Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

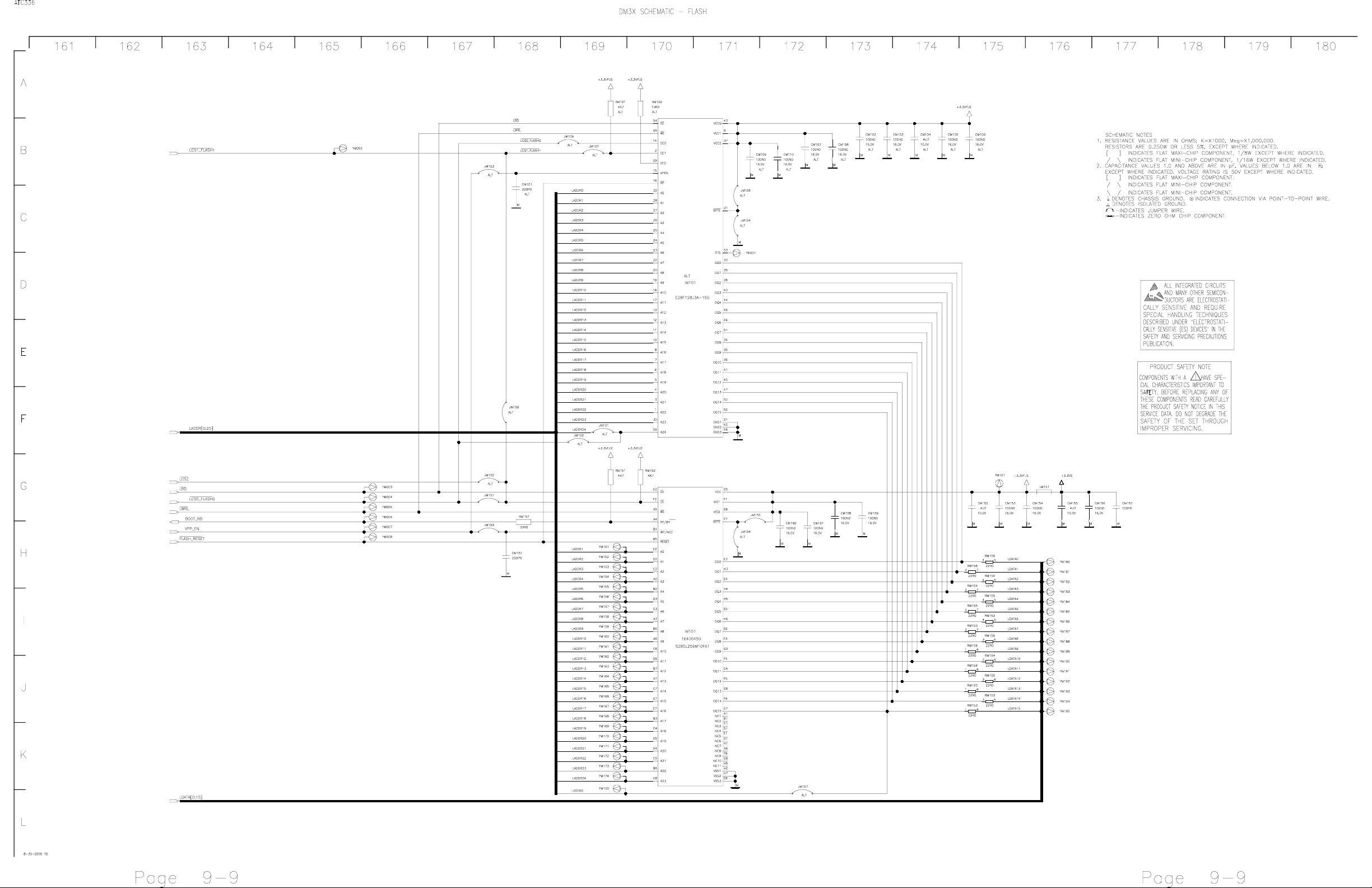

Page 9

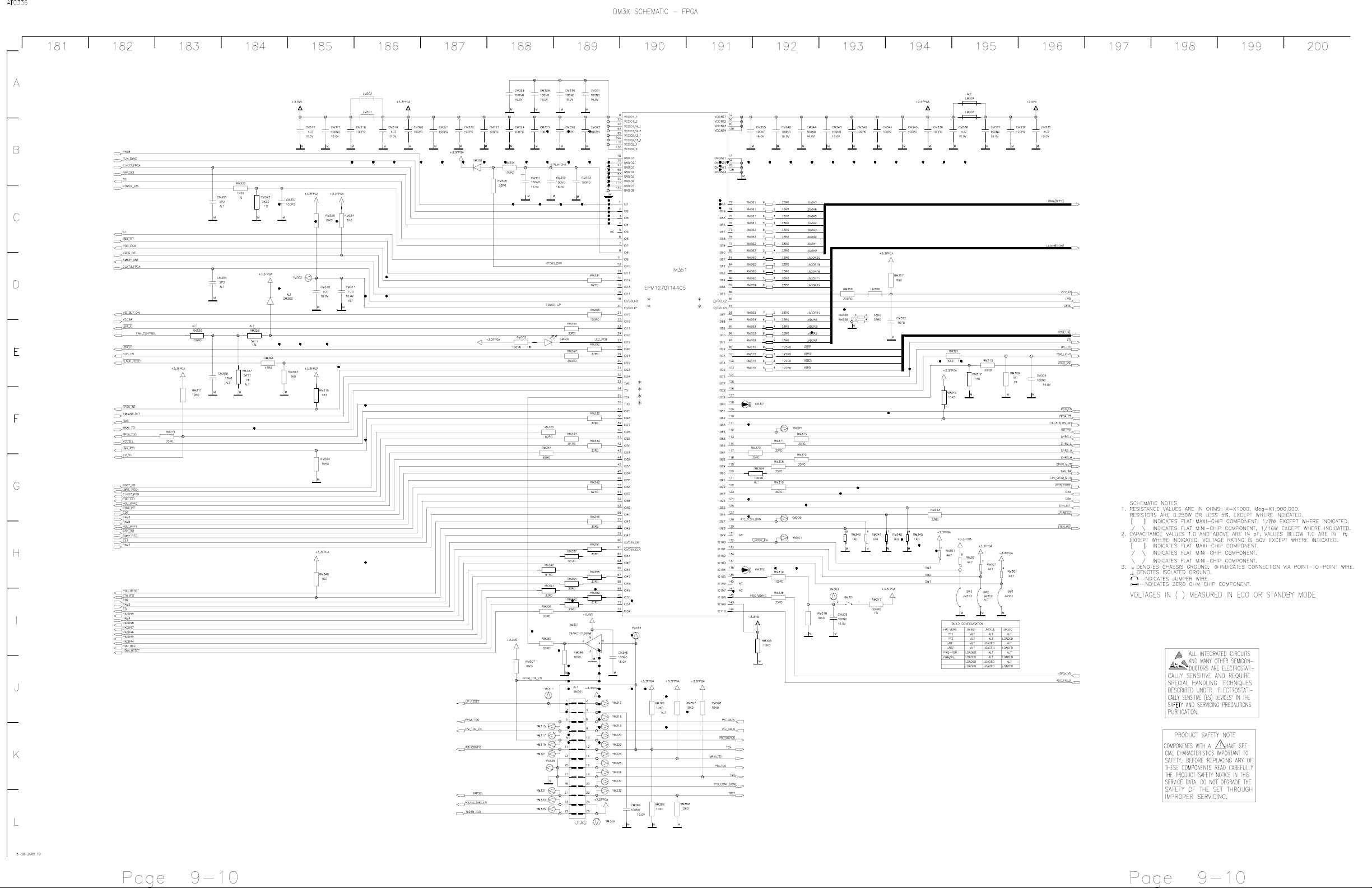

Page 10

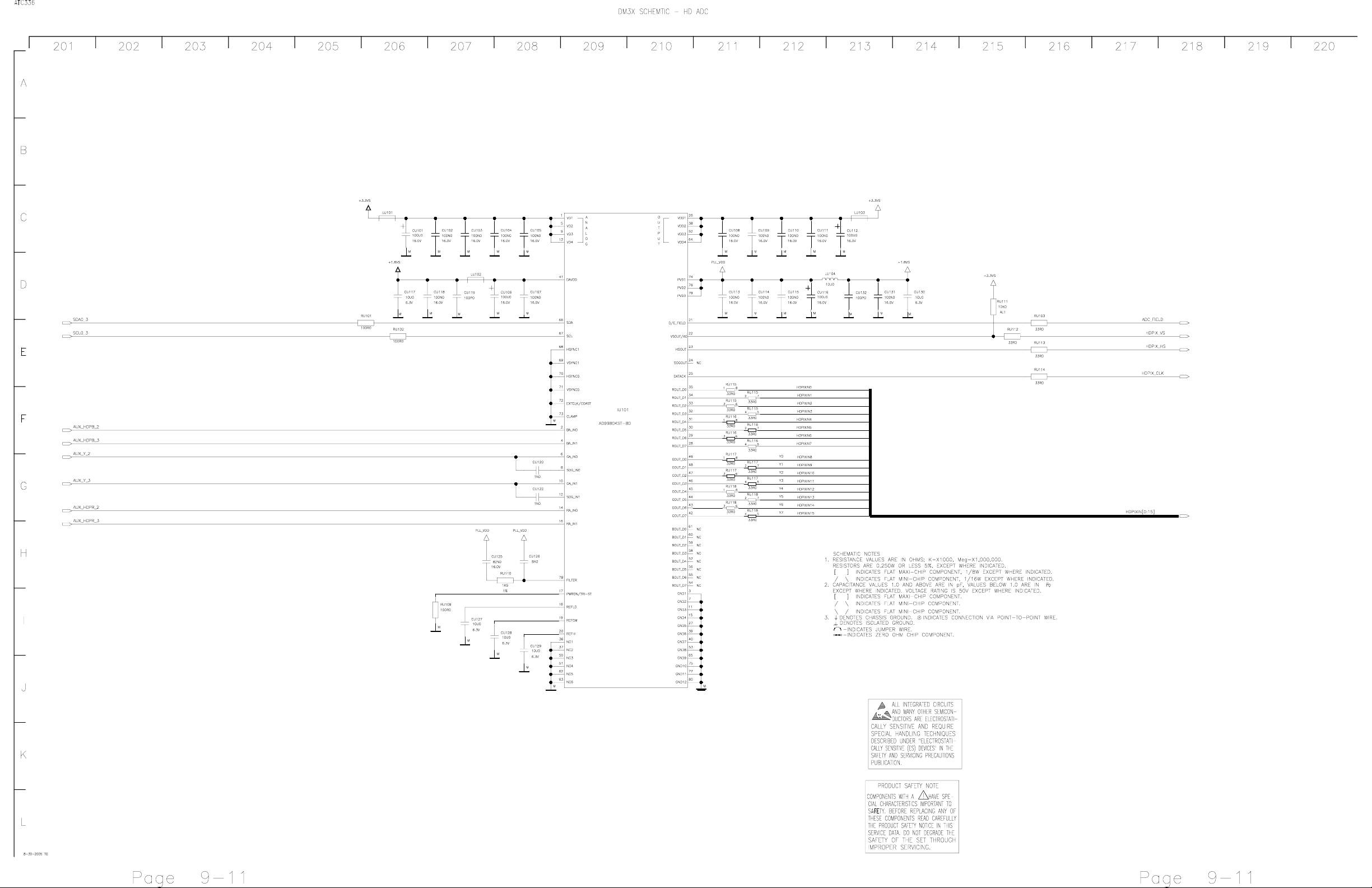

Page 11

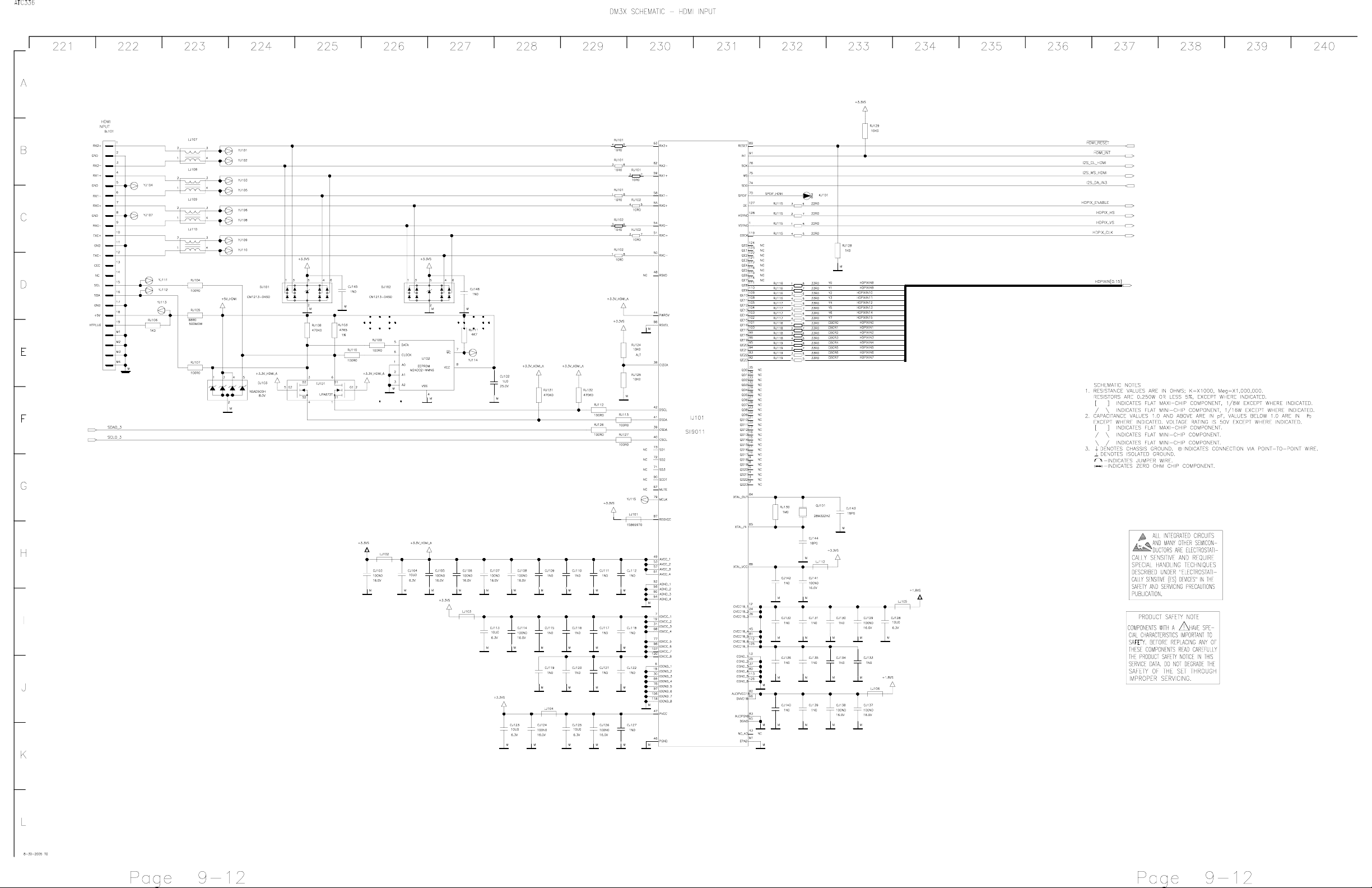

Page 12

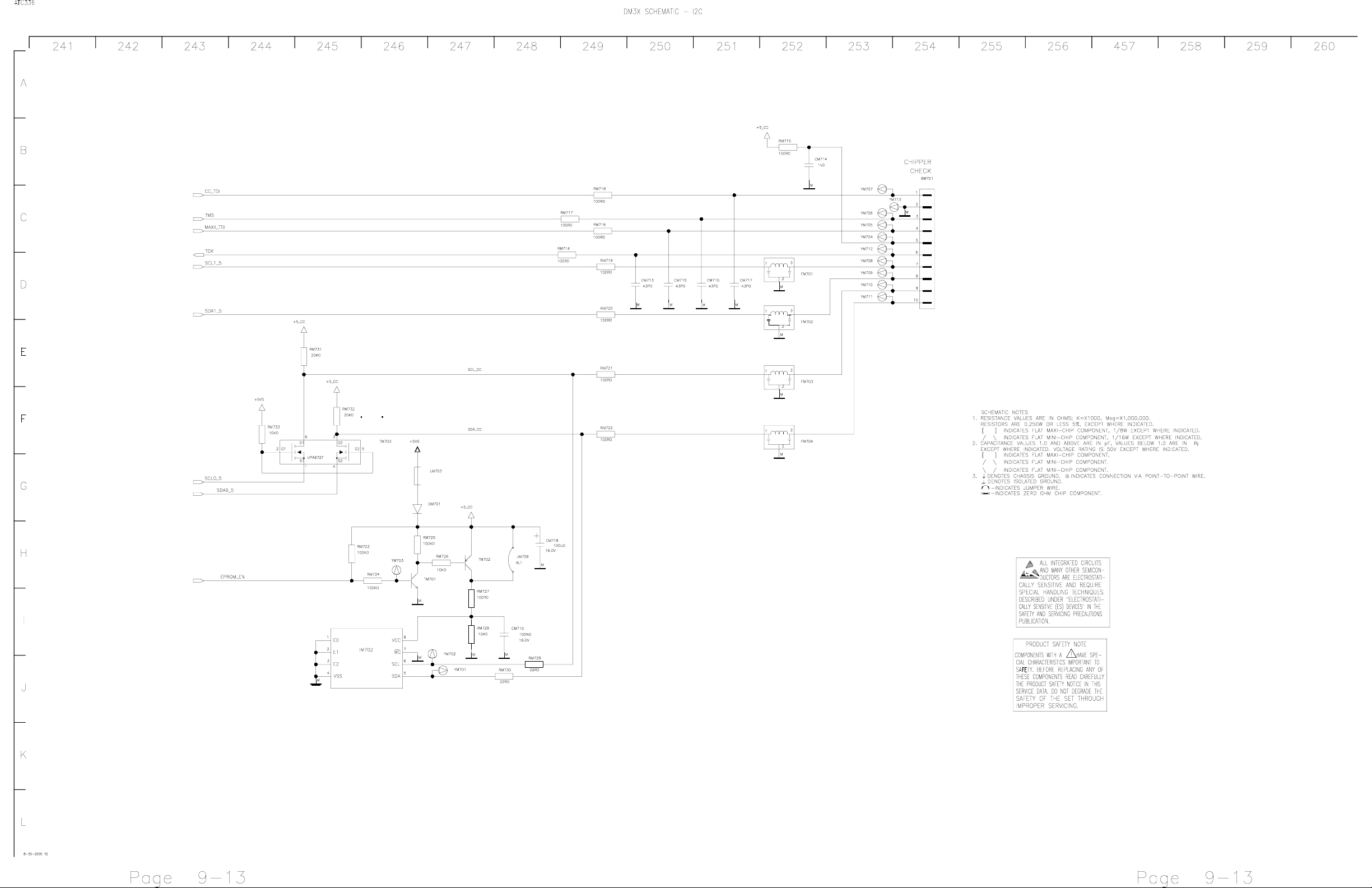

Page 13

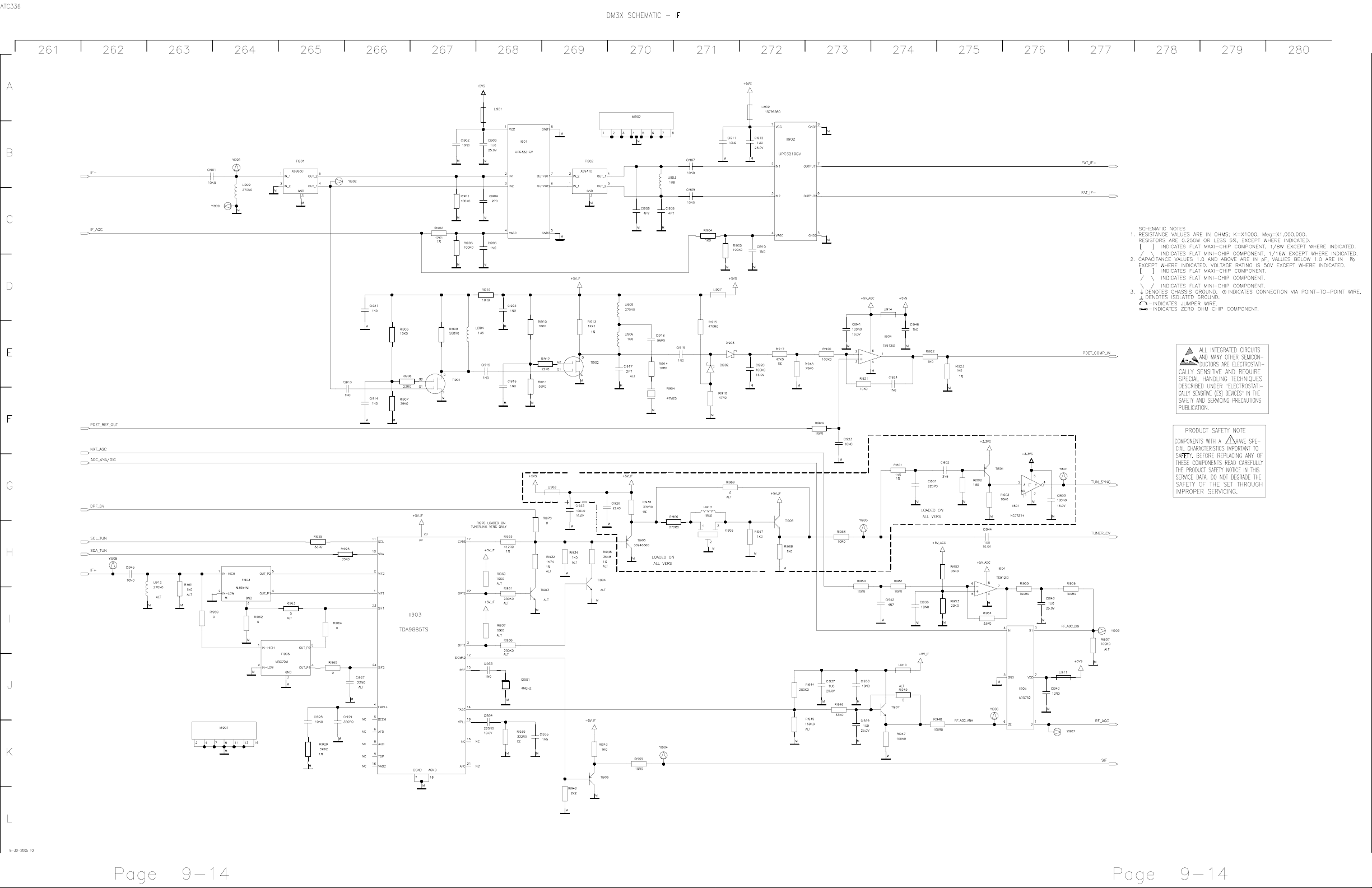

Page 14

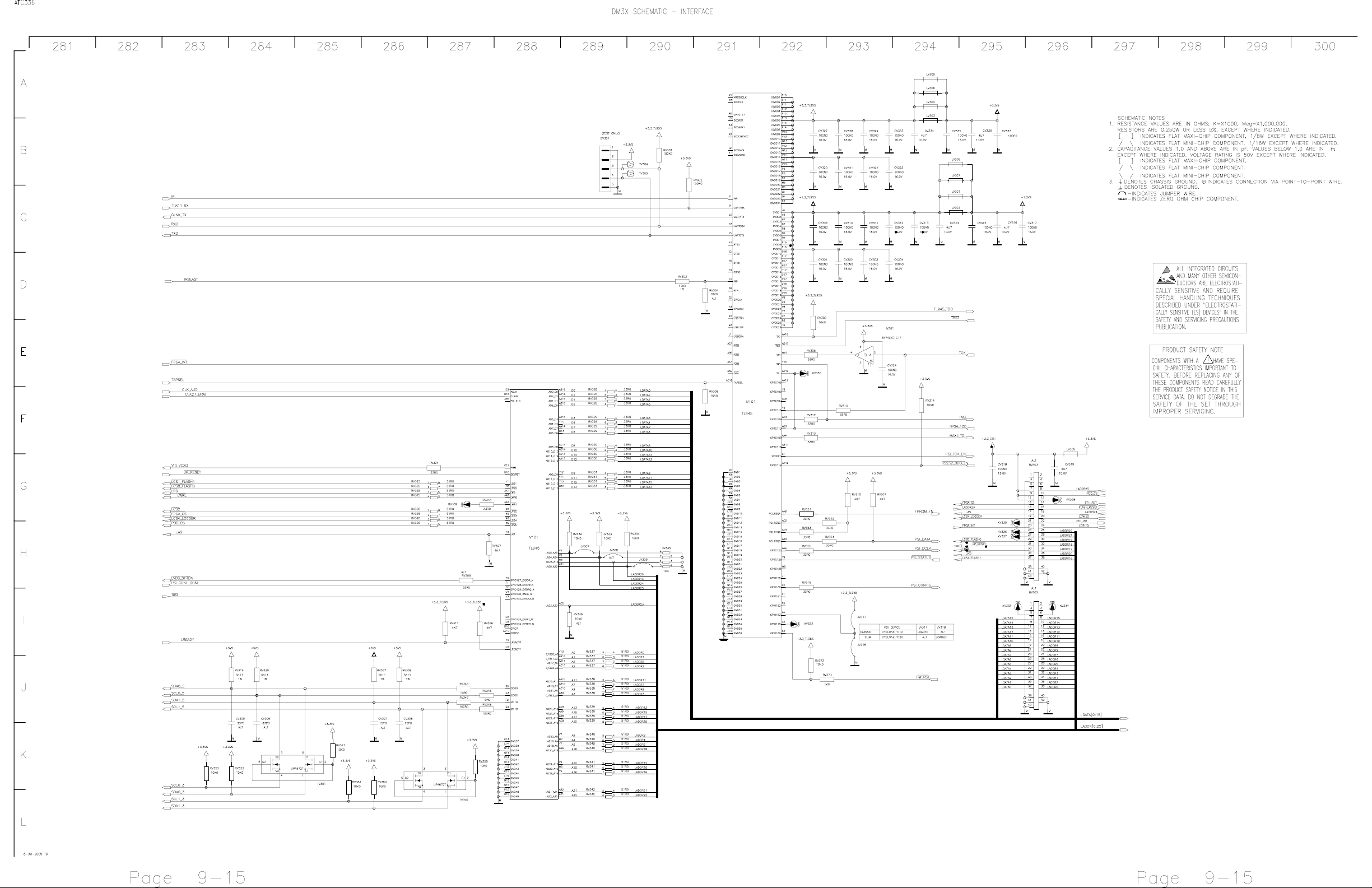

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

ATC336

ALIGNMENT PROCEDURES

Operating Conditions

Unless otherwise noted, the following conditions must be

observed when aligning the TV:

1. Chassis must be operated from a 120 VAC isolation transformer with line voltage set to 120 VAC.

2. All voltages and waveforms referenced are with respect

to Ground

3. A 10X probe must be used for oscilloscope and frequency

measurements.

TV Service Screen

The service screen is provided to facilitate instrument alignment and service adjustments. The service screen is accessed

by pressing a two-button combination on the front control

panel of the instrument.

Using the Front Panel Controls to enter Service Screen

1. Turn on the TV and select the channel that will be used

for the alignment procedure.

2. With the instrument “ON” press and hold the “Menu”

button and then the “CH q” button.

3. Press the “OK” button on the Remote or Front Panel to

display the service screen Menu as shown.

Fig. 1 Service Screen

Entering the Service Alingment Mode

1. Bring up the Service Screen.

2. Once in the service screen use “CH q” button on the keyboard or the down arrow on the remote control to highlight item “2 Service Alignment”.

3. Press “Menu” on the keyboard or “OK” on the remote

control to activate the Alignment Screen.

Fig. 2 Service Alignment Selection

4. Once the Alingment Screen has been activated use the

“VOLu” button on the keyboard or remote to adjust the

value (V:0) to the desired value.

Fig. 3 Service Alignment Screen

NOTE: When the service mode is accessed, the parameter

will be “0”. Parameter “0” is used to input the security code.

The security code is necessary to protect the factory alignments from inadvertent modification. Attempting to change

the parameter (P) using “CHq” or “CHp” before the proper

security code has been entered will cause the instrument to

exit the service mode. A valid security code is entered (using

“VOLt”or “VOLu”).

Security Codes

When the Service Alignment Screen is first entered, the parameter (P) will come up set at “0”, which corresponds to the

security code function.

1. With the parameter (P) set to “0” adjust the value (V)

(using “VOLt”or “VOLu”) to “76” for access to the

Electrical Alignments.

2. Once the security code has been set, individual alignments can be accessed by pressing “CHq” or “CHp”

changing the parameter (P) number.

ATC336

ALIGNMENT PROCEDURES

3. Once a parameter (P) has been selected for a particular

alignment the “VOLt“and “VOLu” buttons can be

used to change the value (V) of the alignments selected.

Most Electrical adjustments for the DLP instrument must

be done using Chipper Check.

Security

Location (V)

50 Error Codes

76 Instrument Alignment

80 DLP Centering

90 Warranty Clock

196 Reset Shipping Defaults

200 Chipper Check

Description

Warranty Clock

1. Enter the TV Service Mode. Highlight item 2 Service

Alignment. Press “OK” on Remote Control.

2. Using the Volume Buttons, go to V: 90. Press “Channel

Up”. The display will show the number of hours in use,

along with the number of hours plugged in. Press the

“Power” button to exit.

Error Codes

If certain failures occur in the chassis, error codes will be

stored in the chassis EEprom. These error codes can be accessed by entering the service menu and setting the VALUE

to 50. With the VALUE set to 50, pressing the Channel up

button will toggle through the 6 error codes. Error code “0”

stores the error code for the first failure experienced by the

instrument. Similarly, error code “1” stores the error code

for the second failure. Error code “2” stores the error code

for the third failure. Error code “3” displays the error code

for the most recent failure experienced by the instrument. Information is displayed in the following order: Error #, Date,

Time, Type, Count, Code. If an Error of the same TYPE is

Error # Date Time Type Count Code

0: 0.0.0 0:0:0 Type=21 Count=4 Code = 4002010000000000

Fig. 4 Error Code Screen

already logged, then the error will overwrite the existing error of that type and the count will be increased. Error codes

are summarized in Fig. 5.

The presence of “Empty” for the error code indicates that

no failures have occurred since the time the error codes were

reset. The error codes can (and should) be reset to “0” after

servicing. Press the clear button to clear the error code that

is currently being displayed.

1. Enter the Service Menu.

2. Press Volume Up Until V is 50.

3. Press Channel Up to View The First Error.

4. Press Channel Up/Down to View the Next/Previous Error.

5. Press Clear to Clear the Error Code that is Currently

Being Displayed.

6. Press Power Off to Return to the P:0 V:50 Display.

7. Press Power Off Again to Return to Normal TV Viewing.

To use the Error Code charts, first look up the “Type”

displayed in the error code (Fig. 4). Then find the Type

number (Hex) in the first error code chart (Fig. 5). The description column indicates the general area of the problem

and the Detail column gives additional information for some

Error Codes.

If the Error Code “Type” is 21 or 22, additional information is available as shown in Fig. 6. Refer to the last string

of hex characters referred to as Data or Code in Fig. 4. The

first two characters hex value of the string refer to the “Chip”

information in Fig. 4. The second two characters hex value

in the string refer to the “Bus” information in Fig. 4. The

third two characters hex value in the string refer to the “Details” information in Fig. 4.

If the Error Code “Type” is 41, additional information is

available as shown in Fig. 5. Refer to the last string of hex

characters referred to as Data or Code in Fig. 2. The first

two

characters hex value refer to the “Watchdog” information in

Fig. 5.

Page 3-2Page 3-1

Page 38

ATC336

0123456

7

Chip

Bus000000

SRV

ARC

EXC

SPF

APF

SWR

Apndx E

0000000

E2

DM Hardware Error

VPIP Dropped Ball

0000000

0

Additional Data

Additional Data

ALIGNMENT PROCEDURES

Type

(hex)

1 Chassis (General) 0 0 0 0 0 0 0 0

2 Convergence Parity Error 30 0 0 0 0 0 0 0

3 Chassis Power Initial Power Fault 10 0 0 0

4 Deflection EEProm Corrupt 11 0 0 0 0 0 0 0

5 XRP XRP 13 0 0 0 0 0 0 0

6 Back End Processor BEP POR 0 0 0 0 0 0 0 0

7 Back End Video Algorithm Error 0 0 0 0 0 0 0 0

8 DLP Driver Fan Fail 40 0 0 0 0 0 0 0

21 IIC Read Chip Bus Details 0 0 0 0 0

22 IIC Write Chip Bus Details 0 0 0 0 0

23 IIC Bus Latched

31 App (General) ? ? ? ? ? ? ? ?

32 Reset Count

41 Software Watchdog

42 Hardware Watchdog 0 0 0 0 0 0 0 0

51 Guide Process Termination 0 0 0 0

61 Audio Audio Exception 0 0 0 0 0 0 0 0

71 Other Fan Max Speed 0 0 0 0 0 0 0 0

81 POD SCTE28

82 POD Bad Certs 0 0 0 0 0 0 0 0

83 POD Trans Timeout 0 0 0 0 0 0 0 0

84 POD FR Timeout 0 0 0 0 0 0 0 0

85 POD Session Timeout 0 0 0 0 0 0 0 0

E1 DM Hardware Error Revert to Auto DLL 0 0 0 0 0 0 0 0

Description

Loop Fault 31 0 0 0 0 0 0 0

Output Inactive 32 0 0 0 0 0 0 0

Bus Fault 33 0 0 0 0 0 0 0

Other 34 0 0 0 0 0 0 0

I2C 35 0 0 0 0 0 0 0

REF_EE 36 0 0 0 0 0 0 0

Other 14 0 0 0

Invalid Handle 15 0 0 0

Power Supply Fault 16 0 0 0

POR 12 0 0 0 0 0 0 0

Lamp Fail 41 0 0 0 0 0 0 0

No Lamp Strike 42 0 0 0 0 0 0 0

No Lamp Lit 43 0 0 0 0 0 0 0

DDP1010 Reset 47 0 0 0 0 0 0 0

Color Wheel Blower 48 0 0 0 0 0 0 0

System Fan Fail 49 0 0 0 0 0 0 0

Process Exit Code

Fig. 5 Error Code Chart

Data ("Code") (hex)

Additional Data

Additional Data

Reset Count

Task ID(s) - See Below

ATC336

ALIGNMENT PROCEDURES

Additional Data Description IIC Errors ("Code")

21,22,23 Bus 0

21,22 Details 1

Chip Bus Module

24 AVIO AVIO

28 Tuner DM3

2A Tuner DM3

30 DM DM3

34 DLP LE

40 Deflection Deflection

42 DLP LE

54 DM DM3

60 DM DM3

68 DM DM3

80 DM DM3

84 Tuner DM3

86 Tuner DM3

88 Deflection BEP

8C Deflection Deflection

90 AVIO AVIO

92 AVIO AVIO

96 DM DM3

98 DLP LE

98 DM DM3

A0 DM DM3

A0 Deflection Deflection

A2 Deflection Deflection

A8 AVIO AVIO

AC DLP LE

AE DLP LE

B8 AVIO AVIO

C0 Tuner DM3

C2 Tuner DM3

C6 Tuner DM3

3 Bus: DM

1

3 Bus: Tuner

2

Run Bus: AVIO

3

Run Bus: DLP

4

Run Bus: Deflection

chip did not acknowledge when was expected to

2

some hardware error detected, maybe one of the lines is grounded

3

some software error, e.g. not enough memory, or could not acquire the mutex

Comment

TA1270 Chroma Decoder

Nextwave

Nextwave

Picture Signal Improvement (PSI) FPGA

DDP1010 Light Engine Controller

Deflection DAC

PCF8574 I/O Expander

GPIP

9993 HDMI Receiver

9993 HDMI Receiver

Micronas Audio Processor

Cable IF

Air IF

TA1316 Back End Video Processor

TA1317 Deflection Processor

LA79500 1H A/V Switch

CXA2189Q HD Switch

LM77 Digital Temperature Sensor

LM75 Digital Temperature Sensor

9883A HDADC

DMx Main EEProm

Deflection EEProm (lower 256 bytes)

BEP EEProm (upper 256 bytes of Deflection EEProm)

AVIO Eeprom

Light Engine Eeprom (lower 256 bytes)

Light Engine Eeprom (upper 256 bytes)

Frame Comb

Cable Tuner PLL -1

Air Tuner PLL

Cable Tuner PLL - 2

Fig. 6 Error Code Data

Page 3-3 Page 3-4

Page 39

ATC336

Page 3-5

Additional Data Description (Type 41)

The first Task Id is the first task to count down to zero. The remaining 7 Ids are any tasks whose counts are at or below 16.

Thread Name

Hex Value

Thread Name

Hex Value

AV_DRV_CTL_MAIN_ID,

06

AV_DRV_CTL_PIP_ID,

07

CC_DRAW_MAIN_ID,

09

POD_IST_ID,

3D

3E

IEEE1394P2POUTPUT_TASK_ID

POD_UPGRADE_TASK_ID

Not Assigned

Not Assigned

Not Assigned

TL9_VIDEO_SERVICE_TASK_ID

POD_CPMAIN_TASK_ID,

EXT_CHAN_MAIN_TASK_ID,

POD_HOMING_TASK_ID,

MMI_MAIN_TASK_ID,

POD_RESMGR_MAIN_TASK_ID,

POD_SESSION_MAIN_TASK_ID,

4B4C7B7A794D47

48

43

4445464142

KEYMGR_MAIN_TASK_ID,

POD_CAMAIN_TASK_ID,

Additional Data Description (Type 51)

The guide process should never terminate but if it does, the exit code will likely be one of the following exception values:

Value

Exception

Value

C000008E

C0000025

C000008F

C00000FD

C0000090

C0000026

C0000008

Additional Data Description (Type 32)

Byte

Data

07:

00:

Corresponds to errors listed in Appendix E of SCTE28

This is a count of all system resets since the field code was last cleared. This includes AC dropouts, forced system resets in the

code, and resets due to unknown causes.

SRV: Software Reset Vector was hit. (not yet implemented)

EXC: Exception - An exception occurred in the kernel. (not yet implemented)

SWR: Software Reset - Software wrote to an Altera register to force a reset.

CT0: Low byte of 16 bit reset counter (legacy)

INVALID_DISPOSITION

INVALID_HANDLE

FLT_INVALID_OPERATION

FLT_STACK_CHECK

FLT_UNDERFLOW

INT_OVERFLOW

PRIV_INSTRUCTION

ILLEGAL_INSTRUCTION

NONCONTINUABLE_EXCEPTION

FLT_DENORMAL_OPERAND

FLT_DIVIDE_BY_ZERO

ACCESS_VIOLATION

BREAKPOINT

SINGLE_STEP

Exception

ALIGNMENT PROCEDURES

ATC336

ALIGNMENT PROCEDURES

UNKNOWN_TASK_ID = 0, 00 POD_PHYS_LINK_MAIN_TASK_ID,

CC_TASK_DRAW_MAIN_ID, 01 POD_LINK_SEND_MAIN_TASK_ID,

CC_TASK_MAIN_ID, 02

CC_TASK_WINMAIN_ID, 03

DM_MAIN_TASK_ID, 04

AV_DRV_MONITOR_ID, 05

CA_MAIN_TASK_ID, 08

CC_MAIN_TASK_ID, 0A

CHANACQ_MAIN_TASK_ID, 0B

CHANACQ_PIP_TASK_ID, 0C

CHANACQ_VBI_TASK_ID, 0D

CHANACQ_RECORD_TASK_ID, 0E

CHANACQ_1394_TASK_ID, 0F

CHANACQ_P2P_TASK_ID, 10 Not Assigned 4E

CHANEPG_MAIN_TASK_ID, 11 Not Assigned 4F

CHANEPG_PIP_TASK_ID, 12 Not Assigned 50

CHANEPG_VBI_TASK_ID, 13 Not Assigned 51

CHANEPG_RECORD_TASK_ID, 14 Not Assigned 52

CHANEPG_1394_TASK_ID, 15 Not Assigned 53

CHANEPG_P2P_TASK_ID, 16 Not Assigned 54

EAS_MAIN_TASK_ID, 17 Not Assigned 55

EPG_ACQ_TASK_MAIN0_ID, 18 Not Assigned 56

EPG_ACQ_TASK_MAIN1_ID, 19 Not Assigned 57

EPG_ACQ_TASK_MAIN2_ID, 1A Not Assigned 58

EPG_ACQ_TASK_MAIN3_ID, 1B Not Assigned 59

EPG_ACQ_TASK_MAIN4_ID, 1C Not Assigned 5A

EPG_ACQ_TASK_MAIN5_ID, 1D Not Assigned 5B

EPG_ACQ_TASK_MAIN6_ID, 1E Not Assigned 5C

EPG_ACQ_TASK_MAIN7_ID, 1F Not Assigned 5D

EPG_ACQ_TASK_MAIN8_ID, 20 Not Assigned 5E

EPG_ACQ_TASK_MAIN9_ID, 21 Not Assigned 5F

EPG_ACQ_TASK_MAIN10_ID, 22 Not Assigned 60

EPG_ACQ_TASK_MAIN11_ID, 23 Not Assigned 61

IEEE1394_INPUT_TASK_ID, 24 Not Assigned 62

IEEE1394_OUTPUT_TASK_ID, 25 Not Assigned 63

IEEE1394_MONITOR_TASK_ID, 26 Not Assigned 64

HWCTRL_TASK_ID, 27 Not Assigned 65

POD_CTRL_OOB_MONITOR_TASK_ID, 28 Not Assigned 66

POD_CTRL_MAIN_TASK_ID, 29 Not Assigned 67

SCHED_TASK_MAIN_ID, 2A Not Assigned 68

TP_BRIDGE_TASK_ID, 2B Not Assigned 69

TP_EXT_CHAN_TASK_ID, 2C Not Assigned 6A

TP_RECEIVE_TASK_ID, 2D Not Assigned 6B

TUNER_CABLE_TASK_ID, 2E Not Assigned 6C

TUNER_AIR_TASK_ID, 2F Not Assigned 6D

UI_MAIN_TASK_ID, 30 Not Assigned 6E

IEEE1394_CONNECTISOC_TASK_ID, 31 Not Assigned 6F

XDS_MAIN_TASK_ID, 32 Not Assigned 70

ASW_MODE_DETECT_TASK_ID, 33 Not Assigned 71

AUDIO_STATUS_TASK_ID, 34 Not Assigned 72

DEFLECTION_TASK_ID, 35 Not Assigned 73

DLP_POWER_TASK_ID, 36 Not Assigned 74

DLP_TASK_ID, 37 Not Assigned 75

FIREWALL_TASK_ID, 38 Not Assigned 76

FPA_SCAN_TASK_ID, 39 Not Assigned 77

FPIR_REMOTE_IST_ID, 3A Not Assigned 78

FPIR_KEYBD_IST_ID, 3B

FPIR_KEYBD_PTR_IST_ID, 3C

POD_TRANSPORT_MAIN_TASK_ID,

IEEE1394P2PINPUT_TASK_ID

3F

40 TV_POWER_TASK_ID,

49

4A

DATATYPE_MISALIGNMENT

ARRAY_BOUNDS_EXCEEDED

FLT_INEXACT_RESULT

FLT_OVERFLOW

06:

ARC: Altera Reconfigure - Altera has been reset.

05:

04:

03:

SPF: Software Power Pail - power fail software was triggered by an interrupt from the Altera

APF: Altera Power Fail - Altera triggered power fail interrupt.

02:

01:

CT1: High byte of 16 bit reset counter (legacy)

Additional Data Description (Type 81)

C0000005 C0000093

80000002 C0000094

INT_DIVIDE_BY_ZERO

80000003 C0000095

80000004 C0000096

C000008C C0000006

IN_PAGE_ERROR

C000008D C000001D

STACK_OVERFLOW

C0000091 80000001

GUARD_PAGE

Fig. 7 Error Code DataFig.

Page 3-6

Page 40

ATC336

When in Color Wheel Index: Starts the sequence to overwrite the factory

aligned values.

ALIGNMENT PROCEDURES

ATC336

ALIGNMENT PROCEDURES

Service Menu Items

Alignment Range Description/Default Value

OSD Background 00 - 01 00 = Black: 01 = Transparent

NTSC Video Align 0 - 3 1

Cable Tuner Analog RFAGC 0 - 31 17

Tuner Digital RFAGC 256QAM 0 - 255 160

Tuner Digital RFAGC 8VSB 0 - 255 48

Tuner Digital RFAGC 64QAM 0 - 255 88

Guide OSD H Pos 00 - 255

Guide OSD V Pos 00 - 255

Guide PIP H Pos 00 - 255

Guide PIP V Pos 00 - 255

Vertical and Horizontal Centering

Vertical and Horizontal centering adjustments should only

be performed after replacing the Light Engine.

Accessing Internal Test Patterns

1. Turn on the TV and select the channel that will be used

for testing.

2. Select the Service Screen Menu.

3. Select “2 Service Alignment” item.

4. Once the Service Alignment screen is displayed use the

“VOLu” on the keyboard or remote to adjust parameter

zero (P:0) to a value of eighty (V:80).

5. With parameter zero (P:0) value at eighty (V:80) press

the “CHp” button on the front keyboard or remote

control. This puts the instrument into the vertical and

horizontal centering mode as shown below. This allows

the technician to select one of several internally generated test patterns. (see Pattern Table) These may be used

for alignment or troubleshooting. The Remote Control can

be used to navigate this menu. Use the chart below as a

guide.

Fig. 9 Vertical and Horizontal Centering Screen

PATTERN

Transparent (None)

White Screen

Black Screens

BW Checker Board

Red Screen

Green Screen

Blue Screen

Vertical Lines

Horizontal Lines

Border Lines

Border Crosshatch

Fig. 10 Pattern Table

OSD Background

This sets the the background color of the Service Menu. V:0

= Black, V:1 = Transparent. V:0 is the the default setting.

NTSC Video Align

Is used to adjust the IF_PLL Demodulator IC. The instrument is set to Air Tuner and tuned to a strong NTSC signal.

Increment the alignment until some interference bars or patterns are noticible in the video. Then back the adjustment

down three (3) numbers.

Cable Tuner Analog RFAGC

AGC alignment for the standard tuner. The instrument is set

to Air Tuner and tuned to a strong NTSC signal.

Tuner Digital RFAGC 256QAM

Adjust the digital FRAGC control. The instrument is tuned

to an RF channel broadcasting in QAM256. This asdjustment

is prealigned and should not require no further adjustment or

alignment.

Tuner Digital RFAGC 8VSB

Adjust the digital FRAGC control. The instrument is tuned

to an RF channel broadcasting in 8VSB (Cable or Off-Air

ATSC). This asdjustment is prealigned and should not require no further adjustment or alignment.

to an RF channel broadcasting in 64QAM. This asdjustment

is prealigned and should not require no further adjustment or

alignment.

Guide OSD H Pos

Is used to set the horizontal position of the Guide display.

Adjust so that the guide display is the same on both the left

and right sides of the screen

Guide OSD V Pos

Is used to set the vertical position of the Guide display. Adjust so that the guide display is the same on both the top and

bottom of the screen

Guide PIP H Pos

Is used to set the horizontal position of the Guide PIP display.

Adjust so that the guide display PIP is the same on both the

left and right sides of the PIP window

Guide PIP V Pos

Is used to set the vertical position of the Guide PIP display.

Adjust so that the guide display PIP is the same on both the

top and bottom of the PIP window

Key Fuction

Power Off/Toggle Exit Alignment, return to P:0 V:80 display

Input

Skip &/or Info

Cycles through the available adjustments

Next Test Pattern

Reset or Go Back Display 1st Test Pattern

Menu

Arrow Up/Down

Toggle Current Test Pattern

When in Horizontal/Vertical Adjust: Adjust Vertical Position

Arrow Right/Left When in Horizontal/Vertical Adjust: Adjust Horizontal Position

When in Color Wheel Index or Color Temp or Actuator Adjust: Adjusts

Volume Up/Down

the parameter value up and down

When in Color Temp Adjust: Cycles through Cool CIE x, Cool CIE y,

Channel Up/Down

Antenna

Normal CIE x, Normal CIE y, Warm CIE x, and Warm CIE y.

When in Color Wheel Index or Color Temp or Actuator Adjust: Resets

the value to the factory setup values.

Mute

When in Color Wheel Index: Verification that the user does want to

Swap

overwrite the factory aligned values.

When in the Actuator Adjustment: Swaps between the fine and coarse

modes.

Tuner Digital RFAGC 646QAM

Adjust the digital FRAGC control. The instrument is tuned

Fig. 8 Remote COntrol Function Chart

Page 3-7Page 3-7

Page 41

ATC336

ALIGNMENT PROCEDURES

ATC336

ALIGNMENT PROCEDURES

Electrical Vertical and Horizontal Centering

1. Turn on the TV and select the channel that will be used

for testing.

2. Select the Service Screen Menu.

3. Select “2 Service Alignment” item.

4. Use the “VOLu” on the keyboard or remote to adjust

parameter zero (P:0) to a value of eighty (V:80).

5. With parameter zero value at eighty (V:80) press the

“CHp” button on the front keyboard or remote control

to put the instrument into the vertical and horizontal centering mode.

6. Use the “Skip” or “Info” button on a remote control to

bring up the first test pattern, border crosshatch pattern.

7. Use the “CHq” and “CHp” on the front panel or Up

and Down arrows on a remote control to adjust the vertical positioning of the upper and lower horizontal lines.

Adjust the lines so that they are equal distance from the

edge of the protective shield frame.

8. Use the “VOLt” and “VOLu” on the front panel or

Right and Left arrows on a remote control to adjust the

horizontal positioning of the left and right vertical lines.

Adjust the lines so that they are equal distance from the

edge of the protective shield frame.

9. Press the “Menu” button on the front panel or remote control to toggle the display from the crosshatch to channel

video. Insure proper looking video display.

10.Pressing the “Power” or “On/Off” button on the keyboard

or remote control will cause the instrument to exit the

adjustment mode and return to the (P:0) (V:80) display.

Pressing the “Power” or “On/Off” button on the keyboard

or remote control a second time will cause the instrument

to exit the Service Menu.

Color Temperature

6. Use the Input button on the remote and toggle to COOL

CIE. The Channel +/- will toggle toggle through the six

(6) different adjustments (Cool CIE x/y, Norm CIE x/y

and Warm CIE x/y).

7. Use a Colorimeter specifically designed for DLP applications. Adjust for the following according to the table below.

Cool D14000

Normal D9300

Warm D6500

Note: The Light Engine is prealigned and should NOT re-

quire field adjustment.

Focus

1. If replacing the Light Engine, make sure it is positioned

accordingly for the screen size.

2. Remove the screen assembly and dust cover (See Instrument Disassembly).

3. Remove Focus Lock Ring over Projection Lens.

4. Place the Screen Assembly back on the instrument.

5. Adjust by rotating lens for best possible focus using a

crosshatch pattern adjust until best focus balance is

achieved in the three (3) areas of the screen defined below.

Factory Defaults

This menu starts a software routine that places the instrument

in an “Out Of Box” condition. This reset is identical to the

“Factory Default” menu in the standard service menu.

Fig. 12 Factory Reset Selection

Diagnostic Info

This menu provides software diagnostic information.

LIGHT ENGINE

Actuator Replacement

1. Unplug Actuator cable (BT425).

2. Release clip securing Actuator to the Light Engine.

3. Remove and replace Actuator.

4. Align Actuator (Service Menu V: 80) for best resolution

at the center of the screen.

Lamp Cartridge

Lamp

Lamp Enclosure

Lamp Fan

Illumination Optics

Color Wheel

Projection Lens Cap

Smooth Picture Actuator

DMD Imager

DMD Driver Board

Projection Lens

Fig. 14 Series 2 Light Engine

Color Wheel Replacement

1. Disconnect cables to Color Wheel Assembly (BT401 and

BT451). Remove screws over Color Wheel Housing.

2. Lift Color Wheel Assembly from the Light Engine. Replace housing.

3. Align Color Wheel Index (Service Menu V: 80).

1. Turn on the TV and select the channel that will be used

for testing.

2. Select the Service Screen Menu.

3. Select “2 Service Alignment” item.

4. Use the “VOLu” on the keyboard or remote to adjust

parameter zero (P:0) to a value of eighty (V:80).

5. With parameter zero value at eighty (V:80) press the

“CHp” button on the front keyboard or remote control

to put the instrument into the service mode mode. The

following menu will appear.

INPUT: Change Modes. SKIP: Next Image. MENU: Toggle Image

6. Verify focus across entire screen.

7. Replace Focus Lock Ring.

8. Remove Screen Assembly and reinstall Dust Cover. Reinstall Screen Assembly.

4. Display a full Green Video pattern.

Fig. 13 Diagnostic Selection

5. Adjust the Color Wheel to obtain maximum Green minus Red minus Blue. (Adjust until screen begins to turn

.

Red, then adjust the opposite direction until a Blue Screen

begins to show. Set for a Green Screen at the center of

the two settings.)

Page 3-10Page 3-9

Page 42

ATC336

ALIGNMENT PROCEDURES

ATC336

ALIGNMENT PROCEDURES

Projection Lens Replacemen

1. Remove cap over Projection Lens.

2. Remove lens by rotating it counterclock wise.

3. Replace lens and refocus.

4. Replace Focus Lock Ring.

Mechanical DMD Centering and Rotation

Alignment

Picture centering and rotation are controlled by mechani

cally aligning the position of the DMD module onto the

Light Engine. Prior to alignment, the engine must first be

fully installed into the instrument. Use the following

procedure for centering and rotation alignments. For DMD

Module screw locations see the graphic on the next page.

1. To define the true center of the screen, mark the

projection screen with crosshairs in the center with

0 degrees rotation.

2. Apply a border pattern with cross hair or an appropriate

test pattern.

3. Loosen the three (3) T10 Torx Head DMD Module

mounting screws.

4. Grip the two (2) tabs and adjust the X-Y centering and

rotation of the DMD Mount.

5. Tighten the DMD Module screws when the alignment is

complete.

NOTE: DO NOT loosen the two (2) custom DMD mount-

ing screws.

DO NOT LOOSEN the Two (2) custom DMD

Mounting Screws

Loosen the Three (3) Module

Mounting Screws

Grip the DMD Module at these Two (2)

Locations and Rotate

Light Engine

Page 3-11

Page 3-12

Page 43

ATC336

VOLTAGE CHARTS

ACIN BOARD - STANDBY MODE

152PB

hctiwS(

)desolC

#NIP

CD

STLOV

152PB

hctiwS(

)nepO

#NIP

CD

STLOV

252PB

)sniPssorcA(

#NIP

CD

STLOV

306PB 406PB 107PB 101PI 106PI 206PI 506PI 606PI 806PI

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

19.11 10.0 10.913 10.0 10.0 10.0 10.0 17.61 16.51 10.0 16.5 17.81

29.11

29.11 20.913 29.11 22.61 20.0 20.5- 26.51 20.0 22.12- 29.4 29.11

30.0 30.0 30.0 30.5- 325.0 30.0 36.8- 30.0 30.0

41.5- 49.51- 40.0 40.0 49.01 40.0

50.0 50.0 50.0 50.0

69.4 60.0 60.5- 60.0

70.0 70.0 70.5- 70.0

82.43 80.0 85.2- 85.2

96.5 90.0

010.0 010.0

110.0

CD

STLOV

216.5

310.0

415.4

107PI 101PT 151PT 606PT 906PT 207PT

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

17.81 E7.2- E0.0 E0.0 E2.43 E0.0

20.0

38.71

40.0

B7.3- B0.0 B10.0 B8.43 B0.0

C1.1- C0.0 C8.11 C4.53 C3.71

201PT 106PT 706PT 016PT

50.0 G7.2- G6.1 E0.0 E9.11

67.81 D1.2- D0.751 B0.0 B9.11

73.71 S6.2- S30.0 C3.6 C0.0

87.81 301PT 206PT 806PT 107PT

CD

STLOV

E0.0 E0.0 E0.0 E7.81

B6.2- B25.0 B96.0 B7.81

C5.4 C6.1 C20.0 C0.0

Page 5-1

Page 5-1

Page 44

ATC336

ACIN BOARD - RUN MODE

152PB

hctiwS(

)desolC

#NIP

CD

STLOV

252PB

)sniPssorcA(

#NIP

CD

STLOV

306PB 406PB 107PB 101PI 106PI 206PI 506PI 606PI 806PI

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

19.11 10.503 10.0 10.0 12.3 10.0 11.31 11.21 10.0 16.5 18.41

29.11

20.503 29.11 21.51 28.11 20.5- 21.21 20.0 22.12- 29.4 29.11

30.0 30.0 30.0 30.5- 324.0 30.0 36.8- 30.0 30.0

45.8- 47.41- 43.3 40.0 43.21 40.0

50.0 50.0 50.0 50.0

69.4 63.3 60.5- 60.0

70.0 70.0 70.5- 70.0

82.33 83.3 85.2- 85.2

96.5 90.0

010.0 013.3

110.0

CD

STLOV

216.5

319.2

415.4

107PI 101PT 151PT 606PT 906PT 207PT

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

11.21 E7.2- E0.0 E0.0 E2.33 E0.0

20.0

326.0

40.0

B7.3- B0.0 B10.0 B8.33 B0.0

C1.1- C6.41 C5.2 C1.43 C6.41

201PT 106PT 706PT 016PT

52.1 G7.2- G8.2 E0.0 E9.11

67.41 D1.2- D0.502 B46.0 B1.11

76.41 S6.2- S60.0 C10.0 C8.11

81.21 301PT 206PT 806PT 107PT

CD

STLOV

E0.0 E0.0 E0.0 E7.41

B6.2- B24.0 B96.0 B5.41

C5.4 C8.2 C60.0 C6.3

Page 5-2

Page 5-2

Page 45

ATC336

DM3X MODULE

#NIP

CD

10.0 15.4 17.41- 11.3 14.4

20.0

209/109AB 301PB 991PB 105VB 106VB

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

29.2 20.0 22.3 20.0

36.5 31.51 32.3 30.0

40.0 40.0 42.3 40.0

50.0 51.3 50.0

66.5 62.3 60.0

72.33 78.4 70.0

80.0 839.0 80.0

99.4 99.4 90.0

010.0 015.4 010.0

115.8- 110.0

210.0 210.0

LIGHT ENGINE DRIVER BOARD

#NIP

CD

STLOV

102PB 524MB 152TB 104TB

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

12.3 130.5 19.4 18.1

28.11

30.0

289.4 28.1 28.1

330.5 35.4

43.3 40.0 40.0

50.0 511.0 51.0

63.3

70.0

83.3

90.0

013.3

FAV/FPA BOARDS

#NIP

CD

STLOV

14.4 80.0 11.3 839.0

20.0

30.0

40.0

50.0 210.0 51.3

60.0 62.3

319.11

410.0

401JB 1CW

#NIP

CD

STLOV

#NIP

CD

STLOV

90.0 22.3 99.4

010.0 32.3 010.0

110.0 42.3

104TB 154TB 105TB 205TB

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

#NIP

CD

STLOV

17.8 11.1 178.9 18.9

27.8

#NIP

CD

STLOV

37.8

274.0 220.0 220.0

30.0 30.0 30.0

47.8

70.0 78.4

Page 5-3

Page 5-3

Page 46

ATC336

WAVEFORMS

TP601 -D Standby Mode TP601 - D Run Mode TP601 - G Standby Mode TP601 - G Run Mode

LP601 Pin 7 Standby Mode LP601 Pin 7 Run Mode LP601 Pin 9 Standby Mode LP601 Pin 9 Run Mode

LP601 Pin 14 Standby Mode

Lp601 Pin 14 Run Mode IP701 Pin 1 Standby Mode IP701 Pin 1 Standby Mode

Page 5-1Page 5 - 1

Page 47

ATC336

WAVEFORMS

IP701 Pin 3 Standby Mode IP701 Pin 3 Run Mode BM425 Pin 1

BT251 Pin 1 BT251 Pin 2 BT251 Pin 5

BM425 Pin 2

BT252 Pin 2

BT401 Pin 1 BT401 Pin 2 BT401 Pin 3

BT401 Pin 4

Page 5-2Page 5 - 2

Page 48

ATC336

WAVEFORMS

BT451 Pin 2

Page 5-3Page 5 - 3

Page 49

ATC336 Wiring Diagram

BP603 SIGNAL BP103

1 +12VS_RTN 14

2 +12VS 13

3 -5VS_RTN 12

4 -5VS 11

5 +5VS_RTN 10

6 +5VS 9

7 +33VS_RTN 8

8 +33VS 7

9 +6VIN 6

10 PWR_RTN 5

11 +12VSB 4

12 +6VIN 3

13 RUN_EN 2

14 POWER_FAIL 1

BV601 SIGNAL BJ104

1 FAV_SPKR_MUTE 1

2 FAV_HEAD_R 2

3 FAV_HEAD_L 3

4 FAV_AUD_COM 4

5 FAV_AUD_IN_L 5

6 FAV_AUD_IN_R 6

7 FAV_CV_RET 7

8 FAV_CV 8

9 FAV_Y_RET 9

10 FAV_Y 10

11 FAV_C_RET 11

12 FAV_C 12

BV501 SIGNAL BK401

1 TOP LIGHT CTRL 1

2 KS4 2

3 KS3 3

4 KS2 4

5 KD1 5

6 KS1 6

7 IR OUT 7

8 PWR LED CTRL 8

9 +5V 9

10 GND 10

BP251 SIGNAL BP001

1 +12VS RTN 1

2 +12VS 2

BA901 SIGNAL SPKR

1 SPKR LEFT - 1

2 SPKR LEFT + 2

BA902 SIGNAL SPKR

1 SPKR RIGHT - 1

2 SPKR RIGHT + 2

BP604 SIGNAL BP199

1 NC 4

2 + AUD_VDD 3

3 GND 2

4 - AUD_VSS 1

Lamp

Ballast

BP252 SIGNAL

1

2 HOT GND 2

LAMP BALLAST B+

X1

RAW B+

LAMP HV

Lamp

X3X2

BT401

LAMP CONTROL

Light Engine

BT251

CW

INDEX

X1

1

DRIVER B+

BT451

BP201

BP701 SIGNAL P1

1 POWER_GOOD 1

2 +12VR 2

3 GND 3

4 3.3V_SENSE 4

5 GND 5

6 +3.3VDLP 6

7 GND 7

8 +3.3VDLP 8

9 GND 9

10 +3.3VDLP

BT501

Color

Wheel

Driver

TCO

BT252

10

DMD

Fan

BM425

Actuator

Lamp

Fan

BT502

LVDS SIGNAL/CLOCK

BT201

BM901

BP701

AUDIO B+

DM3X

BV601

BJ104

FAV

ACIN

BP604

BP199

BP252

AC In

DM3X B+

BP202

BP251

BP603

BP103

BA902

BA901

BA901

BV501

WC1

KDB

Left

Speaker

BP001

Subwoofer

Door

Switch

Right

Speaker

Loading...

Loading...