red lion VT-IPm2m-***-D, VT-IPM2M, VersaTRAK IPm2m, VT-IPM2M-113, VT-IPM2M-213 Installation And Maintenance Manual

Page 1

VersaTRAK IPm2m RTU

Installation and Maintenance Manual

April 2014

This manual applies to the following products:

VT-IPm2m-XXX-D, VersaTRAK IPm2m RTU

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 2

© 2014. Red Lion Controls. All Rights Reserved.

2

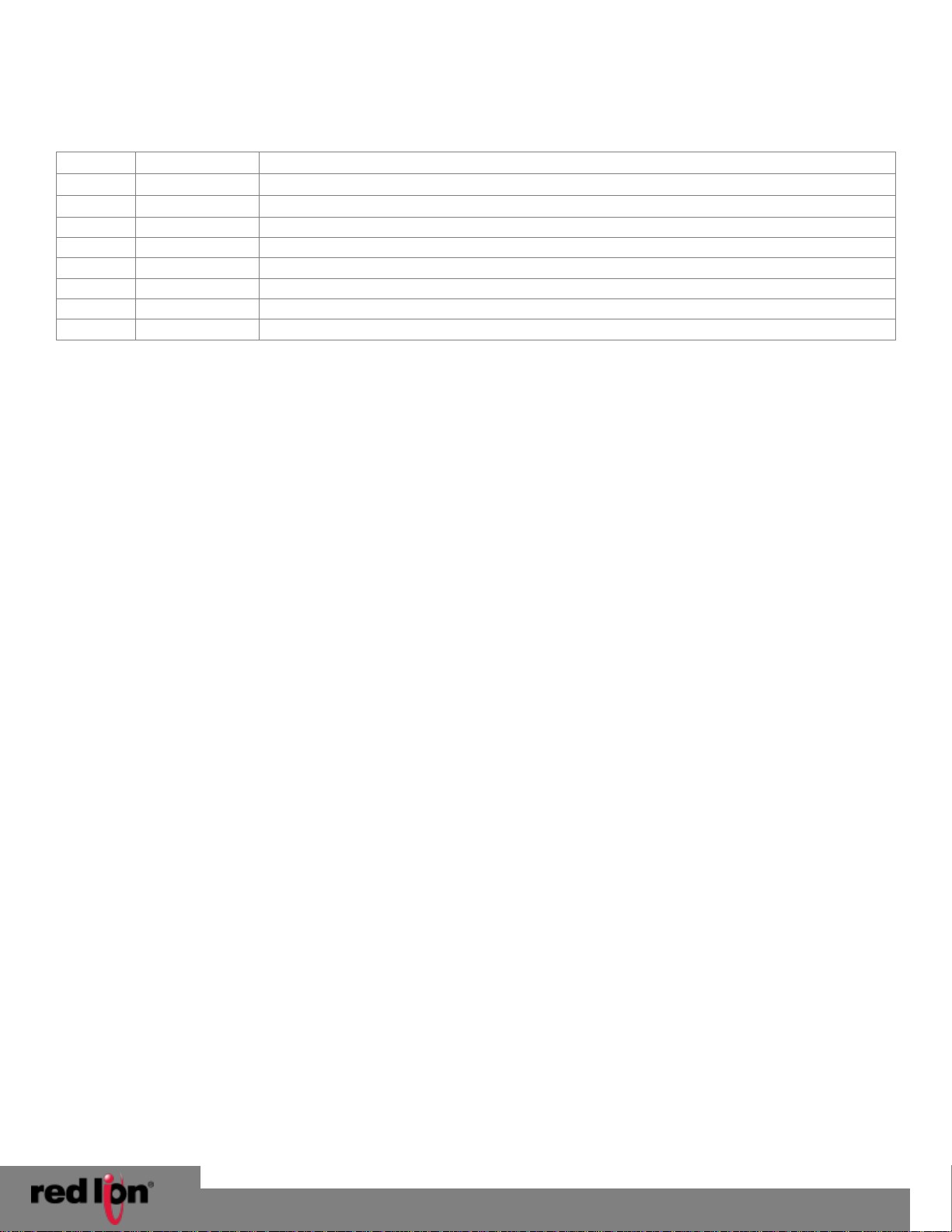

CHANGE HISTORY

Version

Date

Description

r01

2/25/2014

Modifications to the Environmental Specifications

04/17/2014

Updated minimum operating system requirements

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

VersaTRAK IPm2m RTU

Installation and Maintenance Manual

Page 3

VersaTRAK IPm2m RTU

© 2014. Red Lion Controls. All Rights Reserved.

3

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Installation and Maintenance Manual

TABLE OF CONTENTS

INSTALLATION AND HAZARDOUS AREA WARNINGS ............................................................................................... 5

AVERTISSEMENTS POUR INSTALLATION ET ENDROITS DANGEREUX ................................................................. 5

1 Overview ............................................................................................................................................................6

1.1 Getting Started with Red Lion Hardware ................................................................................................................ 6

1.2 Red Lion Software Tools .......................................................................................................................................... 7

1.3 Using Red Lion Windows Software ......................................................................................................................... 7

2 Assembly and Installation ....................................................................................................................................9

2.1 Panel Assembly ....................................................................................................................................................... 9

3 Power and I/O Wiring ........................................................................................................................................ 11

3.1 Power and I/O Wiring ........................................................................................................................................... 11

3.2 Current Requirements .......................................................................................................................................... 12

3.3 On-Board I/O Overview ......................................................................................................................................... 12

4 Communications ............................................................................................................................................... 14

4.1 Communication Ports ........................................................................................................................................... 14

5 Technical Specifications ..................................................................................................................................... 17

6 Maintenance Information .................................................................................................................................. 20

6.1 Local Diagnostics ................................................................................................................................................... 20

6.2 Power and Status LED ........................................................................................................................................... 20

6.3 Controller or RTU Memory ................................................................................................................................... 20

7 Service Information ........................................................................................................................................... 21

7.1 Product Support .................................................................................................................................................... 21

Page 4

VersaTRAK IPm2m RTU

© 2014. Red Lion Controls. All Rights Reserved.

4

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Installation and Maintenance Manual

Statement of Warranty

Red Lion, manufacturer of Red Lion products, warrants to Buyer that products, except software, manufactured by Red

Lion will be free from defects in material and workmanship. Red Lion’s obligation under this warranty will be limited to

repairing or replacing, at Red Lion’s option, the defective parts within two (2) years of the data of installation, or within

two (2) years of the date of shipment from the point of manufacture, whichever is sooner. Products may be returned by

Buyer only after permission has been obtained from Red Lion. Buyer will prepay all freight charges to return any

products to the repair facility designated by Red Lion.

This limited warranty does not cover losses or damages which occur in shipment to or from Buyer or due to improper

installation, maintenance, misuse, neglect of any cause other than ordinary commercial or industrial applications. In

particular, Red Lion makes no warranties whatsoever with respect to implied warranties or merchantability or fitness for

any particular purpose. All such warranties are hereby expressly disclaimed. No oral or written information or advice

given by Red Lion or Red Lion’s representative shall create a warranty or in any way increase the scope of this warranty.

This limited warranty is in lieu of all other warranties whether oral or written, expressed or implied. Red Lion’s liability

shall not exceed the price of the individual units, which are the basis of the claim. In no event shall Red Lion be liable for

any loss of profits, loss of use of facilities or equipment, or other indirect, incidental or consequential damages.

Page 5

VersaTRAK IPm2m RTU

© 2014. Red Lion Controls. All Rights Reserved.

5

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Installation and Maintenance Manual

INSTALLATION AND HAZARDOUS AREA WARNINGS

These products should not be used to replace proper safety interlocking. No software-based device (or any other solidstate device) should ever be designed to be responsible for the maintenance of consequential equipment or personnel

safety. In particular, Red Lion disclaims any responsibility for damages, either direct or consequential, that result from

the use of this equipment in any application.

All power, input and output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods and in accordance

with the authority having jurisdiction.

WARNING – EXPLOSION HAZARD – SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS 1, DIVISION

2.

WARNING – EXPLOSION HAZARD – WHEN IN HAZARDOUS LOCATIONS, DISCONNECT POWER BEFORE REPLACING OR

WIRING MODULES.

WARNING – EXPLOSION HAZARD – DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN SWITCHED OFF OR

THE AREA IS KNOWN TO BE NONHAZARDOUS.

AVERTISSEMENTS POUR INSTALLATION ET ENDROITS DANGEREUX

Ces produits ne doivent pas être utilisés pour remplacer le verrouillage de sécurité approprié. Aucun dispositif basé sur

un logiciel (ou tout autre dispositif à l'état solide) devraient jamais être conçus pour être responsable de l'entretien de

l'équipement consécutifs ou la sécurité du personnel. En particulier, Red Lion décline toute responsabilité pour les

dommages, directs ou indirects, résultant de l'utilisation de cet équipement dans n'importe quelle application.

Tout courant, câblage entrée et sortie (I / O) doit être conforme aux méthodes de câblage à la Classe I, Division 2 et

conformément à l'autorité compétente.

AVERTISSEMENT – RISQUE D’EXPLOSION – LA SUBSTITUTION DE TOUT COMPOSANT PEUT NUIRE À LA CONFORMITÉ DE

CLASSE I, DIVISION 2.

AVERTISSEMENT – RISQUE D’EXPLOSION – LORSQUE DANS DES ENDROITS DANGEREUX, DÉBRANCHEZ LE CORDON

D'ALIMENTATION AVANT DE REMPLACER OU DE BRANCHER LES MODULES.

AVERTISSEMENT – RISQUE D’EXPLOSION – NE DÉBRANCHEZ PAS L'ÉQUIPEMENT À MOINS QUE L'ALIMENTATION AIT

ÉTÉ COUPÉE OU QUE L’ENVIRONNEMENT EST CONNU POUR ÊTRE NON DANGEREUX.

Note: All information in this document applies to the VersaTRAK IPm2m RTU, except where

otherwise noted. Refer to the electronic help system in the Sixnet I/O Tool Kit software

for detailed product specifications and configuration settings.

Page 6

VersaTRAK IPm2m RTU

© 2014. Red Lion Controls. All Rights Reserved.

6

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Installation and Maintenance Manual

Overview

1

The products covered by this manual are designed for use in industrial control and data acquisition systems. Refer to

the Red Lion website and the individual data sheets for complete features and benefits. This user manual covers the

aspects of hardware installation and maintenance for the VT-IPm2m. For software features and capabilities please refer

to the electronic help system in the Sixnet I/O Tool Kit software.

1.1 Getting Started with Red Lion Hardware

Following these steps will make installation and start up easier:

1. Mount the Hardware: Refer to the following sections of this manual or other appropriate user manuals for

information on installing them into an enclosure. (See Section 2 for further details)

2. Install Communication Wiring to I/O Modules: Make the necessary communication connections to any

EtherTRAK -2 I/O,EtherTRAK I/O, RemoteTRAK I/O, or 3rd party devices. Refer to the I/O module manuals as

needed to establish the correct physical connections with the VT-IPM2M.

3. Connect Power and I/O Wiring to On-board I/O and I/O Modules: Connect AC power to the Red Lion or user

supplied power supply. Make DC power connections from the power supply to the Red Lion components. Make

field wiring connections to the Red Lion I/O modules and any peripheral equipment. Refer to the VT-IPM2M

power / wiring diagram (Figure 3-3) for making the appropriate power and on-board I/O connections.

4. Install Communication Cabling: The units covered by this manual come with communication accessories. Snap

the pre-wired RJ45 to DB9 adapter to the RJ45 patch cord (not supplied). Connect this cable between one of the

serial RS232 ports (RJ45 connector) on your RTU and a serial RS232 port (DB9 connector) on your PC. More

details about Ethernet, RS232 and RS485 wiring are provided in Section 4.

Fabricate and install RS232 and RS485 cables as needed to connect to other devices. If you are using Ethernet

units, install the correct cabling and peripherals. Refer to the documentation for your Ethernet communication

devices for details.

5. Apply Power: Power up the Red Lion components and related peripherals. Observe the PWR LED on the RTU. A

solid ON indicates proper operation. The Status LED on EtherTRAK and RemoteTRAK I/O modules should be ON

solid or blinking, depending on whether I/O Transfers have been configured in the RTU. Refer to the appropriate

Red Lion user manual for PWR/Status LED details.

6. Configure Using the Sixnet I/O Tool Kit: Use the Sixnet I/O Tool Kit to create a hardware configuration for each

Red Lion station. Refer to the electronic help in the I/O Tool Kit for details.

7. Test the Hardware: Use the Test I/O window in the I/O Tool Kit program to verify proper I/O operation of all Red

Lion stations. Refer to the I/O Tool Kit electronic help system.

8. Configure Your PC Software to Communicate with the Red Lion Station(s): Refer to the documentation for your

software.

9. If You Have Difficulty: If you experience startup trouble, refer to Section 6 in this document for some

troubleshooting tips or go to Red Lion website. If you still need assistance then please contact Red

Lion.

Page 7

VersaTRAK IPm2m RTU

© 2014. Red Lion Controls. All Rights Reserved.

7

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Installation and Maintenance Manual

1.2 Red Lion Software Tools

Red Lion supplies the "mission oriented" tools you need for every step of your project from the initial specification,

through startup, and years of trouble free operation. Configuration information flows between Red Lion Windows,

saving you time (you don't have to enter data multiple times) and dramatically reducing data entry errors. Refer to the

electronic help in the Sixnet I/O Tool Kit for complete details.

Sixnet I/O Tool Kit

The Sixnet I/O Tool Kit is a configuration, calibration and maintenance tool for Red Lion hardware. Use the I/O Tool Kit to

configure I/O features, perform channel-by-channel calibrations in meaningful engineering units, and perform live

diagnostics at each station. Refer to the electronic help for details.

Here are some of the optional Feature Sets for the Sixnet I/O Tool Kit:

SCS (Scalable Control System) features: Includes importing, tag exporting, I/O transfers and advanced load

options. The SCS option is required to develop ISaGRAF programs using the ISaGRAF Workbench.

Datalogging: Includes Sixlog datalogging (see below) with host transfer and client transfer capability.

Open LINUX features: Gain access to LINUX-visible features in IPm controllers, including file loading and

advanced diagnostics. A library of functions to access the IPm I/O registers and other services is supplied with

this enhanced license.

Sixlog

Sixlog is datalogging software for Red Lion controllers and RTUs. Data is logged into protected memory in the unit. Then

Sixlog uploads the data files and saves them into ASCII format files that are easy to import into databases, spreadsheets

and other Windows applications. Access the Sixlog functions from within the Sixnet I/O Tool Kit.

ISaGRAF

The ISaGRAF Workbench allows you to write an IEC 61131 control program for a Red Lion controller or RTU. All six of the

IEC 61131 languages are supported, including Ladder Logic and Function Blocks.

1.3 Using Red Lion Windows Software

Below is a quick overview of using the Sixnet I/O Tool Kit. Registration for Level 1 (basic features) is free of charge.

Note: An expanded version of this page has been provided as electronic help. To access it, click on the Getting Started

icon in the I/O Tool Kit electronic help.

Basic Configuration

Run the Sixnet I/O Tool Kit program and create your panel layouts. Then configure the operating parameters for each

Red Lion component, including channel tag names. Assign virtual I/O modules and I/O transfers for any EtherTRAK-2,

EtherTRAK or RemoteTRAK modules you wish to have the RTU poll. Once you are satisfied with your configuration, load

your configuration to the RTU. Save this information to a project file. Using the Test I/O function, verify that you can

read and write all your I/O.

Note: Set tag name restrictions in the Sixnet I/O Tool kit program before creating tag names to ensure compatibility when exporting

them for usage in other Windows applications.

Page 8

VersaTRAK IPm2m RTU

© 2014. Red Lion Controls. All Rights Reserved.

8

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Installation and Maintenance Manual

Your Red Lion components are now ready to exchange I/O data with your Windows applications via DDE, OPC, or direct

DLL calls. (Refer to the "How to Access Sixnet I/O from a Windows Application" topic in the Sixnet I/O Tool Kit help

system.) If you will be running a Windows application, then continue with the following steps.

Exporting I/O Definitions (optional, requires the SCS feature set)

Some Windows applications such as ISaGRAF, Citect and Intellution FIX, can import Red Lion tag names. If your Windows

application supports this feature, run the Sixnet I/O Tool Kit and open your project file. Export your tag names to a file

using the appropriate format.

Note: If you are exporting tag names for ISaGRAF, Citect or Intellution, you must create, or already have, a project to export tag

data into.

Datalogging (optional, requires the Datalogging feature set)

If you will be logging data in the Red Lion RTU, then create the appropriate datalog configuration(s) and load them into

the unit. Refer to the Sixlog topics in the Sixnet I/O Tool Kit help system for details.

IEC 61131 Programming (optional, requires the SCS feature set)

If you are using the ISaGRAF IEC1131 programming software, refer to the Red Lion ISaGRAF help system for detailed

instructions.

Linux Capabilities (optional, requires the IPm Advanced feature set)

If you are using the advanced LINUX IPm capabilities, refer to the Sixnet I/O Tool Kit help for detailed instructions.

IPm Advanced documentation and compilers are available for download from Red Lion website.

Page 9

VersaTRAK IPm2m RTU

© 2014. Red Lion Controls. All Rights Reserved.

9

Wire Duct

Wire Duct

Wire Duct

Wire Duct

Wire Duct

Wire Duct

27.0" (68.6 cm)

33.0"

(83.8 cm)

8.0"

(20.3 cm)

6.5"

(16.5 cm)

8.0"

(20.3 cm)

8.0"

(20.3 cm)

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Installation and Maintenance Manual

Assembly and Installation

2

2.1 Panel Assembly

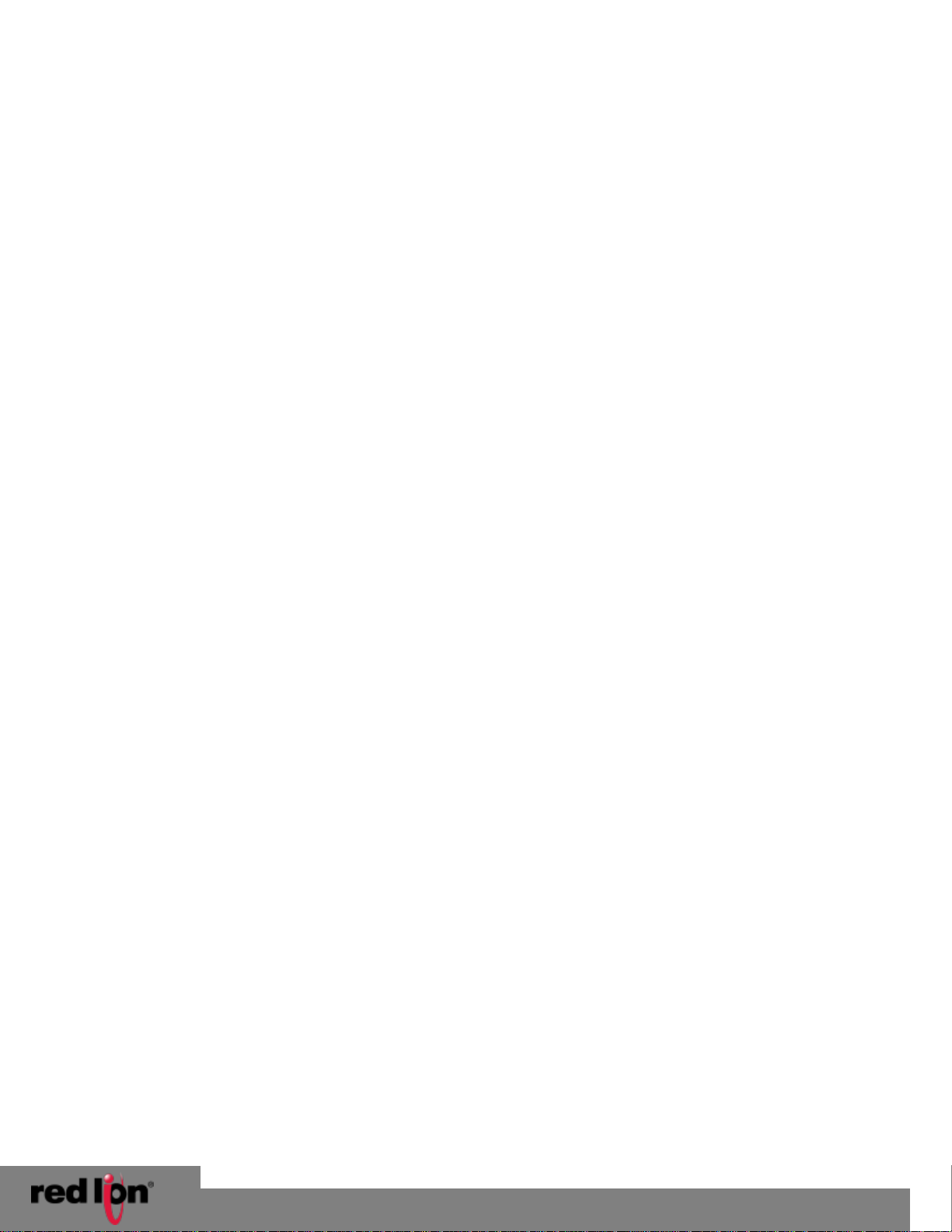

Most Red Lion components snap onto DIN rail strips fastened to a subpanel. Figure 2-1 shows a sample panel with DIN

rail strips and wire duct attached. Recommended DIN rail spacing is 8 inches. This spacing allows room for wire duct to

be installed without obstructing field wiring installation.

The Red Lion components are typically installed against one another, but space may be left between modules to

accommodate other DIN rail mounted components such as terminal blocks and fuse holders. End clamps are

recommended to restrict side-to-side movement. Figure 2-2 shows the physical dimensions of the VT-IPM2M.

Red Lion components can be installed in any orientation and order on your panel.

Figure 2-1 Sample Layout for a 36" x 30" Enclosure

Page 10

VersaTRAK IPm2m RTU

© 2014. Red Lion Controls. All Rights Reserved.

10

353332 3431

45

464342

44 47

414037 38 3936

2.95"

(7.49 cm)

0.28"

(0.71 cm)

4.25"

(10.80 cm)

3.23"

(8.20 cm)

3.83"

(9.73 cm)

1.80"

(4.57 cm)

4.13"

(10.48 cm)

4.47"

(11.35 cm)

4.75"

(12.07 cm)

0.28"

Dia. 0.17"

(0.43 cm)

(clear for

#8 screw)

DIN

EN

50022

FRONT VIEW

SIDE VIEW

Typical

DIN Rail

Dimensions

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Installation and Maintenance Manual

Figure 2-2 - VersaTRAK IPm2m RTU Dimensions

Page 11

VersaTRAK IPm2m RTU

© 2014. Red Lion Controls. All Rights Reserved.

11

AC Power Input

DC Power Output

Voltage Adjust

Power LED

Line

Line

Neutral

Neutral

Chassis GND

DC +

DC +

DC -DC -Chassis GND

Optional

Auxiliary

DC Input

AC

Power

Input

DC

Power

Output

DC Power for controllers,

RTUs, I/O, and user loops

Optional Auxiliary

DC Power Input

GND DC+

Extra terminals

for 4-20 loops,

fields devices

and more

DC GND

DC + IN

DC GND

DC GND

DC GND

DC GND

DC GND

DC GND

DC GND

DC GND

DC+ OUT

DC+ OUT

DC+ OUT

DC+ OUT

DC+ OUT

DC+ OUT

DC+ OUT

DC+ OUT

Chassis

DC GND

DC GND

DC+ OUT

DC+ OUT

DC GND

DC+ IN

Line

Line

Neutral

Neutral

Chassis

4-20

Input

Field

Device

Discrete

Output

Discrete

Input

Wiring Base

Opt. Auxiliary

Power Input

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Installation and Maintenance Manual

Power and I/O Wiring

3

3.1 Power and I/O Wiring

The Red Lion VersaTRAK IPm2m RTU accepts 24 VDC power from a Red Lion power supply or from a user DC power

source of 10 to 30 VDC. The Red Lion ST-PS-024-05N provides 24VDC @ 5A. The Red Lion RM-PS-024-01F provides

24VDC @ 1A.

ST-PS-024-05N (24VDC @ 5A)

The SixTRAK power supply operates on 88-132 and 176 to 264 VAC. Refer to Figure 3-1 for connections. Tighten these

screw terminals to a maximum of 3.48 in-lbs.

ST-PS-024-05 N

Power Connections

Figure 3-1

RM-PS-024-01F (24VDC @ 1A)

The RM-PS-024-01F operates on 85-264 VAC (47-63 Hz) or 120-370 VDC. Refer to Figure 3-2 for connections. Tighten the

screw terminals to a maximum of 3.48 in-lbs.

RM-PS-024-01F

Power Connections

Figure 3-2

Page 12

VersaTRAK IPm2m RTU

© 2014. Red Lion Controls. All Rights Reserved.

12

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Installation and Maintenance Manual

RM-PS-024-01F (Redundant Power)

The RM-PS-024-01F allows you to connect auxiliary 24 VDC power (from another RM-PS-024-01F or other source) to

terminals 17 and 18. When auxiliary power is connected, the RM-PS-024-01F will source most of the power under

normal operating conditions. If the primary power fails then the auxiliary power will immediately take over.

3.2 Current Requirements

To calculate the current requirements, add the wattage required for the VT-IPM2M and other modules in use. Then

divide the total wattage by the DC power source voltage. Then add any current needed for user instrumentation loops.

DC Power Wiring: All Red Lion units and user instrumentation loops may be powered from a single DC source. Refer to

Figure 3-3 DC power connections to the VT-IPM2M. The user DC power source must be in the range of 10 to 30 volts.

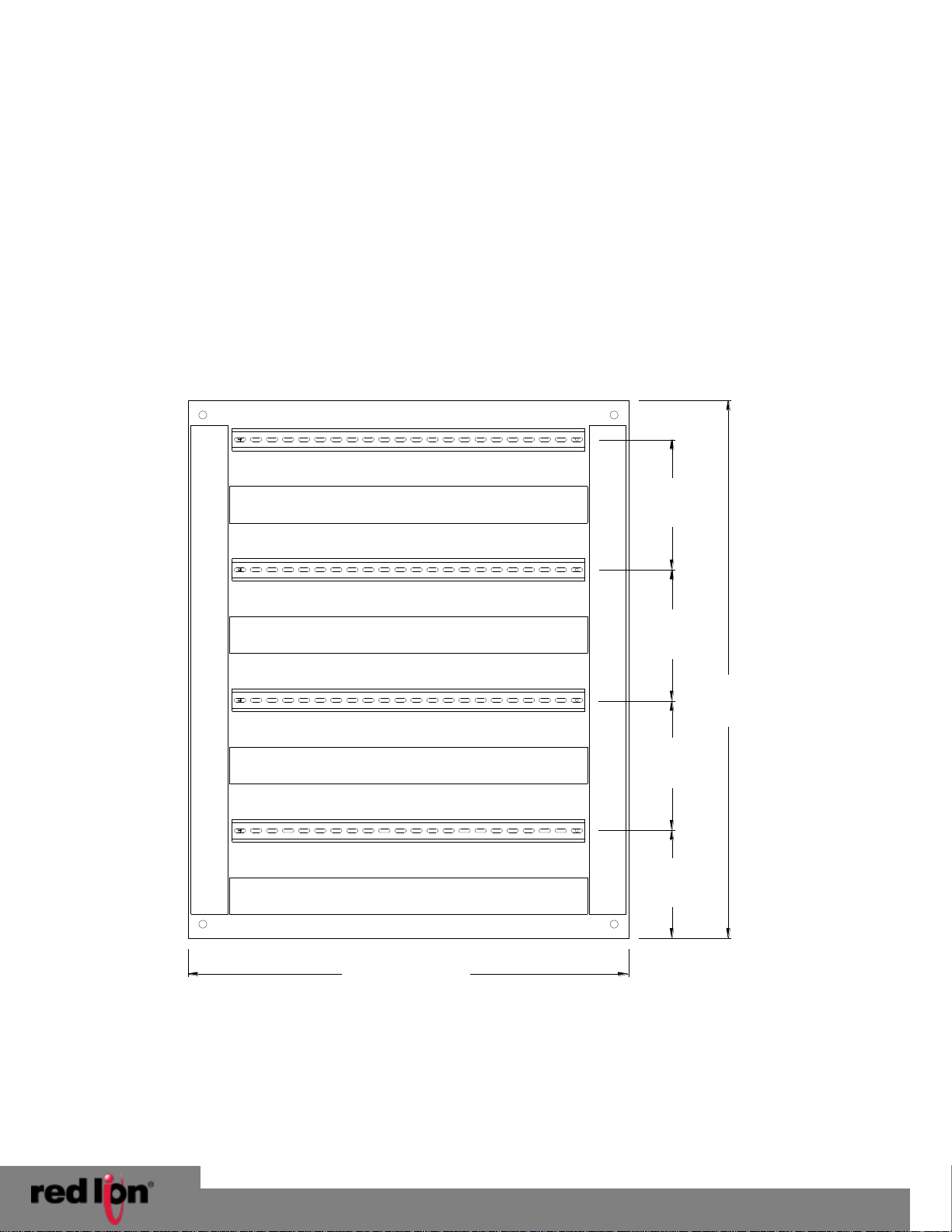

3.3 On-Board I/O Overview

The VT-IPM2M comes with integrated discrete and analog I/O on board. Wiring for the available on-board I/O should be

made based on the wiring diagram shown in Figure 3-3. A hardware summary for each of the available I/O is described

below. Further details on the features available when using the on-board I/O can be found in the electronic help system

in the Sixnet I/O Tool Kit.

Discrete Inputs:

There are twelve discrete inputs in all models of the VT-IPM2M. These inputs may be wired for sourcing or sinking by

selecting the proper DI return jumper position in the base. An input count feature uses analog input registers to

accumulate the positive transitions of each input.

Positive DC voltage must be applied to an input to indicate an ON condition. All channels are referenced to a common

return or supply, which is connected to the negative side (ground) or positive side (DC+) of the DC power source. One

wire from each sourcing field input should be bussed together and connected to terminal 17 (DC +). One wire from each

sinking field input should be bussed together and connected to terminal 18 (DC GND). Refer to the wiring diagram,

Figure 3-3. Set the DI return jumper inside the wiring base to match the wiring configuration of the inputs (sinking or

sourcing).

Discrete Outputs:

Depending on your model of the VT-IPM2M, there are either four or eight discrete outputs integrated into the unit. The

discrete output channels each provide up to 1 Amp DC to power motor contactors, valves, and other loads.

A single terminal is provided for each output channel. All outputs are powered from the DC power terminal. All channels

are referenced to a common return, which is connected to the negative side (ground) of the DC power source.

Analog Inputs:

There are either six or eight 4-20mA analog inputs on your VT-IPM2M. These inputs provide 16 bits of resolution for

precision analog measurements.

A single input terminal is provided for each measurement channel. Care must be taken to externally provide a suitable

instrumentation ground for these single ended input circuits.

Precision 100 ohm current shunts beneath the hinged access door in the wiring base pass current and maintain loop

integrity, even if the plug-in logic module is removed. Each analog channel has built in current protection circuitry, such

that each channel open circuits before any circuit damage will occur.

Page 13

VersaTRAK IPm2m RTU

© 2014. Red Lion Controls. All Rights Reserved.

13

42

13

3531 3332 34 393736 38 40 41

1 243

567

8 9 1110 12

2019 2221 23

46

444345 47

14 1615 1817

24 25

246 8 10 12

3 5 7 9 11 1 3

2

4

1 53 7

246 8

10-30

VDC

DO

DI AI

1

(Loop powered

AI shown)

RS485

(Port A)

RS232

RJ45

(Port B)

-

+

GND

T

10-30 VDC

(User Supplied)

DC+ for

DI Sourcing

or

DC- for

DI Sinking

(must set

jumper

in base)

+

DI Return Jumper:

Select DC- for sourcing (default)

or DC+ for sinking

-

DO

Return

(DC-)

(sourcing or sinking DI)

Equivalent DC Input Circuits

Equivalent DC Output Circuit

(sourcing only)

Sourcing

Input

Switch

Sinking

Input

Switch

5.1Kohms

GND

DC+

DC+

GND

DIN

DOUT

Load

Solid State

Switch

Ref

Jumper

GND

DC+

Jumper

5.1Kohms

DIN

Ref

Equivalent Analog

(4-20 mA) Input Circuit

GND

AIN

100

ohms

Ethernet

RJ45

(10/100)

Chassis

GND

1

AO

2

AO

AIDI

DO

Equivalent Analog

(4-20 mA) Output Circuit

DC+

Loop +

Loop -

VT-IPm2m-213 (12 DI, 4 DO, 8 AI, 2 AO)

VT-IPm2m-113 (12 DI, 4 DO, 8 AI)

NC

No

Connection

DO

DI AI

NC

NC

GND

Chassis

Ethernet

RJ45

(10/100)

(sourcing or sinking DI)

DO

Return

(DC-)

-

DI Return Jumper:

Select DC- for sourcing (default)

or DC+ for sinking

+

DC+ for

DI Sourcing

or

DC- for

DI Sinking

(must set

jumper

in base)

10-30 VDC

(User Supplied)

T

GND

+

-

RS232

RJ45

(Port B)

RS485

(Port A)

(Loop powered

AI shown)

1

AIDI

DO

10-30

VDC

86

4

2

735

14231119

75

3

12108642

2524

17 1815 1614

47454344

46

2321 2219 20

1210 1198

7

6

534

21

41403836 37 393432 3331 35

13

42

No

Connection

NC

No

Connection

No

Connection

NC

NC

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Installation and Maintenance Manual

Analog Outputs:

The VersaTRAK IPm2m model VT-IPM2M-213 has two 4-20mA analog output channels, providing 16 bits of resolution at

each channel.

A single terminal is provided for each output channel. Care must be taken to externally provide a suitable

instrumentation ground for these output circuits.

Figure 3-3 VersaTRAK IPm2m diagram for power, communication and on-board I/O wiring

Page 14

VersaTRAK IPm2m RTU

© 2014. Red Lion Controls. All Rights Reserved.

14

Product

RS485

Port A

RS232

Port B

Etherne

t

Port

VT-IPM2M-113

VT-IPM2M-213

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Installation and Maintenance Manual

Communications

4

4.1 Communication Ports

The VT-IPM2M-XXX has two available port combinations, depending on the model number. See the chart below.

RS232 Port B

An RJ45 female connector is provided for this port. The pin-outs follow the EIA/TIA-561standard (See Figure 4-3). A prewired DB9F to RJ45F adapter is included with these units. Use this adapter along with a RJ45 male to RJ45 male straightthru wired patch cable (not included) to make a connection between a com port on your PC (DB9 male) and Port B (RJ45

female). Refer to the Sixnet I/O Tool Kit help for more wiring information.

When connecting a modem, insert the colored wires of the RJ45 to DB9 male adapter into the appropriate sockets of the

DB9 male connector according to the table below. Then plug the adapter’s DB9 male connector directly onto the DB9

RS232 port of a VT-MODEM-xxx. Connect a straight-through Ethernet cable between the Red Lion RJ45 port and the

RJ45 to DB9 male (modem) adapter.

The RJ45 serial port connector bodies on Red Lion products are metallic and are connected to the Chassis GND terminal.

Therefore, shielded cables may be used to provide further protection. To prevent ground loops, the cable shield should

be tied to the metal connector body at one end of the cable only.

Typical Modem Adapter Wiring:

Red Lion RJ45F to DB9M Red Lion

RJ45F Pin #, Adapter DB9 Male Connector

Signal Name wire color Pin #, Signal Name

1 RI/DSR in Blue 9 RI out

2 DCD in Orange 1 DCD out

3 DTR out Black 4 DTR in

4 GND Red 5 GND

5 RXD in Green 2 RXD out

6 TXD out Yellow 3 TXD in

7 CTS in Brown 8 CTS out

8 RTS out White 7 RTS in

Page 15

VersaTRAK IPm2m RTU

© 2014. Red Lion Controls. All Rights Reserved.

15

Figure 4-1 Figure 4-2

RJ45 Connectors

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Installation and Maintenance Manual

Typical PC Adapter Wiring:

Red Lion RJ45F to DB9F

RJ45F Pin #, Adapter DB9 Female Connector

Signal Name wire color Pin #, Signal Name

1 RI/DSR in Blue 4 DTR out

2 DCD in Orange N/C

3 DTR out Black 6 DSR in

4 GND Red 5 GND

5 RXD in Green 3 TXD out

6 TXD out Yellow 2 RXD in

7 CTS in Brown 7 RTS out

8 RTS out White 8 CTS in

Table 4-1

RS485 Port A

There is one RS485 port available on the unit (See Figure 4-3 for location of this port). The RS485 port establishes a (2-

wire, half duplex only) connection to Red Lion’s RemoteTRAK I/O modules or other equipment. Four terminals (for signal

GND, 485+, 485-, & termination) are provided for each available RS485 interface. Generally, you connect + to + and – to

– between units. However, since there is no standard for RS485 terminal designations you may need to connect + to –

and – to + in some cases. No damage will result if you connect incorrectly. It is highly recommended that you tie the

signal ground to an appropriate ground (if available) between all RS485 units. Make sure to use a good quality

communication cable with three conductors (twisted is preferred) plus a shield. To prevent ground loops, the shield

should be connected to chassis ground on only one end of any cable run.

Note: If you have existing wiring that has only two conductors and a shield, you can use the shield to connect the signal grounds

between stations. This is not optimal (especially for long cable runs) but should work in most situations.

RS485 Termination: The VersaTRAK IPm2m has RS485 termination components (150 ohm resistor and a 0.01 F

capacitor connected in series) already inside for each RS485 port. To terminate your RS485 network just tie the “T”

terminal to the RS485 ‘–‘ terminal. Make sure to use the same type and size conductor as used already used for your

RS485 ‘–‘ connection. It is recommended that both end stations of your RS485 network be terminated. Avoid

terminating more than two stations. Refer to the RemoteTRAK I/O User Manual on how to terminate a RemoteTRAK I/O

Module. For 3rd party devices, please refer to their user manual for termination instructions.

Bias Resistors: On a RS485 2-wire network, a pair of bias resistors (1K ohm typically) acting upon the transmit/receive

wires may be required. If bias resistors are not present, the receive inputs on some RS485 devices may react to noise on

the floating wires. The bias resistors will force the transmit/receive wires to a known (non-floating) state when none of

Page 16

VersaTRAK IPm2m RTU

© 2014. Red Lion Controls. All Rights Reserved.

16

RS485 Port A

Ethernet RJ45 (10/100)

RS232

Port B (RJ45)

RS232 Port B

1. RI/DSR in

2. DCD in

3. DTR out

4. GND

5. RXD in

6. TXD out

7. CTS out

8. RTS out

(EIA/TIA-561)

1.1.1.1.1.1.1 E

t

h

e

r

n

e

t

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Installation and Maintenance Manual

the RS485 devices are transmitting data. Some RS485 devices have bias resistors built-in, and are enabled through DIP-

switch or jumper settings. Make sure there is only one pair of bias resistors acting upon the network.

Note: If your RS485 network is made up exclusively of Red Lion devices then these bias resistors are not necessary.

Ethernet Port

This port is a 10/100BaseTx auto-detecting and auto-crossover Ethernet port (see Figure 4-2 for RJ45 Pin locations). This

means it will auto-detect the speed, and work with either a straight-thru or cross-wired Ethernet cable. A standard

shielded RJ45 connector is provided. See the figures below for the pin-outs. This port has a fixed unique MAC address.

The IP address can be set with the Sixnet I/O Tool Kit software. Refer to the electronic help for details.

Figure 4 -3

Page 17

© 2014. Red Lion Controls. All Rights Reserved.

17

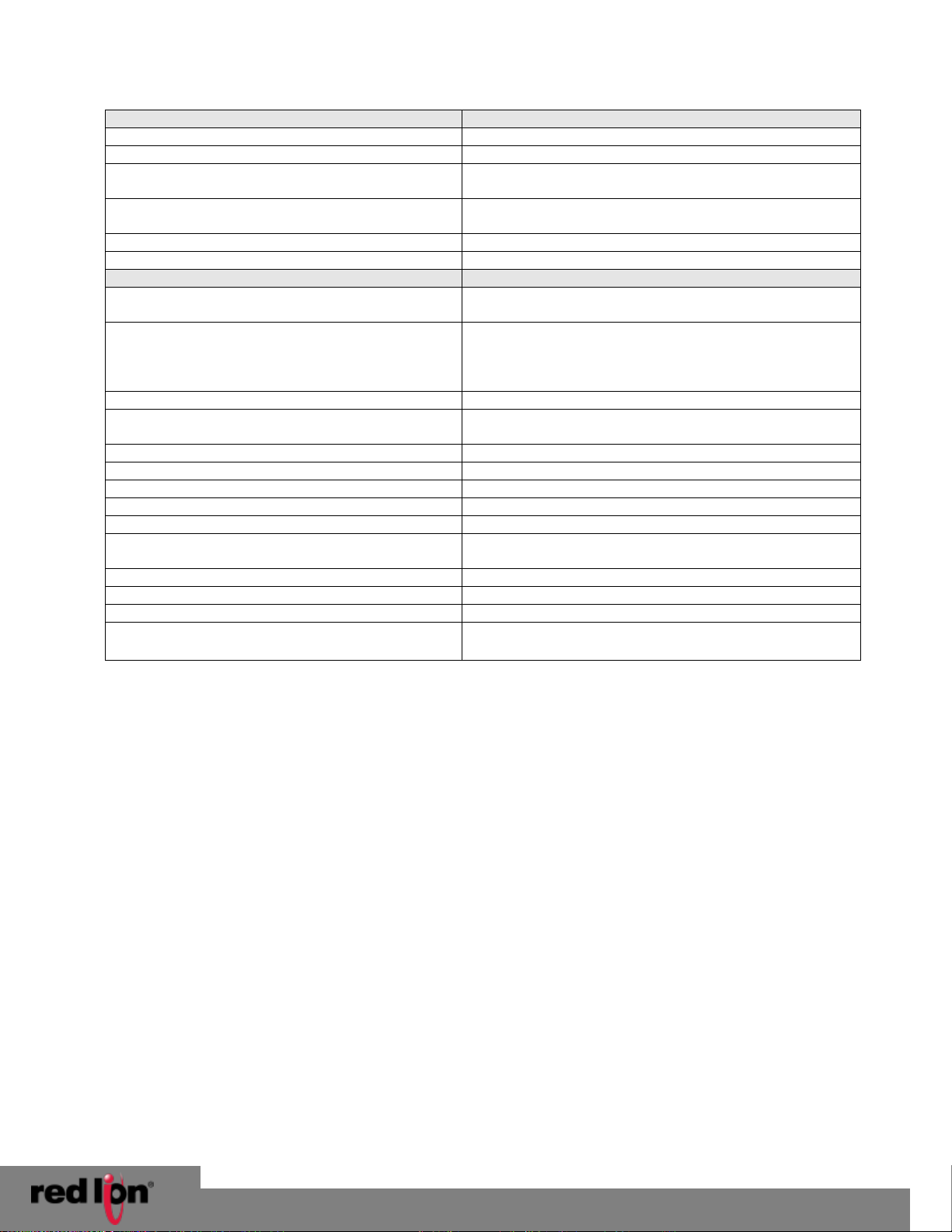

General

Industrial PowerPC (32 bit data bus)

Compatibility with legacy VersaTRAK RTU

Fully compatible with an assortment of on board I/O

Local I/O (on board)

26

Operating system

Embedded LINUX

Unique station addresses (unit Ids)

16,000+ (Sixnet) or 247 (Modbus)

Dynamic memory (RAM)

(for program execution, dynamic variables, dynamic file

system, etc.)

32bit, 0 wait states

32 Megabytes

Program memory (Flash)

(for Linux OS, program storage, and file system)

32 Megabytes

Datalogging memory (RAM)

(for datalogging and retained variables)

Battery-backed – Rechargeable Lithium

512K bytes

Battery-backup time / life

1 year / 10+ years

Real-time clock resolution

10 mS

Real-time clock accuracy

+/-15 seconds per month

I/O expansion

EtherTRAK-2, EtherTRAK, RemoteTRAK

Datalogging support

Yes – Sixnet Sixlog

Datalogging modes

Trending, alarm logging, sequence of events, event initiated, client

transfers, and others

LINUX capabilities

Most Linux commands apply

Programming

High level C and others

Number of applications allowed

As many as there is memory for

Available FREE source code

Practically unlimited

IEC 61131 PLCopen programming

Yes – Sixnet ISaGRAF

Languages supported

Ladder logic, function chart, function block, instruction list,

structured text, and flow chart

Cycle time

10 mS minimum (user settable)

Communication capabilities

Master, slave, peer to peer, report on exception, store and

forward and more

Communication media supported

Ethernet, telemetry, telephone (dialup and leased line), radio

(dumb and smart), other wireless, fiber optic, short haul and more

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Technical Specifications

5

VersaTRAK IPm2m RTU

Installation and Maintenance Manual

Page 18

VersaTRAK IPm2m RTU

© 2014. Red Lion Controls. All Rights Reserved.

18

Watchdogs and Monitors

For run-time diagnostics

CPU watchdog

CPU automatically resets if error is detected; status LED flashes

error code

Communications watchdog

Settable timeout and output action (force off or freeze)

Heartbeat watchdog

Settable timeout & output action (force off or freeze)

Ethernet Port(s)

10/100BaseTx (auto-detecting)

Connection

RJ45 (auto-crossover)

Isolation

1500 Volts RMS 1 minute (60 Hz.)

Message response time (typical)

5 mS

Diagnostic LEDs

Indicates speed and activity

Protocols supported

TCP/IP, ARP, UDP, ICMP, DHCP, Modbus/TCP, Sixnet, and more

Network port

1 shielded RJ45 connector

Serial Ports

300 to 115,200 baud

RS232 Port B

RJ45 (TD, RD, CTS, RTS, CD, DTR, DSR/RI , GND)

RS485 Port A

Screws (GND, 485+, 485-, termination) (2-wire half-duplex)

RS485 network

Up to 32 (full-load) stations

RS485 distance

Up to 0.5 miles (1 km)

Protocols (master & slave)

Sixnet & Modbus (RTU and ASCII); Many others available in LINUX

Diagnostic LEDs on each port

Transmit Data (TD) & Receive Data (RD)

Flow Control

Hardware, software, RTS-party (for radios and RS485)

Discrete Inputs

12 Channels

Guaranteed ON Voltage

9 VDC

Maximum Voltage

30 VDC

Guaranteed OFF

5.0 VDC & 1.5mA DC

Input Resistance

10K Ohms

Input Current @ 24V

3 mA

Filtered ON/OFF delay

25ms (20Hz max. counting)

Fast ON/OFF delay

4 ms (100Hz max counting)

Count Rate

(10khz on channel 1, see above for other rates)

Discrete Outputs

4 or 8 channels (10-30VDC)

Maximum Output per channel

1 Amp

Maximum Output per module

8 Amps

Max. OFF state leakage

0.05 mA

Minimum Load

1 mA

Inrush current

5 Amps (100 ms surge)

Typical ON resistance

0.3 ohms

Typical ON voltage (@1A)

0.3 VDC

Analog Inputs

6 or 8 channels (4-20 mA)

A/D resolution

16 bits (0.003%)

Full scale accuracy

+/- 0.1% (@20C)

Span and offset temp. coef.

+/- 50 ppm per degree C

Input impedance

100 Ohm

Current protection

Self-resetting fuses

DMRR (differential mode rejection)

66 dB at 50/60 Hz

Analog Outputs

Up to 2 channels (4-20mA)

D/A resolution

16 bits (less than 1A)

Full Scale accuracy

+/- 0.02%

Span and offset temp. coef.

+/- 50 ppm per C typical

Max. output settling time

5 ms (to .05%)

Load resistance range (@ +24 VDC supply

0-750 Ohms

Short circuit protection

Current limiting

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Installation and Maintenance Manual

Page 19

VersaTRAK IPm2m RTU

© 2014. Red Lion Controls. All Rights Reserved.

19

I/O Tool Kit Windows Software

Level 1 provided free with all systems

Operating systems

XP SP2 and later

Minimum system requirements

Pentium or equivalent, 32 Mb RAM, 100 Mb hard disk space

Option 1 (Basic)

Configuration, calibration, diagnostics, and limited exporting of I/O

definitions.

Option 2 (SCS)

Full importing and exporting of I/O definitions, peer to peer I/O

transfers, and quick load feature “Load All”..

Option 3 (Datalogging)

Datalogging capability and datalog server

Option 4 (LINUX)

LINUX functionality and support.

Environmental

DIN rail or flat panel mount

Input voltage

10-30 VDC (integrated switching supply),

(External AC/DC or DC/DC supplies optional)

Input power (@ 24 VDC unless otherwise noted) (+/-10%)

(Note: The power consumption variations mostly depend

on the number of Ethernet and/or serial connections.)

VT-IPm:

2.4 W (100mA) – typical (no communications)

Temperature

-40 to 70°C (-40 to 85°C storage)

Humidity

5% to 95% RH (non-condensing)

(optional conformal coating)

Flammability

UL 94V-0 materials

Electrical Safety

UL 508, CSA C22.2/142; EN61010-1; CE

EMI emissions

IEC 61000-6-4, FCC part 15, ICES-003, Class A; EN55022; CE

EMC immunity

I IEC61000-6-2 (EN61000-4-2,3,4,5,6 and 8); CE

Vibration

IEC60068-2-6

Hazardous locations

(Class 1, Div 2, Groups A, B, C, D)

ISA12.12.01, CSA C22.2/213,

ATEX ( Zone 2) IEC60079-0, -15

Marine & Offshore

ABS

Packaging

Lexan Packaging

Mounting

DIN rail (EN50022) or direct to panel

Size

4.75”L x 3.83”W x 4.13”H

(12.07cm L x 9.73cm W x 10.48cm H)

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Installation and Maintenance Manual

Page 20

VersaTRAK IPm2m RTU

© 2014. Red Lion Controls. All Rights Reserved.

20

ON

The VT-IPM2M is operating properly.

OFF

There is no power to the VT-IPM2M or service is required. Contact Red Lion

technical support.

FAST BLINK

This may occur when the VT-IPM2M is being reset, or firmware is to be

downloaded from the I/O Tool Kit software.

SLOW or PERiODIC BLINK

This indicates that the internal watchdog has detected a problem. Try clearing

the memory and reloading the project from the I/O Tool Kit.

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Installation and Maintenance Manual

Maintenance Information

6

6.1 Local Diagnostics

Local diagnostics can be performed through any available port while the VT-IPM2M is responding to messages from the

other port. Diagnostic software, such as the Sixnet I/O Tool Kit, can be used to display the status of the I/O registers.

Refer to the software’s help system for details.

6.2 Power and Status LED

The “PWR” LED on the VT-IPM2M indicates its operational and power status:

6.3 Controller or RTU Memory

The VT-IPM2M has nonvolatile (battery-free) memory for storing configuration data from the I/O Tool Kit utility.

They also have battery-backed memory for storage of program variables and logged data. The battery is a rechargeable

lithium cell that is kept fresh by the power circuitry in the VT-IPM2M. The memory retention period for an unpowered

VT-IPM2M is at least 6-months at room temperature. The retention time will be shorter at higher temperatures. The life

expectancy of the lithium battery is approximately 10 years or more.

Page 21

VersaTRAK IPm2m RTU

© 2014. Red Lion Controls. All Rights Reserved.

21

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Installation and Maintenance Manual

Service Information

7

We sincerely hope that you never experience a problem with any Red Lion product. If you do need service, call Red Lion

at +1 877 432-9908 for Technical Support. A trained specialist will help you to quickly determine the source of the

problem. Many problems are easily resolved with a single phone call. If it is necessary to return a unit to us, an RO

(Repair Order) can be obtained on the Red Lion website.

Red Lion tracks the flow of returned material with our RO system to ensure speedy service. You must include this RO

number on the outside of the box so that your return can be processed immediately.

Be sure to have your original purchase order number and date purchased available.

We suggest that you give us a repair purchase order number in case the repair is not covered under our warranty. You

will not be billed if the repair is covered under warranty.

Please supply us with as many details about the problem as you can. The information you supply will be written on the

RO form and supplied to the repair department before your unit arrives. This helps us to provide you with the best

service, in the fastest manner. Repairs are completed as soon as possible.in two days. If you need a quicker turnaround,

ship the unit to us by air freight. We give priority service to equipment that arrives by overnight delivery.

We apologize for any inconvenience that the need for repair may cause you. We hope that our rapid service meets your

needs. If you have any suggestions to help us improve our service, please give us a call. We appreciate your ideas and

will respond to them.

For Your Convenience:

Please fill in the following and keep this manual with your Red Lion system for future reference:

P.O. #:__________________ Date Purchased: ___________________

Purchased From:______________________________________________

Loading...

Loading...