Page 1

Models

2230 C4-100

2230 C6-100

2230 C4

2230 C6

ICE/SOFT DRINK

PRE-MIX DISPENSER

Part No. 91748

May , 1997

Revision C

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

IMI CORNELIUS INC; 1989-97Ó

PRINTED IN U.S.A

Page 2

TABLE OF CONTENTS

SAFETY PRECAUTIONS 1. . . ............ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DESCRIPTION 1. . . . . . .. .. . . . . . .. .. .. .. .. . . . . . .. .. .. .. . . . . . .. .. .. .. .. . . .

SPECIFICATIONS 1. . . . . . .. .. . . . . . .. .. .. .. .. . . . . . .. .. .. .. . . . . . .. .. .. .. ..

INSTALLATION INSTRUCTIONS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

KIT 27065 3. . . . . . .. .. . . . . . .. .. .. .. .. . . . . . .. .. .. .. . . . . . .. .. .. .. .. . . . . . .

GATE RESTRICTOR PLATE 4. . .. .. .. .. .. .. .. .. .. .. . . . . . .. .. .. .. .. . . . . . ..

ADJUSTMENT 4. . . . . . .. .. . . . . . .. .. .. .. .. . . . . . .. .. .. .. . . . . . .. .. .. .. .. . . .

MAINTENANCE 8.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAILY (OR AS REQUIRED) 8. . . . . . .. .. . . . . . .. .. .. .. .. . . . . . .. .. .. .. . . . . . ..

WEEKLY (OR AS REQUIRED) 8. . . . . . .. .. . . . . . .. .. .. .. .. . . . . . .. .. .. .. . . . .

MONTHLY 8. . . . . . .. .. . . . . . .. .. .. .. .. . . . . . .. .. .. .. . . . . . .. .. .. .. .. . . . . . ..

START-UP & OPERATING INSTRUCTIONS 8. . . . . . .. .. . . . . . .. .. .. .. .. . . . . .

CLEANING INSTRUCTIONS 8. . . . . .. .. .. .. .. .. .. .. .. . . . . . .. .. .. .. .. . . . . . .

DISPENSER 9. . . . . . .. .. . . . . . .. .. .. .. .. . . . . . .. .. .. .. . . . . . .. .. .. .. .. . . . . .

COLD PLATE 9. . . . . . .. .. . . . . . .. .. .. .. .. . . . . . .. .. .. .. . . . . . .. .. .. .. .. . . . .

BEVERAGE SYSTEMS 10. . . . . . .. .. . . . . . .. .. .. .. .. . . . . . .. .. .. .. . . . . . .. .. ..

SANITIZE SYRUP SYSTEMS 10. . . . . . .. .. . . . . . .. .. .. .. .. . . . . . .. .. .. .. .

TROUBLESHOOTING 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

BLOWN FUSE OR CIRCUIT BREAKER. 12. . . . . . .. .. . . . . . .. .. .. .. .. . . . . . .. ..

GATE DOES NOT OPEN. 12. . . . . . .. .. . . . . . .. .. .. .. .. . . . . . .. .. .. .. . . . . . .. ..

GATE DOES NOT OPEN OR IS SLUGGISH. AGITATORTURNS. 12. . . . . . .. ..

GATE OPENS. AGITATOR DOES NOT TURN 12.. .. .. .. . . . . . .. .. .. .. .. . . . . . .

ICE DISPENSES CONTINUOUSLY. 12. . . . . . .. .. . . . . . .. .. .. .. .. . . . . . .. .. .. ..

SLUSHY ICE. WATER IN HOPPER. 12. . . . . . .. .. . . . . . .. .. .. .. .. . . . . . .. .. .. .

NO PRODUCT DISPENSED 13. . . . . .. .. . . . . . .. .. .. .. .. . . . . . .. .. .. .. . . . . . ..

DISPENSED PRODUCT COMES OUT OF DISPENSING VALVE

CLEAR BUT FOAMS IN CUP OR GLASS. 13. . . . . . .. .. . . . . . .. .. .. .. .. . . . . . ..

DISPENSING PRODUCT FOAMS AS IT LEAVES DISPENSING VALVE. 13. . . . .

P ARTS LIST 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

91748

Page 3

TABLE OF CONTENTS (cont’d)

LIST OF FIGURES

FIGURE 1. ICE DIVERTER 3.. . . .. .. .. .. . . . . . .. .. .. .. .. . . . . . .. .. .. .. .. . . .

FIGURE 2. GATE RESTRICTOR 4. . . . . . .. .. . . . . . .. .. .. .. .. . . . . . .. .. .. .. . .

FIGURE 3. MOUNTING TEMPLATE 5. . . . . . .. .. .. . . . . . .. .. .. .. .. . . . . . .. .. .

FIGURE 4. BEVERAGE SYSTEM PLUMBING DIAGRAM 6 VALVES 6. . . . . . .. .

FIGURE 5. BEVERAGE SYSTEM PLUMBING DIAGRAM 4 VALVES 7. . . . . . .. .

FIGURE 6. WIRING DIAGRAM BEV/CP DISPENSER 14. . . . . . .. .. . . . . . .. .. .. .

FIGURE 7. DISPENSER SECTION EXPLODED VIEW 15. . . . . . .. .. . . . . . .. .. ..

FIGURE 8. CABINET SECTION EXPLODED VIEW & PARTS LIST 17. . . . . . .. ..

FIGURE 9. SOLENOID ASSEMBLY AND PARTS LIST 18.. . . .. .. .. .. .. .. .. .. .

LIST OF TABLES

TABLE 1 SPECIFICATIONS 1. . . . . . .. .. . . . . . .. .. .. .. .. . . . . . .. .. .. .. . . . . . ..

Page

Manufactured Under One or More of the Following Patent Numbers:

3,211,336, 3,274,792, 3,393,839 , 3,517,860, 3,739,842, 4,2 15,803, 4,227,377, 4,300,359

4,346,824

Canadian Patent Numbers

912,514 (10/72), 936,855 (11,73), 4,429,543, 4,921,149

Other Patents Pending

91748

ii

Page 4

SAFETY PRECAUTIONS

Always: disconnect power to the dispenser before servicing or cleaning.

Never: place hands inside of hopper or gat e area without disconnecting power to the dispenser. Agitator rota-

tion occurs automatically when dispenser is en ergized!

This ice di spenser has been specifically designed to provide protection against personal injury and elimina tes

contamination of ice. To insure continued protection and sanitation, observe the following:

ALWAYS: be sure the removable lid is properly installed to prevent unauthorized access to the

hopper interior and po ssible contamination of the i ce.

ALWAYS: be sure the upper and lower front panels are securely fastened.

ALWAYS: keep area around the dispenser clean of ice cubes.

CAUTION: Dispenser cannot be used with crushed or flaked ice.

Use of bagged ice which has frozen into large chunks can void warranty. The

dispenser agitator is not designed to be an ice crusher. Use of large chunks of

ice which ”jam up” inside the hopper will cause failure of the agitator motor and

damage to the hopper. If bagged ice is used, it must be carefully and completely

broken into small, cube--sized pieces before filling into the dispenser hopper.

DESCRIPTION

The 2230 series of ice dispensers solves your ice and beverage service needs in the sanitary, space saving,

economical way. Designed to be manually filled with ice from any remote ice making sou rce, or top mount ice

maker, these dispensers will dispense cubes (up to 1--1/4” in size), cubelets and hard--chipped or cracked ice;

and, in addition, several flavors of pre--mix beverages.

The sink can be easily and quickly removed. The unit must never be lifted or moved b y the sink.

Dispensers include faucets and cold plates and are designed to be supplied direct from syrup tanks, with no

additional cooling required.

IMPORTANT: For dispensing nugget ice (Model MH750/NM650 Ice Makers), part number 27065 Ice

Diverter must be installed on the dispenser. (See INSTALLATION INSTRUCTIONS).

Table 1. Specifications

Model: 2230 C4-100 2230 C6-100 2230 C4 2230 C6

Ice Storag e: 100 lbs 100 lbs 150 lbs 150 lbs

Maximum Number of Faucets Available: 4 6 4 6

Built--in Cold Plate : Yes Yes Yes Yes

Electrical: 120/1/60 120/1/60 120/1/60 120/1/60

Dimensions: 22I Wide

29-3/4I Deep

30--1/2I High

Dispensing System Rated 125 psi max 125 psi max 125 psi max 125 psi max

1 91748

22I Wide

29-3/4I Deep

30--1/2I High

22I Wide

29-3/4I Deep

36--3/16I High

22I Wide

29-3/4I Deep

36--3/16I High

Page 5

INSTALLA TION INSTRUCTIONS

1. Locate the dispenser indoors on a level counter top.

A. LEG OPTION

Unpack the four (4) legs and install them into the thre aded holes provided in the bottom of the unit.

The installer must provide flexibility in the pro d uct and utility supply to permit shifting the position of the

dispenser sufficiently to clean the area beneath it.

Note: Before installing legs, remove the four (4) plastic thread plugs; push center in and remove the

plugs.

2. Utilities routing may be made through the rear of the cabinet by removing the plastic rear panel by the inle t

of the cold plat e and removing the knock-out for the d rai n hose.

Optional routing through the bottom of the cabinet:

A. Tip u nit to the side to access the drain block, located behind the drip tray.

B. Replace t he straight fitting with 9 0° fitting that is in the drain kit supplied with the unit.

3. Beverage System: Connect the beverage system product lines as indicated on page 6. This workshould be

done by a qualified service person. Note that the hoses are marked with numbers 1 through 4 or 6 ) for syrup connections.

4. Clean t h e hoppe r interior (see CL EANING INSTRUCTIONS on page 8).

5. Connect the power cord to a 120 volt, 60 cycle, 3-wire grounded receptacle. All electrical wiring mu st conform to n ational and local electrical codes.

291748

Page 6

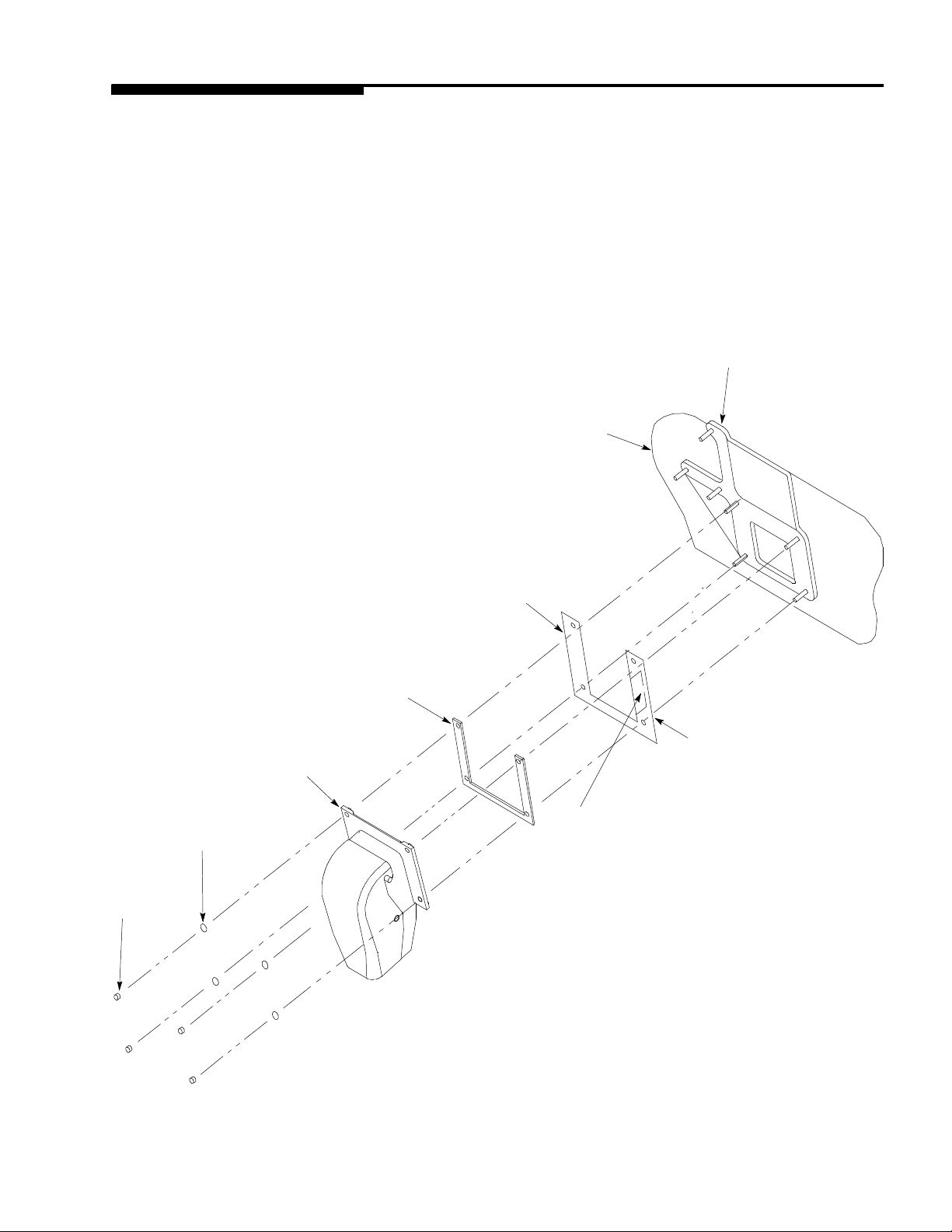

KIT 27065

NOTE: For dispensing Scotsman MH 750 ”nugget” style ice and Wilshire MCC550 and MCC700 compressed

ice cubes:

1. Disconnect power to dispenser.

2. Remove upper front panel from dispenser.

3. Remove ice chute and discard gate restrictor.

4. Install Ice Diverter as shown.

5. Reinstall front panel and energize

unit.

GATE MOUNTING PLATE

STORAGE HOPPER

10-32 WASHER

10-32 NUT

ICE CHUTE

ICE DIVERTER

GASKET

APPLY RTV TO THIS SURFACE

TO SEAL TO HOPPER GATE

MOUNTING PLATE

FLANGE EXTENDS INTO STORAGE

HOPPER THROUGH GATE OPENING

FIGURE 1. ICE DIVERTER

3 91748

Page 7

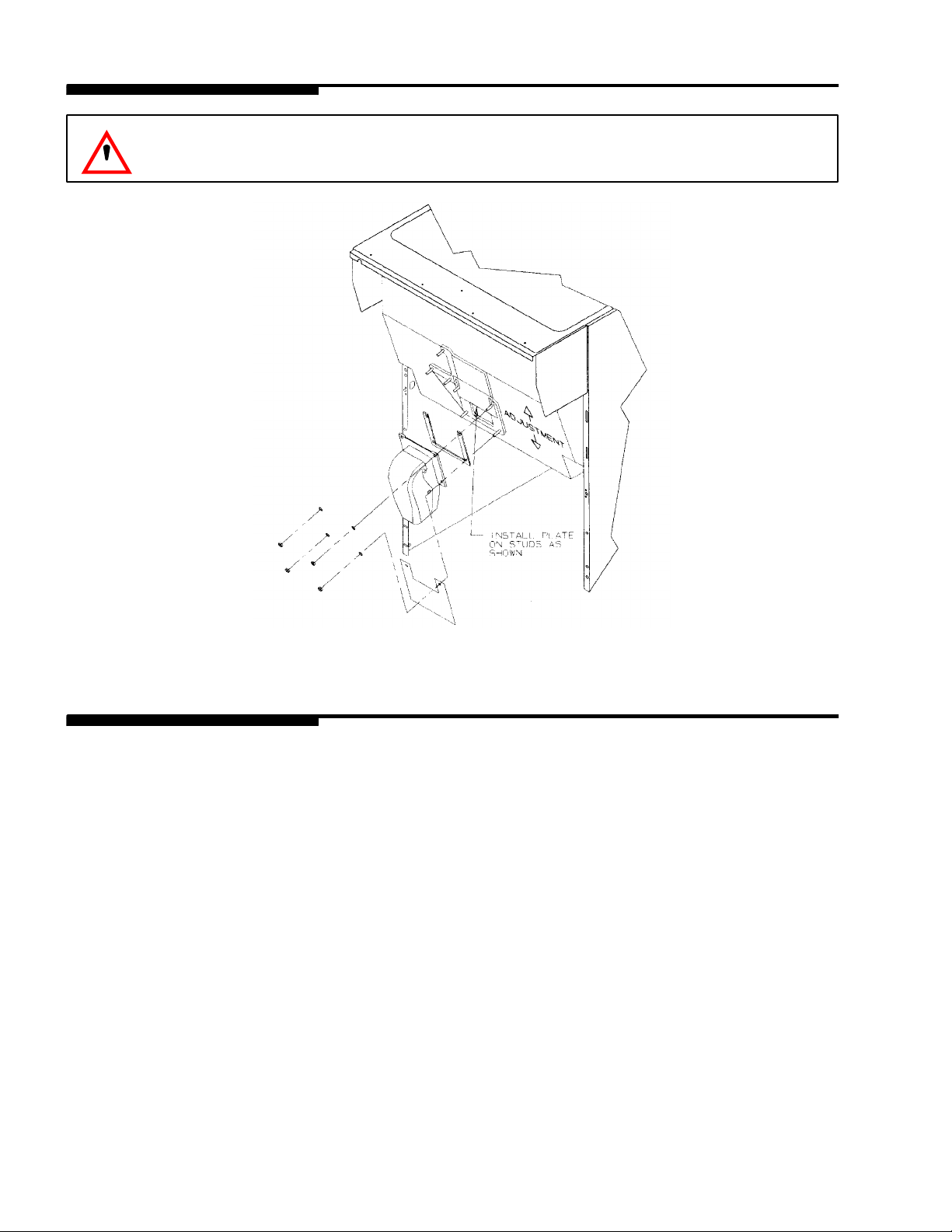

GATE RESTRICTOR PLATE

CAUTION: Disconnect power to dispenser before installing, removing or adjusting

restrictor.

FIGURE 2. GATE RESTRICTOR

ADJUSTMENT

This dispenser is provided with a gate restrictor plate, installed in its highest position. Th is plate adjusts the rate

of ice f lo w from the dispenser. In a ppl i cati on s using buckets, carafes or other large containers, th e plate may be

removed entirely for maximum ice f l ow. For glasses and cups, the plate may be adju sted downward to redu ce

the flow of ice. The best position depends on the type of ice being used and the size container and must be

found by trial and error. Adjustment is mad e by loosening the u pp er two ice chute retaining nuts, sliding the restrictor plat e to the desired po sition and re-tightenin g the nuts.

If the dispenser fails to dispense the ice whe n operate d, check that the hopper has ice in it a nd that power is

being supplied to the unit. If the problem persists, refer to the troubleshoot i n g guide (page 11).

491748

Page 8

22?

18-3/4?

1?

Opening in cabinet

4-1/2?

bottom for drain &

beverage hoses

Optional location for

counter top cut-out

14?

*1-1/8?3-15/16?

16-1/4?

*18-25/32?

29-3/4?

Front of Unit

*19-3/4?1-1/8?

NOTE: Leg mounting locations for ref (5/16--18 threads)

FIGURE 3. MOUNTING TEMPLATE

5 91748

Page 9

FIGURE 4. BEVERAGE SYSTEM PLUMBING DIAGRAM 6 VALVES

691748

Page 10

FIGURE 5. BEVERAGE SYSTEM PLUMBING DIAGRAM 4 VALVES

7 91748

Page 11

MAINTENANCE

The following dispenser maintenance should be performed at the intervals indicated:

DAILY (or as re quired)

Remove foreign material from vending area d rip tray to prevent drain blockage.

WEEKLY (or as required)

Clean vending are a. Check for proper water drainage from the vend in g area drip tray.

MONTHLY

Clean and sanitize the hopper interior (see CLEANING INSTRUCTIONS).

START--UP & OPERATING INSTRUCTIONS

Fill the hopper with ice. Dispense several large cups of ice (approxima tely 1 minute total dispensing time) t o allow

ice to f il l the cold plate. Add ice to the hop per as necessary to refill then replace t he lid. Allow 10 to 15 m in utes for

the cold plate t o cool down. Repeat this procedure whenever t he dispenser has bee n standing overnight or other

long periods without ice use. Start up the beverage system and adjust faucets to the proper brix. Contact your local syrup distributor for complet e informat i o n on the beverage system.

In normal operation, pushing the ice dispenser lever will cause ice to flow from the ice chute. Ice flow will continue

until the dispenser lever is released. Pushing the lever of any faucet will provide beverage of the appropriate flavor.

CAUTION: Use caution to avoid spilling ice when filling dispenser. Immediately clean up any

spilled ice from filling or operating the unit. To prevent contamination of ice, the lid must be

installed on the unit at all times.

CLEANING INSTRUCTIONS

WARNING: DISCONNECT POWER BEFORE CLEANING! Do not use metal scrapers, sharp

objects or abrasives on the ice storage hopper, top cover and the agitator disk, as damage

may result. Do not use solvents or other cleaning agents, as they may attack the plastic

material.

8 91748

Page 12

DISPENSER

1. Clean the ice storage hopper at least once a month

2. Remove the center screw on the agitator disk an d lift off the agitator and the agitator disk assembly. Wash

and rinse them thoroughly.

3. Washdown t h e inside of the h opp er a nd top cover with a mild detergent solution and rinse thoroughly to remove all traces of detergent.

4. Replace the agitator.

5. Sanitize the inside of the hopp e r and agitator with a solution of 1/2 ounce of household bleach in 1 gallon of

water. (200 PPM)

6. Replace the agitator disk. Sanitize as described is Step 5 . Be sure the center screw is replaced and the

screw is tight.

7. Remove Ice Chute Cover as follo ws:

A. Flex sides outward to disengage lower pins.

B. Lift Ice Chute cover to disengage upper pins.

C. Lower Ice Chu te cover down out of unit. NOTE: It may be helpful to twist cover slightly.

8. Clean the inside of the Ice Chute and Ice Chute cover with a mild detergent solution and rinse thoroughly to

remove all traces of detergent.

9. Reverse steps above to reassemble Ice Chute.

10. Sanitize as described in Step 5.

COLD PLATE

1. Remove splash panel a nd merchandiser.

2. Remove bottom two (2) screws on the ice chute and loosen the top two (2) screws. You do n ot have to remove the ice chute. (During re-assembly, make sure the ice gate restrictor is relocated to its’ correct position.

3. Remove the screws, hold the beverage faucet panel and bring forward.

4. Remove the tape holding the lower cold plate cover to the top cold plate cover.

5. Lift the lower cold plate cover up i n to t he top cover.

6. Remove any debris from the drain trough and spring. Check that the drain hole is not clogged.

7. Washdown t h e inside of the cold plate, tray and cover with a mild detergent solution and rinse. A small, long

handled brush will be found helpful in reaching the corners.

8. Slide the cover forward, t a king care that it is securely positioned on the cold plate.

9. Re-assemble.

9 91748

Page 13

BEVERAGE SYSTEMS

WARNING: If necessary to disassemble and clean dispensing valves’ syrup flow

regulators, do not intermix their pistons and cylinders as they are precision matched sets.

WARNING: To avoid possible personal injury or property damage, do not attempt to

remove syrup tank cover until CO2pressure has been released from tank.

WARNING: Ice bin contains hazardous moving parts. Ice rotator is automatically timed to

start and move a short distance to break up ice in ice bin. DO NOT remove ice bin cover

without first unplugging unit power cord from electrical outlet.

WARNING: Flush sanitizing solution from syrup systems as instructed. Residual sanitizing

solution left in system c ould create health hazard.

BEVERAGE SYSTEM CLEANING AND SANITIZING INSTRUCTIONS

1. Prepare the following cleaning, rinsing and sanit i zing solutions using a clean, empty figal (5 gallon syrup

tank) for each solution.

CLEANING TANK -- Fill with a solution of 1/2 ounce of a mild liquid detergent (for example, Ivory liquid) to 1

gallon of warm (120_F) potable water.

RINSING TANK -- Fill with warm (120 _F) potable water.

SANITIZING TANK -- Fill with a chlorine sanitizing solut io n in the strength of 1/2 ounce of household bleach

(sodium hypochlorite) to 1 gallon of cold (ambien t) pot ab le water to obtain a soluti o n strength of 200 PPM.

NOTE: Repeat the following procedure on each of the unit’s syrup product lines and beverage faucets.

2. Using a suitable pail or bucket, fill one wit h a detergent solution and a second container with a sanitizing

solution in the strengths as described in step 1.

A. Remove the syrup line qu ick disconnect fitting from the product tank and submerge in the detergent

solution. Clean wit h a nylon bristle brush (do not use a wire bru sh). Rinse with clean potable water.

B. Wearing sanitary glo ves, next submerge the quick disconnect fitting in the sanitizing container for 15

minutes. Remove and air dry.

3. Hook-up the sanitized product line fitting (step 2) to the cleaning tank. Hook-up a gas disconnect fitting to the

tank and pressurize with 60 t o 80 psig CO2. Energ ize the beverage faucet continuously for 1 m i n ute to remove all air bubbles. Continue to operate the faucet until liqui d dispensed is free of any syrup. Cycle the faucet for 15 seconds on, off and then im mediately on again. Repeat this procedure for 15 cycles. Then energize the faucet to remain flowing for 3 minutes.

4. Hook-up the rinsing tank and pressurize with 60 to 80 psig CO2. Flush the cleaning solution from the product

line by cycling the faucet as described in step 3 and energize the faucet to flow continuously for 3 minutes.

5. Hook-up the sanitizing t an k and pressurize with 60 to 80 psig CO2. Flow the san i tizing solution through the

beverage faucet by cyclin g the faucet as described in step 3. Next energize the faucet continuously to flush

at least 2 cups of the sanitizing solution through the system. Finally deenergize the faucet and allow the sanitizer to remain pressurized in the line to 20 minutes.

10 91748

Page 14

6. Wearing sanitary gloves. re move the faucet nozzle and diffuser. Repeat the cleaning and sanitizing procedures as described in step 2, then reassemble to the faucet.

7. Disconnect the sanitizing tank. Hook-up the produ ct tank to the unit and to the CO2system . Energize the faucet to flush the san i tizing solution from the syrup line and the faucet. Continue flow o n the faucet until only

syrup is dispensed.

11 91748

Page 15

TROUBLESHOOTING

IMPORTANT: Only qualified personnel should serviceinternal components of electrical wiring.

WARNING: Disconnect electrical power to unit before attempting any electrical repairs to

internal components. if repairs are to be made to CO2, syrup or plain water systems, shut off

plain water and CO2supplies then disconnect syrup tanks and bleed systems pressures

before proceeding.

Should your unit fail to operate properly, check that there is power to the unit and that the hopper contains ice. If the unit does not dispense, check the following chart under the appropriate symptoms to aid

in locating the defect.

Trouble Probable Cause

BLOWN FUSE OR CIRCUIT BREAKER. A. Short circuit in wiring.

B. Defective gate solenoid.

C. Defective agitator motor.

GATE DOES NOT OPEN. A. No power.

B. Bent d epressor plate (does not actuate switch).

C. Defective dispensing switch.

D. Blown/defective fuse or jammed gate solenoid.

GATE DOES NOT OPEN OR IS SLUGGISH.

AGITATOR TURNS.

GATE OPENS. AGIT ATOR DOES NOT TURN A. Ice solidified in hopper.

ICE DISPENSES CONTINUOUSLY. A. Stuck or bent depressor plate (does not

SLUSHY ICE. WATER IN HOPPER. A. Blocked drain.

A. Defective gate solenoid.

B. Excessive pressure against gate slide.

C. Weak gate spring .

B. Defective agitator motor.

C. Defective capacitor.

D. Defective agitation timer.

release switch).

B. Defective dispensing switch.

C. Improper switch installat io n.

B. Unit not level.

C. Poor ice quality due to water quality or

icemaker problems.

D. Improper use of fla ked ice.

1291748

Page 16

Contact your local soft drink or beverage equipment distributor for additional information and

troubleshooting of beverage system.

Trouble Probable Cause Remedy

NO PRODUCT DISPENSED A. Product ta nk quick disconnects

A. Connect q uick disconnects.

not properly connected.

B. No product supply (product

tank empty).

B. Replenish product supply as

instructed.

C. No CO2supply. C. Replenish CO2supply as

instructed.

DISPENSED PRODUCT

COMES OUT OF DISPENSING

A. Oil film or soap scum in glass

or cup.

A. Use clean cups and glasses.

VALVECL EAR BUT FOAMS IN

CUP OR GLASS.

B. Ice used for finished drink is

sub-cooled.

B. Do not use ice directly from

freezer. Allow ice to become “wet”

before using. Refer to NOTE.

NOTE: Ice also causes dispensing problem. When finished drink hits sharp edges of ice, carbonation

is released from drink.

DISPENSING PRODUCT

FOAMS AS IT LEAVES

DISPENSING VALVE.

A. Product ta nk CO2regulator

adjusted too high.

A. Adjust product tank CO2regulator

to pro per e quilibrium pressure as

instructed, then repl a ce product

supply.

B. Dispensing valvere stricted or

dirty.

B. Sanitize product system as

instructed.

C. Tube -- swivel nut

overtightened, distorting nylon

C. Replace nylon washer. Make sure

it is properly seated.

set washer inside -- resulting in

restricted product flow.

D. Oil, water or dirt in CO2supply. D. Remove contaminated CO

Clean CO2system (lines,

regulator etc.). Instal l clean CO

supply.

2.

2

13 91748

Page 17

ADJUST TO 7/8-IN. AS SHOWN

WHEN REPLACING SOLENOID,

BEFORE TIGHTENING MOUNTING SCREWS.

FIGURE 6. WIRING DIAGRAM BEV/CP DISPENSER

1491748

Page 18

34

33

15

17

5

32

31

6

30

17

1

2

12

16

11

14

13

4

10

7

8

18

19

25

3

9

29

28

20

21

22

23

FIGURE 7. DISPENSER SECTION EXPLODED VIEW

15 91748

Page 19

DISPENSER SECTION PARTS LIST

Index

No.

1 91498 Wiring Diagram

2 91546 Ice Gate Restrictor Instructions

3 70439 Leg, 4”

4 70855 Sink Grill

5 52030 Sink

6 52028 Lid

7 31163 Switch Boot Adapter

8 31007 Switch Boot

9 30895 Dispenser Switch

10 70847 Switch Spacer

11 215150 Depressor, Cup Activated

12 22644 Depressor Retainer (for 21515)

13 27126 Depressor Push Lever

14 27107 Depressor Retainer (for 27136)_

15 52026* Merchandiser Frame

16 27638 Splash Panel

17 10145 Sink Mtg. Pin

18 70545 Clamp

19 51775 Flexible Drain Fitting

20 51801 Cold Plate Drain Insulation

21 52049 Drain Insulation

22 27470 Mounting Bracket

23 52037 Plastic Drain Fitting

24 52044 O-Ring (2 required)

25 50997 Syrup. Fitting

26 51280 90° Fitting

27 50249 Armaflex, 1/2 ID x 3/8 W x 72”

28 50279 Armaflex, 1-1/8 ID x 3/8 W x 72”

29 28035 Beverage Panel 4 Valve

30 51455 Rear Cover Plate

31 27363 Lower Mounting Bracket

32 27345 Upper Mounting Bracket

33 Graphics Calls Parts Dept.

34 51996* Plexiglass Panel

Part No. Description

28996** Panel, S/S Merchandiser

28036 Beverage Panel, 6 Valve

* For Models 2230C4 and 2230C6

** For Models 2230C4-100 and 2230C6-100

1691748

Page 20

13

14

2

4

5

3

6

16

8

19

17

7

11

10

9

12

1,18

20

FIGURE 8. CABINET SECTION EXPLODED VIEW & PART LIST

Item

No. Part No. Description

1 30794 Agitator Motor Heater

2 31406 Fuse, 1-1/4 Amp

70438 Rebuild Kit

31551 Solenoid Service Kit

3 31093 Solenoid Assembly

4 31763 Agitator Timer

5 30774 Capacitor

6 51891 Gate Gasket

7 53015 Ice Chute Back Section

8 53016 Ice Chute Cover

9 50842 Motor Plate Insulation

10 51860 Motor Gasket

11 51859 Motor Shaft Seal

12 32498 Agitator Motor

13 51916 Agitator Disk

14 26591* Agitator

15 29026** Agitator

16 23062 Foam Shield

17 214910 Gate Slide

18 70341 Heater Spring

19 70260 1/4-20 x 1” Phil Rd Hd Screw

20 70815 1/4-20 Hex Motor Mounting Screw

* For Models 2230C4 and 2230C6

** For Models 2230C4-100 and 2230C6-100

17 91748

Page 21

FIGURE 9. SOLENOID ASSEMBLY

Index

No.

1 21493 1 Solenoid Mounting Plate

2# 31551 1 Solenoid Service Kit

3 70171 2 8--32 x 3/8 Phil Tr HD Screw

4 70121 2 No. 8 Lockwasher

5 50752 3 Isolator

6* 50789 2 Bumper Assembly

7* 70423 1 Cotter Pin

8* 10080 1 Gate Lift Rod

9 10081 1 Gate Lift Rod Bushing

10 50754 1 Gate Arm Bearing

11 21492 1 Gate lift Arm

12 70043 1 Flatwasher

13* 70422 1 Spring

14 70263 1 1/4-20 x 3/4 Hex Hd Screw

15 70048 1 1/4 Lockwasher

16 70066 1 1/4 Flatwasher

17 10077 1 Pivot Bearing

18 30227 1 1/4 Quick Connect T ab

19 50305 ---- Lubricant

20* 21592 1 Solenoid Linkage Pin

21* 70433 2 Retainer Ring

22 51088 ---- Loctite

----* 70438 ---- Rebuilding Kit

Part No. Quantity Description

NOTE: * Parts supplied with rebuilding kit.

# 31551 solenoid supplied with items 20 & 21.

1891748

Page 22

IMI CORNELIUS INC.

ONE CORNELIUS PLACE

ANOKA, MN. 55303- - 6234

TELEPHONE (800) 238--3600

FACSIMI LE (612) 422--3232

TECH SVC 1-800-535-4240

WARRANTY

IMI Cornelius Inc. and Remcor Products Company warrants that all equipment and parts are free from defects

in material and workmanship under normal use and service. For a copy of the warranty applicable to your

Cornelius and or Remcor product, in your country, please write, fax or telephone the IMI Cornelius office nearest you. Please provide the equipment model number,serial number and the date of purchase.

IMI Cornelius Offices

AUSTRALIA D P.O. 210, D R IVERWOOD, D NSW 2210, AUSTRALIA D (61) 2 533 3 122 D FAX (61) 2 534 2166

AUSTRIA D AM LANGEN FELDE 32 D A-1222 D VIENNA, AUSTRIA D (43) 1 233 520 D FAX (4 3) 1-23 35-2930

BELGIUM D BOSKAPELLEI 122 D B-293 0 BRAASCHAA T, BELGIUM D (32) 3 664 0552 D FAX (32) 3 665 23 07

BRAZIL D RUA ITAOCARA 97 D TOMAS COELHO D RIO DE JANEIRO, BRAZIL D (55) 21 591 7150 D FAX (55) 21 5 93 1 829

ENGLAND D TYTHING ROAD ALCESTER D WARWICKSHIRE, B49 6 EU, ENGLAND D (44) 789 763 10 1 D FAX (44) 789 7 63 6 44

FRANCE D 71 ROUTE DE ST.DENIS D F-95170 DEUIL LA BARRE D PARIS, FRANCE D (33) 1 3 4 28 6200 D FAX (33) 1 34 28 6201

GERMANY D CARL LEVERKUS STRASSE 15 D D-401 8 LANGENFELD, GERMANY D (49) 2 173 7930 D FAX (49) 2173 77 438

GREECE D 488 MESSOGION AVENUE D AGIA PARASKEVI D 153 42 D ATHENS, GREECE D (30) 1 600 1073 D FAX (3 0) 1 601 2491

HONG KONG D 1104 TAIKOTSUI CENTRE D 11-15 KOK CHEUNG ST D TAIKOKTSUE, HONG KONG D (852) 789 9882 D FAX (852 ) 391 622 2

ITALY D VIA PELLIZZARI 11 D 1-20059 D VIMARCATE, ITALY D (39) 39 6 08 0817 D FAX (39) 39 608 0814

NEW ZEALAND D 20 LANSFORD C RES. D P.O.BOX 19-044 AVONDALE D AUCKLAND 7, NEW ZEALAND D (64) 9 8 200 357 D FAX (64) 9 8200 361

SINGAPORE D 16 TUAS STREET D SINGAPORE 2263 D (65) 862 5542 D FAX (6 5) 862 56 04

SPAIN D POLIGONO INDUSTRAIL D RIERA DEL FONOLLAR D E-08830 SANT BOI DE LLOBREGAT D BARCELONA, SPAIN D (34) 3 640 2839 D FAX (34) 3 65 4 33 79

USA D ONE CORNELIUS PLACE D ANOKA, MINNESOTA D (612) 421-6120 D FAX (612) 422-3255

91748

19

Page 23

IMI CORNELIUS INC.

Corporate Headquarters:

Anoka, Minnesota 55303-6234

One Cornelius Place

(612) 421-6120

(800) 238-3600

Loading...

Loading...