Page 1

IMI CORNELIUS INC g One Cornelius Place g Anoka, MN 55303-6234

Telephone (800) 238-3600 Facsimile (612) 422-3246

Installation/Service Manual

CHALLENGER I PRE--MIX AND

POST-MIX COOLING UNITS

IMPORTANT:

TO THE INSTALLER.

It is the responsibility of

the Installer to ensure that

the water supply to the

dispensing equipment is

provided with protection

against backflow by an air

gap as defined in

ANSI/ASME A112.1.2-1979;

or an approved vacuum

breaker or other such

method as proved effective

by test.

Water pipe connections

and fixtures directly

connected to a potable

water supply shall be

sized, installed, and

maintained according to

Federal, State, and Local

Codes.

Part No. 314920000

October 31, 1972

Revised: January 30, 1996

Control Code A

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

IMI CORNELIUS INC; 1972--96Ó

PRINTED IN U.S.A

Page 2

TABLE OF CONTENTS

SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RECOGNIZE SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNDERSTAND SIGNAL WORDS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FOLLOW SAFETY INSTRUCTIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CO2 (CARBON DIOXIDE) WARNING 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SHIPPING, STORING, OR RELOCATING UNIT 1. . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT DESCRIPTION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRE-MIX COOLING UNIT WITH FIVE-FLAVOR BAR VALVE 3. . . . . . . . . . .

PRE-MIX COOLING UNIT WITH AND WITHOUT SEVEN-FLAVOR BAR

VALVE 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

POST-MIX SEVEN FLAVOR COOLING UNIT 3. . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY REFERENCE INFORMATION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

THEORY OF OPERATION 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRE--MIX SYSTEM WITH FIVE--FLAVOR BAR VALVE 5. . . . . . . . . . . . . . . . .

PRE--MIX SYSTEM WITH SEVEN--FLAVOR BAR VALVE 5. . . . . . . . . . . . . .

PRE--MIX SEVEN--FLAVOR SYSTEM WITHOUT BAR VALVE 5. . . . . . . . . .

POST--MIX SEVEN--FLAVOR SYSTEM 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLA TION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

UNPACKING AND INSPECTION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SELECTING COOLING UNIT INSTALLATION LOCATION 8. . . . . . . . . . . . . . . . . .

SEALING COOLING UNIT TO THE FLOOR 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FILL WATER TANK AND START COOLING UNIT 8. . . . . . . . . . . . . . . . . . . . . . . . . .

CONNECTING COOLING UNIT INLET AND OUTLET LINES 9. . . . . . . . . . . . . . .

INLET LINES 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OUTLET LINES 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREPARATION FOR OPERATION 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ACTIVATING CO2 SUPPLY 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING CO2 REGULATORS 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ACTIVATING SYRUP, CARBONATED WATER, AND PLAIN WATER SUPPLIES 11

ACTIVATING SYRUP SUPPLIES TO THE COOLING UNIT 11. . . . . . . . . . . . .

ACTIVATING CARBONATED WATER SUPPLY SUPPLY TO THE

COOLING UNIT 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ACTIVATING PLAIN WATER SUPPLY TO THE COOLING UNIT 11. . . . . . . . .

UNIT OPERATION 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERA TORS INSTRUCTIONS 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATING CONTROLS 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BAR VALVE 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSING STATION 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAILY PRE--OPERATION CHECK 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENTS 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING CO2 REGULATORS 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING WATER--TO--SYRUP ‘‘RATIO’’ (POST --MIX SYSTEM) OF

DISPENSED PRODUCT 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

314920000

Page 3

TABLE OF CONTENTS (cont’d)

CLEANING AND SANITIZING 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SANITIZING PRODUCT (PRE-MIX) OR SYRUP (POST-MIX) SYSTEMS 14.

COOLING UNIT MAINTENANCE 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING CONDENSER COIL 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHECKING ICE WATER BATH 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REMOTE CARBONATOR YEARLY MAINTENANCE OR AFTER WATER

SYSTEM DISRUPTIONS 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE AND MAINTENANCE 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREPARING COOLING UNIT FOR SHIPPING, STORING, OR RELOCATING 15

PERIODIC INSPECTION 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENTS 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CO2 REGULATORS ADJUSTMENTS 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING DISPENSER (POST-MIX SYSTEM) DISPENSING VALVES FOR

WATER-TO-SYRUP “RATIO” OF DISPENSED PRODUCT 16. . . . . . . . . . . . . .

CLEANING COOLING UNIT CONDENSER COIL 17. . . . . . . . . . . . . . . . . . . . . . . . . .

CHECKING COOLING UNIT ICE WATER BATH 17. . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING COOLING UNIT WATER TANK 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAILY CLEANING 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAILY CLEANING OF BAR VALVE. 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAILY CLEANING OF DISPENSING STATION. 18. . . . . . . . . . . . . . . . . . . . . . .

PERIODIC CLEANING OF COOLING UNIT. 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING AND SANITIZING 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAILY CLEANING OF UNIT 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SANITIZING POST-MIX SYRUP SYSTEMS 19. . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

TROUBLESHOOTING PRE--MIX SYSTEM 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NO PRODUCT DISPENSED. 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSED PRODUCT COMES OUT OF DISPENSING VALVE OR BAR

VALVE CLEAR BUT FOAMS IN CUP OR GLASS. 23. . . . . . . . . . . . . . . . . . . . .

DISPENSED PRODUCT FOAMS AS IT LEAVES DISPENSING VALVE OR

BAR VALVE. 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING POST--MIX SYSTEM 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSED PRODUCT WATER--TO--SYRUP ‘‘RATIO’’ TOO LOW OR

TOO HIGH. 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENT OF DISPENSING VALVE SYRUP FLOW CONTROL DOES

NOT INCREASE TO DESIRED WATER--TO--SYRUP ‘‘RATIO’’. 24. . . . . . . . . .

ADJUSTMENT OF DISPENSING VALVE SYRUP FLOW CONTROL DOES

NOT DECREASE TO DESIRED WATER--TO-- SYRUP ‘‘RATIO’’ 24. . . . . . . . .

DISPENSED PRODUCT CARBONATION TOO LOW. 24.. . . . . . . . . . . . . . . . .

DISPENSED PRODUCT COMES OUT OF DISPENSING VALVE CLEAR BUT

FOAMS IN CUP OR GLASS. 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSED PRODUCT PRODUCES FOAM AS IT LEAVES DISPENSING

VALVE. 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ONLY CARBONATED WATER DISPENSED. 25. . . . . . . . . . . . . . . . . . . . . . . . . .

ONLY SYRUP DISPENSED. 26.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

314920000

ii

Page 4

TABLE OF CONTENTS (cont’d)

TROUBLESHOOTING REFRIGERATION SYSTEM 26. . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSOR DOES NOT OPERATE. 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSOR WILL NOT STOP AFTER SUFFICIENT ICE BANK IS

PRODUCED 26.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSOR OPERATES CONTINUOUSLY BUT DOES NOT FORM

SUFFICIENT ICE BANK. 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONDENSER FAN MOTOR NOT OPERATING. 27. . . . . . . . . . . . . . . . . . . . . . .

AGITATOR MOTOR NOT OPERATING. 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIST OF FIGURES

FIGURE 1. CHALLENGER COOLING UNIT 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

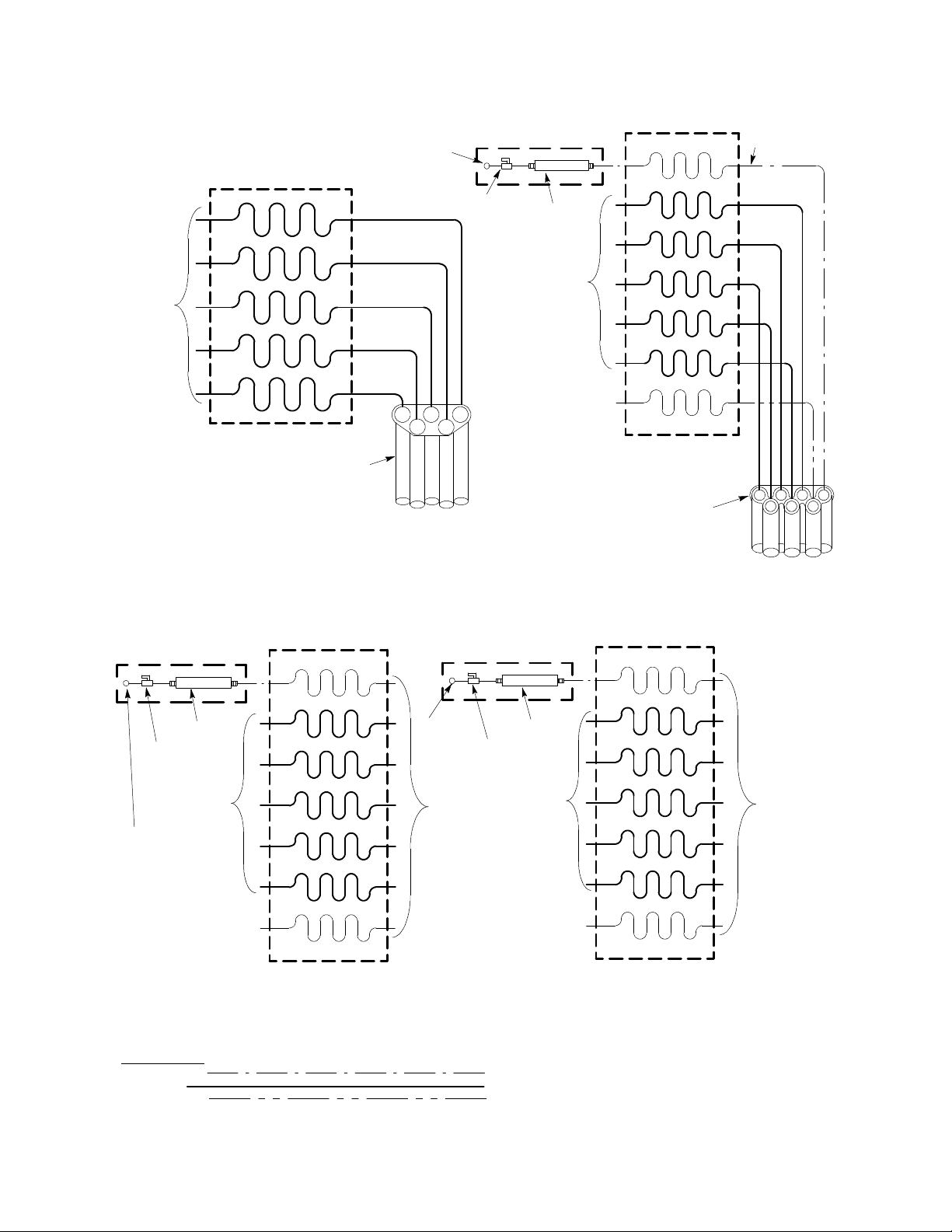

FIGURE 2. FLOW DIAGRAM (PRE-MIX SYSTEM WITHFIVE-FLAVOR BAR

VALVE) 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 3. FLOW DIAGRAM (PRE-MIX SYSTEM WITH SEVEN-FLAVOR

BAR VALVE) 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 4. FLOW DIAGRAM (PRE-MIX SEVEN-FLAVOR SYSTEM WITHOUT

BAR VALVE) 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 5. FLOW DIAGRAM (POST-MIX SEVEN-FLAVOR SYSTEM) 6. . . . . . .

FIGURE 6. PARTS IDENTIFICATION 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 7. WATER TANK COMPONENTS 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 8. WIRING DIAGARAM 22.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

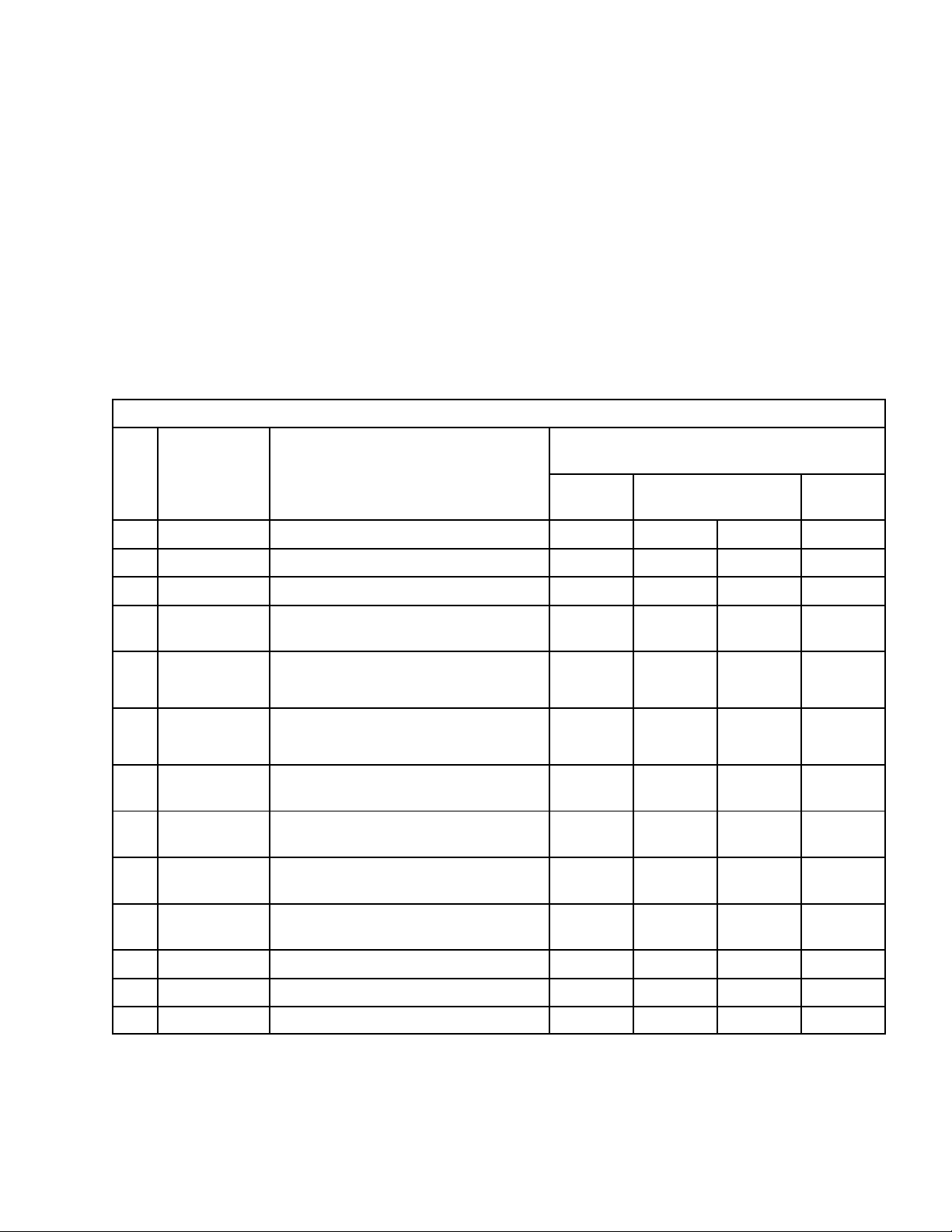

LIST OF TABLES

TABLE 1. DESIGN DATA 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE 2. LOOSE-SHIPPED PARTS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

314920000

Page 5

SAFETY INFORMATION

Recognize Safety Information

This is the safety-alert symbol. When you see this

symbol on our machine or in this manual, be alert to

the potentially of personal injury.

Follow recommended precautions and safe operating

practices.

Understand Signal Words

A signal word - DANGER, WARNING, OR CAUTION

is used with the safety-alert symbol. DANGER identifies the most serious hazards.

DANGER

Safety signs with signal word DANGER or WARNING

are typically near specific hazards.

General precautions are listed on CAUTION safety

signs. CAUTION also calls attention to safety messages in this manual.

WARNING

CAUTION

Follow Safety Instructions

Carefully read all safety messages in this manual and on your machine safety signs. Keep safety signs in

good condition. Replace missing or damaged safety signs. Learn how to operate the machine and how to

use the controls properly . Do not let anyone operate the machine without instructions. Keep your machine in

proper working condition. Unauthorized modifications to the machine may impair function and/or safety and

affect the machine life.

CO2(Carbon Dioxide) Warning

CO2Displaces Oxygen. Strict Attention must be observed in the prevention of CO2(carbon dioxide)

gas leaks in the entire CO2and soft drink system. If a CO2gas leak is suspected, particularly in a

small area, immediately ventilate the contaminated area before attempting to repair the leak. Personnel exposed to high concentration of CO2gas will experience tremors which are followed rapidly by

loss of consciousness and suffocation.

Shipping, Storing, Or Relocating Unit

CAUTION: Before shipping, storing, or relocating this Unit, the applicable syrup or product systems

must be sanitized and all sanitizing solution must be purged from the syrup or product systems. All

water must also be purged from the plain and carbonated water systems. A freezing ambient temperature will cause residual water remaining inside the Unit to freeze resulting in damage to internal components of the Unit.

1 314920000

Page 6

THIS PAGE LEFT BLANK INTENTIONALLY

2314920000

Page 7

GENERAL DESCRIPTION

This manual is a guide for installing, operating, and maintaining this equipment. Refer to Table of Contents for

page location of detailed information pertaining to questions that may arise during installation, operation, service

and maintenance, or troubleshooting this equipment.

This section gives the description, theory of operation, and design data for the Challenger I Pre-Mix Cooling Unit

with or without Seven-Flavor Bar Valve, the Challenger I Pre-Mix Cooling Unit with Five-Flavor Bar Valve, and

the Challenger I Post-Mix Seven-Flavor Cooling Unit.

UNIT DESCRIPTION

The Challenger I Cooling Units are equipped with a 1/5 H.P. refrigeration compressor.

PRE-MIX COOLING UNIT WITH FIVE-FLAVOR BAR VALVE

(See Figure 2)

The Cooling Unit is equipped with a five-flavor bar valve. The only requirements for operation are placing the

Cooling Unit in operating position, filling Cooling Unit water tank with water, connection of product tanks to the

Cooling Unit, and plugging the Cooling Unit power cord into an electrical outlet.

PRE-MIX COOLING UNIT WITH AND WITHOUT SEVEN-FLAVOR BAR VALVE

(see Figures 3 and 4)

This Cooling Unit may or may not be equipped with a seven-flavor bar valve. The Cooling Unit not equipped

with a seven-flavor bar valve requires connection of a dispensing station to the Unit. The only requirements for

operation are placing the Cooling Unit in operating position, connecting dispensing station to the Cooling Unit if

applicable, filling Cooling Unit water tank with water, connection of product tanks and a carbonated water tank to

the Cooling Unit, and plugging Cooling Unit power cord into an electrical outlet.

POST-MIX SEVEN FLAVOR COOLING UNIT

(see Figure 5)

This Cooling Unit requires connection to a dispensing station. The only requirements for operation are placing

the Cooling Unit in operating position, connection of dispensing station to the Cooling Unit, connection of syrup,

plain water, and carbonated water sources to the Cooling Unit, and plugging Cooling Unit power cord into an

electrical outlet.

WARRANTY REFERENCE INFORMA TION

Unit Part Number:

Serial Number:

Install Date:

Local Authorized

Service Center:

Warranty Registration Date

(to be filled out by customer)

3 314920000

Page 8

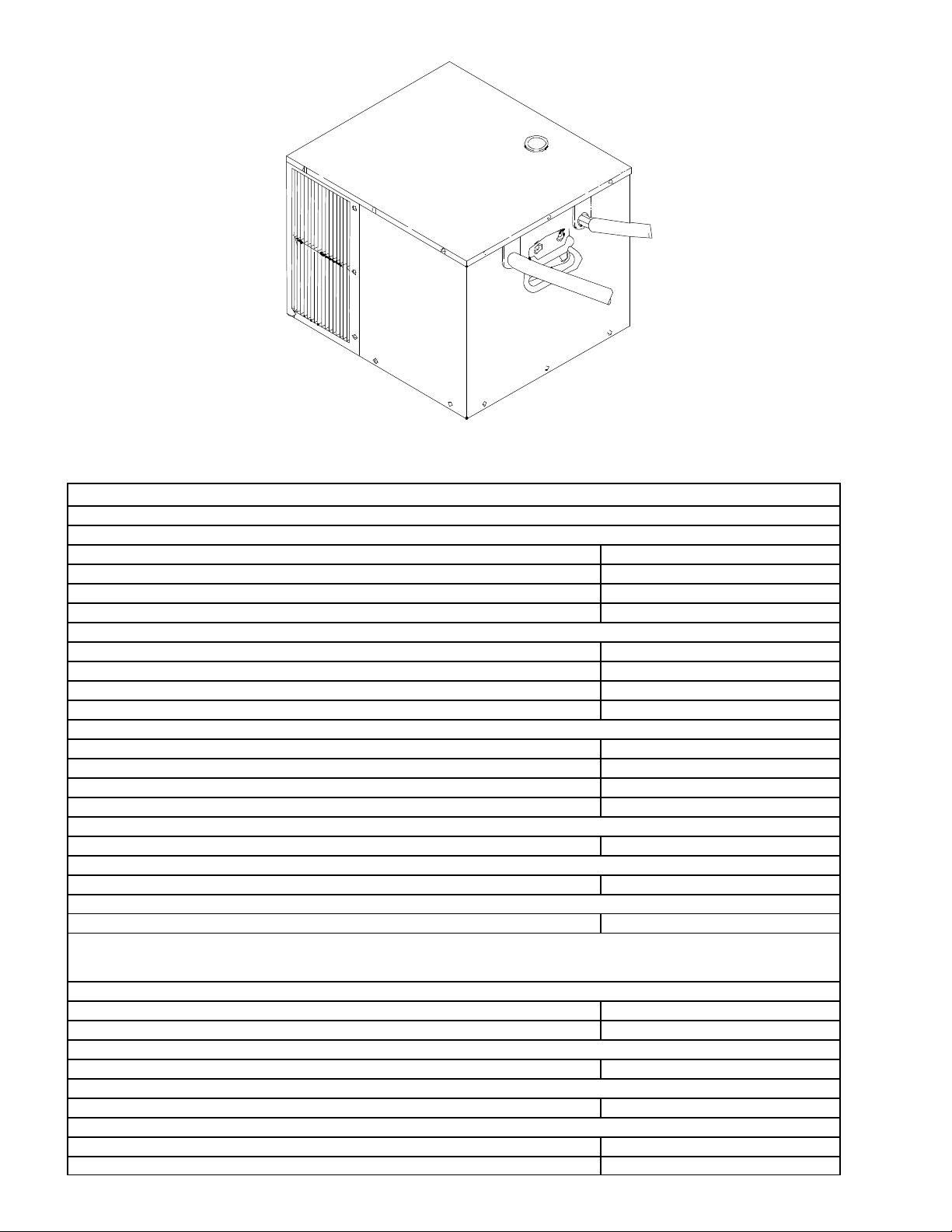

FIGURE 1. CHALLENGER COOLING UNIT

Table 1. Design Data

Part Numbers:

Challenger I with Seven--Flavor Pre--Mix Bar Valve 2844632000

Challenger I w/o Seven--Flavor Pre--Mix Bar Valve 2844642000

Challenger I with Five--Flavor Pre--Mix Bar Valve 2844652000

Challenger I Seven Flavor Post--Mix 4163430000

Overall Dimensions:

Height 13--1/8 inches

Width 14--3/8 inches

Length 16--3/8 inches

Weight:

Dry 60 pounds

With water tank full of water 82 pounds

Shipping Weight (Approx.) 75 pounds

Water Tank Capacity 9--1/2 quarts

Ice Bank (approx.) 6 pounds

Cooling Capacity (see NOTE) 50 six oz. drinks at 4/min.

NOTE: Figures represent the number of 6 ounce drinks dispensed below 40° F with inlet product temperature of 75° F and 75° F ambient. The compressor has a recovery of one 6 ounce drink per minute.

Refrigeration Requirement:

Refrigerant Type and Amount See Unit Nameplate

Ambient Operating Temperature 40° F to 100° F

Electrical Requirements:

Operating Voltage 115VAC, 60Hz

Current Draw 4 amps

4314920000

Page 9

THEORY OF OPERATION

PRE-- MIX SYSTEM WITH FIVE--FLAVOR BAR VALVE

(see Figure 2)

A CO2cylinder delivers carbon dioxide (CO2) gas through adjustable CO2regulators to the product tanks. When

valve on the bar valve is opened, CO2pressure exerted upon the product tank pushes product from the tank,

through the Cooling Unit cooling coil, and on to the bar valve resulting in a dispensed drink.

PRE-- MIX SYSTEM WITH SEVEN--FLAVOR BAR VALVE

(see Figure 3)

A CO2cylinder delivers carbon dioxide (CO2) gas through adjustable CO2regulators to the product tanks and to

the carbonated water tank. When applicable valve (pre-mix drink or carbonated water) on the bar valve is

opened, CO2pressure exerted upon the product tank or the carbonated water tank pushes product or

carbonated water from the tank, through the Cooling Unit cooling coil, and on to the bar valve resulting in either

product or carbonated water being dispensed. Opening the plain water valve on the bar valve allows plain water

to pass through the Cooling Unit cooling coil and on to the bar valve resulting in cold plain water being

dispensed.

PRE-- MIX SEVEN--FLAVOR SYSTEM WITHOUT BAR VALVE

(see Figure 4)

A CO2cylinder delivers carbon dioxide (CO2) gas through adjustable CO2regulators to the product tanks and to

the carbonated water tank. When applicable dispensing valve (pre-mix drink or carbonated water) on the

dispensing station is opened, CO2pressure exerted upon the product tank or the carbonated water tank pushes

product or carbonated water from the tank, through the Cooling Unit cooling coil, and on to the dispensing

station resulting in either product or carbonated water being dispensed. Opening the dispensing station plain

water dispensing valve allows plain water to pass through the Cooling Unit cooling coil and on to the dispensing

station resulting in cold plain water being dispensed.

POST --MIX SEVEN--FLAVOR SYSTEM

(see Figure 5)

A CO2cylinder delivers carbon dioxide (CO2) gas through adjustable CO2regulators to applicable syrup tanks

or bag-in-box syrup pumps and also to the remote carbonator. Plain water entering the remote carbonator water

tank is carbonated by regulated CO2gas also entering the tank. When the dispensing station dispensing valve

is opened, CO2pressure exerted upon the applicable syrup tank or bag-in-box syrup pump pushes syrup from

the syrup supply, through the Cooling Unit cooling coil, and on to the dispensing station. Carbonated water is

pushed from the carbonator water tank by CO2gas head pressure through the Cooling Unit cooling coil and on

to the dispensing station. Syrup and carbonated water meet simultaneously at the dispensing valve resulting in

a carbonated drink being dispensed. Opening the dispensing station plain water dispensing valve allows plain

water to pass through the Cooling Unit cooling coil and on to the dispensing station resulting in cold plain water

being dispensed.

5 314920000

Page 10

COOLING UNIT

PLAIN

WATER

SOURCE

WATER FILTER INSTALLATION

FOR FILTERS WITHOUT

BUILT -INWATER SHUTOFF VALVE

COOLING UNIT

PLAIN

WATER INLET

PRODUCT

INLET

FIGURE 2. FLOW DIAGRAM

(PRE-MIX SYSTEM WITH

FIVE-FLA VOR BAR VALVE)

WATER FILTER INSTALLATION

FOR FILTERS WITHOUT

BUILT -INWATER SHUTOFF VALVE

FIVE-FLAVOR

BAR VAL VE

COOLING UNIT

SHUTOFF

VALVE

123

45

FILTER

PRODUCT

INLET

CARB

WATER INLET

FIGURE 3. FLOW DIAGRAM

(PRE-MIX SYSTEM WITH

SEVEN-FLA VOR BAR VALVE)

WATER FILTER INSTALLATION

FOR FILTERS WITHOUT

BUILT -INWATER SHUTOFF VALVE

SEVEN-FLAVOR

BAR VAL VE

COOLING UNIT

1234

567

FILTER

SHUTOFF

VALVE

PRODUCT

INLET

PLAIN

WATER

SOURCE

CARB

WATER INLET

FIGURE 4. FLOW DIAGRAM

(PRE-MIX SEVEN-FLAVOR SYSTEM

WITHOUT BAR VALVE)

LINE LEGEND

PLAIN WATER

PRODUCT

CARB WATER

PLAIN

WATER

SOURCE

TO

DISPENSING

STATION

FILTER

SHUTOFF

VALVE

PRODUCT

INLET

CARB

WATER INLET

FIGURE 5. FLOW DIAGRAM

(POST-MIX SEVEN-FLA VOR SYSTEM)

6314920000

TO

DISPENSING

STATION

Page 11

INSTALLATION

5

6

This section covers unpacking and inspection, selecting installation location, installing the Cooling Unit,

preparing the Unit for operation, and Cooling Unit operation.

UNPACKING AND INSPECTION

NOTE: The Cooling Unit was thoroughly inspected before leaving the factory and the carrier has

accepted and signed for it. Any damage or irregularities should be noted at the time of delivery (or not

later than 15-days from date of delivery) and immediately reported to the delivering carrier. Request a

written inspection report from the Claims Inspector to substantiate any necessary claim. File claim with

the delivering carrier, not with IMI Cornelius Inc.

1. After Cooling Unit has been unpacked, remove shipping tape and other packing material.

2. Unpack LOOSE--SHIPPED PARTS. Make sure all items are present and in good condition.

Table 2. Loose-Shipped Parts

Quantity

Item

No. Part No. Name

1 178025100 Tapered Gasket, White 14 -- -- -2 178025200 Tapered Gasket, Red -- 7 5 14

3 312109000 Decal, Franchise (as ordered) -- 1 1 -4 200468012 Sheet Metal Screw, Phil Truss Hd,

Type A, No. 8 by 3/4--in.

5

151459001 Drip Receptacle, Bar Valve -- -- 1 -151715039 Drip Receptacle, Bar Valve -- 1 -- --

6

151714039 Bracket, Bar Valve -- 1 -- -151458001 Bracket, Bar Valve -- -- 1 --

7 150807200 Adapter Fitting, 1/2--16 male by

1/2--16 male

8 150807100 Adapter Fitting, 7/16--20 male by

1/2--16 male

9 311245000 Reducer Fitting, 7/16--20 female by

1/2--16 male

10 176193000 Adapter Fitting, 7/16--20 male by

7/16--20 male

Post-Mix

7-fl

-- 4 4 --

-- 7 5 7

-- 7 5 7

-- 7 5 7

14 -- -- --

w/Bar Valve

7-fl 5-fl

w/o Bar

Valve

11 150920000 Flavor Clips (as ordered) -- 7 5 -12 314490000 Clamp, Drain Hose -- 1 1 -13 315865000 Drain Hose -- 1 1 --

7 314920000

Page 12

SELECTING COOLING UNIT INSTALLATION LOCATION

IMPORTANT: Ambient temperature for the Cooling Unit must not exceed 100° F. Operating ambient in

excess of 100° F will automatically void the factory warranty and will eventually result in Cooling Unit

refrigeration system failure. Several means are available to achieve proper ambient temperature and air

circulation around the Cooling Unit which are wall air intake grilles and ceiling exhaust fans, air

conditioning, etc. Check local codes.

Select Cooling Unit installation location that meets the following requirements:

1. Meets operating ambient (100° F maximum) as outlined in preceding IMPORTANT note.

1. Near a properly grounded electrical outlet with proper electrical requirements. The electrical circuit should

be fused at 15-amps (slow blow) or circuit must be connected through an equivalent HACR circuit breaker.

No other electrical appliance should be connected to this circuit. ALL ELECTRICAL WIRING MUST

CONFORM TO NATIONAL AND LOCAL ELECTRICAL CODES.

2. Close to a plain water inlet supply line if Cooling Unit requires plain water or remote carbonator to be

connected.

3. Easily accessible for service and maintenance.

NOTE: Air required to cool the condenser coil, is drawn in through bottom half of the coil

(see Figure 6) and is discharged out through top half of the coil. The condenser coil opening on front

of the Cooling Unit must be open to the room at all times so as not to restrict air circulation in and out

of the Unit. This open to the room clearance must be provided to allow for proper air flow in and out of

the condenser coil to cool the refrigeration system.

4. Make sure when Cooling Unit is installed in operating position, the condenser coil on front of the Unit is not

restricted and is open to the room.

SEALING COOLING UNIT TO THE FLOOR

In areas within the United States, the National Sanitation Foundation (NSF) requires that the Cooling Unit be

sealed to the floor. Perform the following procedure to seal the Cooling Unit to the floor.

1. Place Cooling Unit in operating position meeting installation location requirements.

2. Tilt the Cooling Unit up (maximum of 45°) to expose the bottom of the Cooling Unit base.

3. Liberally apply silastic sealant such as Dow Corning RTV 731 or equivalent on the Cooling Unit base

bottom edges.

NOTE: Do not move the Cooling Unit after positioning or seal from the base to the floor will be broken.

4. Lower the Cooling Unit into operating position to complete the seal from base to floor. Apply additional

sealant around bottom of the base. The seal must have a minimum radius of 1/2--inch to prevent cracks

and crevices and to insure a complete seal.

FILL WATER TANK AND START COOLING UNIT

1. Remove fill cap from the Cooling Unit top cover (see Figure 6) .

2. Fill the water tank with clean water to top of the stainless steel cooling coils inside the water tank. USE

LOW--MINERAL--CONTENT WATER WHERE A LOCAL WATER PROBLEM EXISTS.

3. Install fill cap in Cooling Unit top cover.

NOTE: As ice bank forms in the water tank, water expansion will take place and the excess water will

escape through the water tank overflow tube into bottom of the Cooling Unit where the water will

evaporate.

8314920000

Page 13

4. Plug the Cooling Unit power cord into a properly grounded electrical outlet. The compressor, condenser fan

motor, and the agitator motor will start and begin forming an ice bank. Approximately four to six hours will

be required to freeze a full six-pound ice bank starting with 90° F water. When a full ice bank has been

formed, the compressor and condenser fan motor will stop but the agitator motor will continue to operate

circulating ice water bath in the water tank.

CONNECTING COOLING UNIT INLET AND OUTLET LINES

NOTE: The Cooling Units that do not have bar valves connected to them at the factory are equipped

with both inlet and outlet lines. All internal line connections have been made at the factory and all lines

are labeled.

INLET LINES

Pre-Mix System With Five-Flavor Bar Valve.

(see Figure 2)

The Cooling Unit product inlet lines may be connected directly to the product tanks quick disconnects (use

REDUCER FITTINGS (item 9) if applicable). Seal (if metal--to--metal connections) connections with TAPERED

GASKETS, RED (item 2). If lines must be extended, use applicable ADAPTER FITTINGS (item 7 or 8) and

minimum of .265--inch I.D. tubing.

Pre-Mix System With and Without Seven-Flavor Bar Valve.

(see Figures 3 and 4)

The Cooling Unit product and carbonated water inlet lines may be connected directly to the product and the

carbonated water tanks quick disconnects (use REDUCER FITTING (item 9) if applicable).The plain water

source line may be connected directly to the Cooling Unit plain water inlet line. Seal (if metal-to-metal

connections) with TAPERED GASKETS (item 2). If lines will be extended, use applicable ADAPTER FITTINGS

(item 7 or 8) and minimum of .265-inch tubing.

Post-Mix Seven-Flavor System.

(see Figure 5)

If using a syrup tanks system, the Cooling Unit syrup inlet lines may be connected directly to the syrup tanks

quick disconnects. If using a syrup bag-in-box system, the Cooling Unit syrup inlet lines may be connected

directly to the bag-in-box syrup pumps syrup outlets. The remote carbonator carbonated water outlet line and

the plain water source line may be connected directly to the Cooling Unit carbonated water and the plain water

inlet lines. If metal-to-metal connections are to be made, use TAPERED GASKETS (item 1) to seal the

connections. If syrup, carbonated water, and plain water lines must be extended, use ADAPTOR FITTINGS

(item 10) and a minimum of .265-inch I.D. tubing.

9 314920000

Page 14

OUTLET LINES

Pre-Mix Systems With five and Seven-Flavor Bar Valves.

(see Figures 2 and 3)

The bar valves are installed on the Cooling Units at the factory. The BRACKET, BAR VALVE (item 6) and DRIP

RECEPTACLE, BAR VALVE (item 5) must be installed on underside of the counter. Use SHEET METAL

SCREWS (item 4) to mount the bar valve bracket to underside of the counter, then attach the drip receptacle to

the pins on the bar valve bracket. Install DRAIN HOSE (item 13) on the bar valve drip receptacle. Secure the

drain hose with CLAMP, DRAIN HOSE (item 12). Install FLAVOR CLIPS (item 11) and DECAL, FRANCHISE

(item 3) on the bar valve.

Pre-Mix System Without Seven-Flavor Bar Valve.

(see Figure 4)

The Cooling Unit outlet lines must be connected directly to inlet fittings on backs of the dispensing station

dispensing valves. If the dispensing station is shipped with inlet lines connected to the dispensing valves,

disconnect and remove inlet lines and connect Cooling Unit outlet lines directly to the dispensing valves. Make

sure the product outlet lines from the Cooling Unit to the dispensing station are well insulated.

Post-Mix Seven-Flavor System.

(see Figure 5)

The Cooling Unit insulated outlet lines must be connected to the dispensing station.

PREPARATION FOR OPERATION

ACTIVATING CO2SUPPLY

WARNING: CO2displaces oxygen. Strict attention must be observed in the prevention of

CO2(carbon dioxide) gas leaks in the entire CO2and soft drink system. If a CO2gas leak is

suspected, particularly in a small area, immediately ventilate the contaminated area before

attempting to repair the leak. Personnel exposed to high concentration of CO2gas will experience

tremors which are followed rapidly by loss of consciousness and suffocation.

1. Turn on CO2supply to the CO2regulators

2. Check CO2system connections for leaks and tighten any loose connections

ADJUSTING CO2REGULATORS

Pre-Mix System With Five-Flavor Bar Valve.

(see Figure 2)

Adjust the product tanks CO2regulator to the proper operating pressure using either the Cornelius PRE-MIX

COMPUTER slide rule or the bottling room chart.

10314920000

Page 15

Pre-Mix System With and Without Seven-Flavor Bar Valve.

(see Figures 3 and 4)

Adjust the product tanks and the carbonated water tank CO2regulator to the proper operating pressure using

either the Cornelius PRE-MIX COMPUTER slide rule or bottling room chart.

Post-Mix Seven-Flavor System.

(see Figure 5)

ADJUSTING SYRUP SUPPLIES CO2REGULATOR:

Sugar Syrup Tanks CO2Regulator.

Adjust syrup tanks CO2regulator to a minimum of 45-psi.

Syrup Pumps (Bag-In-Box System) CO2Regulator.

Adjust the syrup pumps CO2regulator to 70-psi. DO NOT EXCEED MAXIMUM CO2PRESSURE SPECIFIED

ON THE SYRUP PUMPS.

ADJUSTING CARBONATOR CO2REGULATOR

Adjust carbonator CO2regulator for the remote carbonator as instructed in manual provided with the

carbonator.

ACTIVATING SYRUP, CARBONATED WATER, AND PLAIN WATER

SUPPLIES

ACTIVATING SYRUP SUPPLIES TO THE COOLING UNIT

IMPORTANT: All systems should be sanitized as instructed before Cooling Unit is put into operation.

1. Sanitize all syrup systems as instructed in the SERVICE AND MAINTENANCE section of this manual.

2. Activate syrup supplies to the Cooling Unit.

ACTIVATING CARBONATED W ATER SUPPLY SUPPLY TO THE COOLING UNIT

Pre-Mix Systems--Connect full tank of carbonated water into the Cooling Unit carbonated water system.

Post-Mix System-- Activate remote carbonator to provide carbonated water supply to the Cooling Unit.

ACTIVATING PLAIN WATER SUPPLY TO THE COOLING UNIT

Activate plain water supply to the Cooling Unit.

11 314920000

Page 16

UNIT OPERATION

1. Dispense from applicable bar valve or dispensing station dispensing valve until all air is purged from the

dispensing systems.

2. Check entire system for CO2, syrup, carbonated water, and plain water leaks and repair if evident.

12314920000

Page 17

OPERATORS INSTRUCTIONS

This section covers operators instructions for operating controls, daily pre-operation check, adjustments,

cleaning and sanitizing, and Cooling Unit maintenance.

WARNING: Disconnect electrical power from the Unit to prevent personnel injury before

attemping any internal maintenance. Only qualified personnel should service the internal

components or electrical wiring.

OPERATING CONTROLS

BAR VALVE

Place cup or glass under the bar valve nozzle. Press applicable flavor dispense button until cup or glass is full,

then release the button.

DISPENSING STATION

Place cup or glass under the dispensing valve nozzle, then operate dispensing valve as instructed in manual

provided with the dispensing station.

DAILY PRE --OPERATION CHECK

1. The CO2supply should be checked daily to make sure there is an adequate supply of CO2. If necessary,

replenish the CO2supply .

2. Make sure there is a sufficient product (pre-mix) or syrup (post-mix) supply and replenish if necessary.

3. Pre-Mix system--Make sure the carbonated water supply is adequate. If not, replace the carbonated water

tank with a full one.

ADJUSTMENTS

ADJUSTING CO2REGULATORS

The CO2regulators should be checked periodically for proper pressure settings by a qualified Service Person

and if necessary, adjusted as instructed in SERVICE AND MAINTENANCE section of this manual.

ADJUSTING W ATER--TO--SYRUP ‘‘RATIO’’ (POST--MIX SYSTEM) OF DISPENSED

PRODUCT

The Water-to-Syrup ‘‘Ratio’’ of the dispensed drink should be periodically checked by a qualified Service Person

and if necessary, adjusted as instructed in manual provided with the dispensing station.

CLEANING AND SANITIZING

CLEANING

Daily Cleaning of Bar Valve (Pre-Mix System).

The bar valve (pre-mix system) should be cleaned at end of daily operation as instructed in SERVICE AND

MAINTENANCE section of this manual.

13 314920000

Page 18

Daily Cleaning of Dispensing Station (Post-Mix System).

The dispensing station (post-mix system) should be cleaned at end of the daily operation as instructed in

manual provided with the dispensing station.

Periodic Cleaning of Cooling Unit.

The Cooling Unit should be periodically cleaned as instructed in SERVICE AND MAINTENANCE section of this

manual.

SANITIZING PRODUCT (PRE-MIX) OR SYRUP (POST-MIX) SYSTEMS

Sanitizing product (pre-mix) or syrup (post-mix) systems should be performed every 90-days by a qualified

Service Person as instructed in SERVICE AND MAINTENANCE section of this manual.

COOLING UNIT MAINTENANCE

CLEANING CONDENSER COIL

NOTE: Air required to cool the condenser coil, is drawn in through bottom half of the coil

(see Figure 6) and is discharged out through top half of the coil. The condenser coil opening on front

of the Cooling Unit must be open to the room at all times so as not to restrict air circulation in and out

of the Unit. This open to the room clearance must be provided to allow for proper air flow in and out of

the condenser coil to cool the refrigeration system.

The Cooling Unit condenser coil must be cleaned every 30-days as instructed in the SERVICE AND

MAINTENANCE section of this manual to maintain proper cooling of the condenser coil. The condenser coil

cleaning procedure should be performed by a qualified Service Person.

CHECKING ICE W ATER BATH

A ‘‘gurgle’’ heard from the Cooling Unit indicates water level in water tank is low and more water should be

added for maximum product cooling as instructed in the SERVICE AND MAINTENANCE section of this manual.

This procedure should be performed by a qualified Service Person.

REMOTE CARBONAT OR YEARLY MAINTENANCE OR AFTER WATER

SYSTEM DISRUPTIONS

The remote carbonator water pump water inlet screen and the liquid double check valve assembly must be

inspected and cleaned by a qualified Service Person as instructed in the SERVICE AND MAINTENANCE

section of this manual.

14314920000

Page 19

SERVICE AND MAINTENANCE

This section describes service and maintenance procedures to be performed on the Cooling Unit.

IMPORTANT: Only a qualified Service Person should service the Cooling Unit internal components or

electrical wiring.

PREPARING COOLING UNIT FOR SHIPPING, STORING, OR RELOCATING

CAUTION: Before shipping, storing, or relocating this Unit, the applicable syrup or product

systems must be sanitized and all sanitizing solution must be purged from the syrup or

product systems. All water must also be purged from the plain and carbonated water

systems. A freezing ambient temperature will cause residual water remaining inside the Unit to

freeze resulting in damage to internal components of the Unit.

PERIODIC INSPECTION

1. Check Cooling Unit condenser coil for obstructions and dirt. DO NOT place objects in front of condenser

coil. Restricting circulating air in and out of Cooling Unit will decrease its cooling efficiency.

2. The CO2supply should be checked to make sure there is an adequate supply of CO2. If necessary,

replenish the CO2supply .

3. Check applicable syrup (post-mix system) or product (pre-mix system) supply and replenish if necessary.

4. Check carbonated water supply (pre-mix system) and if necessary, replace carbonated water tank with a

full one.

5. Check entire system for leaks and repair as necessary.

ADJUSTMENTS

CO2REGULATORS ADJUSTMENTS

WARNING: CO2displaces oxygen. Strict attention must be observed in the prevention of

CO2(carbon dioxide) gas leaks in the entire CO2and soft drink system. If a CO2gas leak is

suspected, particularly in a small area, immediately ventilate the contaminated area before

attempting to repair the leak. Personnel exposed to high concentration of CO2gas will experience

tremors which are followed rapidly by loss of consciousness and suffocation.

Pre-Mix System Product Tanks CO2Regulator.

Adjust the product tanks CO2regulator to the proper operating pressure using either the Cornelius PRE-MIX

COMPUTER slide rule or the bottling room chart.

15 314920000

Page 20

BAR VAL VEBRACKET (ITEM 6)

BAR VAL VES

TOP COVER

OUTLET LINES

INLET LINES

WATER FILL PLUG

CONDENSER COIL

FIGURE 6. PARTS IDENTIFICA TION

BAR VAL VEDRIP

RECEPTACLE (ITEM 5)

CLAMP (ITEM 12)

DRAIN HOSE (ITEM 13)

Pre-Mix System Carbonated Water Tank CO2Regulator.

Adjust the carbonated water CO2regulator to the proper operating pressure using either the Cornelius

PRE-MIX COMPUTER slide rule or the bottling room chart.

Post-Mix System

SUGAR SYRUP TANKS CO2REGULATOR

Adjust syrup tanks CO2regulator to a minimum of 45-psi.

SYRUP PUMPS (BAG-IN-BOX SYSTEM) CO2REGULATOR

Adjust the syrup pumps CO2regulator to 70-psi. DO NOT EXCEED MAXIMUM CO2PRESSURE SPECIFIED

ON THE SYRUP PUMPS.

REMOTE CARBONATOR CO2REGULATOR

Adjust remote carbonator CO2regulator as instructed in manual provided with the carbonator.

ADJUSTING DISPENSER (POST-MIX SYSTEM) DISPENSING VALVES FOR

W ATER-TO-SYRUP “RATIO” OF DISPENSED PRODUCT

Refer to manual provided with the dispensing station for instructions to adjust the dispensing valves for

Water-To-Syrup “Ratio” of the dispensed product.

16314920000

Page 21

ICE BANK CONTROL

ANODE

AGITATOR

MOTOR

BRACKET

(SEE NOTE)

NOTE; AGITATOR MOTOR LO-

CATED BELOW BRACKET.

FIGURE 7. WA TER TANK COMPONENTS

CLEANING COOLING UNIT CONDENSER COIL

(see Figure 6)

NOTE: Air required to cool the condenser coil, is drawn in through bottom half of the coil

(see Figure 6) and is discharged out through top half of the coil. The condenser coil opening on front

of the Cooling Unit must be open to the room at all times so as not to restrict air circulation in and out

of the Unit. This open to the room clearance must be provided to allow for proper air flow in and out of

the condenser coil to cool the refrigeration system.

Vacuum or use soft brush to clean Cooling Unit condenser coil. If available, use low--pressure compressed air.

CHECKING COOLING UNIT ICE WATER BATH

A ‘‘gurgle’’ heard from Cooling Unit indicates water level in water tank is low and more water should be added

for maximum cooling. Before adding more water, ice water bath and ice bank should be checked for cleanliness

and water tank components checked for excess mineral deposit build-up.

1. Remove screws securing the Cooling Unit top cover, then remove the cover.

2. Inspect the ice water bath and the ice bank for cleanliness. The ice water bath should be clear and the ice

bank should be free of foreign particles.

3. Check the water tank components for mineral deposit build-up. If cleaning of the water tank is necessary,

proceed to CLEANING COOLING UNIT WATER TANK.

4. Fill the water tank with clean water to top of the stainless steel coils. USE LOW-MINERAl-CONTENT

WATER WHERE A LOCAL WATER PROBLEM EXISTS.

5. Install the Cooling Unit top cover and secure with screws.

CLEANING COOLING UNIT WATER T ANK

(see Figure 7)

1. Unplug Cooling Unit power cord from electrical outlet.

2. Remove screws securing the Cooling Unit top cover, then remove the cover.

3. Using a syphon hose, syphon water out of the water tank.

NOTE: If ice bank is clear and contains no foreign particles, it does not have to be melted down. Skip

steps 4 and 5 and proceed with 6.

17 314920000

Page 22

4. If ice bank is dirty, allow ice to melt. Hot water may be used to speed up melting of the ice.

CAUTION: Never use an ice pick or other instrument to remove ice from inside the water

tank. Such practice can result in a punctured refrigerant circuit or damage to the corrosion

protective coating on the water tank.

5. Wash inside of the water tank, then rinse tank with plain water.

CAUTION: Function of the anode in the ice water bath is to draw corrosive agents to itself

and away from the water tank. Make sure the ice bank sensing bulb and the anode, with its

rubber insulator in place on the top end, are properly placed in their respective positions.

The anode must be completely insulated from the other metal components and only an aluminum

screw must be used to secure its connecting wire to the water tank. If the anode is allowed to

contact other metal parts, its effectivity will be destroyed, allowing corrosive action to take place

on the water tank.

6. Use a fiber brush and carefully clean mineral deposit build-up from the agitator motor shaft, ice bank

sensing bulb, and the anode. If after cleaning the anode, and it is found to be badly corroded, replace the

old anode with a new one. Make sure only an aluminum screw is used to secure the anode connecting wire

to the water tank.

7. Rinse all water tank components, then flush the water tank with clean water.

8. Using a syphon hose, syphon flush water from the water tank.

9. Fill the water tank with clean water to top of the stainless steel coils. USE LOW-MINERAL-CONTENT

WATER WHERE A LOCAL WATER PROBLEM EXISTS.

10. Install the Cooling Unit top cover and secure with screws.

NOTE: As ice bank forms in the water tank, water expansion will take place and excess water will

escape through the water tank overflow hose to the bottom of the Cooling Unit where the water will

evaporate.

11. Plug Cooling Unit power cord into electrical outlet. The compressor, condenser fan motor, and the agitator

motor will start and begin forming an ice bank. When full ice bank has been formed, the compressor and

condenser fan motor will stop, but the agitator motor will continue to operate circulating ice water bath in

the water tank.

DAILY CLEANING

Daily Cleaning of Bar V alve.

At end of daily dispensing, wash bar valve in mild soap solution, then rinse thoroughly with plain water. Wipe bar

valve dry with clean soft cloth. DO NOT USE ABRASIVE TYPE CLEANERS.

Daily Cleaning of Dispensing Station.

Daily cleaning procedure for the Dispensing is outlined in DAILY CLEANING OF UNIT.

PERIODIC CLEANING OF COOLING UNIT.

Wash exterior of the Cooling Unit, rinse with clean water, then wipe the Cooling Unit dry with a soft cloth. DO

NOT USE ABRASIVE TYPE CLEANERS.

CLEANING AND SANITIZING

DAILY CLEANING OF UNIT

1. Remove cup rest from the drip tray .

18314920000

Page 23

2. Wash drip tray in place on the Unit, then rinse drip tray with hot water allowing water to drain out through

the drain hose.

3. Wash cup rest, then rinse the cup rest with clean water. Install cup rest in the drip tray.

4. Clean all external surfaces of the Unit with a sponge. Rinse out the sponge with clean water, then wring

excess water out of the sponge and wipe off all external surfaces on the Unit. Wipe Unit dry with a clean

soft cloth. DO NOT USE ABRASIVE CLEANERS.

5. Remove nozzle and syrup diffusers from the dispensing valves. Place nozzles and syrup diffusers in

sanitizing solution.

6. Wash the nozzles and syrup diffusers in sanitizing solution, then rinse them with potable water.

7. Re-install nozzles and syrup diffusers back on the dispensing valves.

SANITIZING POST-MIX SYRUP SYSTEMS

IMPORTANT: Only qualified Service Personnel should perform sanitizing procedure on the post-mix

syrup systems.

The post-mix syrup systems should be sanitized every 90-days using a non-scented household liquid bleach

containing a 5.25 % sodium hypochlorite concentration. Proceed as follows to sanitize the post-mix syrup

systems.

1. Disconnect syrup supplies from syrup systems.

2. Rinse quick disconnects (syrup tanks systems) or bag-in-box connectors (syrup bag-in-box systems) in

warm potable water.

STEP 1. WASH SYRUP SYSTEMS

3. Using a clean syrup tank (syrup tank system) or a five-gallon container (bag-in-box system), prepare a full

tank or container of liquid dishwasher detergent by using 70_ F (21_ C) to 100_ F (38_ C) potable water

and 0.5 oz. (15 ml) of liquid dishwasher detergent to one gallon of potable water. Stir detergent solution to

thoroughly mix the solution.

4. Syrup Tank Systems.

A. Observe and note CO2pressure setting on the syrup tanks CO2regulator, then re-adjust CO

2

regulator to 60 to 80-psi. Pressurize syrup tank containing detergent solution to 60 to 80-psi.

B. Connect detergent solution tank, pressurized at 60 to 80-psi, into one of the syrup systems.

Bag-in Box Syrup Systems.

C. Install bag valves, cut from empty bag-in-box syrup containers, on ends of syrup containers syrup

outlet tubes connectors.

D. Place all syrup outlet tubes, with bag valves on their ends, in container containing detergent solution.

5. Flush the syrup system and dispensing valve as follows:

A. Place waste container under applicable dispensing valve.

B. Activate the dispensing valve for one minute to purge all syrup and flush out the syrup system.

C. Continue to activate the dispensing valve in cycles (“ON” for 15-seconds, “OFF”, then “ON” for

15-seconds). Repeat “ON” and “OFF” cycles for 15-cycles.

6. Connect detergent solution to the remaining syrup systems and flush syrup out of the syrup systems as

instructed in step NO TAG preceding.

7. Remove detergent solution source from the syrup system.

19 314920000

Page 24

STEP 2. FLUSH SYRUP SYSTEMS

8. Syrup Tank Systems.

Connect syrup tank containing potable water, pressurized at 60 to 80-psi, into one of the syrup systems.

Bag-in-Box Syrup System.

Fill five-gallon container with potable water, then place all bag-in-box syrup containers syrup outlet tubes in

container containing potable water.

9. Flush detergent solution out of the syrup system and dispensing valve as follows:

A. Place waste container under applicable dispensing valve.

B. Activate the dispensing valve for one minute to purge all detergent solution and flush out the syrup

system.

C. Continue to activate the dispensing valve in cycles (“ON” for 15-seconds, “OFF”, then “ON” for

15-seconds). Repeat “ON” and “OFF” cycles for 15-cycles.

10. Connect potable water source to the remaining syrup systems and flush detergent solution out of the syrup

systems as instructed in step NO TAG preceding.

11. Remove potable water source from the syrup system.

STEP 3. SANITIZE SYRUP SYSTEMS

12. Using a clean syrup tank (syrup tanks system) or a five-gallon container (bag-in-box system), prepare

sanitizing solution using 70_ F (21_ C) to100_ F (38_ C) potable water and 0.5 oz. (15 ml) of non-scented

household liquid bleach that contains a 5.25 % sodium hypochlorite concentration to one gallon of potable

water. This mixture must not exceed 200 PPM of chlorine. Stir sanitizing solution to thoroughly mix.

13. Syrup Tank Systems.

Connect sanitizing solution tank, pressurized at 60 to 80-psi, into one of the syrup systems.

Bag-in-Box Syrup System.

Place all bag-in-box syrup containers syrup outlet tubes in container containing sanitizing solution.

14. Sanitize the syrup system and dispensing valve as follows:

A. Place waste container under applicable dispensing valve.

B. Activate the dispensing valve for one minute to purge all water from and install sanitizing solution in

the syrup system and dispensing valve.

C. Continue to activate the dispensing valve in cycles (“ON” for 15-seconds, “OFF”, then “ON” for

15-seconds). Repeat “ON” and “OFF” cycles for 15-cycles.

15. Repeat stepsNO TAG and NO TAG to flush water out of and install sanitizing solution in the remaining

syrup systems and dispensing valves.

16. Remove sanitizing solution source from the syrup system.

17. Allow sanitizing solution to remain in the syrup systems for not less than 10 or no more than 15-minutes

(max.) contact time.

STEP 4. WATER FLUSH SYRUP SYSTEMS

WARNING: Flush sanitizing solution from the syrup systems as instructed. Residual

sanitizing solution left in the syrup systems could create a health hazard.

20314920000

Page 25

18. Fill syrup tank (syrup tank system) or a five-gallon container (bag-in-box system) with potable water.

19. Syrup Tank Systems.

Connect syrup tank containing potable water, pressurized at 60 to 80-psi, into one of the syrup systems.

Bag-in-Box Syrup System.

Place all bag-in-box syrup containers syrup outlet tubes in container containing potable water.

20. Flush sanitizing solution from the syrup system and the dispensing valve as follows:

A. Place waste container under applicable dispensing valve.

B. Activate the dispensing valve for one minute to purge all sanitizing solution out of the syrup system

and the dispensing valve.

C. Continue to activate the dispensing valve in cycles (“ON” for 15-seconds, “OFF”, then “ON” for

15-seconds). Repeat “ON” and “OFF” cycles for 15-cycles.

21. Repeat steps NO TAG and NO TAG preceding to purge sanitizing solution out of the remaining syrup

systems and

dispensing valves.

22. Remove potable water source from the syrup system.

STEP 5. PURGE WATER OUT OF SYRUP SYSTEMS (RESTORE OPERATION)

23. Syrup Tank Systems.

A. Noting syrup tanks CO2regulator pressure setting observed in step 4 preceding, readjust CO

2

regulator to the observed pressure setting,

B. Connect tanks containing syrup into syrup systems.

Bag-in-Box Syrup System.

C. Remove all bag valves from bag-in-box syrup containers outlet tubes connectors.

D. Connect bag-in-box syrup containers into the syrup systems.

24. Place waste container under dispensing valves. Dispense from all dispensing valves to permit syrup to

purge all potable water from the syrup systems and the dispensing valves. Continue to dispense from the

dispensing valves until only syrup is dispensed from the syrup systems and valves.

WARNING: To avoid possible personal injury or property damage, do not attempt to

remove the syrup tank cover until CO2pressure has been released from the tank.

25. Dispose of waste sanitizing solution in a sanitary sewer, not in a storm drain, then thoroughly rinse the

inside and the outside of the container that was used for sanitizing solution to remove all sanitizing solution

residue.

21 314920000

Page 26

FAN MOTOR

CONDENSER

OVERLOAD

WHITE

MOTOR

AGITATOR

RELAY

COMPRESSOR

BLACK

GROUND

ICE BANK

BLACK

CONTROL

BLOCK

FIGURE 8. WIRING DIAGARAM

BLACK TERMINAL

CONTROL BOX

WHITE

GREEN

SERVOCE CORD

BLACK

22

Page 27

TROUBLESHOOTING

IMPORTANT: Only qualified personnel should service internal components or electrical wiring.

WARNING: If repairs are to be made to a product system, remove quick disconnects from

the applicable product tank, then relieve the system pressure before proceeding. If repairs

are to be made to the CO2system, stop dispensing, shut off the CO2supply , then relieve the

system pressure before proceeding. If repairs are to be made to the refrigeration system, make sure

electrical power is disconnected from the unit.

TROUBLESHOOTING PRE--MIX SYSTEM

Trouble Probable Cause Remedy

NO PRODUCT DISPENSED. A. Product tank quick

disconnects not securely

connected.

B. No product supply (product

tank empty).

C. No CO2supply . C. Replenish CO2supply .

D. Product frozen in Cooling Unit

cooling coil.

DISPENSED PRODUCT

COMES OUT OF

DISPENSING VALVE OR BAR

VALVE CLEAR BUT FOAMS IN

CUP OR GLASS.

NOTE: Crushed ice also causes dispensing problems. When finished drink hits sharp edges of the ice,

carbonation is released from drink.

DISPENSED PRODUCT

FOAMS AS IT LEAVES

DISPENSING VALVE OR BAR

VALVE.

A. Oil film or soap scum in cups

or glasses.

B. Ice used for finished drink is

sub-cooled.

A. Refrigeration recovery rate of

Cooling Unit exceeded, ice

bank depleted.

A. Secure product tank quick

disconnects.

B. Replenish product supply.

D. Call Service Person.

A. Use clean cups or glasses.

B. Do not use ice directly from

freezer. Allow ice to become ‘‘wet’’

before using. (Refer to following

NOTE)

A. Allow ice bank to recover, then

resume dispensing.

B. Improper product tanks CO

operating pressure.

C. Dispensing valve or bar valve

restricted or dirty.

D. Tapered nylon washer inside

tube swivel nut connector

distorted from being

overtightened.

E. Oil, water, or dirt in CO

supply .

23 314920000

2

2

B. Call Service Person to readjust

product tanks CO2regulator.

C. Call Service Person to sanitize

system.

D. Call Service Person to replace

nylon washer and make sure it

seats properly.

E. Call Service Person to remove

contaminated CO2. Clean CO

system (lines, regulators, etc.)

using a mild detergent. Install

clean CO2supply .

2

Page 28

Trouble RemedyProbable Cause

TROUBLESHOOTING POST --MIX SYSTEM

DISPENSED PRODUCT

WATER--TO--SYRUP ‘‘RATIO’’

TOO LOW OR TOO HIGH.

ADJUSTMENT OF

DISPENSING VALVE SYRUP

FLOW CONTROL DOES NOT

INCREASE TO DESIRED

WATER--TO--SYRUP ‘‘RATIO’’.

A. Dispensing valve syrup flow

control not properly adjusted.

A. Call Service Person to adjust

Water--to--Syrup ‘‘Ratio’’ of

dispensed product.

B. CO2gas pressure to syrup

tanks insufficient to push syrup

B. Call Service Person to adjust CO

regulator for syrup tanks.

out of tanks.

A. No syrup supply. A. Replenish syrup supply.

B. Syrup Tanks System.

B. Call Service Person to adjust CO

regulator for syrup tanks.

Syrup tanks CO2regulator out

of adjustment.

Syrup Bag-In-Box System.

Call Service Person to adjust

syrup pumps CO2regulator.

Syrup pumps CO2regulator

out of adjustment.

C. Product tanks CO2regulator

out of adjustment.

C. Call Service Person to adjust

product tanks CO2regulator.

2

2

ADJUSTMENT OF

DISPENSING VALVE SYRUP

FLOW CONTROL DOES NOT

DECREASE TO DESIRED

WATER--TO-- SYRUP ‘‘RATIO’’

DISPENSED PRODUCT

CARBONATION TOO LOW.

D. Dispensing valve syrup flow

control or syrup line restricted.

D. Call Service Person to sanitize

system.

E. Improper syrup Baume. E. Replace syrup supply.

F. Dirty or inoperative dispensing

valve syrup flow control.

F. Call Service Person to

disassemble and clean dispensing

valve syrup flow control.

A. Dirty dispensing valve syrup

flow control.

A. Call Service Person to

disassemble and clean dispensing

valve syrup flow control.

B. Tapered nylon washer inside

tube swivel nut connector

distorted from being

B. Call Service Person to replace

nylon washer and make sure it

seats properly.

overtightened.

A. Carbonator CO2regulator out

of adjustment for existing

A. Call Service Person to adjust

carbonator CO2regulator.

water conditions or

temperature.

B. Air in carbonator tank. B. Call Service Person to vent air out

of carbonator tank through relief

valve. Open dispensing valve to

make carbonator pump cycle on.

C. Water, oil, or dirt, in CO

supply .

24314920000

2

C. Call Service Person to remove

contaminated CO2. Clean CO

2

system (lines, regulators, etc.)

using a mild detergent. Install a

clean CO2supply .

Page 29

Trouble RemedyProbable Cause

DISPENSED PRODUCT

COMES OUT OF

A. Oil film or soap scum in cup or

glass.

A. Use clean cups or glasses.

DISPENSING VALVE CLEAR

BUT FOAMS IN CUP OR

GLASS.

B. Ice used for finished drink is

sub--cooled.

B. Do not use ice directly from

freezer. Allow ice to become ‘‘wet’’

before using. (refer to following

NOTE)

NOTE: Crushed ice also causes dispensing problems. When finished drink hits sharp edges of ice,

carbonation is released from drink.

DISPENSED PRODUCT

PRODUCES FOAM AS IT

A. Recovery rate of Cooling Unit

exceeded, ice bank depleted.

A. Allow ice bank to recover.

LEAVES DISPENSING VALVE.

B. Carbonator CO2regulator

pressure too high for existing

water conditions or

B. Call Service Person to reduce

carbonator CO2regulator

pressure setting.

temperature.

C. Syrup over-carbonated with

CO2as indicated by bubbles in

inlet syrup lines leading to

Cooling Unit.

C. Remove syrup tanks quick

disconnects. Relieve tank CO

pressure, shake tank vigorously ,

then relieve tank CO2pressure as

many times as necessary to

remove over-carbonation.

2

D. Dispensing valve restricted or

dirty .

E. Tapered nylon washer inside

tube swivel nut connector in

carbonated water system

D. Call Service Person to sanitize

syrup system.

E. Call Service person to replace

nylon washer. Make sure it is

properly seated.

distorted from being

overtightened.

F. Dirty water supply. F. Check water filter. Replace

cartridge. (see NOTE)

NOTE: If water supply is dirty, Service Person must be sure to flush lines and carbonator completely. It

may be necessary to remove lines to carbonator tank, invert tank, and flush tank and all inlet lines to

remove any foreign, particles or dirt.

ONLY CARBONATED WATER

DISPENSED.

A. Quick disconnects not secure

on syrup tanks.

A. Secure quick disconnects on

syrup tanks.

B. Out of syrup. B. Replenish syrup supply .

C. Syrup Tanks System.

C. Call Service Person to adjust

syrup tanks CO2regulator.

Syrup Tanks tanks CO

2

regulator not properly

adjusted.

Syrup Bag-In-Box System.

Call Service Person to adjust

syrup pumps CO2regulator.

Syrup pumps CO2regulator

not properly adjusted.

D. Inoperable dispensing valve. D. Call Service Person to repair

dispensing valve.

25 314920000

Page 30

Trouble RemedyProbable Cause

ONLY CARBONATED WATER

DISPENSED. (CONT’D)

E. Dispensing valve syrup flow

control not properly adjusted.

F. Syrup flow control or syrup

system restricted.

ONLY SYRUP DISPENSED. A. Carbonator water inlet supply

line shutoff valve closed.

B. Carbonator power cord

unplugged from electrical

outlet.

C. Carbonator CO2regulator not

properly adjusted.

TROUBLESHOOTING REFRIGERATION SYSTEM

COMPRESSOR DOES NOT

A. Ice bank sufficient. A. Refrigeration not called for.

OPERATE.

B. Cooling Unit power cord

unplugged.

C. No power source (blown fuse

or tripped circuit breaker).

E. Call Service Person to adjust

Water--to--Syrup ‘‘Ratio’’ of

dispensed product.

F. Call Service Person to sanitize

syrup system.

A. Open water inlet supply line

shutoff valve.

B. Plug carbonator power cord into

electrical outlet.

C. Call Service Person to adjust

carbonator CO2regulator.

B. Plug in Cooling Unit power cord.

C. Replace or reset circuit breaker.

(Note: Fuse is not part of Cooling

Unit.)

COMPRESSOR WILL NOT

STOP AFTER SUFFICIENT

ICE BANK IS PRODUCED.

(NOTE--ICE BANK SHOULD

JUST COVER CONTROL

BULB)

D. Low voltage. D. Voltage must be at least 103 volts

at compressor terminals when

compressor is trying to start.

E. Loose, disconnected, or

broken wiring.

F. Overload protector cut out;

overheated compressor.

Condenser fan motor not

operating as required.

E. Tighten connections or replace

broken wiring.

F. Compressor will cool enough to

restart. Do not overdraw Cooling

Unit. Refer to ‘‘CONDENSER

FAN MOTOR NOT OPERATING’’

in this section.

G. Inoperative overload protector

G. Replace inoperative part.

or start relay.

H. Inoperative ice bank control. H. Replace ice bank control.

I. Inoperative compressor. I. Replace compressor.

A. Ice bank control cap tube

A. Replace ice bank control.

kinked or broken.

B. Ice bank control stuck in

B. Replace ice bank control.

closed position.

26314920000

Page 31

Trouble RemedyProbable Cause

COMPRESSOR OPERATES

CONTINUOUSLY BUT DOES

NOT FORM SUFFICIENT ICE

BANK.

NOTE: Ice bank freezes from bottom of evaporator upward. A refrigerant leak or insufficient charge

might show an ice bank at bottom and not at top of evaporator.

CONDENSER FAN MOTOR

NOT OPERATING.

A. Cooling Unit capacity is

exceeded by overdrawing.

B. Cooling Unit located in

excessively hot area or air

circulation through condenser

coil is restricted.

NOTE: If overload protector cuts out compressor, condenser fan motor

will continue to operate; otherwise; troubleshooting condenser fan mo -

tor problems is same as for ‘‘COMPRESSOR DOES NOT OPERATE’’

paragraph plus the following:

A. Jumper cord loose or

disconnected from condenser

fan motor or compressor

terminals. Broken wire in cord.

B. Fan blade obstructed. C. Remove obstruction.

C. Inoperative condenser fan

motor.

A. Reduce amount of drinks drawn

per given time.

B. Relocate Cooling Unit or check

and if necessary, clean condenser

coil.

A. Tighten connections or replace

cord.

D. Replace condenser fan motor.

AGITATOR MOTOR NOT

OPERATING.

A. Cooling Unit power cord

unplugged.

B. No power source (blown fuse

or tripped circuit breaker).

C. Agitator motor propeller

obstructed.

D. Low voltage. D. Voltage must be at least 103 volts

E. Loose, disconnected, or

broken wiring.

F. Inoperative agitator motor. F. Replace agitator motor.

A. Plug in Cooling Unit power cord.

B. Replace fuse or reset circuit

breaker. (Note: Fuse is not part of

cooling unit.)

C. Remove obstruction.

at compressor terminals when

compressor is trying to start.

E. Tighten connections or replace

broken wiring.

27 314920000

Page 32

WARRANTY

IMI Cornelius Inc. warrants that all equipment and parts are free from defects in material and workmanship

under normal use and service. For a copy of the warranty applicable to your Cornelius, Remcor or Wilshire

product, in your country, please write, fax or telephone the IMI Cornelius office nearest you. Please provide the

equipment model number, serial number and the date of purchase.

IMI Cornelius Offices

AUSTRALIA D P.O. 210, D RIVERWOOD, D NSW 2210, AUSTRALIA D (61) 2 533 3122 D FAX (61) 2 534 2166

AUSTRIA D AM LANGEN FELDE 32 D A-1222 D VIENNA, AUSTRIA D (43) 1 233 520 D FAX (43) 1-2335-2930

BELGIUM D BOSKAPELLEI 122 D B-2930 BRAASCHAAT , BELGIUM D (32) 3 664 0552 D FAX (32) 3 665 2307

BRAZIL D RUA ITAOCARA 97 D TOMAS COELHO D RIO DE JANEIRO, BRAZIL D (55) 21 591 7150 D FAX (55) 21 593 1829

ENGLAND D TYTHING ROAD ALCESTER D WARWICKSHIRE, B49 6 EU, ENGLAND D (44) 789 763 101 D FAX (44) 789 763 644

FRANCE D 71 ROUTE DE ST. DENIS D F-95170 DEUIL LA BARRE D PARIS, FRANCE D (33) 1 34 28 6200 D FAX (33) 1 34 28 6201

GERMANY D CARL LEVERKUS STRASSE 15 D D-4018 LANGENFELD, GERMANY D (49) 2173 7930 D FAX (49) 2173 77 438

GREECE D 488 MESSOGION AVENUE D AGIA PARASKEVI D 153 42 D ATHENS, GREECE D (30) 1 600 1073 D FAX (30) 1 601 2491

HONG KONG D 1104 TAIKOTSUI CENTRE D 11-15 KOK CHEUNG ST D TAIKOKTSUE, HONG KONG D (852) 789 9882 D FAX (852) 391 6222

ITALY D VIA PELLIZZARI 11 D 1-20059 D VIMARCATE, ITALY D (39) 39 608 0817 D FAX (39) 39 608 0814

NEW ZEALAND D 20 LANSFORD CRES. D P.O. BOX 19-044 AVONDALE D AUCKLAND 7, NEW ZEALAND D (64) 9 8200 357 D FAX (64) 9 8200 361

SINGAPORE D 16 TUAS STREET D SINGAPORE 2263 D (65) 862 5542 D FAX (65) 862 5604

SPAIN D POLIGONO INDUSTRAIL D RIERA DEL FONOLLAR D E-08830 SANT BOI DE LLOBREGAT D BARCELONA, SPAIN D (34) 3 640 2839 D FAX (34) 3 654 3379

USA D ONE CORNELIUS PLACE D ANOKA, MINNESOTA D (612) 421-6120 D FAX (612) 422-3255

LD004

4/21/98

314920000 28

Page 33

THIS PAGE LEFT BLANK INTENTIONALLY

29 314920000

Page 34

IMI CORNELIUS INC.

CORPORATE HEADQUARTERS:

One Cornelius Place

Anoka, Minnesota 55303-6234

(612) 421-6120

(800) 238-3600

Loading...

Loading...