SUB-CUB 1/2 - COMPLETE 6-DIGIT COMPONENT COUNTERS

.080 (2.0)

.670

C. BD.)

.C. BD.)

APPLICATIONS INCLUDE:

VENDING MACHINES

VIDEO GAMES

COMPUTERS

UTILITY METERS

OFFICE COPIERS

P.C.’S

FLOW METERS

TEST EQUIPMENT

DISPENSING EQUIP.

MACHINE CONTROLS

MEDICAL EQUIPMENT

PORTABLE INSTRUMENTS

* ACCESSORY HARDWARE AVAILABLE FOR PANEL MOUNTING SUB-CUB 2

DESCRIPTION

As a completely self-contained counter/display module, SCUB1/SCUB2 (5 V)

and SCUB1LV (3.3 V) can be treated like an I.C. The module contains a custom

counter/driver chip that performs all the counting functions together with a

6-digit LCD readout. The latchable display with the separate reset function

permits the module to be used as frequency or rate meter, timer, phase-angle or

pulse width indicator and for other complex readout requirements in addition to

simple high speed counting.

The module is ideal for internal “on-board” applications where a readout of

count, frequency, time, etc. is needed within a circuit enclosure for

- LSI COUNTER CHIP WITH LCD DISPLAY

- SNAP MOUNTS DIRECTLY ON P.C. BOARD

SUB-CUB 1 - 0.2" (5 mm) HIGH DISPLAY

SUB-CUB 2 - 0.35" (8.9 mm) HIGH DISPLAY

SOLDERLESS, ELASTOMERIC INTERCONNECTS

ULTRA-LOW POWER

5 V: SUB-CUB 1 AND 2

3.3 V: SUB-CUB 1 ONLY

LATCHABLE DISPLAY WITH LEADING ZERO BLANKING

COUNT RATES TO 10 KHz

IDEAL IN APPLICATIONS FOR:

REGISTER, STATUS & USAGE COUNTING

FREQUENCY, EPUT, & RPM INDICATION

TIMER, PULSE-WIDTH & PERIOD READOUT

maintenance, diagnostic, tune-up, or other data readout requirements. The SUBCUB 2, with its larger display, can also be mounted with the convenient bezel

kit to provide a very flexible and econmical panel instrument.

SUB-CUBs snap-mount directly on any 1/16" P.C. board that has been etched

to provide a mating interconnect pad pattern with two mounting holes and a

polarizing “key” hole. Interconnections to the P.C. Board as well as internal

connections are made with elastomeric connectors that provide corrosion-proof,

gas tight, interface contacts for high reliability.

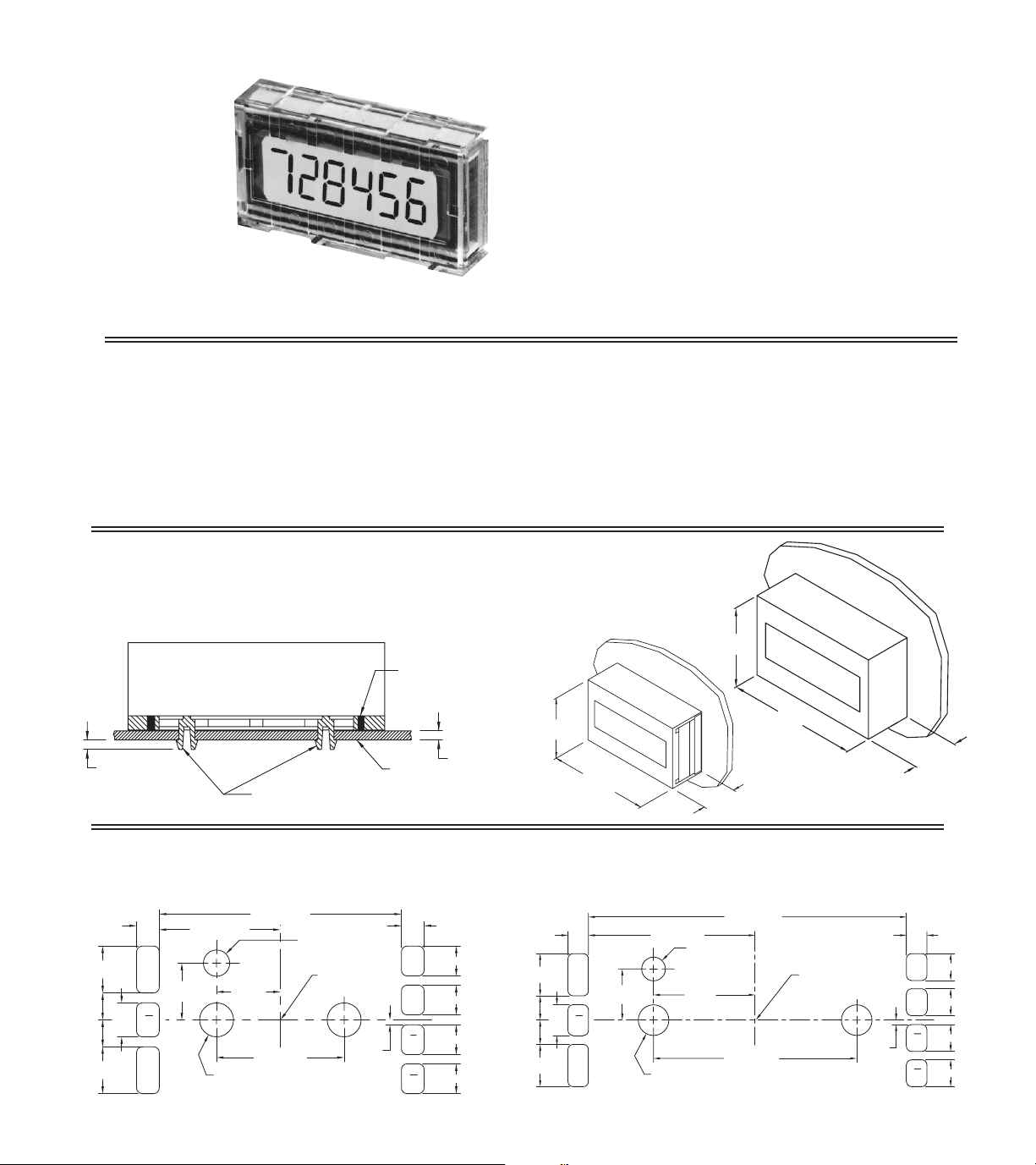

MOUNTING & DIMENSIONS

Snap in mounting on the P.C. Board is facilitated by two, split, lock-ramp pins

which engage mounting holes drilled in the P.C. Board. The silicone rubber

elastomeric connectors compress to accommodate P.C. Board thickness variation

of ±0.005" (0.13 mm).

ELASTOMERIC

CONNECTOR

STRIP

.065

PC BOARD

LOCK-RAMP PINS

.062±.005

P.C. BOARD LAYOUT

P.C. Board pads may be gold or tin-lead plated. Pad surface must be flat

without excessive tin-lead build-up. (Layout views are from SUB-CUB

mounting side of board.)

.080 (2.0)

.165 (4.2)

.095

(2.4)

.095

(2.4)

.165 (4.2)

Vss

.12

(3)

VDD

.427 (10.8)

.20 (5.1)

C

.854 (21.7)

.093 (2.5) DIAM.

POLARIZING HOLE

CENTER POINT

.225

(5.7)

.45 (11.4)

.120 (3) DIA. MOUNTING

HOLE, 2- PLCS.

OF MODULE

SCUB1/SCUB1LV

.0175

(.44)

N.C.

L

R

T

.080 (2.0)

.105 (2.7)

.0325 (.83)

.105 (2.7)

.0325 (.83)

.105 (2.7)

.0325 (.83)

.105 (2.7)

DIMENSIONS

In Inches (mm)

SUB-CUB1

P.C. BOARD

212674

(17)

1.045

(26.6)

Note: All hole size tolerances ±0.003" (0.08 mm)

All other tolerances ±0.005" (0.13 mm)

.080 (2.0)

.165 (4.2)

.095

(2.4)

.095

(2.4)

.165 (4.2)

VSS

.20 (5.1)

.12

C

(3)

VDD

.680 (17.3)

.120 (3) DIA. MOUNTING

HOLE, 2- PLCS.

1

.393 (10)*

(ABOVE P.

.093 (2.5) DIAM.

POLARIZING HOLE

.475

(12.5)

1.040

(26)

1.360 (34.5)

.950 (24.1)

SCUB2

P.C. BOARD

212674

1.880

(47.7)

* BASED ON P.C.

BOARD THICKNESS

OF .062 (1.6)

CENTER POINT

OF MODULE

SUB-CUB2

.0175

(.44)

.470 (11.9)*

(ABOVE P

.105 (2.7)

N.C.

.105 (2.7)

L

.105 (2.7)

T

.105 (2.7)

R

.0325 (.83)

.0325 (.83)

.0325 (.83)

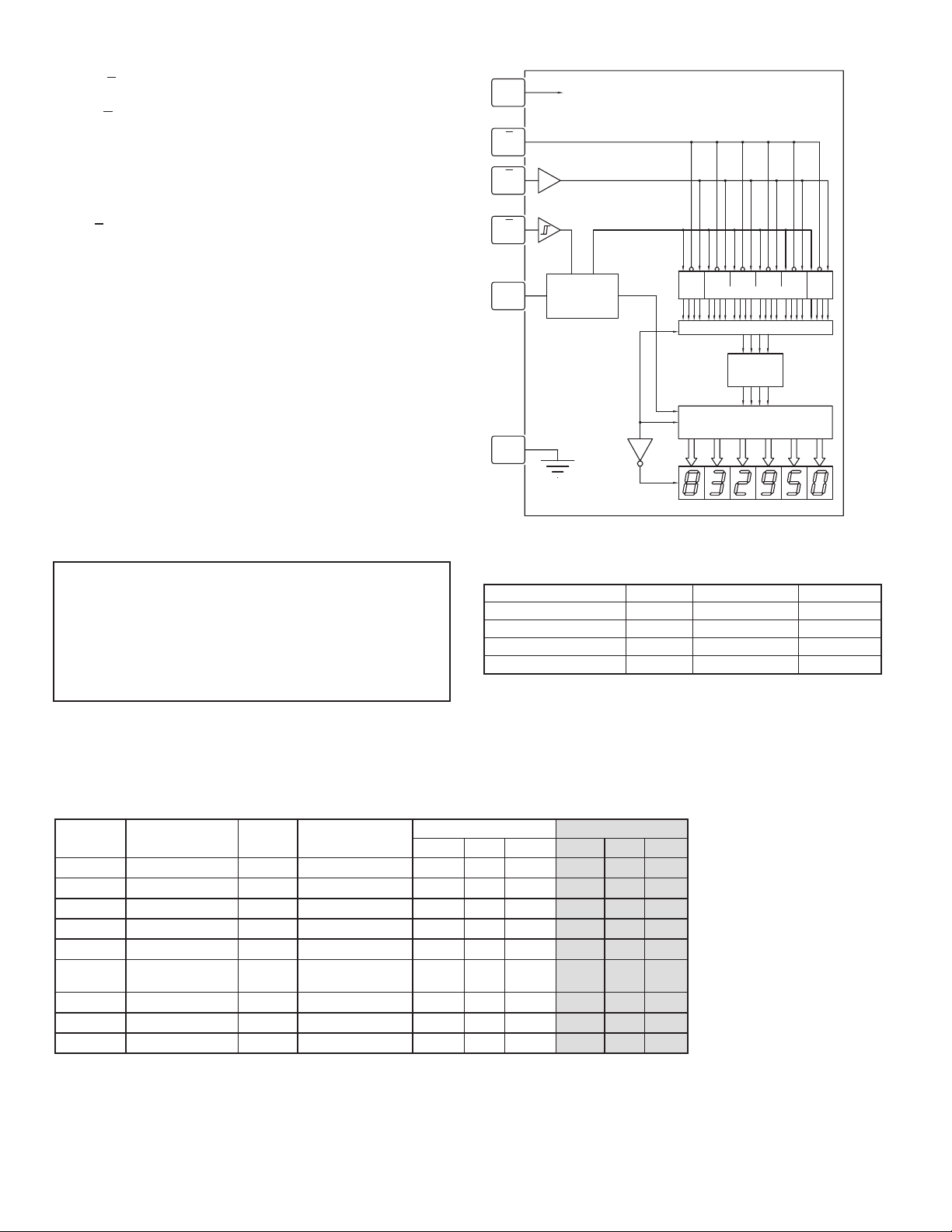

DEVICE CONNECTIONS *

BLOCK DIAGRAM

COUNT (C) - CMOS, Schmidt Trigger; counter increments on negative going

transition.

RESET (R) - CMOS, Schmidt Trigger; counter is reset to zero when input is

low. Counter should always be reset to zero whenever power is first applied

to the unit.

LATCH (L) - CMOS, Schmidt Trigger; when pulled low, the latches are

transparent and display is updated as new counts are received. When latch

input is pulled high, the display registers count existing immediately prior to

activating the latch.

TEST (T) - CMOS, Schmidt Trigger; Input must be connected to VDD. This

input is used by manufacturer during factory testing.

VDD - +VDC Supply.

VSS - Common for D.C. Supply and Inputs.

* All unused inputs must be tied to either VDD or VSS, whichever is appropriate.

VDD

T

TEST

R

RESET

C

COUNT

L

LATCH

VSS

+V

LATCH &

MULTIPLEX

LOGIC

COUNT PULSES

LATCH

BACK

PLANE

DIG.6 DIG.5 DIG.4 DIG.3DIG.2 DIG.1

(MSD)

DISPLAY LATCHES & DRIVERS

COUNTER

MULTIPLEXER

BCD TO 7

SEGMENT

DECODER

MUX REASSEMBLER WITH

LEADING ZERO BLANKING,

6-DIGIT LCD DISPLAY

(LSD)

777777

CAUTION

This device contains CMOS circuitry which requires special anti-static

handling to the same degree required by standard CMOS integrated circuits.

Units should be stored in the conductive packaging used to ship the devices.

Containers should be opened and units handled only on a conductive table

top by personnel wearing wrist-strap grounding equipment. These devices

have the same protection circuits as standard CMOS devices to prevent

MAXIMUM RATINGS (VOLTAGE REF. TO VSS)

RATING SYMBOL VALUE UNIT

DC Supply Voltage V

Input Voltage, All Inputs V

Operating Temperature T

Storage Temperature T

damage to inputs due to nominal over-voltage.

ELECTRICAL CHARACTERISTICS VDD TYP, 25 °C UNLESS OTHERWISE SPECIFIED

SYMBOL PARAMETER UNIT TEST CONDITION

V

I

I

DDQ

V

V

I

Supply Voltage VDC 3.5 5.0 5.25 2.7 3.3 3.6

DD

Supply Current µA 10 KHz Count Rate 55 30

DD

Quiescent Current µA 0 on display 45 20

Input High Voltage VDC 2.45 3.675 1.89 2.52

IH

Input Low Voltage VDC 1.575 2.3625 1.215 1.62

IL

IL

Input Leakage

Current

µA VDD ≥ VIN ≥ V

SS

Frequency Count Frequency KHz 10 10

T

T

LATCH

RST

Reset Pulse Width µsec 25 25

Latch Pulse Width µsec 25 25

SCUB1/SCUB2 SCUB1LV

MIN. TYP MAX MIN. TYP MAX

0.01 0.01

DD

I

A

STG

-0.5 to +5.25 VDC

-0.5 to (VDD +0.5) VDC

-35 to +85 °C

-35 to +85 °C

2

TYPICAL APPLICATIONS

OR PERIOD

COUNT & CONTROL FROM REMOTE INPUTS

Inputs to SUB-CUB are CMOS inputs and must be adequately buffered if

remote “off-board” signal sources are used. This illustration shows a SUBCUB being used in an elementary counting application to depict some of the

buffering methods that can be used.

The Count Input is buffered by the NPN Transistor input circuit. The base

resistance is split into two 10 K resistors, with a filter cap to eliminate spurious

counts due to electrical interference pickup. The filter network will allow count

rates to 10 KHz with Symetrical +5 V input count pulses. The 4.7 K across the

input would not be required if the circuit supplying the count pulses has a low

off-state output impedance.

The Remote Button-actuated Reset input is buffered by a simple RC circuit

consisting of two 47 K resistors and a 0.01 µf capacitor.

FREQUENCY, SPEED, FLOW, SPEED-RATIO,

PERIOD & CYCLE TIME INDICATIONS

This circuit uses a dual monostable I.C. to generate the proper latch and reset

coordination required for frequency or time-period readouts.

When frequency readout is desired, the pulse train whose frequency is to be

displayed, is applied to the CLK-A input, (the inverter, in the CLK-A input,

causes the SUB-CUB to increment on the positive going edge of CLK-A pulses

and can be onitted if negative edge incrementing is satisfactory). The CLK-B

input is supplied with standard time-base pulses whose period determines the

measuring time. For frequency measurement, this time is 1 second so CLK-B

input would be supplied with 1 pulse/sec. from a crystal clock or line-reference

divider. At the positive going edge of each CLK-B pulse, the first monostable

opens the SUB-CUB latch momentarily to update the display to the count

existing at that instant of time. Immediately after the latch closes, freezing the

updated count on the display, the internal counter in the SUB-CUB display is

reset to zero in preparation for a new counting cycle. Thus, at the end of each

measuring time interval the SUB-CUB display is updated to readout the number

of pulses received during the period, while it is accumulating new counts for the

next update.

Frequency ratio can be displayed by replacing the standard time-base (CLK-

B) input with a pulse train related to the second variable (or denominator) of

the ratio. Normally this pulse train is divided by 10, 100, or 1000 before being

applied to the CLK-B input to provide a higher resolution reading.

For period or cycle-time indication, CLK-A and B inputs are simply

interchanged. CLK-A input is now supplied with standard Clock Pulses, say 1

Hz to readout in seconds, while the pulse train whose period is being measured

is applied to the CLK-B input.

COUNT

INPUTS

4.7K

CLK-B

CLK-A

CLK-A

CLK-B

L-LATCH

R-RESET

+5VDC SUPPLY

10K

100K

14

12

11

10K

.005

+5V

1/2-4528

A

B

µf

COMMON

Q

815

VDD

2

4

5

1/2-4528

A

B

31613

Q

1

.01 µf

7

VDD

VSS

VSS

T

R

SUB-CUB

C

L

T

R

SUB-CUB

C

L

47K

100K

47K

REMOTE

RESET

100K

9

.001 µf.001 µf

PULSE WIDTH OR DWELL-TIME READOUT

This circuit also uses two monostables, however for pulse-width readout they

function at two different times.

A train of standard clock pulses, whose period determines the readout

increments, is applied to the CLK-A input. For example if readout in seconds is

desired, CLK-A would receive 1 pulse/second, or 1 Hz The pulse whose width

is to be measured is applied to CLK-B input. At the positive going edge of the

CLK-B pulse, the first monostable momentarily resets the SUB-CUB internal

counter to zero, and it then begins accumulating counts from the CLK-A time

reference pulses. At the conclusion of the CLK-B pulse, the negative going

edge momentarily opens the SUB-CUB display latch, and the number of timereference pulses that have been counted, since reset, is latched on the display to

provide a direct readout of CLK-B pulse-width.

31613

1/2-4528

A

B

1

TIME BASE

7

Q

VDD

VSS

UPDATE

DISPLAY

T

R

SUB-CUB

C

L

CLK-B

CLK-A

100K

14

12

11

+5V

1/2-4528

A

B

UPDATE

DISPLAY

100K

2

9

Q

815

4

5

.001 µf.001 µf

3

PANEL BEZEL KIT FOR THE SUB-CUB 2 (P/N HWK40000)

This kit provides a convenient way to adapt the SUB-CUB 2 to panel mounting. The kit includes

the black plastic bezel, the panel and internal window gaskets, P.C. Board, 12" ribbon cable and

mounting screws.

ASSEMBLY

BEZEL

PANEL

GASKET

INTERNAL

WINDOW

GASKET

SUB-CUB 2

CUSTOMER'S PANEL

.05"-.150" THICK

4-40 SCREWS

1/4" LONG FOR

.05"-.12" PANELS

PC BOARD

DIMENSIONS & PANEL CUT-OUT In inches (mm)

GRN

+V

DD

T

BLU

(TEST)

R (RESET)

VIO

GRY C (COUNT)

WHT

L (LATCH)

BLK

V (COMMON)

SS

.30

1.55

(39.37)

(7.62)

SUB

CUB

PANEL CUT-OUT FRONT VIEW

A

A

2.75 (69.85)

.38

(9.65)

.25

(6.35)

PC BOARD

(CUSTOMER

FURNISHED)

1.88 (47.75)

2.187 (55.55)

1.03

(26.16)

SECTION A-A

EVALUATION BOARD

The SUB-CUB evaluation board, DMOSCB02, can be used for bread board

evaluation of the SCUB1 or SCUB2. The SCUB will mount directly to the

evaluation board and all connections to the SCUB are made accessible via

header pins. Note that the DMOSCB02 evaluation board does not include the

SUB-CUB Display/Counter Module, which must be ordered separately.

SUB-CUB

MOUNTING BOARD

P/N DMOSCB02

CUSTOMER DESIGNED

BREAD BOARD

2X 1/8" DIA.

2X 1/4" DIA.

ORDERING INFORMATION

MODEL NO. DESCRIPTION PART NUMBER

SCUB1 SUB-CUB 1 Display/Counter Module SCUB1000

SCUB1LV SUB-CUB 1 Low Voltage Display/Counter Module SCUB1LV0

SCUB2 SUB-CUB 2 Display/Counter Module SCUB2000

HWK 4 *SUB-CUB 2 Panel Bezel Kit with P.C. Board & Cable HWK40000

HWK 3 *SUB-CUB 2 Panel Bezel Kit w/o P.C. Board & Cable HWK30000

SUB-CUB Mounting P.C. Board DMOSCB02

* SUB-CUB Evaluation Board Does Not Include SUB-CUB Dislay/Counter Module.

Order SUB-CUB Module Separately.

Loading...

Loading...