Page 1

IMI CORNELIUS INC One Cornelius Place Anoka, MN 55303-6234

Telephone (800) 238-3600 Facsimile (612) 422-3246

Service Manual

REMOTE CONDENSING UNIT

(PART NUMBERS 416117 AND 496117)

Part No. 1128

June 11, 1991

Revised: March 1, 1995

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

IMI CORNELIUS INC; 1991

PRINTED IN U.S.A

Page 2

UNPACKING AND INSPECTION 2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SELECTING LOCATION 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLING REMOTE CONDENSING UNIT 2. . . . . . . . . . . . . . . . . . . . . .

SERVICE AND MAINTENANCE 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PERIODIC INSPECTION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LUBRICATION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING CONDENSER COIL 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

troubleshooting refrigeration compressor 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

compressor cools but is very noisy especially when stopping and starting 7. . . . .

COMPRESSOR COOLS, BUT IS MODERATELY NOISY; LOUD ENOUGH TO BE NOĆ

TICED, BUT NO SHARP BANGS OR CLATTERING 7. . . . . . . . . . . . . .

COMPRESSOR OPERATES BUT REFRIGERATION SYSTEM DOES NOT COOL . . .

7

COMPRESSOR STARTS AND OPERATES FOR A FEW SECONDS, THEN STOPS . .

7

COMPRESSOR WILL NOT START 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSOR STARTS BUT WILL NOT OPERATE FOR MORE THAN A FEW SECĆ

ONDS 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compressor starts but will not operate for more than a few seconds (cont'd) 9.

troubleshooting 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING REMOTE CONDENSING UNIT 10. . . . . . . . . . . . . . .

COMPRESSOR DOES NOT OPERATE. 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSOR OPERATES CONTINUOUSLY BUT DOES NOT COOL SUFFICIENTĆ

LY 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONDENSER FAN MOTOR NOT OPERATING. 11. . . . . . . . . . . . . . . . . . . . . .

WARRANTY 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 3

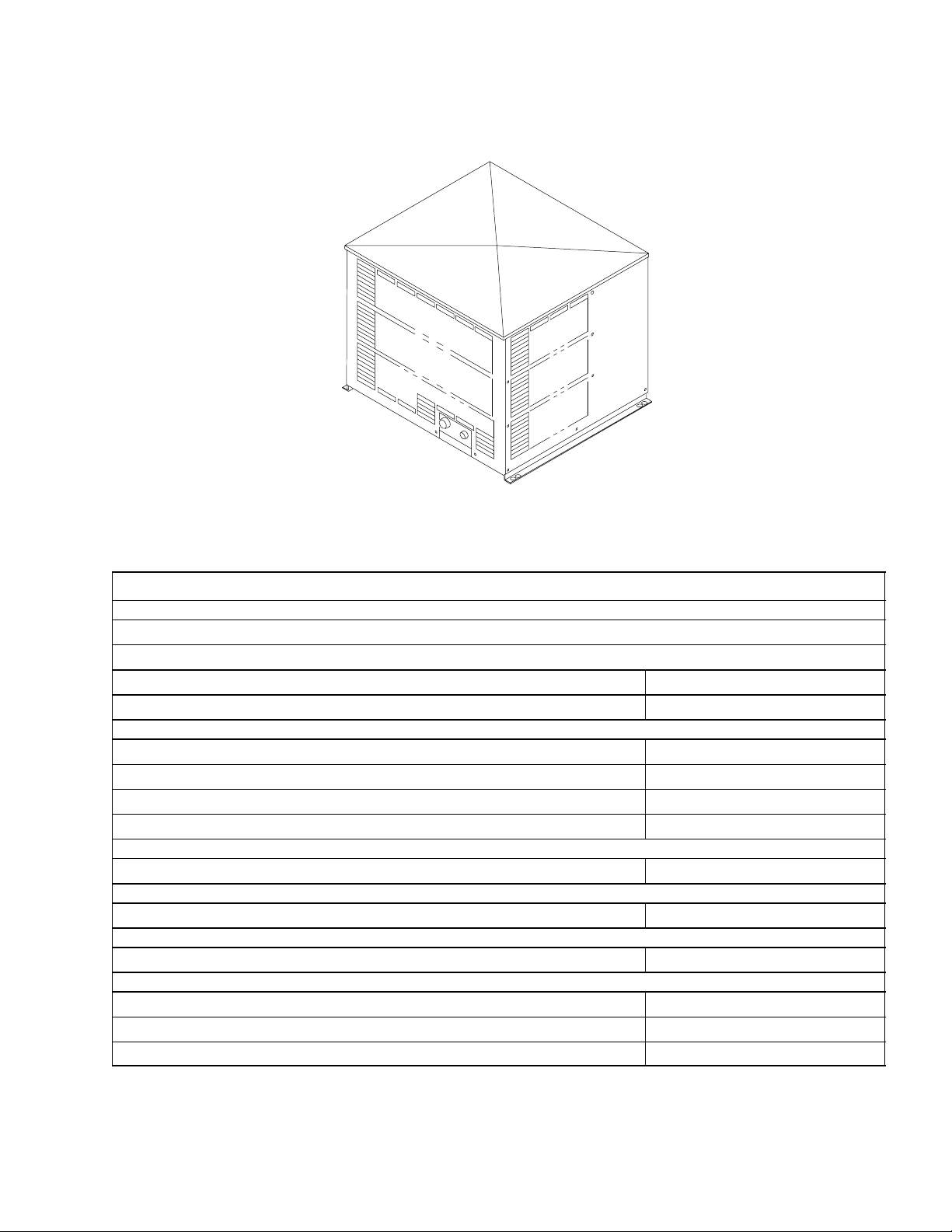

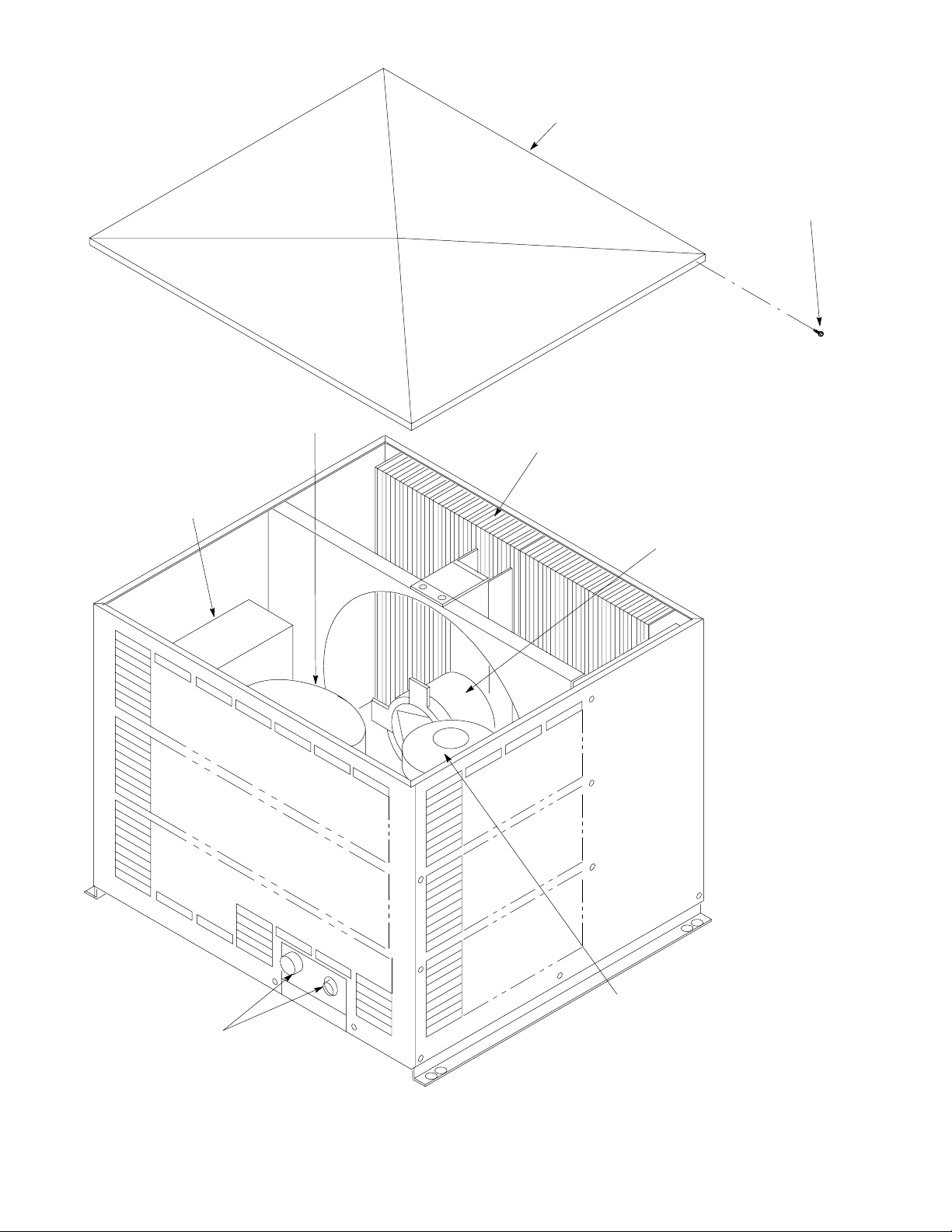

The Remote Condensing Unit P/N 416117 (230V, 60HZ) and P/N 496117 (230V, 50 HZ) consists basically of a

refrigeration compressor, a receiver tank, a fan cooled condenser coil, a head pressure control, and a

strainer/dryer mounted on an enclosed platform. The Remote Condensing Coil Unit (see FIGURE 1) is designed

to be used with any Evaporator Assembly with a rated temperature range of -10F to -32F. The Evaporator

Assembly is connected by refrigeration lines to and is refrigerated by the Remote Condensing Unit.

FIGURE 1. REMOTE CONDENSING UNIT

Table 1. Design Data

REMOTE CONDENSING UNIT

Part No.

230V, 60 HZ Unit 416117

230V, 50 HZ Unit 496117

Overall Dimensions:

Height 22-1/4 inches

Width 28-1/2 inches

Depth 25-3/4 inches

Shipping Weight (approx) 240 Pounds

Compressor Horsepower 2 H.P.

Ambient Operating Temperature –20 F to 120 F

Electrical Requirements:

Operating Voltage See Unit Nameplate

Current Draw See Unit Nameplate

1

1128

Page 4

UNPACKING AND INSPECTION

NOTE: The Remote Condensing Unit was thoroughly inspected before leaving the factory and the carrier has accepted and signed for it. Any damage or irregularities should be noted at time of delivery (or

not later than 15 days from date of delivery) and immediately reported to the delivering carrier. Request

a written inspection report from Claims Inspector to substantiate any necessary claim. File claim with

the delivering carrier, not with IMI Cornelius Inc.

1. Unpack Remote Condensing Unit. Remove all shipping tape and packing materials.

2. Inspect and make sure Remote Condensing Unit is in good condition as instructed in preceding NOTE.

SELECTING LOCATION

Locate the Remote Condensing Unit so the following requirements are satisfied:

1. The Remote Condensing Unit must be installed in a location which will allow shortest possible refrigeration

lines route from Condensing Unit to the Evaporator Assembly.

2. Close to a properly grounded 208/230 VAC 60HZ or 220/240 VAC 50HZ single-phase electrical circuit with

a 30-amp minimum-rated disconnect switch (not provided) fused at 25-amps (‘‘slow-blow’’) or power circuit

connected through an equivalent HACR circuit breaker must be available to the Unit. Use No. 8 AWG copper wire, or larger, depending upon line length, in suitable conduit or BX sheath. POWER CIRCUIT MUST

BE MADE UP OF COPPER CONDUCTORS AND ALL WIRING MUST CONFORM TO NATIONAL AND

LOCAL CODES. MAKE SURE UNIT IS PROPERLY GROUNDED.

3. An extreme warm climate installation may require extra caution in Remote Condensing Unit location. Avoid

hot sunny locations and seek shaded area if possible. If Remote Condensing Unit is to be installed on the

rooftop, the use of a structure to shade the Unit from direct sun exposure and/or a platform extending Unit

an additional 18–inches above the is highly recommended and will improve performance. Ample space

(24 inches on all sides and 48 inches above Unit) must be provided for proper air circulation through the

Unit and also access for service and maintenance. DO NOT BLOCK AIR CIRCULATION THROUGH THE

UNIT.

4. If the Remote Condensing Unit is installed on the rooftop, the Unit must be installed in a level position and

must be anchored with adequate fastening devices.

INSTALLING REMOTE CONDENSING UNIT

(see Figures 2, 3, and 4)

1. Install Remote Condensing Unit meeting requirements of SELECTING LOCATION. The Unit must be

installed in a level position and must be anchored with adequate fastening devices.

NOTE: The following Refrigeration Lines Kits are recommended to connect the Remote Condensing

Unit to the Evaporator Assembly.

Part No. Description

300598025 Refrigeration Lines Kit, 25-ft. long 90

300598050 Refrigeration Lines Kit, 50-ft. long 90

2. Route refrigeration lines from Remote Condensing Unit to the Evaporator Assembly.

3. Connect ends of refrigeration lines to Remote Condensing Unit refrigeration connectors.

4. Remove four screws securing Remote Condensing Unit top cover, then remove cover for access to electrical control box.

5. Remove one screw securing electrical control box cover, then remove cover.

1128

2

Page 5

WARNING: The Remote Condensing Unit must be electrically grounded to avoided

possible fatal electrical shock or serious injury to the operator. A green ground wire is

provided inside electrical control box to connect power circuit ground wire which

electrically grounds the Unit.

6. Connect 208/230 VAC 60HZ or 220/240 VAC 50 H

ments of SELECTING LOCATION) to L1 and L2 terminals on contactor inside the Unit electrical control box

as shown in FIGURE 4. MAKE SURE POWER CIRCUIT GREEN GROUND WIRE IS INSTALLED UNDER

GREEN GROUND SCREW INSIDE ELECTRICAL CONTROL BOX TO PROPERLY GROUND THE UNIT.

POWER CIRCUIT MUST BE MADE UP OF COPPER CONDUCTORS AND ALL WIRING MUST CONFORM TO NATIONAL AND LOCAL ELECTRICAL CODES.

7. A 24 VAC power circuit, which must conform to national and local electrical codes, must be routed and

connected between the Evaporator Assembly Temperature Control and the Remote Condensing Unit. Purpose of the 24VAC power control circuit is to allow the Evaporator Assembly Temperature Control to control ‘‘ON’’ and ‘‘OFF’’ operation of the Remote Condensing Unit. Route and connect 24VAC power control

circuit between the Evaporator Assembly and the Remote Condensing Unit as follows:

A. Route 24 VAC power control circuit electrical wires through hole in end panel to inside of the Remote

Condensing Unit.

B. Connect 24 VAC power control circuit electrical wires to labeled 24 V grey and red wires hanging out

of the electrical control box.

C. Install electrical control box cover and secure with screw.

D. Route 24VAC power control circuit from Remote Condensing Unit to the Evaporator Assembly loca-

tion.

E. Refer to manual provided with the Evaporator Assembly for instructions to connect 24VAC power cir-

cuit to Evaporator Assembly Temperature Control.

Single-Phase electrical power circuit (meeting require-

Z

SERVICE AND MAINTENANCE

WARNING: Disconnect electrical power to Remote Condensing Unit to prevent personal

injury before attempting any internal maintenance. Only qualified personnel should service

internal components or electrical wiring.

PERIODIC INSPECTION

Make sure Remote Condensing Unit Condenser Coil is free from debris. Restricting air through the condenser

coil will decrease the refrigeration systems cooling efficiency.

LUBRICATION

The Remote Condensing Unit condenser fan motor must be lubricated once every six months with S.A.E. 20W

oil. DO NOT OVER OIL.

3

1128

Page 6

ELECTRICAL

CONTROL BOX

TOP COVER

TOP COVER

RETAINING SCREW(4)

COMPRESSOR

CONDENSER

COIL

CONDENSER

FAN MOTOR

REFRIGERATION

LINES CONNECTORS

1128

RECEIVER

TANK

FIGURE 2. PARTS IDENTIFICATION

4

Page 7

CLEANING CONDENSER COIL

CAUTION: Remote Condensing Unit is equipped with a condenser coil that must be

cleaned every 30 days. Allowing condenser coil to become clogged will cause refrigeration

system to overheat which will automatically shut refrigeration system down. After

condenser coil has been cleaned, high–pressure cutout sensing switch (located inside the Remote

Condensing Unit electrical control box) will automatically reset to restart the refrigeration system.

OPERATING IN THIS MANNER FOR PROLONGED PERIODS OF TIME COULD RESULT IN

COMPRESSOR FAILURE.

The Remote Condensing Unit condenser coil must be cleaned every 30 days. Circulating air, required to cool

the coil, is drawn in through the coil and is exhausted out through grilles on end and back of the Unit. Clean

condenser coil as follows:

1. Disconnect electrical power from Evaporator Assembly 24VAC Temperature Control.

2. Disconnect electrical power to Remote Condensing Unit at disconnect switch.

3. Remove four screws securing top cover on Remote Condensing Unit, then remove cover.

4. Clean condenser coil using vacuum cleaner, whisk broom, or a soft–bristle brush to remove any debris

from coil.

5. Make sure fan blade is not out of balance, is not bent, and is not striking any surface during rotation.

6. If the Remote Condensing Unit has been installed on the rooftop check and make sure roof area

immediately surrounding the Remote Condensing Unit is free and clear of any debris that may have

collected such as leaves, paper, trash, etc.

7. Install top cover on Remote Condensing Unit and secure with four screws.

8. Restore electrical power to Remote Condensing Unit at disconnect switch.

9. Restore electrical power to Evaporator Assembly 24VAC Temperature Control.

5

1128

Page 8

THIS PAGE LEFT BLANK INTENTIONALLY

1128

6

Page 9

TROUBLESHOOTING

IMPORTANT: Only qualified personnel should service internal components or electrical wiring.

WARNING: If repairs will be made to Remote Condensing Unit, turn off electrical power to

Evaporator Assembly, then disconnect power to Remote Condensing Unit at disconnect

switch before proceeding.

Trouble Probable Cause Remedy

TROUBLESHOOTING REFRIGERATION COMPRESSOR

COMPRESSOR COOLS BUT

IS VERY NOISY ESPECIALLY

WHEN STOPPING AND

STARTING

COMPRESSOR COOLS, BUT

IS MODERATELY NOISY;

LOUD ENOUGH TO BE

NOTICED, BUT NO SHARP

BANGS OR CLATTERING

COMPRESSOR OPERATES

BUT REFRIGERATION

SYSTEM DOES NOT COOL

A. Compressor cools, but is very

noisy, especially when

stopping and starting. This is

either a broken suspension

spring or loose crank shaft

extension.

A. Compressor cools but is

moderately noisy, loud enough

to be somewhat annoying, but

no sharp bangs or clattering.

A. Look for a refrigerant leak or

oil at tubing joints. If

compressor is moderately

noisy and no leaks are

evident, it is probably a broken

valve inside compressor

A. Compressor must be changed.

A. This is probably a discharge or

suction tube rattling inside the

compressor. If noise level can be

tolerated, compressor need not

be changed. The noise will not

affect the performance or shorten

compressor life.

A. Compressor must be changed.

COMPRESSOR STARTS AND

OPERATES FOR A FEW

SECONDS, THEN STOPS

COMPRESSOR WILL NOT

START

Note: If all above checks have been made and compressor will not start, increase start capacitor value

by about 15% and try to start. This can be done two ways: (The substitute capacitor must have voltage

rating equal to or greater than the existing start capacitor) a. Remove existing capacitor and replace with

one having a 15% greater MFD rating or (step b). b. Wire capacitor that has 15% of the MFD rating in paral-

lel with the existing capacitor. c. Try to start compressor. If all the previous (steps a and b) will not

make compressor operate, label compressor ‘‘stuck’’ and replace.

A. Compressor running too hot

due to condenser coils

plugged with dust, lint, and

grease restricting cooling air

flow through the condenser

coil.

A. Check line voltage across ‘‘T‘’

terminals on contactor.

B. loose or disconnected wires. B. Correct the loose or

C. Check control circuit; C. Contactor must pull in.

D. Examine start capacitor for

signs of excessive heat (blown

up). Check for open by

connecting test cord and

checking amp draw.

A. Clean condenser coil with vacuum

cleaner, low-pressure

compressed air, or soft brush,

then allow compressor to cool and

restart.

A. Voltage cannot be less than 208 V

(60 HZ Unit) or 220 V (50 HZ Unit)

nominal to start compressor.

disconnected wires.

D. If no current is drawn (or very

little), capacitor is open and must

be replaced.

If capacitor is blown, look for

inoperable start relay or low

voltage..

7

1128

Page 10

Trouble Probable Cause Remedy

COMPRESSOR STARTS BUT

WILL NOT OPERATE FOR

MORE THAN A FEW

SECONDS

WARNING: To avoid electrical shock even after electrical power has been disconnected

from Unit, run capacitor must be discharged by momentarily touching both capacitor

terminals at the same time using an insulated handled screwdriver.

A. Inoperable Start Relay.

Note: To check relay, remove

wire from No. 1 terminal on start

relay and touch to No. 2 terminal. Start compressor and immediately remove wire from No.

2 terminal. If compressor starts

and operates, problem is in the

start relay.

B. Low Voltage.

Note: Remove compressor terminals cover and connect voltmeter test leads between ‘‘C’’ (top

terminal) and ‘‘R’’ (lower right

terminal). Start compressor. A

minimum of 208 VAC (nominal)

must be present to operate compressor

A. Replace start relay.

B. If less than 208 V (60 HZ Unit) or

220 V (50 HZ Unit) is present,

upgrade Unit power source.

C. Inoperative Run Capacitor. C. Inspect capacitor for bulges,

cracks, or any external

deformation. If found, assume

capacitor is inoperable and

replace. If none of the above

conditions are evident, disconnect

wires from capacitor. Connect test

cord to capacitor terminals.

Connect ammeter to one wire of

test cord, Plug test cord into

electrical outlet and record amp

reading. *See formula on next

page at end of this trouble topic.

1128

8

Page 11

Trouble Probable Cause Remedy

COMPRESSOR STARTS BUT

WILL NOT OPERATE FOR

MORE THAN A FEW

SECONDS (CONT’D)

D. Grounded or Shorted Motor

Windings.

D. Disconnect all electrical wires

from compressor terminals. Set

ohmmeter on 100,000 ohm scale.

touch one lead to copper line or

bare metal of compressor. Touch

other lead to each of the

compressor terminals in

succession. Continuity must not

be indicated. If an ohmmeter

reading is obtained, then

compressor is grounded and must

be replaced. To check for shorted

windings, set ohmmeter on 10

ohm scale. Attach one lead to ‘‘C’’

(top terminal). The reading should

be approximately 1 to 1-1/2 ohms.

Leave one lead on ‘‘C‘’ terminal

and touch other lead to ‘‘S‘’ (lower

left terminal).The reading should

be 3-1/2 to 5 Ohms. Leave one

lead on ‘‘S’’ terminal and touch

other lead to ‘‘R’’ terminal. This

reading should be exactly the sum

of the first two readings obtained.

If the resistance readings do not

fall within these limits, the

compressor is ‘‘shorted’’ or has an

‘‘open’’ winding and must be

replaced. Replace compressor.

2650xAmp

*Use amps reading in formula

voltsń60HZ

= M.F.D. to determine actual value of capacitor. If calculated actual val-

ue is 10% more or less than rated value, replace capacitor.

9

1128

Page 12

TROUBLESHOOTING

IMPORTANT: Only qualified personnel should service internal components or electrical wiring.

WARNING: If repairs are to be made to a product system, remove quick disconnects from

the applicable product tank, then relieve the system pressure before proceeding. If repairs

are to be made to the CO

system, stop dispensing, shut off the CO

2

system pressure before proceeding. If repairs are to be made to the refrigeration system, make sure

electrical power is disconnected from the unit.

Trouble Probable Cause Remedy

TROUBLESHOOTING REMOTE CONDENSING UNIT

supply, then relieve the

2

COMPRESSOR DOES NOT

OPERATE.

A. Evaporator Assembly not

A. Refrigeration not called for.

calling for refrigeration.

B. Electrical power to Remote

Condensing Unit turned off.

C. Electrical power to Evaporator

Assembly turned off.

D. No Remote Condensing Unit

power source. Blown fuse or

B. Turn on electrical power to

Remote Condensing Unit.

C. Turn on electrical power to

Evaporator Assembly.

D. Replace fuse or reset circuit

breaker.

tripped circuit breaker.

E. Loose, disconnected, or

broken wiring.

F. High–pressure cutout switch

tripped.

E. Tighten connections or replace

broken wiring

F. High-pressure cutout switch will

automatically reset after

refrigeration system pressure has

lowered (see CAUTION note

under CLEANING CONDENSER

COIL).

G. Low voltage. G. Voltage must be at least 208 V

(60 HZ Unit) or 220 V (50 HZ Unit)

nominal at compressor terminals

when compressor is trying to

start.

COMPRESSOR OPERATES

CONTINUOUSLY BUT DOES

NOT COOL SUFFICIENTLY

1128

H. Inoperable run capacitor, or

H. Replace inoperable part.

start relay.

I. Inoperable compressor. I. Replace compressor.

A. Refrigeration capacity is

exceeded by product

A. Reduce amount of product drawn

per given time.

overdrawing.

B. Air circulation through Remote

Condensing Unit condenser

B. Check and if necessary, clean

condenser coil as instructed.

coil is restricted.

C. Insufficient refrigerant charge. C. Check Remote Condensing Unit

sight glass for bubbles or liquid

break. Find and repair

refrigeration leak, then replenish

refrigerant charge.

10

Page 13

Trouble RemedyProbable Cause

CONDENSER FAN MOTOR

NOT OPERATING.

A. Fan blade obstructed A. Remove obstruction.

B. Inoperative condenser fan

B. Replace condenser fan motor.

motor.

C. Compressor contactor

C. Replace compressor contactor.

inoperable.

D. Disconnected or broken

electrical wire.

D. Connect or repair broken

electrical wire.

11

1128

Page 14

STRAINER/DRYER HIGH-PRESSURE

PROCESS

LINE

CUTOUT SWITCH

SIGHT GLASS

COMPRESSOR

CONDENSER

FAN/HEATER

REFRIGERATION

LINES

SWITCH

RECEIVER

TANK

HEAD PRESSURE

CONTROL

SERVICE V ALVE (2)

CONDENSER

MOTOR/FAN

EVAPORATOR

ASSEMBLY

REMOTE ROOFTOP

CONDENSING UNIT

CONDENSER COIL

1128

FIGURE 3. REFRIGERATION FLOW DIAGRAM

12

Page 15

4

FIGURE 4. WIRING DIAGRAM

(REMOTE CONDENSING UNIT)

13

1128

Page 16

41.

25.

34.

1.

37.

36.

35.

32.

33.

43.

26.

2.

1.

6.

9.

1.

28.

42.

30.

29.

31.

1.

27.

21.

1.

1.

22.

24.

46.

44.

1.

5.

1.

42.

17.

12.

13.

14.

15.

16.

19.

20.

1.

1.

7.

18.

8.

1.

11.

10.

45.

1128

10.

38.

23.

4.

1.

3.

FIGURE 5. REMOTE CONDENSER ASS’Y

14

1.

Page 17

REMOTE CONDENSER ASS’Y (CON’T)

Item Part No. Description

416117 Remote Condenser Ass’y, 230V 60HZ

496117 Remote Condenser Ass’y, 230V 50HZ

1. *319941 Thread Rolling Screw , SL Hex Washer HD. No. 8-32 By 3/8 in. Long

2. 324153-068 Cover, Remote Condenser

3. 324151-068 Panel, Right-Side

4. 324152-068 Panel, Back

5. 324150-068 Panel, Left-Side

6. 324148 Condenser Coil

7. 309215 Pressure Control

8. 319871 Dryer

9. 319882 Sight-Glass

10. *189429 Hex Nut, 1/4-20

11. 324198 Receiver

12. *186146 Hex Nut, 5/16-18

13. *186148 Washer, Lock, .319 I.D.

14. 320737 Washer .343 I.D.

15. 325530 Spacer

16. 325529 Grommet

17. 324147 Compressor, 230V 60HZ

2240 Compressor, 230V 50HZ

18. 309919 Flange, 3/8

19. 309920 Flange, 1/2

20. 309895-011 Bracket, Coupler

21. 324155 Bracket, Motor

22. 324144 Motor, 1/6 H.P., 230V. 60HZ

2115 Motor, 1/6 H.P., 230V. 50HZ

23. 324145 Blade, Fan

24. 324154 Shroud

25. 324146 Control Box

26. 324156 Cover, Control Box

27. 324172 Strap, Capacitor Fan

28. 324143 Capacitor, Start, Fan

29. 325956 Strap, Capacitor

30. 325939 Capacitor, Run, 230V 60HZ

2162 Capacitor, Run, 230V 50HZ

31. 325938 Capacitor, Start

32. 325940 Relay, Start, 230V 60HZ

197466 Relay, Start, 230V 50HZ

33. 324209 Pressure Switch, HI, 200 PSI

34. 329473 Contactor, 2 4 V.

35. *325069 Machine Screw, S: Hex HD, No. 10-24 by 1/2-in. Long

36. 325145 Washer, # 1 0

37. 325644 Lug

38. 324149-068 Base

39. *187552 Machine Screw, Phil RD HD, No. 8-32 by 1/4-in. Long (Not Shown)

40. 309524-011 Cord (Not Shown)

41. 320734 Self-Threaded Screw, Phil Pan HD. No. 6-32 by 3/8-in. Long

42. 313802 Snap Bushing

43. 324208 Pressure Switch, HI, 475 PSI

44. 319960-005 Edging, Grommet

45. 324215 Heater, 138 Watt, 220V. 60Hz

46. 321818 Button Plug

15

1128

Page 18

WARRANTY

IMI Cornelius Inc. warrants that all equipment and parts are free from defects in material and workmanship under normal use and service. For a copy of the warranty applicable to your Cornelius, Remcor or Wilshire product, in your country, please write, fax or telephone the IMI Cornelius office nearest you. Please provide the

equipment model number, serial number and the date of purchase.

IMI Cornelius Offices

AUSTRALIA P.O. 210, RIVERWOOD, NSW 2210, AUSTRALIA (61) 2 533 3122 FAX (61) 2 534 2166

AM LANGEN FELDE 32 A-1222 VIENNA, AUSTRIA (43) 1 233 520 FAX (43) 1-2335-2930

AUSTRIA

BOSKAPELLEI 122 B-2930 BRAASCHAAT, BELGIUM (32) 3 664 0552 FAX (32) 3 665 2307

BELGIUM

RUA ITAOCARA 97 TOMAS COELHO RIO DE JANEIRO, BRAZIL (55) 21 591 7150 FAX (55) 21 593 1829

BRAZIL

ENGLAND

TYTHING ROAD ALCESTER WARWICKSHIRE, B49 6 EU, ENGLAND (44) 789 763 101 FAX (44) 789 763 644

71 ROUTE DE ST. DENIS F-95170 DEUIL LA BARRE PAR IS, FRANCE (33) 1 34 28 6200 FAX (33) 1 34 28 6201

FRANCE

CARL LEVERKUS STRASSE 15 D-4018 LANGENFELD, GERMANY (49) 2173 7930 FAX (49) 2173 77 438

GERMANY

488 MESSOGION AVENUE AGIA PARASKEVI 153 42 ATHENS, GREECE (30) 1 600 1073 FAX (30) 1 601 2491

GREECE

KONG 1104 TAIKOTSUI CENTRE 11-15 KOK CHEUNG ST TAIKOKT SUE, HONG KONG (852) 789 9882 FAX (852) 391 6222

HONG

VIA PELLIZZARI 11 1-20059 VIMARCATE, ITALY (39) 39 608 0817 FAX (39) 39 608 0814

ITALY

ZEALAND 20 LANSFORD CRES. P.O. BOX 19-044 AVONDALE AUCKLAND 7, NEW ZEALAND (64) 9 8200 357 FAX (64) 9 8200 361

NEW

SINGAPORE

SPAIN

USA

16 TUAS STREET SINGAPORE 2263 (65) 862 5542 FAX (65) 862 5604

POLIGONO INDUSTRAIL RIERA DEL FONOLLAR E-08830 SANT BOI DE LLOBREGAT BARCELONA, SPAIN (34) 3 640 2839 FAX (34) 3 654 3379

ONE CORNELIUS PLACE ANOKA, MINNESOTA (612) 421-6120 FAX (612) 422-3255

LD004

4/21/98

1128 16

Page 19

IMI CORNELIUS INC.

CORPORATE HEADQUARTERS:

One Cornelius Place

Anoka, Minnesota 55303-6234

(612) 421-6120

(800) 238-3600

Loading...

Loading...