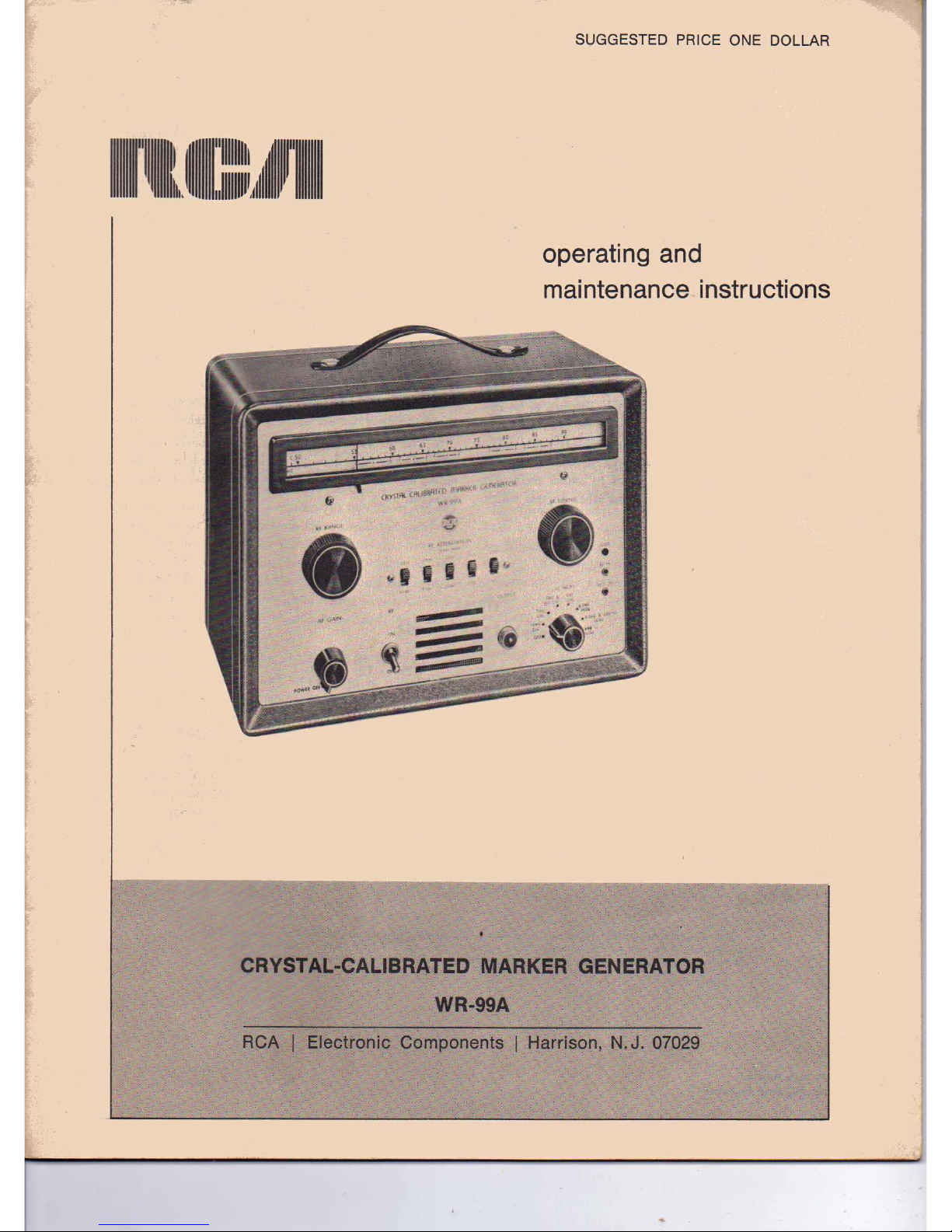

Page 1

SUGGESTED PRICE ONE DOLLAR

operating and

maintenance instructions

CRYSTAL-CALIBRATED MARKER GENERATOR

WR-99A

RCAIElectronic ComponentsIHarrison, N.J.07029

Page 2

can provide a ground. Working with one hand in your

pocket and standing on a properly insulated floor les-

sens the danger of shock.

2. Filter capacitors may store a charge large enough

to be hazardous. Therefore, discharge filter capacitors

before attaching test leads.

3. Remember that leads with broken insulation pro-

vide the additional hazard of high voltages appearing

at exposed points along the leads. Check test leads for

frayed or broken insulation before working with them.

4. To lessen the danger of accidental shock, discon-

nect test leads immediately after test is completed.

5. Remember that the risk of severe shock is only

one of the possible hazards. Even a minor shock can

place the operator in hazard of more serious risks such

as a bad fall or contact with a source of higher voltage.

6. The experienced operator continuously guards

against injury and does not work on hazardous circuits

unless another person is available to assist in case of

accident.

Safety Praca utions

ITEMS

Supplied

with

WR·99A

The metal case of this instrument is connected to

the ground of the internal circuit. For proper opera-

tion, the ground terminal of the instrument should

always be connected to the ground of the equipment

under test. Therfoutput cable has a shield through.

out its entire length which is connected to the instru-

ment ground and case. It is always best to handle the

cable by the insulation.

An important point to remember is that there is

always danger inherent in testing electrical equipment

which operates at hazardous voltages. Therefore, the

operator should thoroughly familiarize himself with

the equipment under test before working on it, bearing

in mind that high voltages may appear at unexpected

points in defective equipment. Additional precautions

which experience in the industry has shown to' be im-

portant are listed below.

1. It is good practice to remove power before con-

necting test leads to high. voltage points.

If

this is

impractical, be especially careful to avoid accidental

contact with equipment racks and other objects which

I

Output Cable

I

Warranty Registration Card

I

Phone Tip (Red)

1 RCA·6AF4·A

2 RCA-6U8

1 IO-Mc Crystal

1 RCA·12AT7

1 Instruction Booklet

I Phone Tip (black)

1 RCA OA2

2 RCA-6AS6

I RCA-6X4

I 4.S·Mc Crystal

Information furnished by RCA is believed to be accurate and reliable. However, no responsibility is assumed

by RCA for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of RCA.

All Rights Reserved

TMK®,Marco Registrada

(4) 3/69

TP·WR·99A

(3)

6/67

Printed in U.S.A.

Page 3

When the generator is set up as a heterodyne-

frequency meter, the frequency of an external signal

may be determined quickly by feeding the signal into

the WR-99A and zero beating it with the

vfo

signal.

The frequency is then read directly from the dial scale.

A slide-switch type of attenuator is used with the

WR-99A to provide attenuation in continuous steps

over a range of 60 db on all frequencies. A special

coaxial cable is provided with the unit for coupling

into the test circuit.

Circuit design and layout provide a flexible system

of modulating therfoutput. For example, when the

WR-99A is used in conj unction with a sweep generator

and an oscilloscope to reproduce a sweep-response

curve, the 4.5-Mc crystal oscillator will modulate the

output from the WR-99A to produce dual markers

spaced exactly 4.5 Mc apart on the curve. With output

set to the frequency of the picture carrier, for example,

the second marker will appear at the point on the

curve corresponding to the sound-carrier frequency.

The vfo signal also may be modulated internally with

both 4.5 Me and 600 cps, a useful feature for adjust-

ment and alignment of sound-if amplifiers and de-

tectors. The 600-cps modulation is also used to produce

a horizontal-bar pattern when the output signal is set

to the frequency of the picture carrier or picture inter-

mediate frequency. The 4.5-Mc output signal may be

modulated with 600 cps for visual alignment of the

detector.

A special socket located at the rear of the WR-99A

permits the connection of an external crystal or L-C

circuit into one of the internal calibrating oscillators.

When an external frequency-determining unit is used

it is possible to produce calibrating beats at intervals

other than 1 or 10 Mc.

The RCA WR-99A is designed for both general

service and production use. The unit measures 10" H

x 13%" W x 7" D and weighs 17 pounds. The

WR-99A is housed in a blue-gray hammeroid case

with a satin-aluminum panel.

Description

The RCA WR-99A Crystal-Calibrated Marker Gen-

erator is designed for use in alignment and trouble-

shooting of black-and-white and color-TV receivers, fm

receivers, and other equipment operating in the fre-

quency range from 19 to 260 Mc. The WR-99A pro-

vides an rf-output signal from 19 to 260 Mc in eight

bands on fundamental frequencies, A wide choice of

modulation facilities is provided, including 4.5 Mc,

which produces dual markers on a sweep-response

curve to mark the picture- and sound-carrier points

on the

curve,

An extremely versatile instrument, the WR-99A

combines the functions of a marker generator, a hori-

zontal bar pattern generator, and a heterodyne-fre-

quency meter. The frequency of the internal variable-

frequency oscillator, as well as the frequency of an

external signal, may be checked with high accuracy

against internally generated calibrating beats at 1- or

10-Mc intervals throughout the tuning range. The

WR-99A includes a harmonic crystal oscillator and a

I-Mc oscillator which is coupled to the 10-Mc crystal

oscillator for accuracy. Both these oscillators may be

switched in or out from the front panel and provide

audio calibrating beats from the speaker in the

WR-99A. Calibration of the WR-99A may be checked

at 242 intervals throughout the tuning

range,

Calibra-

tion of the instrument is straightforward; no charts

are needed.

The tuning dial is specially marked with all vhf

sound- and picture-carrier frequencies as well as im-

portant intermediate frequencies in the 20· to 30-Mc

and 40- to 50-:'\1c regions. In addition, important

color-TV frequencies are also marked on the dial scales.

In

TV servicing, the WR·99A may be used in check.

ing alignment and bandpass characteristics ofrfand

if circuits and the scanning linearity of vertical-de-

flection circuits. The instrument may also be used to

signal trace and trouble-shoot television receivers, and

is useful in locating defective sections and stages.

• 3 •

Page 4

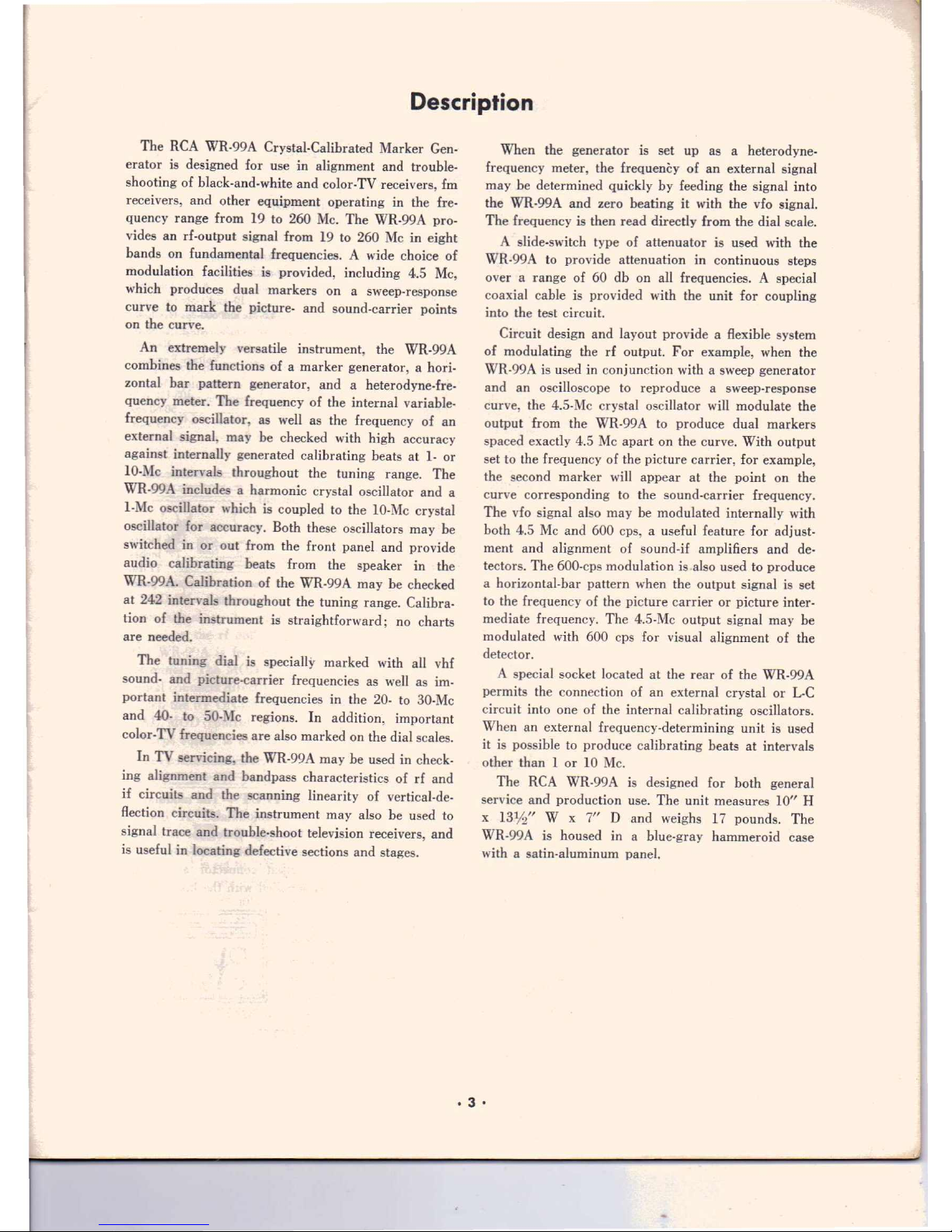

Specifications

Crystal Controlled

hg ~~

Output Voltages:

VFO Ranges " . approx. 0.1 volt rms

Crystal Frequencies .. . approx. 0.05 volt rms

Tonin,.Dial Characteristics:

RF tuning-dial ratio 3.5 to 1

RF

Attenuator:

Range of attenuation 0 to 60 db

Number of steps 12 (5 db each)

Type of attenuator Matched-Impedance Pad

Output.Cable Impedance: 90 ohms

IO·MC Crystal Calibrator:

Accuracy ±0.01%

Number of check points ~..................................... 24

I·MC Calibrator:

Accuracy ± 0.01%

Number of check points 242

4.5·MC Crystal Oscillator:

Accuracy ± 0.02%

Electrical

RF-Oulput Frequencies (fundamentals):

19·28 Mc

27-40 Mc

39·50 Mc

SO·90Mc

75·140 Mc

140-180 Mc

170·220 Mc

20().260 Mc

Internal Modulation:

1 Mc, 10 Mc, 4.5 Mc, 4.5 Mc and 600 cps, 600 cps.

External Modulation:

From external source up to 10 Mc

From plug-infundamental crystal 1 Mc to 30 Mc

From plug-in L-C circuiL. 100 Kc to 10 Mc

Tube Complement:

1 RCA·6AF4A Variable Frequency Oscillator

1 RCA-6AS6 Modulator

1 RCA-6U8 Audio Amplifier

1 RCA·12AT7 10·and I·Mc Oscillator

1RCA·6US 4.5·Mc and 6OO.cpsOscillator

1RCA-6AS6 Mixer

1RCA-6X4 Rectifier

1 RCA·OA2 Voltage Regulator

Power Supply:

Voltage _ 105·125volts

Frequency 50·60 cps.

Power Consumption 45 watts

Mechanical

Hei,ht ~ 10 inches

Width. .. 13lh inches

Depth 7 inches

Weight 171bs.

Finieh Blue-gray hammeroid case, satin-aluminum panel

Functions of Controls

RF RANGE-Selects one of

eight rf ranges from 20 to

260 Mc. This control simul-

taneously switches the inter-

nal oscillator circuits and

rotates the dial drum so the corresponding frequency

scale is in view.

RF TUNING - Is a fine-

tuning control used in con-

junction with the RF

RANGE

control to select the desired

output frequency.

OUTPUT - The modulated

or un modulated rf output

from the generator is avail-

able at this connector. The

output connector

accommo-

dates the

rf-output

cable supplied with the instrument.

RF ON· OFF-When set to

"OFF" position, removes B+

voltage from the variable-

frequency oscillator and reno

ders the oscillator inopera-

tive. This control must be set to "OFF" to obtain the

separate 1.,4.5-, and 10·Mc output.

I

·4·

Page 5

RCA Crystal-Calfbrared Marker Generator WR·99A

o IIt.(O§

0

0:0

0

RF ATTENUATION-Uti·

lizes frye slide switches to

provide step attenuation of

the rf-output signal. When

the slide switches are placed

in their "down" positions, attenuation in steps of IS,

10, or S db is provided. When the switches are set to

their "up" or "out" positions, no attenuation occurs.

Because the attenuation provided by each switch is

additive, the switches may be used to provide attenua-

tion in any amount from zero to 60 db.

RF IN-External

rf

signal is

fed in here when the WR·

99A is used as a heterodyne

frequency meter. This ter-

minal connects to therfde-

I

I

tector. When an external signal is beat with the vfo or

1· or IO·Mc oscillator signal from the WR·99A, an

audio beat note will be heard from the loudspeaker.

AF GAIN·POWER OFF-

Turns power off when set to

"POWER OFF" position; in-

creases volume level from

loudspeaker when turned

clockwise.

MOD IN-External modula-

tion signal to be superim-

posed on the rf output from

the WR-99A is fed into this

terminal. The MOD IN ter-

I·

minal connects directly to the internal modulator stage.

When the RF ON-OFF control is set to "OFF" and the

CAL/MOD control is set to "600

"V",

the internal

600·cps signal is available separately at this terminal.

I I

CAL/MOD-Selects type of

modulation applied internally

o

0 00 0 0

0

§

or externally to the rf-output

o

0

E

o._

signal or made available at

t=:======-=-""'=::;r"'"

the output terminal. When

this control is set to "OFF", no modulation is applied.

When set to one of the seven remaining positions,

modulation is as given below. NOTE: With the RF

ON-OFF control set to "OFF", any type of modula-

tion except "600""\.,", is available at the OUTPUT

connector.

"10 MC CAL"-Crystal-controlled audio calibrat-

ing beats are provided at 10-Mc intervals at fre-

quencies which are multiples of 10 Mc throughout

the tuning range of the WR·99A. Makes possible

precise calibration of the variable-frequency oscilla-

tor from 20 to 260 Mc.

·5·

"1 MC CAL"-Audio calibrating beats are pro-

vided at I·Mc intervals at frequencies which are

multiples of 1 Mc throughout the tuning range of

the WR-99A. Makes possible calibration of the

variable-frequency oscillator from 20 to 260 Mc.

"1 MC&EXT CAL"-When a crystal or L-C

circuit is plugged into the socket at the rear of the

instrument, the external unit can be synchronized

with the I-Mc internal oscillator to give calibrating

markers at intervals of less than 1 Mc.

An

audio

beat signal will be heard from the speaker. NOTE:

The crystal frequency must be at least 1 Mc or

higher.

"EXT CAL"-When an external 1- to 30-Mc

fundamental-frequency crystal is plugged into the

socket at the rear of the instrument, the WR-99A

will give harmonic output at frequencies which are

multiples of the crystal frequency.

"4.S MC MOD"-When the WR-99A is tuned to

any frequency from 20 to 260 Mc, the 4.S-Mc modu-

lation will appear as dual markers spaced exactly

4.S Mc away from the vfo marker on a sweep-re-

sponse curve. When the WR-99A is tuned to a pic-

ture-carrier frequency, the 4.S-Mc modulation will

mark the sound-carrier frequency, or vice versa, on

the response curve. NOTE: The 4.S-Mc markers

cannot be heard as audio beats.

"4.S MC&600 '\., MOD"-AppJies both 4.S-MC

and 6OO-cpsmodulation to the output signal. When

the RF control is set to "OFF" and the CAL/MOD

control is set to "4.5 MC&600~MOD", only these

two modulating frequencies are available at the

OUTPUT connector. This type of output is desirable

for use in aligning sound-if amplifiers and FM

detectors.

"6OO'"V MOD"-lmposes 600-cps audio modula-

tion on the rf-output signal. When the output is

tuned to the frequency of a TV picture carrier or

picture intermediate frequency, the WR·99A may be

used to produce approximately 6 to 11 horizontal

bars on the picture-tube screen for checking vertical

linearity. The 600-cps modulation is also used to

align FM detectors by the "zero signal" method.

•I

o

o

0'

t~

GND-connects directly to

chassis ground and case.

00000

O

-

o~o

Page 6

Calibration and Operation

General

Before the WR·99A is put into use, it is important

that the functions of controls and uses of the con-

nectors be understood. The purposes of the controls

and connectors are described under "Functions of

Controls".

This section explains how to calibrate the WR·99A

and how to set up the instrument to provide an un-

modulated marker signal of a desired frequency, or

.a

marker signal which is modulated with one or more

different modulating signals. Some important sugges-

tions are also given for connecting the WR·99A to the

equipment under test and to auxiliary test equipment.

Because the Applications section does not include

instructions for setting up and adjusting the WR·99A,

the user should first make sure he understands the

operation of the instrument before using it in align.

ment applications.

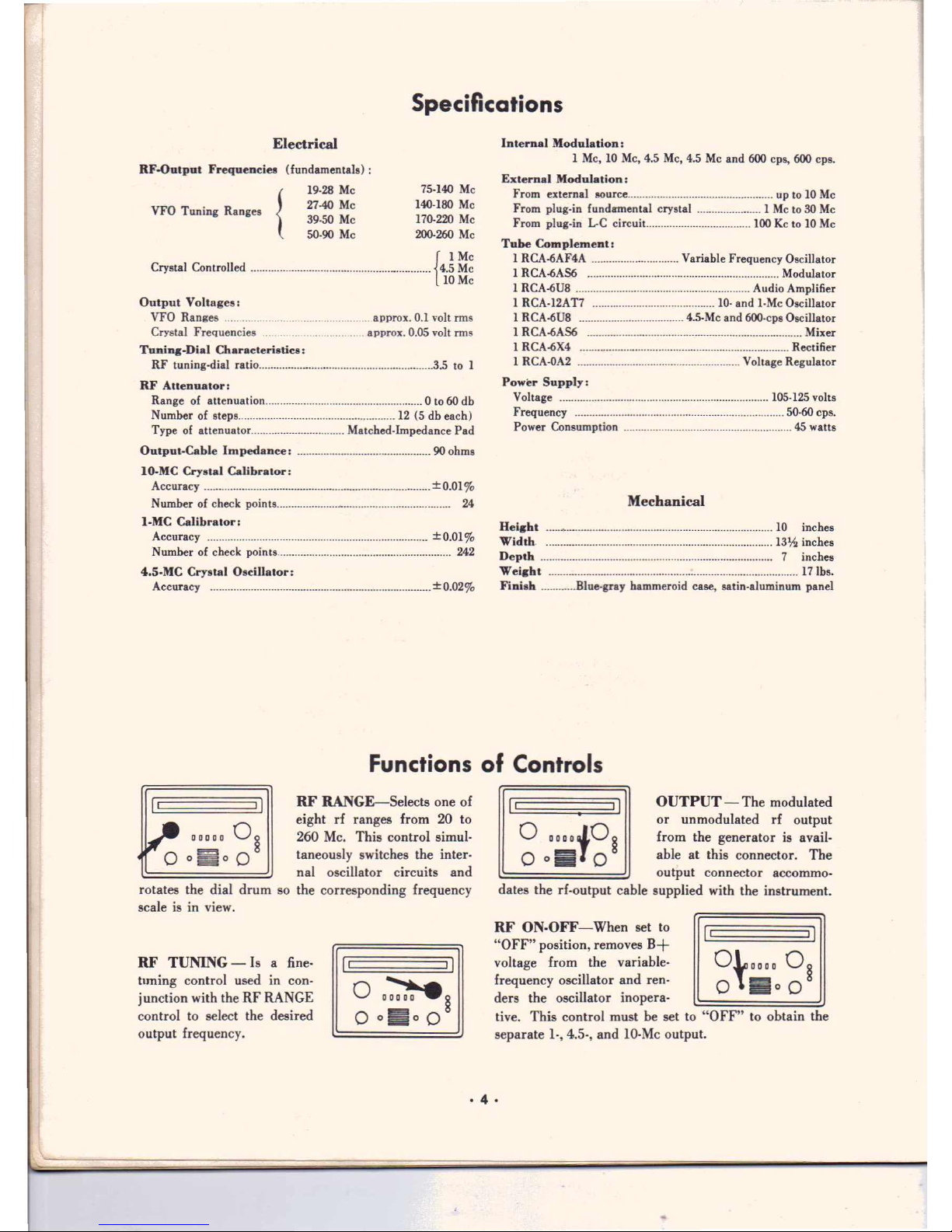

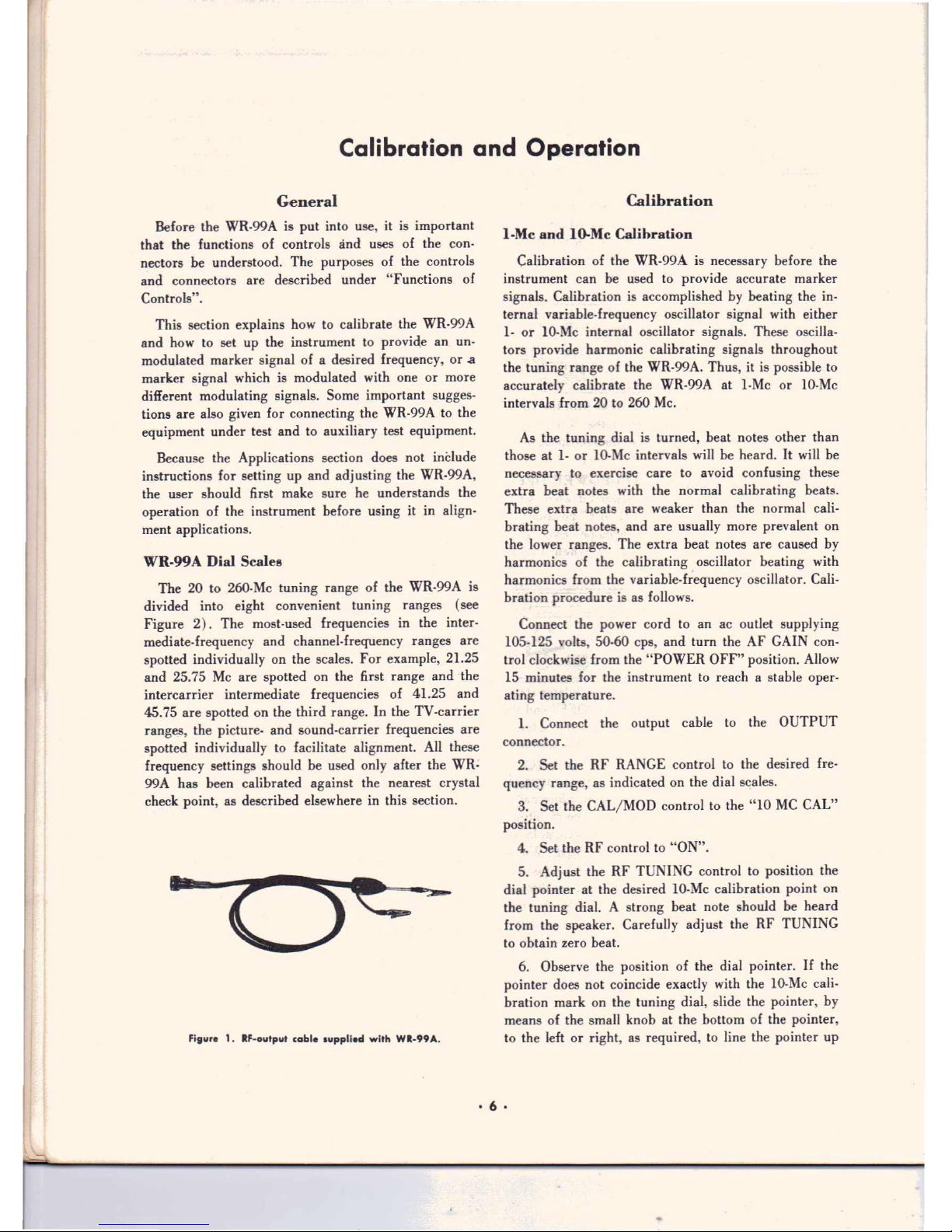

WR·99A Dial Scales

The 20 to 260·Mc tuning range of the WR·99A is

divided into eight convenient tuning ranges (see

Figure 2). The most-used frequencies in the inter-

mediate-frequency and channel- frequency ranges are

spotted individually on the scales. For example, 21.25

and 25.75 Mc are spotted on the first range and -the

intercarrier intermediate frequencies of 41.25 and

45.75 are spotted on the third range. In the TV -carrier

ranges, the picture. and sound-carrier frequencies are

spotted individually to facilitate alignment. All these

frequency settings should be used only after the WR·

99A has been calibrated against the nearest crystal

check point, as described elsewhere in this section.

I

(

Figure 1. IF· output

cobl.

lupplled with WI-99A.

Calibration

I·Me and IO-Mc Calibration

Calibration of the WR·99A is necessary before the

instrument can be used to provide accurate marker

signals. Calibration is accomplished by beating the

in-

ternal variable- frequency oscillator signal with either

1· or IO·Mc internal oscillator signals. These oscilla-

tors provide harmonic calibrating signals throughout

the tuning range of the WR·99A. Thus, it is possible to

accurately calibrate the WR·99A at I·Mc or lO·Mc

intervals from 20 to 260 Mc.

As

the tuning dial is turned, beat notes other than

those at 1· or 10·Mc intervals will be heard. It will be

necessary to exercise care to avoid confusing these

extra beat notes with the normal calibrating beats.

These extra beats are weaker than the normal cali-

brating beat notes, and are usually more prevalent on

the lower ranges. The extra beat notes are caused by

harmonics of the calibrating oscillator beating with

harmonics from the variable-frequency oscillator. Cali-

bration procedure is as follows.

Connect the power cord to an ac outlet supplying

105·125 volts, 50·60 cps, and tum the AF GAIN con-

trol clockwise from the "POWER OFF" position. Allow

15 minutes for the instrument to reach a stable oper·

ating temperature.

1. Connect the output cable to the OUTPUT

connector.

2. Set the RF RANGE control to the desired fre-

quency range, as indicated on the dial scales.

3. Set the CAL/MOD control to the "10 MC CAL"

position.

4. Set the RF control to "ON".

5. Adjust the RF TUNING control to position the

dial pointer at the desired IO·Mc calibration point on

the tuning dial. A strong beat note should be heard

from the speaker. Carefully adjust the RF TUNING

to obtain zero beat.

6. Observe the position of the dial pointer.

If

the

pointer does not coincide exactly with the IO·Mc cali-

bration mark on the tuning dial, slide the pointer, by

means of the small knob at the bottom of the pointer,

to the left or right, as required, to line the pointer up

• 6 •

Page 7

RCA Cryaral-Cahbrated Marker Generator WR-99A

C

19

20

21 22 23 24

25

26

27

28

I

!

!

I

I ! I !

I

! I I ! !

!

!

~

MC

C

27

28

29

30 31 32 33

34

35

36

37 38 39

40

I

~

I I !

I

I

!I

,!'.

I

I!'

,,!" ,!,,,!" ,!I I

,! ' I!

I

I

!

I!I

!

MC

C

39

40

41 42 43 44 45 46 47 48

49

50

I

! I !I

'!

I

I

i

,! 'I,! '

I

,

..

,

I

,!'

I~

I

!

I

! ! !

i

MC

•

G G

.

c

50 55

60

65 70 75 80 85 90

I

!

!

I

I

I

I!I

I

I I

!

I

I

I I !

I I

I

I ! III ! I

,

I

I

,

I ! I

,

I

!

i i i i i i

MC

.--,--,

;-3-S

'-A._S

P-S-'

P_6_~

.C

I

75

! '

MC

80 90

100

110 120

130 140

I"" "'1'.""""'."""'1'1""""'.""" "' •• ,.",,,

II

150

160

210

C 140

I !

,,',,,!, ,,,,

,,,! '

MC

C

I

170 190

!',,,\',,,

1\' ,,

'I

'I'

,!,

u' ','

I ,

'I

'.1' ,

'I' " , ,,

'1 " ' ,

, !

180

MC

170

,!

180

!

200

220

C

I

200 210

230

P-7_~ P-8-5 '_9_~ '-IO-S

,-n-s

.-I2-S '-13-'

250220

240

260

,! '

,!',,,,,,,,!I , , , , , , ,

'I' ,,,,,I"I' ,,,,,,I'I' ,,,, ,, , ,

!, I

MC

Figure 2_ Dial scale. for WR-99A. N,ote the most-u.ed TV frequenci •• are spotted individually.

with the dial-scale calibration mark. NOTE: Leave the

RF TUNING control set to the zero-beat setting while

making this adjustment. The dial pointer has approxi-

mately 1 inch of play, permitting correct calibration at

the nearest· calibrating point.

After setting the dial pointer at the 10 MC check

point which is closest to the desired frequency, set

the CAL/MOD control to the "IMC CAL" position.

Adjust the RF TUNING control to pick up the 1 MC

beat at the point nearest the desired frequency.Ifthe

pointer does not coincide exactly with the 1 MC cali-

bration mark on the tuning dial, slide the pointer to

the left or right as required to line the pointer up with

the dial scale calibration mark. Leave the RF TUNING

control set for zero beat while making this adjust-

ment. The calibration is now accurate at this 1 MC

point and for some distance on either side.

The WR·99A should always be calibrated at

the beat point whichisnearest to the frequency

toheused.

As an example, if it is desired to set the generator

accurately to 45.75 MC, the procedure is 'as follows:

1. With the CAL/MOD control in the 10 MC CAL

position, pick up the 50 MC beat on the 39 to 50 MC

dial scale. Slide the pointer,ifnecessary, to coincide

with the 50 MC dial scale calibration mark.

2. With the CAL/MOD control in the 1 MC CAL

position, pick up the beat at 45 MC. Slide the pointer,

if necessary, to coincide with the 45 MC dial scale

calibration mark.

3. The calibration is now accurate at 45 MC. Adjust

the RF TUNING control so that the pointer lines up

with the 45.75 MC mark on the dial.

Calibration from an External Source

The two-pin socket in the rear of the WR-99A case

(see Figure 4) connects to internal circuitry and per-

mits use of an external crystal or L-C circuit in cali-

brating the WR·99A at other than 1- or 10·Mc inter-

vals. In addition, when the vfo in the WR-99A is made

inoperative the modulating signal of the external unit

is available separately at the OUTPUT connector. For

example, any fundamental-cut crystal in the range

from 1 to 30 Me or a Colpitts-type L-C circuit designed

to operate from 100 Kc to 10 Mc, in which the point

between the two capacitors is grounded, may be syn-

chronized with the internal oscillator circuit. The ex-

ternal unit will produce audio beat signals up to about

the tenth harmonic at frequencies which are multiples

of the natural resonant frequency of the crystal or L-C

circuit. In addition to these two special applications,

an appropriate external unit may be synchronized with

the internal I-Mc crystal oscillator to give accurate

·7.

Page 8

RCA Crystal-Calibrated Marker Generator WR-99A

calibrating beats at less than I-Mc intervals. Procedure

for using the external feature is as

follower

1.

With power applied to the WR-99A and the out-

put cable connected to the OUTPUT connector, set the

RF

control to "ON".

2.

Set the CAL/MOD control to "EXT CAL". Turn

up theAFGAIN control.

3. Plug a fundamental-cut

1-

to 30;Mc crystal into

the socket at the rear of the instrument case.

4. Tune the

RF

TUNING control and note that

audio-beat signals occur at intervals which are mul-

tiples of the fundamental frequency of the external

crystal, up to about the tenth harmonic.

NOTE:

If

an external Colpitts-type L-C circuit is

connected in place of the crystal, ground the center of

the two capacitors by means of a soldering lug to the

screw adjacent to the crystal socket.

To obtain locked-in calibrating markers at less than

I-Mc intervals, the same procedure used above should

be followed except that the CAL/MOD control is set

to "1 MC&EXT CAL" and an L-C circuit must be

used. The external L-C circuit must be an exact sub-

multiple of 1 Mc to avoid the generation of an exces-

sive number of intermediate beat notes. For example,

an O.25-McL-C circuit can be plugged in and adjusted

by means of a tunable slug in the coil to zero beat with

the I-Mc crystal in the WR-99A to give O.25-Mccheck

points throughout the tuning range of the WR-99A. In

all these applications described above, the external

crystal or L-C circuit will give sideband markers when

the RF control is set to "ON". When the RF control is

set to "OFF", the modulating signal is available sep-

arately at the OUTPUT connector.

--

-

-

---

-

Figure 3. Rear ·iocket-for c~nnection of external crystal or

ColpiHs-type L-C circuit.

Use of 4.5-Mc Sideband Markers

When the WR-99A is set up to deliver an output sig-

nal on either the picture-carrier or sound-carrier fre-

quency of a TV channel, sideband markers which are

spaced exactly 4.5-Mc each side of the vfo marker may

be obtained by setting the CAL/MOD control to the

"4.5 MC MOD" position. For example, if the WR-99A

is tuned to deliver an output signal at the channel 4

picture-carrier frequency of 67.25 Mc and 4.5-Mc

modulation is applied, an additional marker

win

be

observed on the sweep-response

curve.

at the

sound-

carrier frequency of 71.75 Mc. Thi; feature facilitates

checking of bandpass response curves from tuners and

the overall response of both color and black-and-white

TV receivers.

Cottpling the WR-99A to the Test,Circuit

Wherever possible in alignment applications, the

WR-99A should be used with a marker-adder unit,

such as the RCA WR-70A RF/IF /VF Marker Adder.

Test setups which utilize marker-adder units are de-

scribed in the "'Applications" section.

If

the signal

from the WR-99A is coupled directly into the test cir-

cuit, the recommendations which follow should be

observed.

The rf-output cable provided with the WR-99A

should always be used for coupling the instrument to

other equipment. The cable is shielded throughout its

length to prevent excessive radiation of the output

signal and to minimize hum pickup. The output clip

should be connected as closely as possible to the point

of signal injection and the ground clip should be

grounded close to the injection point. When the marker

is fed into the tuner, the ground should be connected

to the tuner shield. Do not connect the output cable to

any circuit containing B+ voltage. Failure to observe

this precaution may result in damage to the WR-99A.

Figure 4. RCA WR-70A Marker Adder.

·8·

Page 9

RCA Crystal.Calibrated Marker Generator WR·99A

When the WR·99A is used to provide a marker for

a high.gain circuit, such as a TV receiver, direct con-

nection of the cable to the injection point may not be

necessary. Often, it is sufficient to lay the output clip

near the injection point, or to connect both clips to the

chassis near the injection point. This arrangement has

the advantage of extremely low circuit loading but has

the disadvantage of possible injection of the signal

into adjacent circuits. For overall alignment, the

marker may be coupled into the receiver by connecting

the output cable directly to the antenna terminals, to

the tuner mixer stage, or to the grid circuit of the first

picture-if stage.

One of the best methods of injecting the signal into

the if strip consists of lifting up the shield on the tuner

mixer tube and clipping the rf-output cable to the tube

shield. The shield should be kept in an elevated po-

sition to prevent shorting the injected signal to ground.

The ground clip should be connected to the tuner

shield. With this method of injection, the marker is

capacitively coupled into the circuit through the ca-

pacitance between the tube shield and the plate of the

mixer tube. It may be necessary to increase the rf

output from the WR·99A when this procedure is used.

The advantage of this method is that circuit loading is

slight compared with direct-coupling methods, and dis-

tortion of the sweep curve is minimized.

Another method consists of clipping directly to the

insulated portion of the grid lead of the mixer stage.

Unless care is taken when this method is used, how-

ever, detuning of the high impedance mixer circuits

may occur and result in a distorted sweep curve and an

erroneous picture of alignment.

In general, the RF OUTPUT attenuator should be

set to give the smallest amount· of output necessary to

obtain a marker of the desired height on the response

curve.Iftoo strong a marker signal is injected into the

circuit under test, it is possible that overloading may

cause distortion of the curve and result in an erroneous

picture of the alignment. The vertical gain control on

the oscilloscope should be set at or near the maximum

gain point so the oscilloscope furnishes a good share of

the signal amplification.

If

this technique is used, the

amount of injected signal can be kept low.

• 9 •

Page 10

Application

General

Eliminating AGe Action

Because the agc voltage in a TV receiver varies in

accordance with the signal fed through the if amplifier

to the agc rectifier, a varying dc voltage is present on

the agc bus. This voltage is applied to the grids of

some or all of the if-amplifier tubes and may also be

fed to the grid of therfamplifier tube.Ifthis voltage

is not rendered inoperative during alignment, difficulty

may be experienced in shaping the response curve, and

final results may be misleading.

This difficulty may be avoided by either disconnect-

ing the age system or rendering it inoperative through

application of an external amount of fixed bias which

is

the same as that provided during normal operation

of the agc system. The RCA WG-307B TV Bias Supply

(See Figure 5) is recommended. This supply furnishes

three output voltages continuously adjustable from 0

to -15 volts, as well as -100 volts (fixed) for use in

color-TV receivers.

If

the RCA WR-69A Television/FM Sweep Genera-

tor is employed in the alignment setup, bias may be

taken from the bias-supply terminals on the generator.

In addition to being a valuable aid during if alignment,

the external bias voltages are highly useful in tracking

down trouble in agc circuits.

Alignment Test Setups

In sweep-frequency alignment, the sweep generator

is tuned to sweep the band of frequencies normally

passed by the wide-band circuits in the TV receiver,

and a trace representing the response characteristics of

the circuits will be displayed on the oscilloscope. The

WR-99A is used to provide calibrated markers along

the response curve for checking the frequency settings

FigureS.RCA WG-307B TV Bias Supply.

of traps, adjustment of capacitors and coils, and for

measuring overall bandwidth of the receiver.

When the marker signal from the WR-99A is coupled

into the test circuit, a vertical "pip" or marker will

appear on the curve. When the WR-99A is tuned to a

frequency within the pass band accepted by the re-

ceiver, the marker will indicate the position of that

frequency on the sweep trace. The technician then

adjusts the circuit components to obtain the desired

waveshape, using the different frequency markers as

check points.

The order in which various sections of the television

receiver should be aligned may differ between different

models of receivers. In all cases, the alignment order

given by the manufacturer in his service notes should

be followed.

Itisnot possible, therefore, to recommend a single

alignment procedure which can be applied with equal

success to all television receivers. Instead, the applica-

tion data given in the following pages are designed for

use in conjunction with the manufacturer's service

notes to aid the technician in aligning a receiver cor-

rectly and efficiently.

Receiver alignment requires, in addition to the

WR-99A Calibrator, a sweep generator having essen-

tially fiat output and good sweep linearity, a cathode-

ray oscilloscope, and a vacuum-tube voltmeter. An

RCA WR-69A or WR-59-series Sweep Generator, an

RCA WO-9lA Oscilloscope, and an RCA VoltOhmyst*,

such as the WV-77E, WV-87B, or WV-98B are recom-

mended. A marker-adder unit, such as the RCA WR-

70A RFIIF/VF Marker Adder, can be used to advan-

tageinthe alignment setup.

Tuner Alignment

To clear up any misconception that a tuner is a

complicated device, consider the tuner when stripped

to its essentials. Except for the switching arrangement

and the usual high and low-pass filters, it is about as

simple as the input of a broadcast receiver. This fact

should be remembered when trouble-shooting problems

arise which are common to all channels. In these cases,

it is good practice to work with the tuner set to only

one channel position until the trouble is corrected.

Afterwards, other channel positions can be compared

·TMK Reg. U.S. Pat. Off.

• 10 •

Page 11

RCA Crystal-Calibrated Marker Generator WR-99A

with the initial one for sensitivity, switching noise,

and general performance.

If

the tuner is satisfactory· in these respects, it is

advisable to check the alignment by observing the

response curves for each channel. Curves for the in-

dividual channels should be examined and compared

with those shown in the manufacturer's service notes.

If

a response-curve check indicates that alignment is

required, the technician should refer to the alignment

curves given in the service notes as guides and follow

closely the recommended alignment procedure.

Alignment should not be attempted until these pre-

liminary tests have been completed. Futhermore, the

technician should be aware that most tuners, unless

tampered with, are correctly aligned. This knowledge

can often prevent misalignment of a good tuner.

The primary purpose of alignment is to obtain a

response curve of proper shape, frequency coverage,

and gain. Most tuners merely require "touch-up"

alignment in which relatively few of the adjustments

are used. Generally, complete over-all alignment is

required only when a person with inadequate knowl-

edge or equipment has worked on the tuner. For a

complete alignment job, it is desirable to follow a

specific sequence of adjustments, the sequence depend-

ing upon the type of tuner. However, where only

touch-up alignment is required, the sequence of adjust-

ment is usually unimportant.

In principle, complete front-end alignment includes

alignment of the antenna input circuits and adjustment

of the amplifier andrfoscillator circuits. The antenna

input circuits are usually aligned to give a response

curve which has a sharp drop-off slightly below channel

2 and which is flat up through channel 13.

In effect, the input circuits, which consist of two or

more traps and high-frequency peaking circuits, act as

a high-pass filter. Their correct alignment is important

in keeping low-frequency interference from entering

the receiver through the tuner circuits. Adjustment of

P 5

Figur.6.Typical tuner curve for channel

8.

the input circuits is usually critical but they seldom

require service.

Alignment of the rf, amplifier and oscillator stages,

however, is a more familiar job. Adjustments include

setting the oscillator. frequencies for channels 2 through

13, setting one or more traps to their correct frequen-

cies, and adjustment of tracking with the rf amplifier.

The converter transformer may also require adjust-

ment along with the tuner.

Al! these adjustments require that a sweep signal

from the sweep generator and a marker signal from

the WR-99A be fed into the tuner so that a response

curve with markers will be reproduced on the oscillo-

scope screen, Alignment is accomplished by setting

adjustments so the waveshape on the oscilloscope

screen resembles the waveshape shown by the manu-

facturer in his service notes. The notes show separate

curves for each of the 12 channels. Each channel is

aligned separately to obtain the desired curve shape.

The marker signals from the WR-99A are USEdto pro-

vide frequency reference points to aid in shaping the

curve.

With the sweep generator set to deliver output on

channel 8, for example, and 4.5-Mc interval markers

injected from the WR-99A at 181.25 and 185.75 Mc,

a typical tuner curve for channel 8 will resemble that

shown in Figure 6. The markers on the curve show

the separation between the picture and sound carriers.

Since the rf sections of the TV receiver must pass both

sound and picture signals, a bandpass of approximately

6 Me is required. The locations of the sound and pic-

ture carrier frequencies for all vhf channels, which are

shown in Table Ilpage] 7' ,are individually marked

on the dial scales.

A necessary preliminary to alignment is a check of

!he test setup. For example, rf bias should be checked

and proper connection points for test equipment deter-

mined. All equipment should be given a 20-minute

warm-up time to enable circuits to stabilize operation.

If

the tuner is to be aligned in the receiver, the tuner

curves should be observed with the first if-amplifier

stage out of operation. Removal of the first if-amplifier

tube is generally sufficient to avoid any curve distortion

caused by the if amplifier. In some tuners, resonance

in the mixer plate circuit may also produce undesirable

reflections. Generally, to remedy this situation, the

picture-if amplifier input must be loaded or the

if-

transformer primary must be detuned.

The tuner oscillator should be in operation during

alignment.

If

it is not, the lack of oscillator injection

voltage at the mixer grid will alter the mixer bias,

.

"

.

Page 12

RCA Crystal-Calibrated Marker Generator WR·99A

resulting in an increase in amplitude of the response

curve and distortion of the waveshape. The oscillator

frequency of intercarrier-type receivers should be

checked by use of the heterodyne. frequency meter

method or the method recommended by the receiver

manufacturer.

Serious misalignment of the tuner or considerable

difficulty or failure in alignment may indicate a defec-

tive component.Ifproper alignment procedure fails to

produce correct tuner curves, the technician should

check individual components in the rf umt.

Over-all Picture-IF Alignment

The general procedure forifalignment of split-sound

and intercarrier types of television receivers is the

same; the major differences being in the number of

intermediate frequencies used and the frequencies. ern-

ployed. As in tuner alignment, the procedure described

in the manufacturer's service notes should be followed

carefully and response waveforms checked against

those shown in the service notes.

If

a television receiver is to give wide-band amplifi-

cation to the television signal, the picture-if system of

the receiver must pass a frequency band approximately

3.5 to 4 Mc wide. This is necessary to insure that all

the video information is fed through to the kinescope

grid and that the resultant picture has full definition.

The bandpass of color TV receivers must be essen-

tially flat to beyond 4 Me to insure that color informa-

tion contained in the color side bands is not lost. Two

special marks are provided on the WR·99A dial to aid

in checking alignment. One mark is placed at 42.17

Mc, the color sub-carrier intermediate frequency. The

other mark is placed at 41.65 Mc, which is the "knee"

or drop-off point on the response curve.

The sweep generator, marker generator, and the

oscilloscope provide the means for determining the

shape of the response curve and the width of the band-

pass. With the equipment set up to obtain a response

curve, the WR·99A is used to check the bandwidth

directly in terms of frequency as follows.

Tune the WR-99A so the marker falls at a point ap-

proximately 70% up the curve slope. Read the Ire-

quency at this point directly from the marker generator

dial scale. Tune the generator so the marker appears

on the opposite side of the bandpass curve at the 70%

response point. The frequency is read from the dial

scale. The difference between the two settings is equal

to the bandwidth of the amplifier.

Two kinds of picture-if systems are generally used

to give the necessary bandwidth. The overcoupled

if

system employes transformers which have their pri-

mary and secondary windings tuned to the same

frequency. The transformers are overcoupled to obtain

a flat-topped response curve of the desired bandwidth.

The other method, the stagger-tuned system, employs

transformers (coils) which are stagger tuned to dif-

ferent frequencies to produce a final over-all if reo

sponse of the desired bandwidth. Some television

receivers employ if systems which utilize both these

principles. It is important, then, that the alignment

instructions given in the service notes be followed

closely.

To obtain an over-all picture-if response curve, con-

nect the direct probe of the oscilloscope across the

second-detector load resistor, which provides a de-

modulated signal to the oscilloscope. Connect the

ground cable to the receiver chassis. Because of the

high degree of signal amplification in the if-amplifier

section, the oscilloscope gain may need to be reduced

to a low level, but not to the point where it is necessary

to use a high level of output from the sweep generator.

An over-all if response curve may be obtained by

feeding theifsweep signal into the amplifier at the

input to the firstifstage or into the mixer stage.Ifthe

markers from the WR·99A are injected into the same

point, intermediate marker frequencies should be used.

Manufacturer's procedure usually calls for stage-by-

stage alignment, starting with the lastifstage and

working forward. Sometimes it may be necessary to

change the sweep oscillator injection point to the grid

of the stage being aligned, or to the plate of the stage

preceding the stage being aligned. This insures that

the response curve is not affected by characteristics of

forward, misaligned stages. As the grid and plate tun-

ing adjustments of .each stage are checked, the fre-

quency of theifmarker is changed accordingly.

Analysis of the Sweep-Response Curve

As

an example of a typical response curve for a TV

receiver is shown in Figure 7. The frequency relation

of the sound carrier to picture carrier is reversed in

the if amplifiers because the .receiver local oscillator

operates at a frequency higher than that of the trans-

mitted carrier. Examination of the waveform will

show that the sound component has been sharply

attenuated.

The following two characteristics of the picture-if

response curve should be noted: (1) the picture-carrier

is set at approximately 50% of maximum response and

• 12 •

Page 13

RCA Crystal-Calibrated Marker Generator WR-99A

Figure 7. Sweep-response curve for picture-if amplifier and de'-

tector. Marker shows picture-carrier frequency.

(2) the sound carrier frequency must be at 1.0% or

less of maximum response. The picture carrier is

placed at approximately 50% of maximum response

because of the nature of single' sideband transmission,

the system used in transmitting television signals.

If

the circuit is adjusted to put the picture carrier too

high on the response curve, the effect will be a general

decrease in picture quality caused by the resulting low-

frequency accentuation; placing the picture carrier too

low on the curve will cause loss of the low-frequency

video response and result in poor definitio~. Loss of

blanking and proper synchronization will also occur.

The skirt selectivity of the picture-if curve is made

sharp enough to reject the sound component of the

composite signal. The sound carrier is kept at a low

level to prevent interference with the video signal. To

achieve this selectivity in split-sound receivers, an

absorption circuit, consisting of a trap tuned to the

sound intermediate frequency, is used. Some receivers

include additional traps tuned to the higher frequency

of the adj acent channel sound carrier. These traps have

a marked effect on the shape of the response curve.

Alignment of traps is described under the headinz

"T ~

rap Alignment".

Checking Response of Individual Stages

The response of individual 'if-amplifier stages or of

two or more stages together may be checked by setting

up the sweep generator and WR-99A as shown in

Figure 8, The sweep signal is fed into the stage im-

mediately preceding the stage being checked, The re-

sponse curve is checked on the oscilloscope, which is

connected across the second-detector load resistor. Be-

fore attempting sweep alignment of the amplifier sec-

tion, the age circuit should be rendered inoperative by

either disconnecting the age bus or by using a bias box,

as described in the section, "Eliminating AGC Action".

Therfcable from the sweep generator is connected

to the grid of the if-amplifier stage ahead of the stage

CRO,

WR-8tA

o

TO

MIXER

o

0

TI

1

OtT

LOAD

RES

Figure 8. Method for checking response of third if-amplifier stage

and detector.

to be checked to isolate the test equipment from the

stage being checked. Therfoutput cable should not be

connected to the grid of the stage being checked be-

cause even slight loading of the high-impedance grid

circuit may cause a change in circuit impedance and

result in distortion of the normal response character-

istic, The marker signal from the WR-99A should be

fed to the grid of the mixer tube.

With equipment set up as shown in Figure 8, a re-

sist-or of small value, such as 470 ohms, should be

connected across the primary of the following if trans-

former. The resistor acts to swamp the primary winding

and prevents inductive reactance of the winding from

affecting the bandpass characteristics of the amplifier

being checked. The shape of the response curve on the

oscilloscope will be determined by the bandpass char-

acteristics of the amplifier stage and the detector

circuits.

If

it is desired to check the bandpass characteristics

of the detector circuit only, the sweep generator output

cable should be moved from point "B" to point "C"

and the swamping resistor, R., placed across the pri-

mary of T4. Response of the second and thirdifampli-

fier stages and the detector stage together may be

checked by moving the rf output cable to point "A"

and connecting the swamping resistor across the pri-

mary of T2.

Trap Alignment

One or more traps may be contained in the rf unit

and picture and sound if amplifiers, depending upon

the type of receiver. Traps are included to attenuate

specific frequencies, such as adjacent picture and sound

carriers, or picture. and sound-if signals in v.ari~us

parts of the receiver.

(Continued on page 18)

. 13·

Page 14

r------------------------------------------------ --- ---- ------- --- ------

I

I

I

I

I

I

I

I

I

i

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

SIF

SIC

SIA

SIB

I

: L------/VI.I\r____J

I RI

: 12

I

~----------------------------------------------------

---------~!-I:l

~ 1500

V5

6AS6

MIXER MOD.

V48

l/z12AT7

1M C OSC

R 39

470

K

R44

f,

330

K

YI

0

'0

MC

C22

R36

3300

R35

470

100

K

K

~:

I. ALL RESISTANCEVALUES ARE IN OHMS EXCEPTt>S NOTED.

2.CAPACITANCEVALUES LESS THAN

1.0

ARE IN UF S 1.0

S ABOVE ARE IN UUF EXCEPT t>S INDICATED.

3.

SWITCHSI B S2 VIEWED FROM FRONT WHEN IN MAX.

COUNTERTERCLOGKWISE POSITION.

4 ALL VOlJAGES MEt>SUREDWITH A·'VOLTOHMYST.'

INDICATED VOLTAGES ARE FOR REFERENCE ONLY

ANO MAY VARY WITH DIFFERENT INSTRUMENTS.

VOLTAGES MEASURED WITIi CONTROLS SET AS FOLLOWS'

51 ON

50'90

MC RANGE.

~~ <?~N':~ MC CAL' POSITION.

S9

.Qtj".

. 14 .

Schematic I

Page 15

ATTENUATOR

r--------------------- ------ -- ----- - ----.,

I ,

i

150B 150B 15DB 100B 5 DB :

: \.~ 0--0 0--0 0--0 0--0 :

I-{

4_7_K

j-J.~~(b:---t+-(1-++-+-i

--<0

\--;~U~-:U~-~U~-6U~~ \>---+l_+n_f-'-.-JRI~,F.(OUT

~OO

J5I~(P2 ~

!

RIO RII RI2 RI3 RI4 I

+

IOOV

ls5g1 .~~

=

i ~

1~1O ~ ,~30 ~

i

C9::r: 39K : R15}> RlliS RI7S RIS R19~ R20~ R21 R22~ R23 «~,~24:

eoo

T IW

!

130'(>1:30? 13d? 130 130>130 ~ 180 ISQ~ 330 <,,30:

CIO ....

I '

1500

T L_ --- -------- - ---- ------1-------------- ----- ----:

i

~'C

AO;" '"""'"

.:lOU'"

I

>'~6

R27 tR2~~ CIS

~t'>

RED~lllkl~~1

V3A

<

470K

MEG

,022 155Vji ~

l/roUlr-~~,OV ~

I

HETERODYNE -~

<> ,/ ~

V ":<.8

OE~;;;:R

l~

r!~

23V ~~

> \

g\'~8 '~~U8

R25> ~

CR2 100<> C 14

~r8

C 16 C17 '

IN34AK ~

0

I 3:30

C 19 R

32

Ie

54

330 K'

t~

>130 10 MFD

1,~47 ~

25 V.

--------.,

I

R4

I

C7..l!5OO

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

CI2

I

f-_,

f- - - - -

J

fO------+--+-+-+--'

F

R6

>2700

IW

'>

R7

'>

2700

IW

r

CI3

47

"-55

100

,

,

J2

,

\

.MQll!J

\

=r:

I

\

1

I

J3

,

\

.BE..!ti

.

,

=r=

\

,

I

\

\

,

J4

I

GND

I

I

I

\

I

I

V7

I

EXTERNAL

I

CRYSTALORLC

OA2

'.

I

I

I

I

\

XI

C 20 R 33

4.7

~~c;"

,..----1

vv

58

r

l1~--!{[f.

i

~ sbolsbo):

: L~2_

Ll3):

i : C47 :}:

I II

120

?:

:~~tr::

:---s-----J

PI

3 WIRE POWER CORD

USED ON SOME MODELS

VFO-"ON-OFF"

6.3

7

~

R4Z.

ICQ:r' 560>

C38

QI

S9

.--

.AA

J

R\'2V'I1 ~

2

5DOO

5W

260

t.u

800~

V~

C42A 42 B

3OtJF13OUF

HI

C4t3

7

3300

300 V

V8 .

6X4

~lb

c4o

H9r

75V 210.0 4.5MC

,..-~ [tC41

: -'- \. I 5-25

\

--

\ 1""""1

J

V68

'eV'20V

~6U8

c39 4.5 MC OSC

3300

R51.>

470K>

'Q'RM<

TI

I

2\;

-

~

~""'"

6

?q.;

..._~

~

........

63V

11

[2

12AT7

6l1l

6U8

6X4

6AS6 r~,C44

3300

t

NOT USED IN ALL INSTRUMENTS.

pm of WR-99A

232899-9

. '5 .

Page 16

Replacement Parts List

WR-99A

When ord.rlng r.plocement port" Includ. ,erlol number ond code number of In,trument.

Order ports throullh a local RCA distributor.

Symbol

No.

Description

ClA C1B

CIC ClD

C2

C3

C4 C5

C6

C7toC12

C13

C14

CIS

C16

C17

C18

C19

C20

C21

C22

C23

C24

C25

C26

C27 C28

C29

C30

C31

C32

C33 C34

C35

C36

C37

C38

C39

C40

C41

C42AC42B

C43

C44

C45 C46

C47

C48

C49

C50

C51

C52

C53

C54

C55

CRI CR2

EI

J1

J2 J3

J4

J5

Ll

12

L3

IA

Capocitors

Variable: 4

-sections .

Trimmer: 0.5-5 I'l'f .

Mica: 100 I'l'f ±10%. 500 volts .

Headed lead: 4.7 I'l'f ±20%. 500 volts

Ceramic disc: 3300 I'l'f +100%

-0%.500 volts .

Ceramic: 1500 I'l'f + 100% -0%.

500 volts : ..

Ceramic: 47 1'1'£±20%. 500 volts ...

Ceramic: 330 I'l'f ±20%. 500 volts ..

Ceramic: 15001'1'£ ±20%. 500 volts.

Paper: O.ll'f ±20%. 200 volts .

Ceramic: 3301'1'£ ±20%. 500 volts ..

Paper: 0.0221'£ ±20%. 400 volts .

Paper: 0.47 1'£±20%. 400 volts .

Headed lead: 4.7 I'l'f ±20%. 500

volts .

Trimmer: 0.5-5 1'1'£.. . . . . .. . .

Ceramic disc: 3300 I'l'f +100%

-0%. 500 volts .

Ceramic: 27 I'~ ±10%. 500 volts .

Variable: 5-25 1'1'£ .

Ceramic: 12 I'l'f ±20%. 500 volts .

Ceramic disc: 3300 I'l'f +100%

-0%. 500 volts .

Ceramic: 391'1'£ ±10%. 500 volts .

Ceramic: 120 I'l'f ±20%. 500 volts ..

Ceramic: 100 I'l'f ±10%. 500 volts ..

Ceramic disc: 33001'1'£+ 100% -0%.

500 volts .

Ceramic: 12 I'l'f ±10%. 500 volts .

Ceramic: 3301'1'£ ±20%. 500 volts ..

Paper: 0.11'£ ±20%. 200 volts .

Ceramic: 12 I'l'f ±20%. 500 volts .

Paper: 0.11'£ ±20%. 200 volts .

Ceramic disc: 33001'1'£ + 100%

-0%.500 volts .

Ceramic: 27001'1'£ ±20%. 500 volts.

Variable: 5-25 1'1'£ .

Electrolytic: 30-301'£ + 100%

-10%.350 volts .

CeJamic: 3300 I'l'f +100% -0%.

00 volts .

Ceramic disc: 33001'1'£ + 100%

-0%. 500 volts .

Ceramic disc: 1500 I'l'f + 100%

-0%. 500 volts .

Ceramic: 1201'1'£ ±20%. 500 volts ..

Variable: 3-121'1'£ .

Ceramic: 5.6 1'1'£± 1.0 I'l'f. 500 volts.

Variable: 3-12 1'1'£ .

Ceramic: 5.6 I'l'f ±LO 1'1'£.500 volts.

Variable: 5-25 I'l'f .

Ceramic: 47 1'1'£±10%. 500 volts .

Electrolytic: 10 I'f. 25 volts .

Ceramic disc: .01

}if.

500 volts .

******

Resistors

Stock

No.

Stock

No.

Description

214763

• 16 •

214767

213732

76373

70392

31048

48982

502012

502222

502410

502347

502147

512227

512339

502410

502127

33571

502056

33571

502118

502133

502410

502447

502522

214790

522312

33571

502127

502410

502447

502347

Crystal: type IN34-A .

Post. binding .

Connector:

RF

Output .

Jack: ModInand RF

In .

Jack: single contact .

Connector .

Inductor. adjustable .

Inductor, adjustable .

Inductor, adjustable .

Inductor, adjustable .

502447

502410

512333

Symbol

No.

L5

L6toL9

LIO

Lll

LSI

PI

P2

P501

Inductor. adjustable .

Inductor .

Inductor, adj ustable .

Reactor. filter: 13.35

H .

Speaker: 3" P::\l

type .

Cord.

power:

78" long. with plug .

Connector: for attenuator .

Connector:

coaxial-type,

for

RF

cable .

502456

503433

214769

93463

103856

102235

213734

214789

75609

75792

75610

73784

75792

73562

78977

102235

93463

213734

205918

204811

94228

213734

75450

76347

214787

213734

214792

75792

Rl Composition: 12 ohms ±10%.

}1

watt .

R2 Composition: 2200 ohms ±10%.

Y2

watt .

R3 Composition: 100.000 ohms ±10%.

Y2

watt .

R4 Composition: 47.000 ohms ±10%.

Y2

watt .

R5 Composition: 470 ohms ±10%.

}1

watt .

R6 R7 Composition: 2700 ohms ±10%. 1

watt .

R8 Composition: 39,000 ohms ±10%.

1

watt .

R9 Composition: 100,000 ohms ± 10%,

Y2

watt. .

RIOtoR12 Composition: 270 ohms ±10%.

}1

R13

I

Co":n~ti~~~·

i30'~h~~'·±5·%·. ~.

watt .

R14 Composition: 56 ohms ±10%,

}1

watt .

R15toruo Composition: 130 ohms ±5%.

Y2

watt .

R21 R22 Composition: 180ohms ±10%.

}1

watt .

R23 R24 Composition: 330 ohms ±10%.

Y2

R25

I

Co':~iJ.~~·:

·ioo.ooo

'~h~{s'

±

iO%: .

Y2

watt .

R26 R27IComposition: 470.000 ohms ± 10%.

:Y2

watt .

ru8 Composition: 2.2 meg ±10.Y2watt.

ru9 Variable: 0.5 meg ±20%. ~ watt

(includes 89) .

R30 R31 Composition: 12.000 ohms ±10%. 2

watt .

R32 Composition: 130ohms ±5%.

Yz

watt .

R33 Composition: 270 ohms ±10%.

Yz

watt .

R35 Composition: 100.000 ohms ±%10.

Yz

watt .

R36 Composition: 470.000 ohms ±10%.

Yz

watt .

R3i Composition: 47.000 ohms ±10%.

}1

watt .

R38 R3.l) Composition: 470.000 ohms ±10%.

Y2

watt .

R40 Composition: 100.000 ohms ±10%.

Yz

watt ~ .

R41 Composition: 33.000 ohms ±10%. 1

R42 Co':;'~iiio~':

·iio.ooO·ohl~;s·

±iO%:'

Yz

watt .

R43 Composition: 560.000 ohms ±10%.

Yz

watt .

R44 R45 Composition: 330.000 ohms ±IO%.

}1

watt , .

73784

94228

73784

213734

214791

204811

214788

213734

213734

73748

76347

56231

74182

56231

74182

204811

77531

59395

2.12151

96257

214783

214782

51388

214766

214765

214764

214764

Page 17

Symbol

No.

R46

R4i

R48

R49

R50

R51

R52

R53

R54

R55

R50l

81

82

S3 to 87

88

S9

Tl

T2

Xl

Yl

Y2

Delcription

Composition: 210.000 ohms ± 10%.

~ watt .

Composition: 560 ohms ±10%. ~

watt .

Composition: 68.000 ohms ± 10%,

~ watt .

Composition: 220,000 ohms ±10%,

Y2

watt .

Composition: 100,000 ohms ±10%,

~ watt .

Composition: 470.000 ohms ±10%,

Y2

watt .

Wire Wound: 5000 ohms ±20%,

5 watt .

Composition: 12 ohms ±10%.

~ watt .

Composition: 270 ohms ±10%.

~ watt .

Composition: 100 ohms ±10%,

~ watt _ .

CORrc~~\~).:

.9.1~~~~'. ~

.~a~~?~r..

••••••

Siock

No.

Symbol

No.

502427

502156

502368

502422

502410

502447

205065

502012

502127

47452

214798

214770

214469

214760

214793

37806

214781

214795

214796

D.lcriptlon

Milc.llon.oul

Bezel: polystyrene, silver .

Cable, rf-output: complete .

Capacitor: ceramic-disc, 10.000

jl.jI.f

+100%, -0%,500 volts .

Clip alligator: for rf cable .

Foot, rubber: for carrying case .

Handle, carrying .

Insulator: black, for alligator clip .

Insulator: red. for alligator clip .

Knob, control: 1~6'" dia, blue .

Knob. control:

134'" dia,

with pointer,

blue .

Knob. control:

134'"

dia, blue .

Lamp: 6.3 volts .

Pointer assembly: complete with

slider, slider spring, pointer handle,

and pointer .

Pulley. dual: I'" O. D.X1~6'" long ..

Pulley, single:

34'"

x 1.5'" dia .

Pulley; drive: for tuning shaft, 2'"dis

x

1.4'" wide .

Pulley. single:

34'"

thick

x

2Ys

M

dia ..

Pulley, single: ~6'" thick x 3~" dia ..

Pulley. single:

%4'"

thick x

Ys

M

dia,

aluminum .

Pulley, single: ~ .. thick x ~'" dia,

aluminum : .

Scale. dial: calibrated .

Shell: for rf cable. match pair .

Socket. tube: 7-pin .

Socket, tube: 9-pin .

Socket, pilot lamp .

Spring. coil: 0.156'" dia x

U6

M

long .

Spring, coil: 0.185'" dia x I'" long .

Stud: for carrying handle .

Window: for dial .

Stock

No.

214785

214797

73960

35262

211887

212102

99539

204879

212148

214778

214779

11891

214772

214777

214776

204480

214775

214774

214761

214762

214768

47452

204899

204900

214780

214784

214771

214786

214773

Switch. rotary: 4 sections. 8 positions.

12 circuits .

Switch,

rl_ltary: 2 sections. 8 positions

5 circuits .

'Switch, slide: DPDT, 0.5 amp, 125

volts .

Switch, toggle: SPST, 6 amps. 125

volts; 3 amps. 250 volts .

(Part of R 29)

Transformer, power .

Transformer, audio output .

Socket, crystal .

Crystal: 10 Mc .

Crystal: 4.5 Mc .

TABLE I

Chonn.1 Chonn.1

l'ictvr...cafTl.r Soun"-c .... I.r

No. Fr.... IMel Fre... IMeI. Fr.... IMeI

t

2

54-60

55.25

59.75

3 60·66

61.25 65.75

4

66·72

67.25

71.75

5

76-82 77.25

81.75

6 82·88 83.25

87.75

7 174·180

175.25 179.75

8 180-186 181.25 185.75

9 186·192 187.25 191.75

10 192·198 193.25 197.75

11 198·204 199.25 203.75

12 204·210 205.25 209.75

13 210·216 211.25 215.75

.Value. given in thi. colum,Dare ideDtified on. dial

le.Ie

al

"2P''.

u3P". etc.

tV.luel

liveninthi.

column are

identified

on di.al

Kale ••

"2S", 0.35",

etc.

17 •

Page 18

RCA Crystal. Calibrated Marker Generator WR·99A

SCOPE

M~RKER

GENER~TOR

WR-b4A

LOW-C~P~CITANcE

PROBE HERE

INTERMEDIATE

__.-o'IJ\

rREQUENCY

MARKER

o

o

0

SOUND

TR~NS

FM

DETECTOR

Figure 9. Test-equipment setup for alignment of sound-if

ClIlpJilier.

The test-equipment setup for alignment of traps in

theifamplifier is the same as that used in conventional

if

alignment described above. A sweep·response curve

is obtained on the oscilloscope screen, and a marker

from the WR·99A, which is set to the frequency of the

trap, is fed into the mixer stage.

Because the response of the amplifier is very low at

the trap frequencies, the marker may often be difficult

to see on the response curve. The use of a marker-

adder unit, such as the RCA WR-70A RF /IF /VF

Marker Adder is recommended for trap alignment. The

unit is especially valuable in trap-alignment applica-

tions because the marker is added to the response

curve

after

the sweep signal is taken out of the receiver,

thus eliminating all suckout.Ifa marker adder is not

used, the WR·99A should be set for maximum output

and the scope gain set to maximum to increase the size of

the marker.

If

difficulty is experienced, more precise

adjustment may be achieved by connecting a Volt-

Ohmyst, set for de-voltage measurements, across the

second-detector load resistor, and tuning the trap for

minimum voltage reading on the meter.

The general procedure in aligning picture-if ampli-

fiers is first to set the traps and then to align the am-

plifier circuits. Since any adjustment of the amplifier

circuits usually will slightly detune the traps, the traps

may have to be "touched up" during the picture-if am-

plifier alignment. The manufacturer's alignment in-

structions will again determine the exact procedure to

follow.

Alignment of Sound-If' Amplifiers and

FM

Detectors

A typical test set-up for aligning an intercarrier-type

sound-if amplifierisshown in Figure 9. This system

employs a ratio detector which reeei..es its signal di-

rectly from the

last

sound-if amplifier stage. Circuits

which use a discriminator detector will employ a lim-

iter stage ahead of the detector circuit.

An

over-all response curve of the sound-if amplifier

and detector is ohtained

by

connecting the sweep gen·

erator and the "\\R·99A at point "A", the grid of the

first sound-if amplifier. Set the CAL/MOD control on

the WR·99:\ to "4.5 :\-IC". The oscilloscope is con-

nected at point "C", where a demodulated signal ap·

pears. The sweep width control on the sweep generator

shouldbeset to ~ve a sweep width of approximately

1 Me.

An "S'vshaped

curve, similar to the curve shown

in Figure 10. will appear on the oscilloscope screen.

To check alignment of the first if-amplifier stage

only, the oscilloscope probe should be moved to point

"B" where a sweep response curve similar to that

shown in Figure 11 should be obtained. The marker

indicates the 4.5·Mc center frequency of the curve.

If

the marker does not appear exactly at the center of the

curve, the amplifier should be adjusted as recom-

mended by the manufacturer until the marker is

exactly at the center of the curve. This assures that re-

sponse is symmetrical and adequate audio bandwidth

is obtained.

• 18 •

Page 19

RCA Crystal-Cal ibrated Marker Generator WR·99A

Figure 10. Response curve for fm-sound detector. Symmetrical Figure 12. FM-detector curve showing 600-cps modulation. Mod-

shape indicates correct alignment. ulation causes wide trace or waviness on base line. When center

frequency of detector is tuned exactly to the sound intermediate

frequency, modulation will disappear.

Figure 11. Sound-if response curve. Marker shows center of pass

band and is the sound intermediate frequency.

If

a discriminator detector is used, the stage will be

preceded by a limiter. The over-all response of the if

amplifier is checked by connecting the oscilloscope

across the resistor in the grid circuit of the limiter, In

some receivers, the time constant of the grid circuit

may be large enough to cause distortion of the pattern

when the scope is connected.Ifthe pattern is distorted,

the difficulty may be eliminated by temporarily remov-

ing the capacitor from the rf circuit or by shunting the

resistor with another resistor of a value determined by

experimentation.

The response of the sound-if amplifier alone in a

system using a discriminator-type detector may be

checked by using the same procedure as for checking

an amplifier using a ratio- type detector. Set the CALI

MOD control to "4.5 Mc&600 CPS". The sound-if

point should appear at the intersection of the response

curve and the zero-reference line. Tune the detector

transformer as indicated in the manufacturer's service

notes.

If

the detector is not correctly aligned, the 600 cps

will

modulate the "S" curve, as shown in Figure 12.

When the detector is set to exactly 4.5 Mc, the modula-

tion will be cancelled out.

Use of WR·99A as Heterodyne Frequency

Meter

The WR-99A may be used with good accuracy to de-

termine the frequency of an external signal between

20 and 260 Mc. In general, the procedure consists of

feeding the signal of unknown frequency into the

WR-99A, mixing it with the vfo signal from the WR-

99A, and, by use of the zero-beat method and inter-

polation, reading the frequency directly from the WR-

99A dial. This feature is particularly useful in checking

the oscillator frequency in intercarrier receivers. Pro-

cedure is as follows:

1.

Connect a lead from therfoutput of the external

signal source to the RF IN connector.

2. Set the tuning dial of the WR-99A to read the

approximate estimated frequency of the external signal.

3_ Calibrate the WR·99A at the I-Mc or 10-Mc

check point nearest the frequency of the external sig-

nal, as described under "Calibration".

4.Ifthe unknown signal is of very low level, turn

the AF GAIN control fully clockwise. It may also be

necessary to connect a ground lead from the external

signal source to the GND terminal of the WR-99A.

5. Turn the tuning dial of the WR·99A until zero

beat is obtained with the external signal.

6. Determine the frequency of zero beat by observ-

ing the dial setting and interpolating, as described un·

der "Calibration".

• 19 .

Page 20

Maintenance

Figure 13. Block diagram of WR-99A .

Caution:

See

"Safety Precautions", Page 2

~neral

Performance of the WR-99A depends upon the

qnality of the components employed.Ifit should be

necessary to replace any of the component parts, only

Rc..~ replacement parts or equivalents of those shown

:=:

the Replacement Parts List of this instruction book-

ott

should be used.

The chassis may be removed from the case by re-

moring two screws from the bottom of the front bezel,

removing the bezel by sliding it off the bottom and

lifting upward, removing two screws from the back

of the case, and removing 14 screws from around the

edge of the front panel. Pull the panel and chassis

out of the case.

If

any alignment adjustments are made, the line

yol.tage should be 117 volts, at 60 cps.Iftrouble is

encountered, voltage readings should be taken and

compared with the operating voltages shown on the

schematic diagram. Conventional trouble-shooting tech-

niques should be used to locate trouble.

p

=

rRONT PANtl..

/>OJ

Circuit Desceiption and Operation

The WR-99A is built around a Colpitts-type variable-

frequency oscillator (VI) which utilizes an RCA-

6AF4-A. (See Figure

13).

This oscillator is tunable by

means of capacitor sections CIA, CIB, CIC, and CID

over a band of frequencies from 20 to 260 Mc. This

band is divided into eight overlapping

rf

ranges. On

ranges 1 through 5, capacitor sections CIC and CID

and sections CIA and CIB are paralleled. On ranges 6,

7, and 8, only sections CIB and CIC ar-e used.

Output from VI is taken from the grid and fed to

the grid of the modulator stage, V2. Any internal or

external modulation is mixed with therfsignal in this

stage. Output from the V2 modulator stage is fed

through capacitor C6 to the attenuator network.

Internal crystal-controlled calibrating markers are

generated by a Miller-type crystal oscillator stage,

V4A, which generates lO·Mc harmonic signals. One-

megacycle calibrating markers are generated by a

I-Mc Colpitts oscillator, V4B, which is locked to the

V4A osciUator in a lO·to-l ratio. These oscillators may

be switched out of operation from the front panel.

. 20 .

Page 21

RCA Crystal-Calibrated Marker Generator WR-99A

The 10- and I-Me signals from V4A and V4B are

fed to the mixer/modulator stage, V5, which mixes

the two signals and feeds them through CI3 and C5 to

grid No. 1 of V2. The output from V5 also contains

harmonics of the two signals. The 4.5-Mc signal is

generated by V6B, a Pierce oscillator. The 4.5-Mc is

fed through C37 to grid No. 3 of V2. The 6OO-cps

modulating signal is generated by a phase-shift oscil-

lator, V6A, which feeds the signal to grid No. 3 of

V2. Any signal fed into the MOD IN terminal is also

fed to grid No.3 of V2.

Crystal diodes CRI and CR2 comprise a voltage-

doubler beat-frequency detector. In this circuit, the

I-Mc, IO-Mc, or external signals are beat with the vfo

signal from VI to produce an audio-beat signal from

the speaker. V3A and V3B are audio-frequency ampli-

fiers.

Regulation of the B+ voltage for the vfo stage, VI,

is accomplished by use of OA2 regulator tube, V7.

IO·Mc Crystel-Oscllfatcr Adjustment

1.

Connect the WR-99A to a 1- and 10-Mc standard

oscillator, as shown in Figure 15. A Measurements

model III or equivalent unit may be used as the

standard.

2. Set the RF control on the WR-99A to "OFF". Set

the CAL/MOD control to "10 MC CAL". Turn the AF

GAIN control about three-quarters turn clockwise. Set

the standard oscillator to deliver a 10-Mc output signal.

3. With an insulated alignment tool, turn the slug

in inductor L9 until about one-quarter inch protrudes

from the coil form. (See Figure 14 for locations of in-

ternal adjustments.]

4. Screw the core slowly back into the coil form and

listen for an audio beat between the two 10-Mc signals.

Continue screwing in the core until the beat note disap-

pears; then, back the core out of the form one full

turn. Switch the CAL/MOD control between "10 MC

CAL" and "OFF" several times to make sure that the

WR-99A 10-Mc oscillator starts promptly.1£oscillator

starts erratically, back out the cere until oscillation is

satisfactory.

S. Adjust trimmer capacitor C24 to zero beat the

two 100Mc signals as closely as possible.

I·Mc Oscillator Adjustment

1.

With power applied to the WR-99A, set the RF