Page 1

VERTICAL

TO

E8

RED BIAS

<21-B>

TO

E7

GRN BIAS

E5003

E5007

TP50

RED OUTPUT

TP24

194V

TECHNICAL TRAINING

1

0

1

0

1

0

1

0

1

0

1

1

0

1

0

1

0

1

0

1

1

0

1

0

0

1

0

1

0

0

1

1

0

0

1

1

0

0

1

0

1

1

0

0

0

1

0

1

0

1

0

1

0

0

1

1

0

0

1

0

1

0

10

1

1

0

ATC010

Technical Training Manual

0

1

1

Page 2

Page 3

FOREWORD

This manual provides the service technician circuit information and troubleshooting

steps to be used while repairing the ATC010 chassis. It is intended as a training tool

and is to be used in conjunction with the ESI service information. As wi th other

training manuals, circuit description is represented with partial schematics and not

all components in a circuit are listed.

SAFETY INFORMATION CAUTION

Safety information is contained in the appropriate Service Data. All product safety

requirements must be complied with prior to returning the instrument to the

consumer. Servicers who defeat safety features or fail to perform safety checks may

be liable for any resulting damages and may expose themselves and others to

possible injury.

All integrated circuits, all surface mounted devices, and

many other semiconductors are electrostatically sensitive

and therefore require special handling techniques.

First Edition - First Printing

Copyright 2005 TTE Technology, Inc.

Trademark(s)

RCA and associated marks are trademarks of

THOMSON S.A. used under license to TTE

CORPORATION.

Printe d in U.S. A.

®

Registered Marca(s) Registrada(s)

Prepared by

Thomson, Inc for TTE Technology, Inc.

Technical Training Department, INH905

PO Box 1976

Indianapolis, Indiana 46206 U.S.A.

Page 4

Contents

FOREWORD ............................................................. 3

SAFETY INFO RMATION CAUTION ......................... 3

Overview .................................................................. 5

Standby Power Supply............................................ 6

Run Power Supply................................................. 10

System Control (All-IN-ONE Processor).............. 13

Horizontal Deflection............................................. 15

V ertical Deflection ................................................. 17

Shutdown............................................................... 18

ADM1 Module (ATSC Tuner) ................................. 20

Standby Power Supply Troubleshooting ............. 22

Run Power Supply Troubleshooting.................... 23

System Control Troubleshooting.........................25

ADM1 T roubleshooting ......................................... 26

Shutdown Troubleshooting.................................. 27

Page 5

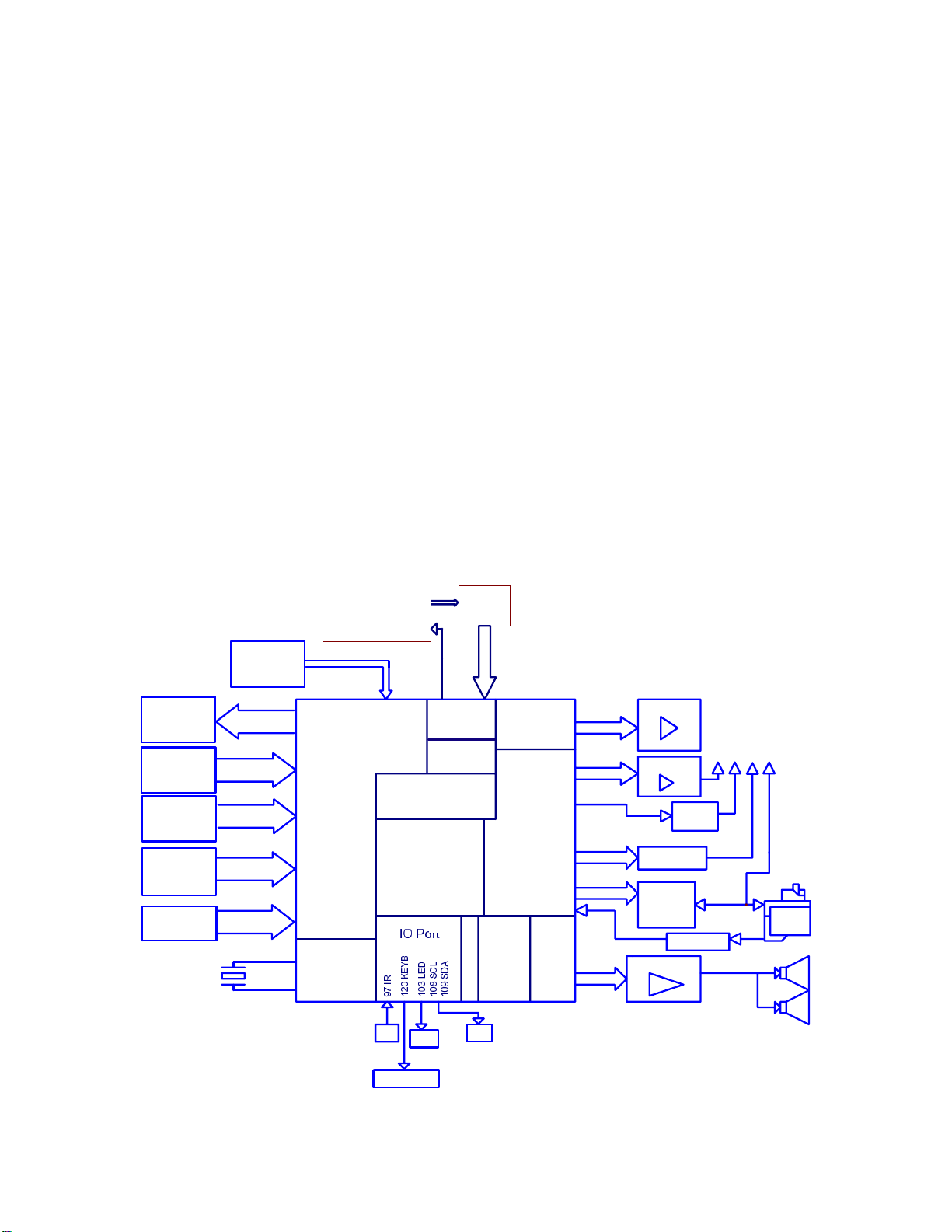

Overview

The ATC010 Training Manual covers the key circuits found i n the new ATC010

chassis. These circuits include:

· Standby Power Supply

· Run Power Supply

· System Control (ALL-IN-ONE P rocessor)

· Horizontal Deflection

· Vertical Deflection

· Shutdown Circuits

· ADM1 Module

This new chassis combines previous NTSC technology with new High Definiti on

technology. This combination allows HD programming to be received and displayed

on a standard NTSC (4:3) set. It also combines all processing and switching into a

single IC package the ALL-IN-ONE Processor.

The ALL-IN-ONE Processor is just that a single IC that handles all video switching,

audio switching, deflection processi ng, video processing, audio processing, a nd

system control functions. The only processing not performed by this IC is the ATSC

signal tuning and decoding.

P900 REAR

AV OUTPUT

P902

REAR AV IN

P901/P903

REAR AV IN

S-SHS IN

P960/P905

SIDE AV IN

SIDE SVHS IN

P904 REAR

Y Pb Pr IN

24.576MHZ

P203

from

ADM1

Y Pr Pb

36 A-OUTSL

37 A-OUTSR

48 SVO

53 AUDIO INL

54 AUDIO INR

55 CVBS2/Y2

49 AUDIO INL

50 AUDIO INR

51 CVBS4/Y4

52 C4

56 AUDIO INL

57 AUDIO INR

58 CVBS3/Y3

59 C2/C3

78 R/PrIN3

79 G/YIN3

80 B/PbIN3

PLL

10 XTAL IN

11 XTAL OUT

TUNER

NTSC

70 R/Pr

72 G/Y

71 B/Pb

AV Port

AGC

31

AGC OUT

VIF & SIF

Decoder

YUV Processor

Micro

CC V-Chip

IO Port

IR

LED

VIF / SIF

Color

P

O

W

E

R

SAW

NVM

Jungle

DSP

Stereo

IC200

RGB

RGB OUT

85,86,87

ROTATION

113

SVM 65

VDRA 23

VDRB 22

E-W 21

HD 67

FeedBack 16

AUDIO

PRE

OUT

RGB

PWM

RGB Amp

Rot Amp

VM

V-out

Pin out

H-drive

HOT

Feedback

AUDIO AMP

to YOKE

FBT

L

R

Key buttons

ATC010 System Block

Page 5

Page 6

ATSC decoding and receiving is performed on the ADM1 modul e. This module

receives and processes high definition signals and converts them to a format used

by the chassis.

Troubleshooting procedures covering key ci rcuits is also provided in this manual.

These key circuits include:

· Standby Power Supply

· Run Power Supply

· System Control

·ADM1

Each troubleshooting procedure is a step by step circuit verification process.

Knowledge of the circuit is critical to following these procedures. It is recommended

the servicing technician become familiar with the circuits before using the procedures

to troubleshoot the ATC010 chassis.

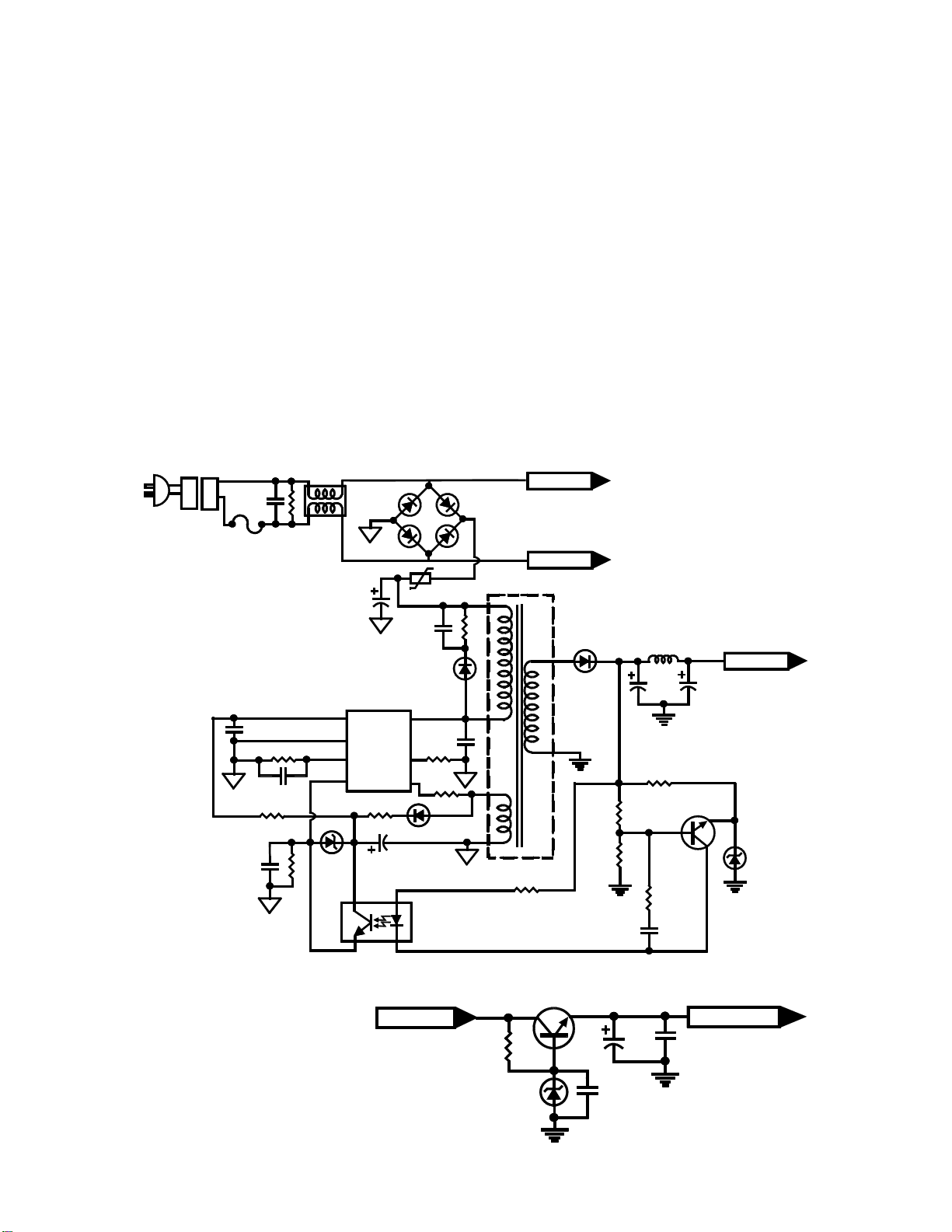

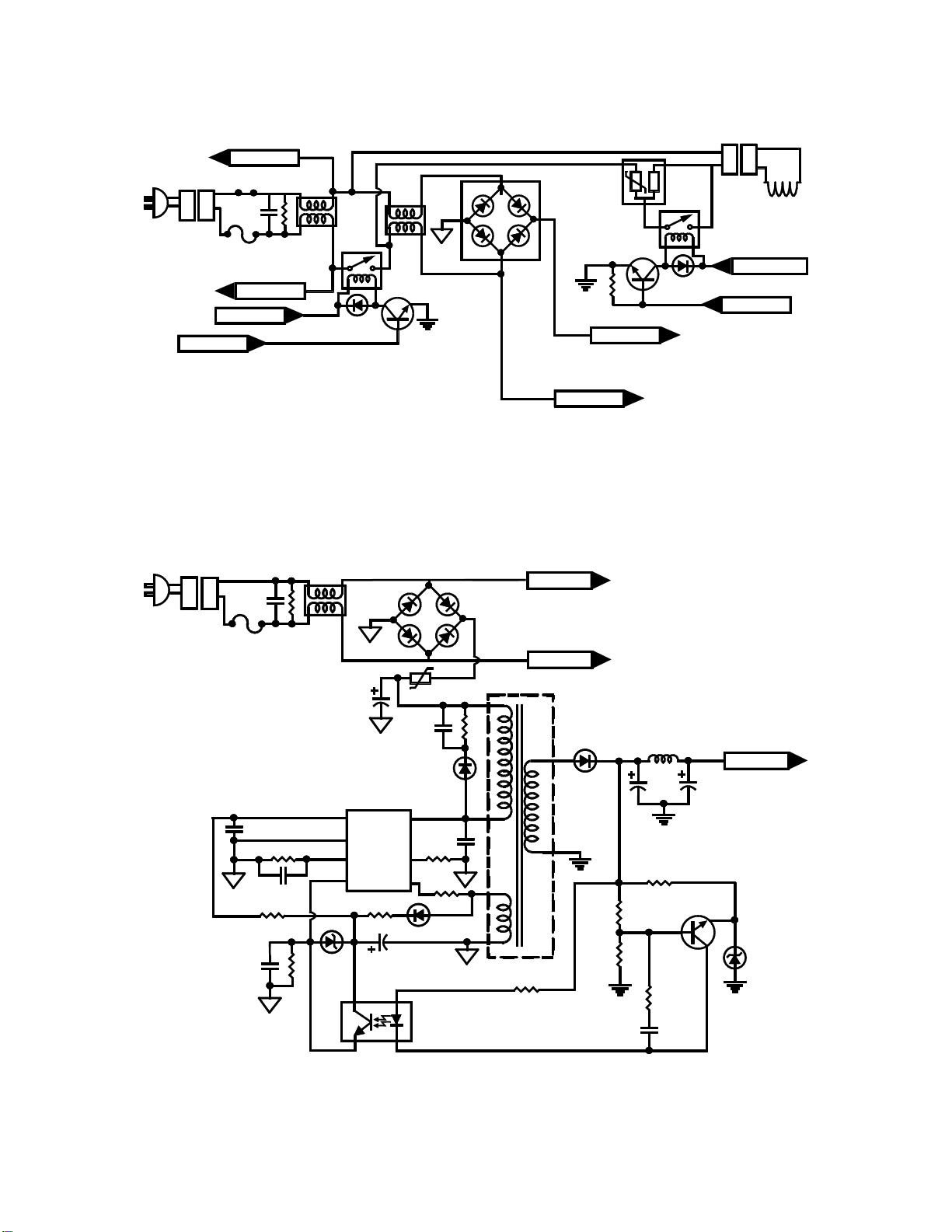

Standby Power Supply

The standby power supply in the ATC010 is operational when ever AC power is

applied to the chassis. The supply operates with an AC voltage level between 108V

to 132V. It is a switch m ode power supply that generates the +5V STB voltage from

the 120VAC input. This voltage is further regulated to a +3.3VSTBY that is used by

System Control and other circuits that require standby voltage.

The heart of the standby suppl y is IC860 switch mode controller IC. IC860 uses

voltage mode control and Pulse Width Modulation (PWM) to drive the power

transformer T860. Voltage mode control is at start up when the vol tage on pin 1

passes the start level of IC860. The PWM frequency is determined by the time it

takes for the transformer to demagnetize and an external RC network on pin 3.

Start-up

Startup of the supply occurs when AC is applied to bri dge rectifier di odes D861,

D862, D863, and D864. The AC is converted to Raw B+ (approximately +150VDC

DC) by the bridge rectifier and C860 filter. Raw B+ is the source voltage for switching

transformer T860 supplied by current limiting resistor RT860.

The switching transformer (T860) allows connection of the Raw B+ to the switch

mode controller IC through its primary winding between pin 5 and 3. Pin 3 of T860

is connected to pin 8 of IC860. IC860-8 is the Drain supply and startup for the IC.

As the Raw B+ increases on pin 8 of IC860, the IC starts to conduct through pin 6

and the current source resistor R862. As the vol tage at pin 6 of IC860 increases,

over-current is detected shutting down the IC. This releases the stored energy in the

primary of T860 to the secondary windings.

Page 6

Page 7

The induced voltage between secondary winding pins 1 and 2 of T860 is rectified by

D865 and filtered by C864. This voltage is used as VCC for IC860-1 and IC804-4

feedback regulation circuit. IC860 starts switching when the voltage on pin 1 passes

the VCC start level. Once this voltage is high enough to operate the IC, voltage from

pin 8 (Raw B+) is no longer used to power the IC.

IC860 operates in discontinuous conduction mode. This means that as long as there

is a pulse on the secondary of T860, the oscillat or (IC860) will not start a new p rimary

pulse. Pin 5 of IC860 m onitors the current in T860 and suppresses start of the next

cycle while there a re s t ill s e c ondary pulses from T860.

Regulation

There are two regulation circuits in the ACT010 standby power supply. D866 and

the winding from T860 pins 1 and 2 make up the secondary or fail safe regulation and

IC804 provides secondary monitoring regulation as the primary regulation. Both are

sent to IC860 pin 4 (REG input).

P802

P801

F800

C893

R849

C862

R864

C801

R801

R863

C863

T801

C861

D866

18V

IC860

1

2

3

4

4

3

R865

C864

C860

R860

D860

8

C890

7

R862

6

5

D865

1

IC804

2

RT860

R861

D861

D862

D863

D864

T860

5

3

2

1

AC-RUN

AC-RUN

R890

D868

6

L861

+5VSTB

C866

C868

10

R869

R868

R867

Q860

D869

3.3V

R891

C895

+5VSTB

R081

D080

3.9V

Q080

C083

+3.3VSTB

C082

C081

Page 7

Page 8

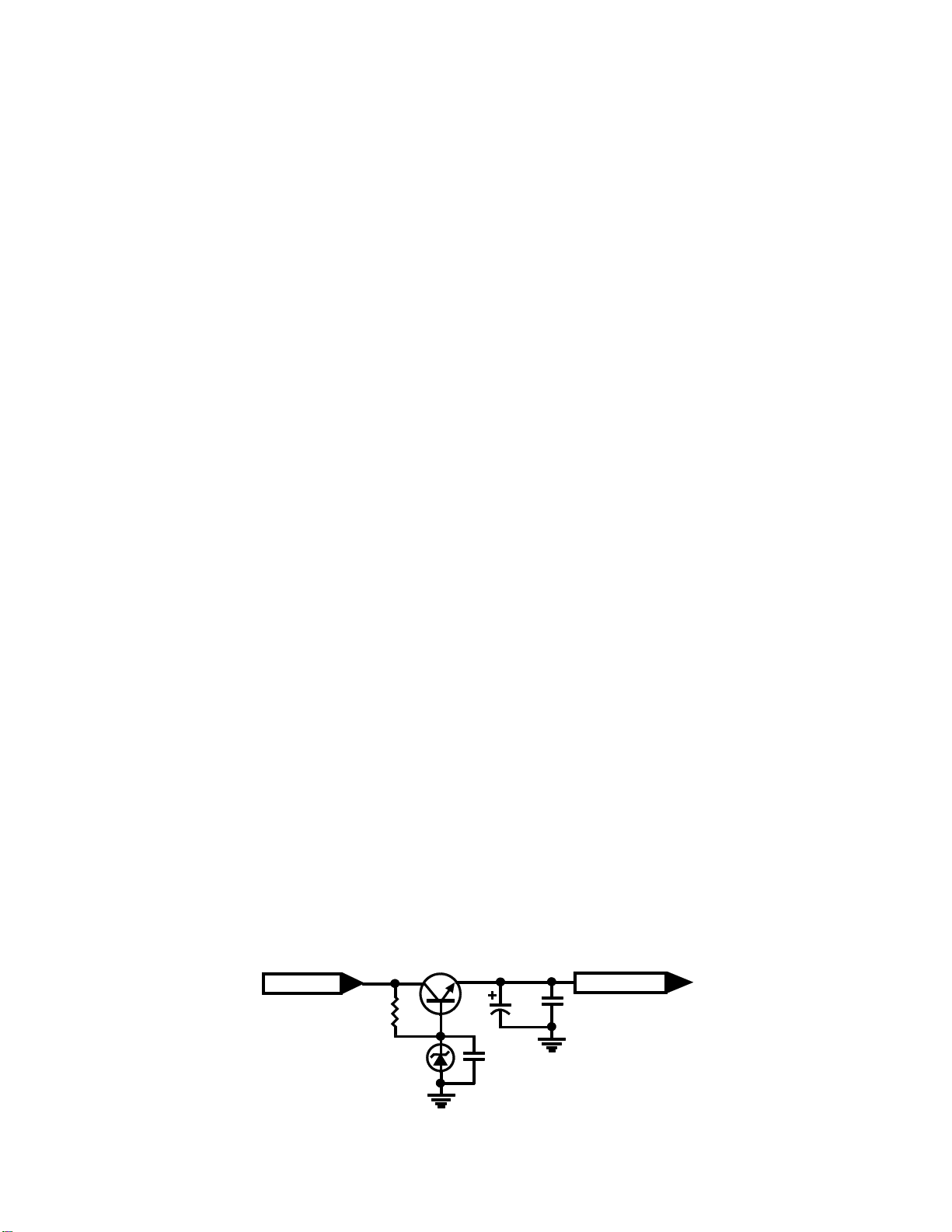

The primary regulation is feed back from the secondary +5VSTB source through

opto-coupler IC804. As the +5VSTB increases, current through IC804 (LE D side)

pin 1 and 2 increases. This increase is detected by the photo transistor on pins 3 and

4 causing IC804 pins 3 and 4 to conduct more. This increase in current is sent to pin

4 of IC860 causing i t to limit on time. The output voltage, in this case +5V, is

determined by Q860, D869, and voltage divider circuit R868 and R867.

Over Voltage Pr otection

The over voltage protection level is determined by D866. If the primary feed back

fails to control regulation D866 will prevent the po we r supply from reaching unsafe

levels. As the voltage increases in the secondary the voltage on the cathode of D866

also increases. Once this voltage reached the break over point of D866 (18V) D866

conducts and pin 4 of IC860 voltage increases shutting down IC860.

Over Current Protection

The current source resistor R861 determines the amount of current the power supply

can generate. As the current increases in R861, the voltage at pin 5 of IC860 starts

to increase. Once this voltage reaches the internal threshold of the IC, IC860 goes

into over current protection.

Other protections for IC860 incl ude Over Temperature and Short Circuit Winding

Protection. These protection circuits are internal of IC860 and can not be measured.

However; they both have unique circumstance that a servicer can use to determine

which shutdown it is. First is thermo shutdown, as the name implies, thermo

shutd o wn is temperatu r e r e la t ed . I f I C 8 60 g e ts t o o h ot , it will shutdo wn. With this

type of shutdown the power supply will run until the shutdown temperature is m et and

then the power supply will shutdown. Cooling down the IC will resume normal

operation of the power supply. Second, the Short Circuit Winding requires a power

on res et to c lea r. On ce activ at ed , t he s ho rt cir cu it w in din g shu td ow n will not allow

the power supply to operate until the short is removed. This results in a com pletely

dead power supply (no pulsing or oscillations).

The only supply voltage generated by the standby supply is +5VSTB. This voltage

is used to run all standby circuits and is further regulated to +3.3V that is used by

system control functions. Relay K802, run supply switch, also uses the +5VSTB

Q080

+5VSTB

R081

D080

3.9V

C083

+3.3VSTB

C082

C081

Page 8

Page 9

P801

P802

AC-STBY

F800

T801

T802

D801

RT801

X800

P803

K801

P801

+5VSTB

ON/OFF

IC200

Pin99

SysCon

P802

R849

C862

R864

C801

R801

AC-STBY

F800

C801

R801

C893

R863

C863

T801

C861

D866

18V

K802

D867

IC860

1

2

3

4

4

3

Q861

R865

C864

C860

R860

D860

8

C890

7

R862

6

5

D865

1

IC804

2

RT860

R861

D861

D862

D863

D864

T860

5

3

2

1

AC-RUN

AC-RUN

R890

Run Supply

Start-UP

to R810

Run Supply

D868

6

10

R868

R867

Q880

Raw B+

to RT802

L861

R869

+12V RUN

D880

RELAY

IC200

Pin 112

SysCon

+5VSTB

C866

C868

Q860

D869

3.3V

R891

C895

Page 9

Page 10

P802

P801

ON/OFF

IC200

Pin99

AC-STBY

F800

C801

R801

AC-STBY

+5VSTB

4

1

8

C

C811

T801

IC801

4

VCC

Logic

Control

6

R815

SSFB

5

7

D813

K802

D867

OCP

1

D

S

3

T802

Q861

D812

R816

.12

2W

C815

D810

R814

R818

C812

IC802

R810

C806

D811

C813

R812

3

4

D801

R813

RT802

T803

1

9

4

7

R830

1

2

R831

RT801

18

17

10

12

16

14

15

C809

Q880

R820

L808

R822

R823

D824

D820

D822

C841

D823

D821

IC803

K801

D880

+13V

C821

L801

R835

X800

P803

+12V RUN

RELAY

R826

+12V

C838

+12V

C837

R839

R841

IC200

Pin 112

+33V

+130V

C828, C823

to

P807

Run Power Supply

The ATC010 run power supply is a switch m ode power supply generating the +13V

source, the +33V source, Regulated B+ (+130V), and two +12V sources. It is turned

on / off by a relay switching the AC in. The heart of this switch mode pow er supply

is IC801 switch mode controller IC. IC801 is a self starting internal logic controlled

switching device that drives the transformer T803.

The run supply utilizes two shutdown circuits and feedback regulation circuit for

voltage and current control. Both shutdowns, Over-Voltage and Over Current are

monitored internal of IC801 with feedback coming from monitoring the +130V source

and the +12V source.

Start-up

Once the power on relay is energized and pin 4 of IC801 reaches the start voltage

of approximately 10.3VDC, IC801 starts to conduct through pins 1 (Drain) and 3

(Source). Raw B+ from D801 is supplied through the sw itch mode transform er T803

pins 1 and 9 to IC801 pin 1. As current increases in the source resistor R816, IC801

detects this increase at pin 5 (slow start) and starts the first cycle. The VCC from

D801 through R810 is not sufficient to operate IC801. Re-supply for VCC comes

Page 10

Page 11

Start-UP

from

D801

4

1

8

C

R810

C811

Raw B+

from D801

IC801

4

VCC

Logic

Control

OCPSSFB

6

5

7

R815

D813

1

D

S

3

R816

.12

2W

RT802

D810

C815

R814

R818

C812

C806

D811

C813

R812

IC802

3

4

R813

T803

1

9

4

7

1

2

R831

R830

C809

18

17

10

12

16

14

15

R820

L808

R822

R823

D824

D820

D822

C841

D823

D821

IC803

+13V

C821

L801

R835

+12V

C838

+12V

C837

R839

R841

+33V

R826

+130V

C828, C823

to

P807

from D810 and the secondary w inding of T803 pins 4 and 7. C814 is the filter for resupply. This re-supply voltage is also bias for the feedback opto-coupler IC802.

Feedback Regulation

There are two key components (IC802 and IC803) used for feedback regulation.

IC802 and IC803 work together to monitor the +130V source for any changes. As

the +130V increases or decrease so does the current through IC803. IC803 allows

more or less current through IC802 to occur. IC802 in turn controls the amount of

feedback being sent to IC801. IC801 uses this feedback information to control the

switching frequency.

Feedback Regulation starts with a reference voltage from the +130V source being

divided down by R835, R841, and R839. The voltage from the divider goes to IC 803

for reference. This reference voltage is 2.5V and follows the +130V as i t varies.

Increases in the reference voltage cause IC803 to conduct harder with a decrease

in reference voltage causing IC803 to conduct less.

IC803 is connected between pin 2 of IC802 (LED side) and ground. Bias for pin 1

of IC802 comes from the +12V source through R830 and R831. The voltage on pin

2 drops as the current increases in IC803 turning on the LED in IC802. The more

current IC803 draws the brighter the LED in IC802 gets. The emitted light is detected

by the photo transistor across pins 3 and 4 of IC802. The photo transistor reacts to

the amount of light being generated by the LED and conducts more current as the

light increases.

Page 11

Page 12

The photo transistor of IC802 is connected across pin 4 (VCC) and pin 6 (Feed Back)

of IC801. D813 (6.2V zener) prevents voltages lower then 6.2V from falsely tripping

the feed back and shutting down the supply.

Shutdown (Over-Voltage)

Over-voltage is detected at pin 4 (VCC) of IC801. Typically the voltage at pin 4 of

IC801 is around 9.7V during norm al operation. During Over-Voltage shutdown, the

voltage will eithe r be below 8.8V or above 10.6V. As the voltage increases at pin 4,

the internal monitor detects this increase and shuts down the IC when the voltage

exceeds +10.6VDC. Because this voltage comes from T803 pin 4, it is a good

representation of what the power supply is doing. Under voltage is also detected at

pin 4 of IC801 with the minimum requirements for operation being 8.8V. If the voltage

at pin 4 decreases below 8.8VDC, IC801 shutdowns drive.

Shutdo wn ( O ver Curre nt )

The standby supply is protected from over current conditions by shutting down IC801

when excessive current is detected. Pin 7 of IC801 is the OCP or over current protect

pin. Detection is when the voltage on pin 7 drops below zero volts. During normal

operation voltage on this pin is .46Vdc.

Start-UP

from

D801

4

1

8

C

R810

C811

Raw B+

from D801

IC801

4

VCC

Logic

Control

OCPSSFB

6

5

7

R815

D813

1

D

S

3

R816

.12

2W

RT802

D810

C815

R814

R818

C812

C806

D811

C813

R812

IC802

3

4

R813

T803

1

9

4

7

1

2

R831

R830

C809

18

17

10

12

16

14

15

R820

L808

R822

R823

D824

D820

D822

C841

D823

D821

IC803

+13V

C821

L801

R835

+12V

C838

+12V

C837

R839

R841

+33V

R826

+130V

C828, C823

to

P807

Page 12

Page 13

System Control (All-IN-ONE Processor)

The ATC010 system control is contained in an all in one processor (IC200). IC200

is a 128 pin processor capable of A/V switching and processing, Deflection

processing and drive output, Y Pr Pb processing, and CRT drive output (RGB).

IC2001 requires several voltage sources because of the different internal processing

circuits. These voltage sources come from both standby and run supplies. The

following voltages are required by IC200:

· +1.8V

· +3.3V

·+5V

·+8V

Reset for IC200 is in the form of power on reset controlled internal of the IC. When

power is applied to the set and the standby +3.3V is in the range of 2.7V to 3.3V,

IC200 will res e t . Th e re is n o e xternal indic a t io n t h a t re s e t h as o c c u r re d .

The EEPROM (IC001) is for storage of ali gnment data and customer settings is

IC001. Standard IIC bus communication is used to communi cate between IC001

and IC200. Other bus communications on the clock and data lines are between

IC200 and the ADM1 module and the Tuner (NTSC).

+5VSTB

+3.3VSTB

A (1.8V)

+5VSTB

≈

1 2 3 4 5

5 4 3 2 1

R034

Z200

L201

R047

R024

R036

L202

VDA1

VDD

D006

D005

120

5

7

9

93

96

103

97

10

11

4

R033

NTSC

Tuner

IC200

99

R049

+3.3V

to

109

108

126

100

117

118

124

SDA

SCL

98

14

3

SDA

SCL

R094

R214

R211

FPA

R027

R025

R026

R034

R093

TV STB

Q200

Q201

R029

R011

R009

R212

R213

R215

Q202

+5VSTB

IC001

4 3 2 1

5 6 7 8

Q203

+1.8V

1.5V = ON

0V = OFF

R010

SDA

SCL

IRQ

to

ADM1

+5VSTB

R216

A (1.8V)

Page 13

Page 14

A/V Processing and Switching

Another function of IC200 is to switch and process the audio and video signals. All

inputs (A/V) are switched and processed by IC200 before the signals are output from

the IC. Output from IC200 for video is RGB that is sent to the CRT video drivers.

Audio from IC200 is Right and Left signals being sent to the audio output stage.

User Interface

IC200 has two lines for user interface; pin 97 and pin120. These two lines allow the

user to control functions of the set. Pin 97 is the IR input and Pin 120 is the Key board

input. The IR signal is +5V p-p serial information stream detected by the IR sensor.

The key board input is a voltage representation of the key being pressed. A series

of resistors connected to the +3.3V source make up the voltage divider. Each key

switch is connected across a junction in the chain of resistors and ground. When a

key is pressed, the voltage drop at that junction is detected by pin 120 of IC200.

+5VSTB

+3.3VSTB

A (1.8V)

+5VSTB

≈

1 2 3 4 5

5 4 3 2 1

R034

Z200

L201

R047

R024

R036

L202

VDA1

VDD

D006

D005

120

5

7

9

93

96

103

97

10

11

4

R033

NTSC

Tuner

IC200

99

R049

+3.3V

to

109

108

126

100

117

118

124

SDA

SCL

98

14

3

SDA

SCL

R094

R214

R211

FPA

R027

R025

R026

R034

R093

TV STB

Q200

Q201

R029

R011

R009

R212

R213

R215

Q202

+5VSTB

IC001

4 3 2 1

5 6 7 8

Q203

+1.8V

1.5V = ON

0V = OFF

R010

SDA

SCL

IRQ

to

ADM1

+5VSTB

R216

A (1.8V)

Page 14

Page 15

Horizontal D eflection

The ATC010 horizontal ci rcuit consi sts of a pre-dri ver, dri ver, dri ver transformer,

HOT, E-W circuit, and IHVT. Drive for East / West correction and deflection come

from the system control processor (IC200). The purpose of horizontal is to drive the

deflection yoke and the IHVT. The IHVT generates the necessary voltages to bias

the CRT and the Vertical circuit. Other signals from the IHVT are used by the system

control for timing and control. These signals are Automatic Beam Limiter (ABL),

Sandcastle (SANCAS), and X-ray Protect (XRP).

Drive for the horizontal circui t comes from the system control (IC200-67) through

C405. This drive signal is amplified by Q403 pre-amp before being sent to the driver

Q402. Bias for Q403 is through R413 from the +12V initially and then from the +14V

after horizontal is operational. Q402 drives the horizontal driver transformer (T401)

that is directly connected to the horizontal output Q405. Bias for Q405 is through

T402 (IHVT) from the +130V run source.

As Q405 (Horizontal Output Transistor) conducts, current through T402 and the

horizontal yoke windings increases. When Q405 stops conducting, energy stored

in T402 primary is transferred to the secondaries. The secondary voltages are:

· +200V for CRT cathode

· EHT or High Voltage

·Focus

· Screen

· + / – 14V for vertical and horizontal operation

· ABL or Automatic Beam Limiter

+ 12V

+ 14V

H-OUT

E-W

D409

D411

C402

C405

D412

R413

R412

R406

C406

Q403

C407

Q402

+ 130V

R409

R410

T401

L404

+ 200V

Q405

D408

5.6V

C408

R418

R419

R420

Q407

L400

C400

D401

C414

D402

R401

D400

L403

C411

C412

C410

C413

T402

2

9

1

HORIZ -

HORIZ +

8

R424

6

10

7

3

4

SCREEN

R407

R427

R426

to Yoke

Plug P400

EHT

FOCUS

ABL

C420

D413

5.1V

D406

D405

D404

R433

R425

SANCAS

HEATER

XRP

C417

- 14V

C416

+ 14V

C415

Page 15

Page 16

The changing current in the horizontal deflection yoke windings force the beam to

move back and forth across the screen. How far (Width) across the screen the beam

travels is controlled by the E-W circuit connect to the low side of the deflection yoke.

E-W Correction

East West correction starts with drive from IC200 pin 21 going to Q407 gate. Q407

modulates the current flowing it the deflection yoke by changing the waveform

present on the low side of the yoke. Bias for Q407 comes from D402, C411 and C412

through L403 and R420.

Width is controlled by Q407s on time. The longer Q407 rem ains on, the more pulled

in the pic tur e w ill look . Sh ort er o n tim e cre ate s a w id er pict ur e. IC 200 digital data

(adjustable data) allows adjustment of the wi dth and pin correction through the

service menu. These adjustments affect the dri ve signal going to Q407. See the

electronic service data for instructions regarding how to make these adjustments.

+ 12V

+ 14V

H-OUT

E-W

D409

D411

C402

C405

D412

R413

R412

R406

C406

Q403

C407

Q402

+ 130V

R409

R410

T401

L404

+ 200V

Q405

D408

5.6V

C408

R418

R419

R420

Q407

L400

C400

D401

C414

D402

R401

D400

L403

C411

C412

C410

C413

T402

2

9

1

HORIZ -

HORIZ +

8

R424

6

10

7

3

4

SCREEN

R407

R427

R426

to Yoke

Plug P400

EHT

FOCUS

ABL

C420

D413

5.1V

D406

D405

D404

R433

R425

SANCAS

HEATER

XRP

C417

- 14V

C416

+ 14V

C415

Page 16

Page 17

V ertical Deflection

The ATC010 uses a ramp generator IC200 and deflection booster IC301 to drive the

vertical yoke windings. IC301 uses the + and – 14V to generate enough flyback

voltage for vertical deflection. Drive for IC301 comes from the system control IC200

and is labeled VDRA and VDRB. Vertical deflection is monitored by V-Loss circuit

that forces shutdown the set if vertical deflection is lost.

VCC is supplied to pin 2 from the +14V source and the -14V supplies pin 4 of IC301.

The +14V source is used through first half of the screen with 0 volts being center of

the screen. The second or bottom half is driven by the -14V source. Return or retrace

to the top comes from the flyback generator circuit between pins 3 and 6. C323 and

D309 assist with the flyback generator to create the voltage necessary to move the

beam from bottom of the screen back to top of the screen. This is known as retrace.

During retrace more voltage needs to be applied to the yoke so the beam will retu rn

to the top much quicker than when it scanned down. Because the vertical circuit uses

two supplies (-14V and +14V) and because retrace must occur in such a short time

compared to trace, a higher positive supply is needed. During trace, the negative

lead of C323 (pin 3) i s connected to the -14V suppl y internal of IC301. With the

positive lead of C323 connected to the +14V supply, there is approx imately 28 volts

across C323. At retrace, the flyback generator connects pin 3 to pin 2 applying the

+14V supply to the negative side of C323. D309 blocks current flow between C323

and the +14V supply. With the stored charge on C323 and the +14V supply on the

negative terminal, about +42 volts is supplied to pin 6. The increased voltage quickly

retraces the beam to the top of the screen.

Output from pin 5 drives the deflection yoke. The return from the yoke goes to pin

1 as feedback reference through R315 and C337.

D309

V-Loss

3

FLYBACK

GENERATOR

THERMAL

PROTECTOR

C325

C323

IC301

5

R324

R313

R321

D311

R315

C337

1

1W

P400

1

2

3

4

VDRB

VDRA

R350

+14V

-14V

R314

C308

R316

-14V

C360

62

1

+

Power Amp

-

7

4

C324

Page 17

Page 18

Drive for IC301 comes from IC200 and is applied to pins 1(non-inverting input) and

7 (inverting input). These two signals are combined in IC301 to generate the vertical

ramp needed to drive the deflection yoke. Protection from residual energy in the

vertical yoke windings is provided by R324 and D311. Also in the output circuit is

R321. R321 provides ground reference for the low side of the vertical yoke.

D309

V-Loss

C360

C323

+14V

3

FLYBACK

THERMAL

PROTECTOR

IC301

5

R313

R324

R315

C337

D311

R321

1

1W

P400

1

2

3

4

VDRB

VDRA

R350

-14V

R314

C308

R316

-14V

62

GENERATOR

1

+

Power Amp

-

7

4

C325

C324

Shutdown

The ATC010 chassis has three deflection type shutdowns Vertical, XRP, and ABL.

Each of these shutdowns com municate back to IC200 through the XRP detect pin

119. All the deflection shutdowns are detected as XRP. XRP shutdown is active low.

Vertical Shutdown

The vertical shutdown is active when loss of vertical deflection occurs. The detection

circuit for vertical shutdown consists of D300, D307, D308, C300, C307, C313, and

R300. The circuit is designed as a voltage divider between R030 and R300 that is

active only when vertical deflection is lost.

W ith verti cal defl ecti on at decoupling capaci tor C313, D307 and D308 rectify the

vertical pulse, D306 regulates the pulse and C307 filters it. With 3.9V on the anode

of D300 it is not conducting. During vertical loss, D300 is forward biased and R300

is in series with R030 creating a voltage divider, dropping the voltage on pin 119 of

IC200. This causes the set to shutdown when vertical deflection is lost.

XRP Shutdow n

The XRP circuit monitors the flyback Heater pulse for both excessive and m inimal

voltage. D406 rectifies the heater pulse from pin 10 of T402 to be used by the X RP

circuit. The rectified voltage is in the range of +10V to + 30V. A ny voltage outside

of this range will cause t h e X R P circuit to tr ip sh ut t in g do wn the se t .

Page 18

Page 19

The XRP circuit is made up of two transistors (Q280, and Q280), diodes D280, D281,

D282, and D283. A +12V source provides bias to the circuit. Q280 is used to detect

the lack of high voltage or high voltage too low. If the voltage on the base of Q280

drops below the emitter voltage of +12V, Q280 turns on and supplies Q281 base with

.7Vdc from the +12V source. Q281 turns on pulling the XRP line low making it active

and shutting down the set.

For excessive high voltage, D280 (24V zener) is used. As high voltage increases,

the voltage from D406 also increases. Once this voltage exceeds the break over

voltage of D280, D280 conducts supplying Q281 base with .7Vdc to turn on. Once

Q281 turns on, XRP is activated and the set is shutdown.

IC200 will sh utdow n h orizo ntal driv e w hen t he DC voltage on pin 119 (XRP) is less

then or equal to 1.9Vdc. Once in shutdown, restart can only be initiated by pressing

the power on from remote or key pad.

ABL Shutdown

The ABL serves two functions. First, it provides feedback to IC200 to regulate beam

current. Second, it provides protection against excessive beam current such as

found when the CRT shorts. As beam current increases ABL information is sent to

IC200 which in turn limits the output or dr ive to the CRT. Shutdown occurs when

there is enough current flowing in the CRT to lower Q408 collector below ground

potential (-Vdc). As ABL becomes more negative, Q408 turns on harder. The

positive 3.9V on D304 cathode and a negative voltage on D305 cathode cause both

diodes to conduct lowering the XRP voltage and shutting down the set.

to

IC200

pin 119

+12V

+5VSTB

XRP

+14V

ABL

to

IC200 pin 16

R031

D010

R030

3.9V

R428

C300

D304

2.4V

D305

D283

Q408

D300

R300

D282

Q281

D306

3.9V

R282

R286

R283

R429

C307

D307

Q280

D280

24V

C313

VERT

D308

D281

XRP

from D406

R285

R284

ABL

from

T402 Pin 8

Page 19

Page 20

ADM1 Module (ATSC Tuner)

The ADM1 front end is comprised of a terrestrial/cable tuner module and a Link IC

(Broadcom). The tuner module consists of a tuner and IF capable of receiving ATSC

signals and providing the Link chip with ATSC 8-VSB. The Link chip is responsible

for digital demodulation and error correction of 8-VSB and providing a serial

transport stream to the ADM1 back end for processing.

The digital decoder function of the ADM1 is performed by the BCM3510 (II101).

II101 is a digital receiver compatible with digital terrestrial broadcast television

(ATSC A/53) standards. It is capable of receiving all standard-definition and highdefinition digital television formats (SDTV/HDTV).

II101 accepts an analog signal centered at the standard television IF frequencies or

near baseband signal from the ATSC tuner. The signal is amplified and digitized with

an integrated programmable gai n amplifier and 10-bit A/D converter. II101 then

demodulates and filters the signal with an 8-VSB demodulator and adaptively filters

the signal to remove multi-path propagation effects and NTSC co-channel interference

before being sent to the MPEG decoder processor.

The MPEG decoder (IM101) is a high definition decoder that has a CPU core and

transport filtering. IM101 also process the audio from the ATSC tuner. The signals

are then output from the ADM 1 m odule as Y Pr Pb on connector BV101. Pins 4, 6,

and 8 make up the Y Pr Pb signal respectively with Right and Left audio on BA101.

Other IC’s on the ADM1 module are:

· IM201 and IM202 DDR SDRAM for audio and video decoding

· IM102 Flash Memory for MPEG programmi ng

· Power Supply Regulators (+1.5V, +1.8V, +2.5V, +3.3V, and +5V)

An external pow er source (+12Vdc found on connector BP101) is used as a source

voltage for the +5V regulator.

Page 20

Page 21

Front End

ATSC

Tuner

DeMod

II101

2.5V

1.8V

5V

3.3V

1.2V

EEPROM

MPEG IC

IM101

Audio DAC

Video Driver

System Memory

FLASH

DDR RAM

DDR RAM

A DM1 Module

+1.5V PIN

LP107

LP104

+3.3V PIN

RESET

BP101

+3.3V IN

+2.5V OUT

411

+

+

5

V

1

2

O

V

U

I

N

T

GND

IM201

DDRx2

IM202

GND

+3.3V IN

BV101

GND

9

1

BM403

+1.8V OUT

BA101

1

Video Driver

3

6

IV101

IM101

MPEG Deocd er

CPU

IM102

Flash

LED

BM401

Audio DAC

ATSC Tuner

DEMOD

II101

5

1

1

0

1

A

I

BM402

JTAG

Page 21

Page 22

Standby Power Supply Troubleshooting

1. Apply AC power and measure the DC voltage on pin 8 of IC860. If the voltage

is 160Vdc, go to the next step. If the voltage is low or missing suspect F800,

D861-D864, RT860 or T860.

2. Measure the DC voltage on pin 1 of IC860 (9Vdc norm al). If voltage is pulsing

or low, suspect an over current condition on the secondary side of T860 or resupply problem from D865 through R849. If voltage is high (above 10Vdc)

suspect regulation problem and go to the next step.

3. If the voltage on pin 1 is above 10Vdc and pulsing, check IC804 for proper

operation. NOTE: Normal operation of IC804 is as the current between pins

1 and 2 increases; the photo transistor across pins 3 and 4 conducts harder.

4. Measure the DC voltage on pin 4 of IC860. If the voltage is greater than

2.7Vdc, suspect IC860, if the voltage is low, suspect IC804 or a problem in

the feedback circuit off the +5VSTB supply. (Q860, D869, R890 etc.) If the

voltage is pulsing high above 2.8Vdc, short across pins 3 and 4 of IC804. If

the voltage drops and is pulsing suspect feedback problem of D866. If the

voltage is pulsing high, suspect IC860.

P801

P802

R849

C862

R864

F800

C893

C801

R801

R863

C863

T801

C861

D866

18V

IC860

1

2

3

4

4

3

R865

C864

C860

R860

D860

8

C890

7

R862

6

5

D865

1

IC804

2

RT860

R861

D861

D862

D863

D864

T860

5

3

2

1

AC-RUN

AC-RUN

R890

D868

6

L861

+5VSTB

C866

C868

10

R869

R868

R867

Q860

D869

3.3V

R891

C895

Page 22

Page 23

Run Power Supply Troubleshooting

In order for the run supply to be powered on it is necessary to force on the relay K802.

This is accomplished by shorting C-E of Q861 and applying AC power to the set.

NOTE: The standby power supply needs to be operational for this to work.

1. With C-E of Q861 shorted together, apply AC power and measure IC801 pin

4 for DC voltage reference to HOT ground. If there is no voltage suspect R810

or D801 bridge rectifier. If voltage is pulsing, go to step 3.

2. Unsolder pin 1 of IC801 and measure the DC voltage on the pad. If the voltage

on the pad is equal to or greater than 120Vdc go to the next step. If lower than

120Vdc, suspect RT802, D801, or T803.

3. Reconnect pin 1 of IC801. Apply AC power and see if secondary supplies are

pulsing. If all the secondary supplies are pulsing, suspect a feedback or resupply problem. If any secondary suppl y is not pulsing but the others are,

suspect a problem w ith the supply that is not pulsing. NOTE: The +12V off

D823 and the +130V have to be operational for feedback to work properly. A

proble m with e it h er will result in ov e r v olt age shutdow n of the supply.

a. Feed back problem; Monitor the +130V supply and apply AC power.

If the supply is pulsing ab ove 130Vdc (reference cold ground), the

supply is in over voltage shutdown. Go to step 4.

b. Re-supply problem; Monitor the voltage on pin 4 of IC801 and apply

AC power. If the voltage at pin 4 i s pulsing but never goes above

10Vdc, suspect D810, C814, or R813. If the voltage is pulsing between

10Vdc and 17Vdc, go to the next step.

4. Suspect IC803, IC802, R835, R839, R841, D824, D813, and the +12V

supply. If still pulsin g s u s pe c t I C 801 or over current condition.

P801

P802

F800

+5VSTB

ON/OFF

IC200

Pin99

SysCon

AC-STBY

C801

R801

AC-STBY

T801

K802

D867

T802

Q861

D801

RT801

Raw B+

to RT802

Run Supply

Start-UP

to R810

Run Supply

X800

P803

K801

Q880

+12V RUN

D880

RELAY

IC200

Pin 112

SysCon

Page 23

Page 24

RT802

Raw B+

R820

L808

R822

R823

D824

D820

D822

C841

D823

D821

IC803

+13V

C821

L801

R835

+12V

C838

+12V

C837

R839

R841

+33V

R826

+130V

C828, C823

to

P807

Start-UP

from

D801

4

1

8

C

R810

C811

from D801

IC801

4

VCC

Logic

Control

OCPSSFB

6

5

7

R815

D813

1

D

S

3

R816

.12

2W

D810

C815

R814

R818

C812

C806

D811

C813

R812

IC802

3

4

R813

T803

1

9

4

7

1

2

R831

18

17

10

12

16

14

15

R830

C809

Feedback Regulation Troubleshooting

The Feedback regulation circuit in the run supply uses two supply vol tages for

operation, the +12V and the +130V. The +12V supply is for biasing IC802 and IC803.

The +130V is the monitored supply for regulation thus provides IC803 a reference

voltage. Testing all active components in the feedback regulation circuit is the best

way to troubleshoot it.

Page 24

Page 25

System Control Troubleshooting

There are basic items to check on IC200 that are required for the IC to operate. Not

all will be listed in this troubleshooting procedure but general description of them w ill

be indicated.

1. Make sure all standby supply vo ltages and ground pi ns are at the correct

potential. If missing troubleshoot the appropriate circuit.

2. Ch e c k fo r osc illa t o r on pins 1 0 and 1 1. If missing sus p e c t Z200 or IC200.

3. Check for clock and data on pins 108 and 109 when set is first plugged in.

If missing suspect IC200 or other devi ce connected to the clock and data

lines. (IC001, Tuner, and ADM1) The clock and data need to be 5V P-P in

order for communication to occur. Any thing less there is a problem on the

lines.

4. Key scan input and IR input. Check for proper voltage (3.3V) on pin 120 of

IC200. If the voltage is not 3.3V, suspect one or more of the keys are

defective or a problem with the Front Panel Assembly.

5. Check IR input pin 97 for signal. If signal is present, IR sensor problem or

noise on the line. Signal is only present when an IR signal is received. Any

other time there should be no signal.

6. Monitor pin 99 of IC200 and press the power switch. If the voltage comes up

to 1.5V, system control i s trying to turn on the set and is functi onal. If the

voltage remains low, IC001 or IC200 are suspect.

+5VSTB

+3.3VSTB

A (1.8V)

+5VSTB

≈

1 2 3 4 5

5 4 3 2 1

R034

Z200

L201

R047

R024

R036

L202

VDA1

VDD

D006

D005

120

5

7

9

93

96

103

97

10

11

4

R033

NTSC

Tuner

IC200

99

R049

+3.3V

to

109

108

126

100

117

118

124

SDA

SCL

98

14

3

SDA

SCL

R094

R214

R211

FPA

R027

R025

R026

R034

R093

TV STB

Q200

Q201

R029

R011

R009

R212

R213

R215

Q202

+5VSTB

IC001

4 3 2 1

5 6 7 8

Q203

+1.8V

1.5V = ON

0V = OFF

R010

SDA

SCL

IRQ

to

ADM1

+5VSTB

R216

A (1.8V)

Page 25

Page 26

ADM1 T r oubleshooting

Troubleshooting the ADM1 module is in the form of does it have the necessary inputs

and is there output from the m odule. To start troubleshooting all inputs need to be

checked.

1. Apply AC power to the set and turn on. Verify the set is working on NTSC

station. If not troubleshoot the chassis not the ADM1.

2. Set receives and displays NTSC signals ok, measure the DC voltage on pins

1 and 2 of BP101 on the ADM1 module. +12V present on both go to the next

step. If missing troubleshoot the +12V supply.

3. Check for clock and data on pins 1 and 2 of BM403. +5V P-P signal present

when changing High Definition channels, go to the next step. Signals missing

or low troubleshoot the clock and data lines.

4. Check for output on pins 2, 4, 6, and 8 of BV101. Signals present problem

is on the main chassis or with IC200. Signals missing, suspect ADM1 module.

NOTE: audio is on BA101 pi ns 1 and 3. If audio problem on HD channels is the

complaint, check for signal at this connector. If missing ADM1 is suspect. If present

the main chassis or IC200 is suspect.

LP107

LP104

+3.3V PIN

RESET

Page 26

BP101

+1.5V PIN

+3.3V IN

+2.5V OUT

411

+

+

5

V

1

2

O

V

U

I

N

T

GND

IM201

DDRx2

IM202

GND

+3.3V IN

BV101

GND

9

1

BM403

+1.8V OUT

BA101

1

3

6

IV101

Video Driver

IM101

MPEG Deocd er

CPU

IM102

Flash

LED

BM401

Audio DAC

ATSC Tuner

DEMOD

II101

5

1

1

0

1

A

I

BM402

JTAG

Page 27

Shutdown Troubleshooting

With only three shutdowns and the usual power supply shutdowns, troubleshooting

the ATC010 chassis shutdown is a mater of eliminating each shutdown. The

following steps will use a logical order to determine which shutdown is being

activated. Common sense should be used when performing these steps as they

disable the shutdown to determine w hich shutdown is being triggered. NOTE: XRP

should never be disabled!

1. Verify both standby and run supplies are working and at proper voltage. For

the standby measure the +5V and the +3.3V. If either is low or missing

troubleshoot the standby supply. If ok go to the next step.

2. Verify the run supply is working by forcing on the supply. To force on the run

supply jumper between E-C of Q861 and m easure all supply voltages. If they

are low or missing troubleshoot the run supply. If they are ok, go to the next

step.

3. Remove the j um per on Q861. A pply AC power and press the power sw itch.

Does the set cycle on and off? If the set is pulsing or cycli ng on and off,

measure the voltage ad the cathode of D010. If the voltage is pulsing below

+3V, measure the base of Q281. If there is .7V pulsing on the base of Q281,

the set is in XRP shutdown; suspect Horizontal circuit, IHVT, or XRP detect

circuit problem. If 0V is on the base of Q281, go to the next step.

4. Unsolder D304 cathode. Apply AC power and press the power sw itch. If the

set starts, ABL shutdown is being activated. Troubleshoot the ABL shutdown.

If it s t ill puls e s , g o to t h e next step.

5. Unsolder D300 anode. Remove the CRT drive board from the CRT to prevent

possible burning of the CRT. Apply AC power and press the power switch.

If the set starts, Vertical shutdown is being activated, troubleshoot the vertical

circu it . I f t h e s e t s t ill p u ls e s , s us p e c t X R P o r p ower supply problem getting

to the shutdown circuit. Power supply problem with the shutdown circuit,

suspect R030, D282, D280, the +5VSTB or the +12V.

to

IC200

pin 119

+12V

+5VSTB

XRP

+14V

ABL

to

IC200 pin 16

R031

R030

D010

3.9V

R428

C300

D304

2.4V

D305

D283

Q408

D300

R300

D282

Q281

D306

R282

R286

R283

R429

3.9V

C307

D307

Q280

D280

24V

C313

VERT

D308

D281

XRP

from D406

R285

R284

ABL

from

T402 Pin 8

Page 27

Page 28

NOTES

Page 29

Page 30

TTM_ATC010

Loading...

Loading...