IMPORTANT:

This booklet should be left with the user after

installation and demonstration.

Installation and User Guide

EXPRESSIONS REVIVE and

EXPRESSIONS REVIVE-PLUS

SMARTFIT 2 ELECTRIC SHOWERS

2

THIS APPLIANCE CAN BE USED BY CHILDREN AGED FROM 8 YEARS AND

ABOVE AND PERSONS WITH REDUCED PHYSICAL, SENSORY OR MENTAL

CAPABILITIES, OR LACK OF EXPERIENCE AND KNOWLEDGE IF THEY

HAVE BEEN GIVEN SUPERVISION OR INSTRUCTION CONCERNING USE OF

THE APPLIANCE IN A SAFE WAY AND UNDERSTAND THE HAZARDS

INVOLVED.

CHILDREN SHALL NOT PLAY WITH THE APPLIANCE.

CLEANING AND USER MAINTENANCE SHALL NOT BE MADE BY CHILDREN

YOU MUST DESCALE THE SHOWER HANDSET REGULARLY.

DO NOT SWITCH THE APPLIANCE ON IF YOU SUSPECT THE APPLIANCE

OF BEING FROZEN. WAIT UNTIL YOU ARE SURE IT HAS THAWED OUT.

Your shower has been designed for convenience, economy and safety of use, provided that it is

installed, used and maintained in good working order and in accordance with our instructions and

recommendations.

ALL WIRING AND INSTALLATION MUST BE SUPERVISED BY A SUITABLY

QUALIFIED PERSON.

THIS APPLIANCE MUST BE EARTHED.

The installation must be in accordance with the current edition of BS.7671 (

the ‘IET Wiring

Regulations’)

and ‘Part P’ of the ‘

Building Regulations’

in force at the time of installation.

Installations outside England and Wales must also conform to any local regulations in effect

This appliance is intended to be permanently connected to the fixed electrical wiring of the mains

supply with its own dedicated supply.

This appliance must

NOT

be fitted where it may be subjected to freezing conditions.

DO NOT

switch the appliance on if you suspect it of being frozen.

Wait until you are sure it has thawed out.

This appliance is not suitable for mounting into steam rooms or steam cubicles.

Isolate the mains electrical and water supply before removing the appliance front cover.

DO NOT

fit any sort of tap or control on the appliance outlet.

The appliance is designed to have an open outlet and should only be used with the Manufacturer’s

recommended fittings.

THIS SHOWER IS APPROVED (EN-60335) WITH THE HANDSET PROVIDED

AND UNDER NO CIRCUMSTANCES MUST ANY HANDSET THAT IS NOT

APPROVED BY THE MANUFACTURER BE USED WITH THIS PRODUCT.

YOU MUST REGULARLY INSPECT THE HANDSET FOR WEAR AND

DAMAGE AND REPLACE IF NECESSARY, WITH OUR APPROVED PART.

Take care to avoid restricting the outlet of the pressure relief device (fig.19).

If water is discharged from the pressure relief device, maintenance will be required before the

appliance can be safely used.

We

DO NOT

recommend this appliance be used in heavy or unsupervised commercial

applications.

IMPORTANT SAFETY INFORMATION

3

The following points will help you have a greater understanding of how your shower works:

The heating elements operate at a constant rate, dependent on your chosen power setting.

The water temperature is achieved by adjusting the rate of water flow.

The higher the water flow the lower the temperature and vice versa.

The temperature of the water supplied from the mains can vary considerably throughout the year

from 5 to 20°C.

This means that in the winter, flow rate will be less than in the summer to achieve the same outlet

temperature.

In summer the ‘ECO’ power setting may give adequate hot water.

Your shower is designed to stabilise temperature changes caused by water pressure

fluctuations.

These can result from toilets being flushed or taps being turned on and off.

When this happens your showering temperature will be held within a controlled band, provided

that the minimum pressure required by the shower is maintained (see ‘plumbing’ page.5).

If the water pressure falls below the minimum pressure required, it is likely that the pressure

switch will turn off the power to the heating elements, resulting in a cold shower.

WARNING:

ALL WIRING AND INSTALLATION MUST BE SUPERVISED BY A SUITABLY

QUALIFIED PERSON.

DO NOT INSTALL THIS SHOWER WHERE IT MAY BE SUBJECTED TO

FREEZING CONDITIONS.

1

ADVICE TO USERS

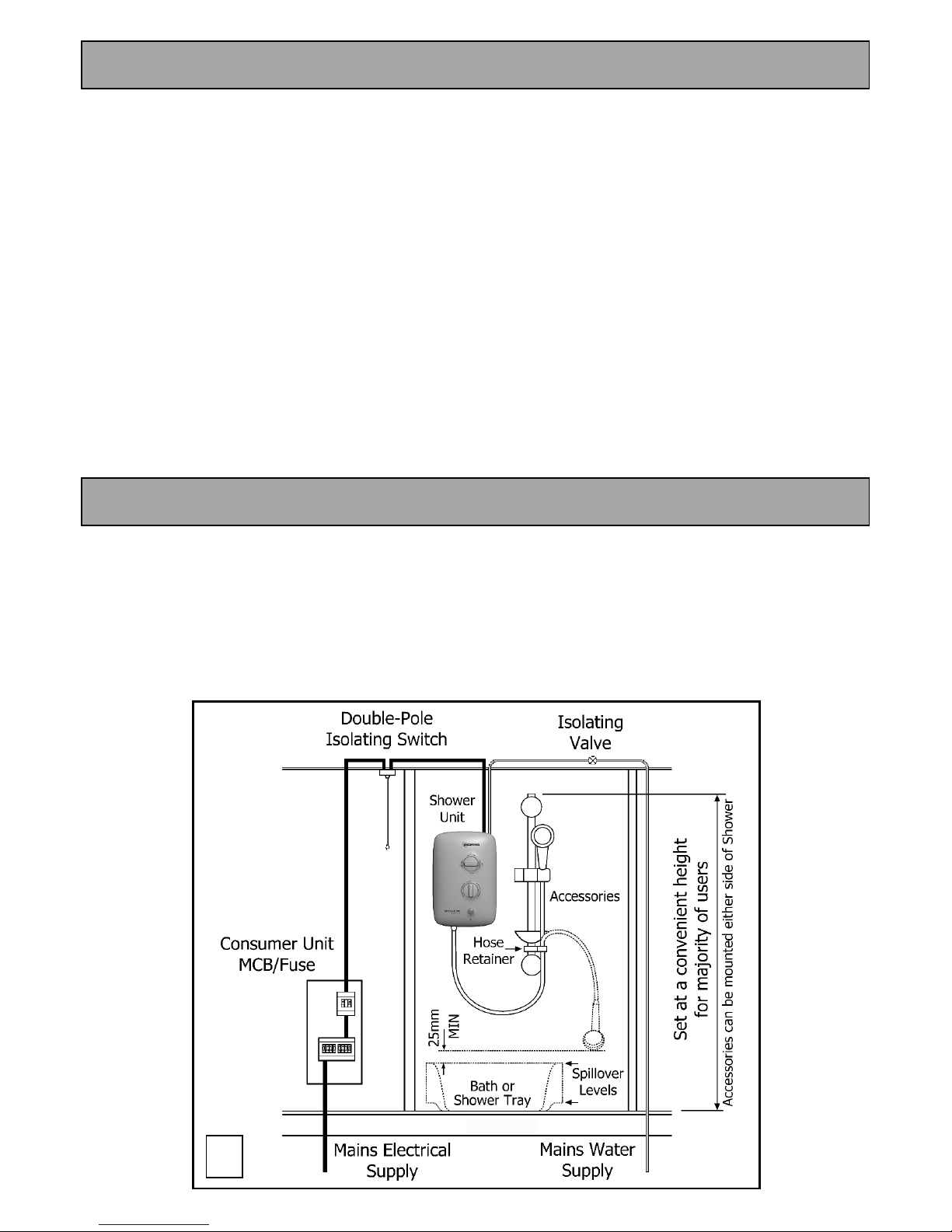

HOW TO INSTALL YOUR SHOWER

4

We recommend that the installation is done in the following sequence.

a. Fixing the shower to the wall (see note below) b. Plumbing c. Electrical connections

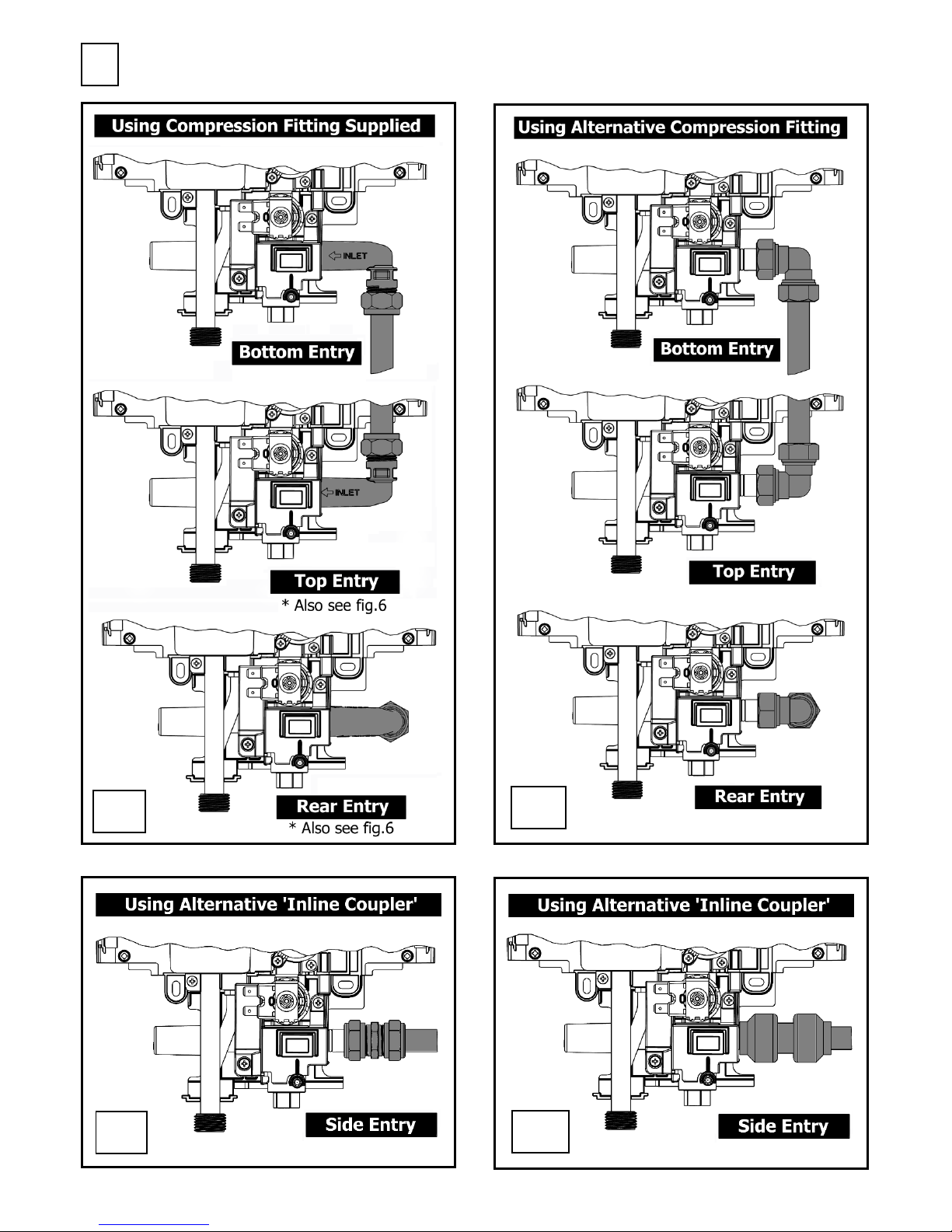

However, we recommend you determine the best configuration for your water inlet

options before fixing the shower to the wall, as it may be easier to adjust/fit connections

whilst unit is still ‘in-hand’.

a. FIXING THE SHOWER TO THE WALL

1. Position the riser rail at a convenient height for majority of users (fig.1) and mark its position

(see fig.12 for accessory details).

2. Position the shower unit so that the showerhead cannot be immersed in the bath or shower tray

when hanging down.

Choose a flat piece of wall to avoid the possibility of distorting the backplate thus making the

front cover a poor fit.

3. Adjust the position to get the most convenient arrangement taking the following into account.

DO NOT MOUNT THE UNIT IN THE DIRECT HANDSET SPRAY.

The handset must not be able to come into contact with used water in the cubicle,

bath or basin.

If it can, even after the hose has been retained by hose-retainer (fig.12), a vacuum breaker

must be fitted.

4. Fix the riser rail with screws provided (fig.12)

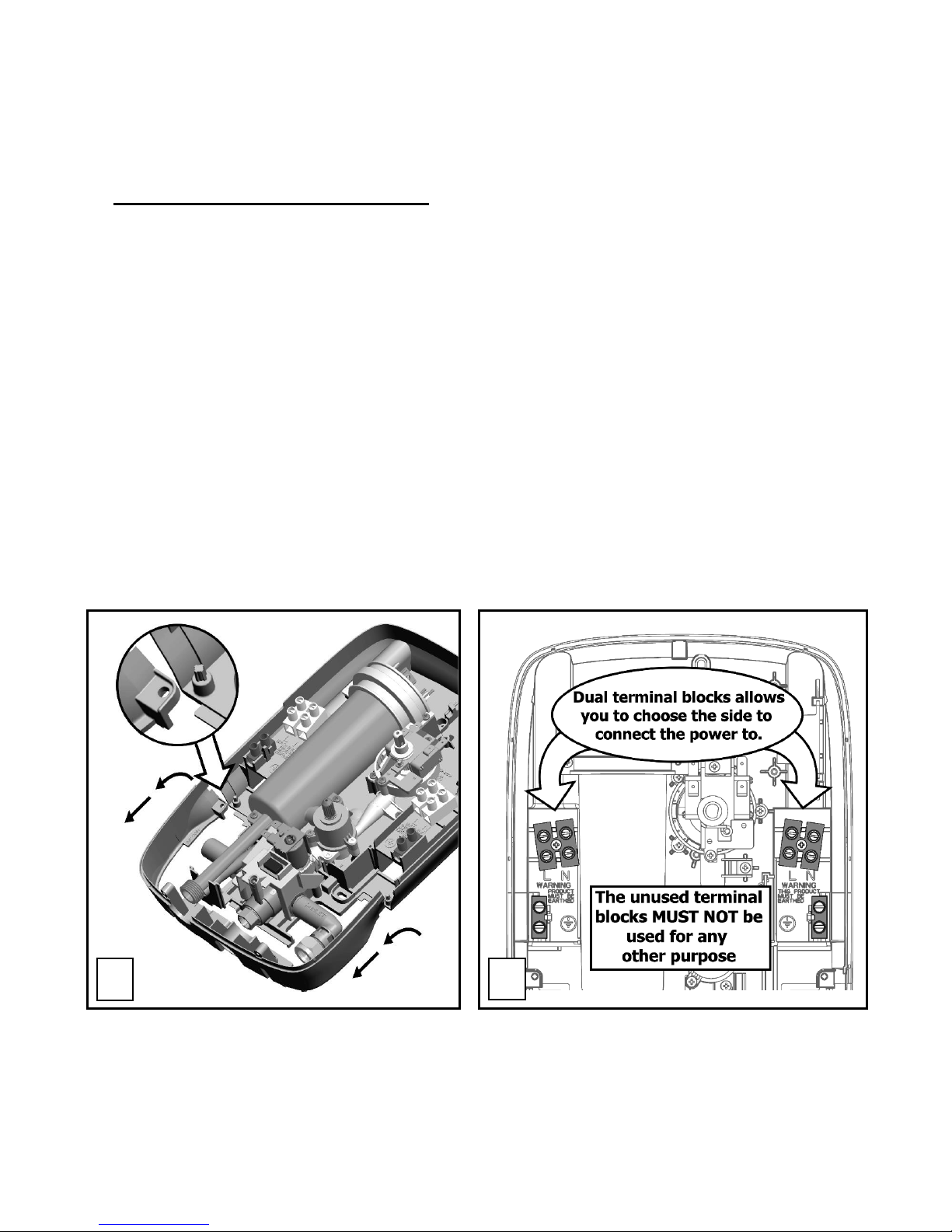

5. Remove the front cover by undoing the retaining screws at the top and bottom of the unit and

lifting the cover off.

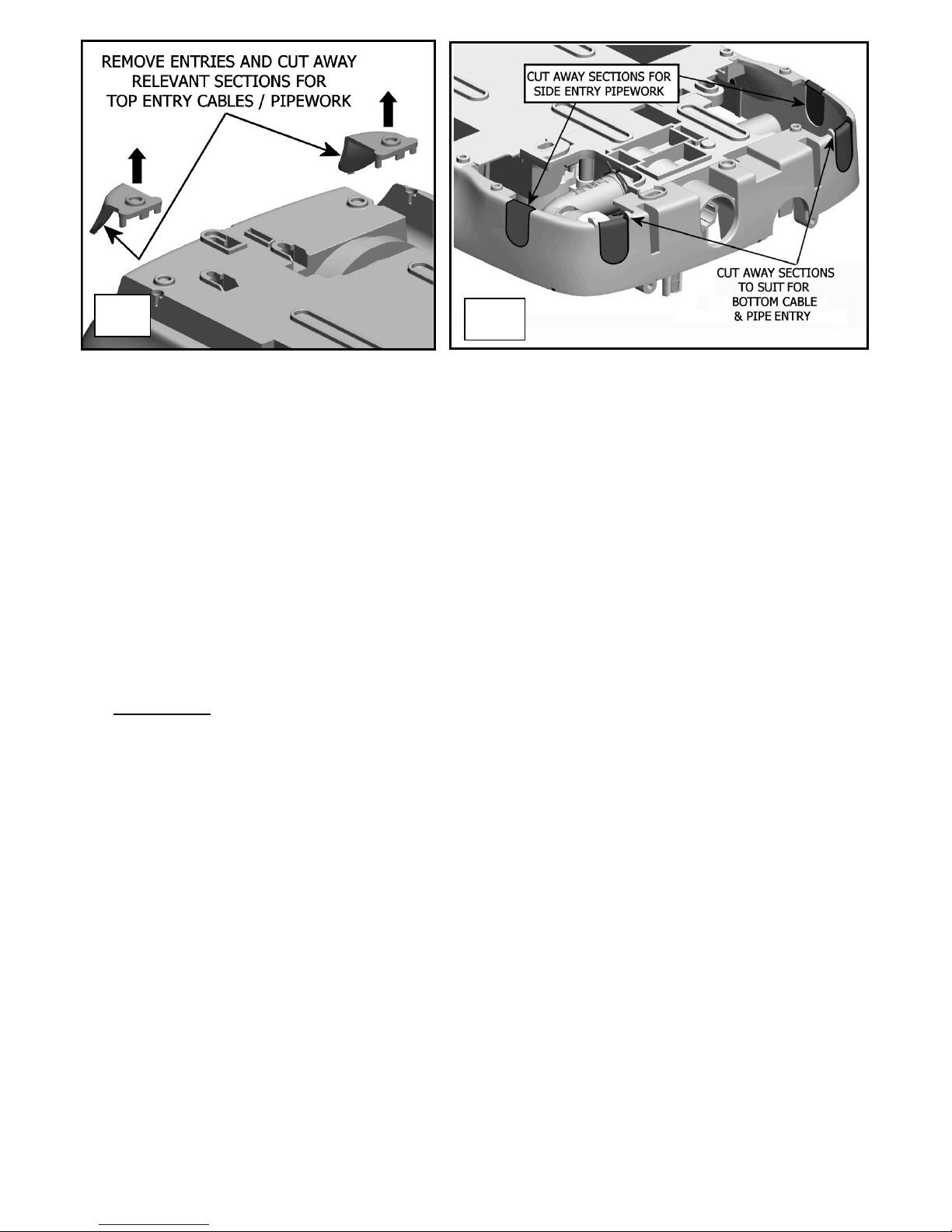

6. Decide the position of the electrical cable into the unit.

Your shower offers the ability to have the connections on the right side or the left (see fig.3).

If the top entries are chosen, remove the cable/pipe entry from fixing kit bag and cut away as

shown (fig.4a).

If rear, bottom or side entries are chosen, remove the relevant cable/pipe entry from the

detachable lower section as shown (fig.4b).

2

3

5

7. Your shower is provided with 6 x wall-fixing positions in the backplate (fig.19)

These have been especially designed to match a number of previous ‘Redring Showers’,

as well as providing flexibility for new installations.

The 3 x top-fixing holes are a ‘key-hole’ slot design (‘k’ or ‘l’ fig.19), and the single most

convenient should be marked and drilled first.

Tighten fixing screw with head protruding about 10mm from the wall and hook the backplate

over the screw head. This allows for correct and accurate alignment of your shower before

marking and fixing the bottom positions.

Mark and drill the other 2 x most convenient wall fixing slots (‘m’ fig.19),

ensuring the slot in

the detachable lower section is used.

Remove the detachable lower section by lifting away from the 2 x fixing posts/pegs (fig.2).

Tighten fixing screw in main shower, leaving the detachable lower section screw until later.

You may wish to leave both fixing screws loose at this stage, as the holes are elongated to allow

for adjustment after other connections have taken place.

b. PLUMBING

WARNING:

ENSURE THAT THE MAINS WATER SUPPLY MEETS THE REQUIREMENTS BELOW BEFORE

CONTINUING INSTALLATION.

The shower unit must be connected to the mains cold water supply.

This must have a minimum supply running pressure of 100kPa (1.0 bar, 15 psi) at a minimum

flow rate of 8 litres/minute*.

The maximum static supply pressure must be no greater than 1000kPa (10 bar, 150 psi).

*

Minimum running pressure must be obtained at 9 litres/minute for 9.5kW.

WARNING:

BEFORE CONNECTING THE PIPE WORK TO THE SHOWER, ENSURE THAT THE PIPE WORK

IS FULLY FLUSHED OUT.

1. It is recommended that a WRAS (Water Regulations Advisory Scheme) listed isolating valve is

fitted to the incoming mains cold water before the shower unit.

This will allow the unit to be serviced or exchanged without having to turn off the water at the

water stop valve.

2.

Connect the mains water supply to the shower using Ø15mm copper pipe (BS.EN.1057) or

Ø15mm plastic pipe (with insert).

We recommend the use of copper olives.

If you choose to use a ‘push-fit’ connection rather than the compression elbow supplied (see

fig.5 and details on page.8),

DO NOT

use stainless steel or chrome plated pipe work.

In multiple installations, calculate correct pipe work sizes to maintain adequate flow to each unit.

4b

4a

6

Showing Right Side Entry

Left Side Entry is available for all options by exchanging the fitted end cap (fig.7)

5

5a

5b

5c

5d

Loading...

Loading...