Page 1

®

RAYTEK

COMPACT SERIES

MI3

Noncontact Temperature Measurement for Industrial Applications

Safe Smart Versatile

Page 2

Fast Measurements

MI3 Series – Smart and Innovative

Infrared thermometers measure the energy

radiated from an object, without touching it.

This measurement technique is important in

applications where contact would damage or

alter the surface, such as a sheet of plastic

film; or contaminate the product, such as food

processing.

Unlike contact sensors, there is no delay while

the infrared thermometer reaches the correct

temperature. This makes it ideal for measuring

moving or discrete processes. The result

is fast, accurate noncontact temperature

measurement and tighter control of your

process.

Standard Features MI3

■

Extended temperature range up to 1650 °C

(3002 ºF)

■

Optical resolution up to 22:1

■

Dedicated close focus lens for spot sizes

down to 0.5 mm (0.02 in)

■

Short response time down to 20 ms

■

Industrial rugged cable: Silicone and Halogen

free, resistant against oil, bases, and acids

■

USB 2.0 interface as standard and

selectable field busses

■

Ambient temperatures up to 180 °C (356 °F)

without the need for costly cooling

Most IR temperature sensors on the market transfer

measurements from the sensing head to the electronics as

interference-prone analog signals in a very sensitive µV range,

the MI3 models allow calibrated, digital temperature output

directly from each sensor head.

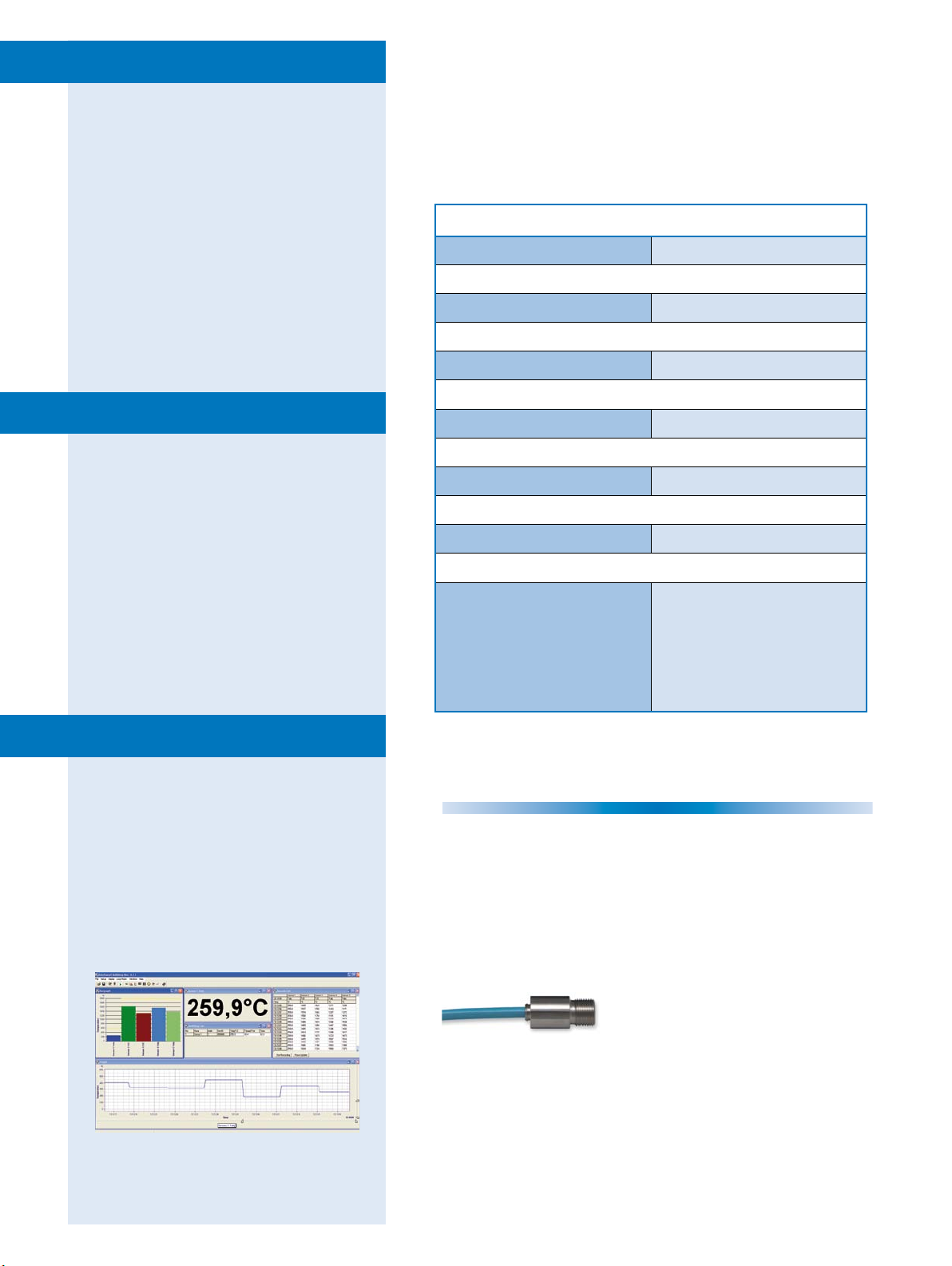

Models

MI3* MI3100*

Temperature Range

-40 to1650 °C (-40 to 3002 °F) 250 to 1800 °C (482 to 3272 °F)

Response Time

20 ms 130 ms 10 ms

Optics

22:1 10:1 2:1 100:1

Spectral Range

µm 8-14 µm 1 µm 1.6 µm

5

Accuracy

1 % or 1 °C (2 °F) 0.5 % + 2 °C

Outputs

0-5/10 V

0/4-20 mA,

J, K, R, S**

Alarm, USB, RS485,

Profibus, Modbus, Ethernet, Profinet

Galvanically isolated analog outputs

Profibus, Modbus, Ethernet, Profinet

Galvanically isolated analog outputs

0-5/10 V

0/4-20 mA,

J, K, R, S**

Alarm, USB, RS485,

Process Software

More MI3 features are available with the

USB or optional RS485 communications

and the DataTemp

including remote control and monitoring of

all sensor variables, an 8-position “recipe”

table that can be easily interfaced to an

external control system, and even external

inputs for analog emissivity adjustment or

reflected energy compensation.

Plot temperature values of multiple sensors

simultaneously. High and low alarms are

shown, making it easy to identify an out-ofrange condition.

®

MultiDrop Software

* Explosion proof sensing heads available (option)

** Thermocouple type

MI3 – The World’s Smallest

Stand-alone Pyrometer

The Raytek® MI3 is a rugged, IP65 stainless steel miniature

pyrometer with integrated electronics that can measure a wide

range of temperatures. Just 14 mm (0.55 in) in diameter and

28 mm (1.1 in)

OEM version is the smallest fully

functional, stand-alone infrared

temperature sensor for fixed

installation on the market today. Designed for a wide range of

applications, the sensor is housed in a rugged stainless steel

enclosure to ensure long term performance, even in harsh

industrial environments with ambient temperatures up to 180 °C

(356 °F) without cooling. Cooling accessories not only add

installation costs, they can leak and contaminate products, or

condensation produced by cooling can obscure the sensor’s

field of view and interfere with measurement accuracy.

long, the single piece

Page 3

For use with standard industrial outputs, the

MI3 sensor comes with the separate

communication box MI3COMM,

which provides all the functionality

of the proven MI series sensors

with numerous exciting new

features.

The multi-channel MI3MCOMM

communication box for multiple

sensing head applications with USB

interface as standard and a wide

range of network communication

interfaces is available in a convenient

DIN-rail mountable package.

4 sensing heads can be directly

connected to the MI3MCOMM box.

Multi-channel sensor interface box

for connecting up to 8 individually

addressable heads to the

communication box.

Highlights: MI3 Series

■

Lowest installation costs per

measurement point due to multiple

sensing head system design

■

Self diagnostic features: break of a head

wire, head internal temperature

■

Plug & Play exchangeability for sensing

heads (no heads parameter anymore;

Raytek patent)

■

Robust EMI immunity due to digital

head-to-box communication

■

No cable bending/moving effects, allowing

continuous reliable measurement in

moving installations (robotic arms, linear

drives, chains, etc.)

■

Optional network communication

interfaces: RS485, Profibus , Modbus ®,

Ethernet, Profinet

■

64 MB data logger for communication

boxes with Ethernet

■

Optional 4 analog outputs with galvanic

isolation

■

OEM version allows direct digital

communication with the host machine

controller without the need for an

additional communication box

The OEMMI3 version of all MI3 sensor models

allows direct digital connection to the host

machine controller. No communication

box is required. This is ideal for high

volume OEM applications requiring

MI3 performance with the best possible

value and minimum installation costs.

MI3100

High Temperature Sensor

The MI3100 high temperature sensing head represents a

further extension of performance and innovation in continuous

noncontact temperature monitoring for specific OEM applications

and high temperature manufacturing processes. The short

wavelength sensor delivers more accurate measurements vs.

long-wavelength units in case of emissivity changes (for example:

metals, ceramics).

The MI3100 is a rugged, IP65 stainless steel sensing

head to handle many applications in a wide

temperature range.

The compact MI3100 sensing head

with integrated laser sighting.

MI3 digital

Multiple sensing head design of the

digital MI3 saves installation costs.

Sensor analog

Comm.Box

Comm.Box

Comm.Box

Conventional analog sensors require

one box for one sensing head.

Highlights: MI3100

■

Wide temperature range up to 1800 °C

(3272 °F)

■

Laser sighting

■

100:1 optical resolutions

■

Spectral models 1 µm/1.6 µm

■

Ambient temperatures to 120 °C (248 ºF)

without cooling

Page 4

MI3 Ex Proof Sensors

Explosive atmospheres at the workplace can be

caused by flammable gases, mists or vapors,

or by combustible dust. Explosions

can cause loss of life and serious

injuries, as well as significant damage.

If you are working in this hazardous

environment and need instruments

with special certification, Raytek MI3

ATEX/IECEx certified sensors can

be used safely to monitor the right

temperature of your process. All standard

MI3 and MI3100 heads can be ordered with

optional ATEX/IECEx certification. Raytek

MI3 ATEX/IECEx products provides you

with a broad variety of sensors for your

application

Highlights: MI3 Ex-Proof

■

■

■

■

.

ATEX and IECEx-proof for dust and gas atmospheres

Same feature set as standard models

Field exchangeability of all components without the need for

re-calibration

One Ex-proof power supply can be used with 2 sensing heads

(saves installation cost)

Monitoring edge temperature and drying uniformity for

paper production results in higher yields and reduced

downtime.

Intrinsically safe infrared sensors for temperature

measurement and monitoring in hazardous areas.

Raytek Service Ensures Long Use

With over fifty years experience, Raytek knows infrared temperature

measurement. Our application specialists are located around the

world to help answer your technical questions. Each Compact product

includes a two year warranty. In addition, maintenance, training,

calibration, and other customized services are available to ensure

that you receive the maximum benefits from your Raytek infrared

noncontact thermometer. For more information on our solutions,

contact your Raytek application specialist today!

The Worldwide Leader in Noncontact Temperature Measurement

Worldwide Headquarters

Raytek Corporation

Santa Cruz, CA USA

Tel: +1 800 227 8074 (USA/Canada)

831 458 3900

+1

solutions@raytek.com

European Headquarters

Raytek GmbH

Berlin, Germany

Tel: +49 30 4780 080

raytek@raytek.de

To find a Raytek office near you and service information, please visit www.raytek.com

China Headquarters

Beijing, China

Tel: +86 10 6438 4691

info@raytek.com.cn

From paint curing to thermoforming, noncontact

temperature measurement provides consistent

product quality in the automotive industry.

www.raytek.com

Raytek, the Raytek logo and DataTemp are registered trademarks of Raytek Corporation.

© 2015 Raytek Corporation (3783599 Rev. F) 8/2015

Windows is a registered trademark of Microsoft Corporation.

All other trademarks are the property of their respective owners.

Specifications subject to change without notice.

Loading...

Loading...