Page 1

1

2

3

4

5

6

7

8

9

10

11

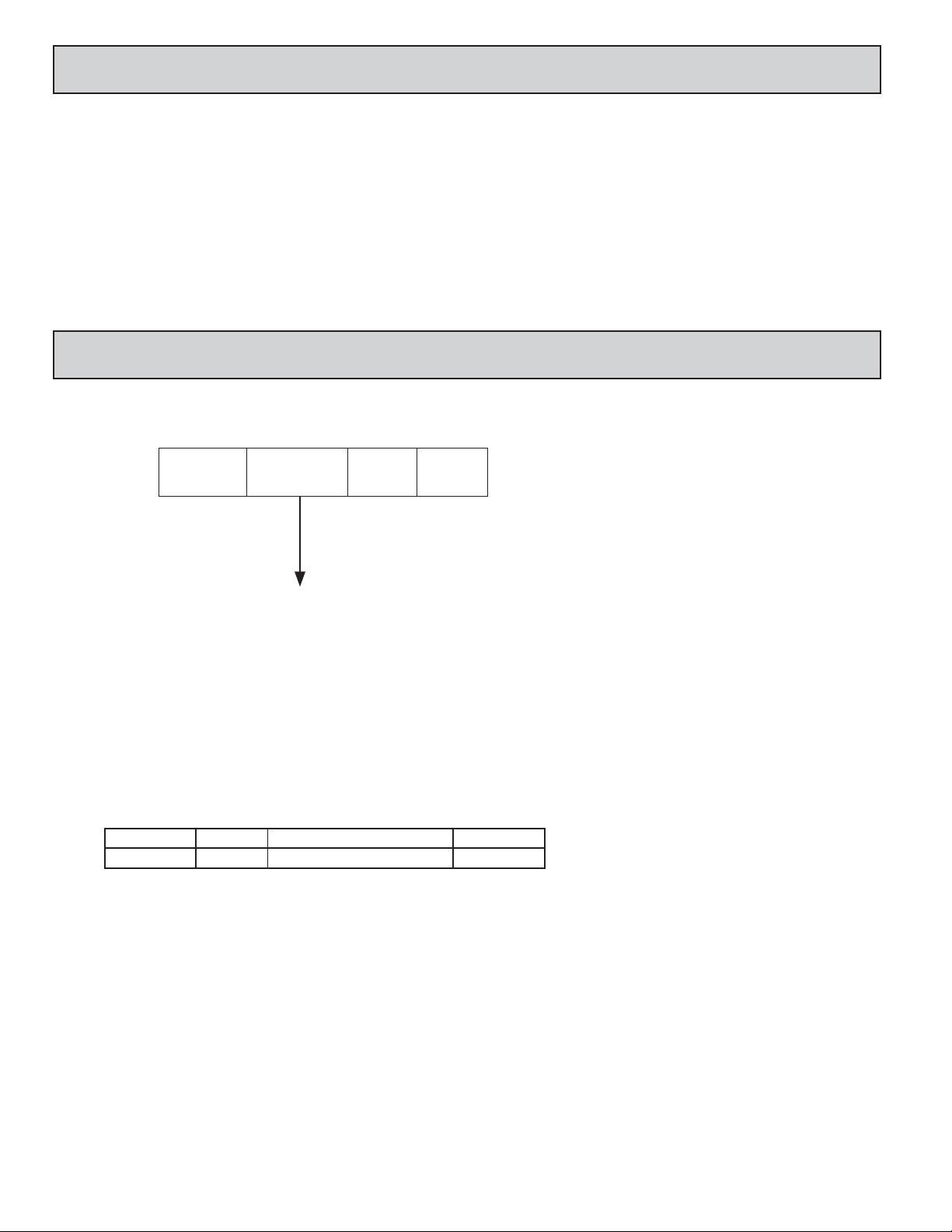

3.60 (91.4)

(44.5)

1.75

(96.5)

3.80

1.95

(49.5)

(2.5)

.10

(104.1)

4.10

(44.5)

1.75

1.8.8.8

mV

Tel +1 (717) 767-6511

C

US LISTED

Fax +1 (717) 764-0839

www.redlion.net

MODEL PAXLSG - PAX LITE STRAIN GAGE METER /

MILLIVOLT METER

3 1/2-DIGIT, 0.56" (14.2 MM) HIGH RED LED READOUT

HIGH SENSITIVITY, 10 MV FULL SCALE

WIDE RANGE GAIN AND OFFSET ADJUSTMENTS

BUILT-IN EXCITATION 5 OR 10 VDC

APPLICABLE AS REGULAR MILLIVOLT INDICATOR

(SINGLE-ENDED OR DIFFERENTIAL INPUT)

SELECTABLE DECIMAL POINTS

OVER-RANGE INDICATION

NEMA 4X/IP65 SEALED FRONT BEZEL

OPTIONAL CUSTOM UNITS OVERLAY WITH BACKLIGHT

Bulletin No. PAXLSG-B

Drawing No. LP0571

Released 01/12

U

R

C

L

US LISTED

IND. CONT. EQ.

51EB

GENERAL DESCRIPTION

The Model P AXLSG expands the PAX Lite capabilities into the indication of

pressure, load, force, and other parameters measured with strain gages. The unit

features broad range scaling and can be used with a wide variety of strain gage

resistances and bridge configurations. A built-in excitation source is jumper

selectable for 5 or 10 VDC @ 120 mA maximum, and can power up to four full

350 bridges in load averaging applications. Although designed primarily for

strain-gage indication, the P AXLSG is also ideal for single-ended or dif ferential

millivolt input applications, with full-scale input ranges from 0 to 10 mV thru 0

to 2 VDC. Adjustable scaling and offset allow direct readout in nearly any

engineering unit.

The meter has a NEMA 4X/IP65 sealed bezel and extensive testing of noise

effects to CE requirements, allowing the meter to provide a tough yet reliable

application solution.

DIMENSIONS In inches (mm)

Note: Recommended minimum clearance (behind the panel) for mounting clip installation is

2.1" (53.4) H x 5.0" (127) W.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

literature or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

CAUTION: Risk of Danger.

Read complete instructions prior to

installation and operation of the unit.

CAUTION: Risk of electric shock.

1

Page 2

TABLE OF CONTENTS

Ordering Information . . . . . . . . . . . . . . . . . . . .2

General Meter Specifications . . . . . . . . . . . . .3

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Installing the Meter . . . . . . . . . . . . . . . . . . . . . 4

Setting the Jumpers and Switches . . . . . . . . . 4

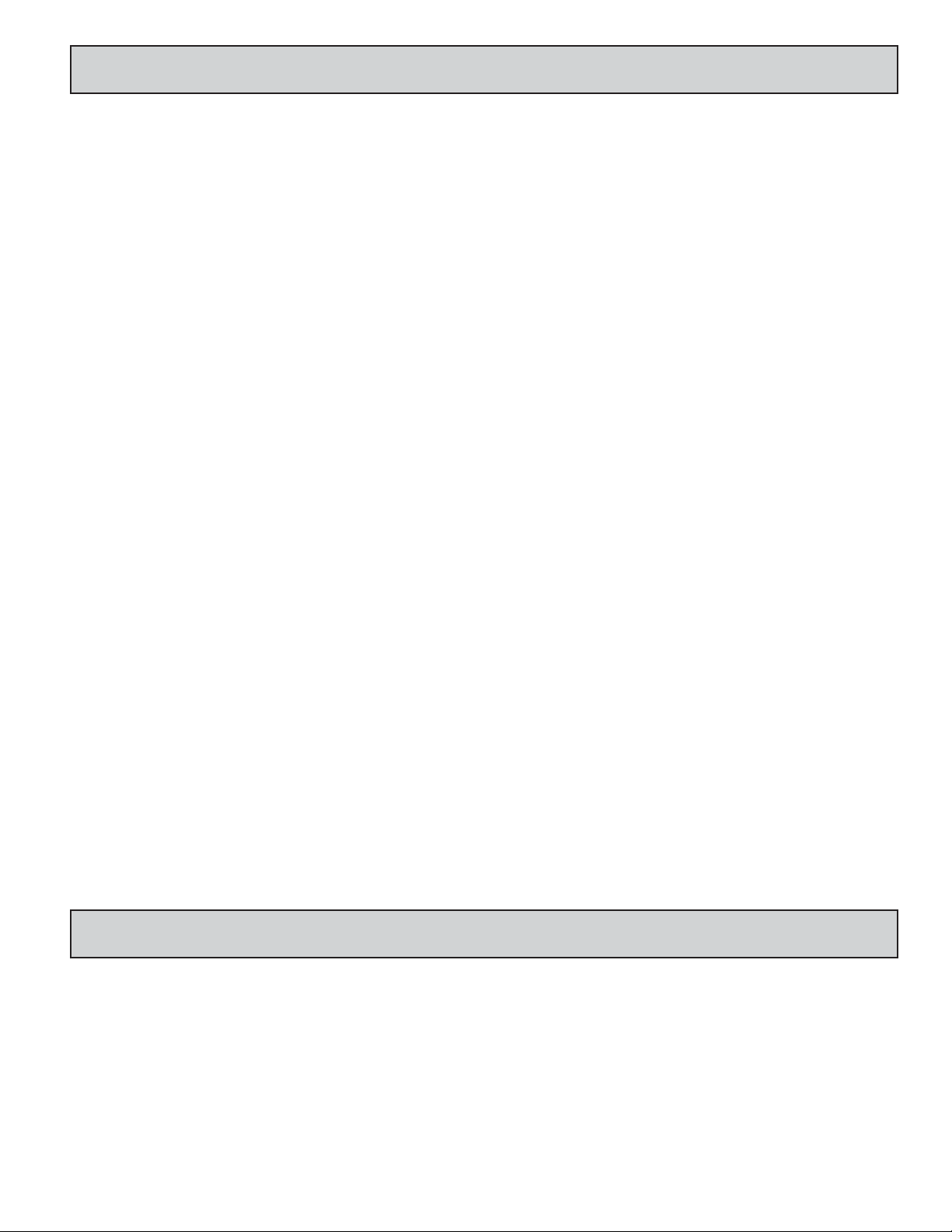

ORDERING INFORMATION

Meter Part Numbers

PAXL

SG

0

Wiring the Meter . . . . . . . . . . . . . . . . . . . . . . . 5

Scaling the Meter . . . . . . . . . . . . . . . . . . . . . .6

Calibrating the Meter . . . . . . . . . . . . . . . . . . . .7

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . .8

0

SG - Strain Gage Meter

Accessories Part Numbers

TYPE MODEL NO. DESCRIPTION PART NUMBERS

Accessories PAXLBK Units Label Kit Accessory PAXLBK30

2

Page 3

GENERAL METER SPECIFICATIONS

1. DISPLAY: 3 1/2-digit, 0.56" (14.2 mm) high, 7-segment red LED, (-) minus

sign displayed when voltage is negative. Decimal points inserted before 1st,

2nd, or 3rd least significant digits by DIP switch selection.

2. OVER-RANGE INDICATION: Indicated by blanking 3 least significant

digits.

3. POWER:

AC Power: 85 to 250 VAC, 50/60 HZ, 6 VA

Isolation: 2300 Vrms for 1 min. to all inputs.

4. INPUT SIGNAL: Single-ended or differential input, ±2.0 V max. Gain

(Sensitivity) is adjustable from 200 Units of Numerical Readout/millivolt input

(gives full scale readout of 1999 at 10 mV input), to less than 1 Unit of

Numerical Readout/mV (gives full scale readout of 1999 at 2.0 V input).

Maximum common mode voltage swing with respect to signal ground, 0 to 7 V.

Note: Absolute maximum voltage that can be applied between the two input

terminals or between input and signal common is 50 VDC.

5. INPUT IMPEDANCE: 100 M

6. LINEARITY: ±(0.05% ±1 digit)

7. LOW FREQUENCY NOISE REJECTION:

Normal Mode Rejection: 84 dB @ 50/60 Hz

Common Mode Rejection: 50 dB with respect to excitation common;

110 dB with respect to earth ground.

8. RESPONSE TIME: 2.0 seconds to settle from step input.

9. READING RATE: 2.5 updated readings/second, nominal.

10. EXCITATION SUPPLY:

Jumper Selectable: 5 VDC @ 60 mA max., ±2%

10 VDC @ 120 mA max., ±2%

Temperature coefficient (ratio metric): 20 ppm/°C max.

11. ENVIRONMENTAL CONDITIONS:

Operating Temperature: 0° to 60°C

Storage Temperature: -40° to 80°C

Operating and Storage Humidity: 85% max. relative humidity (non-

condensing)

Span Temperature Coeff.: 100 PPM/°C

Offset Temperature Coeff.: 100 PPM/°C

Vibration According to IEC 68-2-6: Operational 5 to 150 Hz, in X, Y, Z

direction for 1.5 hours, 2g.

Shock According to IEC 68-2-27: Operational 30 g, 11 msec in 3 directions.

Altitude: Up to 2000 meters

12. CERTIFICA TIONS AND COMPLIANCES:

SAFETY

UL Recognized Component, File # E179259, UL61010A-1, CSA C22.2 No. 61010-1

Recognized to U.S. and Canadian requirements under the Component

Recognition Program of Underwriters Laboratories, Inc.

UL Listed, File # E137808, UL508, CSA C22.2 No. 14-M95

LISTED by Und. Lab. Inc. to U.S. and Canadian safety standards

Type 4X Enclosure rating (Face only), UL50

IECEE CB Scheme Test Certificate # UL/8843A/UL

CB Scheme Test Report # 04ME11209-20041018

Issued by Underwriters Laboratories, Inc.

IEC 61010-1, EN 61010-1: Safety requirements for electrical equipment

for measurement, control, and laboratory use, Part 1.

IP65 Enclosure rating (Face only), IEC 529

IP20 Enclosure rating (Rear of unit), IEC 529

ELECTROMAGNETIC COMPATIBILITY

Emissions and Immunity to EN 61326: Electrical Equipment for

Measurement, Control and Laboratory use.

Immunity to Industrial Locations:

Electrostatic discharge EN 61000-4-2 Criterion A

4 kV contact discharge

8 kV air discharge

Electromagnetic RF fields EN 61000-4-3 Criterion B

10 V/m

Fast transients (burst) EN 61000-4-4 Criterion B

2 kV power

2 kV signal

Surge EN 61000-4-5 Criterion A

1 kV L-L,

2 kV L&N-E power

1 kV signal

RF conducted interference EN 61000-4-6 Criterion A

3 V/rms

Power frequency magnetic fields EN 61000-4-8 Criterion A

30 A/m

Voltage dip/interruptions EN 61000-4-11 Criterion A

0.5 cycle

Emissions:

Emissions EN 55011 Class B

Notes:

1. Criterion A: Normal operation within specified limits.

2. Criterion B: Temporary loss of performance from which the unit self-

recovers.

13. CONNECTIONS: High compression cage-clamp terminal block

Wire Strip Length: 0.3" (7.5 mm)

Wire Gage: 30-14 AWG copper wire

Torque: 4.5 inch-lbs (0.51 N-m) max.

14. CONSTRUCTION: This unit is rated for NEMA 4X/IP65 outdoor use.

IP20 Touch safe. Installation Category II, Pollution Degree 2. One piece

bezel/case. Flame resistant. Panel gasket and mounting clip included.

15. WEIGHT: 0.65 lbs (0.24 kg)

ACCESSORIES

UNITS LABEL KIT (PAXLBK)

Each meter has a units indicator with backlighting that can be customized

using the Units Label Kit. The backlight is controlled by a DIP switch.

3

Page 4

Main

Circuit

Board

D.P./ BACKLIGHT

REAR TERMINALS

FRONT DISPLAY

4

3

2

1

ON

OFFSET

SPAN

ON

123456789

OFFSET

GAIN

EXCITATION

SELECT

COARSE

FINE

1.0 INSTALLING THE METER

-.00

(92 )

-.0

+.8

3.62

+.03

(45 )

1.77

-.0

+.5

-.00

+.02

Installation

The PAX meets NEMA 4X/IP65 requirements when properly installed. The

unit is intended to be mounted into an enclosed panel. Prepare the panel cutout

to the dimensions shown. Remove the panel latch from the unit. Slide the panel

gasket over the rear of the unit to the back of the bezel. The unit should be

installed fully assembled. Insert the unit into the panel cutout.

PANEL

BEZEL

While holding the unit in place, push the panel latch over the rear of the unit

so that the tabs of the panel latch engage in the slots on the case. The panel latch

should be engaged in the farthest forward slot possible. T o achieve a proper seal,

tighten the latch screws evenly until the unit is snug in the panel (Torque to

approximately 7 in-lbs [79N-cm]). Do not over-tighten the screws.

Installation Environment

The unit should be installed in a location that does not exceed the maximum

operating temperature and provides good air circulation. Placing the unit near

devices that generate excessive heat should be avoided.

The bezel should be cleaned only with a soft cloth and neutral soap product.

Do NOT use solvents. Continuous exposure to direct sunlight may accelerate the

aging process of the bezel.

PANEL

GASKET

LATCHING

SLOTS

PANEL

LATCH

PANEL

MOUNTING

SCREWS

LATCHING

TABS

PANEL CUT-OUT

2.0 SETTING THE SWITCHES AND JUMPERS

The meter has switches that must be checked and/or changed prior to

applying power. To access the switches, remove the meter base from the case by

firmly squeezing and pulling back on the side rear finger tabs. This should lower

the latch below the case slot (which is located just in front of the finger tabs). It

is recommended to release the latch on one side, then start the other side latch.

Excitation Range Jumper

A jumper is used for selection of the 5 or 10 volt range. It is important that

only one jumper position is used at a time.

Set-Up DIP Switches

Two banks of DIP switches are located inside the meter. The 9 position bank

of switches is used for calibrating the meter. The values of these switches is

discussed in section 5.0 Calibrating the Meter.

The bank of 4 switches located near the front display are used for the

selection of decimal points and backlight annunciator. Selecting “ON” position

enables the function.

Decimal Point 1 (000.0)1

Decimal Point 2 (00.00)2

Decimal Point 3 (0.000)3

Backlight Annunciator for Units Label4

FUNCTIONSWITCH

PAXLSG Jumper Selection

JUMPER SELECTIONS

The indicates factory setting.

REAR TERMINALS

EXCITATION SELECT

10V

5V

4

Page 5

4 5 6

+

- SIG

+ SIG

COMM

3

-

+ EXC

3.0 WIRING THE METER

1 2

AC

AC

85-250 VAC

WIRING OVERVIEW

Electrical connections are made via screw-clamp terminals located on the

back of the meter. All conductors should conform to the meter’s voltage and

current ratings. All cabling should conform to appropriate standards of good

installation, local codes and regulations. It is recommended that power supplied

to the meter (AC) be protected by a fuse or circuit breaker.

When wiring the meter, compare the numbers embossed on the back of the

meter case against those shown in wiring drawings for proper wire position. Strip

the wire, leaving approximately 0.3" (7.5 mm) bare lead exposed (stranded wires

should be tinned with solder). Insert the lead under the correct screw-clamp

terminal and tighten until the wire is secure. (Pull wire to verify tightness.)

EMC INSTALLATION GUIDELINES

Although this meter is designed with a high degree of immunity to ElectroMagnetic Interference (EMI), proper installation and wiring methods must be

followed to ensure compatibility in each application. The type of the electrical

noise, its source or the method of coupling into the unit may be different for

various installations. Listed below are some EMC guidelines for successful

installation in an industrial environment.

1. The meter should be mounted in a metal enclosure, which is properly

connected to protective earth.

2. Never run Signal or Control cables in the same conduit or raceway with AC

power lines, conductors feeding motors, solenoids, SCR controls, and

heaters, etc. The cables should be run in metal conduit that is properly

grounded. This is especially useful in applications where cable runs are long

3.1 POWER WIRING

and portable two-way radios are used in close proximity or if the installation

is near a commercial radio transmitter.

3. Signal or Control cables within an enclosure should be routed as far away as

possible from contactors, control relays, transformers, and other noisy

components.

4. In extremely high EMI environments, the use of external EMI suppression

devices, such as ferrite suppression cores, is effective. Install them on Signal

and Control cables as close to the unit as possible. Loop the cable through the

core several times or use multiple cores on each cable for additional protection.

Install line filters on the power input cable to the unit to suppress power line

interference. Install them near the power entry point of the enclosure. The

following EMI suppression devices (or equivalent) are recommended:

Ferrite Suppression Cores for signal and control cables:

Fair-Rite # 0443167251 (RLC #FCOR0000)

TDK # ZCAT3035-1330A

Steward #28B2029-0A0

Line Filters for input power cables:

Schaffner # FN2010-1/07 (RLC #LFIL0000)

Schaffner # FN670-1.8/07

Corcom #1VR3

Note: Reference manufacturer’s instructions when installing a line filter.

5. Long cable runs are more susceptible to EMI pickup than short cable runs.

Therefore, keep cable runs as short as possible.

6. Switching of inductive loads produces high EMI. Use of snubbers across

inductive loads suppresses EMI.

Snubber: RLC#SNUB0000.

AC Power

Terminal 1: VAC

Terminal 2: VAC

3.2 INPUT SIGNAL WIRING

2-Wire Single Ended Input

4-Wire Bridge Input

COMM

Excitation Power

Terminal 3: Common

Terminal 4: Excitation +

+EXC

+SIG

5 6

43

+EXC.

+SIG.

-EXC.

-SIG.

-SIG

COMM.

3

BRIDGE

-EXC.

5 VDC @ 60 mA max, ±2%

10 VDC @ 120 mA max, ±2%

+EXC.

4

+EXC.

6-Wire Bridge Input

+EXC

COMM

+EXC.

+SIG

+SEN

+SIG.

-SEN

-EXC.

-SIG

643 5

-SIG.

DEADLOAD COMPENSATION

In some cases, the combined deadload and liveload output may exceed the

range of the input. To use this range, the output of the bridge can be offset a

small amount by applying a fixed resistor across one arm of the bridge. This

shifts the electrical output of the bridge downward to within the operating range

of the meter. A 100 K ohm fixed resistor shifts the bridge output approximately

-10 mV (350 ohm bridge, 10 V excitation).

Connect the resistor between +SIG and -SIG. Use a metal film resistor with

a low temperature coefficient of resistance.

BRIDGE COMPLETION RESISTORS

For single strain gage applications, bridge completion resistors must be

employed externally to the meter. Only use metal film resistors with a low

temperature coefficient of resistance.

Load cells and pressure transducers are normally implemented as full

resistance bridges and do not require bridge completion resistors.

5

Page 6

K1

.77K

S1

68.1K

2.2K

7.15K

22.6K

(+)

(-)

50K

S3 S2 S1

DIGITAL DISPLAY

S8

S7

S6

S5

S9

140 U/MV

50 U/MV

16 U/MV

6.6 U/MV

3.3 U/MV

K3

K2

30K 30K

30K30K

5

6

30K

30K

CW5KCW

45K

K4

30K

100K

S3

500

S2

200K

400K

250

125

S4

800K

DECIMAL POINT / BACKLIGHT

SWITCHES

DIGITAL VOLTMETER & DISPLAY

DRIVER CIRCUIT

COARSE OFFSET

SELECT SWS.

FINE OFFSET

ADJ.

+V -V

+SIG.

-SIG.

-EXC. +EXC.

(+)SIG.

(-)SIG.

GAIN COARSE

SELECT SWITCHES

COARSE GAIN

ADJ.

FINE GAIN ADJ.

+/-OFFSET

SELECT

5K

5K

S4

STRAIN GAGE

TRANSDUCER

5K

V

4.0 SCALING THE METER

PAXLSG SCHEMATIC

DESCRIPTION OF OPERATION

The Pax Lite Strain Gage Indicator (PAXLSG) consists of a digital voltmeter

combined with a high-gain, differential input amplifier that has provision for wide

range scaling adjustment (shown above). The unit also incorporates an excitation

power supply (5 or 10 VDC) that delivers up to 120 mA. In the simplified

schematic above, K1, K2, and K3 form a high-gain, high-stability, differential

input preamplifier with a single ended output. The gain of this preamplifier is set

up by coarse gain select switches S5 through S9. These switches can be turned on

in combination to provide discrete steps of gain-range adjustment. The output of

the preamplifier (K3 output) is applied to the summing amplifier (K4) through

coarse and fine adjustable potentiometers. These adjustable potentiometers

provide final vernier gain adjustment over a range of slightly more than 2:1. An

adjustable offset voltage signal is also added in at the input of K4 for zero-balance

or for applications where the transfer curve must be offset from zero.

GAIN ADJUSTMENTS

Gain is defined as the Units of Numerical change seen on the display per mV

(millivolt) of input signal change (disregarding display decimal points). In effect,

gain determines the slope of the transfer curve and is expressed in Units/mV.

GAIN = (Max. Num. Readout) - (Min. Num. Readout)

(Max. mV Input Sig.) - (Min. mV Input Sig.)

Note: Disregarded Decimal Points in Readout.

For example, if an PAXLSG is to display 50.0 @ 2 mV (min.) and 169.0 @

19 mV (max.), the required gain will be:

GAIN = 1690 Units - 500 Units

19 mV - 2 mV

Note: Remember, display decimal points are disregarded.

To establish this gain, the settings of the coarse gain select switches must first

be determined. These switches establish the maximum end of the 2:1 adjustment

range of the coarse and fine vernier gain adjustments.

= 70 Units/mV

COARSE GAIN SELECT SWITCHES

Each of the coarse gain select switches is marked with the amount of

maximum gain it will contribute when turned on. They are turned on singly or

in combination (adding up each of their gain contributions), to arrive at a

maximum gain value that is just above the desired gain value. To achieve the

desired gain of 70 Units/mV in the example just given, the following switches

would be turned on:

S6 (Gain 50) + S7 (Gain 16) + S8 (Gain 6.6) = 72.6 Units/mV

With these switches ON, the coarse and fine vernier adjustments cover a gain

range from about 36 Units/mV (½ of max.) to 72.6 Units/mV. The required gain

of 70 Units/mV falls within this adjustable range.

COARSE AND FINE GAIN ADJUSTMENTS

Once the gain select switches have been set, the final gain calibration is made

with the Coarse and Fine Gain adjustments. Both of these adjustments are

15-Turn, screwdriver adjustable potentiometers that increase gain with

clockwise rotation. The Coarse adjustment has a 2:1 range. The Fine adjustment

has a range of 5-10% (depending on the setting of the Coarse adjustment). Both

pots are located at the rear of the meter.

OFFSET ADJUSTMENTS

without changing the slope (Gain). They are used to “balance” the output of

transducers or to intentionally introduce an offset, such as tare-load compensation.

The Fine Offset Adjustment is a 15-turn screwdriver adjustable potentiometer,

located at the rear of the meter. It has a range of ±125 Numerical Units of offset

which is sufficient for balancing the output of most transducers.

of offset. Like the coarse gain select switches, the offset switches are marked

with the approximate value of offset contributed by each switch, and they can

be turned on in combinations with each switch, contributing its value to the

total. Switch S1 selects the polarity of the offset signal and can be set to either

add or subtract the offset contribution of the switches. The maximum offset that

can be obtained with all switches ON and the Fine Offset at its maximum is

±1000, which is one half of the full scale readout.

6

Offset adjustments move the transfer curve up-and-down along the vertical axis

The Coarse Offset Switches (S2, 3, and 4) can be used to add additional steps

Page 7

5.0 CALIBRATING THE METER

(-)

6

4

DUMMY

BRIDGE

350

Ω

1%

350

Ω

1%

8.0KΩ

R2

1KΩ

BRIDGE

BAL.

R1

1KΩ 10-T HIGH RESOLUTION

CAL. VOLTAGE ADJ.

POTENTIOMETER

ZERO

SWITCH

R3

40KΩ

(+)

5

REFERENCE

MILLIVOLT

METER

(+)

(-)

3

50/60 HZ

A.C. POWER

2

1

EXCITATION

VOLTAGE

SET AT 10VDC

SIGNAL

INPUT

PAXLSG

(+)

(-)

There are three different methods that can be used to calibrate the PAXLSG,

and the method chosen depends largely on the nature of the application. The

three methods are:

VOLTAGE CALIBRATION

In this method, the transducer signal is simply replaced with an accurately

measured input voltage that can be varied through the range normally delivered

by the transducer (See Voltage Calibration Circuit, below). The PAXLSG is then

adjusted to provide the proper readout.

SYSTEM CALIBRATION

In this method, the transducer is connected to the input of the P AXLSG in the

final installation, or in a bench set-up simulating the actual installation.

Accurately known inputs are then applied to the transducer (i.e. load, pressure,

force, etc.), and the PAXLSG adjustments are made to provide the desired

indication. This method is usually preferable to the Voltage Calibration method

since it calibrates both the transducer and the PAXLSG as a combination, and

reduces the inherent risk of inaccuracy or errors accumulated by separate

calibration. However, it can only be used in applications where the parameter to

be indicated can be easily varied and accurately measured or established. It is

also very awkward to use if an offset or transducer unbalance must be dealt with

because of Offset/Gain adjustment interaction.

COMBINATION VOLTAGE/SYSTEM CALIBRATION

In applications where tare-load, offset, or substantial transducer unbalance

exists and where high accuracy is required in the final indication, it may be

desirable to voltage calibrate the unit first to get it very close to its final settings.

Then, after final installation, the unit can be “tweaked” to its final settings while

using accurately known inputs to the system. These various factors make it

impossible to set up one calibration procedure to cover all applications.

However, using the following information on Voltage Calibration together with

the examples given should provide a good basis for handling virtually any

calibration requirement.

CALIBRATION EXAMPLE

“Voltage Calibration” can be easily performed for any application, using the

calibration circuit shown below.

VOLTAGE CALIBRATION CIRCUIT

(Using 350 Ohm Dummy Bridge)

This 350 Ohms “Dummy Bridge” circuit delivers calibration voltages in

ranges of 0 to ±22 mV, 0 to +44 mV, or 0 to -44 mV, depending on the setting

of R2. The range can be increased or decreased by adjusting the value of R3

(shown as 40 K). An accurate reference millivoltmeter is used to set up the

calibration voltage, and a “Zero Switch” facilitates balancing without

readjusting the calibration voltage. High-stability metalized resistors (1% tol.)

should be used. The use of a dummy bridge insures a common-mode voltage

during calibration that is very similar to that of the actual transducer.

SET-UP:

Before starting the procedure, the Input Swing Voltage (Vs), the Readout

Span (Rs) and the required GAIN must be determined.

WHERE:

Rs = (Max. Numerical Display) - (Min. Numerical Display) Disregard Decimal Points

Vs = (mV in @ Max. Display) - (mV in @ Min. Display)

GAIN = Rs = Units/mV

Vs

EXAMPLE: Readout is to be 5.00 Units @ 2 mV minimum, and 15.00 Units

@ 18 mV maximum. The transducer is a 350 strain-gage bridge requiring

10 VDC excitation.

Rs = 1500 - 500 = 1000 Units

Vs = 18 mV - 2 mV = 16 mV

GAIN = 1000 = 62.5 Units/mV

16

Note: While most strain gage readout applications are zero-based (i.e. zero

readout @ zero input) this example was intentionally chosen because it included

an offset reading at zero input. It will be used in the Calibration Procedure

below to illustrate the most convenient way to handle offset situations without

excessive interaction of gain and offset adjustments. If a zero-based example

had been given, the minimum readout and input voltage would have both been

zero. Rs and Vs would then simply be the maximum values of readout and input

voltage respectively, gain would just be the ratio of (Max. Readout/Max. Input

mV), and Steps 7 and 8 of the procedure below could be eliminated.

CALIBRATION PROCEDURE

1. Set the Coarse Gain Select Switches, S5 through S9 to establish a maximum

range just exceeding the required gain. Referring to the example given, the

required gain was calculated to be 62.5 Units/mV. Setting switches S6 and S7

ON gives 50 + 16 = 66 Units/mV, which is just above the required amount. The

following chart gives an approximate gain adjustment value for each switch:

SWITCH NUMBER SPAN VALUE

5

6

7 16

8 6.6

9 3.3

All offset switches, S2, 3, and 4, should be off.

2. Connect the unit to the Calibration Circuit as shown. Set the excitation

voltage range jumper to the 10 V position.

3. Place unit in the case and turn power on to the unit. Allow 10 minutes of

warm-up time for stabilization.

4. Close the “Zero Switch” of the calibration circuit to obtain zero input voltage.

Adjust the fine offset control to get a zero readout.

5. Open the “Zero Switch” of the calibrating circuit and set the input voltage to

the calculated swing voltage, Vs. (Vs is 16 mV in the example given.) Now,

adjust the Gain Coarse and Fine Controls to get a readout equal to the

Readout Span.

(Rs = 1000 Units in the example given.)

6. Repeat Step 4 and readjust zero if required. If zero readjustment was needed,

repeat Step 5, then back to Step 4, etc., until Zero and Rs readings are

acceptable.

*7. Set the calibration voltage to the minimum input level (2 mV in this

example). Record the meter reading (125 in this example). Power the meter

down and remove it from the case. Set the Coarse Offset Select Switches to

get the corresponding minimum readout (add the switch offset value(s) to the

recorded meter reading). In the example given, the minimum readout was

500 units @ 2 mV, therefore setting switches 3 and 4 gives us 125 (meter

reading) + 125 (SW4) + 250 (SW3) = 500. The following chart gives an

approximate offset adjustment value for each switch.

SWITCH NUMBER OFFSET VALUE

2 500

3 250

4 125

*8. Place unit in the case and turn power on to the unit. Use the fine offset

adjustment to fine tune the desired minimum reading (500 in this example).

Vary the input from the minimum to maximum levels and check the

corresponding readouts. Fine-tune if necessary by readjusting the fine gain

adjustment at the maximum end and the fine offset adjustment at the

minimum end. (In the example, readout is 500 @ 2 mV min. and 1500 @ 18

mV max.) Alternate between minimum and maximum inputs as required

until readout is within desired tolerance at the extremes.9. Set appropriate

decimal point switch (S2 for the example given).

The unit is now ready for installation.

* Steps 7 and 8 are not required in zero-based applications.

7

140

50

Page 8

6

4

5

3

PAXLSG

3, MATCHED LOAD CELLS

IN TRIPOD MOUNT

(-)EXC.

(+)EXC.

(+)SIG.

(-)SIG.

6.0 APPLICATIONS

6

4

5

3

POWER

A.C.

2

1

PAXLSG

(+) EXC.

(+) SIG.

(-) SIG.

(-) EXC.CIRCUIT COMMON

DIFF.

SIGNAL

CIRCUIT COMMON

(-) SIG.

6

(-) EXC.

(+) EXC.

(+) SIG.

5

4

3

2

POWER

A.C.

1

PAXLSG

+/- SIGNAL

(-)

6

4

(+)

5

3

2

1

EXCITATION

VOLTAGE

SET AT 10 VDC

SIGNAL

INPUT

PAXLSG

(+)

(-)

+EXC.

-SIG.

+SIG.

-EXC.

350 ± STRAIN GAGE BRIDGE

PRESSURE TRANSDUCER

0-20 MV OUTPUT AT 0-150 PSI

(10 V EXCITATION)

EXAMPLE #1 PRESSURE READOUT & SYSTEM

CALIBRATION

This illustration depicts a common application using an PAXLSG with a

strain-gage pressure transducer for pressure indication. The gain required to

display 150 Units @ 20 mV is 150/20, or 7.5 Units/mV. Setting the Coarse

Gain Select Switches S8 and S9 ON, gives a gain range of 6.6 + 3.3, or 9.9

Units/mV maximum, which brackets the required gain. The transducer curve

is zero-based (i.e. zero readout at zero input), and can be easily System

Calibrated. A variable pressure input is applied to the transducer with a “Dead-

Weight Tester” and the Fine Offset is adjusted to give a readout of zero with

no pressure applied. Then 150 PSI is applied, the Coarse and Fine Gain

controls are adjusted for a readout of 150. Pressure is removed, zero is checked

and readjusted with the Fine Offset control if needed. Pressure is varied

between zero and maximum, with the Fine Gain and Offset adjustments

retrimmed as needed until the readout is within tolerance.

EXAMPLE #2 THE MODEL PAXLSG AS A MILLIVOLT

METER

The PAXLSG can be used as a scaleable millivolt meter and will accept either

single-ended or differential inputs when connected as shown. Input signals are

referenced to the negative (common) side of the excitation supply (Terminal 3).

Maximum common-mode voltage (for differential input) is 0 to +7 VDC.

EXAMPLE #3 MULTIPLE LOAD-CELL INPUT,

AVERAGE READING

The 120 mA excitation output capability of the PAXLSG allows it to operate

multiple strain gage bridges. In this example, it is used to indicate the quantity

of granular material held in a hopper that is supported by three load cells in a

tripod mounting arrangement. The tare-weight of the empty hopper is about

30% of the full weight, requiring a significant offset for a zero readout when

empty. The PAXLSG is first Voltage-Calibrated (using the known output of the

load cells at the empty and full conditions). Then the unit is installed and fine

trimmed (System Calibration) using known loads.

The Company warrants the products it manufactures against defects in materials and workmanship

for a period limited to two years from the date of shipment, provided the products have been stored,

handled, installed, and used under proper conditions. The Company’s liability under this limited

warranty shall extend only to the repair or replacement of a defective product, at The Company’s

option. The Company disclaims all liability for any affirmation, promise or representation with

respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC against

damages, claims, and expenses arising out of subsequent sales of RLC products or products

containing components manufactured by RLC and based upon personal injuries, deaths, property

damage, lost profits, and other matters which Buyer, its employees, or sub-contractors are or may be

to any extent liable, including without limitation penalties imposed by the Consumer Product Safety

Act (P.L. 92-573) and liability imposed upon any person pursuant to the Magnuson-Moss Warranty

Act (P.L. 93-637), as now in effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products except

those expressly contained herein. The Customer acknowledges the disclaimers and limitations

contained herein and relies on no other warranties or affirmations.

LIMITED WARRANTY

Red Lion Controls

Headquarters

20 Willow Springs Circle

York PA 17406

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

Red Lion Controls

NL - 3821 AD Amersfoort

Tel +31 (0) 334 723 225

Fax +31 (0) 334 893 793

Europe

Printerweg 10

Red Lion Controls

India

54, Vishvas Tenement

GST Road, New Ranip,

Ahmedabad-382480 Gujarat, India

Tel +91 987 954 0503

Fax +91 79 275 31 350

Red Lion Controls

China

Unit 101, XinAn Plaza

Building 13, No.99 Tianzhou Road

ShangHai, P.R. China 200223

Tel +86 21 6113-3688

Fax +86 21 6113-3683

Loading...

Loading...