Page 1

BARRACUDA 2000U

PORTABLE WALKING FOOT SEWING MACHINE

INSTRUCTION MANUAL

Page 2

Page 3

THE BARRACUDA 2000U

PORTABLE WALKING FOOT SEWING MACHINE

INSTRUCTION MANUAL

MATERIAL IS OWNED BY RELIABLE AND MAY NOT BE

REPRODUCED IN WHOLE OR IN PART WITHOUT EXPRESS

WRITTEN PERMISSION FROM RELIABLE CORPORATION

COPYRIGHT 2014 RELIABLE CORPORATION

Page 4

PR EFACE

The Reliable Barracuda 2000-U zig-zag and straight stitch portable walking-foot

machine is remarkably versatile. Designed for boat owners, hobbyists, and small

businesses, the Barracuda is ideal for medium-to-heavy-weight sewing jobs.

SMALL SIZE, BIG PERFORMANCE

With a stitch quality comparable to an industrial machine, there’s no job too big for

the Barracuda. With top and bottom feeding, it produces a perfect, even stitch, even

when sewing over challenging materials.

Page 5

TABLE OF CONTENTS

Machine speed ...............................................................................................

Oiling ...............................................................................................................

Needle .............................................................................................................

Thread .............................................................................................................

Bobbin winding ..............................................................................................

Threading the machine and needle ...........................................................

Prepare for sewing ........................................................................................

To start sewing ..............................................................................................

To regulate the length of stitch ..................................................................

Reverse sewing ..............................................................................................

Adjusting the tension ...................................................................................

To remove the hook and clean the race ....................................................

Clutch washer/screw-assembly instructions ...........................................

Constructional drawing ................................................................................

External group ...............................................................................................

External group parts list ..............................................................................

Sewing transmission group .........................................................................

Sewing transmission group parts list ........................................................

Shuttle transmission group .........................................................................

Shuttle transmission group parts list .......................................................

Feed transmission group .............................................................................

Feed transmission group parts list ............................................................

Driving & reversing mechanism group ......................................................

Driving & reversing mechanism group parts list .....................................

Electric power & dynamic transmission group ........................................

Electric power & dynamic transmission group parts list ......................

ZigZag mechanism group ...........................................................................

ZigZag mechanism group parts list ..........................................................

To regulate zigzag width and needle position..........................................

Base plate & working plate .........................................................................

Base plate & working plate parts list ........................................................

Cuda crank installation ................................................................................

Optional – Cuda case ....................................................................................

1

1

2

2

3

4

5

5

6

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

24

25

26

27

29

Page 6

SPEED OF MACHINE

The maximum speed recommended for this machine is 900 RPM or “stitches per

minute”. Use regular house-hold circuit 115 Volts, 60 HZ. The machine is equipped with

a one tenth (1/10) HP motor with reduction pulley to provide good power at the recommended speed.

This sewing machine can be mounted on a commercial stand. To do so, requires a special

cut-out table top, a one inch (1 ˝) diameter pulley, a special Balance Wheel Item No. 11,

and a maximum 1725 RPM motor.

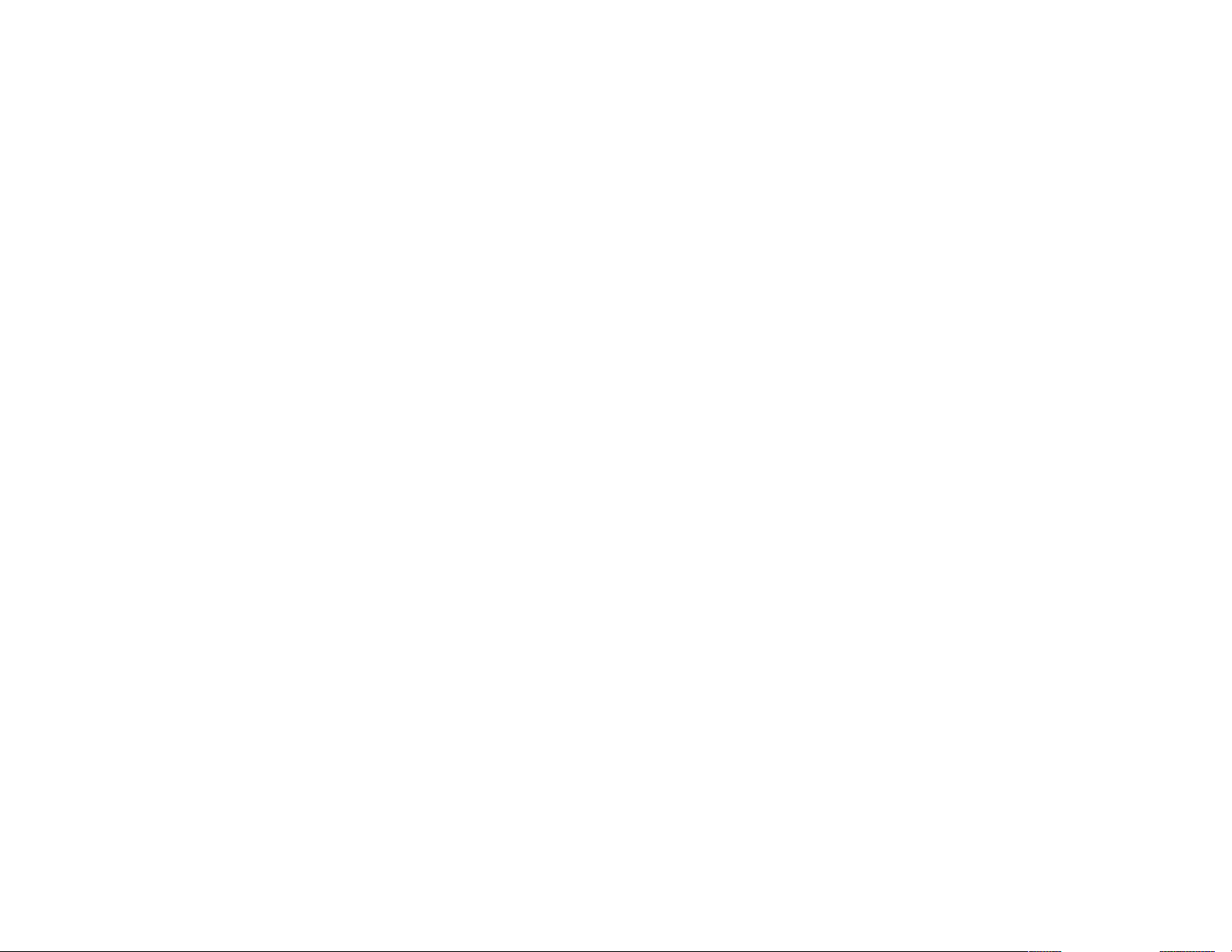

OILING

Before operating , oil all “metal to metal” working parts, and at the places indicated on

diagrams below. Use only genuine sewing machine oil. Operate the machine briefly on

scrap material after oiling to prevent soiling the work. Frequent oiling is recommended.

01

Page 7

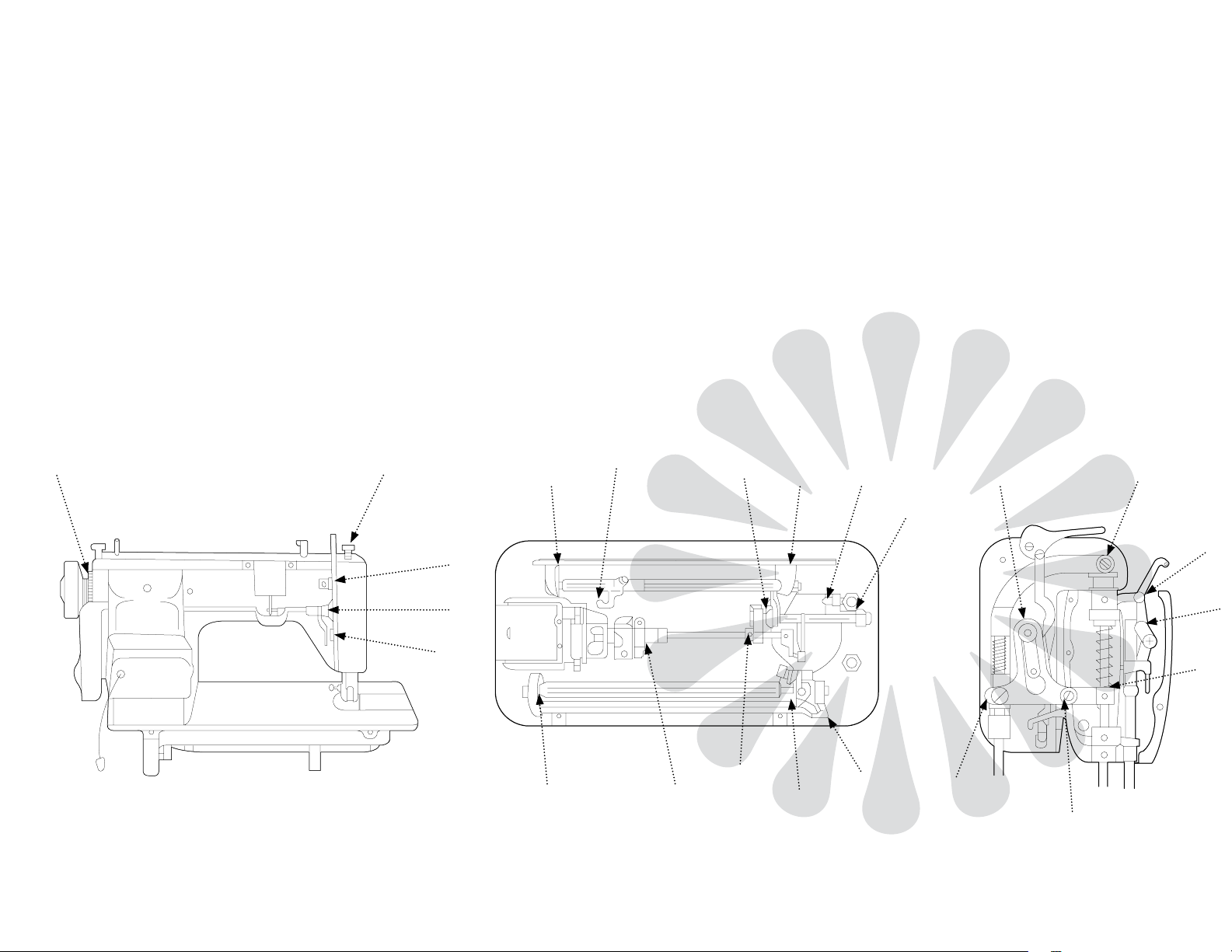

NEEDLE

Use 135x17 needles size 10 to 23. Use size 22 for most

medium to heavy sewing.

Install needle as illustrated.

THREAD

To obtain the best results with your sewing machine, we

recommend size 69 Bonded Nylon Thread.

GROOVE

02

Page 8

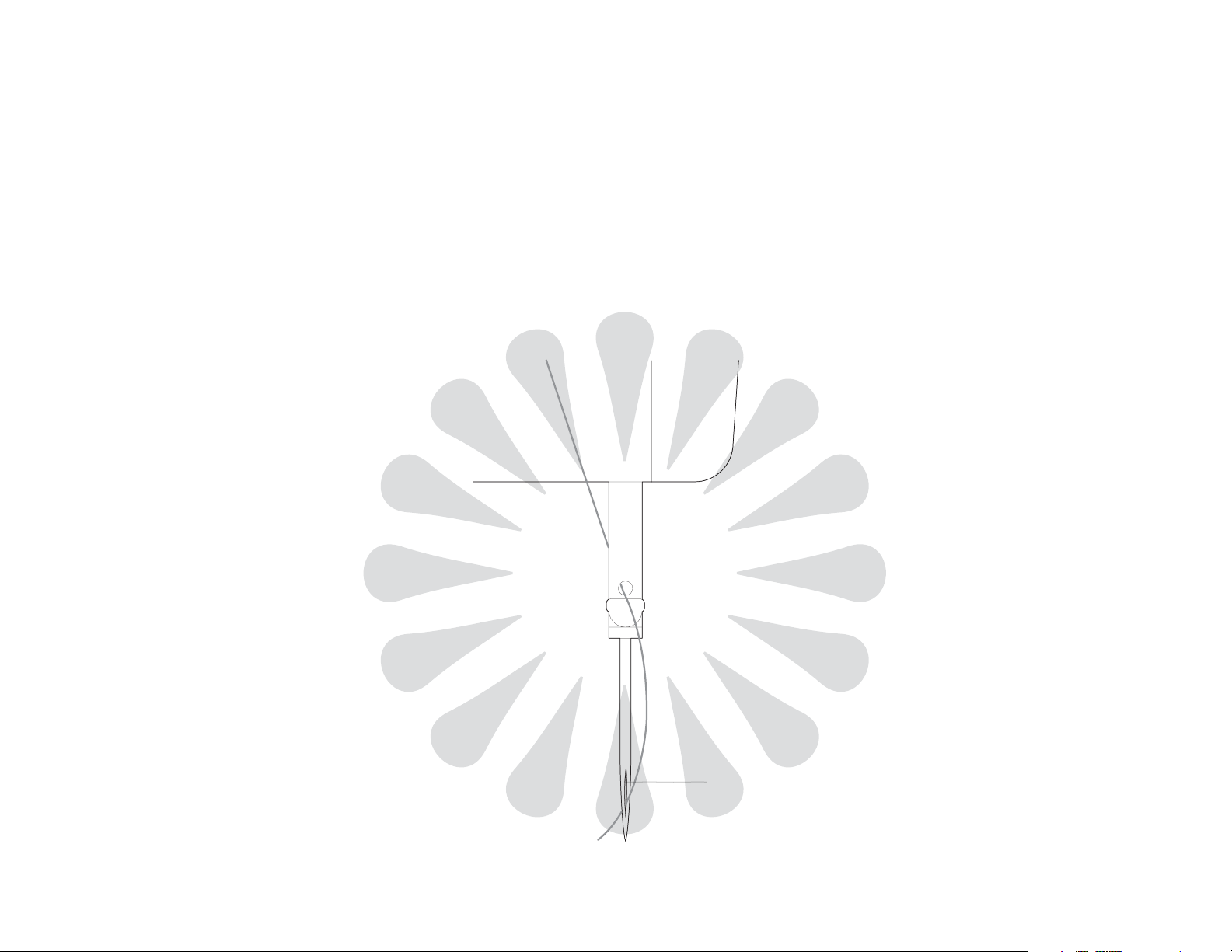

WINDING THE BOBBIN

1

5

2

4

3

03

Page 9

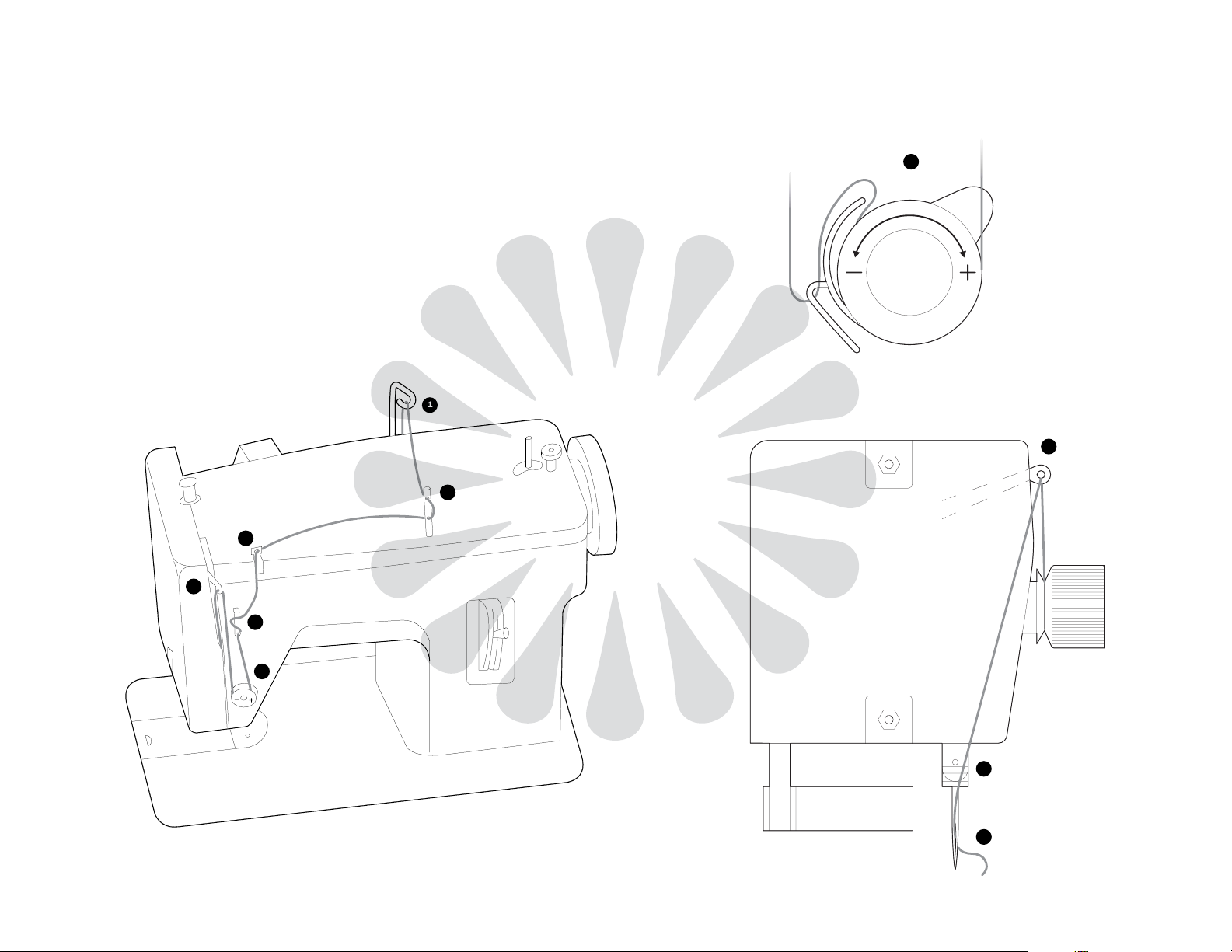

THREADING THE MACHINE AND NEEDLE

1

5

6

2

3

6

4

5

7

8

04

Page 10

PREPARE FOR SEWING

Thread the machine. Then pick up the bobbin thread as follows:

1. While holding the loose end of the needle thread in your left hand, turn the balance

wheel toward you by hand until the needle moves down and up again to its highest

point.

2. Pull the needle thread gently, and the bobbin thread will come up with it in the

form of a loop through the needle hole.

3. With your finger, pull this loop until the end of the thread appears. If the bobbin

thread does not rise, check to see if al least 5 or 6 inches of bobbin thread is hanging loosely from the bobbin case.

TO START SEWING

1. Place the material to be sewn under the presser feet and lower them onto the

material.

2. Hold the upper or needle thread (threaded through the eye of the needle) with the

fingers of the left hand. Turn (he balance wheel toward you with your right hand

until the outside presser foot reaches its most backward position .

3. Now operate the foot control to start sewing.

The above procedure is necessary so the motor will start the machine to sewing. Do not

help the feeding of the machine by hand, as this may bend or break the needle. Also,

damage to the hook can occur.

The machine may run a little slow when it’s new. However, it will begin to “free up” and

run smoothly with continued use.

During operation, the balance wheel of the machine always turns toward the operator.

To avoid tangled thread and jamming of the sewing hook, do not turn the balance wheel

backward (away from the operator).

WARNING: Never operate the machine without material under the presser feet. Your

machine will probably “lock” and cannot be operated until the thread is cleaned out of

the hook race.

05

Page 11

TO REGULATE THE LENGTH OF STITCH

Most sewing will be done with the maximum stitch length. However, the length of the

stitch can be adjusted as follows:

1. Loosen the thumb nut on the stitch length lever.

2. Raise the stitch length (feed regulator) lever until the desired stitch length is

obtained.

3. Tighten the thumb nut.

6

5

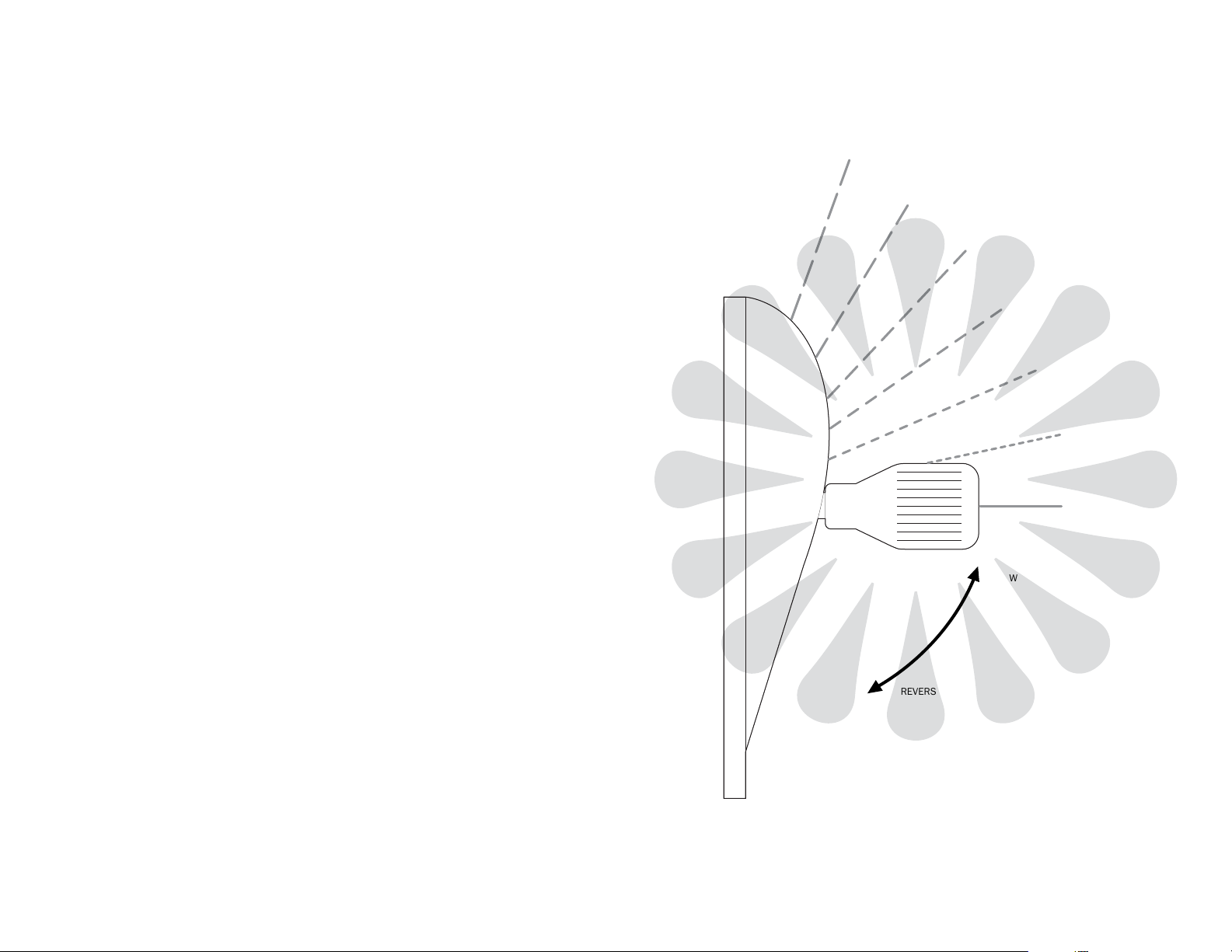

REVERSE SEWING

To sew in reverse:

1. Lower the feed regulator (stitch length) lever all the way to the bottom of the slot

in the stitch length plate.

2. Hold the lever there until reverse sewing is completed.

3. Then return the lever the forward position.

4

3

2

1

0

FORWARD FEED

REVERSE FEED

06

Page 12

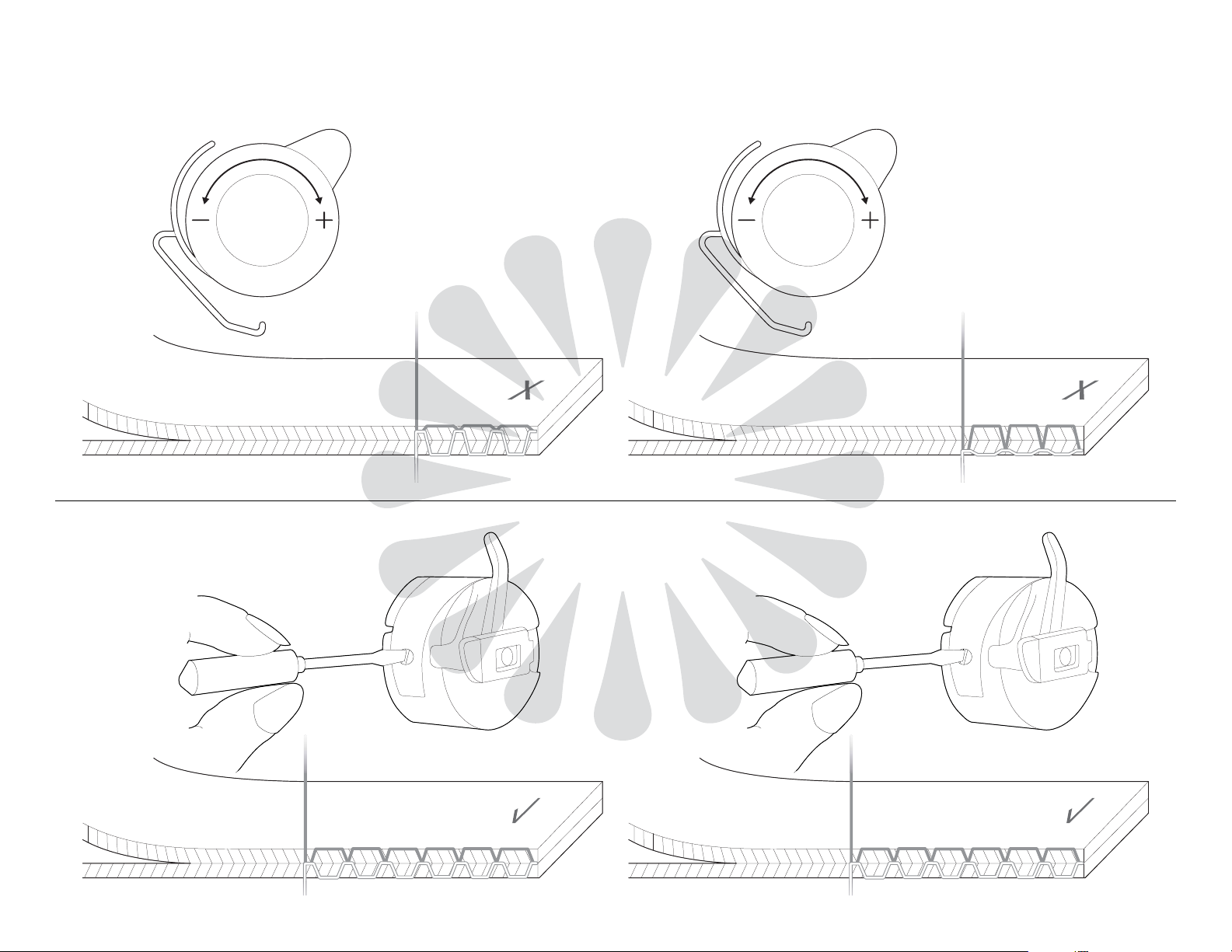

ADJUSTING THE NEEDLE THREAD TENSION

ADJUSTING THE BOBBIN TENSION

07

Page 13

TO REMOVE THE HOOK AND CLEAN THE RACE DO NOT

FORCE ANY OF THESE OPERATIONS

1. Turn the balance wheel by hand until the needle is at its highest point.

2. Remove the bobbin and bobbin case.

3. Turn knob (A) one half turn toward you.

4. Turn knob (B) one half turn away from you.

5. Remove retaining ring (C) and hook (D) by grasping the axle of the hook.

6. Remove accumulated lint and thread from the retaining ring, hook, and race body.

7. Replace hook (D) in race body with the axle facing out, forming a perfect circle with

the driver (E).

8. Replace retaining ring (C). polished side out, so that both pins are under knobs (A)

and (B).

9. Lock the retaining ring knobs (A) and (B).

10. Replace bobbin and bobbin case, and resume sewing.

BOBBIN

BOBBIN CASE

E

D

B

A

AXLE

C

08

Page 14

CLUTCH WASHER/SCREW-ASSEMBLY INSTRUCTIONS

1. Remove clutch stop screw.

2. Remove hand clutch screw.

3. Notice position of prongs on clutch washer in slot of balance wheel bushing.

4. Remove clutch washer and make 1/2 turn and replace.

5. Screw in hand clutch screw very light

6. Screw in stop screw.

7. Back off on hand clutch screw.

8. Run motor and check to see if balance wheel turns freely without running

the machine.

9. Tighten hand clutch screw and the machine should run properly.

BALANCE WHEEL CLUTCH WASHER CLUTCH STOP SCREW

09

SLOT IN BUSHING

CLUTCH WASHER

HAND CLUTCH SCREW

PRONGS ON CLUTCH WASHER POINT OUT.

WILL NOT WORK IF POINTED IN.

Page 15

CONSTRUCTIONAL

10

Page 16

GROUP 1 CONSTRUCTION EXTERNAL GROUP

4

3

9

2

14 13

6

6

5

12

26

8

7

25

12

6

24

17

17

23

27

18-1

12

7

11

19

19

18

20

30

31

31

10

15

21

29

22

28

16

16

11

Page 17

GROUP 1

KEY NO.

1

2

3

4

5

6

7

8

9

10

11

12

PART NO.

W047

B071

EO66

E066-2

W047-1

A092

E070-1

E070

W047-2

WOO1

WOO2

D097

PART NAME

TOP PLATE

TOP PLATE SET SCREW

BOBBIN WINDER STOPPER

BOBBIN WINDER STOPPER SET SCREW

SMALL PLATE COVER

SMALL PLATE COVER SET SCREW

BOBBIN WINDER ASSEMBLY SET SCREW

BOBBIN WINDER TENSION ASSEMBLY SET NUT

BOBBIN WINDER TENSION ASSEMBLY

SPOOL PIN

ARM BODY

BED

NEEDLE BAR SUPPORT SET SCREW

THREE HOLE THREAD GUIDE SET SCREW

Q’TY

1

1

1

1

1

1

2

1

1

1

1

1

2

1

KEY NO.

17

18

19

20

21

22

23

24

25

26

27

28

29

PART NO.

B010

W032

A052

A048-B

W029

W184-1

W030

W025

W025-1

E072

A117

W184-3

W184-2

PART NAME

BOBBIN WINDER SET SCREW

NEEDLE PLATE

NEEDLE PLATE SET SCREW

SHUTTLE RACE SLIDE

THREE HOLE THREAD GUIDE

DIAL TENSION ASSEMBLY

BOBBIN WINDER

CRANK ROO BEARING SET BASE

CRANK ROD BEARING SET BASE SET SCREW

TOP PLATE SET SCREW

BOBBIN WINDER RUBBER RING

THREAD TAKE-UP/CHECK-SPRING

TENSION RELEASE PIN

Q’TY

2

1

2

1

1

1

1

1

2

1

1

1

1

13

14

15

16

W048

C097

W125

A075

FACE PLATE

FACE PLATE SET SCREW

STITCH LENGTH PLATE

STITCH LENGTH PLATE SET SCREW

1

2

1

1

30

31

18-1

A049

AO5O

W032-1

SHUTTLE RACE SLIDE SPRING

SHUTTLE RACE SLIDE SPRING SET SCREW

ZIG ZAG NEEDLE PLATE

1

1

1

12

Page 18

GROUP 2 SEWING

TRANSMISSION GROUP

11

17

24

10

18

16

25

19

20

31

33

32

34

4

35

26

13

21

15

16

2230

4

12

14

9

4

38

6

5

3

27

37

7

2

8

1

28-1

29

28

23

27

13

Page 19

GROUP 2

KEY NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

PART NO.

E053

B007

B051

A012

B048

A029

E048-1

W028-4

W028-2

W028-3

W028-1

E020

E02O-2

B018

A042

A092

A031

WO10

PART NAME

ARM SHAFT

FEED CAM

ARM SHAFT BUSHING

THREAD TAKE-UP ASSEMBLY SET SCREW

ARM SHAFT BUSHING SET SCREW

TENSION RELEASE LEVER DRAG LINK

PIN SET SCREW

THREAD TAKE-UP LEVER CAM

THREAD TAKE-UP ASSEMBLY SET SCREW

THREAD TAKE-UP LEVER CAM SET PIN

CRANK ROD LEVER CAM FOLLOWER

CRANK ROD LEVER CAM FOLLOWER ADJUST NUT

CRANK ROD LEVER CAM FOLLOWER LOCK SCREW

CRANK RO D LEVER CAM FOLLOWER LOCK NUT

THREAD TAKE-UP ASSEMBLY

NEEDLE BAR CONNECTING ROD SET SCREW

NEEDLE BAR CONNECTING ROD

NEEDLE BAR CONNECTING STUD

NEEDLE SET SCREW

PRESSER REGULATING THUMB SCREW

PRESSER REGULATING THUMB SET SCREW

Q’TY

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

KEY NO.

21

22

23

24

25

26

27

28

28-1

29

30

31

32

33

34

35

36

37

38

PART NO.

A021

W015

B099

WO66

WO67

W008

A036

W012

B043-1

A035-1

B028

W039

A046

W043

D020

W045

8046

W016

WO65

PART NAME

NEEDLE BAR CONNECTING JOINT SET SCREW

ZIGZAG CONNECTING ROD

NEEDLE BAR CONNECTING JOINT PIN

NEEDLE BAR

NEEDLE THREAD GUIDE

NEEDLE

PRESSER FOOT SET SCREW

INSIDE PRESSER FOOT

ZIG ZAG PRESSER FOOT

PRESSER BAR

PRESSER BAR LOWER BUSHING

PRESSER BAR BRACKET

PRESSER BAR ACTUATOR GUIDE SCREW

TENSION RELEASE LEVER DRAG LINK

TENSION RELEASE LEVER DRAG LINK SET PIN

TENSION RELEASE LEVER

TENSION RELEASE LEVER SET SCREW

ZIGZAG CONNECTING ROD SET BASE

PRESSER BAR ACTUATOR “CAM”

Q’TY

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

19

20

A032

B016

PRESSER BAR SPRING

NEEDLE BAR SUPPORT

1

1

14

Page 20

GROUP 3 SHUTTLE TRANSMISSION GROUP

19

19

1

2

6

5

3

15

4

16

17

18

4

14

10

13

6

9

9

11

8

7

20

12

15

Page 21

GROUP 3

KEY NO.

1

2

3

4

5

6

7

8

9

10

11

12

PART NO.

B139

A027B

A0278

A023

A024

A018

A021

B179

B177

B155

A084

B153

PART NAME

CRANK CONNECTING ROD

CRANK CONNECTING ROD SET SCREW

CRANK CONNECTING ROD SET NUT

OSCILLATING SHAFT SET SCREW & NUT

OSCILLATING SHAFT

SHUTTLE DRIVER PIN

OSCILLATING SHAFT CRANK SET PIN

OSCILLATING SHAFT CRANK SET SCREW

OSCILLATING SHAFT CRANK. WITH SLIDE BLOCK

LOWER SHAFT COLLAR

SHUTTLE RACE GUIDE

SHUTTLE RACE GUIDE SHAFT

SHUTTLE RACE GUIDE SHAFT SET SCREW

Q’TY

1

1

1

2

1

1

1

1

1

2

1

1

1

13

14

15

16

17

18

19

20

B170

B172

Wl72

D099

A107

D100

B139-2

B177-1

SHUTTLE RACE GUIDE SHAFT COMPLETE

LOWER SHAFT

SHUTTLE DRIVER

SHUTTLE HOOK

BOBBIN

BOBBIN CASE ASSEMBLY

CRANK CONNECTING ROD CAP SET SCREW

LOWER SHAFT COLLAR SET SCREW

1

1

1

1

1

1

2

4

16

Page 22

GROUP 4 FEED TRANSMISSION GROUP

76

4

8

5

9

10

11

18

13

24

3

2

12 1

20

11

17-1

15

11

17

17

15

19

21

14

16

22

23

11

Page 23

GROUP 4

KEY NO.

1

2

3

4

5

6

7

8

9

10

11

12

PART NO.

W109

WIO5

A053B-2

W107

W1O6

B010

W108

A069B

A069A

B103

A023

W046

PART NAME

FEED REGULATOR THUMB NUT

FEED REGULATOR LEVER

FEED REGULATOR LEVER NUT

FEED REGULATOR

FEED REGULATOR SPRING

FEED REGULATOR SCREW SET SCREW

FEED REGULATOR SCREW

FEED CONNECTION SLIDE BLOCK

FEED CONNECTION SLIDE BLOCK STUD

FORKED ROD

FEED ROCK SHAFT CENTER SCREW & NUT

FEED LIFTING ROCK SHAFT SCREW & NUT

DRIVING CRANK

Q’TY

1

1

1

1

1

1

1

1

1

1

2

2

1

KEY NO.

23

24

17- 1

PART NO.

A07IB-1

A067

W011·1

PART NAME

FEED ROCK SHAFT CRANK SET SCREW

FEED LIFTING ROCK SHAFT CRANK SET SCREW

FEED REGULATOR SCREW WASHER

ZIG ZAG FEED DOG

Q’TY

2

1

1

13

14

15

16

17

18

19

20

21

22

A071B

A071A

A0 76

A075

WO11

A078

W046-1

AD61

A072

A073

FEED ROCK SHAFT CRANK

FEED ROCK SHAFT

FEED BAR CENTER SCREW & NUT

FEED BAR

FEED DOG

FEED DOG SCREW

DRIVING CRANK GUIDE NUT

DRIVING CRANK GUIDE SCREW

FEED LIFTING ROCK SHAFT

FEED LIFTING ROCK SHAFT CRANK

1

1

2

1

1

2

1

1

1

1

18

Page 24

GROUP 5 DRIVING & REVERSING MECHANISM GROUP

39

40

37

1

33

5

3

2

4

22

7

13

10

10

9

118

12

19

18

26

6

24

25

21

27

29

38

34

28

38

41

42

36

37

38

35

30

32

29

31

30

32

38

17-1

20

16

17

14

16

15

23

19

Page 25

GROUP 5

KEY NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

PART NO.

W042

W042-3

W026

W042-2

W042-1

W026-1

WO18

WO18-1

W020

A029

W018-2

W018-3

W019-1

PART NAME

PRESSER BAR LIFTER

PRESSER BAR LIFTER HINGE SCREW

LIFT BAR

UPPER LIFT BAR SCREW

SPACER

LIFT BAR GUIDE SCREW

PRESSER BAR TRACK

PRESSER BAR TRACK HINGE SCREW

REAR PRESSER BAR BRACKET

REAR PRESSER BAR SET SCREW

PRESSER BAR TRACK GUIDE SCREW

PRESSER BAR TRACK FEED STUD

PRESSER BAR LOAD SPRING (REAR)

Q’TY

1

1

1

1

1

1

1

1

1

2

1

1

1

KEY NO.

24

25

26

27

28

29

30

31

32

33

34

35

36

PART NO.

C097

W036

W024-1

W022

W041-2

W021

W023

W052

W052-1

W033

W034

W035

W053

PART NAME

BRACKET SET SCREW

PRESSER BAR FEED ROD

PRESSER BAR ACTUATOR SPACER

END PLATE BEARING SET PLATE

REVET

BEARING BRACKET BUSHING

LIFT CRANK ROD BEARING BRACKET PLATE

ROCKER END SET RING

ROCKER SET RING SET SCREW

PRESSER BAR ACTUATOR UP-DOWN ROCKER

PRESSER BAR ACTUATOR FEED ROCKER

CRANK ROD ROCKER

CRANK ROD

Q’TY

2

1

1

1

3

2

2

1

2

1

1

1

1

14

15

16

17

18

19

20

21

22

23

W019

WO17

BO1O

W013

W024

W020-2

W020-1

W041

W041-1

W014

REAR PRESSER BAR

OUTSIDE PRESSER FOOT BRACKET

OUTSIDE PRESSER FOOT BRACKET SCREW

OUTSIDE PRESSER FOOT SET SCREW

OUTSIDE PRESSER FOOT

PRESSER BAR ACTUATOR

FEED SCREW RING

PRESSER BAR ACTUATOR FEED SCREW

END PLATE

END PLATE SET SCREW

OUTSIDE PRESSER FOOT BRACKET LIMITATOR

1

1

2

1

1

1

1

1

2

2

1

37

38

39

40

41

42

17- 1

D197

W034-3

W046-2

W046-3

W046-4

A061-B

WO13-1

PRESSER BAR ACTUATOR UP-DOWN

ROCKER SET SCREW

CRANK ROD ROCKER SET SCREW

PRESSER BAR FEED ROCKER SET SCREW

CRANK ROD ROCKER GUIDE SCREW

UP-DOWN ROCKER GUIDE SCREW

CRANK ROD ROCKER LOCK SPACER

UP-DOWN ROCKER LOCK SPACER

CRANK ROD ROCKER LOCK WASHER

UP-DOWN ROCKER LOCK WASHER

CRANK ROD ROCKER LOCK NUT

UP-DOWN ROCKER LOCK NUT

ZIG ZAG OUTSIDE PRESSER FOOT

2

2

2

1

1

1

1

1

1

1

1

1

20

Page 26

GROUP 6 ELECTRIC POWER & DYNAMIC TRANSMISSION

23

28

27

26

28

4

23

6 3

5

22

20

24

24

25

2

25

21

1

8

21

7

10

11

12

9

13

19

18

14

15

17

21

Page 27

GROUP 6

KEY NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

PART NO.

AOO4

AOO2-1

A005

A003

A006

W060

WOO6

WOO7

D116

W061-5

W061-1

W061-3

W061-4

PART NAME

STOP MOTION CLAMP STOP SCREW

STOP MOTION CLAMP SCREW

STOP MOTION CLAMP WASHER

BALANCE WHEEL BUSHING

BALANCE WHEEL BUSHING SET PIN

HAND WHEEL

BELT (130XLO.18)

BELT (80XLO.25)

E5 RING

IDLE PULLEY SHAFT WASHER

IDLE PULLEY SHAFT

IDLE PULLEY

IDLE PULLEY BEARING

Q’TY

1

1

1

1

1

1

1

1

1

1

1

1

1

KEY NO.

23

24

25

26

27

28

PART NO.

W049-1

W049-2

C097

W003

W062-1

D097

PART NAME

MOTOR BASE SET SCREW

MOTOR SET WASHER

MOTOR SET SCREW

MOTOR

MOTOR PULLEY

MOTOR PULLEY SET SCREW

Q’TY

2

2

2

1

1

2

14

15

16

17

18

19

20

21

22

W061-6

W061-2

W059

LT-2M-4

LT-2M-3

LT-2M-2

W050

A092

W049

IDLE PULLEY LOCK WASHER

IDLE PULLEY SET NUT

PULLEY BRACKET

MOTOR BRACKET SET WASHER

MOTOR BRACKET SET LOCK WASHER

MOTOR BRACKET SET SCREW

BELT COVER

BELT COVER SET SCREW

MOTOR BASE (REAR COVER)

1

1

1

1

1

1

1

2

1

22

Page 28

GROUP 7 ZIG ZAG MECHANISM GROUP

25

18

20

17

4

11

2

3

22

5

6

21

19

25

8

7

1

25

23

24

13

12

15

25

25

6

10

24

11

23

14

16

27

Page 29

GROUP 7

KEY NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

PART NO.

703

704

705-2

707

708

709

710

M711

M712

718

D720

725

725-7

M726

727

728

M729

PART NAME

ZIG ZAG CAM & GEAR (ASSEMBLY)

SET SCREW (3) FOR NO. 703, 707

NEEDLE DISPLACEMENT REGULATOR (ASSEMBLY)

SHAFT FOR NO 705-2

ZIG ZAG WIDTH REGULATOR

ZIG ZAG WIDTH REGULATOR PIN (2) FOR NO. 708, M712

SET SCREW FOR NO 708(1)

ZIG ZAG CONNECTING PLATE

ZIG ZAG REGULATING LEVER

SPRING WASHER FOR NO. 709

ZIG ZAG WIDTH LEVER KNOB (2)

ZIG ZAG CONNECTING LINK SLIDE BLOCK (ASSEMBLY)

COLLAR FOR NO. 725

ZIG ZAG VERTICAL SHAFT

SNAP RING FOR NO. M726 (1)

ZIG ZAG VERTICAL SHAFT ARM

NEEDLE POSITION COMPLETE LEVER

Q’TY

1

2

1

1

1

2

1

1

1

1

2

1

1

1

1

1

1

KEY NO.

23

24

25

26

27

PART NO.

H777

412-1

154

110-1

402

PART NAME

ZIG ZAG CONTROL PLATE

SET SCREW FOR NO. 725(1)

SET SCREW FOR NO. M711(2), M729(1), M732(1), N747(1),

H777(2)

SET SCREW FOR NO. M732(1)

SET SCREW FOR NO. 728(1 )

Q’TY

1

1

7

1

1

TO REGULATE THE WIDTH OF ZIGZAG STITCH

Moving the zigzag width lever to the desire zigzag width as marked on the panel accordingly can regulate the zigzag width. For instance, “0” as straight while “5” will be the

maximum zigzag width

NEEDLE POSITION SELECTION

With the zigzag width lever set at “0” and the needle position selector move to “L”, a

straight line stitches will be sewn at the left side of the needle hole.

With the zigzag width lever set at “0” and the needle position selector move to “C” or

“R”, a straight line stitches will be sewn at the middle or the right of the needle hole.

As adjusting of zigzag width with the needle position selection as mentioned above, a

variety of ornamental stitches can be sewn.

L C R

18

19

20

21

22

M732

M734

741

N746

C 749

CLICK STOPPER FOR NO. M729

NEEDLE POSITION COMPLETE LEVER GUIDE

SNAP RING (2) FOR NO. 707

SPRING FOR NO. M711

ZIG ZAG REGULATING LEVER PIN

1

1

1

1

1

24

Page 30

BASE PLATE & WORKING PLATE

1

2

25

24

14

5

6

7

13

8

3

4

16

11

12

17

6

9

13

13

5

15

Page 31

BASE PLATE & WORKING PLATE

KEY NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

PART NO.

E316

A106

E428

W428-1

E425

E423

E427

E433

E429

E432

W410

E431

E4 24

PART NAME

HEAD SCREW

BASE SlDE SET SCREW

BASE SIDE PRESSER PLATE

BASE SIDE PRESSER PLATE RUBBER

BASE SHAFT SET SCREW

BASE SHAFT

BASE PRESSER PLATE

BASE PRESSER PLATE RUBBER

PRESSER PLATE SET SCREW

SHIM SPRING

BASE COVER

PRESSER PLATE SET NUT

RUBBER PACKING

Q’TY

2

1

1

1

2

2

1

1

1

1

1

1

4

14

15

16

17

E429

E418

E409

E413

SIDE PRESSER PlATE SET SCREW

BIG WORKING PLATE

WORKING PLATE

LEG

1

1

1

2

26

Page 32

CUDA CRANK INSTALLATION

HAND WHEELSTOP MOTION SCREW

1 Unscrew & remove the stop

motion stop screw with screw

driver.

2 By hand, unscrew & remove the

stop motion screw.

3 Remove clamp washer from

under the stop motion screw.

SCREW DRIVER

CLAMP WASHER DRIVE BELT COVER

MAIN BELT

4 Remove the drive belt cover

held by two screws.

5 Remove longer main belt. Turn

hand wheel to assist removal.

6 Remove the hand wheel. Wheel

slides off.

27

Page 33

NEW BELT

BIG WHEEL

7 Install the BIG WHEEL on the

end of the shaft making sure

that the teeth on the wheel are

facing the sowing head.

8 Tighten the BIG WHEEL on the

1/8” Allen key provided.

5/32" ALLEN KEY

ALLEN SCREW

1/8" ALLEN KEY

HANDLE

NEW DRIVEŁ

BELT COVER

9 Install the new mail drive belt.

Slip the drive belt over the BIG

WHEEL first and then slip the

belt over the small idle pulley at the back. Turn the small

pulley slowly clockwise to make

sure that the belt is properly in

place.

10 Put back in place the stop

motion screw & clamp motion

washer. Put back in place the

stop motion clamp stop screw.

11 Install the new belt cover on by

two screws.

12 For hand crank operation only,

install the handle to the BIG

WHEEL by tightening the Allen

screw with the 5/32” Allen key

provided.

28

Page 34

OPTIONAL – CUDA CASE

• 3/4” plywood construction

• Reinforced metal corner guards

• Heavy-duty handle

• Dual exterior case latches

• Seperate insert houses the accessory kit for extra needles, bobbins and more

29

Page 35

RELIABLE CORPORATION 3-YEAR PRODUCT

WARRANTY POLICY FOR THE BARRACUDA

SEWING MACHINE (MODEL 2000U)

Reliable Corporation (“Reliable”) warrants to the original purchaser of the

boiler noted above from Reliable (the “Barracuda”) that for a period of three

(3) years from the date of purchase it will be free from defects in materials and

workmanship when utilized for normal use by the original purchaser only.

Subject to the conditions and limitations set forth below, Reliable will either repair

or replace any part of a Barracuda that proves defective by reason of improper

workmanship or materials. If the defective Barracuda is no longer available and

cannot be repaired effectively or replaced with an identical model, Reliable shall

replace the defective Barracuda with a current Barracuda of equal or greater

value. Repaired parts or replacement products will be provided by Reliable on an

exchange basis, and will be either new or refurbished to be functionally equivalent

to new. If Reliable is unable to repair or replace a Barracuda, it will refund the

current value of that Barracuda at the time the warranty claim is made.

This limited warranty does not cover any damage to a Barracuda that results from

improper installation, accident, abuse, misuse, unreasonable use, natural disaster,

insufficient or excessive electrical supply, abnormal mechanical or environmental

conditions or any unauthorized disassembly, repair or modification. This limited

warranty does not extend to any indirect, consequential or incidental damages that

may be suffered by a user from the use of a Barracuda, including without limitation,

any liability for third party claims for damage, and is limited to the amount paid by

the original purchaser for the Barracuda with respect to which this limited warranty

protection applies. This limited warranty does not apply with respect to products

that have been altered or products not purchased directly from Reliable or a dealer

authorized by Reliable to sell the Reliable Barracuda.

This limited warranty is the only warranty that applies to the Reliable Barracuda,

sewing machine, supersedes any and all terms that may be contained in any other

document or purchase order and may not be altered or amended except expressly in

writing by Reliable.

To obtain a repair or replacement under the terms of this warranty, please contact

our customer service group at 1 800 268 1649. You will be required to submit an

original receipt via fax or e-mail. The receipt must reflect that you are the original

purchaser, the product was bought directly from Reliable or from an authorized

Reliable dealer and that the warranty claim is being made in compliance with the

terms set out in this document or any subsequent document issued by Reliable in

connection with this policy. You will be issued a return authorization number (RA#)

and asked to ship the defective product together with proof of purchase and RA#,

prepaid insured to the following address: Reliable Corporation, 5–100 Wingold Ave,

Toronto, ON M6B 4K7.

Freight collect shipments will be refused. The risk of loss or damage in transit will

be borne by the customer. Once Reliable receives the defective product, it will

initiate the repair or replacement process.

If you have any questions regarding this warranty, you may write to:

Reliable Corporation

100 Wingold Avenue, Unit 5

Toronto, Ontario

Canada M6B 4K7

www.Reliable corporation.com

Page 36

RELIABLE CORPORATION

PRODUCTS WARRANTY

Reliable Corporation (“Reliable ”) warrants to the original purchaser of its

products that every product sold by Reliable (a “Reliable Product”) is free from

defects in material and workmanship for a period of one year from the date

of purchase if properly used and maintained. Subject to the conditions and

limitations set forth below, Reliable will either repair or replace any part of a

Reliable Product that proves defective by reason of improper workmanship or

materials. If the defective Reliable Product is no longer available and cannot be

repaired effectively or replaced with an identical model, Reliable shall replace the

defective Reliable Product with a current Reliable Product of equal or greater

value. Repaired parts or replacement products will be provided by Reliable on an

exchange basis, and will be either new or refurbished to be functionally equivalent

to new. If Reliable is unable to repair or replace a Reliable Product, it will refund

the current value of that Reliable Product at the time the warranty claim is made.

This limited warranty does not cover any damage to a Reliable Product that results

from improper installation, accident, abuse, misuse, natural disaster, insufficient

or excessive electrical supply, abnormal mechanical or environmental conditions,

wear and tear resulting from normal use of the product, or any unauthorized

disassembly, repair, or modification. This limited warranty does not extend to any

indirect, consequential or incidental damages that may be suffered by a user or

from the use of a Reliable Product, including without limitation, any liability for

third party claims for damage, and is limited to the amount paid by the original

purchaser Reliable Product with respect to which this limited warranty protection

applies. This limited warranty does not apply with respect to products that have

been altered or which are missing serial numbers or for products not purchased

directly from Reliable or a dealer authorized by us to sell Reliable Products.

This limited warranty is the only warranty that applies to any Reliable Product,

supersedes any and all terms that may be contained in any other document or

purchase order and may not be altered or amended except expressly in writing

by Reliable.

To obtain a repair or replacement under the terms of this warranty, please contact

our customer service group at 1-800-268-1649 or at support@reliablecorporation.

com. You will be required to submit an original receipt via fax or e-mail. The receipt

must reflect that you are the original purchaser, the product was bought directly from

us or from an authorized Reliable dealer and that the warranty claim is being made

within the warranty period. You will be issued a return authorization number (RA#)

and asked to ship the defective product together with proof of purchase and RA#,

prepaid insured to the following address: Reliable Corporation, 5-100 Wingold Avenue,

Toronto, ON M6B 4K7. Freight collect shipments will be refused. The risk of loss or

damage in transit will be borne by the customer. Once Reliable receives the defective

product, it will initiate the repair or replacement process.

If you have any questions regarding this warranty, you may write to:

Reliable Corporation

100 Wingold Avenue, Unit 5

Toronto, Ontario

Canada M6B 4K7

www.reliablecorporation.com

Page 37

Page 38

Page 39

Page 40

1 800 268 1649

www.reliablecorporation.com

Loading...

Loading...