Regency Ashling Installation Manual

Ashling

WOODBURNING STOVE

SAFETY NOTICE

Please read this entire manual before you install and use your new room heater. Failure to follow instructions may result in property damage, bodily injury or even death.

If this stove is not properly installed, a house fire may result. For your safety, follow the installation directions. Contact local building or fire officials about restrictions and installation inspection requirements in your

area.

Manufactured by Waterford Stanley (Marketing) Limited, Bilberry, Waterford, Ireland.

INSTALLATION & OPERATING INSTRUCTIONS

TABLE OF CONTENTS

PAGE NO.

1. Stove Specifications 1

2. General 2

3. Pre-Installation Assembly 2

4. Blower 4

5. Floor Protection 4

6. Location 5

7. Outside Air Connection 5

8. Mobile Home Installation 6

9. Minimum Clearances to Combustibles 7

10. Additional Clearances to Combustibles 8

11. Flooring Requirements 8

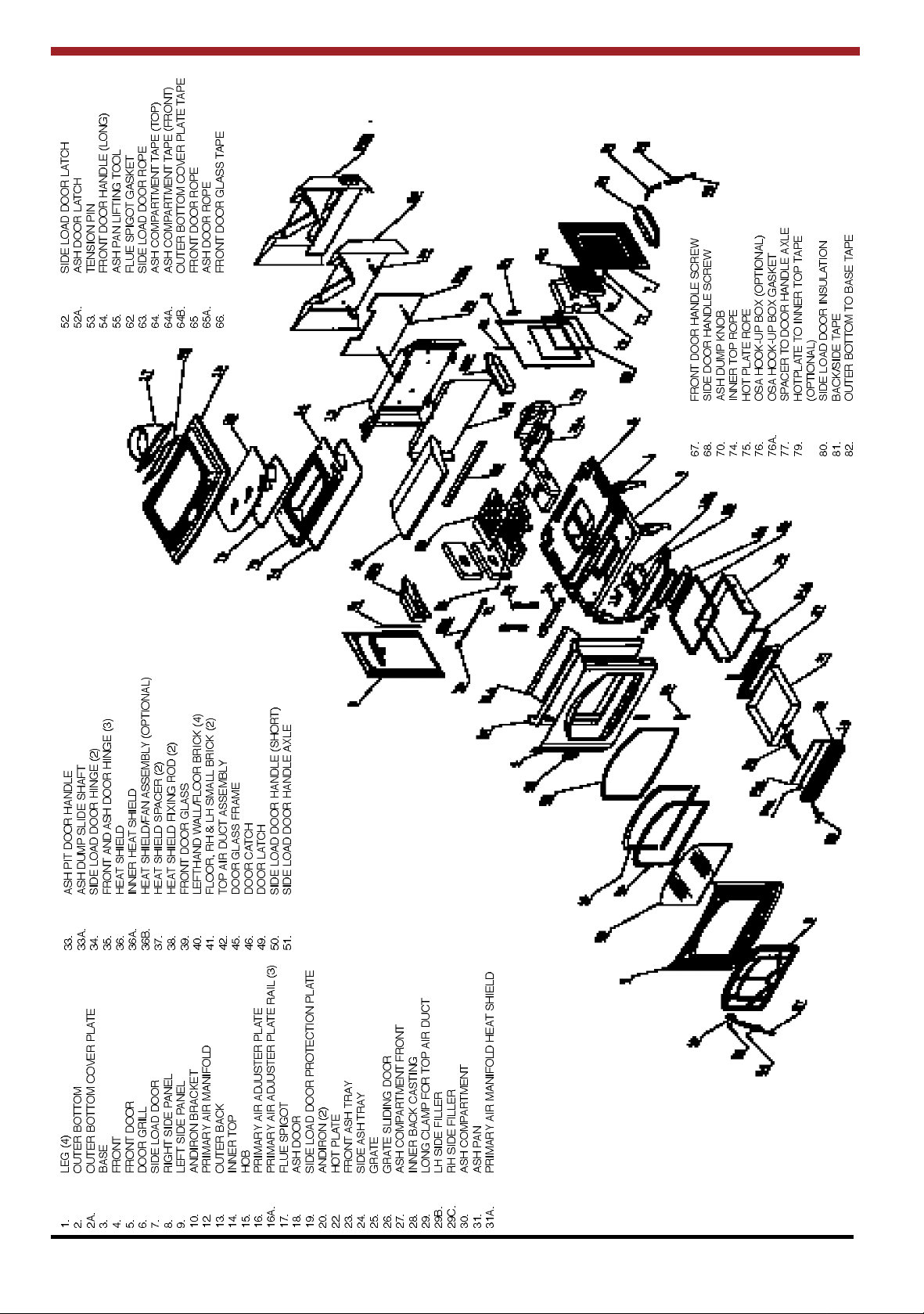

12. Exploded View 9

13. Reduced Clearances 10

14. Double Wall Connections 10

15. Wall Heat Shields 10

16. Chimney 11

17. Chimney Types - USA Only 11

18. Chimney Types - Canada Only 11

19. Chimney Connector 11

20. Connecting to Masonry Chimney 11

21. Masonry Fireplace 12

22. Ventilation & Combustion Air Requirements 13

23. Spillage Test 14

24. Primary Air Settings 14

25. Low Overnight Burn 14

26. Lighting 15

27. Important Notes 16

28. Maintenance 17

29. Disposal of Ashes 17

30. Creosote 17

31. Glass Replacement 17

32. Glass Cleaning 18

33. Vitreous Enamel Cleaning 18

34. Fire Safety 18

35. In the Event of a Chimney Fire 18

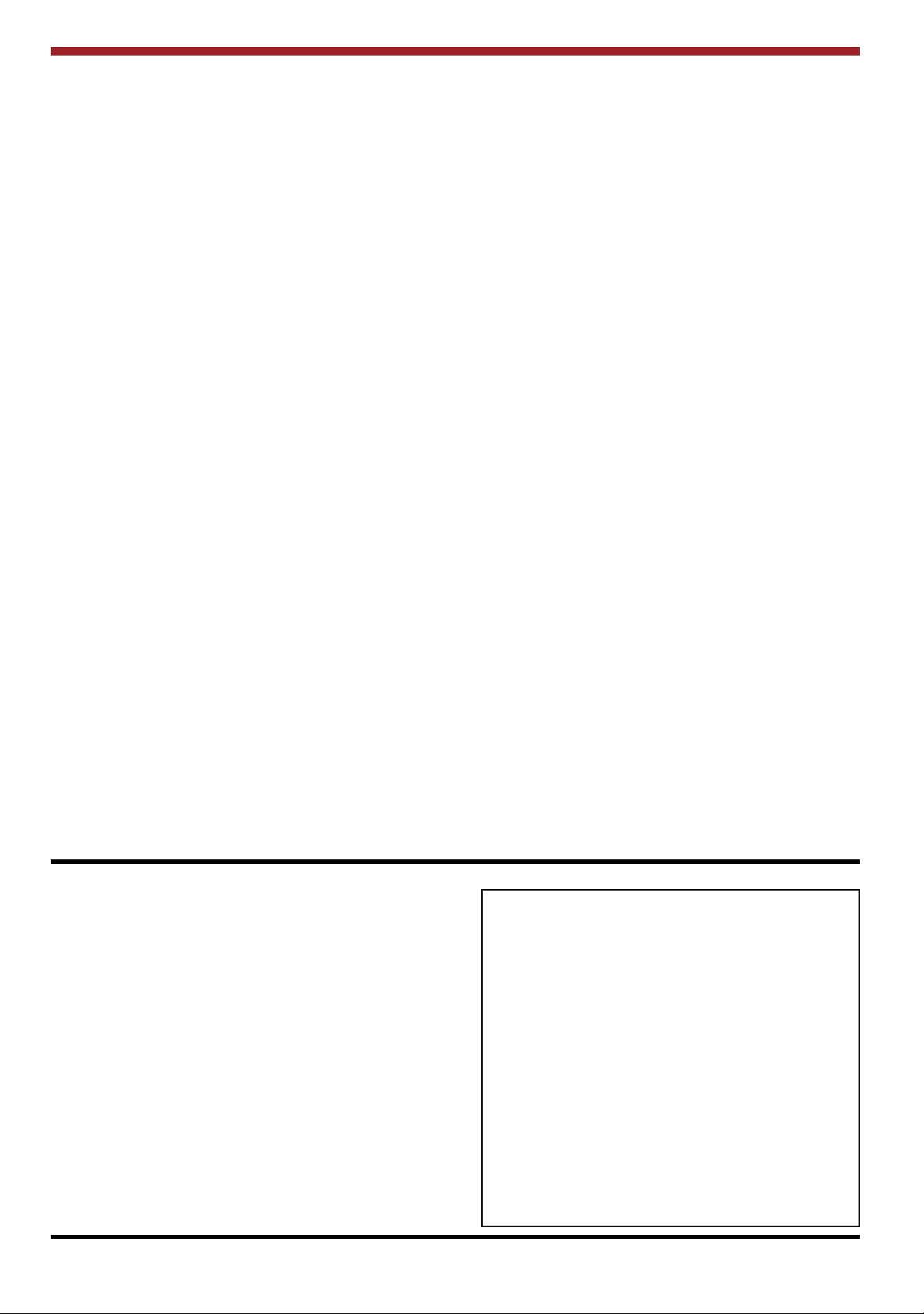

STOVE SPECIFICATIONS

The overall dimensions of the stove are as follows:

LENGTH: 614mm (24.17”)

WIDTH: 650mm (25.58”)

HEIGHT: 669mm (26

FLUE SPIGOT DIAMETER: 152mm (6”)

O.S.A. HOOK UP DIAMETER: 102mm (4”)

HOT PLATE DIMENSIONS: 444mm x 217mm

(17.48” x 8.94”)

HEIGHT TO CENTRE OF FLUE ON REAR

OUTLET CONFIGURATION: 565mm (22.24”)

HEIGHT TO CENTRE OF OSA HOOK UP

CONNECTOR: 109mm (4.25”)

WEIGHT: 432 lbs (196 kgs)

(See Fig.’s 1 through to 4)

1

/3”)

CAUTION:

THIS APPLIANCE IS HOT WHILE IN OPERATION AND RETAINS ITS HEAT FOR A LONG

PERIOD OF TIME AFTER USE. CHILDREN,

AGED OR INFIRM PERSONS SHOULD BE

SUPERVISED AT ALL TIMES AND SHOULD

NOT BE ALLOWED TO TOUCH THE HOT

WORKING SURFACES WHILE IN USE OR

UNTIL THE APPLIANCE HAS THOROUGHLY

COOLED.

DO NOT USE CHEMICALS OR FLUIDS TO

START OR “FRESHEN UP” THE FIRE.

DO NOT BURN GARBAGE OR FLAMMABLE

FLUIDS OR MANUFACTURED LOGS.

1

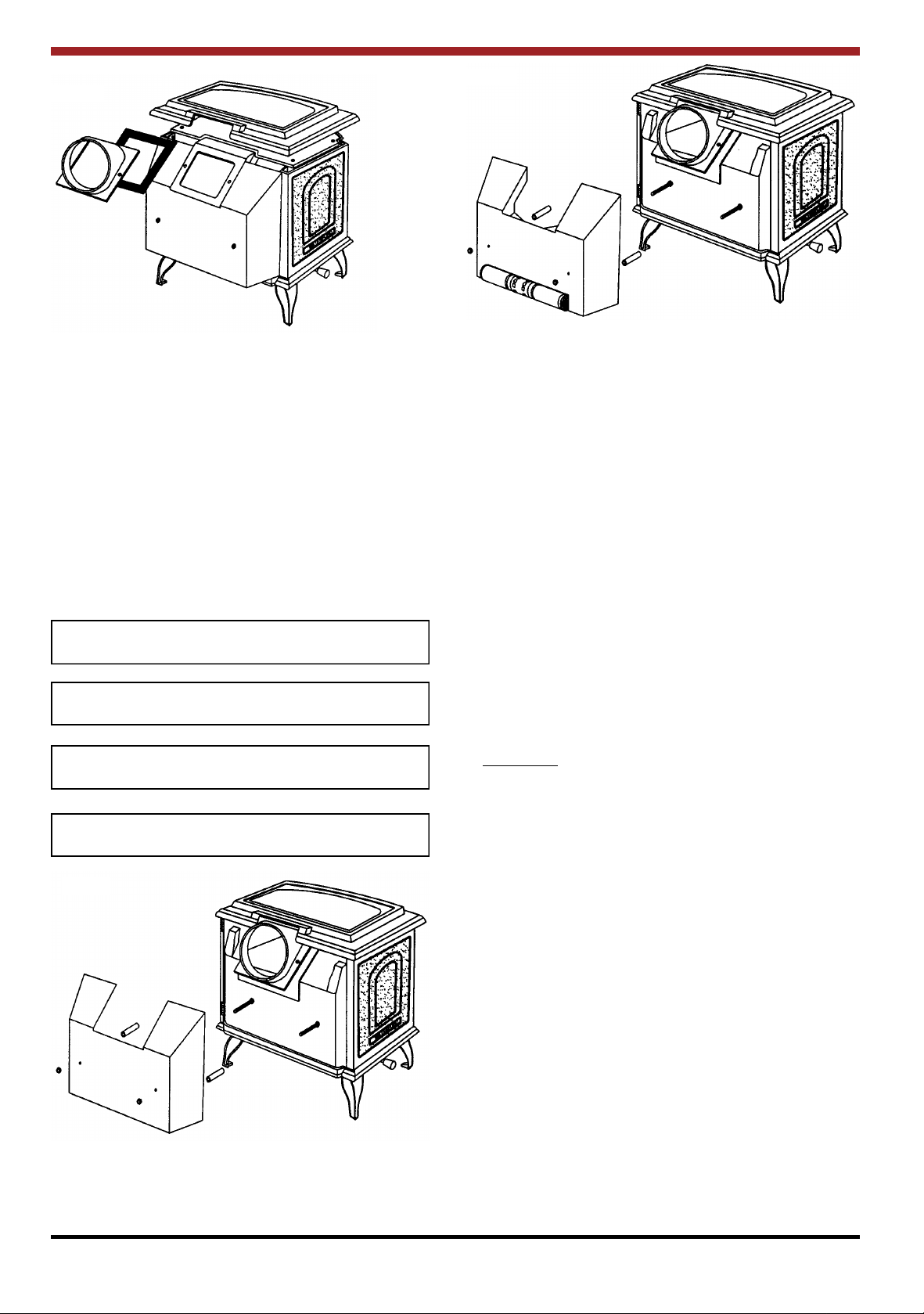

Fig.1

Fig.4

Fig.2

Fig.3

ASHLING WOODBURNING STOVE

INSTALLATION AND OPERATING

INSTRUCTIONS

GENERAL

The complete installation must be done in accordance with current Standards and Local Codes. It

should be noted that the requirements and these

publications may be superseded during the life of

this manual.

The Ashling Wood Stove has been independently

tested by Warnock Hersey in accordance with UL

1482 and ULC S627.

When installing, operating and maintaining your

Ashling Stove respect basic standards of fire safety. Read these instructions carefully before commencing the installation. Failure to do so may

result in damage to persons and property. Consult

your local Municipal office and your insurance representative to determine what regulations are in

force. Save these instructions for further reference.

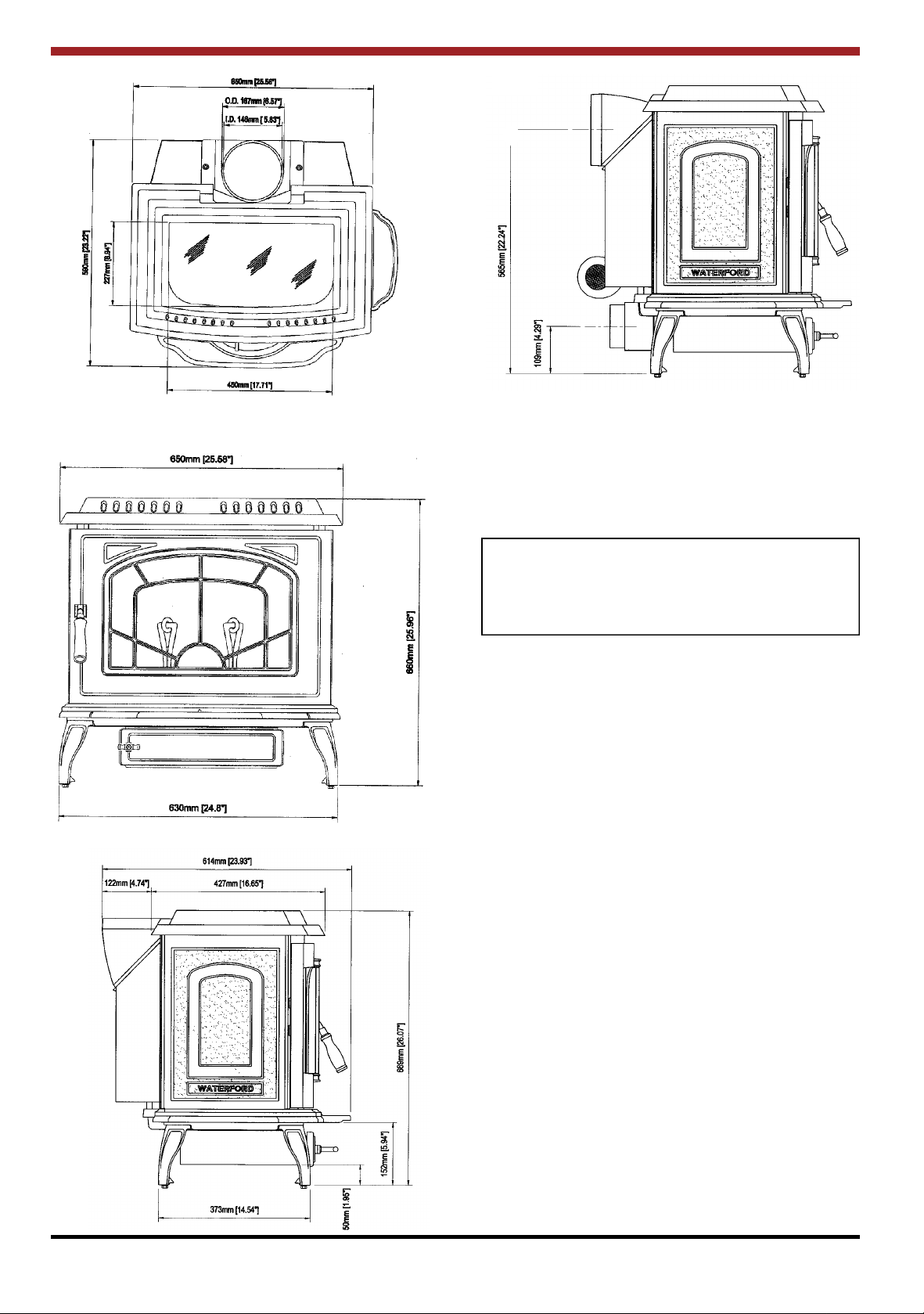

PRE-INSTALLATION ASSEMBLY

(a) After removing the stove from its packing,

open the ash door (item 18 in exploded

view) and remove the contents.

(b) Open the front door (item 5) and remove

the contents of the firebox, leaving the

bricks in place.

(c) Remove the front ashtray (item 23) from

the rear of the stove if you have not already

done so. Remove the loose fitting hob and

place on a non-abrasive surface.

2

Fig.5

Fig.8

(d) Place the plastic packing on the ground at

the left hand side of the stove.

NOTE: As the stove is very heavy take care when

laying the stove on its side on top of the packing.

Fig.6

(e) Remove the two

1

/4” (6mm) x 1/2” (12mm)

hex head bolts from the base (item 3) and

fit the front ashtray (item 23) using the two

hex head bolts. Stand the stove upright

taking care not to strain the leg bolts.

Fig.7

(g) If the side load door (item 7) is to be used,

fit the side ashtray (item 24) using the side

ashtray fixing plate (item 56) and screw

together using four

1

/4” (6mm) x 1/2”

(12mm) hex head bolts provided. Take out

the chrome locking bolt and fit door latch

(item 52), the side door handle axle (item

51) and the side door handle (item 50).

Fig.9

This stove can be connected to either a top or rear

exit by simply reversing the orientation of the flue

spigot (item 17) on the flue spigot flange.

For either the top or the rear exit option place the

ceramic gasket onto the flue spigot flange - located at the top of the back plate.

(f) Fit the front door handle (item 54) using

the front door handle screw (item 67) to

the front door (item 5).

Fig.10

3

Fig.11

Fig.13

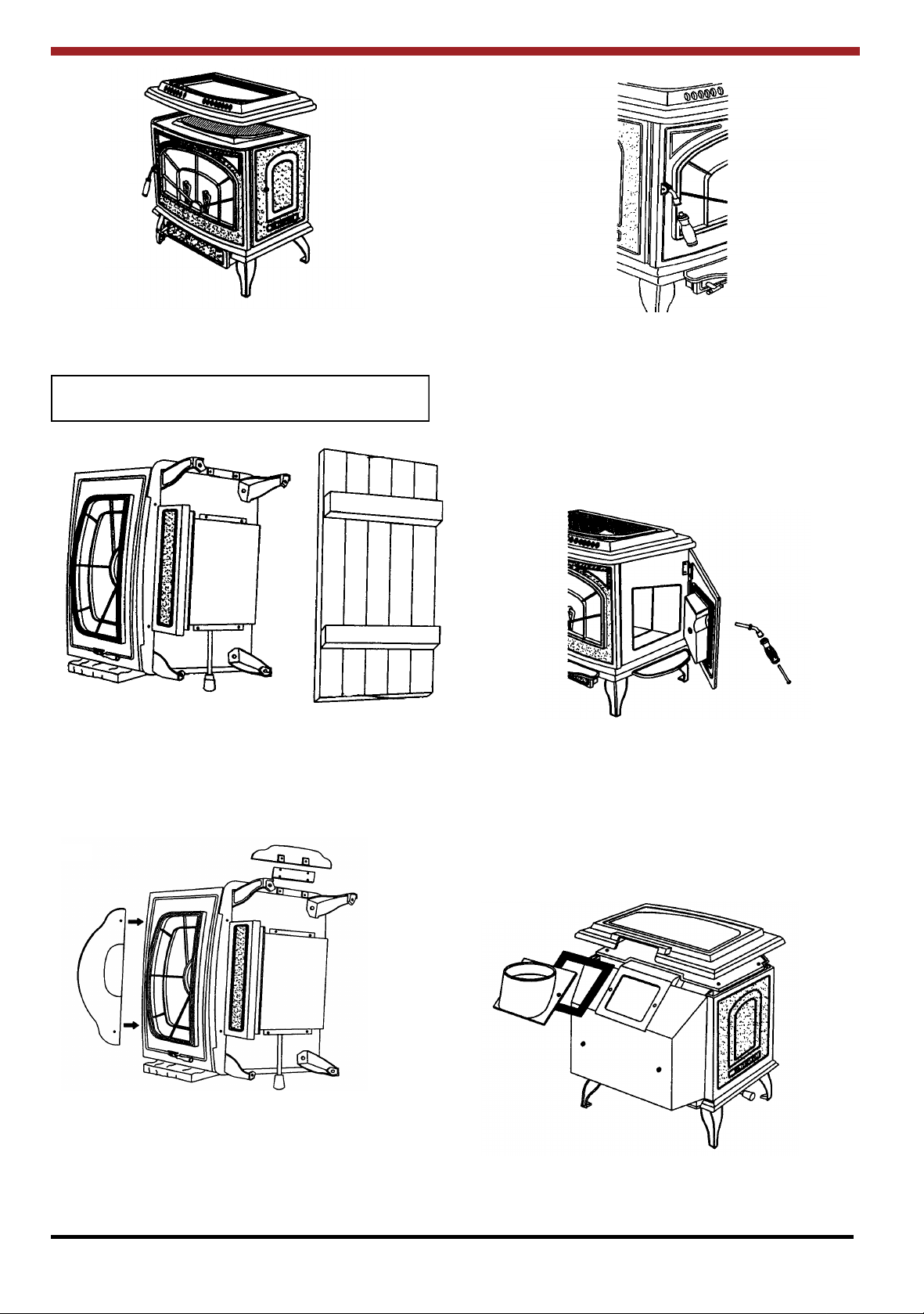

BLOWER

An Optional Blower is available for the Waterford

Ashling. The blower is factory assembled, wired

and ready for attachment to the stove.

This unit must be connected to a grounded, standard 110 volts, 60 Hz electrical outlet. Never route

the power cord under or in front of the unit.

Do not under any circumstances, cut or remove

the grounding prong from the power cord. Do not

use an adaptor plug.

NOTE: For more detailed information see instructions included with the Optional Blower.

CAUTION: Moving parts may cause injury. Do not

operate unit with blower housing removed.

D A N G E R: Risk of electric shock. Disconnect

power before servicing unit.

HOT PARTS: Do not operate unit with blower

housing removed.

Fig.12

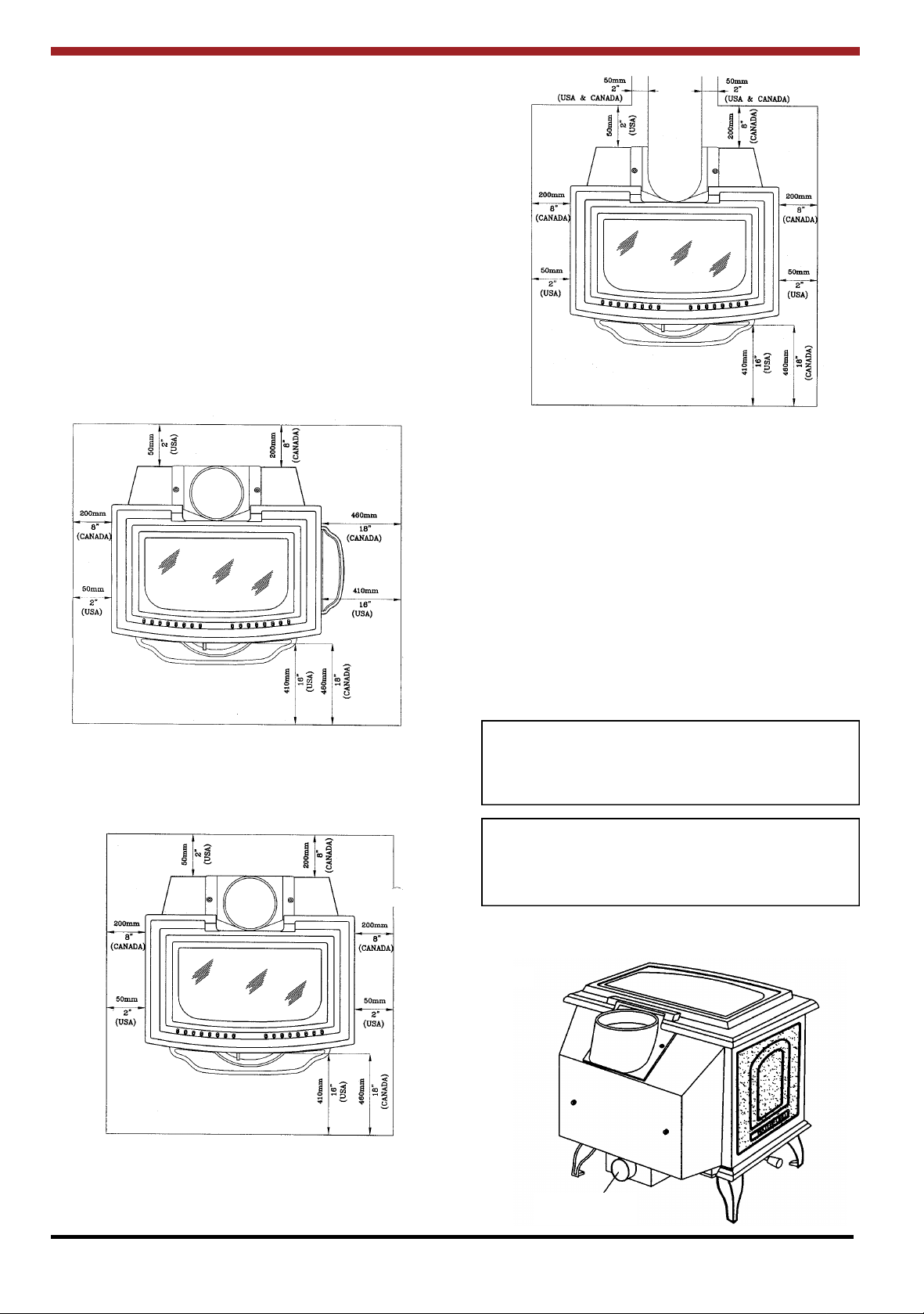

FLOOR PROTECTION

When installing this heater on a combustible floor,

a floor protector, is required. The floor protector is

to consist of a layer of non-combustible material

and cover the area under the heater and extend to

the sides and rear. It must also extend beneath a

horizontal chimney connector and 2” (50mm)

beyond each side. The area 16” (410mm) in front

of the fuel door(s) must have a thermal resistance

R value of 1.2.

Note: For use in Canada, the floor protector must

extend to at least 18” (460mm) in front of the fuel

door(s) and to at least 8” (200mm) from the sides

and rear of the stove.

If alternative materials are used the following

equations and information shall be used to calculate the alternative material thickness required:

Example:

The specified floor protector should be

3

/4” (18mm)

thick material with a K - factor of 0.84.

The proposed alternative is 4” (100mm) brick with

a C-factor of 1.25 over

1

/8” (3mm) mineral board

with a K-factor of 0.29.

Step (a): Use formula above to convert

specification to R-value.

R = 1/k x T = 1/0.84 x .75 = 0.893.

Step (b): Calculate R of proposed system.

4” brick of C = 1.25, therefore

Rbrick = 1/C = 1/1.25 = 0.80

1

/8” mineral board of k = 0.29,

therefore Rmin.bd. = 1/0.29 x 0.125

= 0.431.

Total R = Rbrick + Rmineral board =

0.8 ÷ 0.431 = 1.231.

Step (c): Compare proposed system R of

1.231 to specified R of 0.893.

Since proposed system R is

greater than required, the system is

acceptable.

4

Definitions:

Thermal Conductance =

C = Btu = W

Thermal Conductivity =

k = (Btu)(inch) = W = Btu

Thermal Resistance =

R = (ft2)(hr)(oF) = (m2)(K)

Fig.14

Fig.16

(hr)(ft2)(oF) (m2)(K)

(hr)(ft3)(oF) (m)(K) (hr)(ft)(oF)

Btu W

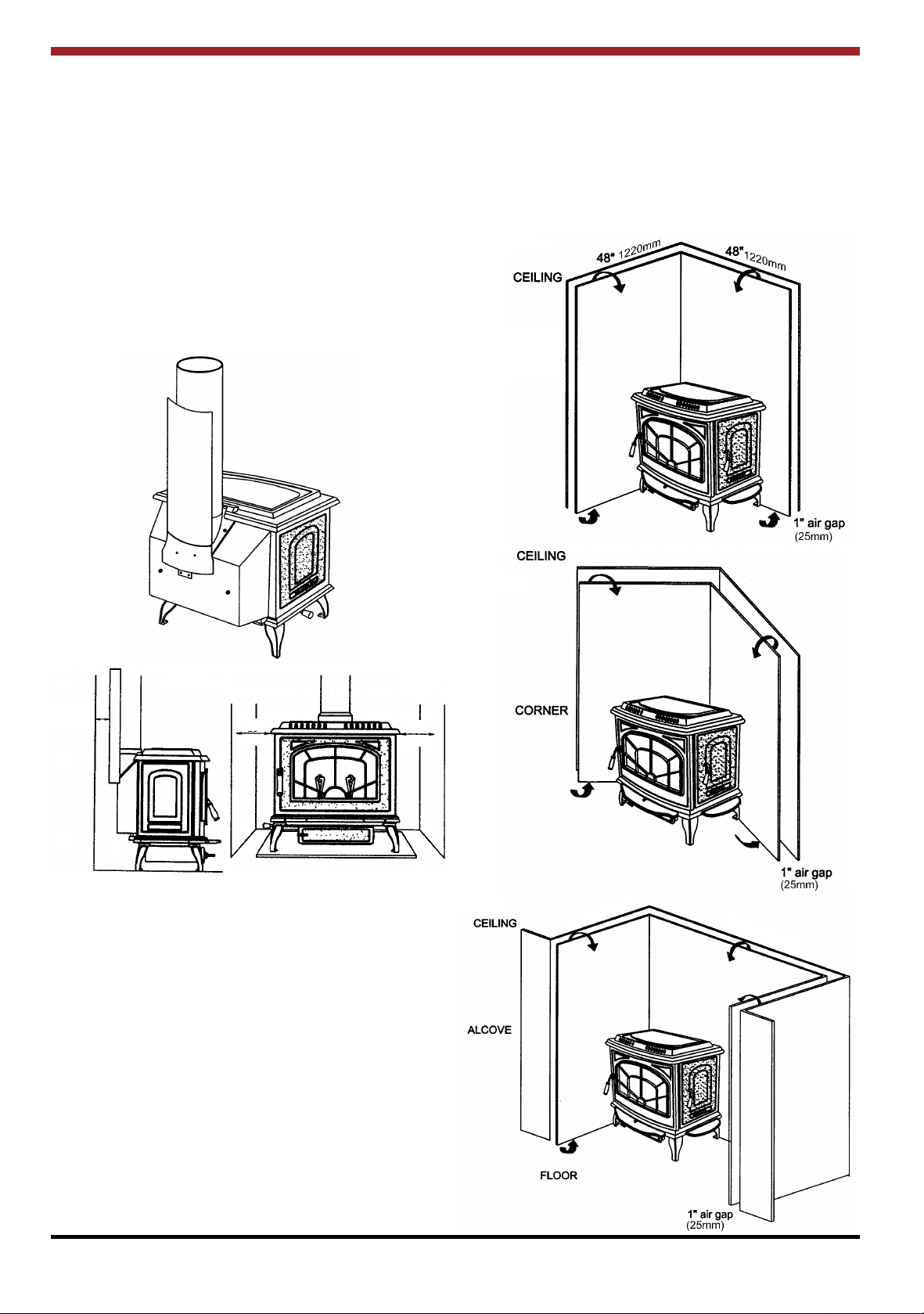

LOCATION

There are several conditions to be considered

when selecting a location for your Ashling Wood

Stove.

(a) Distance from a safe chimney.

(b) Position within the area to be heated - cen-

tral locations are usually best.

(c) Allowances for proper clearances to

combustibles.

(d) Obstruction in the ceiling, upper floor or

roof, for example, ducting, plumbing, electrical fittings and wiring, overhead fixed furnishings etc.

** If the side door is to be used the floor protector

must extend at least 16” from this side.

Fig.15

WARNING:

DO NOT OBSTRUCT FREE AIR SUPPLY TO

THE AIR INLET DUCT LOCATED AT THE BACK

OF THE STOVE.

IMPORTANT: DO NOT CONNECT TO OR USE

IN CONJUNCTION WITH ANY AIR DISTRIBUTION DUCT WORK UNLESS SPECIFICALLY

APPROVED FOR SUCH INSTALLATIONS.

OUTSIDE AIR CONNECTION

Fig.17

Air Inlet Duct

5

If desired, the air for combustion may be drawn

directly from the outside of the house, as detailed

below. It is not obligatory to do this, but it may help

combustion in small or poorly ventilated house.

Connect a 4” (100mm) diameter stainless steel, or

other non-combustible corrosion resistant material, to the O.S.A hook-up box (item 76). In order to

do this the O.S.A. hook-up box (item 76) must be

connected to the base (item 2) using

1

/4” x 2 1/4”

hex head bolts.

Run the pipe (up to 54” (1370mm) long) to the out-

side avoiding sharp bends and joints within cavity

walls. Turn the end down and fit corrosion resistant mesh to prevent the entry of leaves and

rodents. (See Fig.18). Seal the penetration of the

outside wall with silicon.

Fig.18

6. The chimney shall be attached directly to

the room heater and shall extend at least

3ft. (914mm) above the part of the roof

through which it passes. The top of the

chimney should project at least 2ft.

(610mm) above the highest elevation of

any part of the Mobile Home within 10ft.

(3048mm) of the chimney.

7. The chimney system shall comply with

Local Requirements (see page 7).

8. Any openings in a chimney guard where

required must not permit the entrance of

3

/4” (19mm) diameter rod.

9. CAUTION: THE STRUCTURAL INTEGRITY OF THE MOBILE HOME ROOF,

FLOOR WALLS AND CEILING MUST BE

MAINTAINED.

10. Check any other local building code as

other local codes may apply.

11. WARNING: DO NOT INSTALL IN A

SLEEPING ROOM OF A MOBILE HOME.

CAUTION: Do not obstruct combustion air

opening.

Seal

Air Duct

Wire Mesh

MOBILE HOME INSTALLATION

In addition to standard installation instructions the

following requirements are mandatory for installation in a mobile home.

1. The stove must be permanently bolted to

the floor of the Mobile Home using the floor

screws provided.

2. The stove must have a permanent outside

air source for combustion.

3. The stove must be electrically grounded to

the steel chassis of the Mobile Home.

4. A listed chimney system, roof thimble, spark

arrestor and roof flashing kit suitable for use in

Mobile Homes must be used.

5. If the chimney exits the Mobile Home at a

location other than through the roof, and

exits at a point 7ft. (2130mm) or less above

the ground level on which the Mobile Home

is positioned a guard or method of enclosing

the chimney shall be fitted at the point of exit

for a height up to 7ft. (2130mm)

Note: Listed factory built chimney connectors

including elbows are acceptable for use in Mobile

Home Installations.

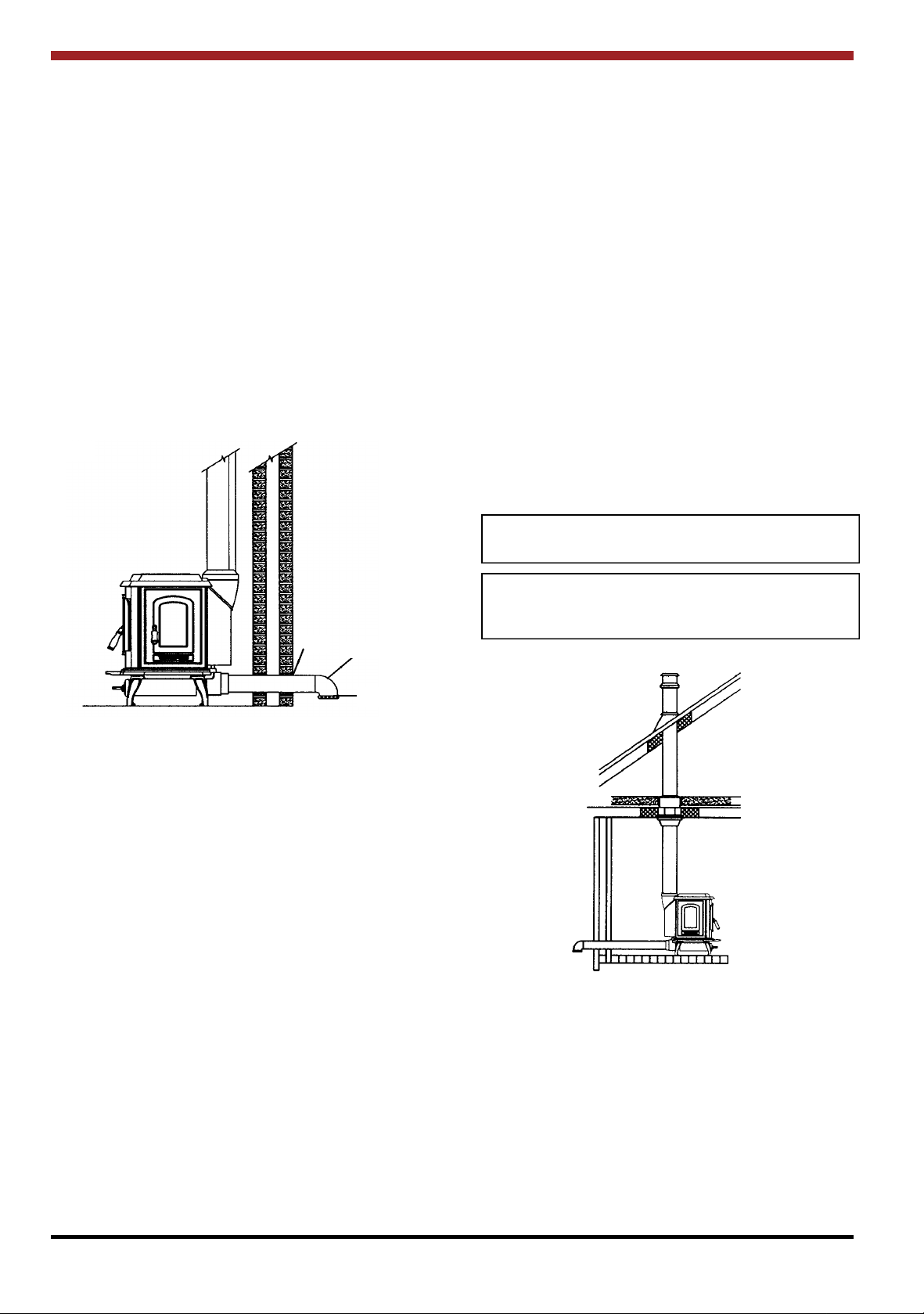

Fig.19

6

MINIMUM CLEARANCES TO COMBUSTIBLE

MATERIALS

Fig.20

Without Side Load Door

Fig.21

From the front of the stove 36” (915mm)

From the side of the stove 16” (406mm)

From wall when installed at 45

o

across a corner 12” (305mm)

From back of stove 12” (305mm)

From back of stove horizontal

installation only 6” (150mm)

If the side door is to be used the clearance at

this side must be increased to 36” (915mm)

Mantle clearance 24” (610mm)

Top Trim Clearance 14” (335mm)

Side Trim Clearance 7” (178mm)

Vertical single wall flue pipe 12” (305mm)

This stove may be installed in an alcove measuring

at least 60” (1525mm) high x 58” (1475mm) wide

and no greater than 48” (1220mm) deep (See Fig.

22)

16” 16”

(405mm) (405mm)

Fig.22

Fig.23

With Side Load Door

(406mm)

Fig.24

36”16”

(915mm)

150mm

6”

12” (305mm)

Fig.25

(305mm)

12”

Fig.26

12”

24”

(305mm)

610mm

7” 7”

Fig.27

58”

(1475mm)

7

ADDITIONAL CLEARANCES TO COMBUSTIBLES

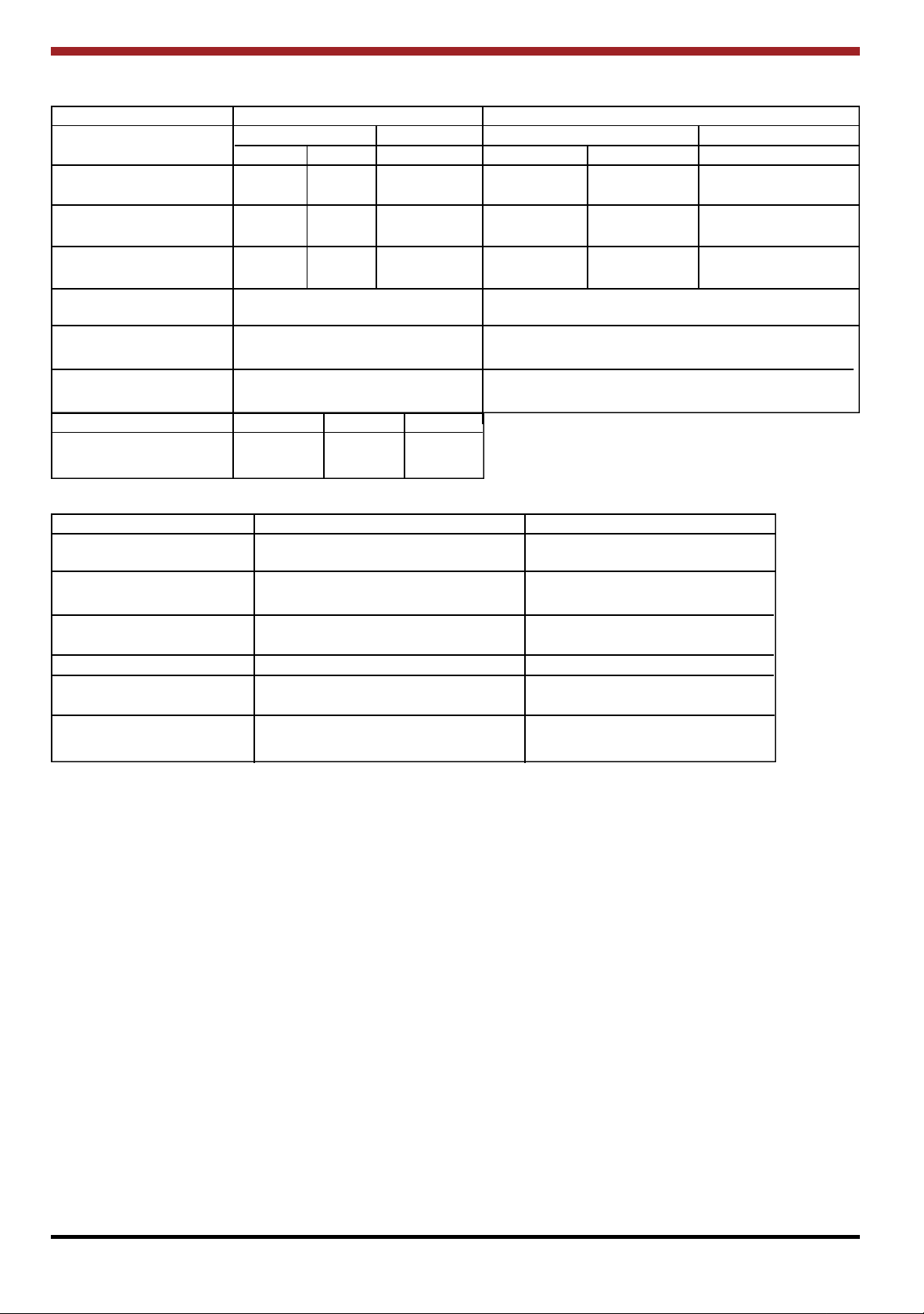

Appliance Clearances Unprotected Surfaces Protected Surfaces (NFPA - 211)

Parallel Corner Parallel Corner

Side Rear Side Rear

No Heat Shields 16-in 12-in 12-in 7-in 6-in 6-in

405-mm 305-mm 305-mm 180-mm 150-mm 150-mm

Flue Collar and 14-in 6-in 10-in 7-in 6-in 6-in

Connector Shield 355-mm 150-mm 255-mm 180-mm 150-mm 150-mm

Double Wall Connector 14-in 6-in 10-in 7-in 6-in 6-in

355-mm 150-mm 255-mm 180-mm 150-mm 150-mm

Minimum alcove 58-in 40-in

Width 1475-mm 1015-mm

Maximum alcove 48-in 48-in

Width 1220-mm 1220-mm

Alcove Ceiling Above 34-in 12-in

Stove top 865-mm 305-mm

Hearth Mount Side Trim Top Trim Mantle

7-in 14-in 24-in

180-mm 355-mm 610-mm

Chimney Connector Unprotected Surfaces (vert) Protected Surfaces (vert).

No heat shields 12-in 6-in

305-mm 150-mm

Using Connector Shield 6-in 6-in

150-mm 150-mm

Double Wall Connector 6-in 6-in

150-mm 150-mm

Unprotected Surfaces (horiz.) Protected Surfaces (horiz.)

Single Wall Connector 18-in 12-in

460-mm 305-mm

Double Wall Connector 6-in 6-in

150-mm 150-mm

FLOORING REQUIREMENTS

The unit must be placed on non-combustible material extending 2-in (50mm) beyond each side, 2-in (50mm)

beyond the rear, and 2-in (50mm) beyond each side of the chimney connector. If the optional side fuelling

door is used, the floor protection must extend 16-in (410mm) beyond the door. Combustible flooring 16-in

(410mm) beyond the front and 8-in (200mm) beyond each side of the front fuel opening must be protected

by either a listed non-combustible insulative floor protector or a field installed non-combustible insulative floor

protection with an R value of at least 1.2.

For use in Canada, the non-combustible floor protection must be extended to 18-in (460mm) beyond the fire

door(s) and 8-in (200mm) beyond the sides and rear of the stove.

8

9

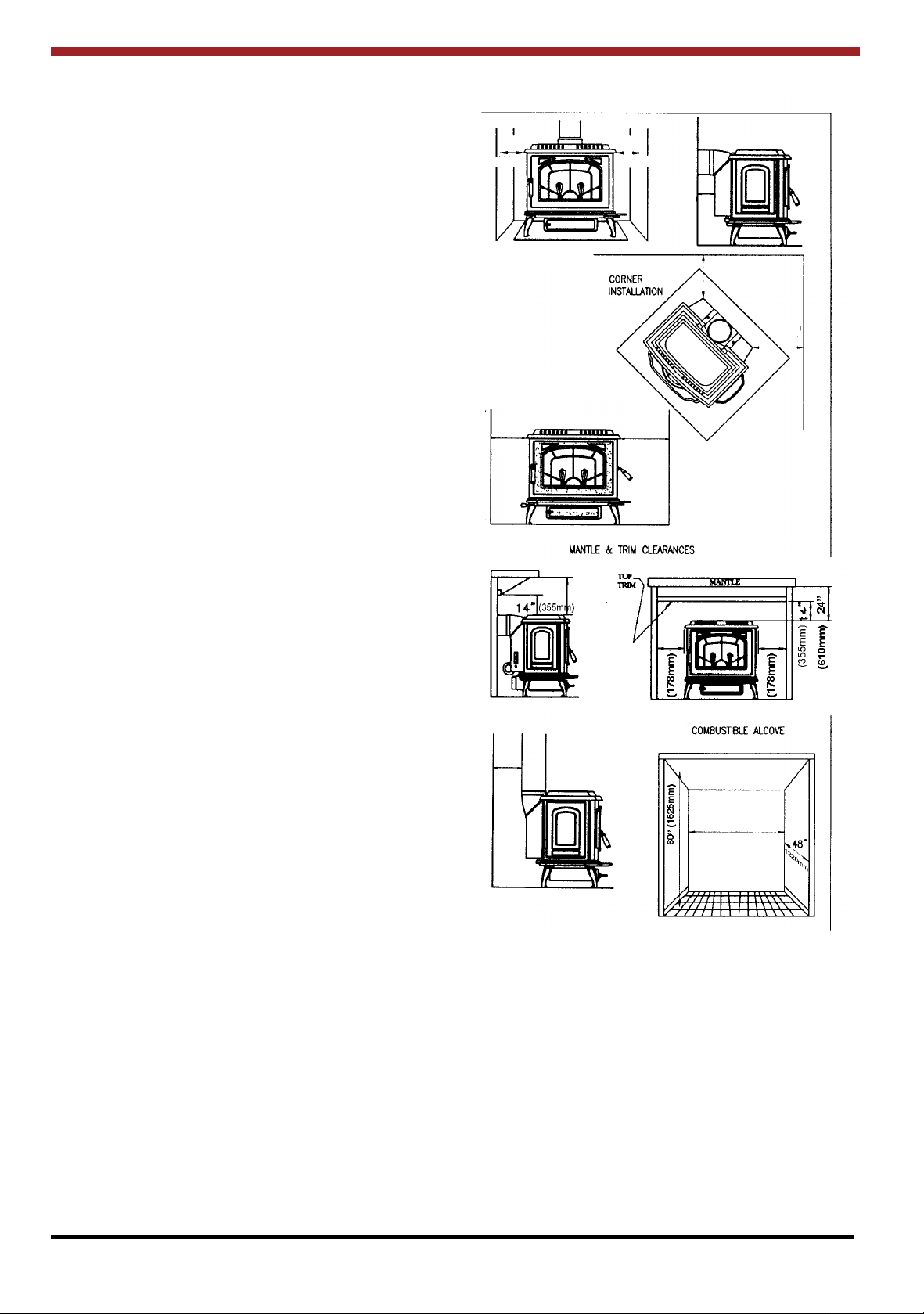

REDUCED CLEARANCES

Under certain conditions the minimum clearances

may be reduced by means of:

(a) The use of Listed pipe shields, installed in

accordance with the manufacturer’s

instructions.

(b) Shields constructed in accordance with NFPA

211 (USA), CAN3-B365 (CANADA) installation

codes.

(c) When listed pipe shields are used - top exit

option only - the clearances may be reduced

to 6” (150mm) from the pipe shield and 8”

(225mm) from stove back.

Fig.28

All clearances must be measured from the outer

surface of the combustible material to the nearest

point on the surface of the stove disregarding any

intervening protection applied to the combustible

material.

Listed Heat Shields must be installed in accordance with the manufacturer’s instructions.

Fig.31

Parallel side

and back

wall to stove

150mm

Fig.29

6”

7”

178mm

Fig.30

7”

178mm

DOUBLE WALL CONNECTIONS

Double wall chimney connectors may be substituted for the shielded pipe provided it is UL/ULC listed for a 9” (225mm) clearance or less.

WALL HEAT SHIELDS/PROTECTORS

Fig.32

Fig.33

Shields intended to reduce clearance to combustibles must be installed in accordance with the

appropriate codes.

To allow for the circulation of cooling air leave a

space of at least 1” (25mm) between the wall and

the shield. Leave a gap of at least 1” (25mm)

between the top of the shield and the ceiling and

between the bottom of the shield and the floor.

10

CHIMNEY

CHIMNEY CONNECTOR

The Ashling is a radiant room heater and must be

connected to a chimney of the proper size and

type capable of providing an adequate continuous

draught of 0.04” wg - 0.06” wg. A 6” diameter

Factory Built Chimney is ideal. Connection to a

larger size may result in somewhat less draught.

DO NOT CONNECT TO A CHIMNEY SERVING

ANOTHER APPLIANCE.

Minimum chimney height is 15 feet from floor on

which stove is installed. An existing masonry

chimney should be inspected and, if necessary,

repaired by a competent mason or relined using an

approved relining system. The stove must be connected to a chimney with a continuous draught of

0.04” wg - 0.06”wg. Poor draught conditions will

result in poor performance.

Excessive draught can cause overfiring. If any

components start to glow red, the stove is operating in an overfiring condition and the primary air

needs to be reduced to eliminate the overfiring as

overfiring voids the warranty. Warped components

are indicative of overfiring and will not be covered

under warranty.

The chimney connector (smoke pipe) is used to

connect the Ashling Stove to the chimney

described above. The chimney connector must be

made of Corrosion Resistant Steel, 24 gauge or

heavier (black or equivalently treated steel). Be

sure to fasten the chimney connectors together

and also to the flue outlet of the stove through the

two holes provided. Use at least two screws for

each joint/connection. Be sure that the joints are

tight and fully sealed.

A chimney connector shall not pass through an

attic or roof space, closet or similar concealed

space, floor or ceiling.

Where passage through a wall or partition of combustible construction is desired, the installation

shall conform to NFPA 211 or CAN/CSA - B365.

The connector should maintain a pitch or rise of at

1

least

/4” per foot from the stove to the chimney. It

should be installed so as to avoid sharp turns or

other combustion features that would create

excessive resistance to the flow of flue gases. It

should be securely supported. The entire length of

a connector should be readily accessible for

inspection, cleaning and replacement.

The use of a surface mounted thermometer is

recommended to monitor the hotplate centre temperature. If the hotplate exceeds 900oF the stove

is overfiring.

Note: The fitting of a flue damper can help reduce

the draught in chimneys with excessive draught.

CHIMNEY TYPES: USA ONLY

The stove must be connected to a UL 103 Listed

HT Type Factory Built Chimney for Residential

Type and Building Heating Appliances, installed in

accordance with the manufacturer’s instructions or

a masonry chimney constructed in accordance

with NFPA 211 Chimney Vents and Solid Fuel

Burning Appliances.

CHIMNEY TYPES: CANADA ONLY

The stove must be connected to an Underwriters

Laboratories of Canada Labelled factory built

650oC chimney, installed in accordance with the

manufacturer’s instructions or to a lined masonry

chimney acceptable to the authority having jurisdiction.

CONNECTING TO MASONRY CHIMNEY

The connector may pass through walls or partitions constructed of combustible material to a

masonry chimney provided the connector system

selected is installed in accordance with the proper

clearances and conditions. The thimble (breach

pipe) must extend to, but not beyond the inner face

of the masonry chimney liner and be firmly

cemented in place. A fire clay liner (ASTM C315

or equivalent) or stainless steel, at least 24 gauge

may be used.

The following methods may be employed:

Method 1:

Minimum 3

1

/2” (90mm) thick brick masonry wall

framed into combustible wall with a min. of 12”

(300mm) brick separation from clay liner to combustibles.

Method 2:

Solid insulated Listed factory-built chimney length

of the same inside diameter as the chimney connector and having 1” (25mm) or more of insulation

with a min. 9” (228mm) air space between the

outer wall of the chimney length and combustibles.

The inner end of the chimney length shall be flush

11

Loading...

Loading...