Page 1

Owner’s Manual

LIQUID

CIRCULATORS

MODELS CFF–330 & 500

Part No. 90538

revision B

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

REMCOR INC: date

PRINTED IN U.S.A

Page 2

TABLE OF CONTENTS

GENERAL INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DESCRIPTION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT PANEL REMOVAL 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOCATION 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIQUID CONNECTIONS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL CONNECTIONS 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

START UP 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT NOT OPERATING. POWER LIGHT OFF 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT DOES NOT PUMP LIQUID. 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT DOES NOT HEAT. 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT DOES NOT COOL; COMPRESSOR RUNS. 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSOR DOESN’T RUN; BODY COOL 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSOR DOESN’T RUN; BODY HOT 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTEM TEMPERATURE ERRATIC. 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CFF PERFORMANCE DATA 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PAGE

REMCOR PRODUCTS COMPANY CHILLER WARRANTY 10. . . . . . . . . . . . . . . . . . . . . . . . .

LIST OF FIGURES

FIGURE 1. TYPICAL CLOSED SYSTEM 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 2. LIQUID CONNECTIONS 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 3. MAJOR PUMP COMPONENTS AND THEIR ASSEMBLY 4. . . . . . . . . . . . .

FIGURE 4. CIRCULATOR DIMENSIONS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 5. MODEL CFF WIRING DIAGRAM 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIST OF TABLES

TABLE 1. SPECIFICATIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i 90538

Page 3

GENERAL INFORMATION

CAUTION: Operating the unit without liquid for more than 5 seconds can result in damage

to the pump. Evidence of dry operation will void the warranty. Read the installation and

start-up sections before operating.

DESCRIPTION

The Remcor Model CFF Liquid Circulator is a self–contained unit consisting of a pump, heater, cooling system,

and 2–stage thermostat housed in a rugged cabinet with a baked-on finished. It will operate with any water

system up to a maximum of 30 gallons (113 liters). The CFF is not designed for continuous cooling at water

temperatures above 85°F (29°C), although short term operation at higher temperatures with no external heat

load is acceptable for pulling down the system temperature.

Table 1. Specifications

PHYSICAL CFF–330 CFF–500

Shipping Weight 130# (59Kg) 135# (61Kg)

Internal Liquid Vol. 1.5 Gal. (5.7 Liters)

Inlet/Outlet Conns. 5/8” I.D. Hose

CONSTRUCTIONS MATERIALS (in Contract with liquid)

Pump Polypropylene, 316 S. S. BUNA–N

Tank 316 S.S.

Tubing PVC

ELECTRICAL

Operating Voltage 115/1/60*

Full Load Current (@ 115V) 10A 14A

Inrush Current (@ 115V) 36A 48A

TECHNICAL

Temp. Range 30–130°F (–2 – +54°C)

Temp. Differential (max.) 3/4°F (.4°C)

Compressor 1/3HP 1/2HP

Heater 1KW (14.3 Kg-cal/min)

Refrigerant – 12 2.5# (1.1Kg) 3# (1.4 Kg)

1

90538

Page 4

INSTALLATION

FRONT PANEL REMOVAL

In order to make connections to the CFF, it will be necessary to remove the front panel by removing the

fasteners on the front of the unit and then sliding the panel forward. When replacing the panel, slide it straight

back until it is engaged under the rear retaining flange, and replace the front fasteners.

Location

The CFF must be located such that the pump inlet is below the normal operating level of the bath to which it is

connected. Failure to do so will cause improper operation and damage to the pump.

The following clearances must be maintained around the unit for proper operation

Top – open

Right Side – 24” (152.4mm)

Left Side – 12”

Liquid Connections

Figure 2 (page 3) shows proper and improper methods of making liquid connections.. Liquid tubing should b

5/8” I.D., and hose clamps should be used to insure a tight connection.

The inlet hose should run through the hole in the rear panel and connect to the pump suction connection. This

line must run from a drain at the lowest point in the bath, and should not contain any inverted traps which could

cause air binding and loss of prime. In open systems where foreign material may be present the bath drain

should be raised slightly and fitted with a screen to prevent the entrance of such material into the inlet hose.

The outlet hose connects to the top of the CFF tank, and may enter the bath at any convenient point. Care

should be taken in larger systems to prevent “short circuiting” of liquid between inlet and outlet connections

which are to close together in the bath, as this will cause wide temperature variations. If and air trap must be

present in the outlet line, then it should be provided with a vent valve to allow the complete removal of air.

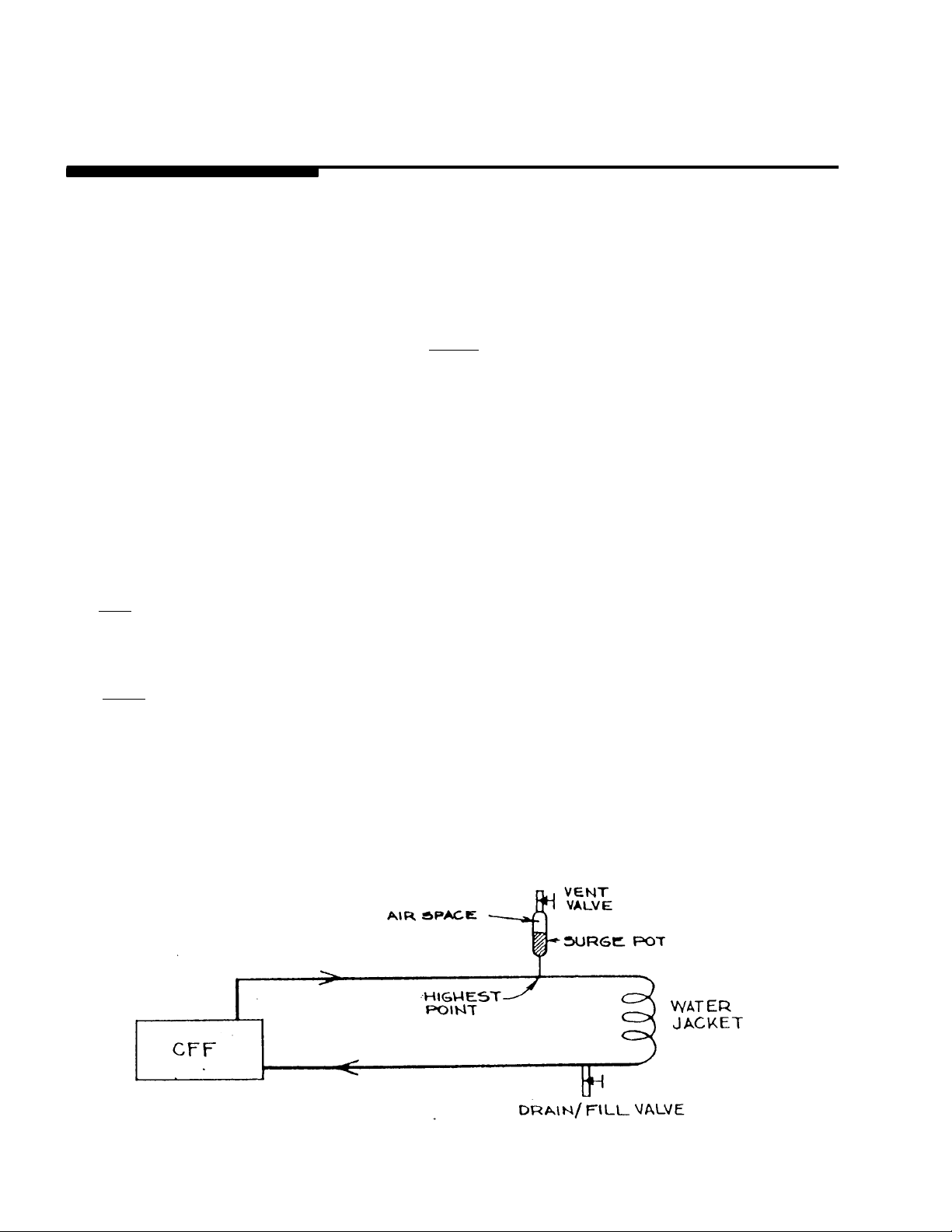

In closed systems (where the system is not open to the atmosphere), the installation should include a “surge

pot” located at the highest point in the outlet line, to facilitate proper purging of air and to allow for expansion

and contraction of the liquid in the system with changes in temperature. This pot should normally have

approximately 1/10th the total volume of the system, and a small air space must remain at the top for proper

operation.

90538

FIGURE 1. TYPICAL CLOSED SYSTEM

2

Page 5

FIGURE 2. LIQUID CONNECTIONS

Electrical Connections

All wiring must conform to NEC and local codes. The unit must be permanently wired by means of conduit. The

conduit should be run through the hole provided in the rear of the cabinet and connected by means of a fitting to

the 1/2” knockout in the electric box. The field supply wires must be spliced to the pigtails provided in the

electric box. Take care to keep all wiring away from the relay, to avoid interfering with its proper operations.

Do not operate the unit until the start–up procedure has been followed.

START UP

When the installation steps have been completed, the system is ready to fill. With the power switch “off” begin

adding liquid to the system until the inlet hose and pump housing are completely full. This will occur

automatically if the unit has been properly installed. If this priming action does not occur, go back and review the

installation to be sure that there are no restrictions or air traps in the inlet hose. Once the inlet hose is full, the

pump may be started by turning the power switch “on”. As liquid is pumped through the system, air will be

expelled from the outlet hose. (In closed systems, the vent valve must be opened to allow air to escape from the

system).

Once the pump has been started, it is important to add liquid at a sufficient rate so the inlet hose remains full.

Continue adding liquid until all of the air has been expelled and the liquid is at its normal operating level.

After filling, check all connections for tightness. In many cases, a leaking connection on the inlet side of the

pump will allow air to enter the system. This can be observed as a stream of bubbles in the hose accompanied

by a “growling” noise in the pump. If not eliminated, this air can interfere with proper system operation and will

shorten the pump life.

Once the system has been properly filled and purged of air, it will maintain its prime automatically when the unit

is shut off. The above procedure needs to be repeated only if the system has be drained.

3

90538

Page 6

OPERATION

The unit may be turned on and off by means of the power switch. The pilot light indicates the presence of power

when the switch is “On”. Setting the thermostat dial to the desired temperature will cause either the heater of

cooling system to operate, depending on the liquid temperature. In applications requiring extreme accuracy, a

thermometer should be used in the liquid bath to determine the temperature.

In operation, the circulating pump runs continuously, drawing liquid from the system and pumping it through the

tank and back out to the system. The 2-stage thermostat senses the liquid temperature in the tank and cycles

the heater or cooling system in response to temperature changes below or above the setpoint respectively.

Heating is accomplished by means of an immersion heater located at one end of the tank. The cooling system

is completely sealed and consists of t compressor, condenser, receiver, thermal expansion valve, and a heat

exchanger which is an integral part of the tank. It utilizes refrigerant 12 to remove heat from the liquid in the

tank.

MAINTENANCE

The CFF requires very little normal maintenance. The condenser fins should be cleaned occasionally with a

brush or compressed air to keep them from becoming blocked by dirt. If the unit is to be shut off for a prolonged

period, it should be flushed with clean water and then drained completely. Every 6 months, the pump should be

oiled with SAE 20 non-detergent oil at the two motor oil ports.

Except for the refrigeration system, the CFF is easily serviced in the field should the need arise. The following

section will serve as a guide to making general repairs.

Pump

The pump consists of only one moving part, the impeller, which is magnetically driven by and open type,

thermally protected motor. The magnetic drive construction eliminates shaft seals and their associated leak

problem. The most common source of pump failure is dry operation, which causes the impeller to bind.

The pump is easily disassembled when required by removing the 4 wing nuts which hold it together. Figure 3

shows the major pump components and their assembly.

90538

FIGURE 3. MAJOR PUMP COMPONENTS AND THEIR ASSEMBLY

4

Page 7

Heater

The immersion heater is instaled in a threaded connection in the tank. Electrical connections are by means of

slip-on terminals. When installing a new heater, teflon tape should be used on the threads to insure leak-proof

seal.

Cooling System

The cooling system is hermetically sealed, and repairs to the refrigeration components should only be made by

he factory. Field replaceable parts include the compressor electrical equipment and the condenser fan.

The compressor electrical equipment consists of a thermal protector, starting relay, and starting capacitor. All

are located in the compressor terminal box. Care should be taken to see that the wires are reconnected

properly when replacing these components.

Thermostat

NOTE: The thermostat consists of a temperature actuated bellows assembly which operates two micro

switches, at slightly different temperatures, to control the heating or cooling of the liquid in the tank. The internal

thermostat parts are not field replaceable of adjustable. In case of any failure, the thermostat should be

replaced.

When replacing the thermostat, note the routing of the capillary, and be sure to avoid any kinks or sharp bends.

The bulb is located in a well in the tank and can be removed or replaced simply by sliding in and out. When

reinstalling a new thermostat, the bulb should be coated with a heat conducting compound such as silicone

grease or “Thermal Mastic”. which is available at most refrigeration supply houses.

5

90538

Page 8

TROUBLESHOOTING

Trouble Probable Cause

UNIT NOT OPERATING. POWER LIGHT OFF A. Power switch off.

UNIT DOES NOT PUMP LIQUID. A. Pump motor burned out of pump impeller frozen.

B. Restriction or air trap in inlet line.

C. Restriction in outlet line.

UNIT DOES NOT HEAT. A. Heater burned out.

B. Bad “heat” switch on thermostat.

UNIT DOES NOT COOL; COMPRESSOR

RUNS.

COMPRESSOR DOESN’T RUN; BODY COOL A. Bad “cool” switch on thermostat.

COMPRESSOR DOESN’T RUN; BODY HOT A. Bad starting relay.

SYSTEM TEMPERATURE ERRATIC. A. Air in system.

A. Fan motor burned out.

B. * Refrigerant leak.

C. *Bad Expansion valve

B. Bad thermal protector.

C. Bad control relay in electric box.

D. *Compressor burned out.

B. Bad start capacitor.

C. * Compressor burned out.

B. Bad thermostat.

690538

Page 9

FIGURE 4. CIRCULATOR DIMENSIONS

7 90538

Page 10

NC

NO

RED

C

RED

BLACK

SW

H5/1/60

HTS

NC

H

REAR

VIEW

NO

C

TEMP.

INCR

START

RELAY

OL

C

CR

START

CAP.

R

S

C

WHITE

GRN

FIGURE 5. MODEL CFF WIRING DIAGRAM

LEGEND

P PUMP CR CONTROL RELAY

T THERMOSTAT C COMPRESSOR

F FAN H HEATER

SW POWER SWITCH L PILOT LIGHT

HTS HI-TEMP. SWITCH OL OVERLOAD

890538

Page 11

CFF PERFORMANCE DATA

heating capacity = 3412 BTUH (858K-CAL/HR)

All data is based on water

4000

(1008)

3000

(756)

2000

(504)

1000

(252)

40(4.4)

COOLING CAPACITY

50 (10.0)

BATH TEMPERATURE - °F (°C)

@ 75°F AMBIENT

(23.9 °C)

PUMP DATA

EXT. HEAD

FT. (METERS)

1 (0.3)

3 (0.9)

6(1.8)

60 (15.6)

FLOW RATE

GPM (LITER/MIN

4.9(18.6)

3.5(13.2)

1.1( 4.1)

70 (21.1)

80

(25.7)

70

(21.1)

60

(15.6)

50

(10)

40

(4.4)

‘130

RATE OF TEMP. CHANGE

10 GAL. SYSTEM (38 LITERS)

@ 75°F(23.9°C) AMBIENT

WELL INSULATED

0

30

60

90

120

(54.4)

120

48.9

110

(43.3)

100

(37.8)

90

(32.2)

TIME (MIN)

9 90538

Page 12

IMI CORNELIUS INC.

ONE CORNELIUS PLACE

ANOKA, MN. 55303–6234

TELEPHONE (800) 238–3600

FACSIMILE (612) 422–3232

TECH SVC 1-800-535-4240

WARRANTY

IMI Cornelius Inc. and Remcor Products Company warrants that all equipment and parts are free from

defects in material and workmanship under normal use and service. For a copy of the warranty applicable

to your Cornelius and or Remcor product, in your country, please write, fax or telephone the

IMI Cornelius office nearest you. Please provide the equipment model number, serial number and the

date of purchase.

IMI Cornelius Offices

AUSTRALIA D P.O. 210, D RIVERWOOD, D NSW 2210, AUSTRALIA D (61) 2 533 3122 D FAX (61) 2 534 2166

D AM LANGEN FELDE 32 D A-1222 D VIENNA, AUSTRIA D (43) 1 233 520 D FAX (43) 1-2335-2930

AUSTRIA

D BOSKAPELLEI 122 D B-2930 BRAASCHAAT, BELGIUM D (32) 3 664 0552 D FAX (32) 3 665 2307

BELGIUM

D RUA ITAOCARA 97 D TOMAS COELHO D RIO DE JANEIRO, BRAZIL D (55) 21 591 7150 D FAX (55) 21 593 1829

BRAZIL

D TYTHING ROAD ALCESTER D WARWICKSHIRE, B49 6 EU, ENGLAND D (44) 789 763 101 D FAX (44) 789 763 644

ENGLAND

FRANCE

D 71 ROUTE DE ST. DENIS D F-95170 DE UIL LA BARRE D PARIS, FRANCE D (33) 1 34 28 6200 D FAX (33) 1 34 28 6201

GERMANY

GREECE

HONG

ITALY

NEW

SINGAPORE

SPAIN

USA

D CARL LEVERKUS STRASSE 15 D D-4018 LANGENFELD, GERMANY D (49) 2173 7930 D FAX (49) 2173 77 438

D 488 MESSOGION AVENUE D AGIA PARASKEVI D 153 42 D ATHENS, GREECE D (30) 1 600 1073 D FAX (30) 1 601 2491

KONG D 1104 TAIKOTSUI CENTRE D 11-15 KOK CHEUNG ST D TAIKOKTSUE, HONG KONG D (852) 789 9882 D FAX (852) 391 6222

D VIA PELLIZZARI 11 D 1-20059 D VIMARCATE, IT ALY D (39) 39 608 0817 D FAX (39) 39 608 0814

ZEALAND D 20 LANSFORD CRES. D P.O. BOX 19-044 AVONDALE D AUCKLAND 7, NEW ZEALAND D (64) 9 8200 357 D FAX (64) 9 8200 361

D 16 TUAS STREET D SINGAPORE 2263 D (65) 862 5542 D FAX (65) 862 5604

D POLIGONO INDUSTRAIL D RIERA DEL FONOLLAR D E-08830 SANT BOI DE LLOBREGAT D BARCELONA, SPA IN D (34) 3 640 2839 D FAX (34) 3 654 3379

D ONE CORNELIUS PLACE D ANOKA, MINNESOTA D (612) 421-6120 D FAX (612) 422-3255

90538

10

SD 99-3

1/16/96

Page 13

CORPORATE HEADQUARTERS:

Glendale Heights, IL 60139

Remcor Incorporated

500 Regency Drive

708. 980.6900

Loading...

Loading...