Page 1

1

2

3

4

5

6

7

8

9

10

11

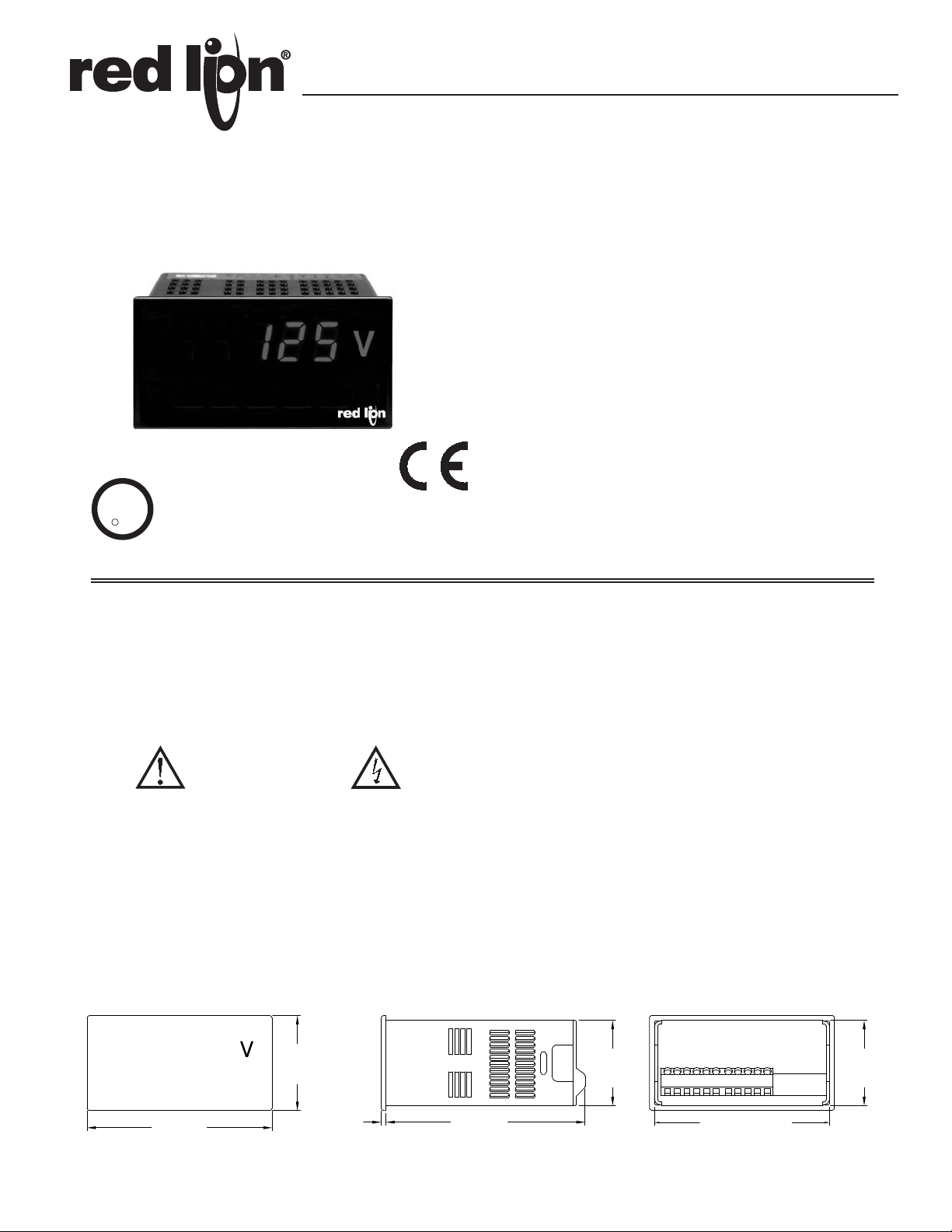

3.60 (91.4)

(44.5)

1.75

(96.5)

3.80

1.95

(49.5)

(2.5)

0.10

(104.1)

4.10

(44.5)

1.75

MODEL PAXLHV - PAX LITE AC VOLTAGE MONITOR

C

US LISTED

3-DIGIT, 0.56" (14.2 mm) HIGH RED LED DISPLAY

AUTO ZEROING CIRCUIT

NEMA 4X/IP65 SEALED FRONT BEZEL

OPTIONAL CUSTOM UNITS OVERLAY W/BACKLIGHT

UP TO 600 VAC MAX

U

R

C

US LISTED

L

IND. CONT. EQ.

51EB

GENERAL DESCRIPTION

The Model PAXLHV is designed for AC voltage monitoring. The half-wave

rectified input signal is calibrated to indicate the RMS value of a pure

sinusoidal wave-form. The front bezel meets NEMA 4X/IP65 requirements

when properly installed.

CAUTION: Read complete

instructions prior to installation

and operation of the unit.

DIMENSIONS In inches (mm)

CAUTION: Risk of electric shock.

Note: Recommended minimum clearance (behind the panel) for mounting clip installation is

2.1" (53.4) H x 5.0" (127) W.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

literature or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

DEFINITION OF TERMS

INSTALLATION CATEGORY (overvoltage category) I:

Signal level, special equipment or parts of equipment, telecommunication,

electronic, etc. with smaller transient overvoltages than Installation

Category (overvoltage category) II.

INSTALLATION CATEGORY (overvoltage category) II:

Local level, appliances, portable equipment, etc. with smaller transient

overvoltages than Installation Category (overvoltage category) III.

1

Page 2

TABLE OF CONTENTS

Ordering Information . . . . . . . . . . . . . . . . . . . .2

General Meter Specifications . . . . . . . . . . . . .3

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . .3

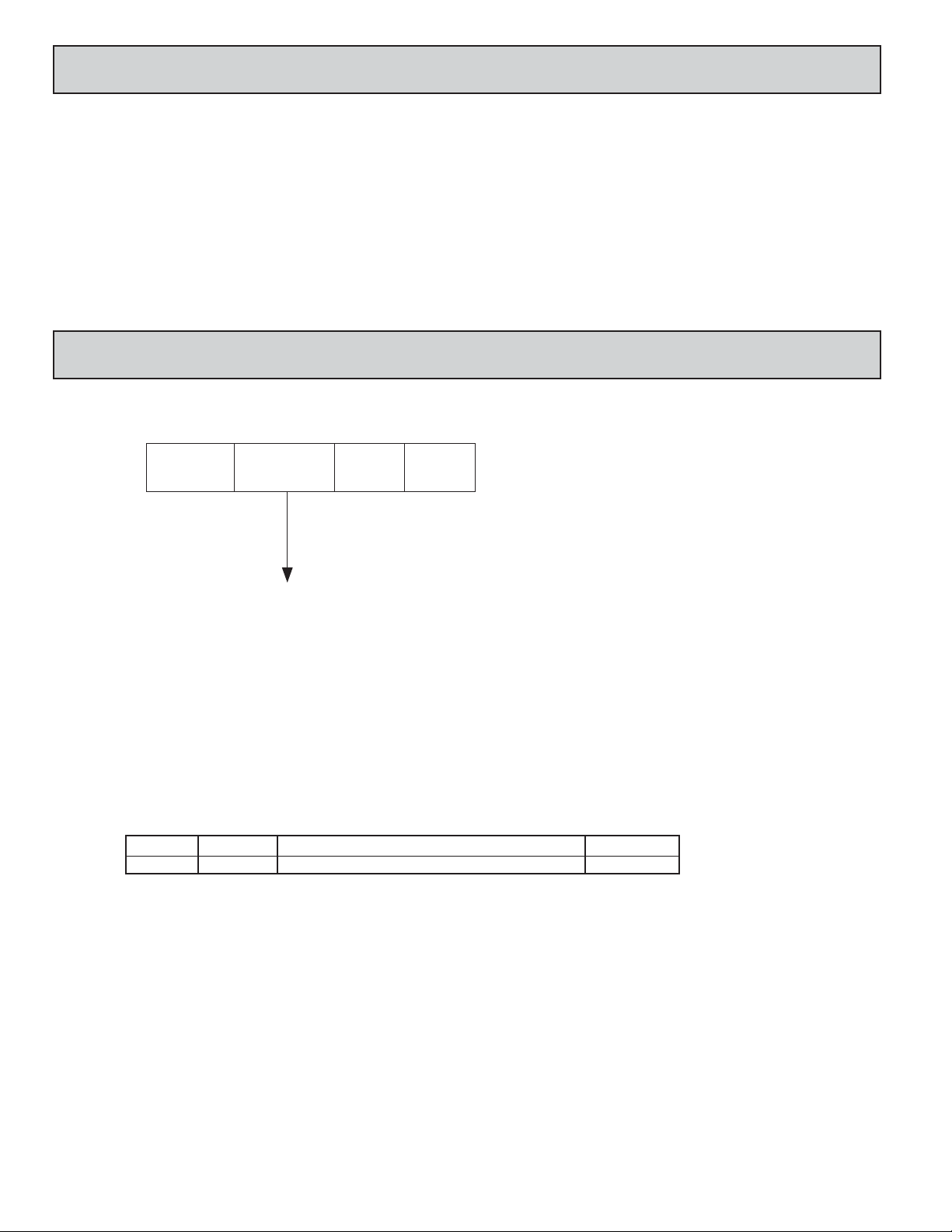

ORDERING INFORMATION

Meter Part Numbers

PAXL

HV 0

0

Installing the Meter . . . . . . . . . . . . . . . . . . . . . 4

Setting the Switches . . . . . . . . . . . . . . . . . . . . 4

Wiring the Meter . . . . . . . . . . . . . . . . . . . . . . . 5

HV - AC Voltage Input

Accessories Part Number

TYPE PART NUMBERSDESCRIPTIONMODEL NO.

PAXLBK30Units Label Kit Accessory PAXLBKAccessories

2

Page 3

GENERAL METER SPECIFICATIONS

1. DISPLAY: 3-digit, 0.56" (14.2 mm) high character, 7-segment Red LED

2. POWER: 115 or 230 VAC, switch selectable. Allowable power line variation

±10%, 50/60 Hz, 6 VA. Installation Category II, Pollution Degree 2.

Isolation: 2300 Vrms for 1 min. to input

Working Voltage: 300 V max., CAT II

3. ACCURACY: At 23°C, 85% R.H.; ±(0.1% of Reading + 2 digits)

4. INPUT IMPEDANCE: 1 M

5. INPUT RANGE: 0 to 600 VAC max. @ 45 to 500 Hz. Installation Category I

6. RESOLUTION: 1 VAC

7. ENVIRONMENTAL CONDITIONS:

Operating Temperature Range: 0° to 60°C

Storage Temperature Range: -40° to 80°C

Operating and Storage Humidity: 85% max. relative humidity (non-

condensing)

Temperature Coefficient: ±150 PPM/°C

Vibration According to IEC 68-2-6: Operational 5 to 150 Hz, in X, Y, Z

direction for 1.5 hours, 2 g’s.

Shock According to IEC 68-2-27: Operational 30 g’ s, 11 msec in 3 directions.

Altitude: Up to 2000 meters

8. READING RATE: 400 msec., nominal

9. RESPONSE TIME: 1 sec. nominal for a step change input.

10. CERTIFICA TIONS AND COMPLIANCES:

SAFETY

UL Recognized Component, File #E179259, UL61010A-1, CSA C22.2 No. 61010-1

Recognized to U.S. and Canadian requirements under the Component

Recognition Program of Underwriters Laboratories Inc.

UL Listed, File #E137808, UL508, CSA C22.2 No. 14-M95

LISTED by Und. Lab. Inc. to U.S. and Canadian safety standards

Type 4X Enclosure rating (Face only), UL50

IECEE CB Scheme Test Report #04ME11209-20041018

Issued by Underwriters Laboratories, Inc.

IEC 61010-1, EN 61010-1: Safety requirements for electrical equipment

for measurement, control, and laboratory use, Part 1.

IP65 Enclosure rating (Face only), IEC 529

ELECTROMAGNETIC COMPATIBILITY:

Emissions and Immunity to EN 61326: Electrical Equipment for

Measurement, Control and Laboratory use.

Immunity to Industrial Locations:

Criterion AEN 61000-4-2Electrostatic discharge

4 kV contact discharge

8 kV air discharge

Criterion B EN 61000-4-3Electromagnetic RF fields

10 V/m

Criterion AEN 61000-4-4Fast transients (burst)

2 kV power

2 kV signal

Criterion AEN 61000-4-5Surge

1 kV L-L,

2 kV L&N-E power

Criterion AEN 61000-4-6RF conducted interference

3 V/rms

Criterion AEN 61000-4-11Voltage dip/interruptions

0.5 cycle; 40 % variation

Emissions:

Class BEN 55011Emissions

Notes:

1. Criterion A: Normal operation within specified limits.

2. Criterion B: Temporary loss of performance from which the unit selfrecovers.

11. CONNECTIONS: High compression cage-clamp terminal block

Wire Strip Length: 0.3" (7.5 mm)

Wire Gage: 30-14 AWG copper wire

Torque: 4.5 inch-lbs (0.51 N-m) max.

12. CONSTRUCTION: This unit is rated for NEMA 4X/IP65 outdoor use.

Installation Category II, Pollution Degree 2. One piece bezel/case. Flame

resistant. Panel Gasket and mounting clip included.

13. WEIGHT: 0.65 lbs. (0.24 Kg)

ACCESSORIES

UNITS LABEL KIT (PAXLBK)

Each meter has a units indicator with backlighting that can be customized

using the Units Label Kit. The backlight is controlled by a DIP switch.

3

Page 4

1.0 INSTALLING THE METER

-.00

(92 )

-.0

+.8

3.62

+.03

(45 )

1.77

-.0

+.5

-.00

+.02

LATCHING

TAB S

PAN EL

LATCH

PAN EL

MOUNTING

SCREWS

LATCHING

SLOTS

PAN EL

GASKET

BEZEL

PAN EL

3

4

1

2

ON

Installation

The PAX meets NEMA 4X/IP65 requirements when properly installed. The

unit is intended to be mounted into an enclosed panel. Prepare the panel cutout

to the dimensions shown. Remove the panel latch from the unit. Slide the panel

gasket over the rear of the unit to the back

of the bezel. The unit should be installed

fully assembled. Insert the unit

into the panel cutout.

While holding the unit in place, push the panel latch over the rear of the unit

so that the tabs of the panel latch engage in the slots on the case. The panel latch

should be engaged in the farthest forward slot possible. T o achieve a proper seal,

tighten the latch screws evenly until the unit is snug in the panel (Torque to

approximately 7 in-lbs [79N-cm]). Do not over-tighten the screws.

Installation Environment

The unit should be installed in a location that does not exceed the maximum

operating temperature and provides good air circulation. Placing the unit near

devices that generate excessive heat should be avoided.

The bezel should be cleaned only with a soft cloth and neutral soap product.

Do NOT use solvents. Continuous exposure to direct sunlight may accelerate the

aging process of the bezel.

PANEL CUT-OUT

2.0 SETTING THE SWITCHES

The meter has a switch, which must be checked and/or changed prior to

applying power. To access the switch, remove the meter base from the case by

firmly squeezing and pulling back on the side rear finger tabs. This should lower

the latch below the case slot (which is located just in front of the finger tabs). It

is recommended to release the latch on one side, then start the other side latch.

Power Selection Switch

Caution: Insure the AC power selection switch is set for the

proper voltage before powering-up the meter. The meter is shipped

from the factory in the 230 VAC position.

Set-Up DIP Switches

A DIP switch is located inside the meter. It is used for the selection of decimal

points and backlight annunciator. Selecting the “ON” position enables the

function.

FUNCTIONSWITCH

Decimal Point 1 (000.0)1

Decimal Point 2 (00.00)2

Decimal Point 3 (0.000)3

Backlight Annunciator for Units Label4

4

Page 5

3.0 WIRING THE METER

1

2

8

5

POWER

SUPPLY

WAVE

SHAPING

CIRCUIT

PROCESS

CIRCUITRY

CALIBRATION

ADJUSTMENT

+V

1M

DISPLAY

INPUT

POWER

COMMON

(NEUTRAL)

600VAC

(HOT)

1 2

AC

AC

5 8

V

600V MAX. AC

COMMON

600 VAC

Neutral

WIRING OVERVIEW

All conductors should meet voltage and current ratings for each terminal. Also,

cabling should conform to appropriate standards of good installation, local codes

and regulations. It is recommended that power supplied to the unit be protected

by a fuse or circuit breaker. As depicted in the drawing of the Model PAXLHV,

all connections are made on the terminal block located at the rear of the unit.

EMC INSTALLATION GUIDELINES

Although this meter is designed with a high degree of immunity to

Electromagnetic Interference (EMI), proper installation and wiring methods

must be followed to ensure compatibility in each application. The type of the

electrical noise, source or coupling method into the meter may be different for

various installations. Cable length, routing and shield termination are very

important and can mean the difference between a successful or a troublesome

installation. Listed below are some EMC guidelines for successful installation

in an industrial environment.

1. The meter should be mounted in a metal enclosure, that is properly connected

to protective earth.

2. Use shielded (screened) cables for all Signal and Control inputs. The shield

(screen) pigtail connection should be made as short as possible. The

connection point for the shield depends somewhat upon the application.

Listed below are the recommended methods of connecting the shield, in order

of their effectiveness.

a. Connect the shield only at the panel where the meter is mounted to earth

ground (protective earth).

b. Connect the shield to earth ground at both ends of the cable, usually when

the noise source frequency is above 1 MHz.

c. Connect the shield to common of the meter and leave the other end of the

shield unconnected and insulated from earth ground.

3. Never run Signal or Control cables in the same conduit or raceway with AC

power lines, conductors feeding motors, solenoids, SCR controls, and

heaters, etc. The cables should be run in metal conduit that is properly

grounded. This is especially useful in applications where cable runs are long

and portable two-way radios are used in close proximity or if the installation

is near a commercial radio transmitter.

BLOCK DIAGRAM

The PAX Lite AC Voltage Monitor incorporates a built-in precision

voltage divider that provides direct measurement from 0 to 600 VAC.

4. Signal or Control cables within an enclosure should be routed as far as possible

from contactors, control relays, transformers, and other noisy components.

5. In extremely high EMI environments, the use of external EMI suppression

devices, such as ferrite suppression cores, is effective. Install them on Signal

and Control cables as close to the unit as possible. Loop the cable through the

core several times or use multiple cores on each cable for additional protection.

Install line filters on the power input cable to the unit to suppress power line

interference. Install them near the power entry point of the enclosure. The

following EMI suppression devices (or equivalent) are recommended:

Ferrite Suppression Cores for signal and control cables:

Fair-Rite # 0443167251 (RLC #FCOR0000)

TDK # ZCAT3035-1330A

Steward #28B2029-0A0

Line Filters for input power cables:

Schaffner # FN610-1/07 (RLC #LFIL0000)

Schaffner # FN670-1.8/07

Corcom #1VB3

Corcom #1VR3

Note: Reference manufacturer's instructions when installing a line filter.

6. Long cable runs are more susceptible to EMI pickup than short cable runs.

Therefore, keep cable runs as short as possible.

3.1 POWER WIRING

Primary AC power is connected to terminal 1 and 2 (Marked AC Power,

located on the left-hand side of the terminal block). For best results, the AC

power should be relatively “Clean” and within the specified ±10% variation

limit. Drawing power from heavily loaded circuits or from circuits that also

power loads that cycle on and off, should be avoided.

AC Power

Terminal 1: VAC

Terminal 2: VAC

115/230

3.2 INPUT SIGNAL WIRING

Input connections are made on terminal 5 and 8. When powering the

PAXLHV with the same voltage that is being measured, terminal 5 (COMM.)

should be connected to neutral for the most stable reading on the display. If an

unstable display results from measuring a voltage that is isolated from the supply

voltage, reversing the supply voltage connections may correct this condition.

Voltage Input

Terminal 5: Common

Terminal 8: 600 VAC

5

Loading...

Loading...