REMEHA GAS 120 ACE Series, GAS 120 ACE - 65, GAS 120 ACE - 90, GAS 120 ACE - 115 User Manual

MW-2000881-02

en

MID control box equipped with a HMI T-control

for Gas 120 ACE boiler

Dear Customer,

Thank you very much for buying this appliance.

Please read through the manual carefully before using the product, and keep it in a safe place for later reference. In order to

ensure continued safe and efficient operation we recommend that the product is serviced regularly. Our service and customer

service organisation can assist with this.

We hope you enjoy years of problem-free operation with the product.

Contents

7717201 - v03 - 25062019 MID _HMI T-control - Gas 120 ACE 3

Contents

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.1 Safety instructions for the installer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.1.2 Safety instructions for the user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Liabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.1 Manufacturer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.2 Installer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.3 User's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.1 Symbols used in the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.2 Symbols used on the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1 Homologations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.1 Standards & Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.2 Factory test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

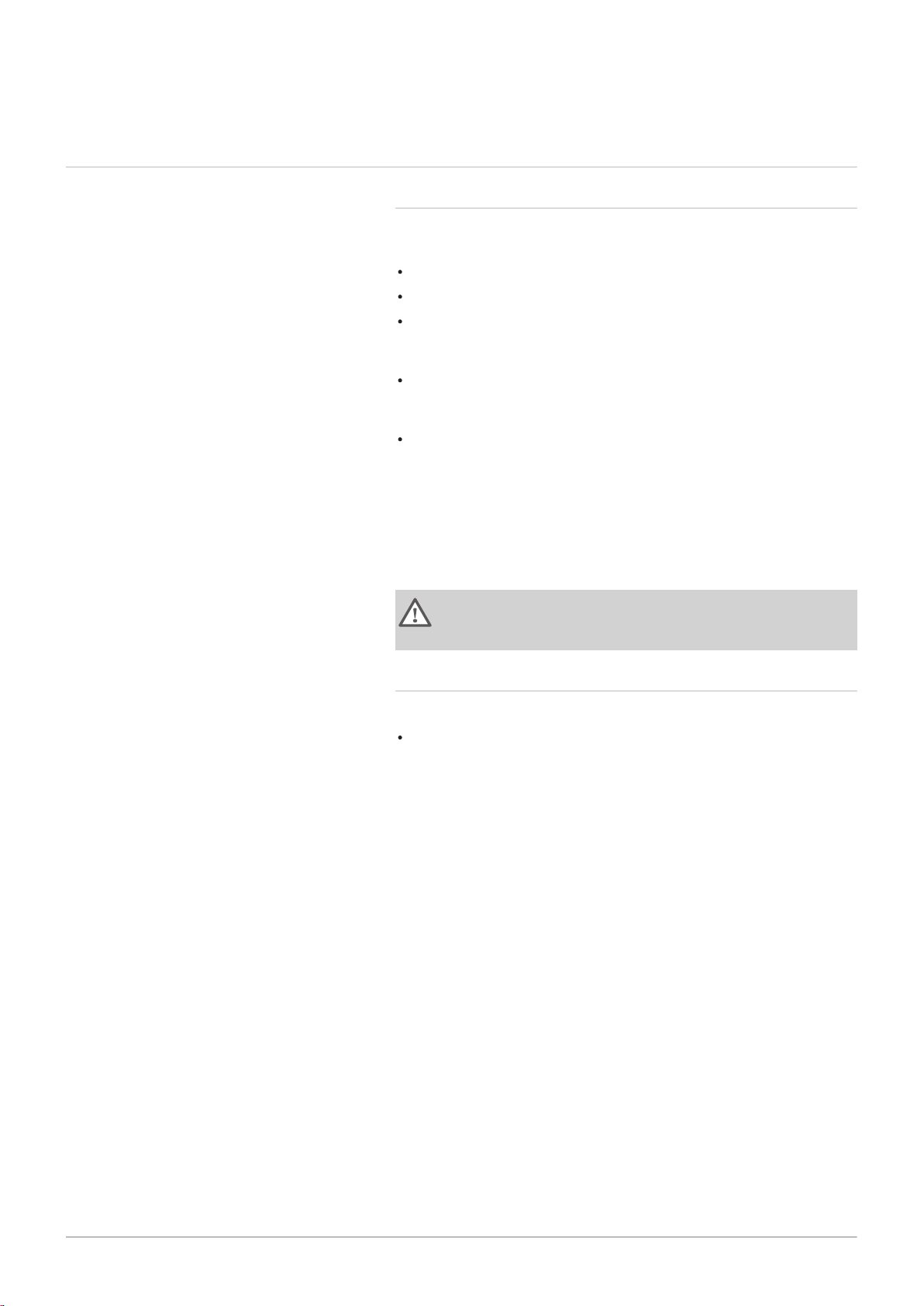

3.2 Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.1 Electrical diagram for the MID control unit HMI T-control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Description of the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.2 Main components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.3.1 SCB-02 expansion board description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3.2 Description of the CB-09 PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3.3 Description of the IF-01 PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.4 Control panel description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.4.1 Description of the user interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.4.2 Description of the main screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5 Standard delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.6 Accessories & options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 Installation regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Unpack and fit the control box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3.1 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5.3.2 Electrical power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3.3 Recommended cable cross section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5.3.4 Cable routing and access to the connection terminal blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5.3.5 Connecting a modulating thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

5.3.6 Connecting an on/off thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.3.7 Frost protection combined with on/off thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.8 Frost protection combined with outdoor temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.9 Connecting an outdoor temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.10 Blocking input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.11 Release input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.3.12 Connecting external sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.3.13 Connecting a tank sensor or thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.3.14 Connecting a PWM pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3.15 Connecting a standard pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.3.16 Connecting a domestic hot water (DHW) pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3.17 Connecting a three-way valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3.18 Connecting a system pump for mix group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3.19 Connecting status notifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3.20 Connecting 0–10 V output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3.21 Connection options for the expansion PCB - IF-01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.3.22 Connecting a PC/laptop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6 Connecting diagrams and configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1 Factory settings for circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Contents

4 MID _HMI T-control - Gas 120 ACE 7717201 - v03 - 25062019

6.2 Connection example - SCB-02 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.2 Check-list before commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.3 Checking the gas inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

7.3.1 Setting the pressure in the gas circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.4 Checking the electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.5 Checking the hydraulic circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.6 Starting and stopping the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.6.1 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.6.2 Shutting down the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.7 Gas settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.7.1 Adapting/adjusting the boiler to different types of gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

7.7.2 Checking/adjusting the combustion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

7.8 Displaying the water pressure on the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.9 Modifying the ΔT value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.10 Points to check after commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

8 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

8.1 Definition of zone and activity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.1.1 Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

8.1.2 Activity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.2 Switching the summer mode on or off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.3 Activating the holiday program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.4 Changing the basic settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.5 Changing the name of an activity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.6 Personalising the name and symbol for a zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.7 Room temperature for a zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.7.1 Selecting the operating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.7.2 Changing the temperature settings of a zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.7.3 Changing the room temperature temporarily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.7.4 Timer programming for heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.8 Domestic hot water temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

8.8.1 Selecting the operating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.8.2 Forcing domestic hot water production (override) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.8.3 Modifying the domestic hot water set point temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.8.4 Timer programming for domestic hot water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.1 Accessing the Installer level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.2 Setting the heating curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.3 Drying screed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.4 Configuring the maintenance message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.5 Saving the installer details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.6 Saving the commissioning settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

9.7 Resetting or re-establishing the parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.7.1 Resetting after replacing the PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.7.2 Auto-detecting options and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.7.3 Reverting to the commissioning settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.7.4 Reverting to the factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.8 Accessing information on the hardware and software versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.9 Menu tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.10 List of parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.10.1 Introduction to parameter codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.10.2 Changing the parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.10.3 Control unit settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.10.4 List of parametersSCB-02 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.11 Reading out measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.11.1 Control unit counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.11.2 SCB-02 counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.11.3 Control unit signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.11.4 SCB-02 signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

10 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

10.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Contents

7717201 - v03 - 25062019 MID _HMI T-control - Gas 120 ACE 5

10.2 Maintenance message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

10.2.1 Viewing the service notifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

10.3 Standard inspection and maintenance operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10.3.1 Checking the combustion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10.3.2 Venting the heating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10.3.3 Draining the heating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.3.4 Check the hydraulic pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.3.5 Topping up the installation with water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.3.6 Cleaning the casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.4 Specific maintenance operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.4.1 Carrying out an auto-detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.4.2 Other specific maintenance operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

11 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

11.1 Displaying and clearing the error memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

11.2 Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

11.2.1 Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

11.2.2 Blockage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

11.2.3 Lock out codes CU-GH-08 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

12 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

12.1 Decommissioning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

12.2 Recommissioning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

13 Disposal and recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

14 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

14.1 Energy savings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

14.2 Room thermostat and settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

15 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

15.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

15.2 Terms of warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

16 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

16.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

16.2 Spare parts lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

16.2.1 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

17 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

17.1 Package fiche - Boilers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

17.2 Product fiche - Temperature Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

17.3 Product fiche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

1 Safety

6 MID _HMI T-control - Gas 120 ACE 7717201 - v03 - 25062019

1 Safety

1.1 General safety instructions

Danger

This appliance can be used by children aged from

8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of

experience and knowledge if they have been

given supervision or instruction concerning use of

the appliance in a safe way and understand the

hazards involved. Children shall not play with the

appliance. Cleaning and user maintenance shall

not be made by children without supervision.

1.1.1

Safety instructions for the installer

Danger

If you smell gas:

1. Do not use a naked flame, do not smoke, do

not operate electrical contacts or switches

(doorbell, light, motor, lift, etc.).

2. Shut off the gas supply.

3. Open the windows.

4. Locate the probable leak and seal it

immediately.

5. If the leak is before the gas meter, contact the

gas supplier.

Danger of electric shock

Before any work, switch off the mains supply to

the boiler.

Danger

If you smell flue gases:

1. Switch off the appliance.

2. Open the windows.

3. Locate the probable source of the flue gas

leak and fix it immediately.

Warning

After any maintenance or repair work, check the

entire heating installation to ensure that there are

no leaks.

1 Safety

7717201 - v03 - 25062019 MID _HMI T-control - Gas 120 ACE 7

Warning

The condensation drain must not be changed or

sealed. If a condensate neutralisation system is

used, the system must be cleaned regularly in

accordance with the instructions provided by the

manufacturer.

Caution

Do not touch the flue gas pipes. Depending on

the boiler settings, the temperature of the flue gas

pipes can rise to over 60°C.

Caution

Do not touch radiators for long periods.

Depending on the boiler settings, the temperature

of the radiators may exceed 60°C.

Caution

Take precautions with the domestic hot water.

Depending on the boiler settings, the domestic

hot water temperature may exceed 65°C.

1.1.2

Safety instructions for the user

Danger

If you smell gas:

1. Do not use a naked flame, do not smoke, do

not operate electrical contacts or switches

(doorbell, light, motor, lift, etc.).

2. Shut off the gas supply.

3. Open the windows.

4. Evacuate the property.

5. Contact a qualified professional.

Danger

If you smell flue gases:

1. Switch off the appliance.

2. Open the windows.

3. Evacuate the property.

4. Contact a qualified professional.

Danger of electric shock

Before any work, switch off the mains supply to

the boiler.

Caution

Do not touch the flue gas pipes. Depending on

the boiler settings, the temperature of the flue gas

pipes can rise to over 60°C.

1 Safety

8 MID _HMI T-control - Gas 120 ACE 7717201 - v03 - 25062019

Caution

Do not touch radiators for long periods.

Depending on the boiler settings, the temperature

of the radiators may exceed 60°C.

Caution

Take precautions with the domestic hot water.

Depending on the boiler settings, the domestic

hot water temperature may exceed 65°C.

1.2

Recommendations

Danger

For safety reasons, we recommend fitting smoke and CO

detectors and alarms at suitable places in your home.

Caution

The boiler must always be connected to the protective earthing.

Earthing must comply with the prevailing installation standards.

Earth the appliance before making any electrical connections.

For the type and calibre of the protective equipment, refer to the

chapter Electrical Connections in the Installation and Service

Manual.

Caution

If a power cord comes with the appliance and it turns out to be

damaged, it must be replaced by the manufacturer, its after sales

service or persons with similar qualifications in order to obviate

any danger.

Caution

A disconnection device must be fitted to the permanent pipes in

accordance with the installation rules.

Caution

Power the appliance via a circuit that includes an omni-polar

switch with contact opening distance of 3 mm or more.

2

Caution

Drain or have the boiler and heating system drained by a qualified

professional if the home is left empty for a long period of time and

there is a chance of frost.

Caution

Remove the boiler casing only to perform maintenance and repair

work. Always put the casing back in place after such work.

Caution

To enjoy warranty cover, no modifications must be made to the

boiler.

Caution

The frost protection function only protects the boiler, not the

heating system.

Caution

The frost protection function does not work if the boiler is powered

off.

1 Safety

7717201 - v03 - 25062019 MID _HMI T-control - Gas 120 ACE 9

Caution

The appliance should be switched to Summer or Frost Protection

mode rather than be switched off in order to guarantee the

following functions:

Avoidance of pumps blocking

Frost Protection

Important

Respect the minimum and maximum water inlet pressure to

ensure correct operation of the boiler: refer to the chapter

Technical Specifications.

Important

Only qualified professionals are permitted to install the boiler, in

accordance with prevailing local and national regulations.

Important

Never remove or cover labels and data plates affixed to the

boiler.

Labels and data plates must be legible throughout the entire

lifetime of the boiler. Immediately replace damaged or illegible

instructions and warning labels.

1.3 Liabilities

Important

Keep this document close to the place where the appliance is

installed.

1.3.1 Manufacturer's liability

Our products are manufactured in compliance with the requirements of the

various Directives applicable. They are therefore delivered with the

marking and any documents necessary. In the interests of the quality of

our products, we strive constantly to improve them. We therefore reserve

the right to modify the specifications given in this document.

Our liability as manufacturer may not be invoked in the following cases:

Failure to abide by the instructions on installing and maintaining the

appliance.

Failure to abide by the instructions on using the appliance.

Faulty or insufficient maintenance of the appliance.

1.3.2 Installer's liability

The installer is responsible for the installation and initial commissioning of

the appliance. The installer must observe the following instructions:

Read and follow the instructions given in the manuals provided with the

appliance.

Install the appliance in compliance with prevailing legislation and

standards.

Carry out initial commissioning and any checks necessary.

Explain the installation to the user.

If maintenance is necessary, warn the user of the obligation to check the

appliance and keep it in good working order.

Give all the instruction manuals to the user.

1.3.3 User's liability

To guarantee optimum operation of the system, you must abide by the

following instructions:

Read and follow the instructions given in the manuals provided with the

appliance.

1 Safety

10 MID _HMI T-control - Gas 120 ACE 7717201 - v03 - 25062019

Call on a qualified professional to carry out installation and initial

commissioning.

Get your installer to explain your installation to you.

Have the required inspections and maintenance carried out by a

qualified installer.

Keep the instruction manuals in good condition close to the appliance.

2 About this manual

1 2

MW-2000068-1

1

2

3

4

5

7717201 - v03 - 25062019 MID _HMI T-control - Gas 120 ACE 11

2.1 Symbols used

2 About this manual

2.1.1 Symbols used in the manual

This manual uses various danger levels to draw attention to special

instructions. We do this to improve user safety, to prevent problems and to

guarantee correct operation of the appliance.

Danger

Risk of dangerous situations that may result in serious personal

injury.

Danger of electric shock

Risk of electric shock.

Warning

Risk of dangerous situations that may result in minor personal

injury.

Caution

Risk of material damage.

Fig.1

Important

Please note: important information.

See

Reference to other manuals or pages in this manual.

2.1.2 Symbols used on the appliance

1 Alternating current.

2 Protective earthing.

3 Before installing and commissioning the appliance, carefully read

the instruction manuals provided.

4 Dispose of used products through an appropriate recovery and

recycling structure.

5 Caution: danger of electric shock, live parts. Disconnect the mains

power prior to carrying out any work.

3 Technical specifications

12 MID _HMI T-control - Gas 120 ACE 7717201 - v03 - 25062019

3 Technical specifications

3.1 Homologations

3.1.1 Standards & Directives

This product complies with the requirements of the following European

directives and standards:

Standards: EN15502

Efficiency Directive 92/42/EC

Low Voltage Directive 2014/35/EU

Generic standard: EN 60335-1

Relevant standard: EN 60335-2-102

Electromagnetic Compatibility Directive 2014/30/EU

Generic standards: EN 61000-6-3, EN 61000-6-1

Relevant Standard: EN 55014

Ecodesign Directive

This product conforms to the requirements of European Directive

2009/125/EC on the ecodesign of energy-related products.

In addition to the legal requirements and guidelines, the supplementary

guidelines in this manual must also be followed.

Supplements or subsequent regulations and guidelines that are valid at

the time of installation shall apply to all regulations and guidelines

specified in this manual.

Warning

The appliance must be installed by a qualified professional in

accordance with applicable local and national regulations.

3.1.2 Factory test

Before leaving the factory, each appliance is tested for the following:

Electrical tests (components, safety).

3.2 Electrical diagram

SCB-02

1

2

3

4 5

BL

YE

RE BK

OR

1

2

3

4 5

BL

YE

RE BK

OR

MW-2000917-01

10 A

L

N

230V/50Hz

BL

G/Y

BR

1

2

3

G/Y

BR

BL

1

2

3

4 5

BL

YE

RE BK

OR

BL

G/Y

BR

BL

G/Y

BR

24V

12 11

BL GR

10 9 8 7 6

OR BK RE YE BL

5 4 3 2 1

OR BK RE YE BL

230V

1 2 3 4 5

G/Y

BR BL

6 7 8 9 10

G/Y

BR BL

WH

BK

RE

YE

BL

GR

OR

BL

YE

RE

BK

OR

CB-09 IF-01

8 9

7

2

3

4

6

5

1

7717201 - v03 - 25062019 MID _HMI T-control - Gas 120 ACE 13

Fig.2

3 Technical specifications

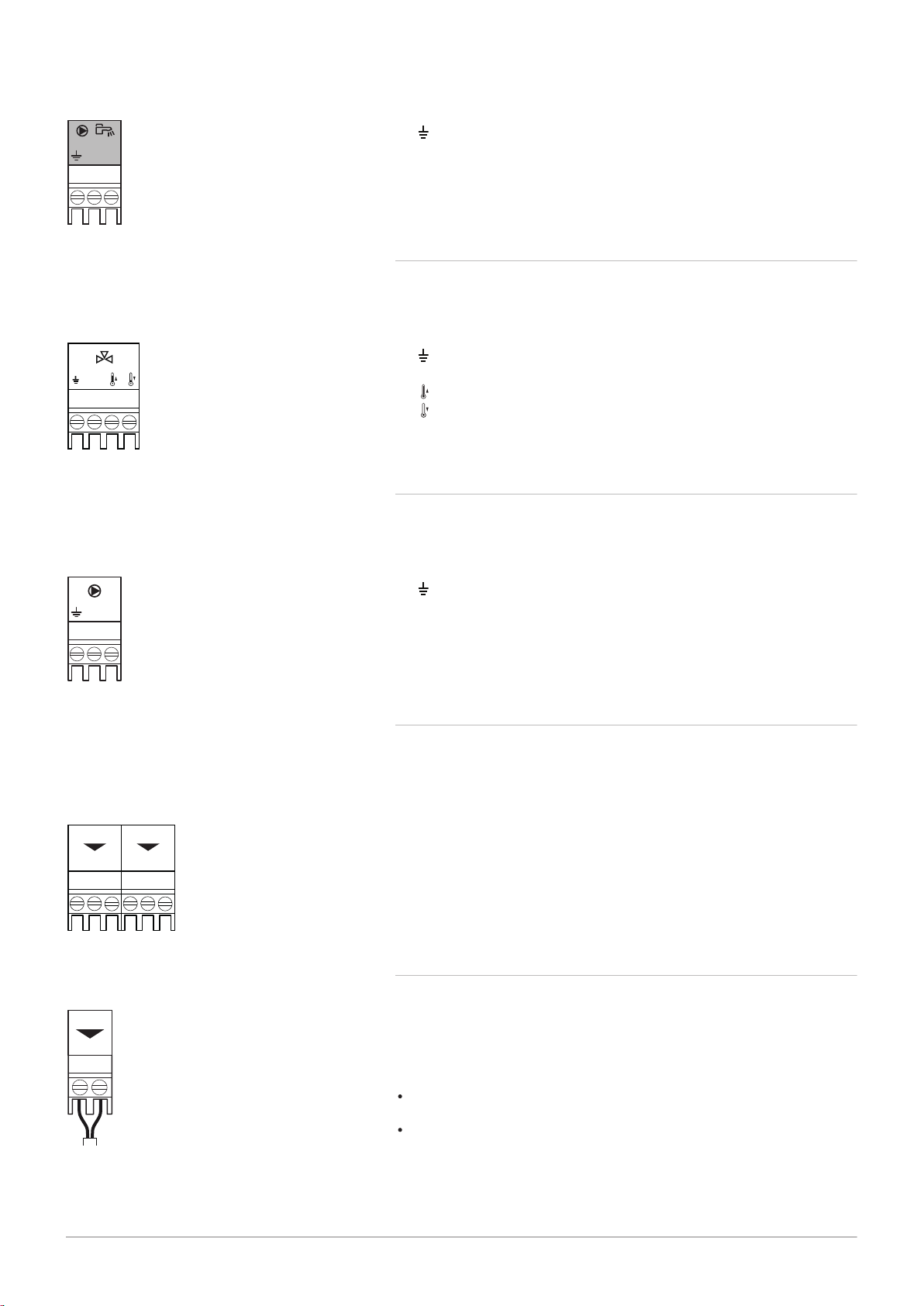

3.2.1 Electrical diagram for the MID control unit HMI T-control

1 MID control panel HMI T-control

2 Service connector, allows the technician to work on

the equipment

3 230 V mains power supply connection with 10 A fuse

4 On/Off switch

5 230 V connector, connection with the boiler

6 24 V connector, connection with the boiler

7 SCB-02 PCB

8 CB-09 PCB

9 IF-01 PCB

BK Black

BL Blue

BR Brown

G/Y Green/Yellow

YE Yellow

OR Orange

GR Green

PI Pink

GY Grey

RD Red

WH White

AD-3001313-01

C No

Nc

Status A

C No

Nc

Status B

N L

+

-

0-10

Tout

N L

N

+

-

0-10

Tdhw Tflow

R-Bus

MW-2000918-01

1

4

3

2

5

7

6

4 Description of the product

14 MID _HMI T-control - Gas 120 ACE 7717201 - v03 - 25062019

4 Description of the product

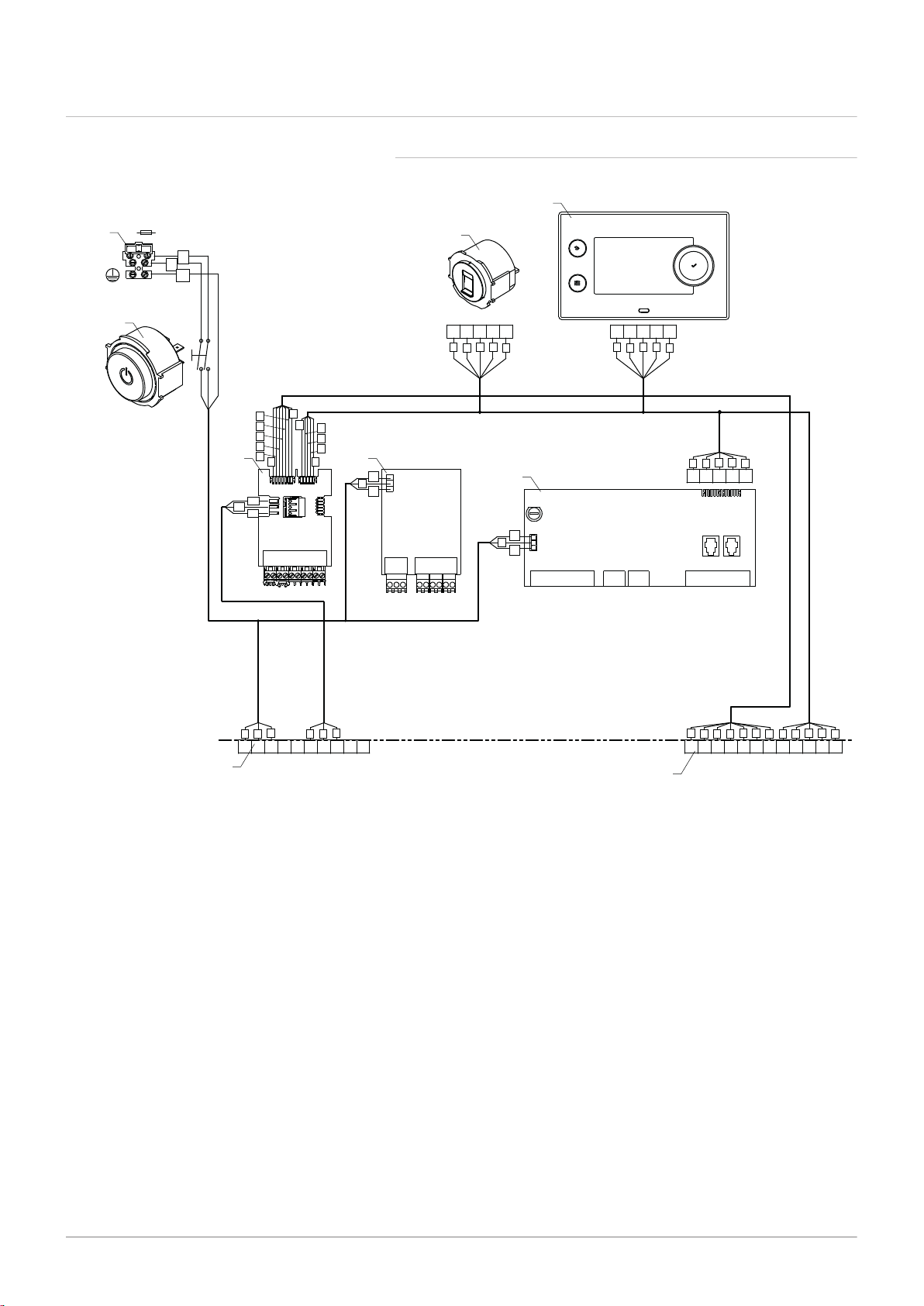

4.1 General description

The control box is used to control the operation of a Gas 120 ACE boiler.

The box is equipped with a HMI T-control control panel.

4.2

Main components

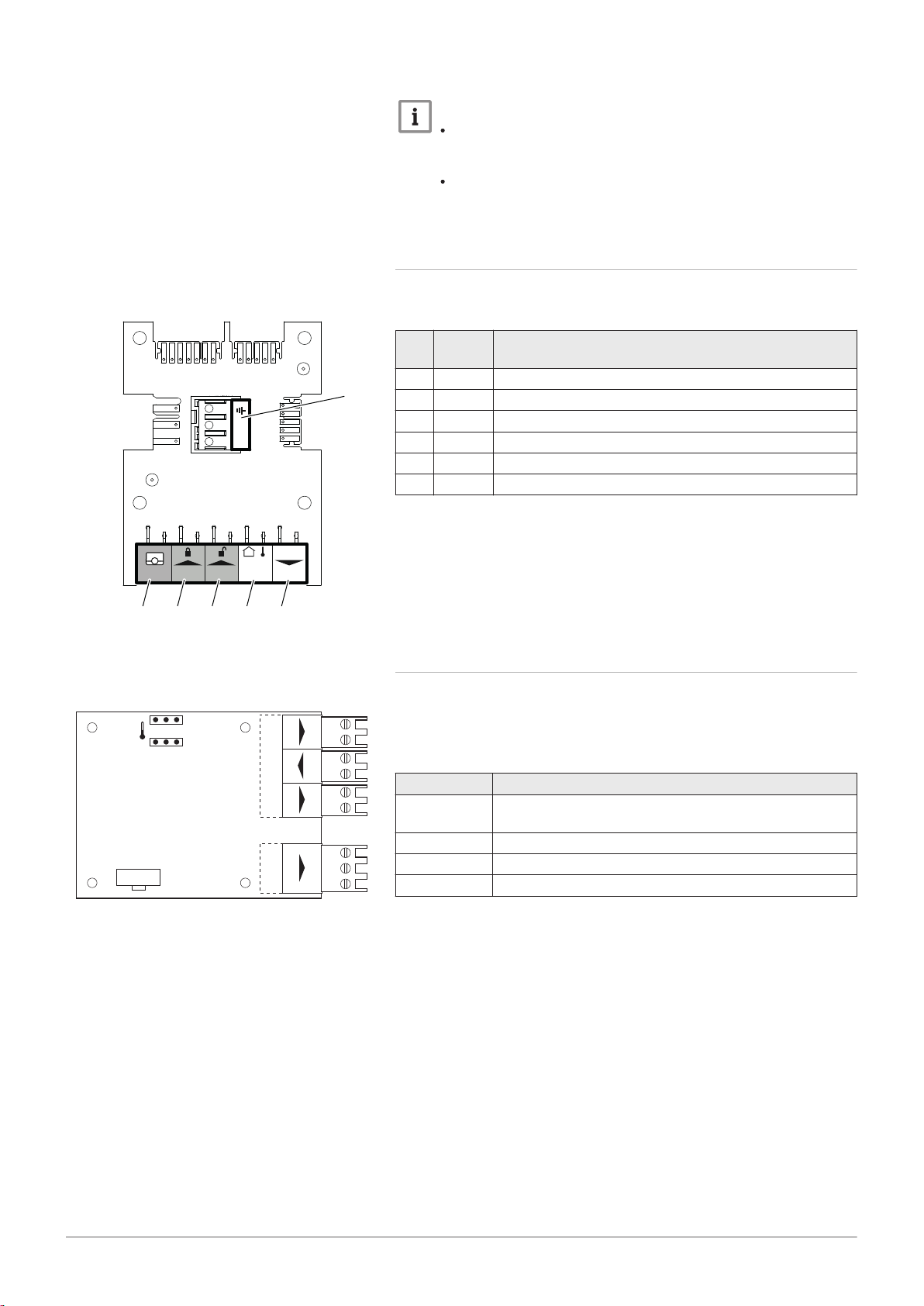

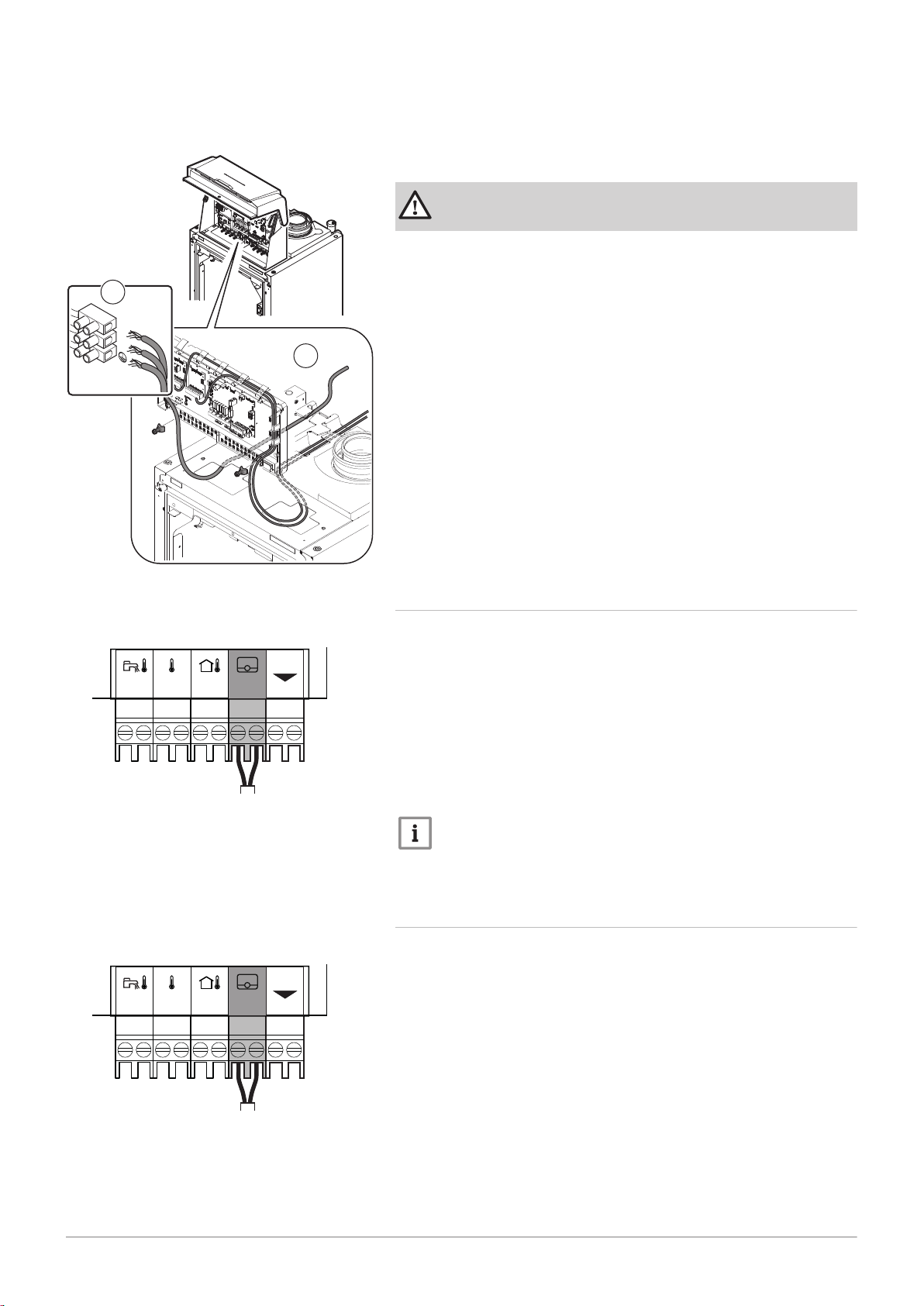

Fig.3

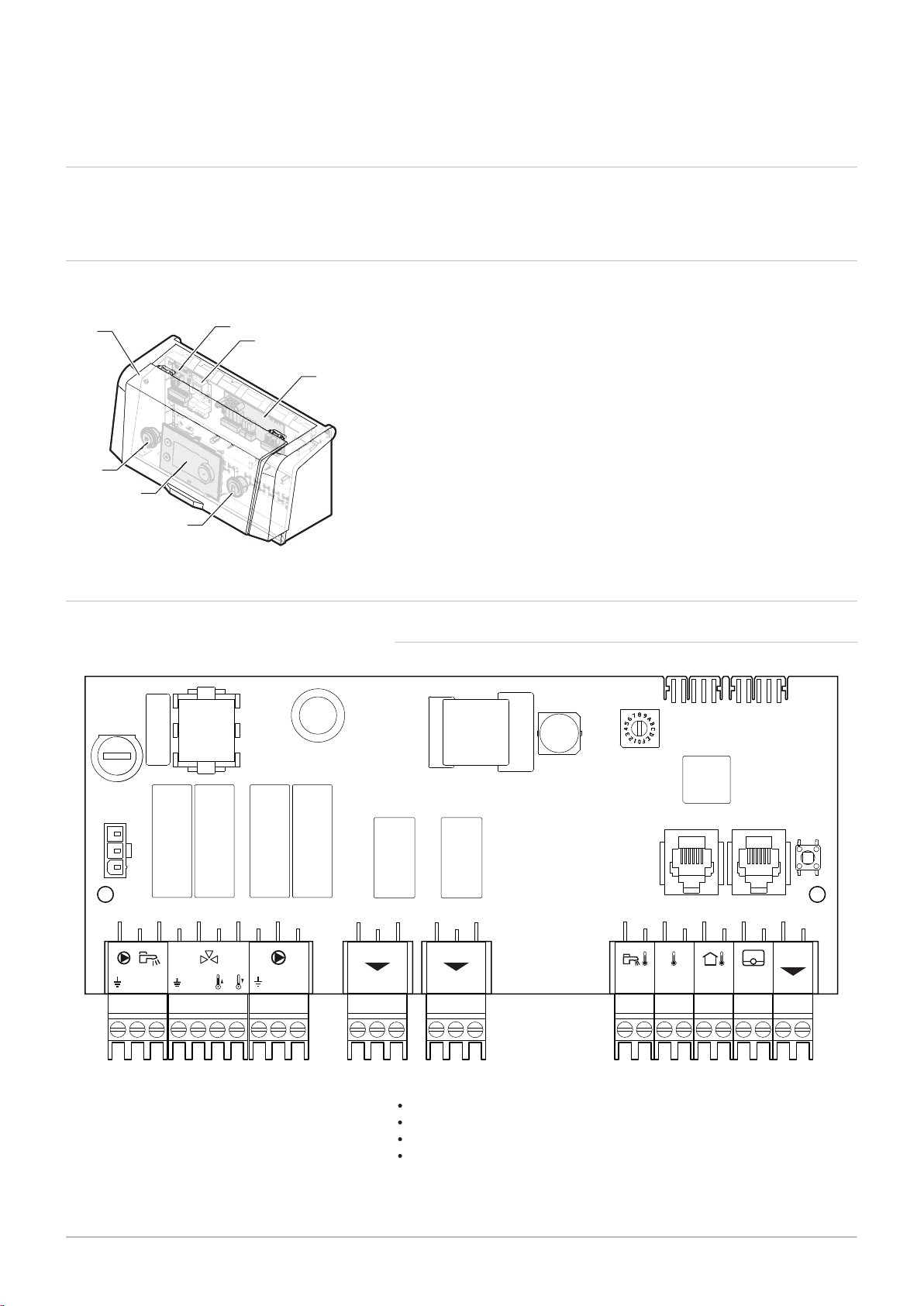

4.3 PCBs

Fig.4

SCB-02 expansion board

1 Protective cover

2 On/Off switch

3 HMI T-control control panel

4 Service connector, allows the technician to work on the equipment

5 SCB-02 PCB

6 IF-01 PCB

7 CB-09 PCB

4.3.1 SCB-02 expansion board description

The expansion board SCB-02 has the following features;

control of a (mixing) zone for heating (or cooling)

control of one domestic hot water (DHW) zone

0–10 V output control for a PWM system pump

two potential-free contacts for status notifications

Important

Tout - +BL RL

LN

R-Bu

s

PWM

1

6

MW-2000826-01

2 3 4 5

AD-0000054-01

Status 0-10 0-10

Nc NoC

Nc No OTm 0 + 0 +C

OTm 0 + 0 +

X5

X4

X1

IF-01

%

1

2

7717201 - v03 - 25062019 MID _HMI T-control - Gas 120 ACE 15

If the boiler is fitted with the SCB-02 board, then this is

automatically recognised by the automatic control unit of the

boiler.

On removing this board, the boiler will show an error code. To

prevent this error, carry out an auto-detect immediately after

removing this board.

4.3.2 Description of the CB-09 PCB

4 Description of the product

Fig.5

Fig.6

The CB-09 PCB allows additional inputs to be connected as per the

following table:

Mar

ker

Con

nector

Description

1 R-Bus Not used

2 BL Boiler frost protection (active if contact open)

3 RL Release open contact

4 Tout Not used

5 PWM Modulating pump control connection

6 X4 Modulating pump power connection

4.3.3 Description of the IF-01 PCB

The IF-01 PCB is factory fitted and allows additional inputs such as a

sensor or switch to be connected to the system.

This PCB controls the boiler with the 0-10V signal from an external control

system.

Connector Description

0-10 (input) The 0-10V signal corresponds to a temperature or power

set point, depending on the position of the jumpers

0-10 (output) Output signal indicating the boiler's operating mode

Status Boiler fault reporting contact output

OTm Communication link with the CU-GH-08 PCB

Off

MW-5000756-1

3

4

1

2

5

6

29,4°C29,6°C

51,2°C 6,7°C

21,8°C

29,4°C

1,8 bar

Not Set

None o OFF

OK

I

I

MW-5000763-2

2 4 31

4 Description of the product

16 MID _HMI T-control - Gas 120 ACE 7717201 - v03 - 25062019

4.4 Control panel description

Caution

Do not connect a frost thermostat or room thermostat to the boiler

if using the 0–10 V PCB.

4.4.1 Description of the user interface

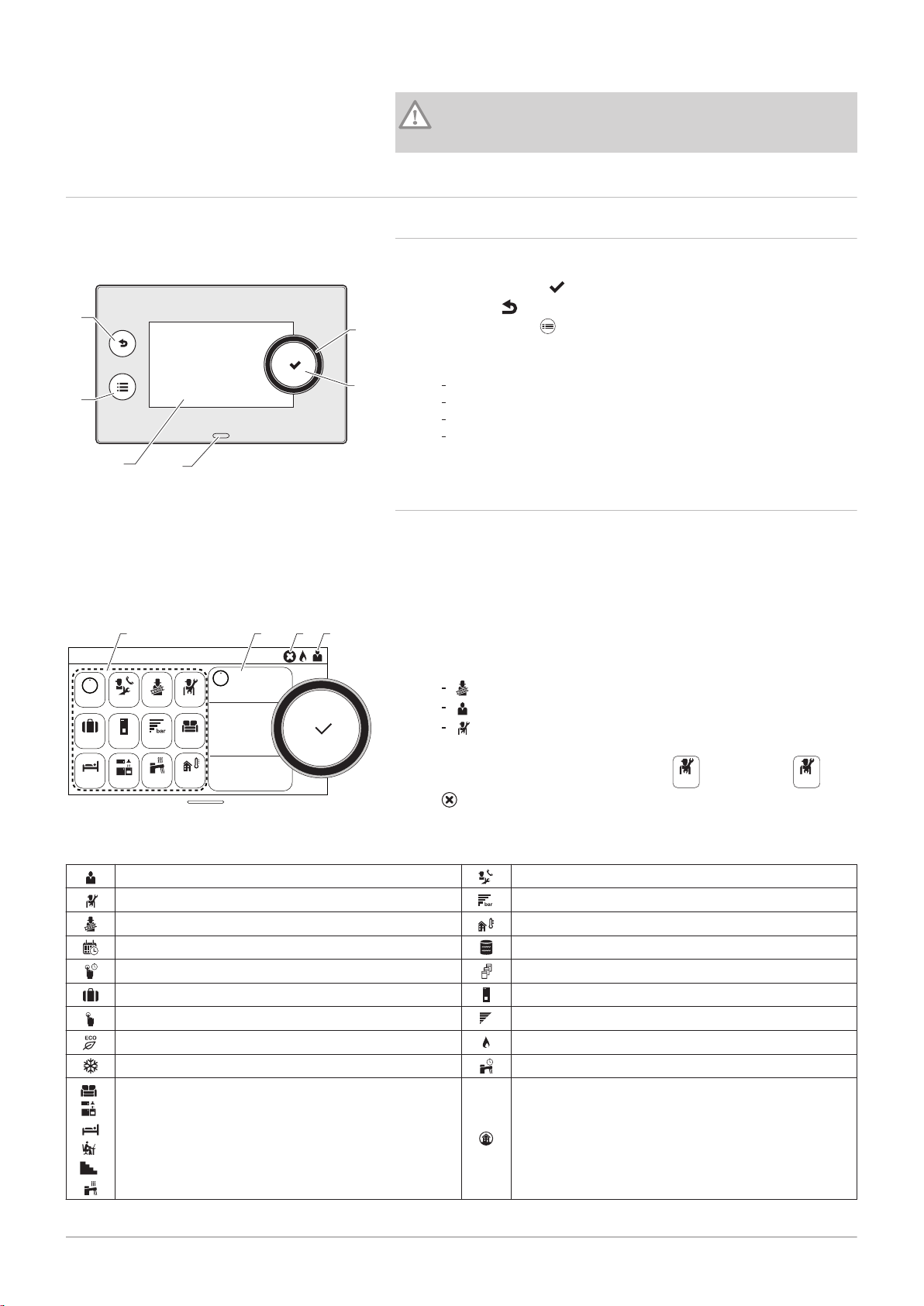

Fig.7

Fig.8

1 Rotary knob to select a menu or setting

2

Validation button

3

Back key to return to the previous level or previous menu

4

Main menu key

5 Display screen

6 LED for status indication:

continuous green = normal operation

flashing green = warning

continuous red = shutdown

flashing red = lockout

4.4.2 Description of the main screen

This screen is displayed automatically after the appliance is started up.

The screen goes into standby if no key is pressed for five minutes. Press

one of the buttons on the control panel to exit standby.

1 Symbols

The selected icon is highlighted.

2 Information on the selected icon

3 Navigation level:

: Chimney Sweep level

: User level

: Installer level

This level is reserved for installers and is protected by an access

Tab.1 Symbols

User Level

Installer Level Water pressure

Chimney Sweep level

Timer programme Buffer tank

Timer programme override Cascade

Holiday mode Boiler

Manual mode

Eco mode Burner on

Frost protection mode Domestic hot water override

,

,

Zone icons All zones

,

,

code. When this level is active, the

4

error notification: only visible if an error occurs.

icon becomes On.

Maintenance message

Outdoor temperature sensor

Burner output level

4.5 Standard delivery

7717201 - v03 - 25062019 MID _HMI T-control - Gas 120 ACE 17

4.6 Accessories & options

4 Description of the product

The package contains:

A complete control box for a Gas 120 ACE boiler

Two mounting bolts with two serrated washers

An outdoor temperature sensor

A control box installation, user and service manual

A detailed list of accessories and options can be found in our catalogue.

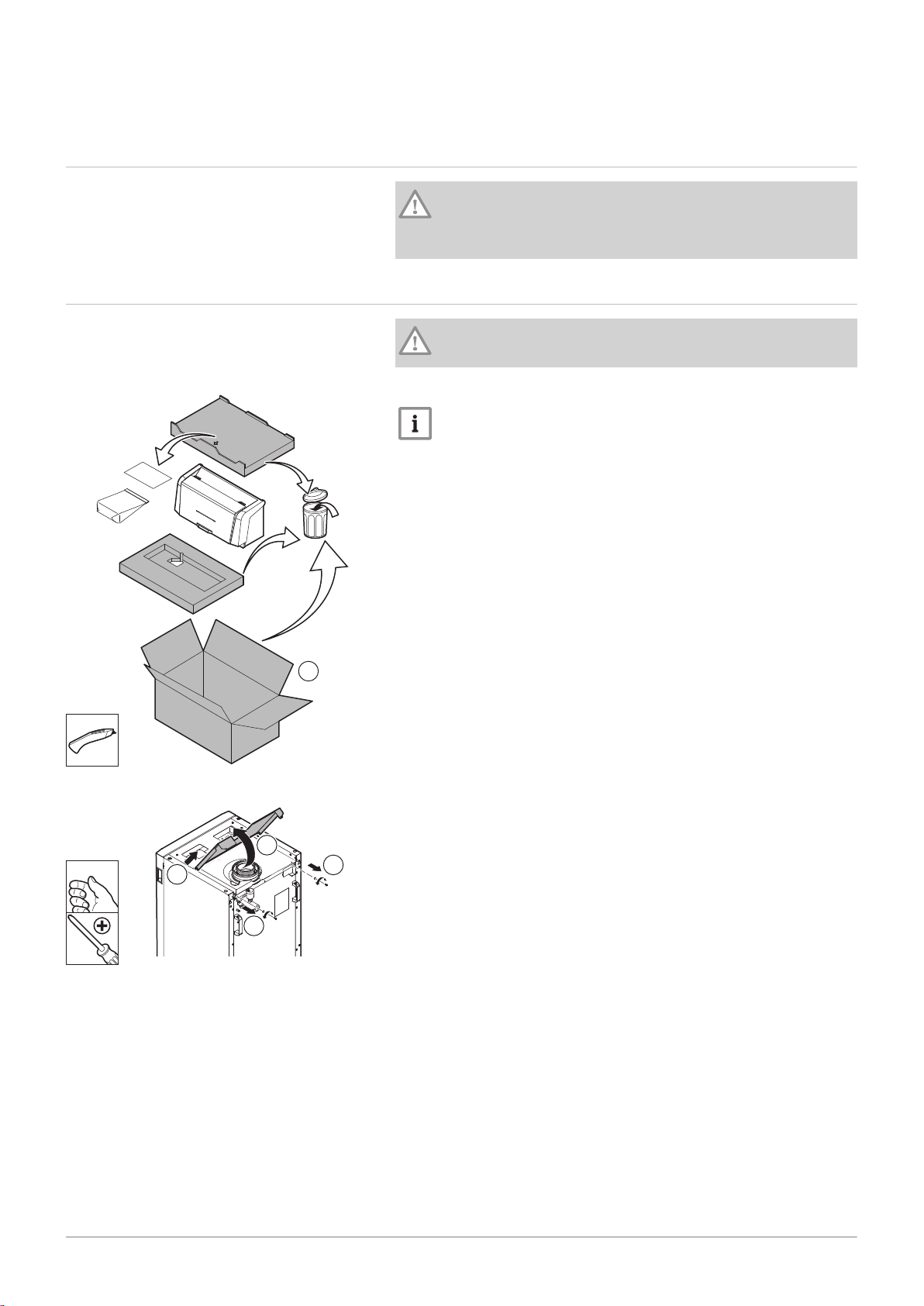

MW-6000750-02

Manual

1

MW-6000760-01

3

4

2

2

5 Installation

18 MID _HMI T-control - Gas 120 ACE 7717201 - v03 - 25062019

5 Installation

5.1 Installation regulations

Caution

The appliance must be installed and maintained by a certified

professional in accordance with prevailing statutory texts and

codes of practice.

5.2

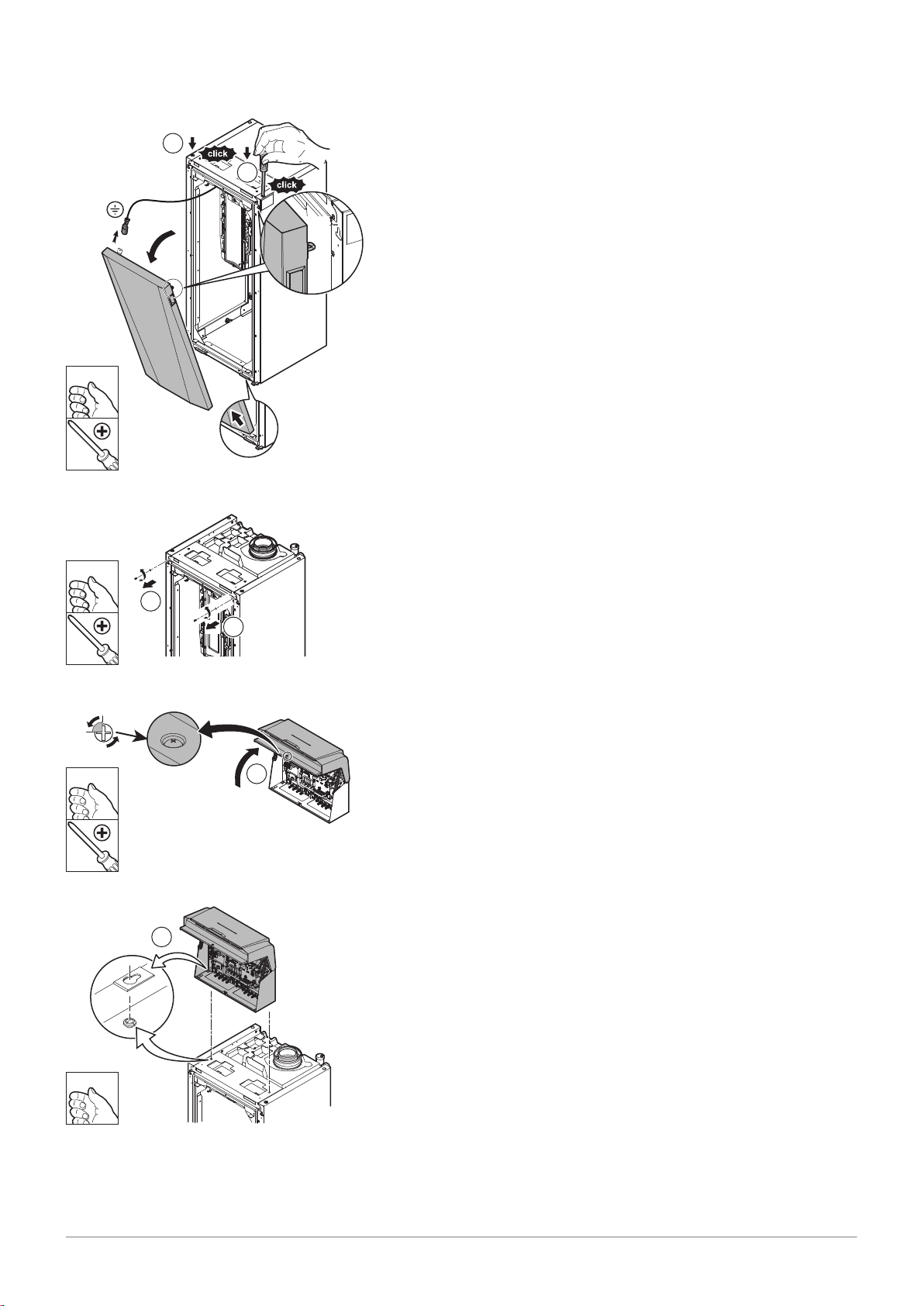

Fig.9

Unpack and fit the control box

Caution

Wear gloves when handling the control box.

1. Cut and remove the packaging.

Important

The technical documentation is housed in the protective block.

Fig.10

2. Remove the two screws from the boiler's rear top panel.

3. Lift the top panel.

4. Remove the top panel.

MW-2000680-03

5

5

MW-6000762-01

6

6

MW-6000763-02

7

90º

MW-6000764-01

8

5 Installation

7717201 - v03 - 25062019 MID _HMI T-control - Gas 120 ACE 19

Fig.11

Fig.12

5. Remove the front door.

6. Remove the two retaining screws from the front top panel.

Fig.13

Fig.14

7. Open the control box cover.

8. Align the boiler's tapered interlocks with the notches on the control

box.

MW-6000765-02

9

9

10

MW-6000766-02

230V

24V

11

12

12

MW-6000767-01

13

MW-6000768-02

14

14

15

MW-6000769-01

16

5 Installation

20 MID _HMI T-control - Gas 120 ACE 7717201 - v03 - 25062019

Fig.15

Fig.16

Fig.17

9. Fit the box and slide it forwards.

10. Lock the box using the two screws and toothed washers supplied in

the bag with the manual.

11. Tilt the assembly backwards.

12. Connect the two connectors from the boiler to the connectors on the

control box.

13. Move the control box back to its original position by tilting it forwards.

Fig.18

Fig.19

14. Lock the control box in position using the two screws and the toothed

washers.

15. Close the box cover.

16. Lock the cover by pressing on the screw head.

17. Refit the front door and the rear top panel and refit the two screws and

the toothed washers.

5.3 Electrical connections

7717201 - v03 - 25062019 MID _HMI T-control - Gas 120 ACE 21

5 Installation

5.3.1 Recommendations

Only qualified professionals may carry out electrical connections, always

with the power off.

Earth the appliance before making any electrical connections.

Power the appliance via a circuit that includes an omni-polar switch with

contact opening distance of 3 mm or more.

When making electrical connections to the mains, respect the polarities.

Danger

Position the various electrical cables in such a way that they never

touch the heating pipes.

Keep the various electrical cables far enough from the heating

pipes so that they cannot be damaged by the effect of the heat.

5.3.2 Electrical power supply

Power supply voltage 230 V AC/50 Hz

Caution

Please ensure the polarities shown on the terminals are followed,

i.e live (L), neutral (N) and earth ( )

5.3.3 Recommended cable cross section

Decide on the cable according to the following information:

Distance of the appliance from the power source.

Upstream protection.

Neutral operating conditions.

Tab.2 Specifications of the power cable and the power source

Cable cross section 3 x 1.5 mm²

Curve C (circuit breaker) 10 A

Differential 30 mA

MW-2000830-02

1

2

1

MW-2000831-01

3

MW-2000832-01

4

90º

5 Installation

22 MID _HMI T-control - Gas 120 ACE 7717201 - v03 - 25062019

Caution

Provide a separate power supply for the pump and a power

switch, if necessary.

The output available per outlet is 450 W (2 A, with cos ϕ = 0.7)

and the inrush current must be less that 16 A. If the load exceeds

either of these values, the control must be relayed using a

contactor that must in no circumstances be installed in the control

panel. The sum of the currents from all outlets must not exceed

5 A.

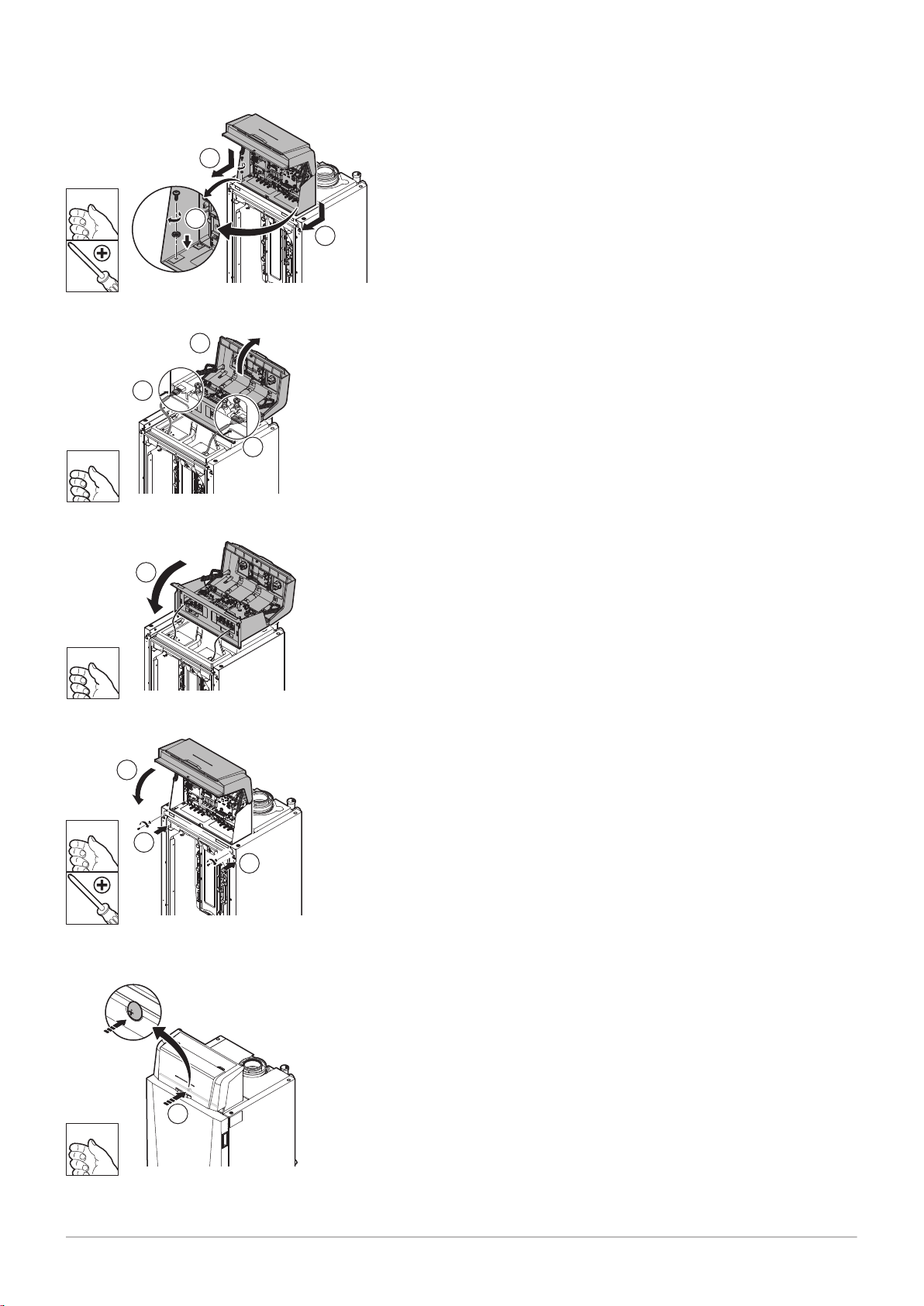

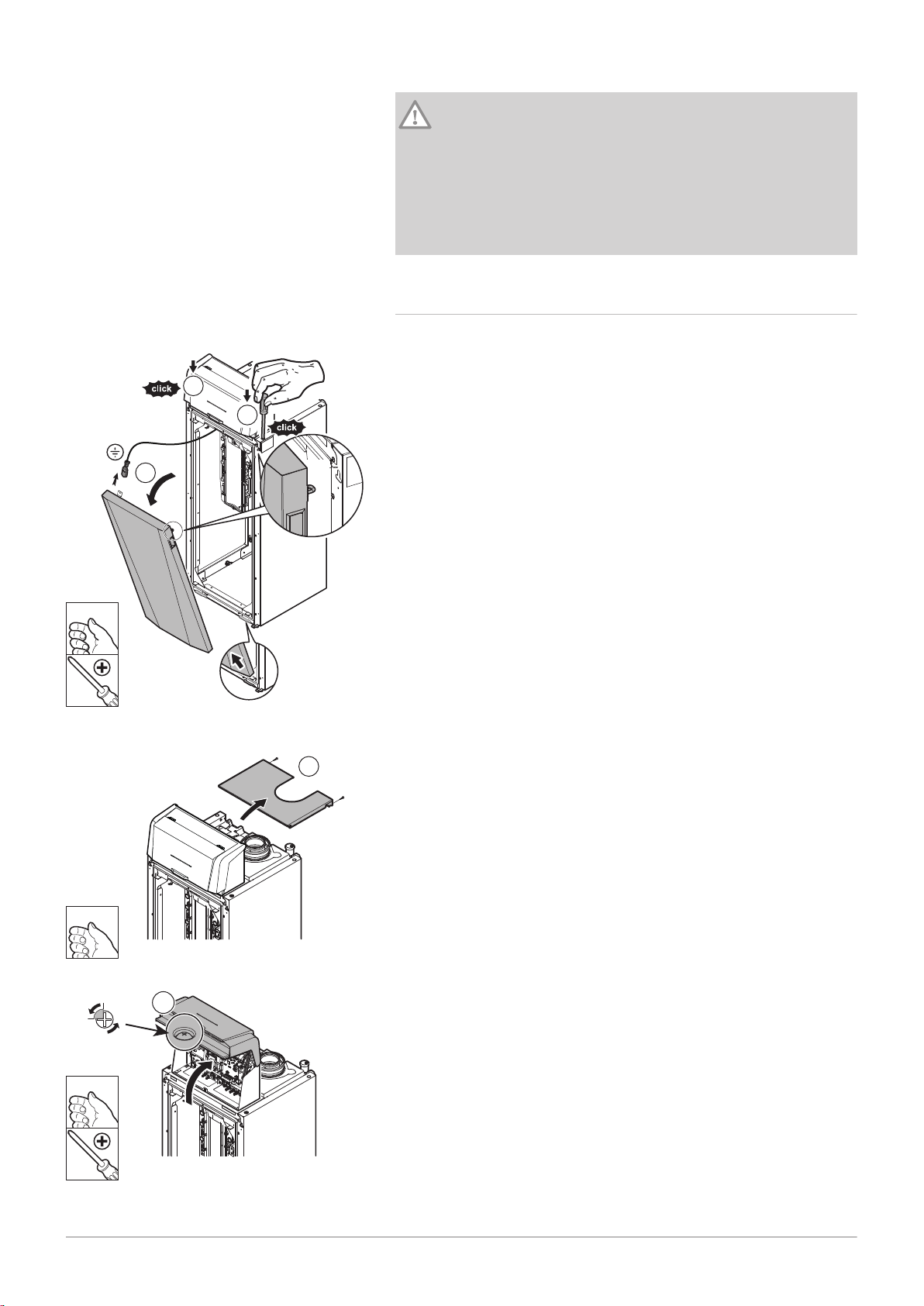

5.3.4 Cable routing and access to the connection terminal

blocks

Fig.20

Fig.21

1. Unlock the front door.

2. Tilt and lift the door to remove it.

3. Remove the two screws and dismantle the rear top panel.

Fig.22

4. Unlock and open the cover on the control box.

Fig.23

MW-2000833-02

Sensor

230V

5

230V

L

N

6

MW-2000919-01

OT

0-10

Tout

+

-

0-10

Tdhw

Tflow

R-Bus

MW-2000920-01

Tk

0-10

Tout

+

-

0-10

Tdhw

Tflow

R-Bus

7717201 - v03 - 25062019 MID _HMI T-control - Gas 120 ACE 23

5 Installation

5. Ensure that the cables are correctly routed and affix the cable(s) using

the traction arrester devices.

230 V 230 V circuits (left)

Sensor Sensor circuits (right)

Danger

Separate the sensor cables from the 230 V circuit cables.

6. Connect the boiler's main power supply cable.

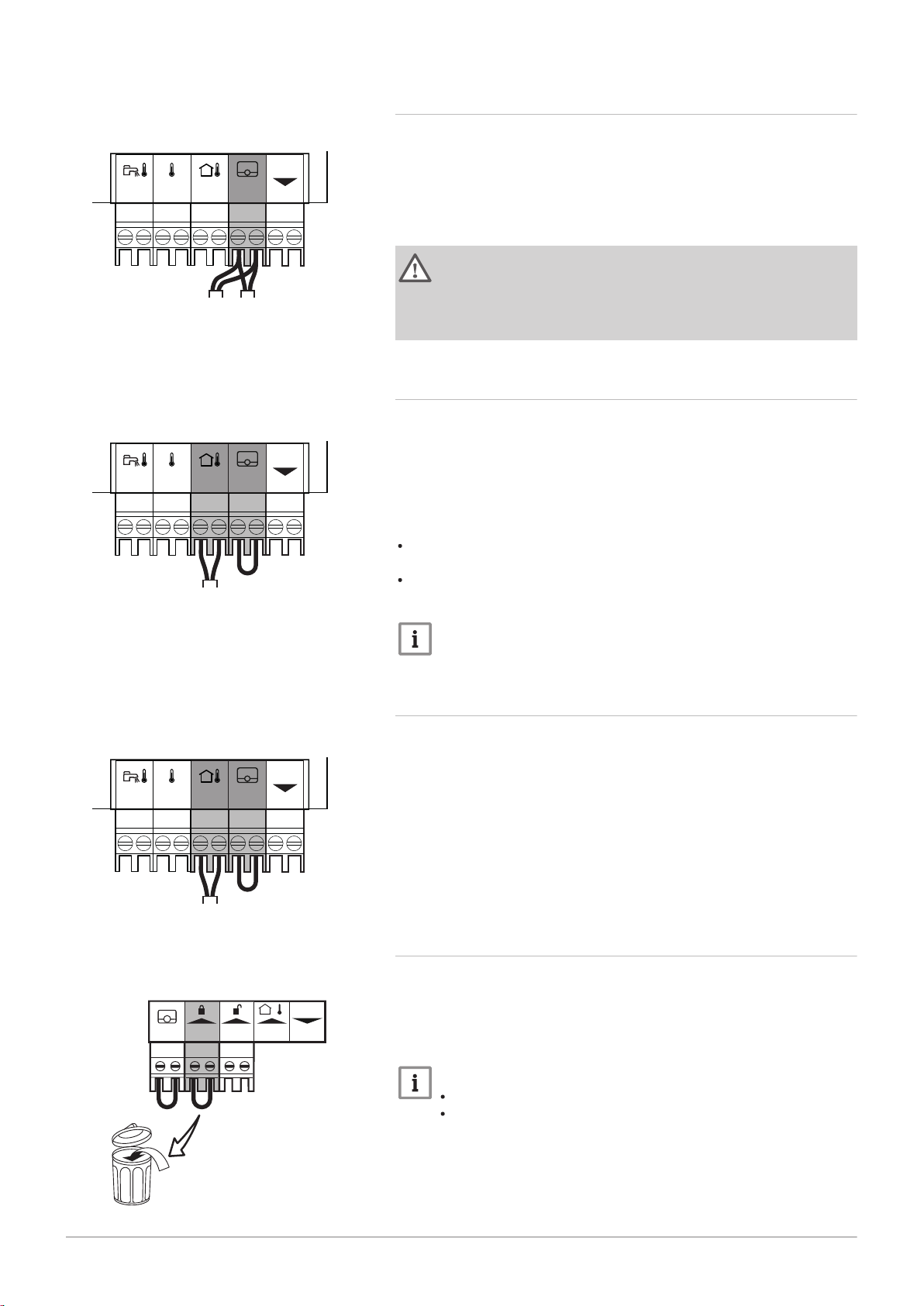

Fig.24 to SCB-02

Fig.25 to SCB-02

5.3.5 Connecting a modulating thermostat

The boiler is fitted with an R-Bus connection as standard. This connection

is also compatible with OpenTherm. This enables the user to connect

OpenTherm modulating thermostats (such as iSense Pro) or R-Bus

thermostats (such as eTwist) without any further adjustments being made

to the appliance. The boiler is also suitable for OpenTherm Smart Power.

1. In the case of a room thermostat: install the thermostat in a reference

room.

2. Connect the two-wire cable for the thermostat to the R-Bus terminals

for the connector. It does not matter which wire is connected to which

terminal block.

Important

If the domestic hot water temperature can be set on the

OpenTherm thermostat, the boiler will supply this temperature,

with the value set in the boiler as a maximum.

5.3.6 Connecting an on/off thermostat

The boiler is suitable for connection to a two-wire on/off room thermostat

(Tk).

1. Fit the thermostat in a reference room.

2. Connect the two-wire cable for the thermostat to the R-Bus terminals

of the connector. It does not matter which wire is connected to which

terminal block.

MW-2000921-01

TvTk

0-10

Tout

+

-

0-10

Tdhw

Tflow

R-Bus

MW-2000922-01

0-10

Tout

+

-

0-10

Tdhw

Tflow

R-Bus

MW-2000922-01

0-10

Tout

+

-

0-10

Tdhw

Tflow

R-Bus

MW-2000873-01

ToutBL RL

R-Bus

- +

PWM

5 Installation

24 MID _HMI T-control - Gas 120 ACE 7717201 - v03 - 25062019

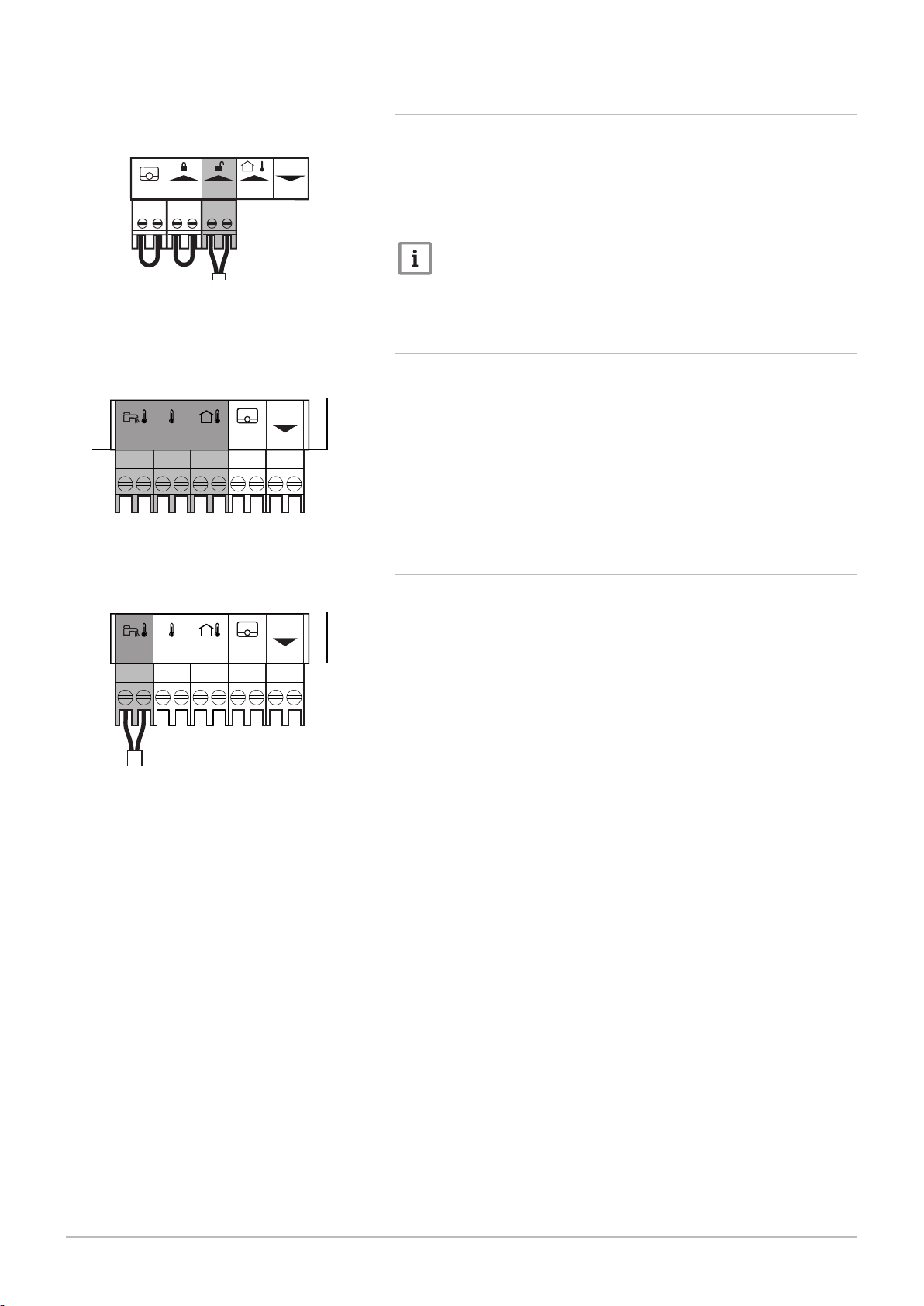

5.3.7 Frost protection combined with on/off thermostat

Fig.26 to SCB-02

Fig.27 to SCB-02

When an on/off thermostat is used, the pipes and radiators in a frostsensitive room can be protected by a frost thermostat. The radiator valve

in the frost-sensitive room must be open.

1. Place a frost thermostat (Tv) in a frost-sensitive room (e.g. a garage).

2. Connect the frost thermostat (Tv) and the on/off thermostat (Tk) in

parallel to the

R-Bus terminals of the connector.

Warning

If a Remeha eTwist or OpenTherm thermostat is used, a frost

thermostat cannot be connected in parallel to the R-Bus terminals.

In this case, ensure frost protection of the central heating system

in combination with an outside sensor.

5.3.8 Frost protection combined with outdoor temperature sensor

The central heating system can also be protected against frost in

combination with an outdoor temperature sensor. The radiator valve in the

frost-sensitive room must be open.

1. Connect the outdoor temperature sensor to the Tout terminals of the

connector.

The frost protection works as follows with an outdoor temperature sensor:

If the outdoor temperature is lower than -10 °C: heat demand from the

boiler.

If the outdoor temperature is higher than -10 °C: no heat demand from

the boiler.

Fig.28 to SCB-02

Fig.29 to CB-09

Important

The outdoor temperature before the start of frost protection can be

changed with the AP080 parameter.

5.3.9 Connecting an outdoor temperature sensor

An outdoor temperature sensor (accessory) can be connected to the Tout

terminals of the connector. If the boiler is equipped with an on/off

thermostat, the temperature is controlled using the setpoint of the internal

heating curve (F). Various parameter settings can be used to change the

internal heating curve.

1. Connect the plug from the outdoor temperature sensor to the Tout

terminal.

5.3.10 Blocking input

The boiler has a blocking input (normally closed contact). This input

relates to the BL terminals of the connector.

If this contact is opened, the boiler will be blocked or locked out.

Change the function of the input by configuring the AP001 parameter.

Important

Remove the bridge if this input is used.

Only suitable for potential-free contacts.

5.3.11 Release input

MW-2000874-01

T

out

BL RL

R-Bus

- +

PWM

MW-2000932-01

0-10

Tout

+

-

0-10

Tdhw

Tflow

R-Bus

MW-2000923-01

0-10

Tout

+

-

0-10

Tdhw

Tflow

R-Bus

7717201 - v03 - 25062019 MID _HMI T-control - Gas 120 ACE 25

5 Installation

Fig.30

Fig.31

to CB-09

The boiler has a release input (normally open contact). This input relates

to the RL terminals of the connection terminal block.

If this contact is closed when there is a heat demand, the boiler will be

blocked after a waiting time.

Change the waiting time of the input by configuring the AP008 parameter.

Important

Only suitable for potential-free contacts.

5.3.12 Connecting external sensors

Tdhw

Tflow

The sensor connection contacts are dry contacts.

Tank sensor (NTC 10 k Ohm)

Boiler flow temperature sensor (NTC 10 k Ohm)

Tout

Outdoor temperature sensor (NTC 10 k Ohm)

5.3.13 Connecting a tank sensor or thermostat

Fig.32 to SCB-02

A sensor or thermostat can be connected to the Tdhw terminals of the

connector.

1. Connect the domestic hot water sensor or the tank thermostat to the

Tdhw connector.

MW-2000878-02

Tout - +BL RL

R-Bus

PWM

X4

CB-09

Tout - +BL RL

R-Bus

PWM

CB-09

MW-2000879-02

X4

5 Installation

26 MID _HMI T-control - Gas 120 ACE 7717201 - v03 - 25062019

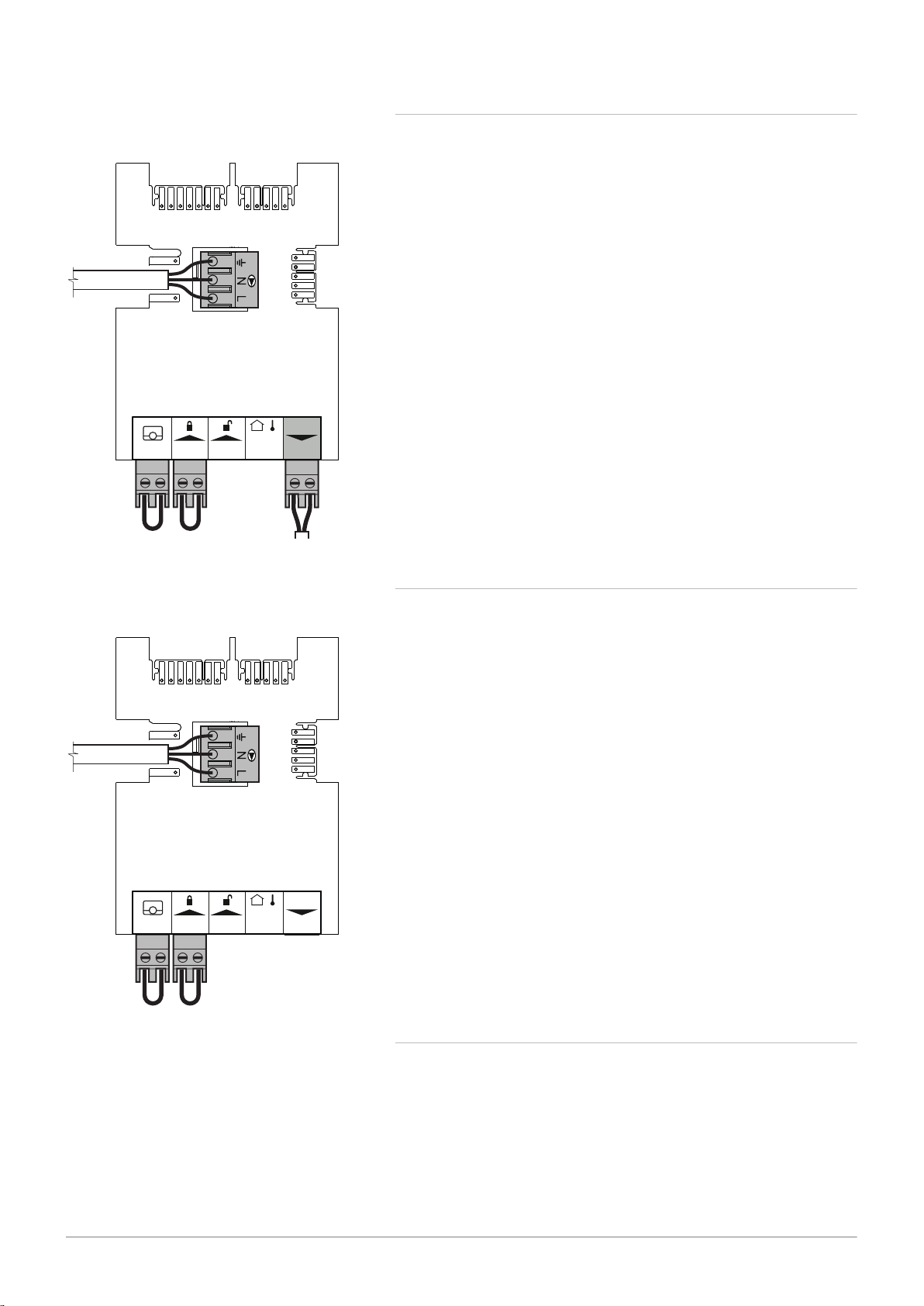

5.3.14 Connecting a PWM pump

Fig.33

to CB-09

1. Connect the modulating pump to the X4 terminal for the power section

and to the PWM terminal for the control section, respecting the pump

polarity.

5.3.15 Connecting a standard pump

Fig.34 to CB-09

1. Connect the pump to the X4 terminal on the PCB.

5.3.16

Connecting a domestic hot water (DHW) pump

Connecting a domestic hot water (DHW) pump. The maximum power

consumption is 300 VA.

AD-4000123-01

N L

AD-4000015-02

N

AD-3001306-01

N L

AD-3001312-01

C No

Nc

Status A

C No

Nc

Status B

AD-3001305-01

+

-

0-10

5 Installation

7717201 - v03 - 25062019 MID _HMI T-control - Gas 120 ACE 27

Fig.35

DHW pump connector

Fig.36 Three-way valve connector

Connect the pump as follows:

Earth

N

Neutral

L

Phase

5.3.17 Connecting a three-way valve

Connecting a three-way valve (230 VAC). The connection can be used for

a boiler group (zone).

Connect the three-way valve as follows:

Earth

N

Neutral

Open

Closed

5.3.18

Connecting a system pump for mix group (zone) The maximum power

consumption is 300 VA.

Connecting a system pump for mix group

Fig.37 Pump connector

Fig.38 Status notifications

Fig.39 0–10 V output connector

Connect the pump as follows:

Earth

N

Neutral

L

Phase

5.3.19 Connecting status notifications

The two potential-free contacts, Status, can be configured as required.

Depending on the setting, a particular status can be transmitted by the

boiler.

Connect a relais as follows:

Nc

Normally closed contact. Contact will open when status occurs.

C

Main contact.

No

Normally opened contact. Contact will close when status occurs.

Select the desired status notification (setting) using parameter EP018 and

EP019.

5.3.20 Connecting 0–10 V output

The 0-10 contact can be used to connect a PWM system pump. The

speed of the pump is modulated based on the signal received from the

boiler. Depending on the make and type of pump, the pump can be

controlled by a 0–10 V or a PWM signal.

Connect the system pump controller to connector 0-10.

Select the type of signal that will be sent from the boiler using the

parameter EP029.

Select the type of signal that controls the pump using the parameter

EP028.

AD-0000054-01

Status 0-10 0-10

Nc NoC

Nc No OTm 0 + 0 +C

OTm 0 + 0 +

X5

X4

X1

IF-01

%

1

2

AD-0000055-01

1

2

%

2 2

5 Installation

28 MID _HMI T-control - Gas 120 ACE 7717201 - v03 - 25062019

Caution

If possible, use the pump modulation signal. This provides the

most accurate pump control.

If the automatic burner unit does not support pump modulation,

the pump will behave as an on/off pump.

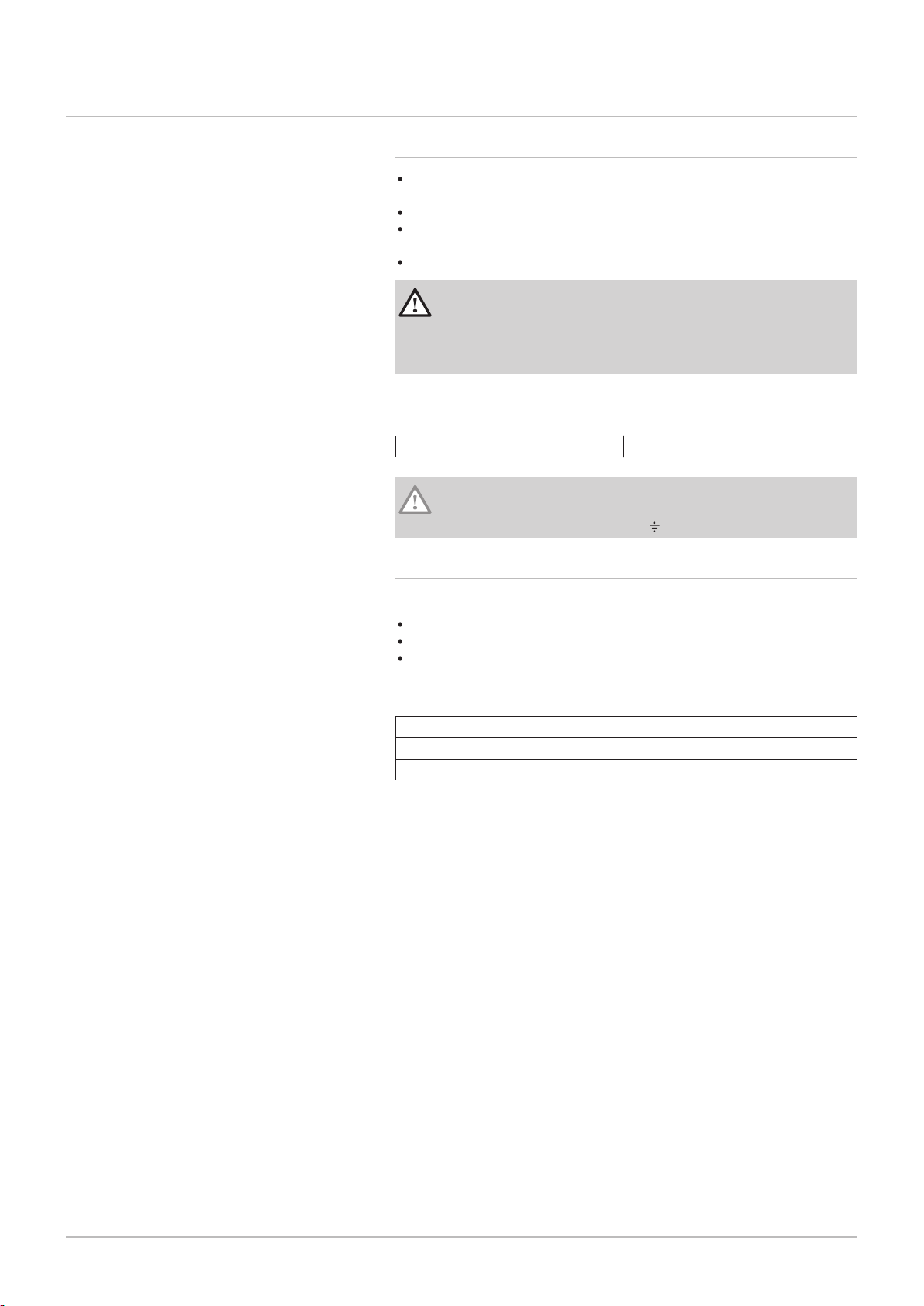

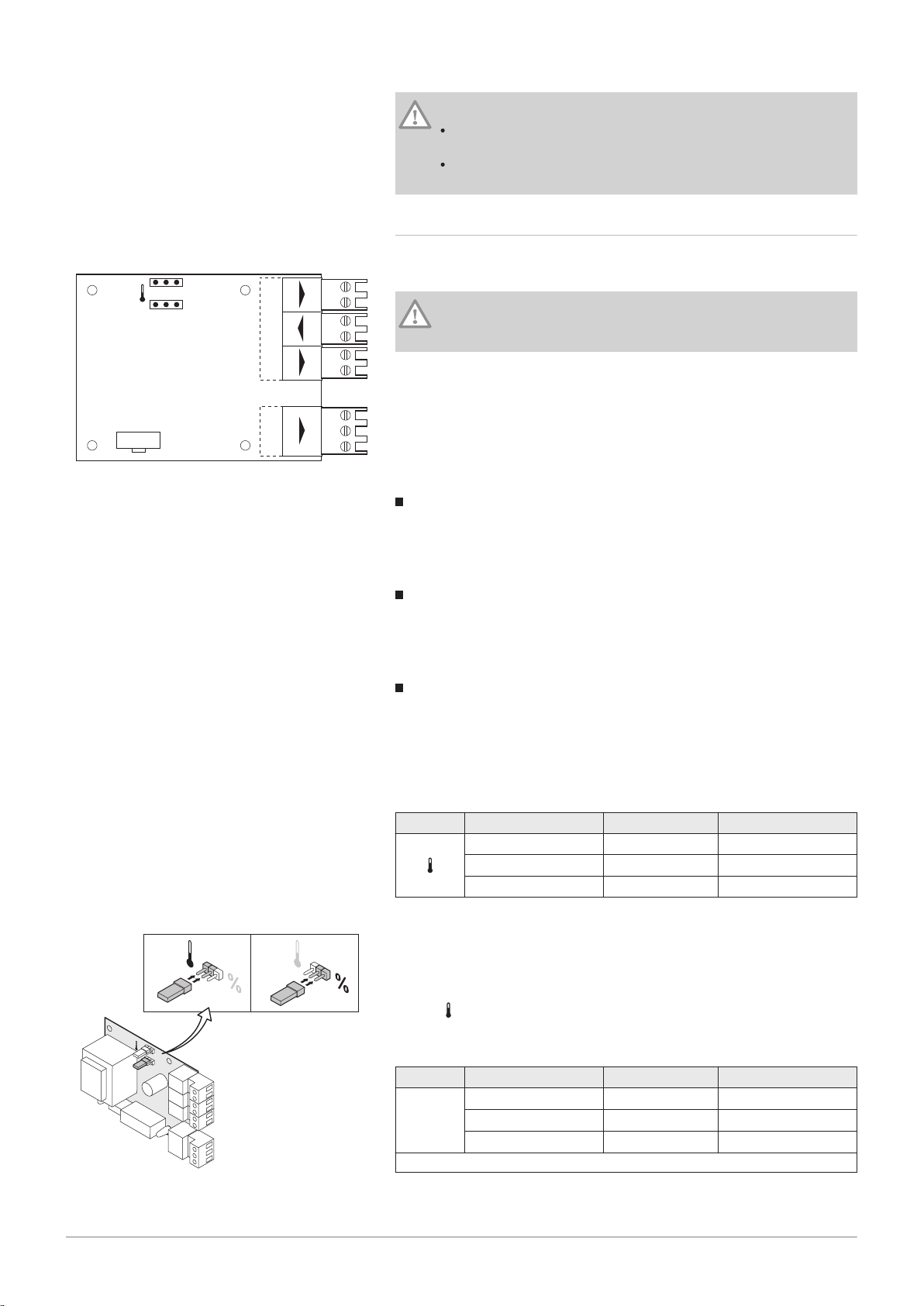

5.3.21 Connection options for the expansion PCB - IF-01

Fig.40 IF-01 PCB

The expansion board IF-01 is pre-installed in the instrument box as

standard.

Caution

Do not connect a frost thermostat or room thermostat to the boiler

if using the 0–10 V control PCB.

Connecting the status relay (Nc)

If the boiler locks out, a relay is de-energised and the alarm can be

transmitted via a potential-free contact (maximum 230 V, 1 A) on terminals

Nc and C of the connector.

Connection (OTm)

The interface uses OpenTherm to communicate with the boiler control

unit. To make this possible, the OTm connection must be connected to the

OpenTherm input of the boiler control unit.OTm

Analogue input (0-10 V)

A choice can be made with this control between control based on

temperature or heat output. The two controls are described briefly below.

1. Connect the input signal to terminals 0–10 of the connector.

Tab.3 Temperature-based control (°C)

Jumper 2 Input signal (V) Temperature °C Description

0–1.5 0–15 Boiler off

1.5–1.8 15–18 Hysteresis

1.8–10 18–100 Desired temperature

Fig.41 Switch jumper (2)

The 0–10 V signal controls the boiler supply temperature. This control

modulates on the basis of flow temperature. The output varies between

the minimum and maximum value on the basis of the flow temperature set

point calculated by the controller.

A jumper (2) on the interface is used to select either temperature-based

control ( ) or output-based control (%).

Tab.4 Control based on heat output

Jumper 2 Input signal (V) Heat output (%) Description

(1)

0–2.0

%

2.0–2.2

2.0–10

(1) Dependent on the minimum modulation depth (set speeds, standard 20%)

(1)

(1)

0–20 Boiler off

20–22 Hysteresis

20–100 Desired heat output

AD-0000056-01

1

2

%

1 1

AD-0001177-01

3

4

5

1

2

5 Installation

7717201 - v03 - 25062019 MID _HMI T-control - Gas 120 ACE 29

The 0–10 V signal controls the boiler output. This control modulates on the

basis of the heat output. The minimum output is linked to the boiler's

modulation depth. The output varies between the minimum and maximum

value on the basis of the value defined by the controller.

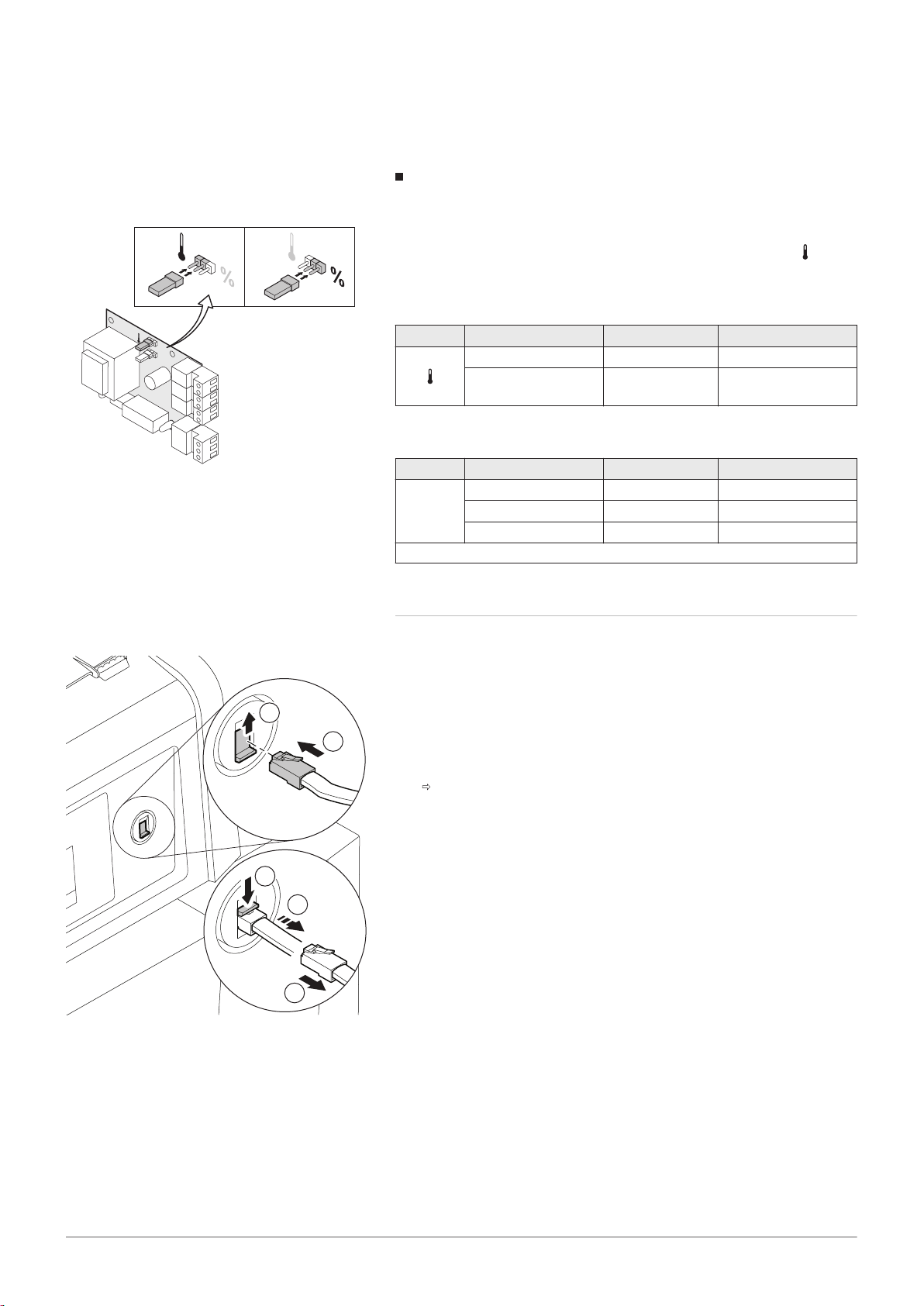

Analogue output (0–10 V)

Fig.42

Switch jumper (1)

Fig.43 Connecting an interface connector

This feedback can be based on temperature or heat output. The two

controls are described briefly below.

A jumper (1) on the interface is used to select either temperature ( ) or

output (%).

Tab.5 Temperature message

Jumper 1 Output signal (V) Temperature °C Description

0.5 – Alarm

1–10 10–100 Supplied tempera

ture

Tab.6 Output message

Jumper 2 Output signal (V) Heat output (%) Description

0 0–15 Boiler off

0.5 15–20 Alarm

%

(1)

2.0–10

(1) Dependent on the minimum modulation depth (set speeds, standard 20%)

20–100 Supplied heat output

5.3.22 Connecting a PC/laptop

There is a Service connector next to the control panel. A Recom interface

can be used to connect a PC, laptop or a Smart Service Tool here. Using

the Recom PC/laptop service software, you can enter, change and read

out various boiler settings.

Connecting an interface connector:

1. Move the Service connector slide upwards.

2. Push the interface connector into place. It should snap shut with a

click.

Disconnect the interface connector again:

3. Maintain slight tension on the interface connector

4. Push the slide downwards. The interface connector will now be

released.

5. Pull the interface connector from the connector.

Loading...

Loading...