Remcor Pump Smart Service Manual

IMI CORNELIUS INC One Cornelius Place Anoka, MN 55303-6234

Telephone (800) 238-3600 Facsimile (763) 422-3246

Installation/Service Manual

PumpSmartCONDIMENT

SERVER

www.pumpsmart.com

The PumpSmart Compact Condiment Servers and the

PumpSmartCompact Condiment Servers Plus Condiment Servers are designed for smooth condiments

only. Attempting to pump condiments containing

particulates (such as salsa) using these servers will

void the warranty.”

Part No. 569000301

March 23, 1998

Revised: March 16, 2000

Control Code B

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

IMI CORNELIUS INC; 1998–2000

PRINTED IN U.S.A

TABLE OF CONTENTS

SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RECOGNIZE SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNDERSTAND SIGNAL WORDS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FOLLOW SAFETY INSTRUCTIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CO2 (CARBON DIOXIDE) WARNING 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SHIPPING, STORING, OR RELOCATING UNIT 1. . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTEM DESCRIPTION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY REFERENCE INFORMATION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

THEORY OF OPERATION 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNPACKING AND INSPECTION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IDENTIFICATION OF LOOSE-SHIPPED PARTS 7. . . . . . . . . . . . . . . . . . . . . . . . . . .

SELECTING LOCATION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLING UNIT 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLACING PUMPSMARTT CONDIMENT SERVER COMPONENTS IN

OPERATING POSITION 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREPARATION FOR OPERATION 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE AND MAINTENANCE 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

PERIODIC INSPECTION 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUMP TUBE AND CHECK VALVE ASSEMBLY SERVICE INTERVAL 11. . . . . . . .

ADJUSTMENTS 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRIMARY CO2/AIR REGULATOR ADJUSTMENT 11. . . . . . . . . . . . . . . . . . . . . . . .

CHECKING AND MAINTAINING THE CONDIMENT BAG 11. . . . . . . . . . . . . . . . . . .

MAXIMIZING BAG EVACUATION (FOR KETCHUP AND MUSTARD

CONDIMENTS) 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOADING BAG INTO THE BASKET (FOR KETCHUP AND MUSTARD

CONDIMENTS) 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STARTUP AFTER INSTALLING NEW BAG 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING AND SANITIZING 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAILY CLEANING 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SANITIZING PRODUCT SYSTEM 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STEP 1 WASH CONDIMENT SYSTEM 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STEP 2 FLUSH CONDIMENT SYSTEM 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STEP 3 SANITIZE CONDIMENT SYSTEM 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STEP 4 FLUSH CONDIMENT SYSTEM 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STEP 5 PURGE WATER OUT OF CONDIMENT SYSTEM AND RESTORE

OPERATION 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUMPSMARTT CONDIMENT SERVER 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

569000301

TABLE OF CONTENTS (cont’d)

LIST OF FIGURES

FIGURE 1. FLOW DIAGRAM 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 2. CIRCUIT BOARD 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 3. PARTS IDENTIFICATION 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 4. PUMPSMARTT CONDIMENT SERVER 18. . . . . . . . . . . . . . . . . . . . . . . .

LIST OF TABLES

TABLE 1. DESIGN DATA 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE 1. DESIGN DATA CONT’D) 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE 2. LOOSE-SHIPPED PARTS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

569000301

ii

SAFETY INFORMATION

Recognize Safety Information

This is the safety-alert symbol. When you see this

symbol on our machine or in this manual, be alert to

the potentially of personal injury.

Follow recommended precautions and safe operating

practices.

Understand Signal Words

A signal word - DANGER, WARNING, OR CAUTION

is used with the safety-alert symbol. DANGER identi-

fies the most serious hazards.

DANGER

Safety signs with signal word DANGER or WARNING

are typically near specific hazards.

General precautions are listed on CAUTION safety

signs. CAUTION also calls attention to safety messages in this manual.

WARNING

CAUTION

Follow Safety Instructions

Carefully read all safety messages in this manual and on your machine safety signs. Keep safety signs in

good condition. Replace missing or damaged safety signs. Learn how to operate the machine and how to

use the controls properly. Do not let anyone operate the machine without instructions. Keep your machine in

proper working condition. Unauthorized modifications to the machine may impair function and/or safety and

affect the machine life.

CO2 (Carbon Dioxide) Warning

CO2 Displaces Oxygen. Strict Attention must be observed in the prevention of CO2 (carbon dioxide)

gas leaks in the entire CO2 and soft drink system. If a CO2 gas leak is suspected, particularly in a

small area, immediately ventilate the contaminated area before attempting to repair the leak.

Personnel exposed to high concentration of CO2 gas will experience tremors which are followed

rapidly by loss of consciousness and suffocation.

Maximum CO

Operating Pressure 75–PSI

2

Shipping, Storing, Or Relocating Unit

CAUTION: Before shipping, storing, or relocating this Unit, the syrup systems must be sanitized and

all sanitizing solution must be purged from the syrup systems. All water must also be purged from

the plain and carbonated water systems. A freezing ambient temperature will cause residual water

remaining inside the Unit to freeze resulting in damage to internal components of the Unit.

1 569000301

GENERAL DESCRIPTION

This section gives the Unit description, theory of operation, and design data for the PumpSmart Condiment

Server.

This Condiments Dispensing System must be installed and serviced by a qualified Service Person. This system

contains no user serviceable parts.

IMPORTANT: To the user of this manual – This manual is a guide for installing, operating, and maintaining this equipment. Refer to the Table of Contents for page location for detailed information pertaining to questions that arise during installation, operation, service, or maintenance of this equipment.

SYSTEM DESCRIPTION

The PumpSmart Condiment Server is a system to dispense smooth condiments such as ketchup or mustard

in dining areas. The PumpSmart Condiment Server is made up of three components which are a Basket or

Bag-in-Box Shelf, a Pump Assembly, and the Dispensing Tower. Also provided with the system is the necessary

tubing and electrical wiring for interconnecting the Pump Assembly and the Condiment Dispensing Tower. The

PumpSmart Condiment Server is easily installed, maintained and cleaned.

W ARRANTY REFERENCE INFORMATION

IMPORTANT: The PumpSmart Compact Condiment Server and the PumpSmart Plus Condiment

Server are designed for smooth condiments only. Attempting to pump any other type of condiment

using these servers will void the factory warranty.

Unit Part Number:

Serial Number:

Install Date:

Local Authorized

Service Center:

Table 1. Design Data

Systems Part Numbers:

PumpSmart Compact Ketchup Server

PumpSmart Compact Mustard Server

PumpSmart Plus Compact Ketchup Server

PumpSmart Plus Compact Mustard Server

Overall Dimensions

Basket/Pump Stand Assembly

Width 20 Inches

Height 16 Inches

Depth 14 Inches

Condiment Dispensing Tower

Width 3 Inches

Height Ketchup/Mustard 8-3/4Inches

Depth 10-1/2 Inches

561500002

561500012

561500003

561500013

Ambient Operating Temperature 40F to 105F

3

569000301

Table 1. Design Data Cont’d)

Electrical Requirement

Operating Voltage 24VAC, 60 Hz

Current Draw (approximate) 300 Milliampere

Gas Requirement 90 PSI @ 1 SCFM

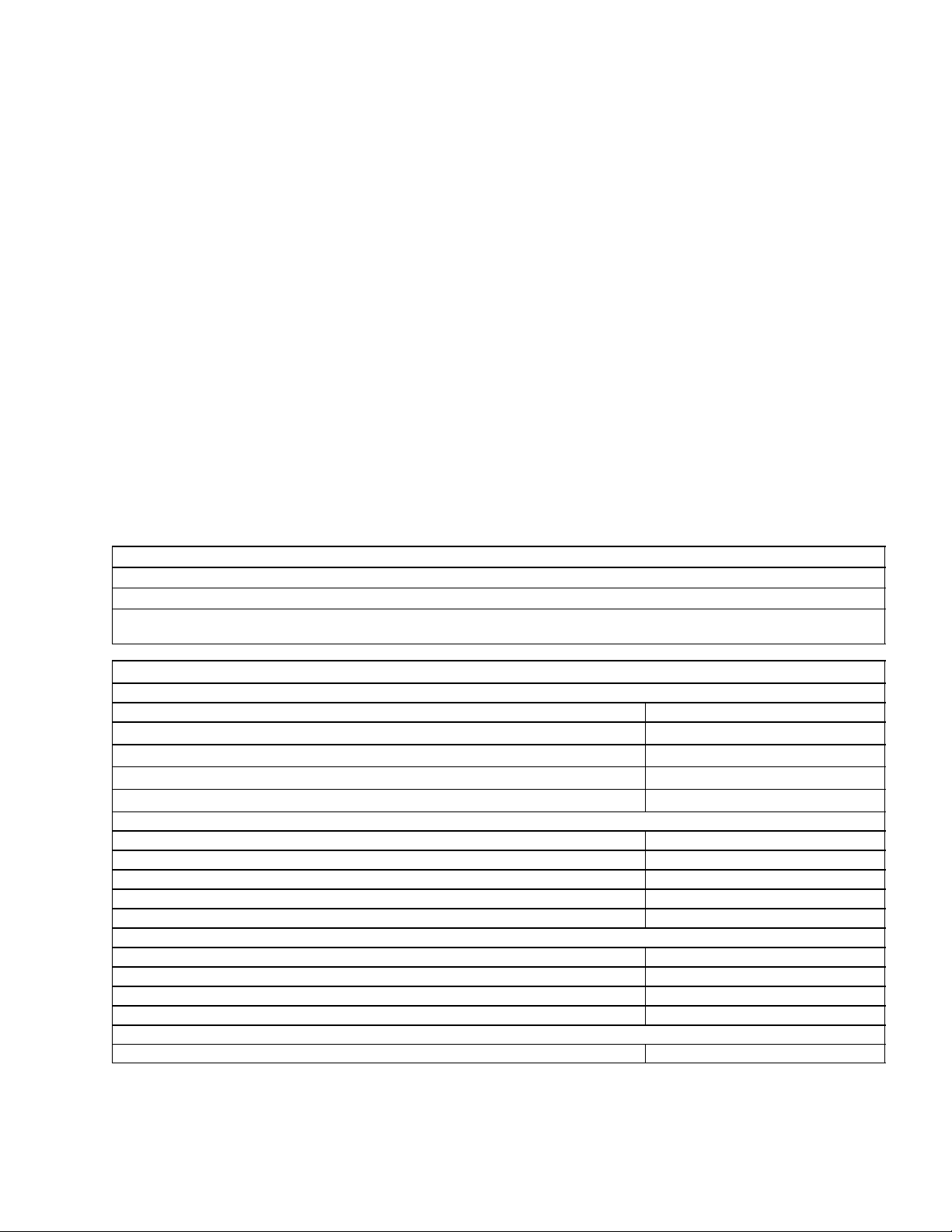

THEORY OF OPERATION

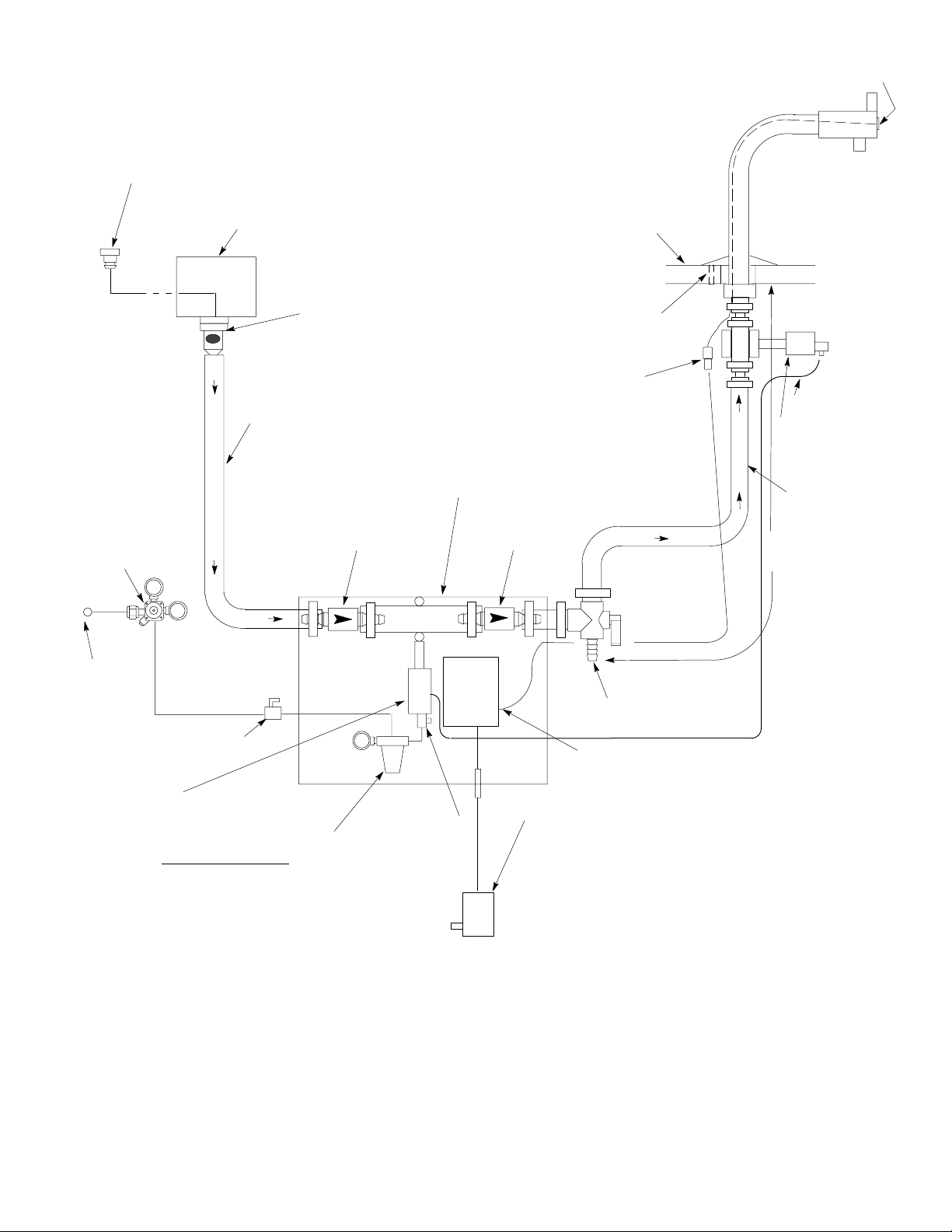

(See Figure 1)

WARNING: CO2 displaces oxygen. Strict attention must be observed in the prevention of

CO

(carbon dioxide) gas leaks in the entire CO

2

suspected, particularly in a small area, immediately ventilate the contaminated area before

attempting to repair the leak. Personnel exposed to high concentration of CO

tremors which are followed by loss of consciouses and suffocation.

The PumpSmart Condiment Server is a device that dispenses smooth condiments such as ketchup and mustard and may be operated with either air pressure or CO2 gas. The Condiment Server uses a linear peristaltic

pump that pumps condiment from a bag-in-box container and pushes condiment through tubing to the Dispense

Tower. Upon demand (pushing dispense button on Dispense Tower), condiment will flow from the Dispense

Tower.

and condiment system. If a CO2 gas leak is

2

gas will experience

2

The Condiment Server may be configured to dispense condiment continuously while the dispense button is held

down (on demand mode) or the Server may be configured to dispense individual portions of condiment (portioncontrol mode). The size of the individual portions may also be set to any level from 0 to 6.0 ounces.

The peristaltic pump has only a few moving parts, requires little maintenance and is fully field repairable. The

straight-through condiment path makes sanitizing easy.

569000301

4

SANITIZING

ADAPTOR

DISPENSE

BUTTON

ADJUSTABLE

PRIMARY CO2/AIR

REGULATOR

SET AT 90 PSI

CONDIMENT BAG

BAG CONNECTOR

PRODUCT INLET

TUBE (30 INCHES LONG)

CHECK

VALVE

PUMP ASSEMBL Y

CHECK

VALVE

COUNTER

SURFACE

ANTI–PIVOT PIN

ELECTRICAL

CONNECTOR

CONDIMENT

DISPENSE TOWER

AIR/CO2 LINE

CHAMBER

CYLINDER

(10’ UNITS

ONLY)

PRODUCT

OUTLET TUBE

(3 FEET LONG OR

10 FEET LONG )

CO

AIR

2 OR

SOURCE

SOLENOID/RELAY

ASSEMBLY

ADJUSTABLE CO2/AIR REGULATOR

KETCHUP & MUSTARD

SHUTOFF

VALVE

SET AT 60 PSI AIR

SET AT 70 PSI CO

BLEED VALVE

CIRCUIT BOARD

(SEE FIGURE 2)

120/24 VAC CLASS 2

CO2/AIR EXHAUST

2

TRANSFORMER

FIGURE 1. FLOW DIAGRAM

5

569000301

THIS PAGE LEFT BLANK INTENTIONALLY

569000301

6

Loading...

Loading...