Remcor DB200S, DB220S, DB275S Installation Manual

ICE/BEVERAGE DISPENSER

MODELS DB200/220/275S

DB200/220/275S-B

Operator’s Manual

DB200/220/275S-BC

DB200/220/275S-KBC

Part No. 91679

May 1997

Revision E

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

âREMCOR INC: 1993--97

PRINTED IN U.S.A

TABLE OF CONTENTS

SAFETY PRECAUTIONS 1. . . ............ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION INSTRUCTIONS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING INSTRUCTIONS 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING GUIDE 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIST OF FIGURES

FIGURE 1. GATE RESTRICTOR PLATE 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 2. MOUNTING TEMPLATE 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 3. MOUNTING TEMPLATE 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

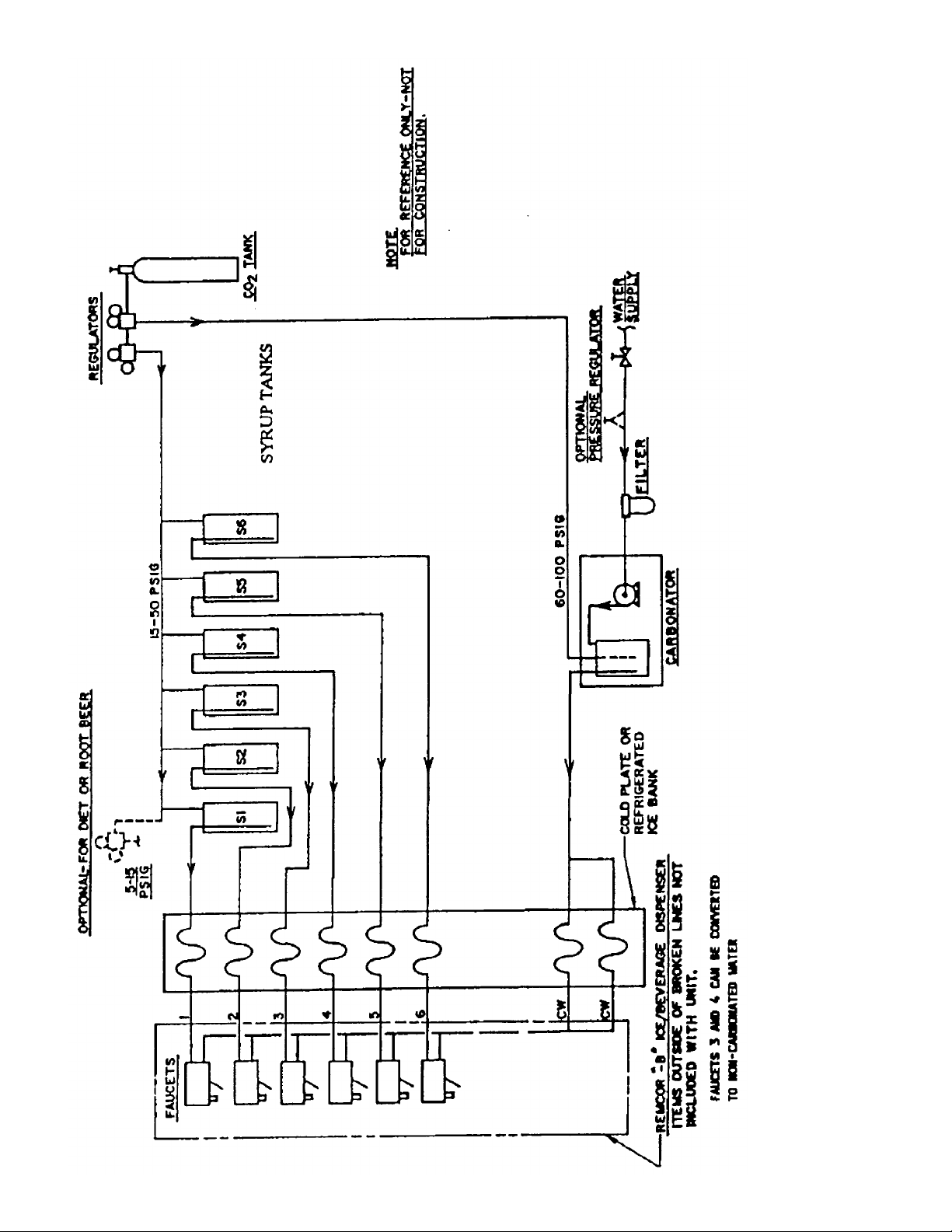

FIGURE 4. BEVERAGE SYSTEM SCHEMATIC -B MODEL 6. . . . . . . . . . . . . . . . .

FIGURE 5. BEVERAGE SYSTEM SCHEMATIC -BC MODEL 7. . . . . . . . . . . . . . . .

FIGURE 6. PLUMBING SCHEMATIC 6 FAUCETS 8. . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 7. PLUMBING SCHEMATIC 8 FAUCETS 9. . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 8. PLUMBING SCHEMATIC 10 FAUCETS 10. . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 9. WIRING DIAGRAM ICE ONLY AND “B” MODELS 15. . . . . . . . . . . . . . .

FIGURE 10. WIRING DIAGRAM “C” AND “K” MODELS 16. . . . . . . . . . . . . . . . . . . . .

FIGURE 11. SOLENOID ASSEMBLY AND PARTS LIST 17. . . . . . . . . . . . . . . . . . . .

FIGURE 12. EXPLODED ASSEMBLY (UPPER AND PARTS LIST) 18. . . . . . . . . . .

FIGURE 13. EXPLODED VIEW (LOWER AND PARTS LIST) 19. . . . . . . . . . . . . . . .

FIGURE 14. MOTOR ASSEMBLY DETAIL AND PARTS LIST 20. . . . . . . . . . . . . . . .

Page

LIST OF TABLES

TABLE 1. SPECIFICATIONS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manufactured Under One or More of the following Patent Numbers:3,211,336, 3,274,792, 3,393,839, 3,517,860

3,739,842, 4,215,803, 4,227,377, 4,300,359, 4,346 ,824

Canadian Patent Numbers 912,514(10/72), 936,855 (11/73), 4,429,543, 4,921,149

Other Patents Pending

i

91679

SAFETY PRECAUTIONS

Always disconnect power to the dispenser before servicing or cleaning.

Never place hands inside of hopper or ga te area without disconnecting power to the dispenser. Agitator rotation

occurs automa tically when the dispenser is energized!

This ice dispenser has been specifically designed to provide protection against personal injury and eliminates

contamination of ice. To insure continued protection and sanit ation, observe the following

ALWAYS be sure the removable lid is properly installed to prevent unauthorized access to the hopper interior and possible contamination of ice.

ALWAYS be sure the upper and lower f ront panels are securely fastened.

ALWAYS keep area around the dispenser clean of ice cubes.

CAUTION: Dispenser cannot be used with crushed or flaked ice.

Use of bagged ice which has frozen into large chunks can void warranty. The dispenser

agitator is not designed to be an ice crusher. Use of large chunks of ice which “jam up”

inside the hopper will cause failure of the agitator motor and damage to the hopper . If bagged ice

is used, it must be carefully and completely broken into small, cube-sized pieces before filling into

the dispenser hopper.

GENERAL DESCRIPTION

The Remcor “DB” series of ice dispensers solve your ice and beverage service needs in a sanitary, space saving, economical way. Designed to be manually filled with ice from any remote ice making source, these

dispensers will dispense cubes (up 1-1/4” in size), cubelets and hard-chipped or cracked ice.

“B” models also contain beverage faucets and must be supplied with cold product from any remote cold plate o r

refrigerated soda factory.

“BC” units include both faucets and cold plates and are designed to be supplied direct from syrup tanks and carbonator, with no additional cooling required.

Table 1. Specifications

Model: DB200S DB220S DB275S

Ice Storage: 200 lbs. 220 lbs. 275 lbs.

Maximum Number of Faucets Available: N/A N/A N/A

Built-in Cold Plate: No No No

Dimension: 30W x 30D x 33H 30W x 30D x 36H 30W x 30D x 40H

Model: DB200S-B DB220S-B DB275S-B

Ice Storage: 200 lbs. 220 lbs. 275 lbs.

Maximum Number of Faucets Available: 10 10 10

Built-in Cold Plate: No No No

Dimension: 30W x 30D x 33H 30W x 30D x 36H 30W x 30D x 40H

Model: DB200S-BC DB220S-BC DB275S-BC

Ice Storage: 200 lbs. 220 lbs. 275 lbs.

Maximum Number of Faucets Available: 10 10 10

Built-in Cold Plate: Yes Yes Yes

Dimension: 30W x 30D x 33H 30W x 30D x 36H 30W x 30D x 40H

Electrical (for all models) 120V, 1ph., 5.5 Amps

Drain Connection 7/8 ID Hose

1 91679

ICE MAKER

REMCOR “K” Model Ice/Beverage dispensers are designed to be used with one of several type top m ount icemakers. This must be obtained from the appropriate manufacturer.

Check with your REMCOR Sales Coordinator for a list of icemaker kits available. This kit will contain parts and

instructions n ecessary to connect the icemaker to the ice dispenser.

INSTALLATION INSTRUCTIONS

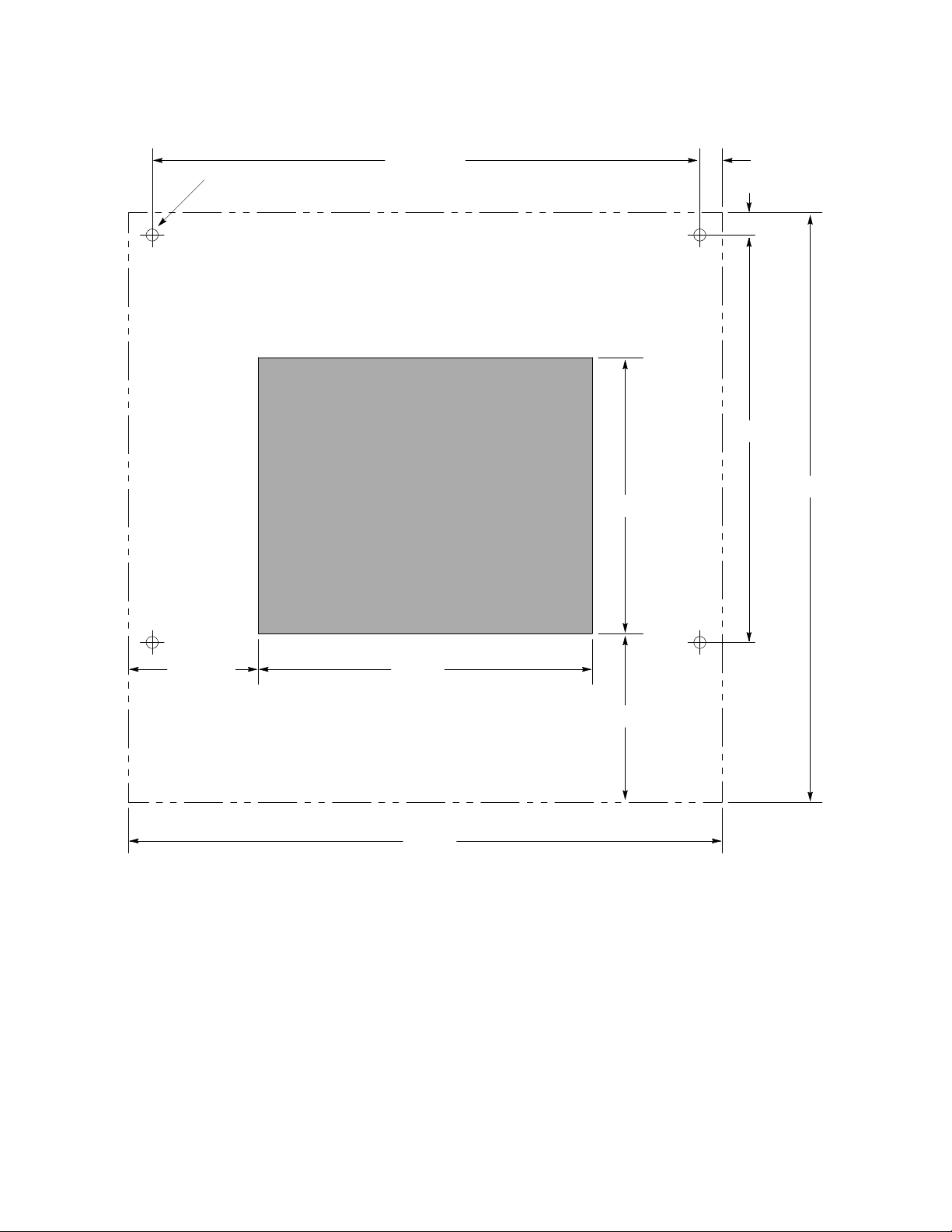

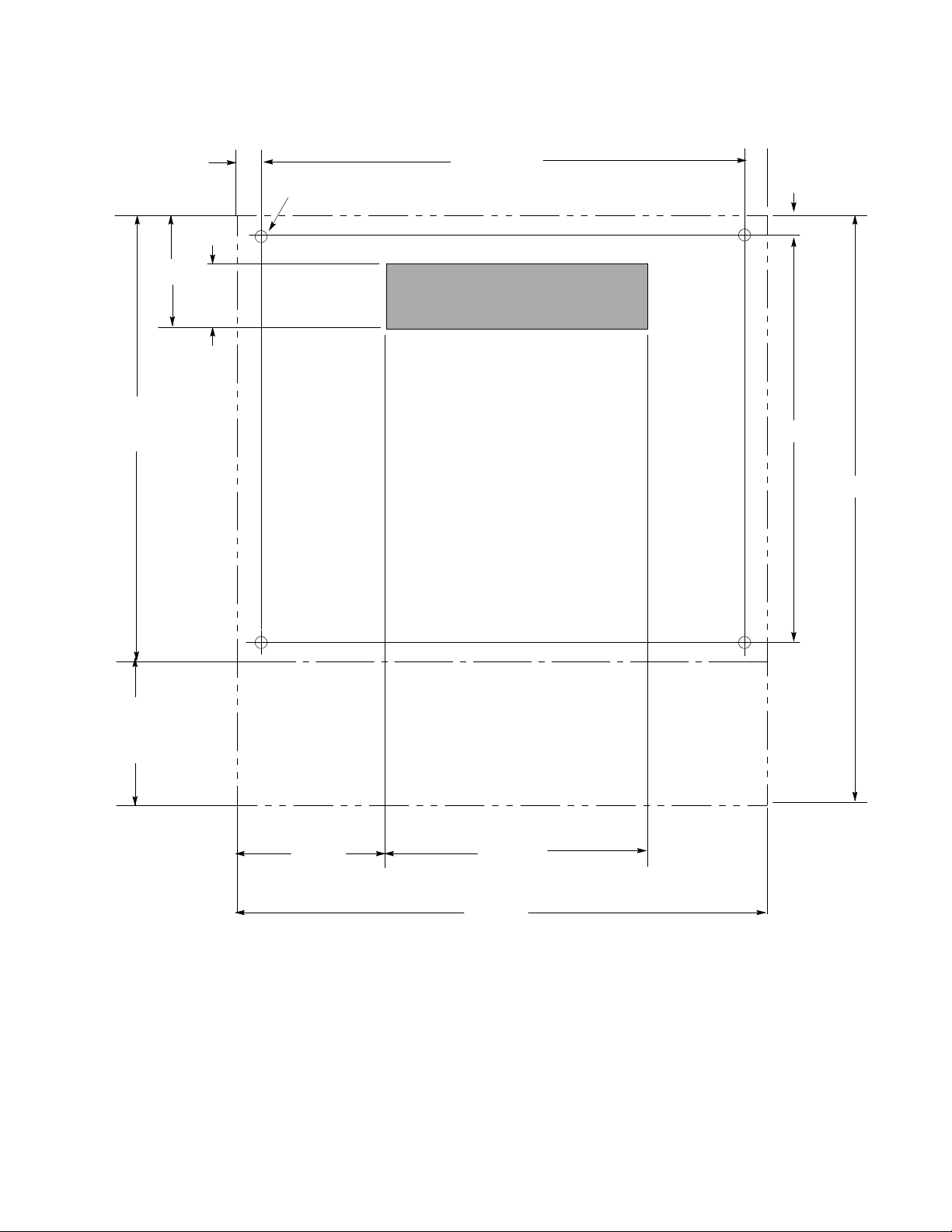

1. The ice dispenser must be sealed t o the counter. The template drawing (See Figure 2) indicates openings

which mu st be cut in the counter. L ocate the desired position for the dispenser, then mark the outline dimensions on the counter using the template drawings. Cut openings in the counter.

Apply a cont inuous bea d of NSF International (NSF) listed silastic sealant (Dow 732 or equal) approximately 1/4” inside of the unit outline dimensions and around all openings. Then position the unit on the counter

within the outline dimensions. All excess sealant must be wiped away immediately. On “BC” Models, the

sink is shipped loose and is not to be sealed. This is needed for installation of the beverage system and for

service.

2. “BC” Model beverage connections are made in the front of the unit. With the lower panel removed using

the plumbing schematics (See Figures 6, 7, or 8) or schematic on the rear of the panel to determine syrup

and water connections.

3. Carefully pull the beverage tubes, drain line and power cord through the large opening in the bot tom of the

unit.

4. “K” Models only: Install ice maker according to instructions supplied with kit and manufacturer’s instruction s

supplied with ice maker.

5. Connect the drain tube to an open drain. If addition al piping is required, it must be 3/4” IPS (or equal) and

must pitch downward away from the unit for p roper drainage.

6. Connect the beverage system product lines as indicated (See Figures 4 or 5). This work should be done by

a qualified service person.

7. Clean the hopper interior (See CLEANING INSTRUCTIONS on pages 11 through NO TAG).

8. Connect the power cord to a 115 volt, 60 cycle, 3-wire grounded receptacle. All electrical wiring must conform to national and local electrical codes.

291679

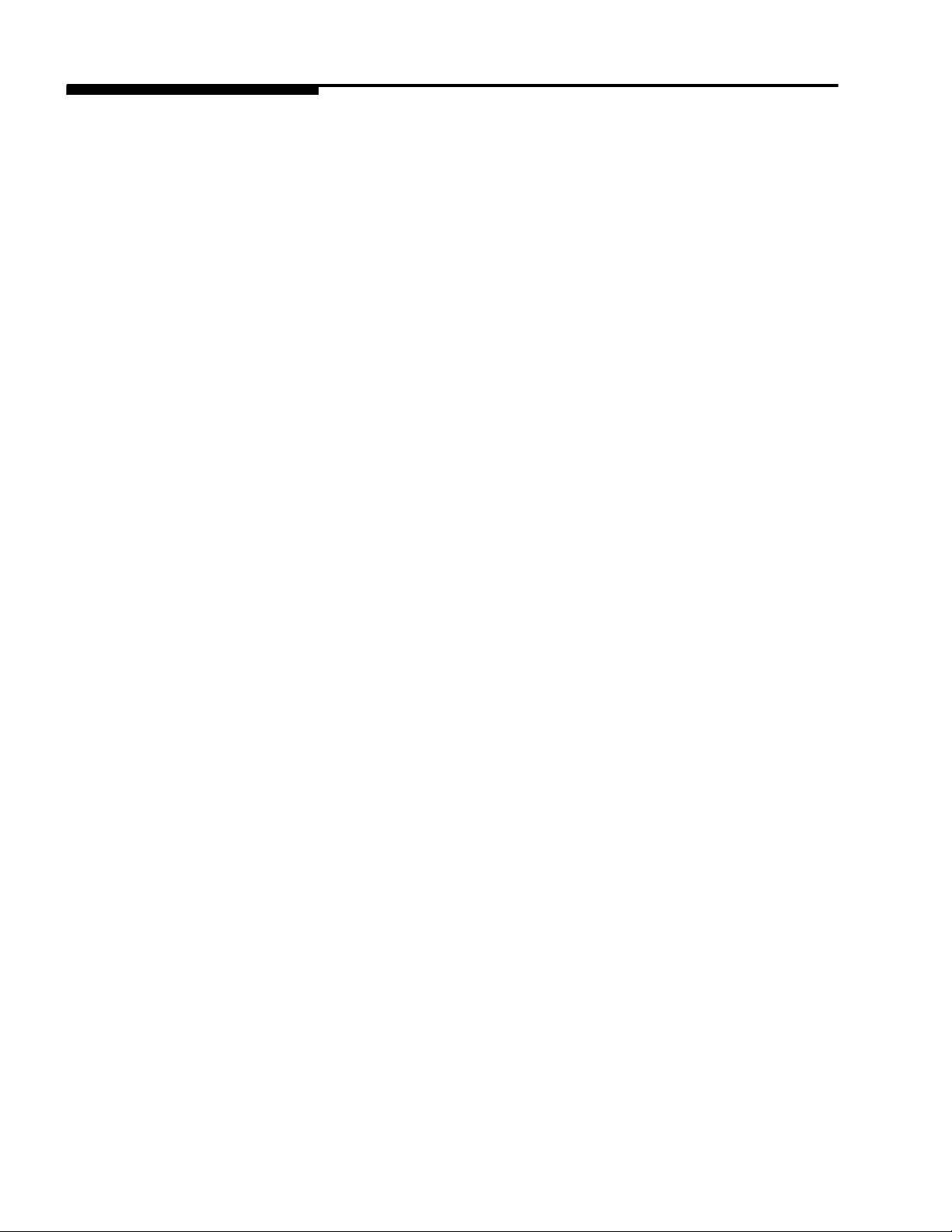

GATE RESTRICTOR PLATE

CAUTION: Disconnect power to dispenser before installing, removing or adjusting

restrictor .

FIGURE 1. GATE RESTRICTOR PLATE

ADJUSTMENT

This dispenser is provided with a gate re strictor plate (Figure1), installed in its highest position. This plate adjusts the rate of ice flow from the dispenser. In applications using buckets, carafes or other large containers, the

plate may be removed entirely for maximum ice flow. For glasses and cups, the plate may be adjusted downward to reduce the flow of ice. the best position depends on the type of ice being used and the size container

and must be found by trial and error. Adjustment is made by loosening the upper two ice chute retaining nuts,

sliding the restrictor plate to the desired position and re-tightening the nuts.

If the dispenser fails to dispense the ice when operated, check that the hopper has ice in it and that power is

being supplied to the unit. If the problem persists, refer to troubleshooting guide on (page 14).

3 91679

3/8 DIA. HOLE (4) PLCS

27 3/4-IN.

1 1/8-IN.

1 1/8-IN.

20 3/4-IN.

30-IN.

14-IN.

NOTE:

17-IN.6 1/2-IN.

8 5/8-IN.

30-IN.

SHADED AREA INDICATE OPENINGS

IN CABINET BOTTOM NEEDED FOR

UTILITIES AND BEVERAGE TUBING

FIGURE 2. MOUNTING TEMPLATE

491679

1 -1/8-IN.

7- 15/16IN.

4-1/2 IN.

3/8 DIA. HOLE (4) PLCS

27- 3/4-IN.

1- 1/8-IN.

BACK

23-IN.

7-IN.

REMOVABLE

SINK

8-IN.

20 -3/4-IN.

30-IN.

FRONT

14-IN.

NOTE:

30-IN.

SHADED AREA INDICATE OPENINGS

IN CABINET BOTTOM NEEDED FOR

UTILITIES AND BEVERAGE TUBING

FIGURE 3. MOUNTING TEMPLATE

5 91679

FIGURE 4. BEVERAGE SYSTEM SCHEMATIC

91679

6

Loading...

Loading...