Page 1

7

8

9

10

11

12

6

5

4

3

2

1

2.37 (60.2)

1.77

(45.0)

SOCKET P/N 2300200

(ORDER SEPARATELY)

.88

(22.4)

4.44

(112.8)

* RANGE ADJUSTMENT (VOLTAGE & CURRENT OUTPUT)

.84

(21.3)

2.69

(68.3)

2.31 (58.7)

.84

(21.3)

SOCKET

P/N 2300200

.16 (4.1) DIA.

2 HOLES

* ZERO ADJUSTMENT (CURRENT OUTPUT ONLY)

* 20 TURN SCREWDRIVER

ADJUSTMENTS ACCESSIBLE

THROUGH TOP

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net

MODEL PRA2 - PULSE RATE TO ANALOG CONVERTER

DELIVERS ANALOG OUTPUT PROPORTIONAL TO INPUT

PULSE-RATE (FREQUENCY)

ACCEPTS VARIABLE PULSE-RATE INPUTS FROM A WIDE

VARIETY OF SENSORS

DUAL SIGNAL OUTPUT, 0 TO 10 VDC PLUS SELECTABLE

SIGNAL CURRENT OUTPUT OF 0 TO 1 MA OR 4 TO 20 MA

SELECTABLE FREQUENCY RANGE RATINGS FROM 30 HZ TO

10 KHZ

ACCURACY (LINEARITY) 0.25%

SWITCH SELECTABLE FOR 115 OR 230 VAC

Bulletin No. PRA2-C

Drawing No. LP0540

Released 10/12

DESCRIPTION

The Model PRA2 is a convenient plug-in module that provides voltage and

current analog output signals proportional to the pulse-rate (frequency) of the

input signal. In typical applications the PRA2 input is supplied by a machine

mounted sensor that generates a signal which has a frequency proportional to

machine or process speed. The PRA2 converts the frequency content of this

signal to analog form for operating chart recorders, supplying speed control

signals, or driving other controls and indicators that require analog input.

The PRA2 develops an internal “constant-area” pulse from the negative

going edge of each input pulse or wave form cycle. These “Constant-area”

pulses are fixed in voltage amplitude and time duration. The PRA2 then takes

the average of a train of these pulses to generate an output voltage level

proportional to the frequency. Another circuit within the PRA2 monitors the

voltage output and produces a current output signal that will deliver either 0 to

1 or 4 to 20 mA, as determined by a set-up switch.

This unit is available with five overlapping adjustable range ratings, each

rating providing a calibration adjustment to deliver maximum output over an

input frequency range of approximately 3.3:1. Since the PRA2 develops an

output by averaging pulses, an inherent response time is involved (See response

table, next page). The minimum response time is fixed for each range rating. It

is longest for the lowest range rating and decreases as the frequency range rating

increases. Response time must be considered, when using the PRA2 to provide

closed-loop speed feedback signals, to avoid stability problems. For speed

feedback applications it is usually advisable to select a high frequency range

coupled with an appropriate sensor arrangement that delivers a high pulse rate.

The internal output filtering supplied for averaging purposes is kept to a

minimum to provide the fastest practical response time for each range rating.

Extra external capacitance can be added to provide more filtering if required.

DIMENSIONS In inches (mm)

The plug-in module mates with a heavy duty, CSA approved base mounting

socket with pressure clamp screw terminals that accept stripped wires without lugs.

SPECIFICATIONS

1. PRIMARY SUPPLY VOLTAGE: Switch selectable for 115 or 230 VAC

±10%, 60 Hz; 8 VA

2. SENSOR OUTPUT POWER: +12 VDC ±5% regulated, 60 mA max.

3. SIGNAL INPUT CHARACTERISTICS: See “Input & Output Switch

Set-up” section.

4. MAX. FREQUENCY ADJUSTMENT: 30 Hz to 10 KHz

5. SIGNAL VOLTAGE OUTPUT: 0 to 10 VDC @ 10 mA max.

6. SIGNAL CURRENT OUTPUT (Selectable):

0 to 1 mA into load resistance range 0 to 4 K.

4 to 20 mA into load resistance range 0 to 250

7. LINEARITY: ±0.25% of full range setting.

8. VOLTAGE/CURRENT OUTPUT TRACKING: Current Signals follow

voltage signals within ±3% of full range setting.

9. RESPONSE TIME: See table on next page.

10. OPERATING TEMPERATURE RANGE: 0 to 60

o

C.

11. WEIGHT: PRA2 - 8 oz (226.8 g); Mating 12-Pin Socket - 2 oz (56.7 g).

ORDERING INFORMATION

MODEL NO. DESCRIPTION PART NUMBERS

PRA2 Pulse Rate to Analog Converter PRA20000

Socket, 12-Pin 2300200

1

Page 2

7

8

9

10

11

12 1

2

3

4

5

6

INPUT

N.C.

COMM.

+12V

TO

SENSOR

A.C.

POWER

(SEE PG. 3)

0-10 VDC

AT 10MA MAX.

OUTPUT

OPTIONAL

FILTER CAP

(-)

(+)

CURRENT

OUTPUT

0-1MA, MAX. R = 4K

4-20MA, MAX. R = 250Ω

L

L

R

L

COMM. COMM.

N.C.

(-)

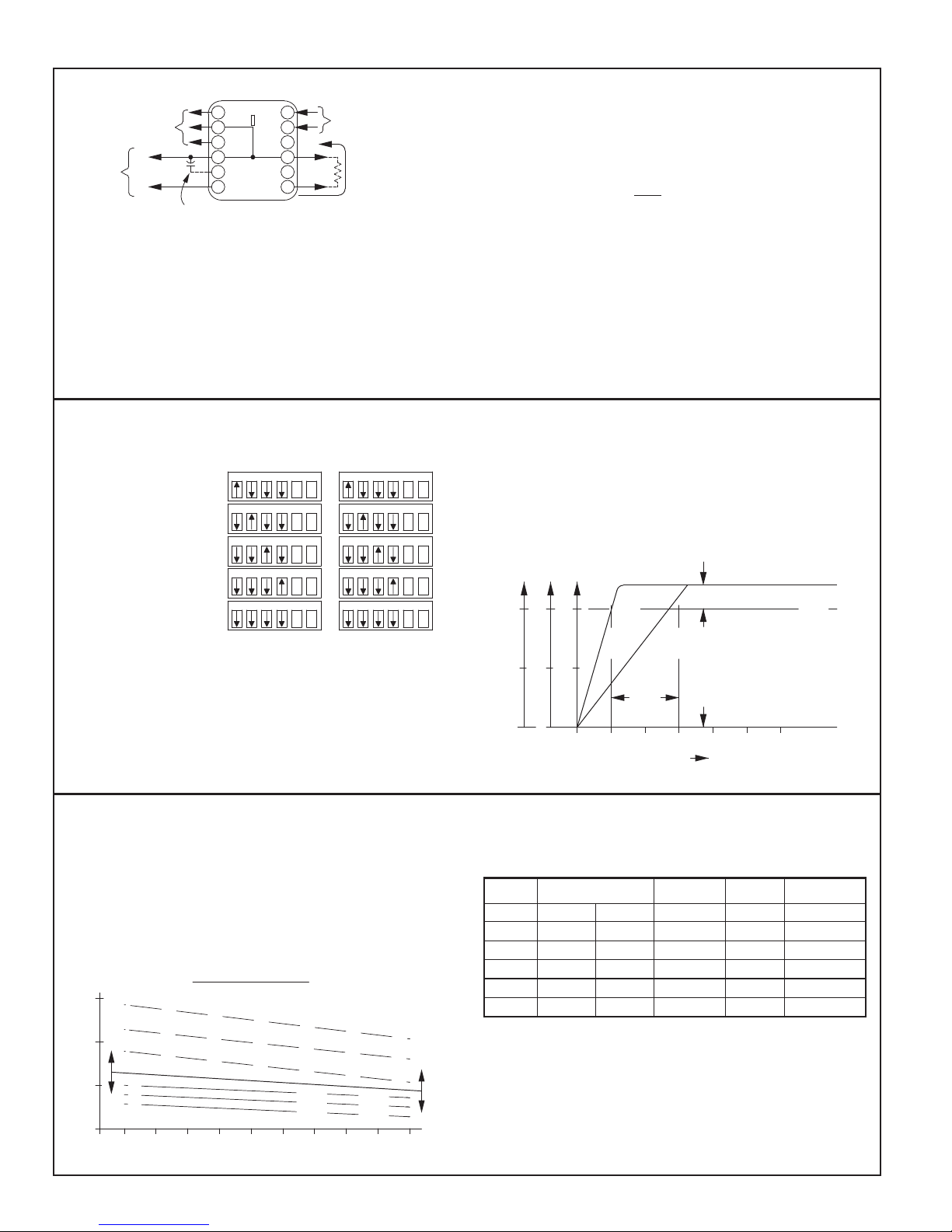

APPLICATION CONSIDERATIONS

OVERRANGE

OUTPUT SATUATION

OUTPUT CURRENT 4-20MA

OUTPUT CURRENT 0-1MA

OUTPUT VOLTS

LINEAR REGION

0123456

4

0

12

.5

20

1

510

ADJUSTABLE

RANGE

FREQUENCY KHZ

TRANSFER CHARACTERISTICS

FOR RANGE 4

(FULL SCALE ADJUSTMENT

RANGE, 1 - 3 KHZ)

FULL SCALE OUTPUT

MINIMUM RANGE

MAXIMUM RANGE

10% 20% 40% 60%

0

1

2

% OF FULL SCALE OUTPUT

3

80% 100%

TYPICAL OUTPUT RIPPLE

(SEE TABLE FOR CURVE KEY

TO PARTICULAR PRA2 RANGE)

MIN. FULL SCALE ADJUSTMENT

MAX. FULL SCALE ADJUSTMENT

PEAK TO PEAK RIPPLE VOLTS

A

B

C

C

B

A

0

3456

43 65

43 65

43 65

43 65

12

12

12

12

21

21 43

12 346556

21 43 65

12 34

21 43

56

65

ON ON

**

**

**

**

**

**

**

**

**

**

CONNECTIONS & SET-UP ADJUSTMENTS

+

(+)

VOLTAGE OUTPUT ADJUSTMENT:

Only the RANGE ADJUSTMENT is effective when voltage output is used.

(Zero Adjustment affects only current output.)

PROCEDURE

1. Set AC power switch to proper position.

2. Connect voltmeter to Terminals 10 & 12.

3. Set the Range Switches for desired max. input frequency.

4. Apply the maximum input frequency and turn the *RANGE

ADJUSTMENT to obtain the desired output voltage.

ADJUSTABLE RANGE RATINGS & OVER RANGE OPERATION

Frequency Range

RANGE

FULL SCALE

ADJUSTMENT

1 30 Hz to 100 Hz

2 100 Hz to 300 Hz

3 300 Hz to 1 kHz

SW1

SW2

CURRENT OUTPUT ADJUSTMENTS:

When current output is used, the ZERO ADJUSTMENT must be set before

RANGE ADJUSTMENT setting is attempted.

PROCEDURE

1. Set AC power switch to proper position.

2. Select current range with switch SW2-6 (OFF 0-1 mA / ON 4-20 mA) .

3. Connect a milliammeter in series with the current loop circuit from Term 1

to Term 3. CAUTION: DO NOT exceed maximum load resistance specified

for the current range.

4. Set the Range Switches for desired max. input frequency.

5. Zero Adjustment:

A) 0-1 mA Range - With input signal removed (zero frequency) turn ZERO

B) 4-20 mA Range - Set ZERO ADJUST until current is 4 mA.

6. *Range Adjustment: Apply maximum frequency input signal and set

RANGE ADJUSTMENT to get desired output.

* RANGE ADJUSTMENT - Turning CW decreases output at a given frequency

(increases range) and turning CCW increases output (decreases range).

and the output voltage or current will be proportional to input frequency. If the

input frequency exceeds the full-scale range setting (over range), the output

will flatten out and saturate at some level above 10 V at all higher frequencies.

CAUTION: Maximum input frequency for PRA2 modules is 10 KHz. At input

frequencies in excess of 10 KHz, the frequency roll-off characteristics of the

input circuit will cause signal dropout and result in discontinuous

operation.

ADJUST CW until positive current flow is indicated. Then, turn back

CCW until the current flow just reaches zero. Stop turning the adjustment

at that point.

4 1 kHz to 3 kHz

5 3 kHz to 10 kHz

Frequency Curves

The Transfer Curve (at right) shows the frequency-input/voltage-output

relationship for the PRA2, Range #4 for both Min. Range (0-1 KHz) and Max.

Range (0-3 KHz) adjustment. These curves are typical and apply to all PRA2

ranges.

As shown by these curves, the PRA2 RANGE ADJUSTMENT allows the

unit to be calibrated to deliver full scale output for any input frequency from

the min. to max. range ratings. As long as the input frequency is equal-to or

less-than the full-scale range setting, the PRA2 is operating in its linear region

OUTPUT RESPONSE & RIPPLE CHARACTERISTICS

PRA2 Modules are supplied with a minimum amount of output ripple

filtering in order to avoid compromising response-time. The data presented

below, permits a reasonable estimate of the amount of ripple and the responsetime that will be experienced in a particular application. As shown by the

curves below, the amount of output ripple depends on the range setting and the

input frequency.

Ripple voltage can be reduced by adding external filter capacitance, but

ripple-reduction is a trade-off against increased response times. This must be

kept in mind, especially if the PRA2 is to be used to supply feedback control

signals.

The values of capacitance given in the table are for reference only and do

not imply a limit to the amount of capacitance that can be added. For example,

an external filter capacitance may be 10 times the reference values shown for

a very high degree of ripple reduction, provided that the resulting long

response time is acceptable.

RANGE

FULL SCALE RANGE

ADJUSTMENT

MIN MAX [1] [2] [3]

1 30 Hz 100 Hz 250 msec A 2.2 mfd

2 100 Hz 300 Hz 75 msec A 0.56 mfd

3 0.3 KHz 1 KHz 25 msec A 0.22 mfd

4 1 KHz 3 KHz 10 msec B 0.1 mfd

5 3 KHz 10 KHz 8 msec C 0.047 mfd

RESPONSE

TIME

RIPPLE

CURVE

EXT CAP (REF)

Note: If large capacitor values are required to achieve a high degree of ripple

reduction, tantalum capacitors rated at 35 V or more are recommended.

(Proper polarity must be observed. See Connection Drawing above.)

[1] RESPONSE TIME - Time required for the output to reach 90% of final value

when the frequency is instantly changed from 0 to full-scale range frequency.

[2] See “Typical Output Ripple” Curves (at left).

[3] External Capacitance can be added between terminals 10 and 11 to decrease

ripple. Reference values shown in MFD, will reduce ripple approximately 50%

and will roughly double response times.

2

Page 3

INPUT & OUTPUT SWITCH SET-UP

825K

39K10K3.4K

37.4K

3.9K1K

8

*BLK COMM.

470pf

0.1

S1-6S1-5

7

*WHT

9

*REDIN+12V

INPUT AMP.

SCHMIDT TRIG.

CONNECTED

SENSOR

POWER

SIGNAL

INPUT

*STD. RLC 3-WIRE

COLOR CODE

SENSOR CONNECTIONS

INPUT

CONFIG.

SWITCHES

S2-5

SNK.

SRC.

LOGIC

5

6*6

5

ON

SW1

SW2

0-1/4-20

7

8

9

INPUT

COMM.

+12V

PRA2

MAGNETIC PICKUP

SHIELD

LOGIC

SRC.

SNK.

55

66

*

SW1

SW2

7

8

9

INPUT

COMM.

+12V

PRA2

SENSOR

PNP O.C.

OUTPUT

+12V

OUTPUT

COMMON

ON

LOGIC

SRC.

SNK.

55

66

*

SW2

SW1

7

8

9

INPUT

COMM.

+12V

PRA2

SENSOR

NPN O.C.

OUTPUT

RED

WHT

BLK

ON

LOGIC

SRC.

SNK.

55

66

*

SW2

SW1

7

8

9

INPUT

COMM.

+12V

PRA2

RLC

SENSOR

BLU

BLK OR BRN

MODELS

PSA-1

PSA-2

ON

LOGIC

SRC.

SNK.

55

66

*

SW2

SW1

7

8

9

INPUT

COMM.

+12V

PRA2

R

C

LOGIC

SRC.

SNK.

55

66

*

SW2

SW1

7

8

9

INPUT

COMM.

+12V

PRA2

SENSOR

-EF

OUTPUT

A

C

B

ON

LOGIC

SRC.

SNK.

55

66

*

SW2

SW1

7

8

9

INPUT

COMM.

+12V

PRA2

+V

ON

SNK.

LOGIC

SRC.

565

6

*

SW2

SW1

The Model PRA2 Pulse-Rate to Analog Converter uses the circuit shown on

the right. The circuit uses a comparator amplifier connected as a Schmidt trigger

circuit to convert the input wave form into the pulse form required for proper

circuit operation. Three set-up switches are used to configure the input circuit

to accept signals from a wide variety of sources, as follows:

SW1-5 - ON: Connects a 3.9 K pull-up resistor for sensors with current sinking

output. (Maximum sensor current is 3 mA.)

SW2-5 - ON: Connects a 1 K pull-down resistor for sensors with sourcing

output. (Maximum sensor output current is 12 mA @ 12 V output.)

SW1-6 - ON: Sets bias of input to trigger at V

level signals.

OFF: Sets the bias of input to trigger at V

increased sensitivity when used with magnetic pickups.

= 2.5 V, VIH = 3.0 V; for logic

IL

= 0.25 V, VIH = 0.75 V; for

IL

SW2-6 - ON: 4-20 mA Output

OFF: 0-1 mA Output

Paralleling With a Counter and/or Rate Indicator Inputs: The PRA2 can be

OTHER CHARACTERISTICS & SPECIFICATIONS

Maximum Operating Frequency: 10 KHz with minimum pulse width ON and

OFF times of 50 μsec.

Maximum Input V oltage: Pin 7 (Input) may be driven from an external voltage

up to ±90V provided SW2-5 and SW1-5 are “OFF” to disconnect internal

load resistors. (Maximum Input Voltage with SW2-5 “ON” is ±24 V)

Input Impedance: With SW2-5 and SW1-5 “OFF”, the resistive input

impedance exceeds 1 Megohm, as long as Pin 7 voltage is greater than zero

and less than +12 V.

operated from a common sensor with current sinking output that is also used

to drive the input of a Counter or Rate Indicator. Connect Pin 8 to the

Common Terminal and Pin 7 to the Input Terminal of the Counter or Rate

Indicator; set SW2-5 and SW1-5 “OFF” and SW1-6 “ON”. DO NOT

PARALLEL CONNECT THE +12V OUTPUT (Pin 9) OF PRA2 UNITS

WITH THE +12V OUTPUTS OF COUNTERS, DITAKS, OR OTHER

PRS1, or PRA2 UNITS. These units have regulated supplies that will not

load-share. Multiple inputs cannot be operated from sensing switches, 2-wire

proximity sensors, or magnetic pickups.

CONNECTIONS & CONFIGURATION SWITCH SET-UP FOR VARIOUS SENSOR OUTPUTS

MAGNETIC PICKUPS

RECOMMENDED RULES FOR MAGNETIC PICKUP CONNECTIONS

1. Mount the PRA2 in a relatively “noise-free” environment, away from motor starters,

control relays, or other sources of electrical interference.

2. Use 2-wire shielded cable for magnetic pickup signal leads.

3. Never run signal cable in conduit, troughs, or cable bundles with power carrying

conductors.

4. Connect the shield to the common Terminal “8” at the input of the PRA2. DO NOT

connect the shield at the pickup end, leave it “open” and insulate the exposed shield to

prevent electrical contact with the frame or case. (Shielded cable, supplied on some

RLC magnetic pickups, has open shield on pickup end.)

2-WIRE PROXIMITY SENSORS A.C. INPUTS FROM INVERTERS, A.C.

INPUT FROM CMOS OR TTL

ON

TACHOMETERS GENERATORS, ETC.

R - Resistor to limit input current to 5 mA peak

C - Filter cap required when input A.C. has “ringing”

characteristics as with inverters.

A.C. Power sources exceeding 50 V output

should be coupled with an isolation transformer.

3

SENSORS WITH CURRENT SINK OUTPUT (NPN O.C.)

RLC SENSOR MODELS:

ASTC, LMPC, PSAC, ZFG, ZCG, ZBG, ZHG, ZCH, HESS, etc.

SENSORS WITH CURRENT SOURCE OUTPUT (PNP O.C.)

OLDER STYLE RLC SENSORS WITH

-EF OUTPUT

ON

RLC SENSOR MODEL: LMPEC

Page 4

SENSOR & FREQUENCY RANGE SELECTION

7

8

9

INPUT

COMM.

+12V

PRA2

MODEL

RRDC

SRC.

LOGIC

SNK.

ON

WHT

BLUE

BRN

*

SW2

SW1

55

66

The PRA2 Pulse-Rate to Analog Converter normally operates from a

variable frequency signal supplied by a machine mounted sensor. The sensor

signal varies in frequency in direct proportion to machine speed, and may be a

sinusoidal, triangular, square, or pulse-type waveform. The sensor arrangement

can take a variety of forms such as a Magnetic Pickup or Proximity Sensor

detecting passing teeth on a sprocket or gear, a Photo-Electric Scanner viewing

passing pulley spokes, a Rotary Pulse Generator coupled to a machine shaft, or

a Length Sensor driven by a web or ribbon of material passing through the

machine. (See Sensor Section of the catalog for more information on sensors.)

Since the PRA2 operates from the frequency content of the incoming signal,

the response time of this device is also related to the signal frequency. This

gives rise to the cardinal rule of selecting a sensor arrangement:

WHEN RESPONSE TIME IS IMPORTANT, SELECT A SENSOR

ARRANGEMENT & LOCATION THAT WILL PROVIDE A HIGH

FREQUENCY OUTPUT AT OPERATING SPEED.

When a PRA2 application is first contemplated, it seems to be natural to

think in terms of applying the sensor to the low speed end of the power drive

train. In some cases this may be the only practical location for the sensor, and

if fast response is needed from the PRA2, a sensor arrangement capable of

delivering a high number of cycles or pulses/revolution (PPR) will be required.

In a great number of applications however, generating a higher frequency

sensor signal is simply a matter of locating the sensor on a intermediate or high

speed shaft such as directly on the drive motor shaft.

Another advantage of moving the sensor location up toward the high speed

end of the drive train is that the shaft rotary motion is usually much smoother

and more regular. Slow speed shafts will often rotate irregularly due to gear

backlash, “slop” in couplings, or slack in chain drives.

SELECTING AN APPROPRIA TE SENSOR ARRANGEMENT

There are no exact rules governing the selection of a sensor arrangement

since machine geometry and conditions can vary widely from one application

to the next. However, the following generalized criteria will prove useful as

guidelines toward selecting the best sensor arrangement. (See Sensor Section of

the catalog for more information.)

ULTRA-LOW SHAFT SPEEDS (10RPM or less) - Proximity Sensors,

Photo-Electric Scanners, or Rotary Pulse Generators, are usually the best

selections. In most ultra-low speed applications, it is advisable to provide as

many pulses per revolution as possible (high PPR) to get acceptable

response times.

LOW-SHAFT SPEEDS (10-100RPM) - LMPC (Super-Sensitive Magnetic

Pickup), Proximity Sensors, Photo-Electric Scanners and RPG’s can usually

be applied in this speed range.

INTERMEDIATE SHAFT SPEEDS (10-1000RPM) - Magnetic Pickups,

the LMPC, RPG’s and some Proximity Sensors are appropriate at these

speeds.

HIGH-SHAFT SPEEDS (1000RPM and up) - Magnetic Pickups, the LMPC

and RPG’s are usually the best choices.

FOR LINEAR SPEEDS ON PAPER WEBS, TEXTILE, RIBBON, STRIP

AND WIRE - The LSC Length Sensor may prove desirable.

CAUTION: When selecting a sensor for operation at any speed, make sure the

sensor is also capable of delivering an output for the entire speed range up

through maximum machine speed.

DETERMINING SENSOR FREQUENCY OUTPUT &

SELECTING THE PROPER FREQUENCY RANGE

Machine speeds are normally expressed in revolutions/minute (RPM) while

the PRA2 has adjustable frequency ranges in cycles/second or Hz. In addition,

sensor arrangements usually deliver a number of signal cycles or pulses for

each shaft revolution. The following formula provides a convenient way to

relate these variables:

FRQ (CPS or Hz) =

RPM x PPR

60

WHERE:

RPM is the speed of the shaft where the sensor is located in revolutions per

minute.

PPR is the number of pulses (or cycles) produced by the sensor for one shaft

revolution.

EXAMPLE 1

A pulley with 6 spokes operates at 650 RPM maximum machine speed.

The spokes are to be sensed with a Model RR Retro-Reflective Photo Sensor.

The application requires a PRA2 to develop a 4-20 mA signal for a chart

recorder (20 mA output at max. speed). What is the frequency range to be

used for the PRA2?

FRQ @ max. speed =

650 RPM x 6 PPR

60

= 65 Hz

SELECT: Range 1 (adjustable for max. output 30 to 100 Hz)

EXAMPLE 2

The speed of a gravity-powered conveyor is restrained and controlled by

a hydraulic brake (pump) which is coupled to a conveyor shaft. A PRA2 is to

be used to supply a speed feed-back signal to the hydraulic control circuit,

with 0-10 VDC corresponding to a speed range of 0-36 RPM on the conveyor

shaft.

SOLUTION: Since the PRA2 is in the speed feed back control loop, fast

response is important and a high PPR will be needed to minimize delay in

output response. By using a 600 PPR Rotary Pulse Generator (ZBG)

coupled by 3:1 speed-increasing instrument belt drive, the effective PPR

of the conveyor shaft is 3 x 600 or 1800 PPR. The PRA2 input frequency

then is:

SELECT: Range 4 (adjustable for max. output, 1 to 3 KHz)

Note: The smoothness of shaft motion can be a factor in this type of

application. Direct coupling a high PPR Rotary Pulse Generator to a slow

moving shaft that dithers or exhibits rotary oscillation can create false

pulses reflected as an output that is erroneously high. A belt drive was

chosen here to help dampen vibration effects. Adding some additional

mass to the RPG shaft, such as a weighted drive pulley, will increase the

inertia and dampen oscillation even further.

36 RPM (max. speed) x 1800 PPR

FRQ =

60

= 1080 Hz

The Company warrants the products it manufactures against defects in materials and workmanship for a period limited to two years

from the date of shipment, provided the products have been stored, handled, installed, and used under proper conditions. The

Company’s liability under this limited warranty shall extend only to the repair or replacement of a defective product, at The

Company’s option. The Company disclaims all liability for any affirmation, promise or representation with respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC against damages, claims, and expenses

arising out of subsequent sales of RLC products or products containing components manufactured by RLC and based upon personal

injuries, deaths, property damage, lost profits, and other matters which Buyer, its employees, or sub-contractors are or may be to any

extent liable, including without limitation penalties imposed by the Consumer Product Safety Act (P.L. 92-573) and liability imposed

upon any person pursuant to the Magnuson-Moss Warranty Act (P.L. 93-637), as now in effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products except those expressly contained herein. The

Customer acknowledges the disclaimers and limitations contained herein and relies on no other warranties or affirmations.

LIMITED WARRANTY

Loading...

Loading...