Page 1

ICE/BEVERAGE DISPENSER

Models DB150--M

Operator’s Manual

DB150--BM

DB150--BCM

Illustration in this space

Remove box after placing the

illustration

Part No. 91773

October, 1993

Revision A

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

IMI CORNELIUS INC; 1993Ó

PRINTED IN U.S.A

Page 2

TABLE OF CONTENTS

LIST OF FIGURES

LIST OF TABLES

Page

i

Doc P/N Here

Page 3

TABLE OF CONTENTS (cont’d)

Doc P/N Here

ii

Page 4

SAFETY INFORMATION

Recognize Safety Information

This is the safety-alert symbol. When you see this

symbol on our machine or in this manual, be alert to

the potentially of personal injury.

Follow recommended precautions and safe operating

practices.

Understand Signal Words

A signal word - DANGER, WARNING, OR CAUTION

is used with the safety-alert symbol. DANGER ident ifies the most serious hazards.

DANGER

Safety signs with signal word DANGER or WARNING

are typically near specific hazards.

General precautions are listed on CAUTION safety

signs. CAUTION also calls at tention to safety messages in this manual.

WARNING

CAUTION

Follow Safety Instructions

Carefully read all safety messages in this manual and on your machine safety signs. Keep safety signs in

good condition. Replace missing or damaged safety signs. Learn how to operate the machine and how to

use the controls properly. Do not let anyone operate the machine without instructions. Keep your machine in

proper working condition. Unauthorized modifications to the machine may impair function and/or safety and

affect the machine life.

CO2(Carbon Dioxide) Warning

CO2Displaces Oxygen. Strict Attention must be observed in the prevention of CO2(carbon dioxide)

gas leaks in the entire CO2and soft drink system. If a CO2gas leak is suspected, particularly in a

small area, immediately ventilate the contaminated area before attempting to repair the leak. Personnel exposed to high concentration of CO2gas will experience tremors which are followed rapidly by

loss of consciousness and suffocation.

Shipping, Storing, Or Relocating Unit

CAUTION: Before shipping, storing, or relocating this Unit, the syrup systems must be sanitized and

all sanitizing solution must be purged from the syrup systems. All water must al so be purged from

the plain and carbonated water systems. A freezing ambient temperature will cause residual water

remaining inside the Unit to freeze resulting in damage to internal components of the Unit.

1

91773

Page 5

THIS PAGE LEFT BLANK INTENTIONALLY

91773

2

Page 6

SAFETY PRECAUTIONS

Always disconnect power to the dispenser before servicing or cleaning.

Never Place ha nds inside of hopper or gate area without disconnecting power to the di spenser. Agitator

rotation occurs automatically when dispenser is energized.

This ice dispenser has been specifically designed to provide protection against personal injury an d

eliminates contamination of ice. To insure continued protection and sanitation, observe the following.

Always be sure the removable lid is pro perly installed to prevent unauthorized access to the hopper

interior and possible contamination of the ice.

Always be sure the upper and lower front panels are securely fastened.

Always keep are a around the dispenser clean of ice cubes.

CAUTION: Dispenser cannot be used with crushed or flaked ice.

Use of begged ice which has frozen into large chunks can void warranty. The dispenser

agitator is not designed to be an ice crusher. Use of large chunks of ice which “jam up” inside the

hopper will cause failure of the agitator motor and damage to the hopper. If bagged ice is used, it

must be carefully and completely broken into small , cube-sized pieces before filling into the

dispenser hopper.

1

91773

Page 7

GENERAL DESCRIPTION

This section gives the Unit description, theo ry of operation, and design data for

IMPORTANT: To the user of this manual -- This manual is a guide for installing, operating, and main-

taining this equipment. Refer to the Table of Contents for page location for detailed information pertaining to questions that arise during installation, operation, service, or maintenance of this equipment.

DESCRIPTION

The REMCORR “DB” series of ice dispensers solve your ice and beverage service needs in the sanitary, space

saving, economical way. Designed to be manually filled with ice from any remote ice making source, these dispensers will dispense cubes (up to 1-1/4? in size), cubelets and hard-chipped or cracked ice, and in addition,

several fla vors of post-mix beverages. “B” models contain beverage faucets only and must be supplied with

cold pro duct from any remote cold plate of refrigerate d soda factory.

“BC” units include faucets and cold plates and are designed to be supplied direct from syrup tanks and carbonator, with no additional cooling required.

IMPORTANT: for dispensing Scotsman “pellet” style ice (Model MH750 Ice Makers), RemcorR part

number 02234 Ice Diverter kit must be installed on the dispenser. (See INSTALLATION INSTRUCTION

on page 5).

Table 1. Specifications

Model: DB150S-M

Ice Storage: 150 lbs.

Maximum Number of Faucets Available: Not Available

Built-in Cold Plate No

Electrical: 120/1/60

Dimensions: 22? W x 32-1/2? D x 36-1/2? H

Model: DB150S-BM

Ice Storage 150 lbs.

Maximum Number of Faucets Available 6

Built-in Cold Plate No

Electrical: 120/1/60

Dimensions: 22? W x 32-1/2? D x 36-1/2? H

Model: DB150S-BCM

Ice Storage 150 lbs.

Maximum Number of Faucets Available 6

Built-in Cold Plate Yes

Electrical: 120/1/60

Dimensions: 22? W x 32-1/2? D x 36-1/2? H

91773

2

Page 8

INSTALLATION

This section covers unpacking and inspection, selecting location, installing Unit, preparing for operation, and

operation.

UNPACKING AND INSPECTION

NOTE: The Unit was thoroughly inspected before l eaving the factory and the carrier has accepted and

signed for it. Any damage or irregularities should be noted at the time of delivery (or not later than 15

days from date of delivery) and immediately reported to the delivering carrier. Request a written inspection report from Claims Inspector to substantiate any necessary claim. File claim with the delivering

carrier, not with IMI Cornelius Inc.

1. Locate the dispenser indoors on a level counter top.

LEG OPTION

Unpack the 4 legs and install them into the threaded holes provided in the bottom of the unit. The installer

must provide flexibility in the product and utility lines to permit shifting the position of the dispenser sufficiently to clean the area beneath it.

NOTE: before installing legs, the plastic plugs must be removed by pushing the center in and

removing plug.

COUNTER MOUNTING

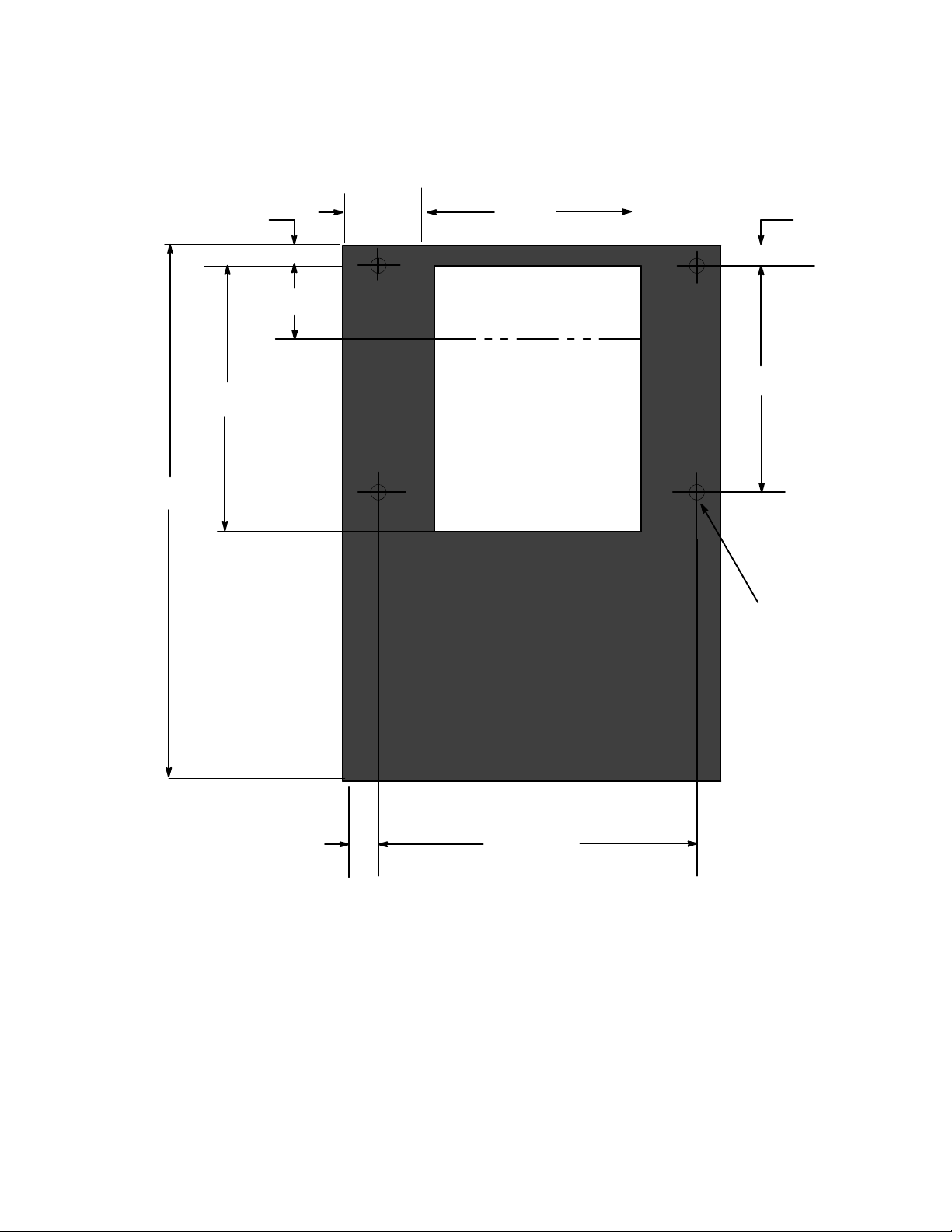

The ice dispenser must be sealed to the counter. The template drawing indicates openings which must be

cut in th e counter. Locate the de sired position for the dispenser, then mark the outline dimensions on the

counter using the template drawings. Cut openings in counter.

Apply a continuous bead of National Sanitation Foundation (NSF) listed silastic sealant (Dow 732 or equal)

approximately 1/4? inside of the unit outline dimensions and around all openings. Then position the unit on

the counter within the outline dimensions. All excess sealant must be wiped away immediately.

2. Utilities: DB150S-M Model: The electrical power cord, air/CO2line and dispenser drain (3/4 FPT) are

located at the rear of the unit.

DB150S-BM Models: All utilities are routed out the bottom of the unit. See “Mounting Template”

on page 6 for locating the required clearance holes in the counter for these utility lines.

3. Connect the drain tube to an open drain. For DB150 models, the drain line size must be 3/4? IPS (or equal)

and must continuously pitch downward a way from the unit and contain no “traps” or improper drainage will

result.

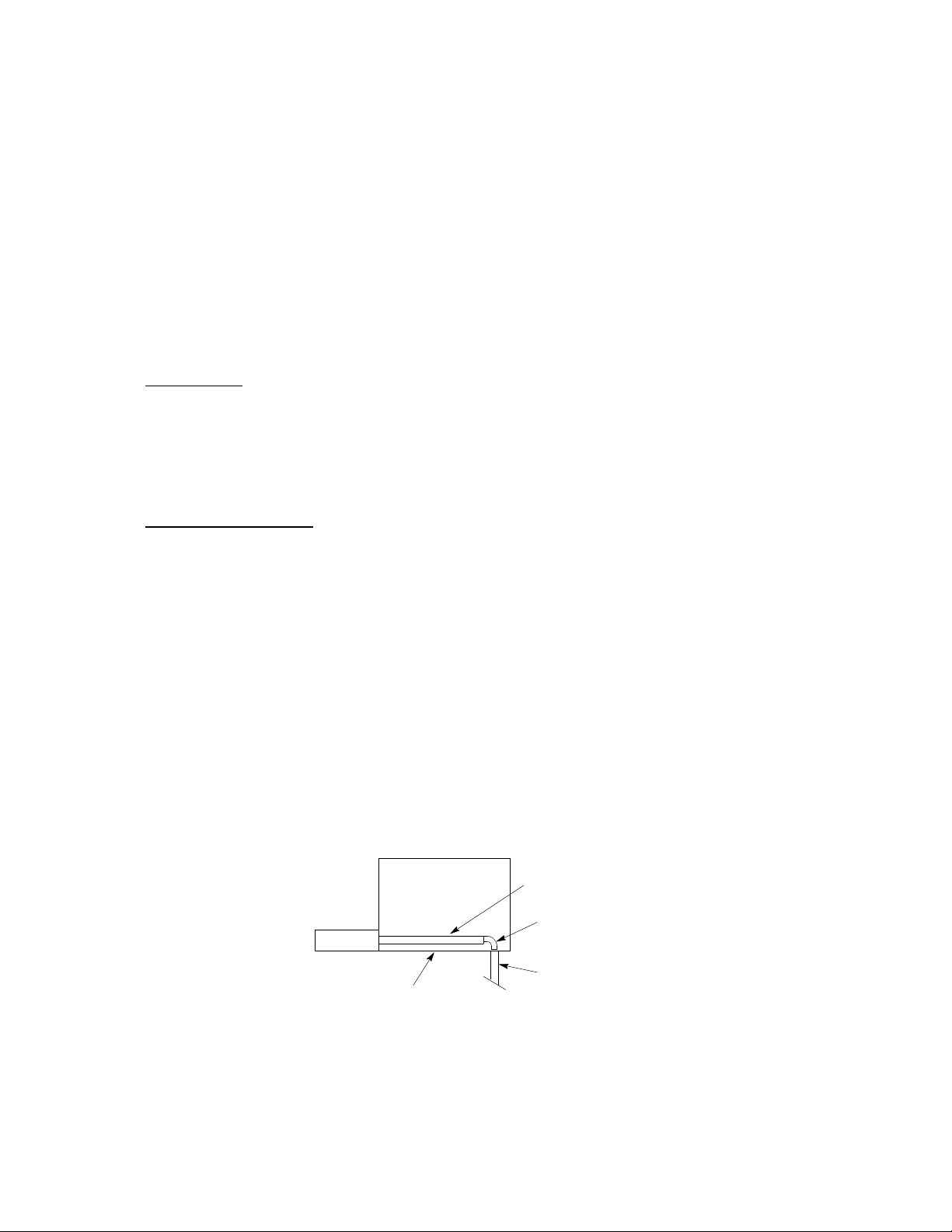

DRAIN LINE

STAINLESS STEEL ELBOW

DRAIN TUBING PROVIDED

DISPENSER BOTTOM

WITH DISPENSER

FIGURE 1. SINK DRAIN ASSEMBLY --B, --BC MODELS

A. Use tube, clamp and insulation provided to assembly drain.

B. To assure p roper drainage, do not allow “trap” to form in drain line. Be sure drain line runs flat with

bottom of dispenser (See Figure 1)

3

91773

Page 9

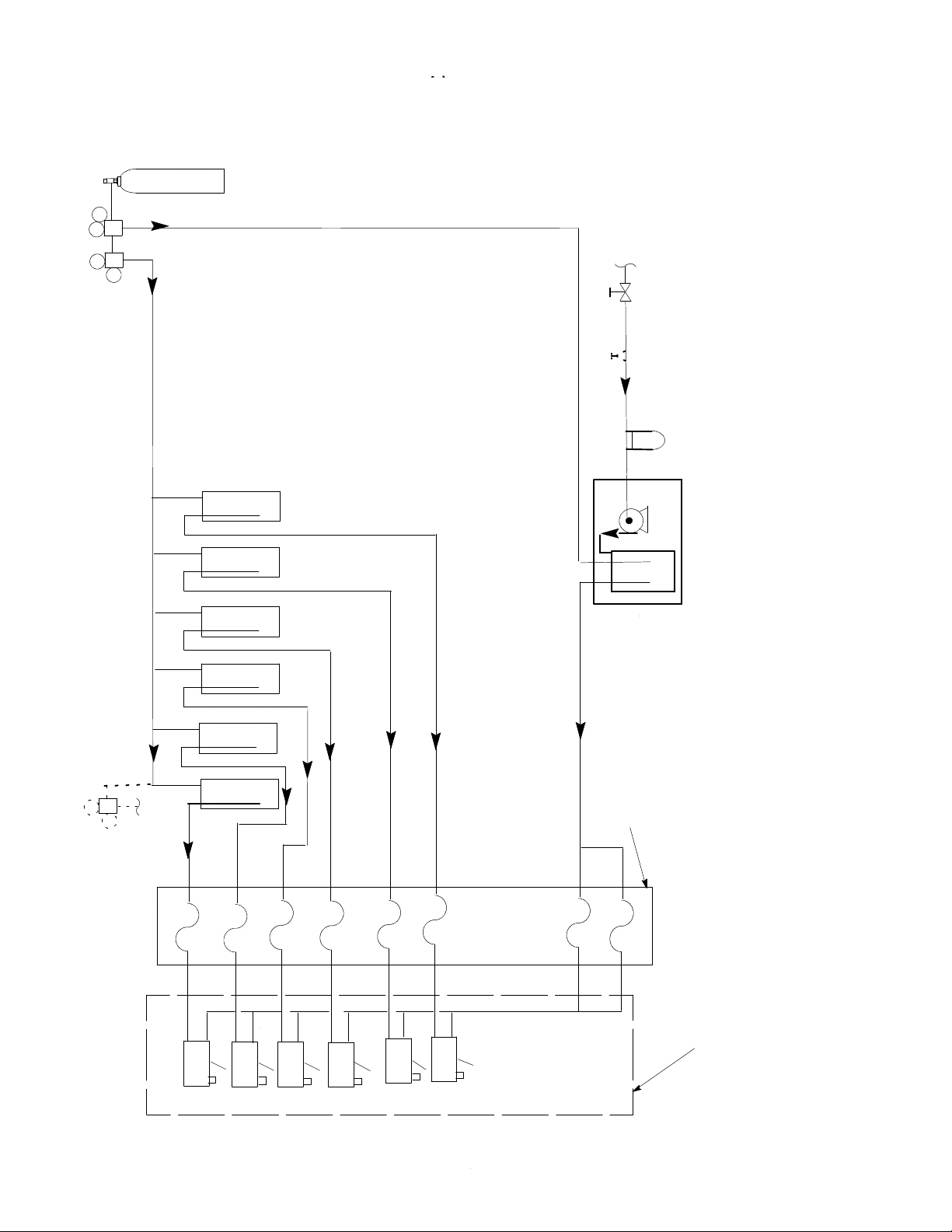

4. “--BM”, “--BCM” models: connect the beverage system pro duct lines as indicated in “B” and “BC” units,

pages 7 and 8 respectively. This work should be done by a qualified serviceman. Note that the hoses are

marked with number (1 through 6) for syrup connections and “CW” for carbonated water connections.

5. Regulated and filtered CO2gas pressure or compressed air is required to op erate the dispenser portion

control ice dispensing system. Proceed as follows to connect CO2gas pressure source line to the dispenser.

A. Connect and route CO2line from outlet side of the CO2regulator assembly up to the dispenser.

B. Connect CO2source line to dispenser inlet line labeled “AIR/CO2”.

C. Set regulator outlet pressure to 50 psi.

IMPORTANT: maximum air/CO2operating pressure is 50 psig.

6. Clean the hopper interior (see CLEANING INSTRUCTIONS).

7. Connect the power cord to a 120 volt, 60 cycle, 3-wire grounded receptacle.

91773

4

Page 10

KIT 02234 INSTALLATION INSTRUCTIONS

NOTE: For dispensing Scotsman NM650 “nugget” style ice and Wilshire MCC500 and MCC700

compressed ice cubes.

1. Disconnect power to dispenser.

2. Remove upper front panel from dispenser.

3. Remove ice chute and discard gate restrictor.

4. Reinstall front panel and energize unit.

5

91773

Page 11

10-32 WASHER

GATE MOUNTING PLATE

STORAGE HOPPER

ICE DIVERTER

GASKET

APPL YRTV TO THIS SURFACE TO SEAL TO HOPPER

GATE MOUNTING PLATE

ICE CHUTE

FLANGE EXTENDS INTO

STORAGE HOPPER THROUGH

GATE OPENING

10-32 NUT

FIGURE 2. ICE DIVERTER

91773

6

Page 12

1?

14?

OPENING

*1-1/8?3-15/16?

31-1/8

4-1/2?

OPENING

18-3/4? AVAILABLE

FOR HOSE OUTLETS

OPENING IN CABINET

BOTTOM FOR DRAIN&

BEVERAGE HOSES

16-1/4?

OPTIONAL LOCATION FOR

COUNTER TOP CUT-OUT

5/16-18 THREADED

HOLE TO SECURE

UNIT TO COUNTER

(4--PLCS)

FRONT OF UNIT

*19-3/4?1-1/8?

TOP VIEW

(COUNTER CUTOUT)

FIGURE 3. MOUNTING TEMPLATE

7

91773

Page 13

TANK

OPTIONSLFORDIETORROOTBEER

2

CO

REGULATORS

S6

NOTE:

FOR REFERENCE ONLY

NOT FOR CONTRUCTION

WATER

SUPPLY

OPTIONAL

PRESSURE REGULATOR

FILTER

60 -- 100 PSIG

15 -- 50 PSIG

5-15

PSIG

1

S5

CARBONATOR

S4

S3

FAUCETS 3 AND 4 CAN BE CONVERTED

S1 S2

COLD PLATE OR

REFRIGERATED

ICE BANK

2

3

4

5

6

CW

CW

TO NON-CARBONATED WATER

FIGURE 4. FLOW DIAGRAM “--B”MODELS

FAUCETS

91773

8

REMCOR “--B” ICE/EVERAGE DISPENSER

ITREMS OUTSIDE OF BROKEN LINES NOT

INCLUDED WITH UNIT.

Page 14

TANK

2

CO

REGULATORS

S6

NOTE:

FOR REFERENCE ONLY

NOT FOR CONTRUCTION

WATER

SUPPLY

OPTIONAL

PRESSURE REGULATOR

FILTER

60 -- 100 PSIG

15 -- 50 PSIG

S5

CARBONATOR

S4

S3

FIGURE 5. FLOW DIAGRAM MODEL “--BC”

S1 S2

5

5-15

PSIG

OPTIONSL FOR DIET OR ROOT BEER

1

2

4

3

6

COLD PLATE

CW

CW

FAUCETS

9

REMCOR “--BC” ICE/EVERAGE DISPENSER

ITREMS OUTSIDE OF BROKEN LINES NOT

INCLUDED WITH UNIT.

FAUCETS 3 AND 4 CAN BE CONVERTED

TO NON-CARBONATED WATER

91773

Page 15

91773

10

Page 16

MAINTENANCE

The following dispenser maintenance should be performed at the intervals indicated.

DAILY (or as required)

Remove foreign material from vending area sink to prevent drain blockage.

WEEKLY (or as req uired)

Clean vending area. Check for prope r water drainage from the vending area sink.

MONTHLY

Clean and sanitize the hopper interior (see CLEANING INSTRUCTIONS).

START-UP AND OPERATING INSTRUCTIONS

Fill the hopper with ice and replace the lid. Allow 10 to 15 minutes for the cold plate to cool down. Repeat this

procedure whenever the dispenser has been standing overnight or other long periods without ice use. On “B”

and “BC” models, start up the beverage system and adjust faucets to the proper brix. Contact your local syrup

distributor for complete information on the beverage system.

To dispense ice, hold cup under ice chute and press the appropriate size button on the ice portion control located above the ice chute. An extra ice portion may be obtained by pressing the increase key (Y) before pressing the size button. Pushing the button/lever on any faucet will provide beverage of the appropriate flavor.

NOTE: Use caution to avoid spilling ice when filling dispenser. Clean up immediately any spilled ice

from filling or operating the unit. To prevent contamination of ice, the lid must be installed on

the unit at all times.

FIGURE 6. ICE PORTIONING

ICE PORTIONING SYSTEM OPERATION

The ice portioning system consists of three main components:

1. Ice portion control

2. Ice gate mechanism

3. Solenoid operated air valve

When a size button on the ice portion control is pressed, the control applies a voltage to the air valve for a brief

period of time. The air cylinder attached to the ice gate will t hen open the ice gate for a short time, allowing ice

to be dispensed from the ice chute.

11

91773

Page 17

The ice portion control has five modes to allow adjustment of the i ce portions and for normal operation they are

as follows:

MODE INDICATOR STATUS

Normal operation Green

Cleaning mode Red/Amber flashing

Normal ice portion adjustment Amber

Extra ice portion adjustment Red

Agitation refill time adjustment Amber flashing

The control will return to Normal Operation Mode (green indicator) automatically if a button has not been operated for a period of one minute whenever one of the three adjustment modes have been accessed.

NORMAL OPERATION

To dispense ice, hold a cup directly under the ice chute, then press the appropriate size button on the ice portion control. To obtain a full cup of ice, press the increase button followed by the appropriate size button. The ice

portion control will not dispense ice and will display a flashing green indicator light if sufficient ice is not available

in the ice chute to dispense the selected size. The indicator light will return to solid green and ice dispensing will

resume after the ice chute has been refilled.

The amount of ice dispensed for each size is changed in the Normal and Extra Ice Adjustment Modes. To access the adjustment modes, press the decrease and increase buttons at the same time. The control will advance to the next mode in the sequence as shown in the table above and the indicator light will change to identify which mode is currently active.

CLEAN MODE

Access this mode when cleaning the ice chute. Refer to Cleaning Instruction s on page 12.

NORMAL ICE PORTION ADJUSTMENT

From the Normal Operation Mode (green indicator), press both the decrease and increase buttons at the same

time twice. The amber indicator verifies that the normal portion adjustment mode has been accessed.

To change the amount of ice dispensed, press and hold down the size button for the desired size to be

changed. While holding the size button, press the decrease or increase button to decrease/increase the ice portion size. The amber indicator turns off briefly each time the decrease or increase button is pressed. When the

minimum ice portion adjustment has been reached, the indicator will flash at a slow rate; at the maximum adjustment, the indicator will flash at a fast rate. After releasing the size button, t he indicator light will flash green

for five seconds. During this time period, a sample can be obtained to check the portion size by pressing the

size key. The indicator light will return to amber (normal portion adjustment mode) after the sample is d

The indicator light will flash red after dispensing a sample, if an open circuit exists in the ice gate cylinder switch

wiring to the ice portion control of if an ice gate binding condition occurred during t he sample. The indicator light

will d isplay solid red briefly after a sample is dispensed if the ice gate cylinder switch was shorted.

To return to Normal Operation, press the decrease and increase buttons at the same time, twice.

EXTRA ICE PORTION ADJUSTMENT

The adjustment of Extra Ice Portions is accomplished in the same manner as Normal Ice Portions, except the

indicator light displays red. To access this mode, press both the decrease and increase buttons simultaneously

three time from the Normal Operation Mode (green indicator). The indicator will display red.

AGITATION REFILL TIME ADJUSTMENT

To adjust the amount of ice chute refill agitation, begin by accessing the Extra Ice Portion Adjustment Mode (red

indicator). Next, press and hold for the decrease and increase buttons for three seconds until the indicator

flashes amber. The indicator will flash up to four times; one fla sh corresponds to the minimum amount of refill

agitation and four flashes corresponds to the maximum amount of refill agitation. Change the amount of refill

agitation buy pressing one of the four size buttons -- -- the small button representing the minimum amount of

refill agitation. Increase the amount of refill agitation if the ice chute does not refill properly after dispensing ice.

To return to Normal Operation Mode, press the decrease and increase buttons at the same time.

91773

12

Page 18

CLEANING INSTRUCTIONS

WARNING: DISCONNECT ALL POWER BEFORE CLEANING. Do not use metal scrapers,

sharp objects or abrasives on the ice storage hopper, top cover and the agitator disk, as

damage may result. Do not use solvents or other cleaning agents, as they may attack the

plastic material.

DISPENSER (All Models)

1. Clean the ice storage hopper at least once a month.

2. Remove center screw and washer on agitator disk and lift off the agitator and the agitator disk assembly.

Wash and rinse them thoroughly.

3. Wash down the inside of the hopper and top cover with a mild detergent solution and rinse thoroughly to

remove all traces of detergent.

4. Replace the agitator.

5. Sanitize the inside of the hopper and agitator with a solution of 1 ounce of household bleach in 2 gallons of

water (200 PPM).

6. Replace the agitator disk. Sanitize as described in Step 5. Be sure center screw and washer are replaced

and screw is tight.

7. Clean and sanitize the ice chute as described below:

A. Enter the Clean Mode of the ice portion control by pressing the de crease and increase buttons at the

same time. The indicator light will alternately display red/amber.

B. To empty the ice from the ice chute, press any of the size buttons. The ice gate will then open to allow

the ice chute to empty. The ice gate will automatically close after the ice chute as been emptied.

C. Remove t he 2 thumbscrews attaching the upper service panel and remove the panel.

D. Remove t he 2 thumbscrews attaching the ice chute strap and remove the strap

E. Remove the 4 thumbscrews that secure the ice tube to the ice hopper. Rmove the ice chute and gate

cover. Power to the ice portion control and beverage valves will be interrupted while the ice chute is

removed.

F. Wash ice chute, gate slide and gate cover in detergent soap solution. Th en rinse thoroughly with plain

water. Sanitize as described in Step 5.

G. Replace components removed for cleaning in reverse order of removal.

H. Portion control will automatically return to Normal Operating Mode (green Indicator) after the ice chute

is repla ced.

COLD PLATE (--BC Models)

1. Carefully remove screws holding beverage faucet panel and bring forward.

2. Slide the cold plate cover back. (Remove shipping tape and discard.)

3. Remove any debris from the drain trough and spring. Check that drain hole is not clogged.

4. Wash down the inside of the cold plate, tray and cover with a mild detergent solution and rinse. A small,

long-handled brush will be found helpful in reaching the corners.

13

91773

Page 19

5. Slide the cover forward, taking care that it is securely positioned on the cold plate.

6. Replace beverage faucet panel.

BEVERAGE SYSTEM (--B, --BC Models)

1. Remove faucet spouts, wash in mild detergent, rinse and replace.

2. Disconnect electrical power to the carbonator. Shut off the water supply and close the CO2regulator to the

carbonator.

3. Disconnect the syrup tanks from the system.

4. Energize the beverage faucets to purge the remaining soda water in the system.

5. Use a clean 5 gallon tank for each of the following:

A. Cleaning Tank -- Fill with hot (120_ - 140_) potable water.

B. Sanitation Tank - Fill with a chlorine sanitizing solution in the strength of 1 ounce of household bleach

(sodium hypochlorite) to 2 gallons of cold (ambient) potable water (200 PPM).

6. Repeat the following procedure on each of the units syrup product lines.

A. Connect the cleaning tank to the syrup line to be sanitized and to the CO2system.

B. Energize the beverage faucet until the liquid dispensed is free of any syrup.

C. Disconnect the cleaning tank and hook-up the sanitizing tank to the syrup line and CO2systems.

D. Energize the beverage faucet until the chlorine sanitizing solution is dispensed through the faucet.

Flush at least 2 cups of liquid to insure that the sanitizing solution has filled the entire length of the

syrup line. Allow sanitizer to remain in lines for 20 minutes.

E. Disconnect the sanitizing tank. Hook-up the product tank to the syrup line and to the CO2system.

F. Energize the faucet to flush the sanitizing solution from the syrup line and faucet. Continue draw on

the faucet until only syrup is dispensed.

7. Repeat Step 2 in reverse order to turn on the carbonator. Dispense at least 1 cup of beverage from each

faucet. Check taste. Continue to flush, if needed, to obtain a satisfactory tasting drink.

91773

14

Page 20

TROUBLESHOOTING

IMPORTANT: Only qualified personnel should service internal components or electrical wiring.

BLOWNFUSEORCIRCUI

T

SLUSHYICE.WATERIN

BEVERAGESDONO

T

BEVERAGETOOSWEET.

BEVERAGENOTSWEE

T

WARNING: If repairs are to be made to a product system, remove quick disconnects from

the applicable product tank, then relieve the system pressure before proceeding. If repairs

are to be made to the CO2system, stop dispensing, shut off the CO2supply, then relieve the

system pressure before proceeding. If repairs are to be made to the refrigeration system, make sure

electrical power is disconnected from the unit.

Should your unit fail to operate properly, check that there is power to the unit and that the hopper

contains ice. If the unit does not dispense, check the following chart under the appropriate symptoms

to aid in locating the defect.

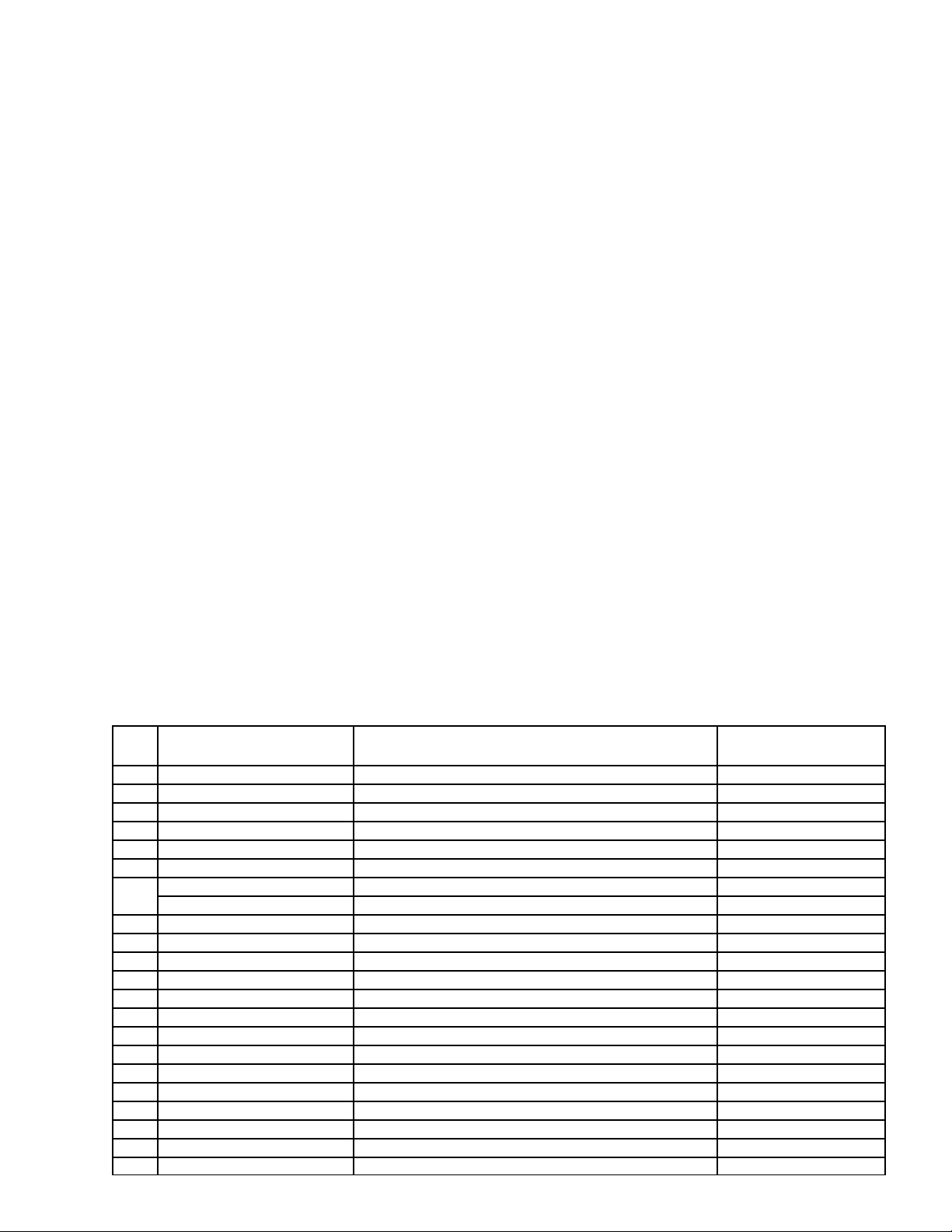

Trouble Probable Cause Remedy

BLOWN FUSE OR CIRCUIT

BREAKER.

SLUSHY ICE. WATER IN

HOPPER.

BEVERAGES DO NOT

DISPENSE.

BEVERAGE TOO SWEET.

BEVERAGE NOT SWEET

ENOUGH.

BEVERAGE NOT COLD

(UNITS WITH BUILT-IN COLD

PLATE)

A. Short circuit in wiring. A.

B. Defective agitator motor. B.

A. Blocked drain. A.

B. Unit not level. B.

C. Poor ice quality due to water

quality or icemaker problems.

D. Improper use of flaked ice. D.

A. No 24 volt power to faucets. A.

B. No CO2pressure. B.

A. Carbonator not working. A.

B. No CO2pressure in

carbonator.

C. Faucet brix requires adjusting. C.

A. Empty syrup tank. A.

B. Faucet brix requires adjusting. B.

A. Unit standing with no ice in

hopper - no ice in cold plate

cabinet.

C.

B.

A.

NOTE: Contact your local syrup or beverage equipment distributor for additional information and troubleshooting of beverage system.

TROUBLESHOOTING ICE DISPENSING SYSTEM

NO ICE DISPENSED. A. Ice bin cover not in place. A. Install ice bin cover.

B. Insufficient ice supply in ice

bin.

C. Ice in ice bin bridged (stuck

together).

D. No electrical power to

dispenser.

E. Insufficient or no CO2supply

to dispenser.

F. Inoperative ice portion

controller.

15

B. Replenish ice supply as

instructed.

C. Gently tap on ice to break it loose.

D. Plug in dispenser power cord, or

check fuse or circuit breaker.

E. Restore CO2supply to dispenser.

F. Replace ice portion controller.

91773

Page 21

Trouble RemedyProbable Cause

G. Inoperative ice agitator motor. G. Replace ice agitator motor.

H. Inoperative gate cylinder. H. Replace gate cylinder.

I. Inoperative gate solenoid. I. Replace gate solenoid.

J. Defective motor capacitor. J. Replace capacitor.

K. Ice gate not aligned to ice

chute.

K. Check alignment of ice gate to

slot in ice chute.

L. Agitate relay wiring incorrect. L. Red wire should be connected to

“t” terminal of relay coil.

91773

16

Page 22

FIGURE 7. ICE/SOFT DRINK POST-MIX DISPENSER

Item

No. Part No. Name Qty.

115 52087 Gasket, Cold Plate Drain 1

116 52089 Ice Bin Cover 1

117 27559 Cup Lid Cover 1

118 27884 Service Panel 1

119 32839 Module Ice Portion Control 1

120 31934 Beverage Valve Power Switch 1

121 31205 Light Indicator, 120 VAC 1

121 32830 Light Indicator, 220 VAC 1

122 70861 Grill 1

123 70478 Clip 4

124 70055 Nut Clip 2

125 27882 Splash Panel 1

126 52064 Drip Tray 1

127 27543 Drip Tray Cabinet Extension 1

128 10145 Mounting Pin, Drip Tray 2

129 51455 Rear, Panel 1

130 70449 Screw 2

131 70450 Washer 2

132 70451 Nut 2

133 70075 Nut 2

134 22139 Bracket, Light Indicator 1

135 70171 Screw 6

17

91773

Page 23

IMI CORNELIUSINC.

ONE CORNELIUS PLACE

ANOKA, MN. 5530 3--6234

TELEPHONE (800) 238--3600

FACSIMI LE (612) 422--3232

TECH SVC 1-800-535-4240

WARRANTY

IMI Cornelius Inc. and Remcor Products Company warrants that all equipment and parts are free from defects

in material and workmanship under normal use and service. For a copy of the warranty applicable to your

Cornelius and or Remcor product, in your country, please write, fax or telephone the IMI Cornelius office nearest you. Please provide the equipment model number,serial number and the date of purchase.

IMI Cornelius Offices

AUSTRALIA D P.O. 210, D RIVERWOOD, D NSW 2210, AUSTRALIA D (61) 2 533 3122 D FAX (61) 2 534 2166

AUSTRIA D AM LANGEN FELDE 32 D A-1222 D VIENNA, AUSTRIA D (43) 1 233 520 D FAX (43) 1-2335-29 30

BELGIUM D B OSKAPELLEI 122 D B-2930 BR AASCHAA T, B ELGIUM D (32) 3 664 0552 D FAX (32) 3 665 2307

BRAZIL D RUA ITAOCARA 97 D TOMAS COELHO D RIO DE JANEIRO, BRAZIL D (55) 2 1 59 1 71 50 D FAX (55) 21 593 1829

ENGLAND D TYTHING ROAD ALCESTER D WARWICKSHIRE, B49 6 EU, ENGLAND D (44) 789 763 101 D FAX (44) 7 89 7 63 644

FRANCE D 71 ROUTE DE ST.DENIS D F-9517 0 DEUIL LA BAR RE D PARIS, FRANCE D (33) 1 34 28 6200 D FAX (33) 1 34 28 6201

GERMANY D CARL LEVERKUS STRASSE 15 D D-4 018 LANGENFELD, GERMANY D (49) 2173 7930 D FAX (4 9) 2173 77 438

GREECE D 488 MESSOGION AVENUE D AGIA PARASKEVI D 153 42 D AT HE NS, GREECE D (30) 1 600 1073 D FAX (30) 1 601 2491

HONG KONG D 1104 TAIKOTSUICENTRE D 11-15 KOK CHEUNG ST D TAIKOKTSUE, HONG KONG D (852) 789 9882 D FAX (852) 391 6222

ITALY D VIA PELLIZZARI 11 D 1-20059 D VIMARCATE, ITALY D (39) 39 608 0817 D FAX (39) 39 608 08 14

NEW ZEALAND D 20 LANSFORD CRES. D P.O. BOX 19-044 AVONDALE D AUCKLAND 7, NEW ZEALAND D (64) 9 8200 357 D FAX (64) 9 8200 361

SINGAPORE D 16 TUAS STREET D SINGAPORE 2263 D (65) 862 5 542 D FAX (65) 862 5604

SPAIN D POLIGONO INDUSTRAIL D RIERA DEL FONOLLAR D E-088 30 SANT BOI DE LLOBREGAT D BARCELONA, SPAIN D (34) 3 640 2 839 D FAX (34) 3 654 3379

USA D ONE CORNELIUS PLACE D ANOKA, MINNESOTA D (612) 421-6120 D FAX (612) 422-3255

91773

18

Page 24

IMI CORNELIUS INC.

Corporate Headquarters:

Manual number

Anoka, Minnesota 55303-6234

One Cornelius Place

Telephone (800) 238-3600

Facsimile (612) 422-3246

19

Loading...

Loading...