiler room must be equipped with the

necessary combustion air supply openings. These openings

must not be obstructed or shut off.

• The combustion air supply must be free of dust and chemically-

aggressive agents (such as trichloroethylene or halogenated

hydrocarbons), as used in aerosol cans, certain types of

adhesive, certain solvents and cleaning agents, and paint, etc.

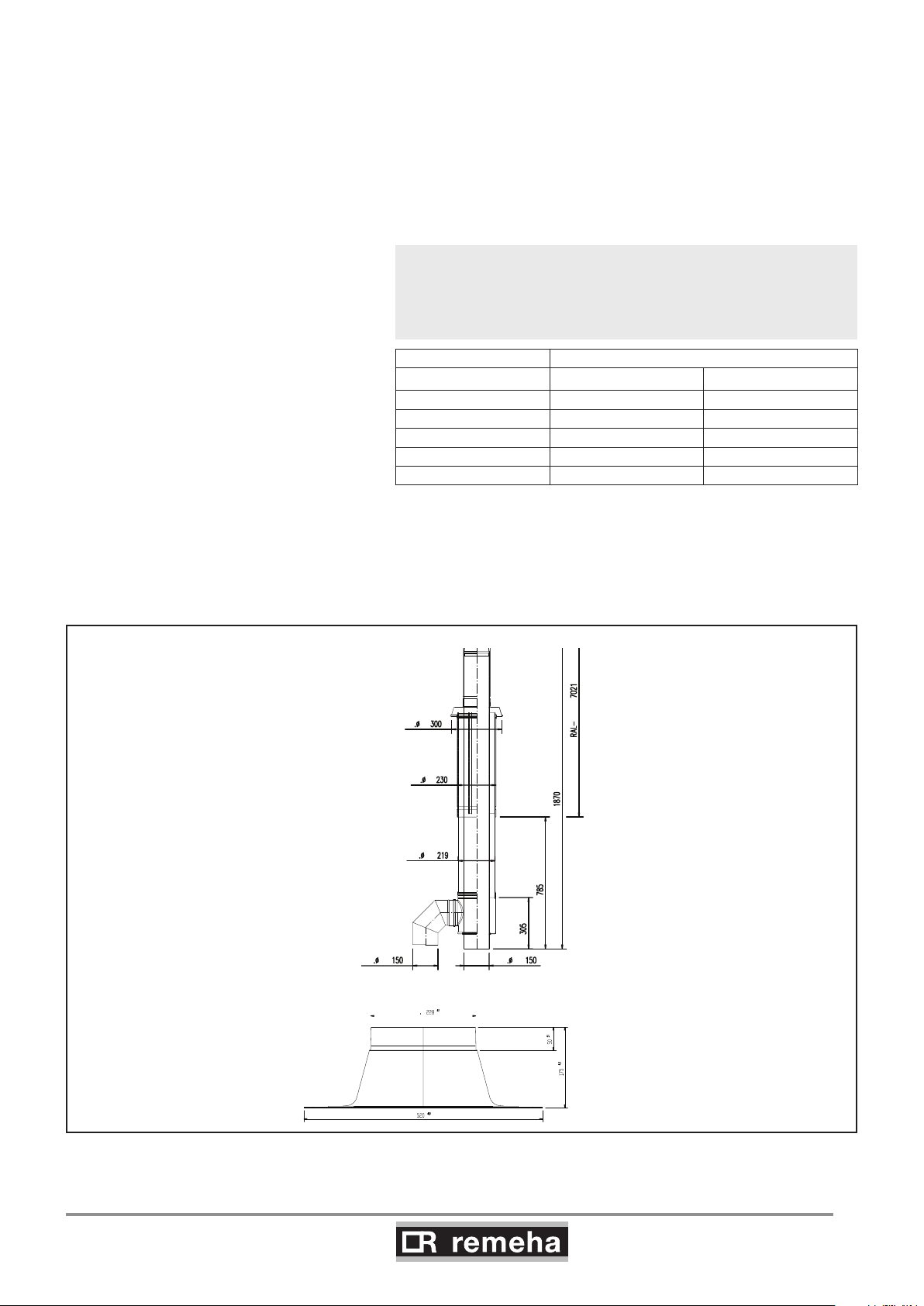

7.2.1 Possible lengths for the flue gas discharge pipe

Conventional room ventilated, type B23 according to CE.

Maximum permitted flue gas discharge lengths (L) in m

Boiler type D (mm) Free discharge

100 18

210-80

110 35

130 +

fig. 05 Piping for the conventional room ventilated

110 20

210-120

210-160

210-200

130 48

150 +

130 22

150 45

180 +

130 14

150 31

180 +

table 01 Flue gas discharge table for the open version

+ = Lengths up to 50m possible. For longer lengths, consult our

Technical department

When flue gas discharge pipes with diameters other than 150 mm

are used, an adapter is required: Ø150/100mm, Ø150/110mm,

Ø150/130mm or Ø150/180mm.

For each additional 90° or 45° bend, the pipe length must be

reduced by the amount shown in table 02.

114494-03

D in mm length in m

90° bend 45° bend

Ø 100 R=½D 4.9 1.4

Ø 110 R=½D 5.4 5.1

Ø 130 R=D 1.8 1.0

Ø 150 R=D 2.1 1.2

Ø 180 R=D 2.5 1.4

table 02 Metres to be deducted per bend

17

Page 18

7. Connecting the flue gas discharge and air supply

7.3 Room sealed installation

GAS 210 ECO PRO

The room sealed installation is based on the use of an air supply

pipe connected directly to the boiler. This increases the number of

installation options within a building, while the discharge location is

subject to less stringent requirements because the air supply and

flue gas discharge can be incorporated in the same pressure field.

Additional ventilation will be required to the room/compartment in

accordance with BS 6644-2005 (compartment ventilation).

In addition, air from outside is usually cleaner, which has a beneficial effect on the boiler service life. An air supply and flue gas

discharge table for the enclosed version of the boiler can be found

in table 03. For discharge in two different pressure fields, see Section 7.3.2.

The boilers can be installed on a flue dilution system, but must

have a total flue break to avoid boiler controls being affected

by the flue dilution fan pressures. For full details please contact

Broag.

7.3.1 Possible lengths for the air supply and flue

gas discharge

Room sealed appliance, type C33 according to CE.

Maximum acceptable flue gas discharge/air supply pipe

lengths (L) in m

Boiler

Model

210-80

210-120

210-160

210-200

Pipe Ø D

(mm)

100 100 8

130 130 +

130 150 +

150 150 +

100 100 3

130 130 22

130 150 25

150 150 +

130 150 11

150 150 22

180 150

130 130 4

150 150 13

180 150 +

table 03 Air supply and flue gas discharge table for the

enclosed version

Calculated with

concentric roof feed-

through D

nominal

(mm)

[m]

+

0021H7900017

fig. 06 Piping for the room sealed appliance

18

+ = Lengths up to 30m possible. For longer lengths, consult

our Technical department

114494-03

Page 19

GAS 210 ECO PRO

7. Connecting the flue gas discharge and air supply

When air supply and flue gas discharge pipes with diameters other

than 150 mm are used, adapters are required: Ø150/100mm,

Ø150/110mm, Ø150/130mm or Ø150/180mm and, for connection to our standard combined vertical roof feed-through sets, also

Ø180/150mm, Ø130/150mm or Ø110/150mm.

For each additional 90° or 45° bend, the pipe length must be

reduced by the amount shown in table 04.

D in mm length in m

90° bend 45° bend

Ø 100 R=½D 4.9 1.4

Ø 110 R=½D 5.4 5.1

Ø 130 R=D 1.8 1.0

Ø 150 R=D 2.1 1.2

Ø 180 R=D 2.5 1.4

table 04 Metres to be deducted per bend

For enclosed versions, combined vertical roof feed-through sets

are available, as well as sealing plates for flat roofs, in accordance

with the following drawings. Please consult our Technical department for this option.

Int

Int

Ext

Ext

Ext

Epo y l y rx a e

Ext

fig. 07 Vertical roof feed-through for room sealed operation

Pdf dakdoorvoer

114494-03

19

Page 20

7. Connecting the flue gas discharge and air supply

GAS 210 ECO PRO

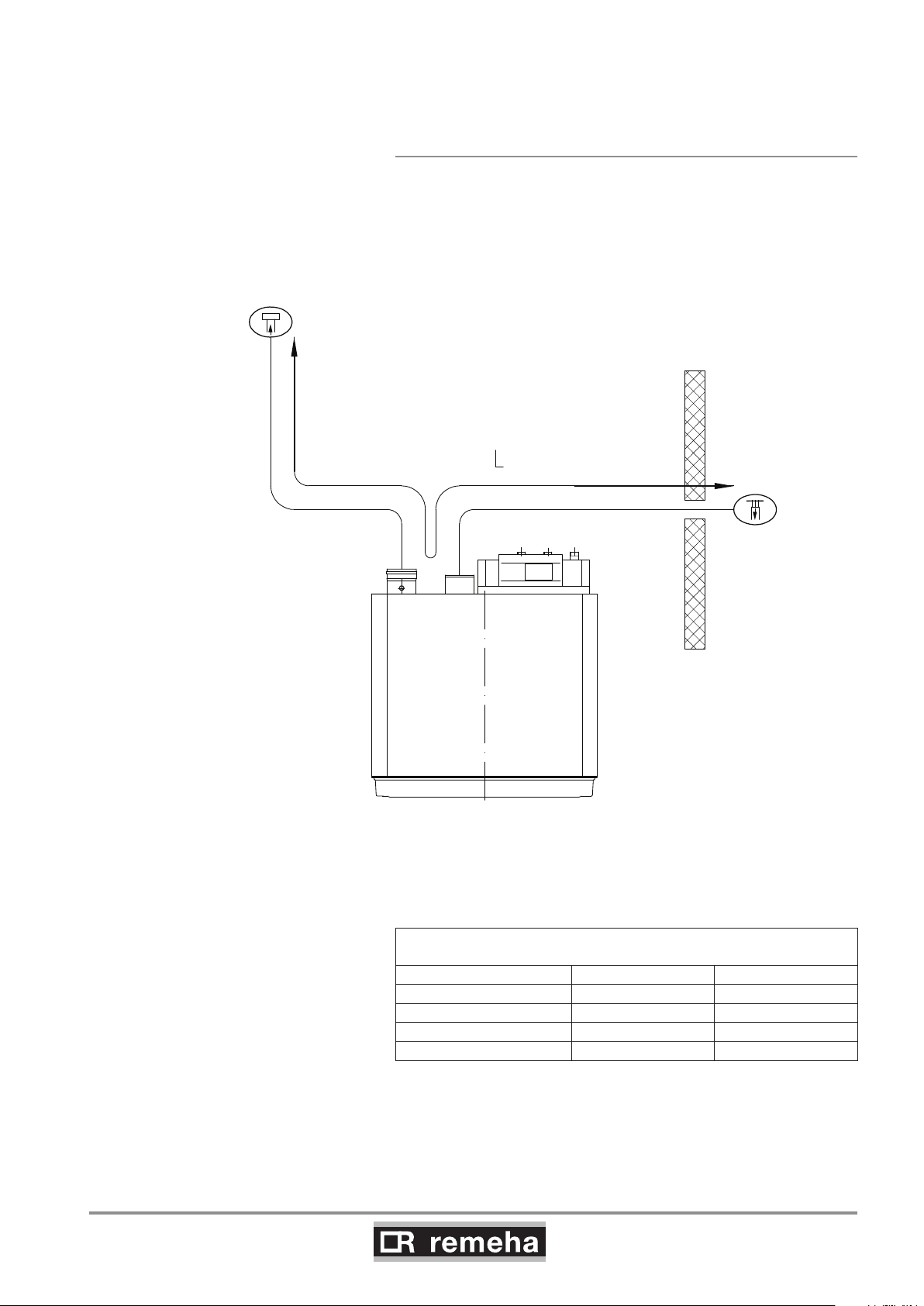

7.3.2 Discharge in different pressure areas

For installations where supply and discharge points are in two different pressure zones CLV system please contact Broag Technical Dept. for further details and advice. The maximum acceptable

height difference between combustion air supply and flue gas

discharge is 36 m and the maximum acceptable length of the air

supply and flue gas discharge combined is shown in table 05.

fig. 08 Discharge in different pressure areas

20

Maximum permitted flue gas discharge and

air supply pipe lengths

Boiler model D in mm L in m

210-80 150 36

210-120 150 36

210-160 150 23

210-200 150 11

table 05 Air supply and flue gas discharge table for 'simplified

CLV system'

114494-03

Page 21

GAS 210 ECO PRO

7. Connecting the flue gas discharge and air supply

7.3.3 Connection of flue gas discharge and choice

of material

Connecting the flue gas discharge:

Remove the cap from the flue gas discharge opening Ñ;

• Fit the flue gas discharge pipes seamlessly together.

• Seams and joints must be airtight and watertight or fit seamlessly.

• Horizontal parts must be oriented towards the boiler at a gradient (min.

5 cm per metre).

• Connect the pipes stress-free.

• Flue gas discharge pipes longer than 2 m must be fixed separately and

must not rest on the boiler.

Flue gas discharge:

Material:

Rigid single walled: stainless steel (316), aluminium or plastic (to comply

with building regulations).

Flexible: stainless steel (316).

Construction: all joints and seams should be gastight and watertight with

the horizontal runs graded towards the boiler (min. discharge 5 cm per

meter) to allow condensate free drainage to the boiler. Flue gas discharges longer than 2 meters must be supported independently and may not

rest on the boiler.

The flue outlet should terminate with reduction cone and bird guard only

(chinamans hat or GLC type terminals etc. should not be used).

7.3.4 Air supply connection and choice of material

Connecting air supply:

Remove air supply grille from the air supply opening Ð;

• Fit the air supply pipes seamlessly together.

• Seams and joints must be airtight and watertight or fit seamlessly.

• Horizontal parts must be oriented towards the discharge at a

gradient (min. 5 cm per metre).

• Connect the pipes stress-free.

Air supply:

Material:

Single walled, rigid or flexible: aluminium, stainless steel and plastic (to

comply with building regulations).

Air supply ducts longer than 2 meters must be supported independently

and may not rest on the boiler air inlet. Care must be taken to ensure that

if water is able to enter the duct it will run away from the boiler air inlet

connection or supply a suitable train c/w water seal trap.

7.3.5 Additional Directives

Please refer to the manufacturer’s instructions for the material in question when installing the flue gas discharge and air supply materials. If the

flue gas discharge and air supply materials are not installed according to

the instructions (e.g. they are not leakproof, not clamped in place etc.),

this may cause hazardous situations and/or result in bodily injury. After

assembly, check at least all flue gas and air–carrying parts for tightness.

114494-03

21

Page 22

8. Control and electrical connections

8. Control and electrical connections

8.1 General

The boiler is equipped with electronic control and safety equipment with ionisation flame protection. The advanced boiler control

(abc®), is a microprocessor that protects and controls the boiler.

The boiler is fully prewired; all external connections are made

on the terminal strips. Connect the boiler to the mains supply in

accordance with the local electricity supplier's instructions and IEE

regulations.

8.1.1 Boiler control

The heat output of the Remeha Gas 210 ECO PRO can be controlled as follows:

- Modulating, where the output modulates between the minimum

and maximum values on the basis of the flow temperature

defined by the modulating controller.

- On/off control, where the heat output modulates between

the minimum and maximum values on the basis of the flow

temperature set in the unit. This can be combined with an

outside sensor so that the internal heating curve is used.

- Analogue control (0-10 V), where the heat output or

temperature is controlled by a 0-10 V signal, see Section 8.4.4.

Only possible with optional 0 - 10 V control PCB (IF-01).

GAS 210 ECO PRO

8.1.2 Modulating controls general

The modulating nature of the boiler is used to maximum effect with

a modulating controller based on room and/or outside temperatures. If the controller demands heat, the boiler supplies the heat

output. If the controller demands a flow temperature, the boiler

modulates to this value. This increases the number of operating

hours and drastically reduces the number of starts. Combined with

the fixed gas/air mixture, this results in greater efficiency.

Various types of modulating controls can be connected, including

the following:

- Modulating room control, see Section 8.1.3;

- Modulating weather-compensated control see Section 8.1.4;

- Modulating cascade control, see Section 8.1.5.

8.1.3 Modulating room control

The boiler is set up for communication via the OpenTherm protocol. Modulating controllers can be connected according to the

OpenTherm protocol, e.g. the Remeha iSense. The controller is

mounted in a reference area. Connection is made with a two-core

cable to the On/off - OT terminals of terminal strip X6 (not polarity

sensitive).

8.1.4 Modulating weather-compensated control

rematic

®

22

The following optional controller can be supplied by Broag-Remeha. The controller is supplied with a connection adapter and interface that are built into the boiler. The connections for this feature

are fully pre-wired.

114494-03

Page 23

GAS 210 ECO PRO

8. Control and electrical connections

rematic® 2945 C3 K

In addition to the weather-compensated boiler pre-control, this

controller provides optimum start, dual zone weather compensation and priority DHW (if required). Fit the controller in the boiler.

Connection takes place using the supplied rematic® adapter and

the supplied interface that can be integrated in the control panel.

Refer to the relevant controller documentation for detailed information.

8.1.5 Modulating cascade controller MC4

The Remeha Celcia MC4 cascade controller is suitable for the

modulated control of 2 to 4 Remeha Gas 210 PRO boilers in cascade. This controller is wall-mounted and communicates according

the OpenTherm protocol. We recommend using our Celcia MC4

modulating cascade controller in conjunction with the iSenseTime/

Weather compensation controller. Refer to the relevant controller

documentation for detailed information.

iSense with MC4 will only control up to 4 boilers

in cascade

8.2 Electrical specifications

230Vac, 50Hz, F6.3AT

L

N

8.2.1 Mains voltage

The boiler is suitable for a 230 V-50 Hz supply with live/neutral/

earth (the control is phase/neutral sensitive). Other connection

values are only acceptable if an isolating transformer is installed.

Connect the mains lead (not supplied) to the 230 V terminal strip.

8.2.2 Control box

Mains voltage : 230 V/50 Hz

Power consumption at: stand-by/low load/full load:

- 210-80 : 4 / 36 / 125 W

- 210-120 : 4 / 37 / 193 W

- 210-160 : 4 / 53 / 206 W

- 210-200 : 4 / 54 / 317 W

Safety time: 3.5 s

Anti-hunting time: Adaptive 1 - 10 minutes.

Pump post-circulation time: adjustable between 0 and 98 minutes

or continuous (= 99 minutes), set by default to 3 minutes

Max. power consumption of external pump: 300 VA.

fig. 09 Connect mains lead

114494-03

114492LTAL21H004a

8.2.3 Fuse ratings

The 230 V terminal strip contains the fuse F - 6.3 AT.

This is a general fuse for all connected components.

The control unit contains the fuse F1 - 1.6 AT.

This is a fuse for the mains voltage of the control unit, gas multiblock and ignition, excluding pump.

23

Page 24

Mainson/of

N

N L

Pump

L

OT BL RL

OT BL RL

X6

X1

X11

X10

X9

X7

X8

X2

X3

X5

X4

F1 1.6 AT

PCU-01

SU

N L

Pump

X9X11 X10

1

4x

2

114492LTAL21H005e

8. Control and electrical connections

8.3 Electrical connection options

GAS 210 ECO PRO

The boiler has several control, protection and regulation connection options. The standard control PCB (PCU-01) can for example

be expanded with:

• an optional 0 - 10 V control PCB (available as an accessory IF-01);

• and/or the optional expanded control/protection PCB (available as

an accessory SCU-SO1).

To install or access these PCBs, the plastic cap must be removed

from the control panel. The required external connections are

made on these (optional) PCBs. The various connection options

are detailed in the following sections.

8.3.1 Connection options of standard control unit

(PCU-01)

Connected on the standard control unit (PCU-01) is the safety unit

(SU) connected, which protects the boiler.

8.3.2 On/off control (OT)

The boiler is suitable for connection to a ‘volt free’ on/off controller.

Connect the controller to the On/off - OT terminals of terminal

strip X6 (not polarity sensitive).

8.3.3 Modulating controls (OT)

The boiler is set up for communication via the OpenTherm protocol. Modulating controllers can be connected.

Connection is made with a two-core cable to the On/off - OT terminals of terminal strip X6 (it does not matter which wire is connected to which cable clamp).

8.3.4 External interlock (BL)

The boiler has an external interlock switch, so that the boiler can

be shutdown in the event that this switch is not made. This input

can be used in combination with a flue gas thermostat (available

as an accessory). This input relates to the BL terminals of terminal

strip X6. Remove the wire bridge before using the input.

The input's behaviour depends on the parameter 33 setting:

1 = Normal shutdown;

2 = Shutdown without frost-protection (= default);

3 = Lock out.

fig. 10 Standard control PCB (PCU-01) with

24

safety unit (SU)

114494-03

Page 25

GAS 210 ECO PRO

8. Control and electrical connections

X3

X2

X11

PCU-01

X9X11 X10

X9

X10

X8

Recom

X1

fig. 11 Connecting a PC

F1 1.6 AT

X7

X4

N L

Pump

Mainson/of

X5

X6

www.remeha.com

Pump

L

N

OT BL RL

N L

The boiler is also equipped with an input release so that the burner can be released/shutdown. This input can be used in combination with the limit switches on flue gas throttle valves, hydraulic

control valves, safety interlocks, etc. This input relates to the RL

terminals of terminal strip X6.

8.3.6 Circulation pump (Pump)

8.3.5 Input release (RL)

OT BL RL

A pump with the following specifications can be connected:

- On/off pump with a mains voltage of 230 VAC (50 Hz) and 300

VA (maximum).

Connect the pump to the Pump terminals of terminal strip X4. The

post-circulation time of the circulation pump at the end of a heat

demand can be set according to requirements by means of a program option at user level, see Section 9.1.6.

8.3.7 Connecting a PC

T000058

Using the optional Recom interface package a PC can be connected to the X7 “telephone connector”.

Using the Recom software you can load, change and download

various boiler settings and readings.

See the user instructions supplied with the software.

8.3.8 Connection options for the PCB - SCU - X01

X3

cN oNC

cN oNC

sutatS

SCU-X01

cN oNC

cN oNC

sutatS

X4

X2a

3

2

4

1

5

0

00

6

9

7

8

3

2

4

1

5

0

6

9

7

8

X2

Nr 0 1 2 3 4 5 6 7 8 9

Alarm

Descrip-

tion

Alarm

inverted

= fail

Burning Burning

safe

Standby C-NO C-NC C-NO C-NC C-NO C-NO NA NA NA C-NO

Active C-NC C-NO C-NC C-NO C-NC C-NC NA NA NA C-NC

114494-03

The PCB - SCU - X01 is equipped with two potential-free outputs

that have a capacity of max. 230 VAC/5 A reactive/2 A inductive

(cos 0.6). It also has two rotary switches with ten positions.

See the table below for the rotary switch settings.

inverted

Burning

low

Burning

high

Service

report

CH-

mode

DWH-

mode

CH-

pump

25

Page 26

8. Control and electrical connections

8.4 Connection options for 0 - 10 V control PCB (IF-01)

8.4.1 Connection status (Nc)

If the boiler locks out, a relay is de-energised and the alarm can

be transmitted via a potential-free contact

(maximum 230 V, 1 A) on terminals Nc and C of terminal strip X4.

8.4.2 OTm connection

The interface uses OpenTherm to communicate with the boiler

control. The OTm connection on terminal strip X5 must therefore

be connected to the OpenTherm OT input of the boiler control.

1

%

2

X5

GAS 210 ECO PRO

IF-01

X1

fig. 12 Jumper 2

X4

Status 0-10 0-10

114492LTAL21H006a

OTm 0 + 0 +

Nc No OTm 0 + 0 +C

Nc NoC

26

114494-03

Page 27

GAS 210 ECO PRO

1

%

2

8. Control and electrical connections

8.4.3 Analogue input (0 - 10 V)

This control can be based on temperature or heat output (optional). The two controls are described briefly below. Connect the 0

- 10 V signal to the interface input for analogue control.

Analogue temperature-based control ()

The 0-10 V signal controls the boiler flow temperature between

0°C and 100°C. This control modulates on the basis of flow temperature, where the heat output varies between the minimum and

2

2

maximum values on the basis of the set point flow temperature

calculated by the controller.

Jumper (2) on the interface is used to select either temperature ()

or boiler output (%) control.

fig. 13 Jumper 2

114492LTAL21H023a

Jumper2Input signal

[V]

Temperature

[°C]

Description

0 - 1,5 0 - 15 Boiler off

1,5 - 1,8 15 - 18 Hysteresis

1,8 - 10 18 -100 Desired temperature

table 06 Analog input signal for temperature

Analogue output-based control (%)

The 0-10 V signal controls the boiler output between 0% and

100%, where the minimum and maximum values are limited. The

minimum output is linked to the boiler's modulation depth. This

control is output modulated, where the output varies between the

minimum and maximum values on the basis of the value defined

by the controller.

Jumper2Ingput signal

[V]

0 - 2,0* 0 - 20 Boiler off

%

2,0 - 2,2* 20 - 22 Hysteresis

2,0* - 10 20 -100 Desired boiler output

* Dependent on the minimum modulation dept (fan rotation speeds settings, pre set 20%)

Boiler output

[%]

Description

table 07 Analogue input signal for boiler output

1

%

2

fig. 14 Jumper 1

114494-03

1 1

114492LTAL21H024a

8.4.4 Analogue output (0 - 10 V)

If this feedback message is received, temperature or heat output

can be selected. The two are described briefly below.

Jumper (1) on the interface is used to select either temperature ()

or boiler output (%).

Jumper1 Output signal

[V]

0,5 - Alarm

1- 10 10 - 100 Delivered temperature

table 08 Analogue output signal for temperature

Temperature

[°C]

Description

27

Page 28

8. Control and electrical connections

GAS 210 ECO PRO

Jumper1Output signal

[V]

Boiler output

[%]

Description

0 0 - 15 Boiler off

%

0,5 15 - 18 Alarm

2,0* - 10 20 - 100 Delivered boiler output

* Dependent on the minimum modulation dept (fan rotation speeds settings, pre set 20%)

table 09 Analogue output signal for boiler output

8.5 Connection options of the optional expanded control/protection PCB

(SCU-SO1)

8.5.1 Flue gas damper control (FgV)

In a cascade configuration, a flue gas damper (available as an

accessory) prevents flue gases from being discharged through a

non-operating boiler, with flue gas cascade. Therefore, the boiler

is suitable for flue gas overpressure systems. Consult our Technical department. Connect the flue gas damper to the FgV terminals

of terminal strip X3. Also fit this flue gas damper if flue gases flow

back when the boiler is in stand-by mode.

The running time of the flue gas damper must be programmed

with parameter 29.

8.5.2 Hydraulic valve control (HdV)

N L

N L

FgV

FgV

N L

N L

HdV

HdV

X3

N L

N L

EgV

EgV

NcC

Nc No

Status

C

No

O +S

O +S

Tout

Tout

GPS

GPS

VPS

VPS

fig. 15 Expanded control/protection PCB (SCU-SO1).

X4

Wps

X5

F1 4 AT

X1

SCU-S01

X2

114492LTAL21H007c

In a cascade configuration, a hydraulic valve prevents heat loss

when the boiler is not running. Connect the hydraulic valve to the

HdV terminals of terminal strip X3. The running time of the hydrau-

lic valve must be programmed with parameter 28.

8.5.3 External gas valve control (EgV)

If there is a heat demand, an alternating voltage of 230 V 1 A

(maximum) becomes available on the EgV terminals of terminal

strip X3 to control an external gas valve. The voltage is switched

off when the gas multiblock on the boiler closes.

8.5.4 Operation signal and failure signal (Nc / No)

The alarm or operation signal is selected using the relevant

parameter 25, see Section 9.1.6. If the boiler is operational,

the alarm or operation signal can be switched via a potential-free

contact (maximum of 230 V, 1 A) on the No and C terminals of terminal strip X4. If the boiler locks out, the alarm can be transmitted

via a potential-free contact (maximum 230 V, 1 A) on terminals No

and C of terminal strip X4.

8.5.5 Water pressure sensor (Wps)

The water pressure sensor (available as an accessory) shuts

the boiler down when the minimum water pressure (0.8 bar) is

reached. To activate the water pressure sensor, a minimum pressure must be set with parameter 26 (factory setting 0 = off, see

Section 9.1.6.) The pump does not run during this shutdown.

28

114494-03

Page 29

GAS 210 ECO PRO

8. Control and electrical connections

Connect the water pressure sensor to the Wps terminals of terminal strip X5.

0 = Earth or neutral of the power supply

S = Signal or output from the sensor

+ = Supply voltage

8.5.6 Outside temperature sensor (Tout)

To take advantage of the boiler's modulating operation during the

entire heating season, a Remeha outside temperature sensor

(available as an accessory) can be used in combination with an

on/off control or connection. Connect the on/off control or connection to the On/off terminals of terminal strip X6 on the standard

control PCB (PCU-01) and the outside temperature sensor to the

Tout terminals of terminal strip X5 on the optional expanded con-

trol/protection PCB (SCU-SO1). The unit modulates with a heat

demand from the controller or because of a connection to a flow

temperature corresponding to the outside temperature (see heat-

ing curve graph).

3

fig. 16 Heating curve graph

80

60

40

20

F

0 10 20-15

F = factory setting

2

1

114492LTAL21H025b

Fitting the outside temperature sensor

Fit the external sensor, protected against direct sunlight, to the

north or north-west of the building, at a height of at least 2.5

metres from ground level. Do not fit the outside temperature sensor near windows, doors, ventilation grills and extractors, etc.

Heating curve setting

The maximum flow temperature setting is also the setting for the

‘top’ of the heating curve, i.e. the required flow temperature for an

outside temperature of -15°C. The baseline of the heating curve is

also adjustable and can be changed at service level, see Section

9.1.6. A linear relationship exists between the outside temperatures mentioned and the corresponding flow temperatures.

8.5.7 Minimum gas pressure switch (Gps)

The minimum gas pressure (available as an accessory) switch

shuts the boiler down if the inlet gas pressure becomes too low.

Connect the minimum gas pressure switch to the Gps terminals

of terminal strip X5. The presence of the gas pressure switch

must be activated using parameter 27 in the setting mode (see

Section 9.1.6).

8.5.8 Gas leakage control (VPS; only for 210- 160

and 210- 200 boilers)

The gas leakage control checks and controls the safety valves on

the gas block via a VPS system. The test takes place when the

boiler starts. In the event of a leak in the gas block, the boiler will

lock out. Connect the gas leakage control to the VPS terminals of

terminal strip X5. The presence of a gas leakage control must be

entered using parameter 31, see Section 9.1.6.

114494-03

29

Page 30

9. Commissioning

38

11

X01

X02

123

8.5.9 Wiring diagram

PRIMARY CONTROL UNIT - PCU-01

X03

1234

X04

Pump

12

X05

Mains

3

123

OT

On / Off

1

X06

BL

34RL562

GAS 210 ECO PRO

X07

X08

0

SAFETY UNIT

- SU-01

Ignition

transformer

X05

X01

SU-01

X04

SU-01

PCU-01

X02

X07

X03

X06

X01

PCU-01

X11

X10

X09

X08

CORD COLORS

BL BLUE

BL/WH BLUE/WHITE

BR BROWN

BR/WH BROWN/WHITE

YW YELLOW

GN/YW GREEN/YELLOW

YW/WH YELLOW/WHITE

GN GREEN

GY GREY

OR ORANGE

RD RED

WH WHITE

BK BLACK

BK/WH BLACK/WHITE

GY BK BL BL

BL

11X235 9810 21 3675

GYBLBK

GN/YW

213X21

PE-11

Elektrode

BR BR

PE-6 PE-4 PE-5

GN/YWGN/YWGN/YW

BL

BR

Safety shut-off

valve1

PE-12

GN/YW

21

BL

GN/YW

BR

21

Safety shut-off

valve 2

SCU-X01

X03

0-10V IF-01

X04

X02a

SCU-X01/

SCU-S01

X02

X50

X01

X04

X03

X04

X05

X05

X02

SCU-S01

PE-2

BL

GN/YW

BK

GN/YW

GN/

LN

PE-2

PE-1

GN/YW

X50

YW

BL

BK

X51

BL

BR

LN

Power supply

230V,50Hz

T

BK

BL

6.3AT

Boiler

switch

on / off

PRIMARY CONTROL UNIT - PCU-01

YW

X10

1.....6

213

CNoNc

Status

X03

12 35 4671089

RD BLOR

WH

Flow

temp.

213

CNoNc

Status

X04

X09

1234

WHBRGN

1X91425

Fan

1.....6

X02

1.....6

X02a

SECONDARY CONTROL UNIT

- SCU-X01

NNNLLL

PC

PE-7

GN/YW

14X235 13 12

BR

GN/YW

BL

1X5532

Fan

X11

BK/

BL/

WH

WH

OR

P

Flue gas

pressure

switch

GL/

BR/

WH

WH

PSU

(Parameter

storage unit)

WpsToutGps VPs

Return

temp.

DISPLAY

BK

Heat exch.

temp.

30

+

0-10V

3

+

0-10V

X05

OTm

-

Nc

Status

X04

-

IF-01

12

No

C

X01

13

X01

2

1.....6

X02

21

Fgv

45

X03

Hdv

78369

Egv

213

CNoNc

Status

X04

214567

OS+

X05

9

SECONDARY CONTROL UNIT - SCU-S01 (OPTION)

T002609-04-C

114494-03

Page 31

GAS 210 ECO PRO

9 Commissioning

9.1 Control panel

9. Commissioning

The boiler's control panel contains four function keys, a menu key,

a service engineers key, an on/off switch and a display.

1

2

Bar

8

3

4 5

fig. 17 Control panel

1 = Display 5 = [Central heating temperature] or [-] key

2 = [Menu] key 6 = [+] key

3 = [Service engineers] key 7 = [enter] key or [Service] indicator

4 = [Escape] or [reset] key 8 = On/off switch

The display has four positions and several symbols and provides

information about the operating status of the boiler and any faults.

Numbers, dots and/or letters may be shown. The symbols in the

display above the function keys indicate what the function of the

relevant keys is at that moment. If no key is pressed for three min-

utes, the display lighting switches off and only the and sym-

bols are displayed. Press any key; the current boiler status and

the current operating code appear on the display. This is always

displayed in the event of a fault.

6 7

9.1.1 Normal start-up procedure

114492LTAL21H008a

114494-03

Switch on the mains supply to the boiler; the Gas 210 ECO PRO

will perform the start-up program.

The following will appear in succession in the display:

- a short display test, whereby all of the display's segments are

visible;

fXx software version alternating with 1;

pXx parameter version;

- Afterwards (depending on the operating status), the following

may appear on the display:

N : L (flashes) : live and nutral wires are wrongly connected; chan-

ge wires on the 230V terminal strip!

31

Page 32

9. Commissioning

GAS 210 ECO PRO

With a heat demand:

1 Boiler starts

2 Burner starts

3 Central heating operation; briefly in part load then in full load

When a heat demand ceases:

5 Burner stops

6 Boiler stops

0 Stand-by mode

table 10 Normal operation

9.1.2 Fault during start-up procedure

If nothing appears on the display, check:

- the connection of the mains lead;

- the main fuse in the instrument box (F = 6.3 AT, 230 V);

- the fuse on the control unit (F1 = 1.6 AT, 230 V);

- the mains voltage.

• A fault code in the display is recognised as follows: the fault

symbol appears and

the fault code flashes underneath it;

• The meaning of this fault code can be found in the fault table,

see Section 11.2.

• If possible, solve the fault first.

• Press the RESET key for 3 seconds to restart the Gas 210

ECO PRO.

If the display does not show RESET but SERVICE, the boiler must

be switched off and switched on again after 10 seconds before the

fault can be reset.

32

114494-03

Page 33

GAS 210 ECO PRO

bar

%

114492LTAL21H009c

fig. 18 Reading current values

9. Commissioning

9.1.3 Reading current values

The following current values can be read in the ‘information

menu’

- 5t = Status

- 5u = Sub status

- t1 = flow temperature [°C];

- t2 = return temperature [°C];

- t4 = outside temperature [°C];

(only if outside sensor is connected)

- t6 = boiler block temperature [°C];

- 5p = internal set point [°C];

- fl = ionisation current [uA];

- f = fan rotation speed [rpm];

- pr = water pressure [mbar];

- p = relative output supplied [%];

The current values can be read as follows:

• Press the key, the symbol will then flash, confirm with

the key;

• Press the [+] key again so that 5t appears alternating with

3, the actual status;

• Press the [+] key again so that 5u appears alternating with

, the actual sub status;

• Press the [+] key again so that t1 appears, alternating with,

for example, 60°C, the actual flow temperature;

• Press the [+] key repeatedly so that the remaining temperatures

also appear;

• Press the [+] key again so that 5p appears, alternating with,

for example, 88°C, an internal set point;

• Press the [+] key again so that fl appears alternating with,

for example, u, the actual ionisation current;

• Press the [+] key again so that ñf appears alternating with,

for example, 3000 (rpm), the actual fan rotation speed;

• Press the [+] key again until pr appears alternating and, for

example, 3.0 bar, the actual water pressure

(if no water pressure sensor is connected, --.- bar appears);

• Press the [+] key again until p appears and, for example,

78 %, the actual modulation percentage;

• Press the [+] key again, the read-out cycle starts again with

5t, etc;

• Press the key twice to return to the display with the cur-

rent operating status.

114494-03

33

Page 34

9. Commissioning

9.1.3.1 Status and sub status

In the ‘information menu’ the following status and sub status

numbers are displayed:

Status 5t Sub status 5u

Number Status Number Sub status

0 Stand-by mode 0 Stand-by mode

1 Anti-hunting

1 Boiler starts (heat demand)

2 Burner starts

3 Burning on central heating operation

5 Burner stop

6 Boiler stop (end of heat demand)

8 Control stop

9 Shutdown xx Shutdown xx

table 11 Settings at service level

2 Open hydraulic valve

3 Start pump

4 Wait for the correct temperatures for burner start

10 Open external gas valve

11 Fan running

12 Open flue gas damper

13 Pre-ventilation

14 Wait for release signal

15 Burner on

16 VPS gas leakage control

17 For ignition

18 Main ignition

19 Flame detection

20 Intermediate ventilation

30 Temperature control

31 Limited temperature control (

32 Output control

33 Increase protection level 1

34 Increase protection level 2 (part load)

35 Increase protection level 3 (shut down)

36 Modulate up for flame control

37 Stabilisation time

38 Cold start

40 Burner off

41 Post ventilation

42 Fan running

43 Close flue gas damper

44 Stop fan

45 Close the external gas valve

60 Pump post circulation

61 Pump off

62 Close hydraulic valve

63 Start anti-hunting

0 Wait for burner start

1 Anti-hunting

GAS 210 ECO PRO

∆T safety)

(control modulation)

34

9.1.4 Adjusting the boiler to the system

The boiler's control parameters are set to the most common central heating systems. With these settings, practically all central

heating systems will work well. However, the user or the installer

can optimise the parameters as he/she wishes.

114494-03

Page 35

GAS 210 ECO PRO

2x

2x

fig. 19 Changing parameters

114492LTAL21H021b

9. Commissioning

9.1.5 Changing parameters at user level (without

access code)

The following settings can be changed at user level:

p1 = Flow temperature set point [°C], adjustable between 20

and 90°C;

p2 = Pump post-circulation time 0..98 mins, 99 is continuous;

p3 = Boiler control; central heating on/off.

0 = Central heating

1 = Central heating on (= factory setting)

p4 = Display options

0 = Simple display

1 = Comprehensive display

2 = Display automatically goes to simple after three

minutes (factory setting)

* Consult our Technical department for further information and

demands on the system.

The parameters can be changed at user level as follows:

1. Press the -key several times until the symbol flashes in the

menu bar;

2. Select the users menu using the -key, p1 appears (the

1 flashes);

3. Press the [+]-key; p2 appears (the 2 flashes);

3. Press the -key again; 3 (min) appears and flashes: (fac-

tory setting);

4. Change the value by pressing the [-] -key or the [+] -key, in this

case for example to 15 min, with the [+] -key;

5.

Confirm the value with the -key, p2 appears (the 2 flashes);

6. Press the - key twice, the boiler enters the current operating

status.

off

The p1 to p4 settings can be changed in the same way as

p2.

9.1.6 Changing parameters at service level (with

access code)

To prevent undesired settings, some parameter settings can only

be changed after the special access code 12 is entered. This

code may only be used by qualified installers.

The following settings can be changed at user and service levels:

114494-03

35

Page 36

9. Commissioning

GAS 210 ECO PRO

Codes in

display

Flow temperature set point 20 - 90°C

1

Pump post-circulation time

2

by users

May also

be changed

Boiler control

3

Display

4

Maximum speed

17

central heating (natural gas)

Minimum speed

central heating and hot water

18

(natural gas)

Starting speed

19

(natural gas)

Maximum flow temperature CH 20 - 90°C 90

20

Base point heating curve out-

21

side temperature

Baseline of flow temperature

22

heating curve

Outside temperature climate

23

point heating curve

Outside temperature for frost

24

protection

Fault relay function

25

(available as an accessory)

Minimum water pressure

26

(available as an accessory)

Minimum gas pressure check

27

(available as an accessory)

Hydraulic valve running time

28

(available as an accessory)

Can only be changed by the installer

Flue gas damper running time

29

(available as an accessory)

Maximum time for release

30

VPS gas leakage control

31

(available as an accessory)

Mains detection phase

32

External interlock function

33

(available as an accessory)

Display units

34

Automatic detection of optional

Ad

hardware

df

Resetting factory settings

and

dU

Description Setting range and possible explanation

0 – 98 minutes

99 = continuous

0 = Central heating

1 = Central heating

off

on

0 = Simple display

1 = Comprehensive display

2 = Display automatically goes to simple

10 - 70

x 100 rpm

10 - 40

x 100 rpm

Do not change *

10 - 40

x 100 rpm

Do not change *

0 - 30°C (only with external sensor) 20

0 - 90°C (only with external sensor) 20

-30 - 0°C (only with external sensor) - 15

-30 - 0°C (only with external sensor) - 10

0 = Operation signal

1 = Alarm signal

1 - 60:10 bar (only with water pressure sensor)

0 = off

0 = Off

1 = On (only with a minimum gas pressure sensor)

0 = no waiting time

1 – 255 s (only if connected)

0 = no waiting time

1 – 255 s (only if connected)

0 = no waiting time

1 – 255 s (only if connected)

0 = off

1 = on (only with leakage control)

0 = Off

1 = On

1 = Normal shutdown

2 = Shutdown without frost-protection

3 = Lock out

0 = °C / bar

1 = °F / psi

Do not modify

0 = No

1 = Yes, once

The type plate states the value of

dF (X) and dU (Y); setting these values resets

the factory settings.

Factory setting

210-80210-

120

210-

160

80

3

1

2

51 64 48 57

12 13 10 12

17

1

0

0

0

0

0

0

0

2

0

0

X

Y

210-

200

table 12 Settings at service level

* Change this parameter when converting to flue gas cascade and LPG gas (please refer to Broag).

36

114494-03

Page 37

GAS 210 ECO PRO

4x

9. Commissioning

• The parameters at service level may only be changed by a

qualified installer.

• Changing the factory settings can result in incorrect operation of

the Gas 210 ECO PRO.

The parameters can be changed at service level as follows:

1. Press the -key several times until the symbol flashes in

the menu bar;

2. Select the installers menu using the -key,

appears in the display;

3. Use the [-] -key or [+] -key to set installers code 0012;

4. Confirm with the -key; appears;

5. Press the -key again; value 80°C appears (factory setting);

6. Lower the value, for example to 60°C, with the [-] key;

7. Confirm the value with the -key; appears;

8. Set other parameters where required by selecting them with the

[-] -key or [+] -key;

9. Press the - key twice, the boiler becomes operational.

fig. 20 Setting service code

Gas 210 ECO PRO also returns to operation if no keys are

pressed for 10 minutes.

114492LTAL21H018b

114494-03

37

Page 38

9. Commissioning

114492LTAL21H010a

4x

GAS 210 ECO PRO

9.1.7 Resetting factory settings

• Press the -key several times until the symbol flashes in

the menu bar;

• Select the installers menu using the -key,

appears in the display;

• Use the [-] -key or [+] -key to set installers code 0012;

• Confirm with the -key; appears;

• Press the [+] -key several times, df X appears;

• By default, the current value X for dF appears on the display; as

a check, compare this with the

value of X on the type plate; enter the value of X on the type

plate with the [-] key or the [+] key.

• Press the key again, dU Y appears;

• By default, the current value Y for dU appears on the display;

as a check, compare this with the value of Y on the type plate;

enter the value of Y on the type plate with the [-] key or the [+]

key.

• Press the key to confirm the values; the factory settings

have been reset.

fig. 21 Resetting factory setting

38

114494-03

Page 39

GAS 210 ECO PRO

114492LTAL21H019a

3x

9. Commissioning

9.1.8 Setting manual operation ( symbol)

In some cases, it may be necessary to set the boiler to manual

operation, for example when the controller has not yet been connected. The boiler can be set to automatic or manual operation

under the symbol. Do this as follows:

• Press the -key several times until the symbol flashes in the

menu bar;

• Press the -key once, either the minimum flow temperature

or AUt) (only if an external sensor

has been connected) will appear in the display; the flow

temperature is determined by the internal heating curve;

• or 20°C (minimum flow temperature) will appear in the display;

• Press the [+] -key to increase this value in manual operation

temporarily;

• Confirm with the -key;

• The boiler is now set to manual operation;

• Press the -key twice to exit manual operation; the boiler

enters operating status.

fig. 22 Setting manual operation

Manual operation keeps active after power breakdown.

9.2 Commissioning

Ensure that the boiler is disconnected from the power supply.

1. Remove front panel.

2. Open the main gas cock.

3. Check the electrical connections including earth.

4. Fill the boiler and the system with water

(minimum pressure 0.8 bar).

5. Vent the system.

6. Fill the trap with clean water.

7. Check the flue gas discharge connection and air supply

connection.

8. Vent the gas pipe (only vent pipework from

gas isolation valve).

9. Open the gas cock in the gas pipe to the boiler.

10. Check the gas connection for leakage.

11. Switch on the mains supply to the boiler.

12. Adjust the boiler and any external controls to heat demand.

13. The boiler now starts to run.

114494-03

39

Page 40

9. Commissioning

GAS 210 ECO PRO

Operation can now be monitored via the code window:

With a heat demand:

1 Boiler starts

2 Burner starts

3 Central heating operation; briefly in part load then in full load

When a heat demand ceases:

5 Burner stops

6 Boiler stops

0 Stand-by mode

15 Check and, if necessary, correct the gas/air ratio control

setting.

Perform the check at full load and minimum load for all boiler

models. Only perform settings for the 210-80 and 210-120 models

1

at minimum load. Perform settings for the 210-160 and 210-200

models at full load and minimum load. An electronic CO

or O2

2

meter is required for checking and adjustment purposes. Check

that the opening around the probe is properly sealed when meas

urements are taken.

CO

2

2

15.a Set full load: press the key, the symbol appears in the

menu bar; if h3 appears in the display, full load has been set.

15.b Now measure the CO2 percentage and compare it with the

3

= full load

T000239-C

values in table 13. If the CO2% level deviates from these

values, set the CO2 percentage using the screw under the

cap of the V2 coil on the gas block (this can only be adjusted

on the 210-160 and 210-200 models). Check the flame

through the inspection glass (at full load): the flame must not

fig. 23 Setting values CO

2

Checking and setting values O2/CO2 for natural gas (H) at full load

Boiler type

Fan speed (rpm) CO

Full load h:3

% % % % % %

210-80 5100 8.8 ± 0.7 n/a 5.2 ± 1.3 n/a

210-120 6400 8.8 ± 0.7 n/a 5.2 ± 1.3 n/a

210-160 4800 8.8 ± 0.5 ± 0.3 5.2 ± 0.9 ± 0.5

210-200 5700 8.8 ± 0.5 ± 0.3 5.2 ± 0.9 ± 0.5

table 13 Checking and setting values O2/CO

Checking and setting values O2/CO2 for natural gas (H) at minimum load

Boiler type

210-80 1200 9.3 ± 0.5 ± 0.3 4.3 ± 0.9 ± 0.5

210-120 1300 9.3 ± 0.5 ± 0.3 4.3 ± 0.9 ± 0.5

210-160 1000 9.3 ± 0.5 ± 0.3 4.3 ± 0.9 ± 0.5

210-200 1200 9.3 ± 0.5 ± 0.3 4.3 ± 0.9 ± 0.5

Fan speed (rpm) CO

Minimum load L:3

% % % % % %

blow off and the burner's surface must not be red hot.

2

margin

for natural gas (front housing removed)

2

Control

Control

2

margin

Setting mar-

gin

Setting mar-

gin

O

2

O

2

Control

margin

Control

margin

Setting

margin

Setting mar-

gin

table 14 Checking and setting values O2/CO

40

for natural gas (front housing removed)

2

114494-03

Page 41

GAS 210 ECO PRO

1

3

CO

2

2

= minimum load

T001791-B

9. Commissioning

15.c Set minimum load: press the [-] -key and, when l 3

appears in the display, minimum load has been set.

15.d After minimum output has been reached, check the CO2

percentage and compare it with the value in table 14. If the

CO2% level deviates from these values, set the CO2

percentage using the correction screw of the pressure

controller on the gas block (for the 210-80 and 210-120

models, adjustments are only made at minimum load).

The boiler is supplied with a number of basic settings.

burner control - modulating on the basis of flow temperature

maximum flow temperature - 80°C

If other values are required: see Section 9.1.6.

fig. 24 Setting values CO2 for 210-160 and

210-200

1

CO2

CO2

2

114492LTAL21H020a

fig. 25 Setting values CO

120 (only minimum load)

for 210-80 and 210-

2

Gas / Gaz / Gáz

H (G20)

ø 8.4 mm

.

4

8

15.e Remove measuring equipment and seal measuring points.

16. Check gas leakage control (VPS if installed = available as an

accessory):

Then set the gas leakage control pressure switch to a switch pressure equal to 50% of the inlet pressure. Check that the measured

inlet pressure is not the (higher) closing pressure.

17. Press the ‘reset’ key to reset the boiler to 'user level'.

18. Heat the system up to roughly 80°C if possible and switch

the boiler off.

19. Vent the system and check the water pressure.

20. The boiler is now ready for operation.

21. Set the boiler control to the required values and write down

the connected type of gas on the boiler type plate: e.g. G20

– 25 mbar.

22. Switch the boiler on.

If the CO2% with the 210-80 and 210-120 still deviates on full load:

- adjust part load (see point 15.c and 15.d)

- check full load (see point 15.b) ; if the CO2% deviation is still too

large;

- check the size and placing of the restrictor (natural gas; 8.4 mm)

114492LTAL21H027

fig. 26 Check size and positioning of restrictor

114494-03

The following operating modes are now available:

23.a Modulating operation: The heat output of the boiler

modulates on the basis of the flow temperature demanded by the modulating controller, see ‘Note’ in point 22

and Section 8.1.2.

23.b On/off operation: the boiler modulates between mini-

mum and maximum heat output on the basis of the flow

temperature set in the boiler, see Section 8.3.2.

41

Page 42

9. Commissioning

9.3 Taking the boiler out of operation

The boiler must be switched off for maintenance or repair work. If

the central heating system is not going to be used for a long time

(for example, during holidays in frost-free periods), it is advisable

to put the boiler out of operation.

9.3.1 Boiler with frost protection, out of operation

for a long time

• Set the controller low, for example to 10°C;

The Gas 210 ECO PRO will now only come into operation to protect itself against freezing, (= depending on parameter 33, see

table 11).

To prevent radiators and the system from freezing in rooms where

there is a risk of frost (e.g. garage or storage room), a frost thermostat can be connected to the boiler. The boiler will then keep

the radiators in that room warm.

GAS 210 ECO PRO

This frost protection does not work if the boiler is out of operation.

9.3.2 Boiler without frost protection, out of

operation for a long time

• Isolate the mains power supply from the boiler;

• Close the boiler gas cock.

Drain the boiler and central heating system if you are not going

to use your home or the building for a long time and there is a

chance of frost.

42

114494-03

Page 43

GAS 210 ECO PRO

10. Inspection and maintenance