Page 1

Tel +1 (717) 767-6511

+

+

+

+

+

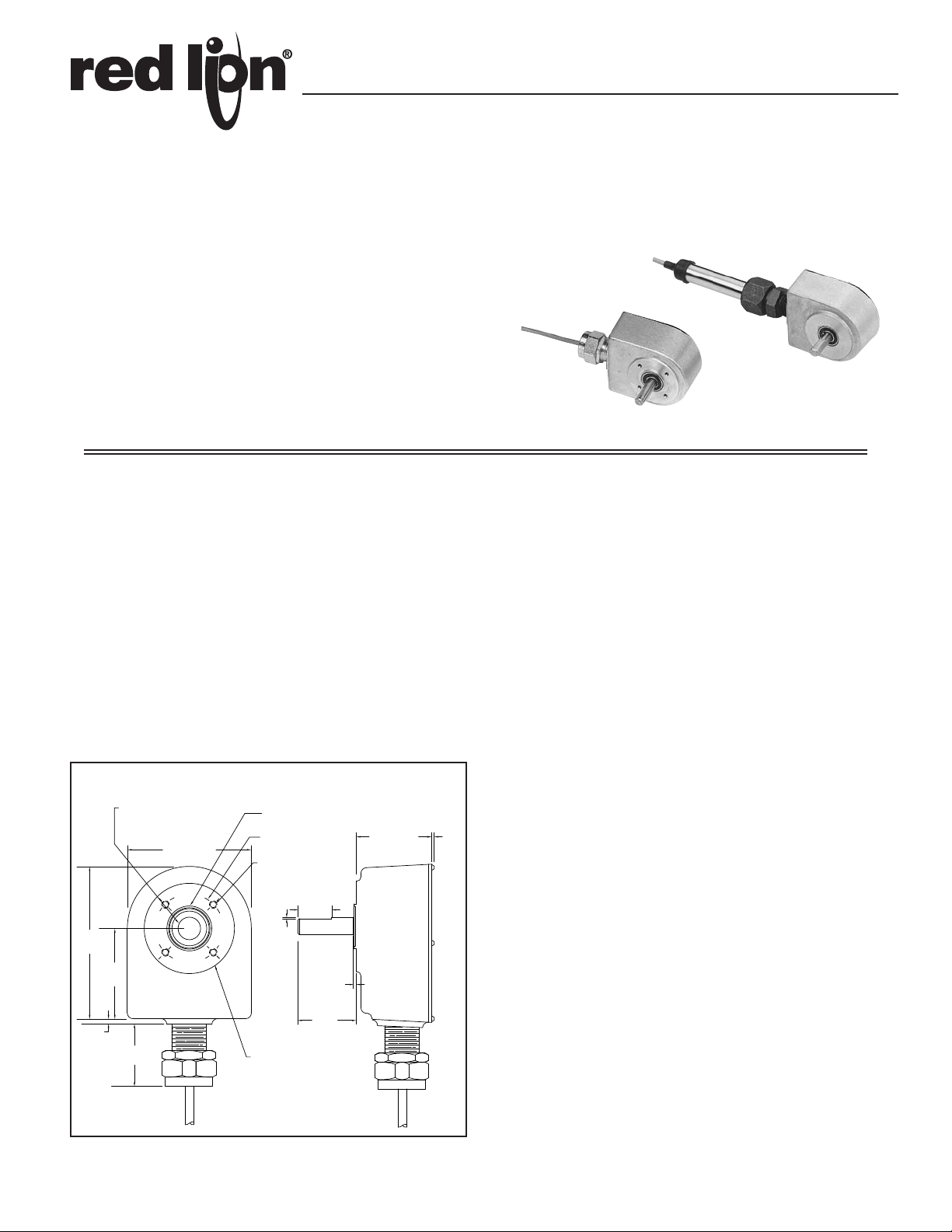

1.25

(31.8)

0.75

0.022

(0.56)

0.05 (1.3)

1.65 (42)

0.08

2.00

1.20

0.13

3.38

2.75

2.00 (50.8)

DIA. MOUNTING

FACE

0.375

(9.53)

DIA. SHAFT

#8-32 UNC

x0.30" (7.6) DP.

4 PL., EQUALLY

SPACED

1.50 (38.1) DIA.

BOLT CIRCLE

0.99 (25.1) DIA

FLANGE

(2)

(19)

(50.8)

(85.8)

(69.9)

(30.5)

(3.3)

Fax +1 (717) 764-0839

www.redlion.net

MODEL ZCH - QUADRATURE OUTPUT ROTARY PULSE GENERATOR

MODEL ZFH and ZGH - QUADRATURE OUTPUT LENGTH SENSORS

(Replaces MODELS RPGQ, LSQS and LSQD respectively)

100, 200 & 500 PULSES PER REVOLUTION

QUADRATURE CURRENT SINKING OUTPUTS TO 50 KHz

For position measurement, bi-directional counting

and systems with mechanical backlash

SEALED PRECISION BALL BEARINGS

RUGGED CAST ALUMINUM HOUSING

3/8" DIA. STAINLESS STEEL SHAFT

WIDE INPUT SUPPLY VOLTAGE RANGE & LOW CURRENT OPERATION

VARIOUS CABLE LENGTHS AVAILABLE

Bulletin No. ZCH/ZFH-A

Drawing No. LP0738

Effective 10/09

DESCRIPTION

The units are rugged, incremental encoders that convert shaft rotation into a

current sinking pulse train.

Internally, a single L.E.D. light source and a photologic sensor in conjunction

with a shaft-mounted, durable, metal-etched encoder disc, provides signal

accuracy and reliability to 50 KHz. The DC input power supply requirement is

a versatile +8 to +28 VDC, and is reverse polarity protected. The NPN Open

Collector Transistor Output is current limited to 40 mA and is compatible with

most RLC counters, rate indicators, controllers and accessories.

All units are packaged in a rugged cast aluminum housing with a gasketed,

rear aluminum cover. The 3/8" (9.53 mm) diameter heavy duty stainless steel

shaft and sealed, lifetime-lubricated precision ball bearings are preloaded for

minimum end play and rated for continuous use up to 6000 RPM. They are

designed to meet NEMA 13/IP54 environmental requirements. All units are

supplied with 10 feet (3M) of PVC jacketed 4-wire, 22 AWG cable with

stranded shield wire and 100% foil shield coverage.

ZCH DIMENSIONS In inches (mm)

ROTARY PULSE GENERATOR

The ZCH can be direct-coupled to a machine shaft by means of a flexible

bellows, spring or rubber sleeve type coupler, etc., that allows for axial and radial

misalignment. They can also be coupled with instrument timing belts and pulleys

or gears. The housing may be rigidly face-mounted with the 4, #8-32 threaded

holes. The 4-wire shielded cable exits through a cord connector.

LENGTH SENSOR

The length sensors are available in both Single Ended Shaft (ZFH) and

Double Ended Shaft (ZGH) versions, both of which include a Stainless Steel

Handle Tube for mounting and 10 feet (3.05 M) of 4-wire shielded cable. When

mounted to a Length Sensor Hinge Clamp Assembly (See Model LSAHC001)

and coupled with one or two Measuring Wheels (See Measuring Wheels), a low

cost, versatile and highly accurate length measurement system can be

configured.

LENGTH SENSOR MEASUREMENT ACCURACY

Factors which affect measurement accuracy include Measuring Wheel

accuracy and wear, and material conditions. Ideally, materials which are hard,

thin and strong provide good readings. Conversely, soft, thick and elastic

materials can present problems in obtaining true readings. Count or Rate

Indicators with “input scaling” can compensate for Measuring Wheel wear and

material elasticity and compliance errors.

LENGTH SENSOR ACCESSORIES

The Length Sensor Hinge Clamp Assembly provides an easy method for

attachment & mounting the Length Sensors and LSCB1 Conversion Bracket.

The removable top on the solid aluminum LSAHC mounting block allows

quick installation of the Length Sensor handle tube and provides secure

clamping retention. The mounting block steel shaft pivots freely in oil

impregnated sintered bronze bushings, and aluminum right angle brackets

allow mounting the assembly via clearance holes for 1/4" (6.35 mm) dia. bolts

(See LSAHC Dimensions & Mounting).

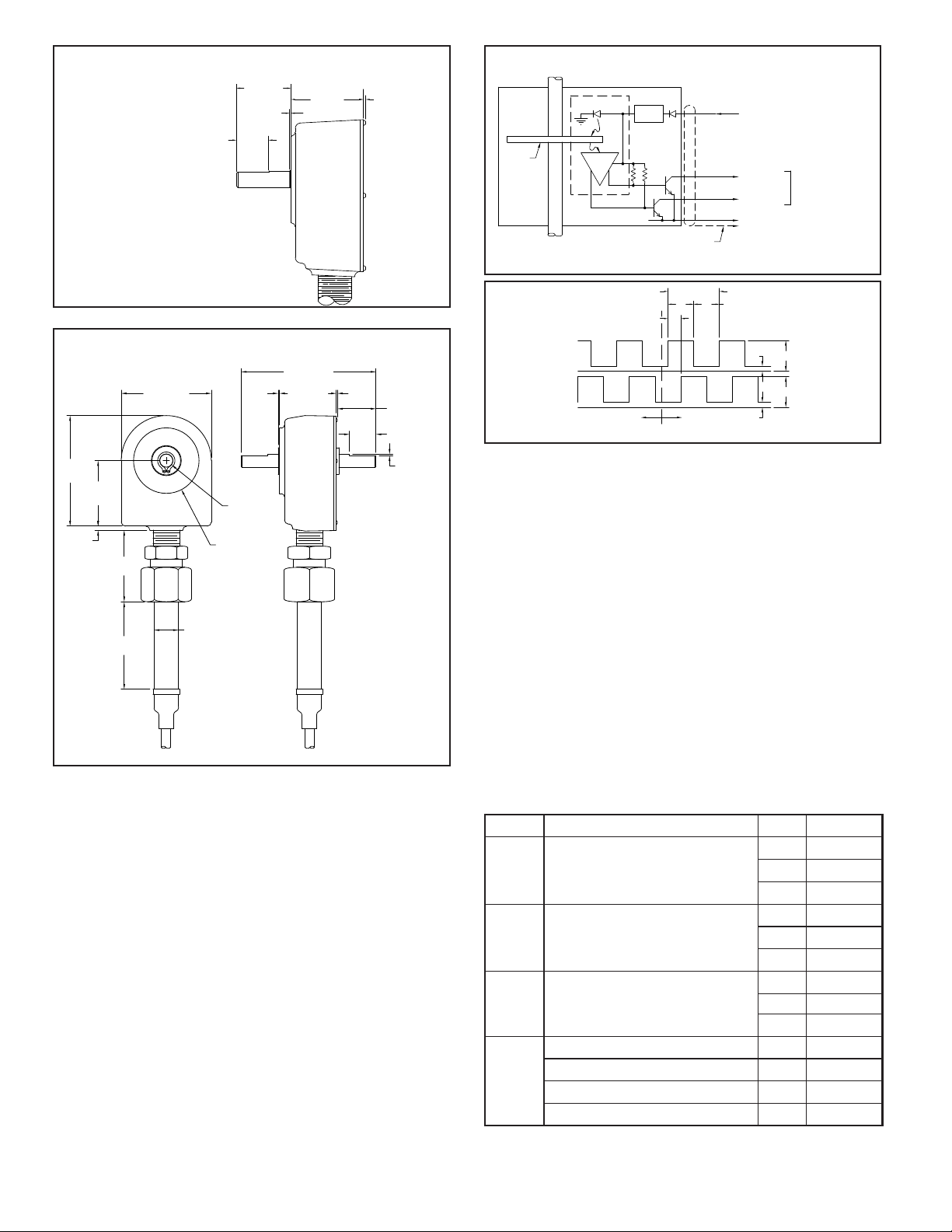

Open Collector Output Wiring

The ZCH, ZFH, and ZGH series of sensors have open collector outputs. An

open collector output brings the uncommitted collector of the encoder switching

device to the external world. Because the collector element is not associated

with the sensor supply voltage, the sensor output collector may be “pulled up”

to external voltages (40 VDC max.) different than the encoder supply voltage .

NPN open collector outputs are current sinking devices. An output signal will

not be generated unless a pull-up resistor is connected from the open-collector

to the positive side of an external supply. The same supply can be used for

powering the unit and for the pull-up resistor.

1

Page 2

1.65

0.08 (2.03)

0.75

0.04

1.20

MAX.

(30.5)

(41.9)

(1.0)

(19.0)

ZFH DIMENSIONS In inches (mm)

.75 (19) DIA.

2.75

(69.8)

2.06

(52.3)

2.00

(50.8)

.13 (3.3)

3.38

(85.8)

2.75 (69.9)

4.00 (101.6)

1.65 (41.9)

0.375 (9.52)

DIA. SHAFT

2.00 (50.8) DIA.

.04

(1.0)

.08

(2.03)

MAX.

USABLE SHAFT

LENGTH

1.08 (27.4)

REF., TYP. 2

.75

(19.0)

TYP. 2

.022 (.56)

TYP. 2

LED

REGU-

LATOR

RED

WHT

BLK

COMMON

8-28VDC @ 30mA

V = 30VDC MAX.

V = 1V MAX. @ 40mA

OL

OH

SHAFT

METAL

ETCHED

OPTICAL

DISC

BARE STRANDED SHIELD WIRE

CONNECTED TO INSTRUMENT

COMMON FOR INCREASED

NOISE IMMUNITY

SENSOR

ARRAY

(TYP.) 50mA MAX.

GRN

CHANNEL A

CHANNEL B

VOLV

OH

COMMON

OH

V

OL

V

COMMON

C.W.C.C.W.

SHAFT ROTATION

(NOTE 1)

CHAN. B

CHAN. A

(NOTE 4)

"c"

"a" "b"

(NOTE 3)

1 CYCLE (360°) (NOTE 2)

This is the side view of the Model

ZFH. All other dimensions (including

the handle tube) are the same as

the Model ZGH. See below.

ZGH DIMENSIONS In inches (mm)

EQUIVALENT CIRCUIT & CONNECTIONS

NOTES:

1. Channel A leads Channel B for clockwise shaft rotation when viewed from

housing front. Conversely, Channel B leads Channel A for Counterclockwise

shaft rotation.

2. The number of lines on the optical disc determines the Pulses Per Revolution

(PPR).

3. Duty Cycle is the relationship of output “High” time, “a”, to output “Low”

time, “b”, and is expressed as a High/Low percentage ratio, ie....% High time

= a/(a+b) x 100; % Low time = b/(a+b) x 100.

4. Quadrature Phase “c” is specified as the lead or lag between Channel A & B

in electrical degrees. Nominally 90° (1/4 cycle).

SPECIFICATIONS

ELECTRICAL SPECIFICATIONS

1. SUPPL Y V OLT AGE: +8 to +28 VDC (including power supply ripple) @ 50

mA max. (30 mA typ.); Reverse polarity protected.

2. OUTPUTS: NPN Open Collector Transistor, VOH = 30 VDC max., VOL = 1

V max @ 40 mA. Output current is limited to 40 mA. Incremental - Two

square waves in quadrature with Channel A leading B for clockwise rotation.

3. OUTPUT FREQUENCY: Up to 50 KHz

4. OUTPUT DUTY CYCLE: Channel A & B: 50/50 nominal. (See Figure 1,

Note 3)

5. QUADRATURE OUTPUT PHASE: 90° ±15° (See Figure 1, Note 3)

6. CABLE CONNECTIONS: RED = +VDC; BLACK = Common;

WHITE = Channel A Output; GREEN = Channel B Output.

MECHANICAL SPECIFICATIONS

1. MAXIMUM MECHANICAL SPEED: 6000 RPM

2. RADIAL SHAFT LOAD: 15 lbs. max. (66.7N)

3. AXIAL SHAFT LOAD: 15 lbs. max. (66.7N)

4. STARTING TORQUE: 3 oz.-in. (21.2N-mm)

5. MOMENT OF INERTIA:

Single Shaft = 1.03 x 10-4 oz. - in. - sec.2 (7.30 x 10-4N - mm - sec2)

Dual Shaft = 1.30 x 10-4 oz. - in. - sec.2 (9.21 x 10-4N - mm - sec2)

6. OPERATING TEMPERATURE: 0°C to +70°C

7. WEIGHT (LESS CABLE):

ZCH: 14.3 oz (406 g)

ZFH: 22.0 oz (623 g)

ZGH: 22.7 oz (643 g)

LENGTH SENSOR MOUNTING CONSIDERATION

1. Length Sensors should be mounted so measuring wheel(s) contact ribbon,

strip or web as it passes over a roller. As an alternative, wheel(s) can be driven

by roller surface next to material being measured.

2. Note: The weight at the Length Sensor unit provides sufficient traction for

accurate operation when mounted, with arm angle from horizonal not

exceeding ±30o.

3. T ension on signal cable can cause wheel(s) to lift. Make sure cable is clamped

to machine frame near the unit and allow slack.

ORDERING INFORMATION

MODEL NO. DESCRIPTION PPR PART NUMBER

100

ZCH0100C

ZCH

ZFH

ZGH

Rotary Pulse Generator

(Replaces RPGQ)

Length Sensor

Single Shaft

(Replaces LSQS)

Length Sensor

Double Shaft

(Replaces LSQD)

Flexible Coupling (1" Length) 0.250" - 0.375"

RPGFC

Flexible Coupling (1" Length) 0.375" - 0.375"

Flexible Coupling (1" Length) 0.375" - 0.500"

Flexible Coupling (1" Length) 0.375" - 6 mm

Note: For 25 foot cable, replace the last character of the part number (“C”) with “D”.

For 50 foot cable, replace the last character of the part number (“C”) with “E”.

2

200

500

100

200

500

100

200

500

--

--

--

--

ZCH0200C

ZCH0500C

ZFH0100C

ZFH0200C

ZFH0500C

ZGH0100C

ZGH0200C

ZGH0500C

RPGFC002

RPGFC003

RPGFC004

RPGFC006

Page 3

LENGTH SENSOR ACCESSORIES

Cast

Alum.

.376"

(9.6)

Bore

+.001"

-.000"

8-32 UNF

Set Screw

3/8"

(9.5)

Round Section Replaceable

Tire .210" Section Dia.

Black Neoprene

Diamond Knurled Aluminum

Tread

10-32 UNF

Set Screw

1"

(25.4)

Alum.

Cast

.376"

-.000"

+.001"

(9.6)

Bore

.376"

(9.6)

Bore

+.001"

-.000"

Tan, Smooth Polyurethane

Tread

10-32 UNF

Set Screw

Alum.

Cast

1"

(25.4)

SEPARATE LENGTH MEASURING WHEELS - DIMENSIONS In Inches (mm)

WHEEL

CODE

OR

FOR USE ON: Metal, paper,

foil, film and hard plastics.

Line contact on material

being measured,

convenient when available

measuring track is narrow

or for measuring on end of

roller beside passing

material.

Max. Speed: 600 RPM

WHEEL

CODE

OF

FOR USE ON: Soft, smooth

materials such as soft

paper, matting,

cardboard, fine weave

textiles. Broad wheel

tread minimizes contact

pressure and tan

polyurethane tread

minimizes marking.

Max. Speed: 600 RPM

Balanced version of 1ft.

circumference available.

Balanced to ANSI S2.191989 Quality Grade 6.3 @

3000 RPM.

WHEEL

CODE

OK

FOR USE ON: Rubber,

coarse weave fabrics,

rough wood surfaces,

foam, insulation.

Max. Speed: 600 RPM

Balanced version of 1ft.

circumference available.

Balanced to ANSI S2.191989 Quality Grade 6.3

@ 3000 RPM.

SELECTING APPROPRIATE WHEEL SIZE & PPR (Pulses Per Rev.) OF ROTARY PULSE GENERATOR

When the desired output of a length sensor and wheel combination is either

in inches, feet, yards, or meters selection of the proper combination is relatively

straight forward. For example, with a 1-foot wheel circumference, a 1 PPR

Rotary Pulse Generator will deliver 1 pulse/ft, 12 PPR would deliver 12 pulses/

ft (1 pulse/inch); 100 PPR would yield 100 pulses/ft; and 120 PPR would permit

measuring to 1/10th of an inch (1/120th of a foot).

WHEELS & REPLACEMENT TIRES FOR CODE OR WHEELS

ORDERING INFORMATION

WHEEL CODE

OR

OF

BF (Balanced)

CIRCUMFERENCE PART NUMBER

1 foot (1/3 yd) ±0.40% WF1000OR

1/3 meter ±0.40% WM0333OR

4/10ths yard ±0.40% WY0400OR

4/10ths meter ±0.40% WM0400OR

1 foot (1/3 yd) ±0.35% WF1000OF

1/3 meter ±0.30% WM0333OF

4/10ths yard ±0.30% WY0400OF

4/10ths meter ±0.30% WM0400OF

1 foot (1/3 yd) ±0.40% WF1000BF

TOLERANCE

WHEEL CODE CIRCUMFERENCE TOLERANCE PART NUMBER

OK

BK (Balanced) 1 foot (1/3 yd) ±0.35% WF1000BK

Replacement Tires

for OR Wheels

Note: After installation of measuring wheels, ensure guards,shields or other

devices are in place to protect personnel from rotating equipment.

1 foot (1/3 yd) ±0.35% WF1000OK

1/3 meter ±0.30% WM0333OK

4/10ths yard ±0.30% WY0400OK

4/10ths meter ±0.30% WM0400OK

1 foot (1/3 yd) TORF1000

1/3 meter TORM0333

4/10ths yard TORY0400

4/10ths meter TORM0400

3

Page 4

MODEL LSAHC - LENGTH SENSOR HINGE CLAMP ASSEMBLY

The Length Sensor Hinge Clamp Assembly provides an easy method for

attachment and mounting of the Length Sensors and LSCB1 Conversion

Bracket. The removable top on the solid zinc LSAHC mounting block

allows quick installation of the Length Sensor handle tube and provides

secure clamping retention. The mounting block pivots freely in zinc right

angle brackets to allow mounting the assembly via clearance holes for 1/4"

dia. bolts.

The lock washers must be used as indicated (between the bolt head and

the top clamp piece). Assemble the top clamp piece as follows.

1. Tighten both bolts so that the top clamp half draws down evenly on

the sensor tube.

2. Tighten the bolts until both lock washers are flat.

3. Then turn each bolt an additional ½

to ¾ turn.

DIMENSIONS In inches (mm)

FRONT

VIEW

TOP

VIEW

(86.4)

2.5 (63.5)

1.25

(31.8)

3.4

2.9

(73.7)

4X Ø 0.31 (7.9)

Lock washers (2) must be

installed between bolt heads

and top clamp piece.

.25 (6.3)

E-clip retaining ring (2)

must be installed in slots.

.88

(22.4)

SINGLE WHEEL

.85

2.93 (74.4)

(21.6)

DUAL WHEEL 4 (101.6)

Model ZGH Shown

WHEEL

RADIUS

OMITTED ON

SINGLE SHAFT UNITS

THIS WHEEL AND SHAFT

6.9 (175.3)

CAUTION: Downward tension

on signal cable can cause

wheel(s) to lift. Make sure

cable is clamped to

machine frame near

encoder and allow slack.

NOTE: The weight at the

Length Sensor unit

provides sufficient traction

for accurate operation

when mounted as shown,

with arm angle from

horizontal not exceeding

±30°, and with hinge clamp

toward the far extreme of

the extension arm.

1.9

(48.3)

0.75 (19.0)

4.50 (114.3)

5.70 (144.8)

2.00

(50.8)

1.50

(38.1)

0.75

(19.0)

ORDERING INFORMATION

MODEL NO. DESCRIPTION PART NUMBER

LSAHC LSAHC001Length Sensor Hinge Clamp Assembly

The Company warrants the products it manufactures against defects in materials and workmanship

for a period limited to two years from the date of shipment, provided the products have been stored,

handled, installed, and used under proper conditions. The Company’s liability under this limited

warranty shall extend only to the repair or replacement of a defective product, at The Company’s

option. The Company disclaims all liability for any affirmation, promise or representation with

respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC against

damages, claims, and expenses arising out of subsequent sales of RLC products or products

containing components manufactured by RLC and based upon personal injuries, deaths, property

damage, lost profits, and other matters which Buyer, its employees, or sub-contractors are or may be

to any extent liable, including without limitation penalties imposed by the Consumer Product Safety

Act (P.L. 92-573) and liability imposed upon any person pursuant to the Magnuson-Moss Warranty

Act (P.L. 93-637), as now in effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products except those

expressly contained herein. The Customer acknowledges the disclaimers and limitations contained

herein and relies on no other warranties or affirmations.

.88 (22.4)

Model ZFH Shown

Length Sensors should be mounted so measuring

wheel(s) contact ribbon, strip or web as it passes over

a roller. As an alternative, wheel(s) can be driven by

roller surface next to material being measured.

LIMITED WARRANTY

Red Lion Controls

Headquarters

20 Willow Springs Circle

York PA 17406

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

Red Lion Controls

Europe

Printerweg 10

NL - 3821 AD Amersfoort

Tel +31 (0) 334 723 225

Fax +31 (0) 334 893 793

Red Lion Controls

India

54, Vishvas Tenement

GST Road, New Ranip,

Ahmedabad-382480 Gujarat, India

Tel +91 987 954 0503

Fax +91 79 275 31 350

Red Lion Controls

China

Unit 101, XinAn Plaza

Building 13, No.99 Tianzhou Road

ShangHai, P.R. China 200223

Tel +86 21 6113-3688

Fax +86 21 6113-3683

Loading...

Loading...