Page 1

WATERFORD

www.waterfordstoves.com

Owners &

Installation

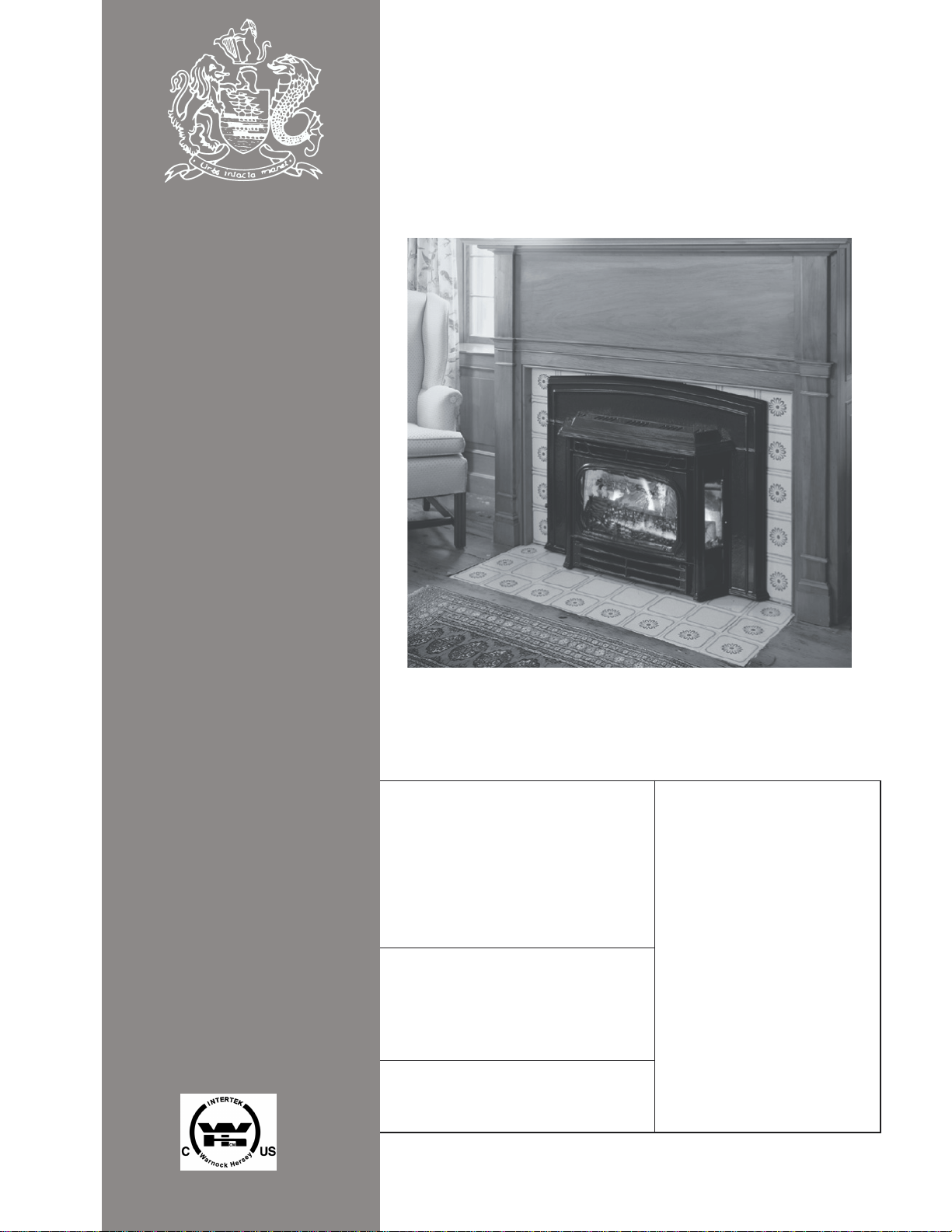

EMERALD GAS INSERT

ZERO CLEARANCE KIT

KIT # 270-900

Tested by:

PLEASE KEEP THESE INSTRUCTIONS FOR

FUTURE REFERENCE

WARNING:

Improper installation, adjustment,

alteration, service or maintenance

can cause injury or property damage. Refer to this manual. For assistance or additional information consult an authorized installer, service

agency or the gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapours and liquids in

the vicinity of this or any other appliance.

Manual

Installation and service must be performed by an authorized installer,

service agency or the gas supplier.

FPI Fireplace Products International Ltd. 6988 Venture St., Delta, B.C. Canada, V4G 1H4

FOR YOUR SAFETY

What to do if you smell gas:

!!

! Do not try to light any

!!

appliance

!!

! Do not touch any electri-

!!

cal switch: do not use

any phone in your building.

!!

! Immediately call your

!!

gas supplier from a

neighbour's phone. Follow the gas supplier's

instructions.

!!

! If you cannot reach your

!!

gas supplier, call the fire

department.

© Copyright 2004, FPI Fireplace Products

International Ltd. All rights reserved.

908-270 01/15/04

Page 2

TABLE OF CONTENTS

General Information ...................................................3

Zero Clearance Kit Specifications..............................3

Listings and Code Approvals .....................................3

Clearances to Combustibles .....................................4

Safety Decal .............................................................5

Framing.....................................................................6

Zero Clearance Kit Assembly....................................6

Assemble the Cabinet ........................................7

Attach Cabinet to Framing ................................10

Install the Insert ................................................11

Venting Introduction ................................................ 11

Simpson Dura-Vent Component List ....................... 11

Venting Arrangements - Horizontal.......................... 13

Venting Arrangements - Vertical..............................13

Horizontal Termination Installation ...........................14

Vertical Termination Installation...............................15

2

Emerald Gas Insert Zero Clearance Kit

Page 3

GENERAL INFORMATION

Using Kit# 270-900 you can convert the Emerald Gas Insert into a highly efficient heat producing Zero Clearance Fireplace.

This kit consists of factory built parts that require minimal assembly to form the Zero Clearance enclosure for the Emer al d

Gas Insert. The enclosure can then be fixed into a framed combustible construction, and a standard Simpson Dura-Vent

Direct Vent GS System installed on the assembly for the required venting. The insert can be installed later. The faceplate

will normally overlap on top of the finished wall.

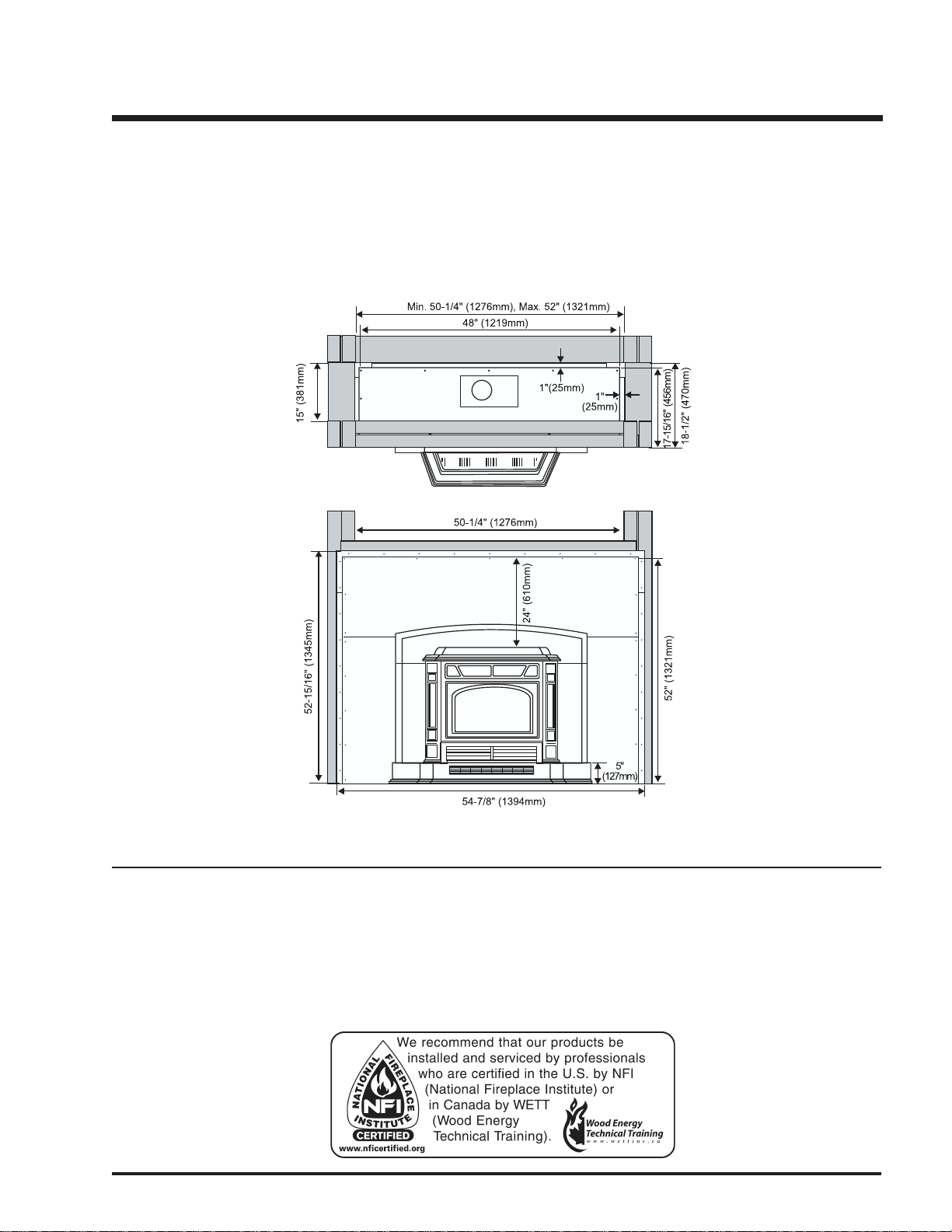

Emerald Insert Zero Clearance Kit Specifications

LISTINGS AND CODE APPROVALS

This gas component has been tested in accordance with National Safety Standards, and has been certified by Warnock Hersey

for installation and operation in the United States, and Canada as described in these Installation and Operating Instructions.

Check with your local building code agency before you begin your installation to ensure compliance with local codes, including

the need for "permits" and follow-up inspections. If any problems are encountered regarding code approvals, or if you wish

clarification on any of the instructions contained here, contact your local dealer.

Emerald Gas Insert Zero Clearance Kit

3

Page 4

INSTALLATION

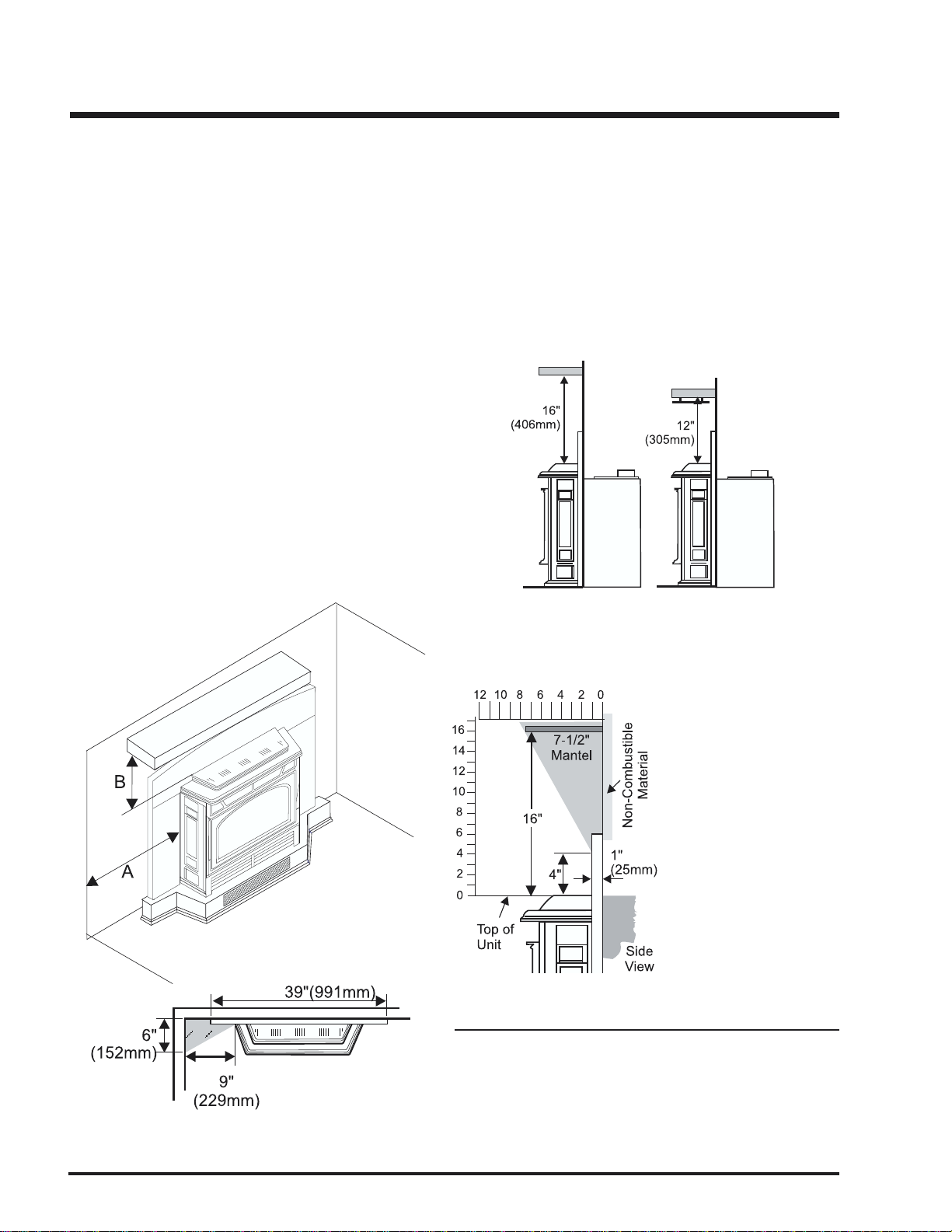

CLEARANCES TO COMBUSTIBLES

The clearances for the Zero Clearance Kit are 0" to combustibles (back, side and floor) but when planning your installation

review the clearances required for the Insert (see below) after it is installed in the Zero Clearance Kit.

Warning: Combustible facing materials must not extend inside the 1/2" (13mm) lip at the edge of the face panels.

Any non-combustible facing materials (such as ceramic tile or masonry face brick) up to 1-1/2" (38mm) thick may be used

to finish the area inside the 1/2" (13mm) lip on the face panels. Non-combustible tile backer board such as Wonderboard or

Durock , or metal lath or screen may be fastened directly to the front of the face panels to provide a base for attaching facing

materials if needed. The Zero Clearance Kit must be installed on a flat, solid, continuous surface (e.g. wood, metal, concrete).

Emerald Insert Clearances to Combustibles:

From Unit

Sides A 12" / 305 mm

Unit to Unprotected Mantel B 16" / 406 mm

(see Mantel clearance diagram below)

Unit to Protected Mantel* C 12" / 305mm

In addition to these clearances, adequate accessibility

clearance for servicing and proper operation must be maintained.

Do not in any way obstruct the combustion air inlets that are

located on the front of the heater.

Clearance from top of hob to

mantel and combustible trim,

unshielded.

Combustibles are permitted within

the shaded area.

Clearance from top of hob to

mantel and combustible trim,

shielded.

*Mantel shield must have a

1" (25mm) air space between the mantel and shield

and a 1" (25mm) gap between on the back of the shield

and the facing.

Floor Protection

If the appliance is installed in a fireplace that is elevated 5"

(127mm) or higher (i.e., a Waterford Zero Clearance Cabinet,

Combustibles are permitted within

the shaded area, on either side.

4

zero clearance fireplace, brick plinth, etc.), no floor protection is

required in front of the appliance.

Emerald Gas Insert Zero Clearance Kit

Page 5

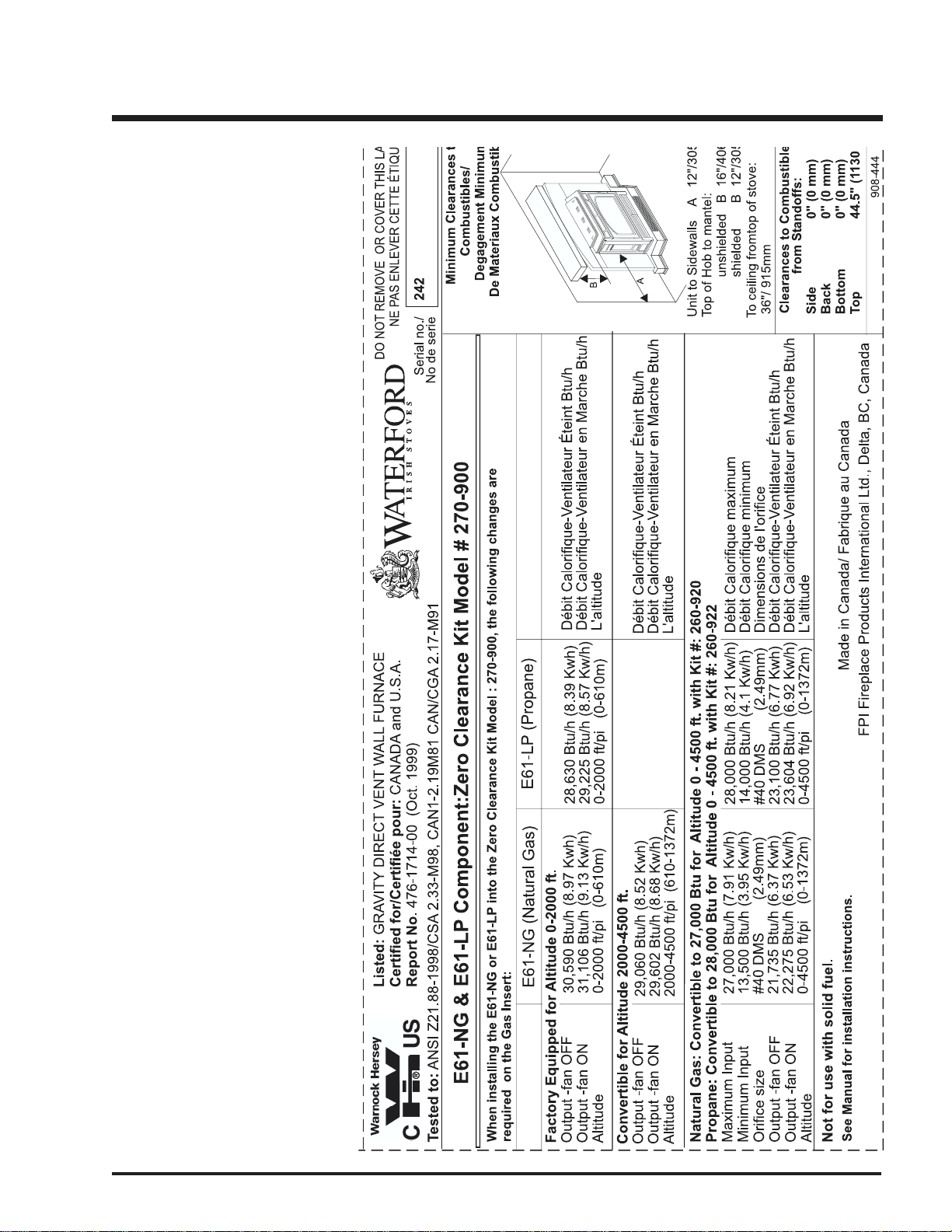

This is a copy of the label that accompanies each Waterford E61 Zero Clearance Kit #270-900. We have printed a

copy of the contents here for your review. The safety label is located on the

top panel.

NOTE: Waterford units are constantly

being improved. Check the label on

the unit and if there is a difference, the

label on the unit is the correct one.

SAFETY LABEL

Emerald Gas Insert Zero Clearance Kit

5

Page 6

INSTALLATION

EXTERIOR VENT TERMINAL LOCATIONS

18"

24"

Vertical

Termination

A

L

V

N

j

H

V

B

V

B

B

Closed

Fixed

Openable

V

A

Area where terminal is not permited

horizontally from the centerline of the regulator.

min 36"/90cm)

air inlet to any other appliance *(12"/30cm)

J= Clearance to service regulator vent outlet *(Canada: min. 72"/1.8m, USA:

K= Clearance to non-mechanical air supply inlet to building or the combustion

property *(min. 84"/2.1m)

L= Clearance to a mechanical air supply inlet *(min. 72"/1.8m)

M = **Clearance above paved sidewalk or a paved driveway located on public

N= Clearance under veranda, porch, deck, or balcony *(min. 12"/30cm)***

A

K

V

B

Air supply outlet

A

Openable

Fixed

Closed

C

V

.

M

V

B

V

F

Vent terminal

V

horizontal distance of (24"/60cm) from the centerline of the terminal (min.

18"/46cm) check with local code.

A = Clearance above grade, veranda, porch, deck, or balcony *(min. 12"/30cm)

B= Clearance to window or door that may be opened *(12"/30cm)

C= Clearance to permanently closed window *(min. 12"/30cm)

D= Vertical clearance to ventilated soffit located above the terminal within a

15cm), with Dura-Vent Termination Cap (min.12"/30cm)

with Dura-Vent Termination Cap (min.12"/30cm)

E= Clearance to unventilated soffit (min. 12"/30cm)

F= Clearance to outside corner: with AstroCap Termination Cap (min. 6"/

G= Clearance to inside corner: with AstroCap Termination Cap (min. 6"/15cm),

H= Not to be installed above a meter/regulator assembly within (3'/90cm)

Note: * As specified in CGA B149 Installation Code. Note: Local codes or regulations may require different clearances.

**A vent shall not terminate directly above a sidewalk or paved driveway which is located between two single family dwellings and serves both dwellings.

***Only permitted if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the floor.

Emerald Gas Insert Zero Clearance Kit

G

corner detail

Vertical

Termination

V

A

B

24"

E

V

D

Inside

6

Page 7

INSTALLATION

FRAMING

1) The cabinet face panels have a 1/2" lip to define the zones for combustible

and non-combustible facing materials: outside the lip, any material up

to 1/2" (13mm) may be used; inside the lip, only non-combustible

materials may be used (with a maximum thickness of 1-1/2" (38mm)).

The kit may be installed directly on and/or against standard combustible

building materials.

2) Frame in the enclosure for the Kit with framing material. The framed

opening for the assembled kit is 52" (1321 mm) high x 50-1/4" (1276 mm)

wide x 18-1/2" (470 mm) deep. See diagram.

If the interior of the cabinet framing is finished (with sheet rock,

for example), The dimensions given are from the inside of the

finished surfaces. The ceiling inside the framed enclosure

should be a minimum of 55-1/2" (1410mm) from the base of

the plinth.

3) For exterior walls, use a vapour barrier and insulate the

enclosure to the same degree as the rest of the house, or

according to local installation codes. In colder climates, if the heater is to be installed against an exterior wall or

chase, insulate the exterior walls according to local installation codes.

ZERO CLEARANCE KIT ASSEMBLY

Parts Included with Kit:

2 Back sections

2 Side

1 Base

1 Top

2 Front Face Side Panel

1 Front Face Top Panel

2 Top Standoffs

2 Extension Legs

1 Plinth

All pieces join together using the sheet metal screws that are

provided with the kit.

Assemble the Cabinet

1) Assemble the Sides and Base sections. The Side sections fit inside the lip of the Base section. The wider flange

on the Side section is on the front of the kit.

Secure with 2 screws on each side. Leave the 3rd screw

(closest to the rear) until the Back section is attached.

screw

Right Side

screw

Do not install the third screw until

the back panel is installed.

Base

Section

screw

screw

Base

Section

Emerald Gas Insert Zero Clearance Kit

Left Side

7

Page 8

INSTALLATION

2) Set the assembled Side and Base sections upright. Slide

the Lower Back (the section with 4 holes) down the inside

of Side flanges (make sure the 4 holes are closest to the

floor - see photo).

Secure with 2 screws on each side, and 11 screws on the

back.

3) Slide the Upper Back Section down the inside of the Side

flanges.

Secure to the Lower Back Section with 4 screws (from the

inside).

Right

Side

screw

Attach with 2 screws on the side. Repeat for Left Side

Attach with 11 screws on the side.

From the outside, secure with 2 screws on each side.

8

Emerald Gas Insert Zero Clearance Kit

Page 9

INSTALLATION

Secure with 6 screws on the back. Leave the top screw

holes until the top is attached.

4) Install the Top. Hold the top so that the large vertical flange

is at the front of the cabinet and fit it down over the Side/

Back assembly. Secure the top to the assembly using 3

screws on each side and 5 through the back and 8 on top.

5) Assemble the 2 top Standoffs. The Top Standoffs are

shipped flat and must be folded at the bend lines into the

correct shape.

Attach the Right Standoff to the top using the 4 holes at the

front right of the top. Install the Left Standoff to the 4 holes

at the front left.

Emerald Gas Insert Zero Clearance Kit

Left and Right Standoffs in position and

attached with 4 screws each.

6) Assemble the flue adaptor box. Slide the flex vent pipe

over the small vent opening on the base of the adaptor box

and secure with a clamp. Repeat for the 2nd flex vent pipe.

Use silicone to seal the connection.

9

Page 10

INSTALLATION

7) Drop the Flue Adaptor assembly into the hole on the top

section and secure from the top with 4 screws.

8) Assemble the Face Panels (left, right, and top), all 3 Face

panels are installed loosely, and then attached to the

cabinet body.

Secure the Left and Right Panels to the top with 1 screw

each. Make sure that the outside edges are aligned.

Secure the flue adaptor box to the top with

4 screws from the top.

Fit the assembled Side & Top Face Panels to the front of

the cabinet and secure with 19 screws.

10

Emerald Gas Insert Zero Clearance Kit

Page 11

INSTALLATION

Attach the Cabinet to the Framing

Slide the cabinet into the frame constructed previously and

secure with nails or sheet rock screws, installing a fastener

into at least every other hole.

Warning: Combustible materials must not extend inside the

stand-offs on the side, top and rear supports. For safety

reasons do not modify or alter any components of the Kit.

Install the Insert

1) Remove the hob and surround from the top of the unit for

access into the cabinet during installation. Slide the unit

into the cabinet on top of the bottom standoffs.

2) Connect the flue and make all connections according to

the instructions in the Venting section.

Any non-combustible facing materials (such as ceramic tile

or masonry face brick) up to 1-1/2" (38mm) thick may be used

to finish the area inside the 1/2" (13mm) lip on the face panels.

Non-combustible tile backer board such as Wonderboard or

Durock , or metal lath or screen may be fastened directly to the

front of the face panels to provide a base for attaching facing

materials if needed.

If a combustible mantel is desired, it must be above the 1/2"

(13mm) lip on the Top Face panel, a minimum of 24" for the

top of the insert hob. This includes both the mantel itself and

any trim below the mantel. A completely non-combustible

mantel, such as stone, may be placed wherever desired.

3) Re-install the hob and surround.

4) Slide the Plinth into position with about 1/8" (3mm)

clearance to the bottom of the insert front and side

surround panels.

Emerald Gas Insert Zero Clearance Kit

11

Page 12

INSTALLATION

VENTING INTRODUCTION

The E61 Emerald Insert uses the "balanced flue"

technology Co Axial system. The inner liner vents products

of combustion to the outside while the outer liner draws

outside combustion air into the combustion chamber thereby eliminating the need to use heated room air for combustion and losing warm room air up the chimney.

Note: These flue pipes must not be connected to

any other appliance.

These venting systems, in combination with the E61 Insert and the

E61 Zero Clearance Kit # 230-900, have been tested and listed as

a direct vent heater system by Warnock Hersey. The location of the

termination cap must conform to the requirements in the Vent

Terminal Locations diagram on page 6.

The gas appliance and vent system must be vented directly to the outside of the building,

and never be attached to a chimney serving a separate solid fuel or gas burning appliance.

Each direct vent gas appliance must use it's own separate vent system. Common vent

systems are prohibited.

SIMPSON DURA-VENT VENTING

All Simpson Dura-Vent components are available directly from Regency.

All components available directly from Regency.

Part # Description

971 Horiz. Termination Kit includes: 90o black elbow,

wall thimble cover, horiz. square termination

cap, 24" black pipe, 11" -14" 5/8" adjustable

black pipe

970 Basic Horiz. Termination. Kit includes: 90o black

elbow, wall thimble cover, horiz. square termination cap

97 8 Vert. Termination Kit includes 0/12 - 6/12 pitch

adjustable flashing, storm collar, low profile

term. cap

908B 6" Pipe Length - Black

907B 9" Pipe Length - Black

90 6 12" Pipe Length - Galv.

906B 12" Pipe Length - Black

90 4 24" Pipe Length - Galv.

904B 24" Pipe Length - Black

90 3 36" Pipe Length - Galv.

903B 36" Pipe Length - Black

90 2 48" Pipe Length - Galv.

902B 48" Pipe Length - Black

911B 11"-14 5/8" Adjustable Pipe Length - Black

917B 17"- 24" Adjustable Length - Black

COMPONENTS LIST

Part # Description

990 90O Elbow - Galv.

990B 90O Elbow - Black

990G 90O Elbow - Swivel - Galv.

990BG 90O Elbow - Swivel - Black

99 1 High Wind Termination Cap (Vertical)

98 0 Vertical Termination Cap

98 4 Horizontal Square Termination Cap

98 5 Horizontal Square High Wind Termination Cap

94 0 Wall Thimble - Support/Box

94 1 Cathedral/Ceiling - Support/Box

3951 Brass Trim for Cathedral

963 Firestop Spacer

943 Flashing 0/12-6/12

943S Flashing 7/12-12/12

953 Storm Collar

95 0 Vinyl Siding Standoff

98 8 Wall Strap

942 Wall Thimble

Parts not supplied by Dura-Vent

946-506/P Vent Guard (Optional)

946-523 AstroCap Termination Cap

12

Emerald Gas Insert Zero Clearance Kit

Page 13

VENTING ARRANGEMENTS -

HORIZONTAL TERMINATIONS

SIMPSON DURA-VENT DIRECT VENT

GS SYSTEM

Diagram 1 shows allowable combinations of vertical run with

horizontal terminations, using one 90o elbow.

ONLY FOR USE WITH THE REDUCTION KIT TO LOWER BTU

RATING KIT# 260-920 (NATURAL GAS AT 27,000 BTU) OR KIT

# 260-922 (PROPANE AT 29,000).

(Propane & Natural Gas)

INSTALLATION

Diagram 1

Simpson Dura-Vent

4" inner diameter

6-5/8" outer diameter

A vent guard should be used whenever the termination is

lower than the specified minimum or as per local codes.

• Maintain a 1-1/4" clearance to combustibles (1-1/2"

with Flex).

• Firestops are required at each floor level and whenever

passing through a wall.

VENTING ARRANGEMENTS -

VERTICAL TERMINATIONS

SIMPSON DURA-VENT DIRECT VENT GS

SYSTEM (Propane & Natural Gas)

Diagram 2 shows allowable straight vertical with Simpson

Dura-Vent Direct Vent GS vent systems for Propane and

Natural Gas.

• Firestops are required at each floor level and whenever

passing through a wall.

• Maintain a 1-1/4" clearance to combustibles

Diagram 2

Emerald Gas Insert Zero Clearance Kit

13

Page 14

INSTALLATION

HORIZONTAL INSTALLATIONS

Install the vent system according to the manufacturer's

instructions included with the components.

1) Set the unit in its desired location. Check to determine if

wall studs or roof rafters are in the way when the venting

system is attached. If this is the case, you may want to

adjust the location of the unit. Rough in the gas preferably

on the right side of the unit and the electrical (junction

block is on the left side) on the left.

2) Direct Vent pipe and fittings are designed with special

twist-lock connections to connect the venting system to

the appliance flue outlet.

3) Put a bead of silicone inside the outer section of the

adapter and a bead of Mill-Pac on the inner collar. Slip the

adapter over the existing inner and outer flue collar and

fasten to the outer collar only with the 3 supplied screws

(drilling pilot holes will make this easier). Level the

fireplace and fasten it to the framing using nails or screws

through the nailing strips.

4) Assemble the desired combination of pipe and elbow to

the appliance adaptor and twist-lock for a solid connection.

Note:

a)Twist-lock procedure: Four indentations, located on

the female ends of pipes and fittings, are designed to

slide straight onto the male ends of adjacent pipes and

fittings, by orienting the four pipe indentations so they

match and slide in to the four entry slots on the male

ends, Dia. 1. Push the pipe sections completely together, then twist-lock one section clockwise approximately

one-quarter turn, until the two sections are fully locked.

The female locking lugs will not be visible from the

outside, on the Black Pipe or fittings. They may be

located by examining the inside of the female ends.

Dia. 2

Note:

a) The horizontal run of vent must be level, or have a 1/

4 inch rise for every 1 foot of run towards the termination. Never allow the vent to run downward. This could

cause high temperatures and may present the possibility of a fire.

b) The location of the horizontal vent termination on an

exterior wall must meet all local and national building

codes, and must not be blocked or obstructed. For

External Vent Terminal Locations, see diagram in the

manual.

6) The arrow on the vent cap should be pointing up. Insure

that the 1-1/2" clearances to combustible materials are

maintained (Dia. 3). Install the termination cap.

Note: Apply sealant "Mill-

Pac" to inner pipe

and high temperature silicone sealant

to outer pipe on every twist-lock joint.

Dia. 1

b) Horizontal runs of vent must be supported every three

feet. Wall straps are available for this purpose.

5) Mark the wall for a 10" x 10" square hole. The center of the

square hole should line up with the centerline of the

horizontal pipe. Cut and frame the 10 inch square hole in

the exterior wall where the vent will be terminated. If the

wall being penetrated is constructed of non-combustible

material, i.e. masonry block or concrete, a 7"(178mm)

dia. (7-1/2"(191mm) dia. for flex) hole is acceptable.

Diagram 2.

14

Dia. 3

The four wood screws provided should be replaced with

appropriate fasteners for stucco, brick, concrete, or other

types of sidings.

Emerald Gas Insert Zero Clearance Kit

Page 15

INSTALLATION

Note: If installing termination on a siding covered wall, a

vinyl siding standoff or furring strips must be used to

ensure that the termination is not recessed into the

siding.

7) Before connecting the horizontal run of vent pipe to the

vent termination, slide the Wall Thimble (Part # 620-926)

over the vent pipe.

8) Slide the appliance and vent assembly towards the wall

carefully inserting the vent pipe into the vent cap assembly. It is important that the vent pipe extends into the vent

cap sufficient distance so as to result in a minimum pipe

overlap of 1-1/4 inches. Secure the connection between

the vent pipe and the vent cap by attaching the two sheet

metal strips extending from the vent cap assembly into

the outer wall of the vent pipe. Use the two sheet metal

screws provided to connect the strips to the pipe section.

See Dia. 4.

VERTICAL TERMINATION

1) Maintain the 1-1/2" clearances (air spaces) to combus-

tibles when passing through ceilings, walls, roofs, enclosures, attic rafter, or other nearby combustible surfaces. Do not pack air spaces with insulation. Check page

13 for the maximum vertical rise of the venting system.

2) Set the gas appliance in its desired location. Drop a

plumb bob down from the ceiling to the position of the

appliance flue exit, and mark the location where the vent

will penetrate the ceiling. Drill a small hole at his point.

Next, drop a plumb bob from the roof to the hole previously

drilled in the ceiling, and mark the spot where the vent will

penetrate the roof. Determine if ceiling joists, roof rafters

or other framing will obstruct the venting system.

Dia. 4

9) Install wall thimble in the center of the 10" square and

attach with wood screws (Dia 5).

Dia. 5

Emerald Gas Insert Zero Clearance Kit

15

Page 16

Printed in Canada

Loading...

Loading...