Page 1

MX4

TD

Bluetooth

®

HIGH PERFORMANCE

INFRARED THERMOMETER

Rev. H1

01/2005

57701-E1

™

Worldwide Headquarters

Raytek Corporation

1201 Shaffer Road, PO Box 1820

Santa Cruz, CA 95061-1820 USA

Tel: +1 831458 1110

Fax: +1 831425 4561

solutions@raytek.com

www.raytek.com

Raytek China Company

Beijing, China

Tel: +86 10 64 39 22 55

Fax: +86 10 64 37 02 85

info@raytek.com.cn

Raytek Japan, Inc.

Tokyo, Japan

Tel: +81 3 57 33 60 65

Fax: +81 3 57 33 60 99

info@raytekjapan.co.jp

South American Headquaters

Raytek do Brasil

Sorocaba, SP Brasil

Tel: +55 15 32 17 60 46

Fax: +55 15 32 17 56 94

info@raytek.com.br

European Headquarters

Raytek GmbH

Berlin, Germany

Tel: +49 30 4 78 00 80

Fax: +49 30 4 71 02 51

raytek@raytek.de

United Kingdom

Tel: +44 1908 63 08 00

Fax: +44 1908 63 09 00

ukinfo@raytek.com

France

Tel: +33 1 64 53 15 40

Fax: +33 1 64 53 15 44

info@raytek.fr

WARRANTY

Raytek warrants this product to be free from defects in material and

workmanship under normal use and service for a period of one year*

from date of purchase except as hereinafter provided. This warranty

extends only to the original purchaser (a purchase from Raytek or

Raytek’s licensed distributors is an original purchase). This warranty

shall not apply to fuses or batteries. Factory calibration is warranted for

a period of one year. The warranty shall not apply to any product which

has been subject to misuse, neglect, accident, or abnormal conditions of

operation or storage. Should Raytek be unable to repair or replace the

product within a reasonable amount of time, purchaser’s exclusive

remedy shall be a refund of the purchase price upon return of the

product.

In the event of failure of a product covered by this warranty, Raytek will

repair the instrument when it is returned by the purchaser, freight

prepaid, to an authorized Service Facility within the applicable

warranty period, provided Raytek’s examination discloses to its

satisfaction that the product was defective. Raytek may, at its option,

replace the product in lieu of repair. With regard to any covered

product returned within the applicable warranty period, repairs or

replacement will be made without charge and with return freight paid

by Raytek, unless the failure was caused by misuse, neglect, accident,

or abnormal conditions of operation or storage, in which case repairs

will be billed at a reasonable cost. In such a case, an estimate will be

submitted before work is started, if requested.

The foregoing warranty is in lieu of all other warranties, expressed or

implied, including but not limited to any implied warranty of

merchantability, fitness, or adequacy for any particular purpose or use.

Raytek shall not be liable for any special, incidental or consequential

damages, whether in contract, tort, or otherwise.

GARANTIEBEDINGUNGEN

Raytek gewährt für dieses Produkt eine Garantie von einem Jahr*

ab dem Kaufdatum. Der Hersteller garantiert, daß das Produkt im

genannten Zeitraum bei ordnungsgemäßer Anwendung und Wartung

keine Material- und Bearbeitungsfehler aufweist. Ausnahmen sind im

folgenden festgelegt.

Diese Garantie gilt nur für den Ersterwerber (der Erwerb des Produktes

von Raytek oder einem autorisierten Raytek-Händler gilt als

Ersterwerb). Die Garantie erstreckt sich nicht auf Sicherungen oder

Batterien. Für die im Werk vorgenommene Kalibrierung gewährt

Raytek eine Garantiefrist von einem Jahr. Die Garantie schließt keine

Produkte ein, die mißbräuchlich oder fahrlässig verwendet, beschädigt

oder unzulässig betrieben oder gelagert wurden.

Die vorstehenden Garantiebedingungen ersetzen alle anderen eventuell

gemachten ausdrücklichen oder stillschweigenden Zusicherungen.

Raytek übernimmt keine Haftung für einen besonderen, beiläufigen

oder mittelbaren Schaden, gleich ob dieser im Rahmen des Vetrages,

durch eine unerlaubte Handlung oder auf andere Weise entstanden ist.

* European Union (EU): two years/zwei Jahre

* Bluetooth and the Bluetooth logos are trademarks

owned by Bluetooth SIG, Inc., U.S.A. and licensed

to LinTech GmbH, Berlin Germany.

FCC NOTICE

This device complies with Part 15 of the FCC Rules.

Operation issubject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to

comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against

harmful interference when the equipment is operated in

a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

WARNING: Modifications not expressly approved by

this company could void the user's authority to operate

the equipment.

FCC ID: STG-DFQMX4

Page 2

CONDITIONS DE GARANTIE

Raytek accorde sur ce produit une garantie d’un an* à compter de la

date d’ achat. Le fabricant garantit pendant cette période l’absence de

vice de matériau ou de fabrication, à condition que le produit soit utilisé et entretenu normalement et à l’ exclusion des cas définis

ci-après. La présente garantie ne s’ applique qu’ au premier acheteur

(est considéré comme premier achat l’ acquisition d’un produit vendu

directement par Raytek ou par un distributeur agréé par lui). Les

fusibles et les piles sont exclus de la garantie. Raytek accorde

une garantie d’ un an sur l’ étalonnage effectué en usine.

L‘ utilisation d’ un produit dans un but non conforme à l’ usage

auquel il est destiné, la négligence, l’ utilisation de produits abîmés,

les erreurs d’ utilisation ou de stockage entraînent une exclusion de

garantie.

Dans le cas où Raytek ne serait pas en mesure de réparer ou de

remplacer le produit dans un délai convenable, l’ acheteur pourra

exiger uniquement le remboursement du prix de l’ appareil contre

restitution de ce dernier au vendeur.

Raytek assurera la réparation des appareils tombés en panne pendant

la période de garantie. L’ acheteur expédiera l’ appareil défectueux à

une station technique agréée, à ses frais et pendant le délai de

garantie. Raytek se réserve le droit de procéder à l’ échange de

l’ appareil au lieu de le réparer. La réparation ou le remplacement

seront effectués gratuitement si l’ appareil d éfectueux est retourné

pendant le délai de garantie. Les frais de retour au client seront à la

charge de Raytek. Les frais de réparation seront facturés au client

lorsque la panne sera liée à un défaut de manipulation ou

d‘ utilisation, à de la négligence, à des causes extérieures ou à un

stockage inapproprié. Un devis sera établi avant réparation à la

demande du client.

Les présentes conditions de garantie remplacent toutes les autre

assurances qui auraient pu étre données expressément ou tacitement.

Raytek décline toute respons abilité pour tout dommage particulier,

causé incidemment ou indirectement, que celui-ci soit survenu dans

le cadre du présent contrat ou ait été provoqué par un délit civil ou

par toute autre cause.

* European Union (EU): two years/deux ans

CONDIÇÕES DE GARANTIA

Para o presente produto a Raytek concede uma garantia de um ano*

contados a partir da data de compra. O fabricante garante que

o produto está livre de defeitos de materiais e de fabricação durante o

perídodo mencionado se o produto for devidamente utilizado e

conservado. As exceções são estipuladas a seguir. Esta garantia só

serí1 concedida ao primeiro adquirente (a compra do produto na

Raytek ou num concessioní1rio autorizado da Raytek é considerada

primeira aquisição). A garantia não cobre fusídveis e pilhas. A Raytek

concede uma garantia de um ano para a calibragem feita na fí1brica.

A garantia não inclui produtos utilizados ou danificados indevida

ou negligentemente, produtos usados ou armazenados

inadmissivelmente. Caso a Raytek não esteja em condições de reparar

ou substituir o produto durante um perídodo de tempo apropriado, o

comprador pode solicitar o reembolso do preço contra devolução do

produto como úfanico recurso.

Em caso de um defeito no aparelho durante o perídodo coberto pela

garantia, a Raytek responsabiliza-se pela reparação do mesmo. Cabe

ao comprador enviar o aparelho reclamado por conta própria e durante

o perídodo de garantia para um posto autorizado de assistíancia

técnica. A Raytek reserva-se o direito de substituir o aparelho em vez

de repará-lo. Ao enviar o aparelho defeituoso durante o perídodo de

garantia, a reparação ou a substituição do mesmo são gratuitos. Os

custos da remessa do aparelho ao cliente serão pagos pela Raytek. Se

o defeito resultar de tratamento impróprio, negligíancia, danos

causados por efeitos exteriores, condições inadmissídveis de

utilização ou armazenamento, os custos da reparação serão

correspondentemente faturados. Neste caso é possídvel calcular uma

estimativa dos custos antes da reparação por pedido do clientes

condições de garantia presentes substituem todas as outras garantias

feitas eventualmente explídcita ou implícitamente. A Raytek não se

responsabiliza por danos particulares, acidentais ou diretos, sejam

causados no quadro do presente contrato, em consequíancia de atos

ilídcitos ou de qualquer outra forma.

* European Union (EU): two years/dois anos

CONDICIONES DE GARANTÍA

Raytek concede en relación a este producto una garantía de un año* a

partir de la fecha en que se realice la compra. El fabricante garantiza

que el producto, dentro del espacio de tiempo referido, siempre que se

aplique correctamente y se lleve a cabo el mantenimiento adecuado, no

ha de presentar fallos de material o de fabricación. Más adelante se

mencionará alguna excepción. Esta garantía es válida respecto de la

adquisición primaria (se entiende por adquisición primaria del

producto aquella llevada a cabo directamente de Raytek o bien por

medio de un establecimiento autorizado por Raytek). La garantía no

cubre los fusibles ni las pilas. En relación al calibrado llevado a cabo

en fábrica,

Raytek concede un tiempo de garantía de un año. La garantía no cubre

ningún producto que haya sido usado inadecuada o negligentemente,

se haga hecho funcionar o se haya almacenado estando dañado o de

manera no autorizada.En el caso de que a Raytek no le sea posible

reparar o substituir un producto dentro de un plazo razonable, el

comprador, con carácter de reivindicación jurídica única, puede exigir

la devolución de la suma a la que haya ascendido la compra

devolviendo por su parte el producto en cuestión. En el caso de un

defecto del aparato que tenga lugar durante el tiempo de garantía,

Raytek se hace cargo de la reparación. Para ello, el comprador,

corriendo con los gastos, ha de enviar el aparato que sea objeto de

reclamación a un servicio de reparaciones autorizado dentro del plazo

de validez de la garantía. En caso de que lo considere conveniente,

Raytek se reserva el derecho de substituir el aparato en lugar de

hacerse cargo de la reparación. Si se envía un aparato defectuoso

durante el tiempo en que es válida la garantía, la reparación o bien la

substitución del aparato el cliente una cuenta por los costes

correspondientes a la reparación. En este caso el cliente puede

solicitar un presupuesto para la reparación antes de llevarse ésta a cabo.

Las presentes condiciones de garantía substituyen las demás

eventuales garantías realizadas de modo explícito o implícito. Raytek

no acepta niguna responsabilidad respecto a especiales daños

ocasionales o indirectos, bien hayan acontecido éstos en el marco del

contrato bien se deban a un manejo indebido o a calesquiera otras

causas. defectuoso es gratis. Los costes del envío de vuelta al cliente

corren a cargo de Raytek. En el caso de que el defecto se deba a una

manipulación incorrecta, negligencia, daño causado por agentes

exteriores, almacenamiento o empleo no autorizados, recibirá

* European Union (EU): two years/dos años

Page 3

HIGH PERFORMANCE

INFRARED THERMOMETER

Page 4

Page 5

english

Introduction 3

Features/Accessories 3

Functions (User interface) 4

Display 4

Batteries 5

Measurement (Quick Start) 5

Measurement (Continuous) 6

Measurement (Spot size) 6

Selecting a function 7

Laser On/Off 7

Emissivity explained 8

Emissivity adjustment 8

Emissivity Table of Values 9

Emissivity Unknown value 9

Mode Maximum 10

Mode Minimum 10

Mode Difference 11

Mode Average 11

Mode Probe connection 12

Setup High Alarm 13

Setup Low Alarm 13

Setup Time 14

Setup Date 14

Setup Offset 15

Mode Min-Max values 15

Data Logger (How to store data) 16

Data Recall 16

Display (Graphic Display) 17

Display (Auto or Man. range) 17

Display Begin (Man. range) 18

Display End (Man. range) 18

Display Cycle 19

Settings (DIP switch settings) 19

Appendix A: Special order models 23

Appendix B: Troubleshooting 24

Appendix C: Maintenance 25

Appendix D: Laser Warning Label 26

Appendix E: Cautions 27

Appendix F: Emissivities table 29

Specifications 30

Factory Defaults 31

NIST/DKD CE Conformity 32

Table of Contents

Page 6

Page 7

english

We hope you enjoy using

your infrared thermometer!

It measures the amount of

infrared energy emitted by

a target object, and

calculates the temperature

of that object´s surface.

INTRODUCTION

Your thermometer includes:

- Laser sighting

- Adjustable emissivity

- High/Low Alarm

- MAX, MIN, DIF, AVG

- Data Logger (100 points)

- Trigger lock

- Graphic display ... and

more!

FEATURES

ACCESSORIES

(optional)

The accessories

package for your infrared

thermometer, if ordered,

includes:

- external power supply

- thermocouple type K

- Windows-based software

- RS232 cable

OPTIONAL POUCH

The optional pouch

comes with a belt clip

and helps to protect your

infrared thermometer

when not in use.

3

Page 8

4

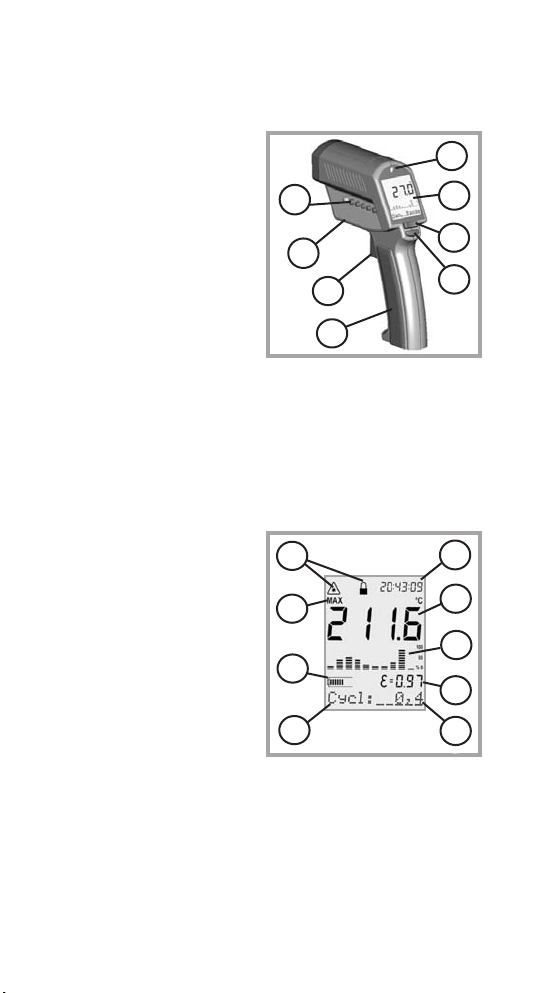

Function keys and display:

(A) Visual and audible

alarm

(B) Display

(C) Up and Down keys

(D) Enter

(E) Handle and battery

compartment

(DIP switches for

adjustments are

inside handle)

(F) Trigger

(G) Tripod mount

(H) 6 main function keys

FUNCTIONS

USER INTERFACE

Displayed functions:

(1) Laser condition /

Lock symbol

(2) Time (or date)

(3) Main temperature

display

(4) Graphic display

(5) Emissivity value

(6) Status bar

(7) Mode indicator

(8) Battery life indicator

(9) MAX, MIN, DIF, AVG

symbols

DISPLAY

A

B

C

D

E

F

G

H

1

2

3

4

5

6

7

8

9

Page 9

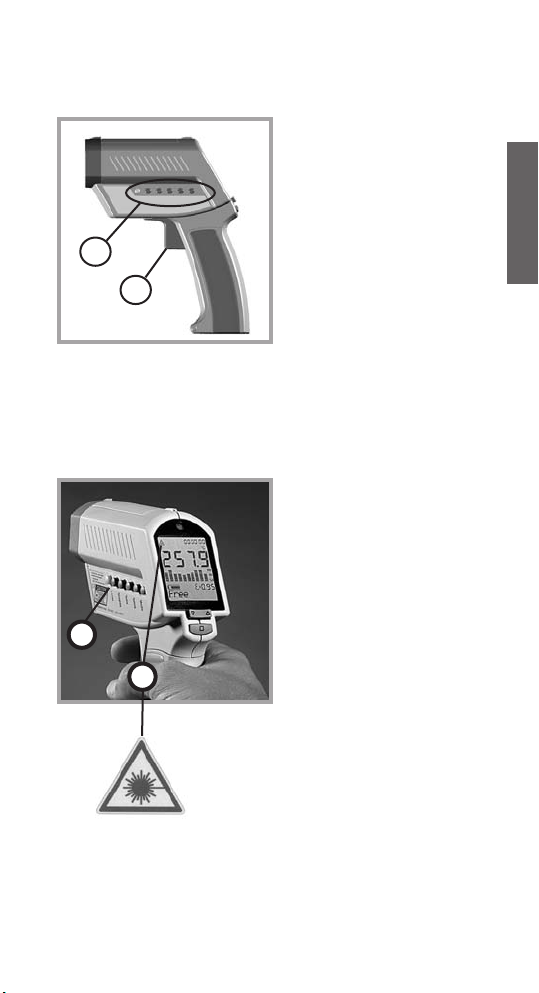

english

5

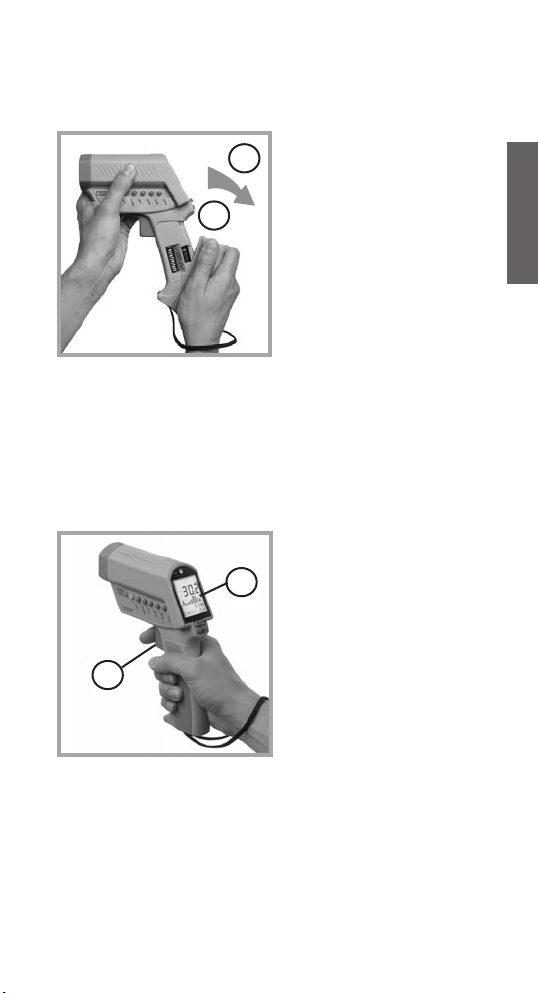

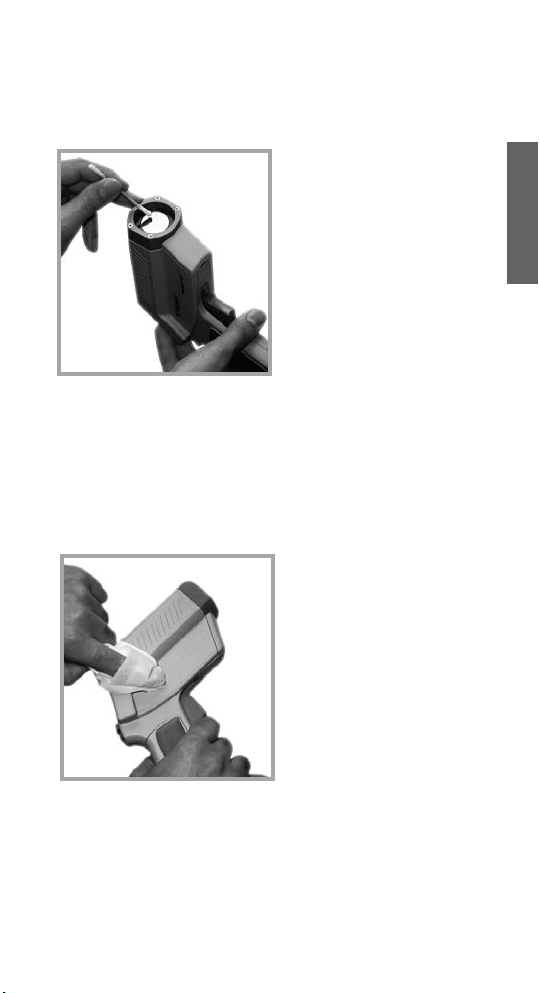

BATTERIES

To open the battery

compartment, press

gently on the top part of

the handle (1) to release

the catch (2) and pivot

the grip as shown in the

figure.

Orient the batteries (two

alkaline R6 (AA, UM3))

as shown on the housing.

MEASUREMENT

QUICK START

To take a temperature

measurement, hold the

unit as shown. Aim at the

target. Pull the trigger (F).

The temperature of the

object being measured is

shown on the display (B).

The temperature will be

displayed for seven

seconds after the trigger

is released.

The unit automatically switches “off” after

7 seconds if a function key is not pressed.

The last settings are stored. The display

returns to the last mode selected.

To recall the last reading, press ENTER

without pulling the trigger.

F

B

2

1

Page 10

6

MEASUREMENT

CONTINUOUS

Open the battery compartment and switch LOCK

"on" to lock the unit on.

You may mount the unit on

a tripod, using the tripod

mount. Pull the trigger for

continuous temperature

measurement. (The laser

will not be locked on.)

To unlock, switch LOCK

off.

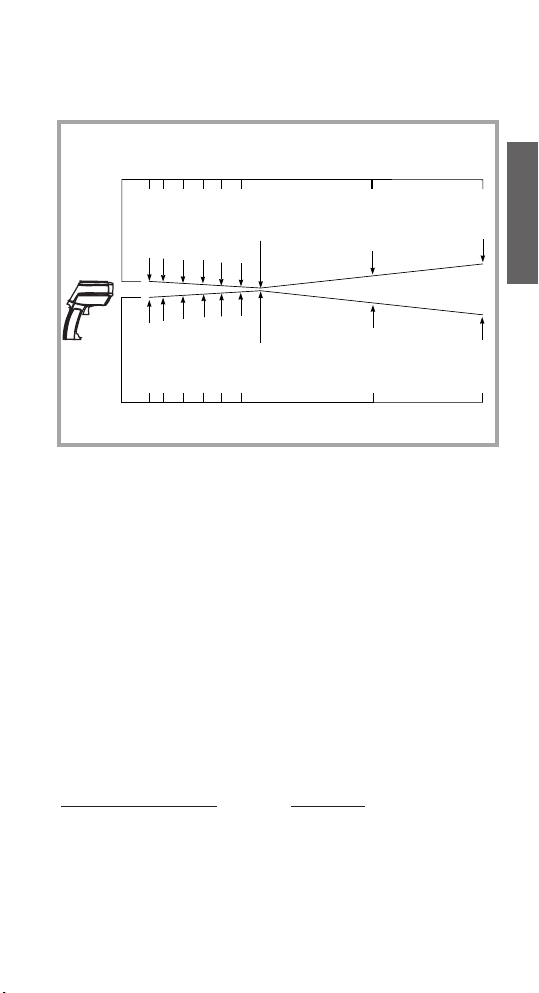

The measured spot size depends on the distance

between the object you are measuring and the infrared

thermometer. The relationship between distance and

spot size is 60:1 at the focus point. The D:S in the far

field (>33ft/10m) is 35:1.

MEASUREMENT

SPOT SIZE

STANDARD MODEL

Optical Chart

DISTANCE: SENSOR TO OBJECT (IN)

0

30

20

36

0.76 IN @ 46 IN

SPOT DIA. (IN)

1.0

0.9

0.81

0.87

84

60

46

48

72

1.51

1.2

0.82

1.85

100

2.3

120

108

2.9

2.5

24

24

0

250

500

100

SPOT DIA. (mm)

DISTANCE: SENSOR TO OBJECT (mm)

FOCUS POINT D:S = 60:1 FAR FIELD D:S = 35:1

29.0

19 mm @ 1150 mm

1000

1500

44.0

2000

58.0

2500

72.0

3000

19.8

23

Page 11

The laser sight simplifies

sighting of the measurement object. It shows the

spot size that includes the

measured target.

To turn the laser on or off

press the LASER button

(K) when the trigger is

pulled. A laser symbol (1)

appears when the laser is

on. The laser automatically

turns off if you release the

trigger.

7

english

To select a function, first

turn the unit on by pulling

the trigger (F). Then push

the button of the desired

function (H). To change

functions, press ENTER

or the function button

again, and then the new

function button.

SELECTING

A FUNCTION

LASER

ON/OFF

H

F

laser ON

symbol

K

1

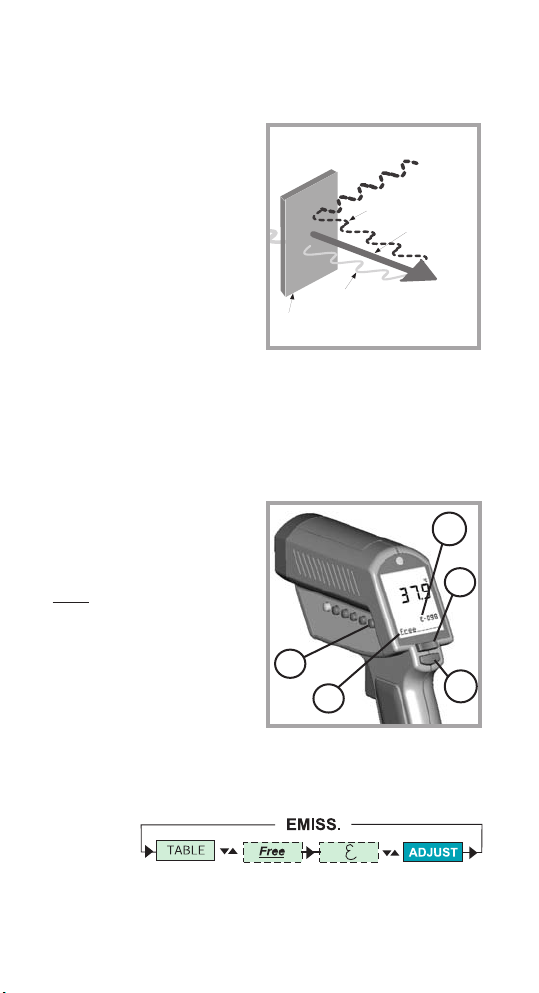

Page 12

8

The amount of infrared

energy radiated by an

object depends on its

emissivity and its

temperature.

The emissivity depends on

the material and its surface

characteristics. For more

accurate readings, adjust

the emissivity value for

the type of material being

measured.

EMISSIVITY

EMISSIVITY EXPLAINED

To adjust the emissivity

value, press EMISS (P).

Use the Up and Down

keys to select “Free“

(“F

ree” will have a

flashing underline) (7).

Press EMISS again.

“Free” is not underlined,

and the emissivity icon (5)

flashes. Use the Up and

Down keys (C) to adjust.

Press ENTER (D) to

activate this setting.

EMISSIVITY

ADJUST EMISSIVITY

P

5

7

C

D

Target

Transmitted energy

Reflected energy

Emitted energy

EMISSIVITY

Page 13

To adjust the unit’s

emissivity value for a

material with unknown

emissivity, plug in the

probe.

Pull the unit’s trigger.

Place the measuring

tip of the probe on the

area to be measured.

Wait for the reading to

stabilize.

EMISSIVITY

TABLE OF VALUES

To choose the emissivity

of a material, press

EMISS (P). The display

shows a material name

(7), an emissivity value,

and the calculated

temperature value (5). To

choose another material,

use the Up and Down

keys (C). Press ENTER

(D) to activate this setting.

EMISSIVITY

UNKNOWN VALUE

Note the indicated probe temperature reading.

Release the trigger. Pull the trigger again. Measure

the same area using infrared measurement. Press

the emissivity button (P). Use the Up and Down keys

(C) to select the material name “Free” which will be

shown in the display (7). Press the emissivity button

(P) again until the emissivity sign (5) flashes. Use

the arrow keys (C) to change the emissivity value

until the temperature matches the probe’s reading.

9

english

P

7

5

C

D

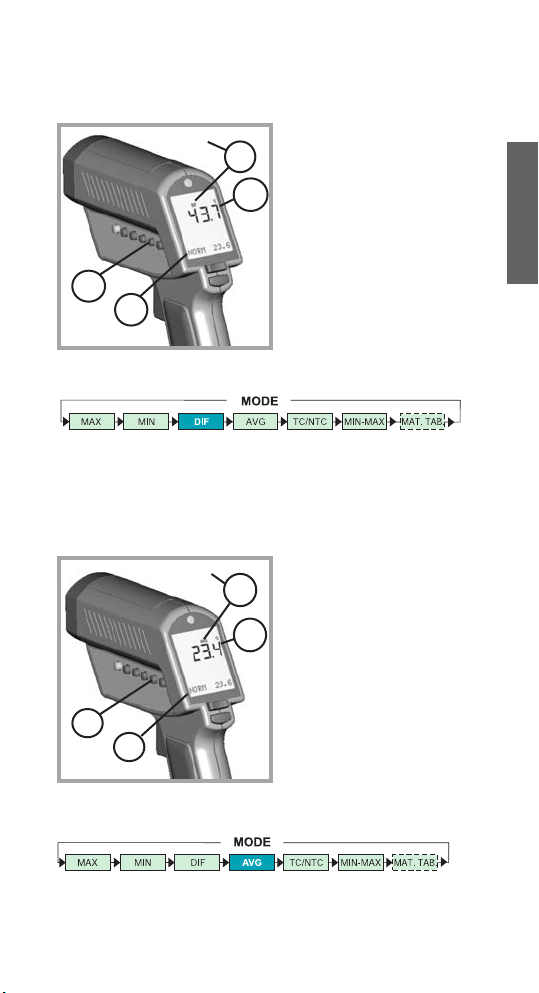

Page 14

O

10

To activate the MAX mode,

press MODE (O) until the

MAX symbol appears (9).

The measured maximum

temperature is displayed

(3) as long as the trigger

is pulled or locked on. The

real time temperature is

shown in the lower part of

the display (NORM) (7).

MODE

MAXIMUM

To activate the MIN mode,

press MODE (O) until the

MIN symbol (9) appears.

The measured minimum

temperature (3) is

displayed as long as the

trigger is pulled or locked

on.

The real time temperature

is shown in the lower part

of the display (NORM) (7).

MODE

MINIMUM

O

9

3

7

MAX

9

3

7

MIN

Page 15

O

3

11

english

MODE

DIFFERENCE

To activate the DIF mode,

press MODE (O) until the

DIF symbol (9) appears.

The difference between

the measured max and

min temperatures is

displayed (3) as long as

the trigger is pulled or

locked on. The real time

temperature is shown in

the lower part of the

display (NORM) (7).

MODE

AVERAGE

To activate the AVG mode,

press MODE (O) until the

AVG symbol (9) appears.

The average value of

measured temperatures

(3) is displayed as long

as the trigger is pulled or

locked on. The real time

temperature is shown in

the lower part of the

display (NORM) (7).

O

9

7

DIF

3

7

AVG

9

Page 16

12

10

11

12

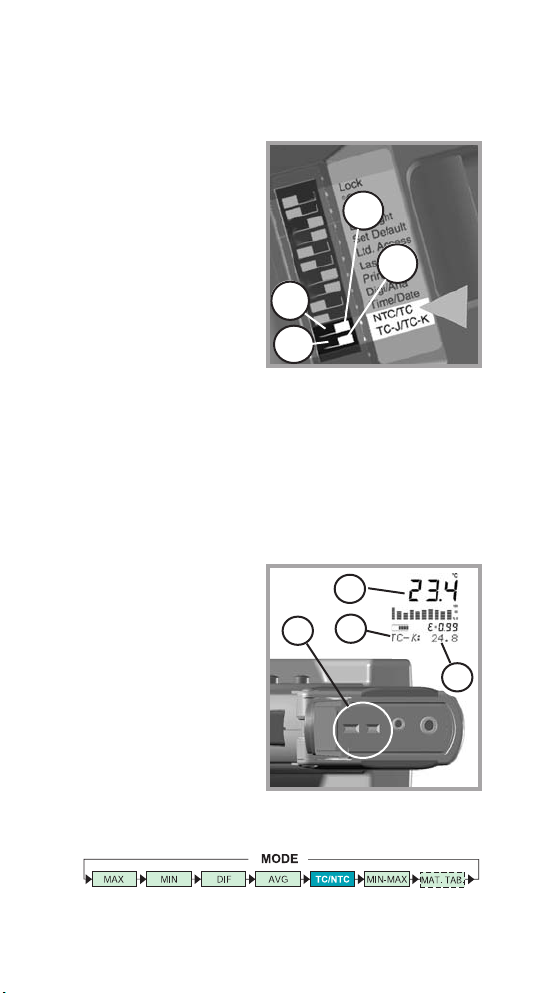

Open the battery compartment and set the switches

ON or Off according to the

desired probe type.

(10) NTC - thermistor

(11) TC - thermocouple

(12) Thermocouple type J

(13) Thermocouple type K

MODE TC/NTC

PROBE

CONNECTIONS

Connect the probe to the

input (U). Press MODE,

until the desired probe

symbol (7) appears. The

probe temperature is

shown in the lower part of

the display (6). The real

time infrared temperature

is shown in the main

display (3).

13

U

7

6

3

Page 17

13

english

SETUP

HIGH ALARM

The high alarm (HiAl)

generates an audible and

visual (flashing LED (A)

and laser) alarm if the

temperature is above the

setpoint.

To set the alarm value (6),

Press SETUP (N) once,

and use the Up and Down

keys (C).

Then press ENTER (D)

to activate this setpoint.

N

A

6

C

D

The low alarm (LoAl)

generates an audible and

visual (flashing LED (A)

and laser) alarm if the

temperature is below the

setpoint. To set the alarm

value (6), Press SETUP

(N) twice and use the Up

and Down keys (C).

Then press ENTER (D)

to activate this setpoint.

SETUP

LOW ALARM

N

A

6

D

C

Page 18

N

14

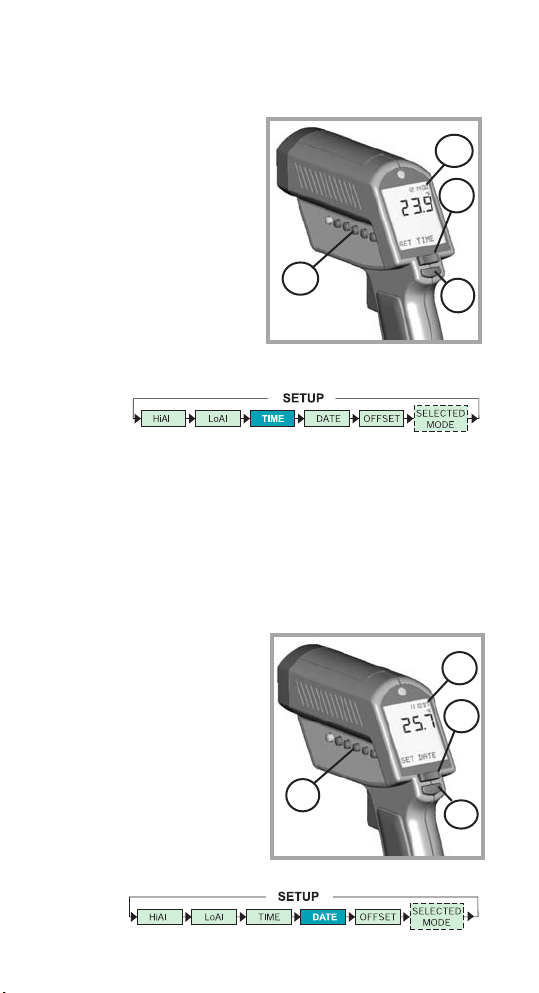

To set the time, press

SETUP (N) three times.

Change the time (2)

using the Up and Down

keys (C).

Then press ENTER (D)

for each time segment to

activate this time setting.

The time appears on the

display, is stored within

the data logger, and is

part of the printer output.

SETUP

TIME

SETUP

DATE

To set the date, press

SETUP (N) four times.

Change the date using the

Up and Down keys (C).

Then press ENTER (D)

for each date segment to

activate this date setting.

The date (2) is stored

within the data logger

and is part of the printer

output.

N

2

C

2

D

C

D

Page 19

SETUP

OFFSET

This function is used with a

selected emissivity to add

or subtract an offset value

(±10°C/±18°F) to the

temperature value. Press

the Setup button (N) until

"Offset" appears in the

display. With the arrow

keys (C) adjust the display

to the corrected value.

Press ENTER (D) to

confirm. If OFFSET is used, a symbol (1) appears in

the display. The OFFSET feature allows the

temperature values for several units to be matched,

correcting for the allowed temperature tolerance

difference between units. The OFFSET function can

also be used to increase the accuracy for a narrow

temperature range.

15

english

N

1

D

C

MODE

MIN-MAX VALUES

To show the minimum

and maximum

temperature values during

a measurement at the

bottom of the display,

press MODE (O) until the

two values appear (6).

O

6

MODE

MAX MIN DIF AVG TC/NTC MIN-MAX

Page 20

16

DATA LOGGER

HOW TO STORE DATA

To Recall stored data,

press the ENTER button

(D), without pulling the

trigger. Then press the

DATA button (M) until RCL

appears on the display. A

log location will be shown

(6).

To select another log location, use the Up and Down

keys (C).

DATA

RECALL

M

6

D

C

By pressing the ENTER

button (D) the LOG

function (6) appears on

the display. Pull the trigger

(F) and hold it. Aim at the

target. Be sure that the

laser sighting is inside

the target. Gently release

the trigger to record the

temperature. The next

location will be shown

on the display.

This function is also initiated by pressing the DATA

button (M) once.

D

6

F

M

Page 21

17

english

The graphic display (4)

shows the temperature as

a picture. The last ten

measurements are shown

(B). It is possible to choose

between Auto Range and

Manual Range. In manual

range the user defines the

beginning and ending

temperature points of the

graph.

DISPLAY

GRAPHIC DISPLAY

DISPLAY

AUTO OR MAN RANGE

Press DISPLAY (L) once.

Use the Up and Down

keys (C) to toggle between

ranges. Auto Range is

automatically defined by

the measured maximum

and minimum value.

Manual Range (Man

Range) is user defined

(see DISPLAY, BEGIN

section).

B

L

C

4

Page 22

18

To set the BEGIN value

for the graphic display

(Man Range is activated),

press DISPLAY (L) until

“Begin” is shown at the

status bar. Use the Up

and Down keys (C) to

select the value (6).

DISPLAY

BEGIN

(Man. Range)

DISPLAY

END

(Man. Range)

To set the END value of

the graphic display (Man.

Range), press DISPLAY

(L) until ”End” is shown at

the status bar. Use the Up

and Down keys (C) to

select the value (6).

L

C

6

L

C

6

Page 23

19

english

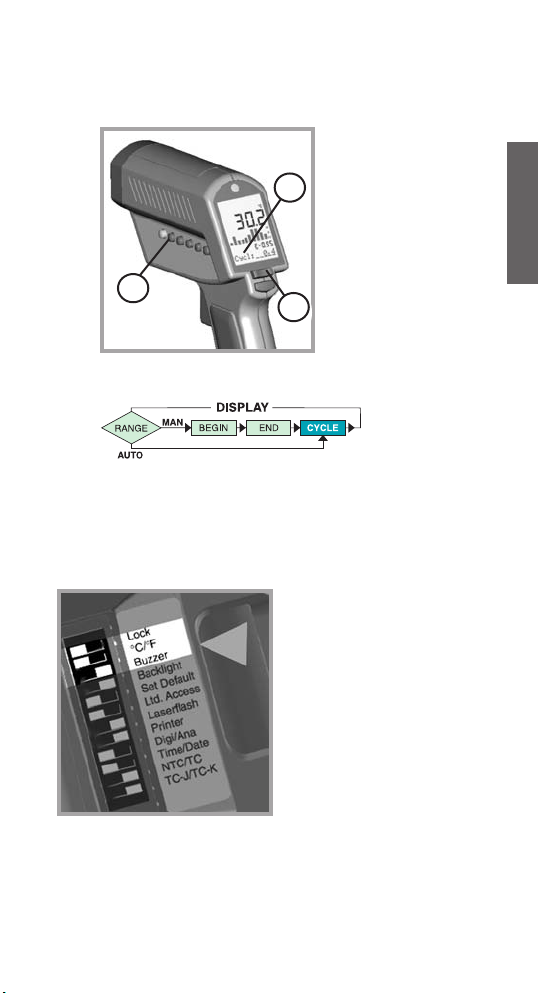

CYCLE allows the

adjustment of the

display interval.

Press DISPLAY (L)

until Cycl.: (7) is

shown at the status

bar. To select the

interval time, use the

Up and Down keys

(C). The default value

is pre-set for 0.2 sec.

DISPLAY

CYCLE

Change the setting in the

unit by using the DIP

switches located in the

battery compartment (see

BATTERIES section).

Lock: Trigger locked

(on) or

unlocked (off).

°C/°F: changes between

°C and °F and

date and time

format.

Buzzer: Audible alarm

On or Off.

SETTINGS

(PART 1)

L

C

7

Page 24

20

Lock

C/ F

Digi/Ana

Laserflash

Ltd. Access

Set Default

Backlight

Buzzer

TC-J/TC-K

NTC/TC

Time/Date

Printer

ON

ON

Lock

Digi/Ana

Laserflash

Ltd. Access

Set Default

Backlight

Buzzer

TC-J/TC-K

NTC/TC

Time/Date

Printer

C/ F

Factory Defaults

DIP-Switch Settings

Celsius setting shown

Fahrenheit setting shown

SETTINGS

(PART 2)

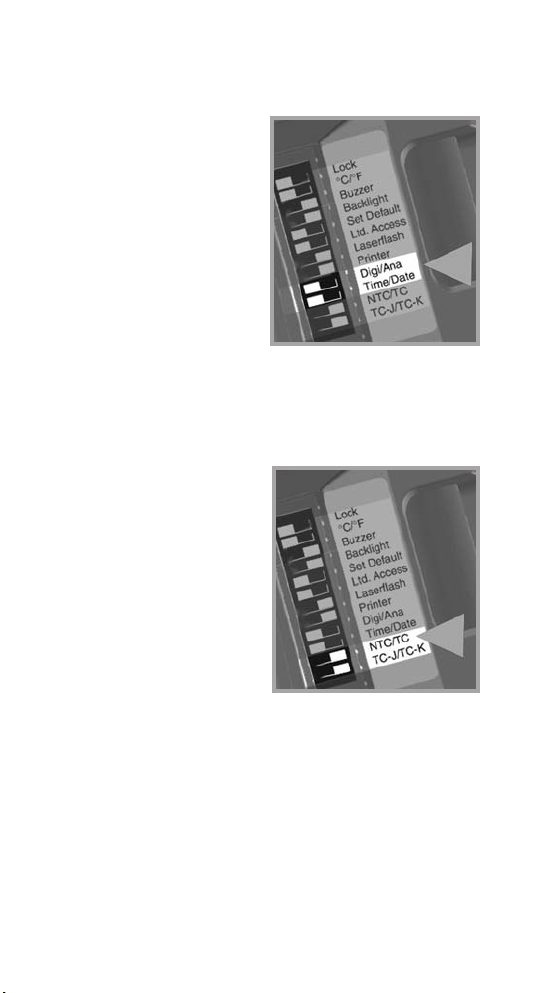

Backlight: Backlight On or Off.

Set Default: Activates the factory defaults

by overwriting listed settings

(see specifications).

Ltd. Access: No function buttons will work.

Laserflash: The laser flashes in case of

over- or underranging of the

alarm values.

Page 25

21

english

Printer: (ON) The printer’s data output

(RS232) is working as long as the trigger

is pulled. The protocol includes:

(14) Date

(15) Time

(16) Target temperature - infrared

(17) Target temperature- probe "X"

See software manual for other printout

options.

15

14

17

16

SETTINGS

(PART 3)

PRINTER

Page 26

22

Digi/Ana:

Digital or Analog output.

Digital (RS232) output

must be used with the

printer or a PC. Analog

output (mV/°) is usually

used for data logging.

Time/Date:

Time or date shown on

the display.

SETTINGS

(PART 4)

SETTINGS

(PART 5)

CONTACT PROBES

NTC/TC:

Thermistor (NTC) or

thermocouple (TC).

TC-J/TC-K:

Type of thermocouples.

The temperature range

for the probes:

K: -30°C to 400°C

(-25°F to 750°F)

J : -30°C to 650°C

(-25°F to 1200°F)

NTC: -30°C to 120°C

(-25°F to 250°F)

Note:

The temperature ranges

given are for the unit’s

optional type K

thermocouple.

Page 27

23

english

The measured spot size depends on the distance

between the object you are measuring and the infrared

thermometer. The relationship between distance and

spot size is 50:1 at the focus point. The D:S in the far

field is 12:1.

The best distance between sensor and object is from

10 cm (4“) up to 50 cm (20“).

APPENDIX A

SPECIAL ORDER MODELS

Close-Focus Model

Sub-Zero Model

Temperature Range: -50 to 500°C (-58 to 932°F)

Following is the accuracy table for the

sub-zero model when the ambient temperature

is 25°C (77°F) ±5°C (9°F):

T

arget Temperature Accuracy

-5 to 500°C (23 to 932°F) ±1% of reading or

±1°C (2°F),

whichever is greater

-30 to -5°C (-22 to 23°F) ±1.5°C (3°F)

-50 to -30°C (-58 to -22°F) ±2°C (4°F)

CLOSE FOCUS MODEL

Optical Chart

DISTANCE: SENSOR TO OBJECT (IN)

6

0

7.9 9.8

4

2

20

40

18,7

0.75

100

0.62

15,5

150

0.24 IN @ 11.8 IN

0.49

0.37

9,2

12,3

6 mm @ 300 mm

200 250

SPOT DIA. (IN)

1

0.9

22

25

0

50

SPOT DIA. (mm)

DISTANCE: SENSOR TO OBJECT (mm)

FOCUS POINT D:S = 50:1 FAR FIELD D:S = 12:1

0.93

23

500

2.81

Close Focus

70

1000

Page 28

24

TROUBLESHOOTING

Code Problem Action

-O- Target temperature is over Select target

or

within unit’s

-U- under range specs

EEPROM-Err EEPROM error Contact

Factory

CalAreaErr calibration errors Contact

ProbCalEr Factory

Battery icon Battery is low Replace

flashes or Batteries

LowBatt

Blank display Battery is dead Replace

Batteries

Laser won’t Low or dead battery Replace

work Batteries

Ambient above 45

o

C (113oF) Operate

unit in

45

o

C

(113

o

F)

ambient or

below

Display “ON” Display locked “ON” Disconnect

the unit from

the PC or

power

supply

APPENDIX B

TROUBLESHOOTING

Page 29

25

english

APPENDIX C

MAINTENANCE

Lens Cleaning: Blow off

loose particles using clean

compressed air. Brush

remaining debris away with

a camel’s hair brush. Wipe

the surface with a moist

cotton swab. The swab

may be moistened with

water or a water based

glass cleaner.

NOTE: DO NOT use

solvents to clean the

plastic lens.

Cleaning the Housing: To

clean the exterior housing,

use soap and water or a

mild commercial cleaner.

Wipe with a damp sponge

or soft rag.

Page 30

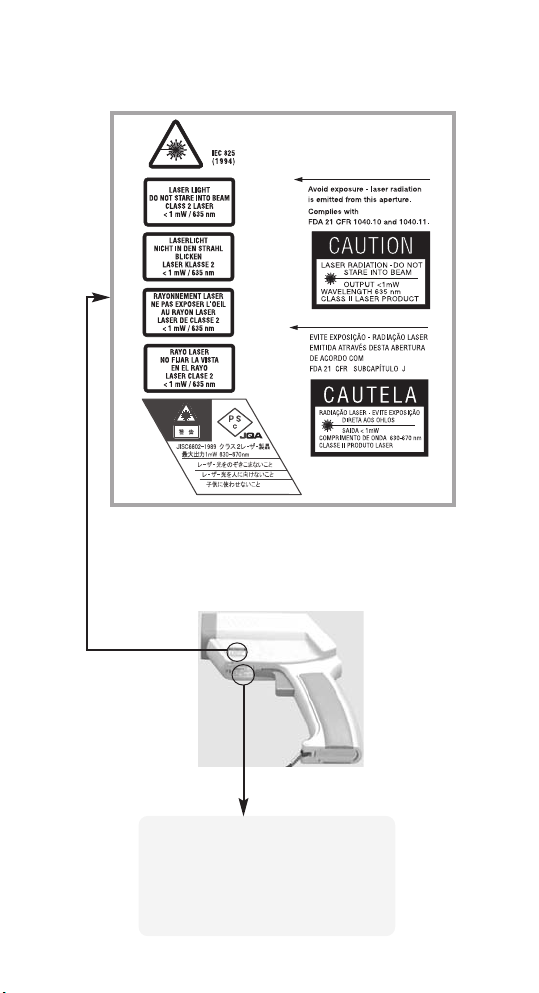

26

CAUTION! Do not stare into beam!

Avoid indirect exposure via

reflective materials!

APPENDIX D

LASER WARNING LABEL

SERIAL NUMBER LABEL

Manufacturer,

Address

Made in Germany: Month, Year

Model: XXXXXXX

Serial: 000000-0000-0000

Power Requirements 3 V

Page 31

english

27

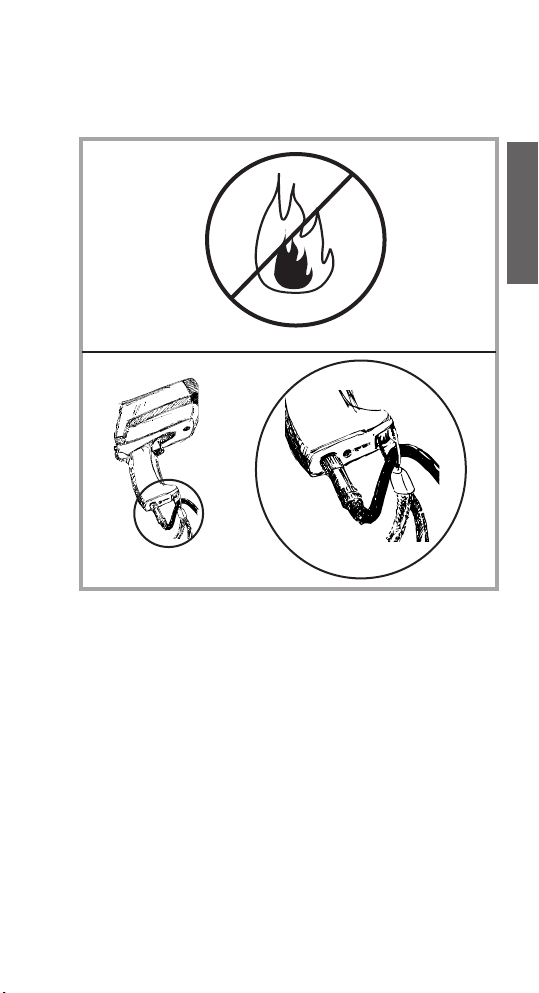

Avoid static electricity, arc welders, and induction

heaters. Keep away from very strong EMF

(electromagnetic fields). Don’t leave the unit

on or near objects of high temperature.

WARNING: DO NOT touch live voltage with

contact probe. Use the wrist strap for cable

support.

APPENDIX E

CAUTIONS

Page 32

28

Avoid abrupt changes in temperature.

If this occurs, allow 40 minutes for

thermal stabilization before use to

prevent the possibility of inaccurate

temperature readings. Use only the power

supply from the manufacturer.

APPENDIX E

CAUTIONS (cont.)

Thermal Shock

Page 33

29

english

APPENDIX F

EMISSIVITIES

Aluminum* 0.30

Asbestos 0.95

Asphalt 0.95

Basalt 0.70

Brass* 0.50

Brick 0.90

Carbon 0.85

Ceramic 0.95

Concrete 0.95

Copper* 0.95

Dirt 0.94

Frozen food 0.90

Hot food 0.93

Glass (plate) 0.85

Ice 0.98

Iron* 0.70

Lead* 0.50

Limestone 0.98

Oil 0.94

Paint 0.93

Paper 0.95

Plastic** 0.95

Rubber 0.95

Sand 0.90

Skin 0.98

Snow 0.90

Steel* 0.80

Textiles 0.94

Water 0.93

Wood*** 0.94

* oxidized

** opaque, over 20 mils

***natural

Page 34

SPECIFICATIONS

Temperature Range - 30 to 900°C (- 25 to 1600°F)

Display Resolution 0.1°C (0.2°F)

Accuracy ± 0.75% of reading or

(Infrared) ± 0.75K (± 1,5°F), whichever is greater

at 25°C (77°F) ambient temperature,

± 2K (± 4°F) for targets

below -5°C (23°F)

Ambient derating < 0.05K/K or < 0.05%/K,

whichever is greater at

+ 25°C (77°F) ± 25K (± 45°F)

Optical Resolution 60:1 (19mm spot size at 1.15 M.)

(Standard Focus) (0.75in. spot size at 3.8 feet)

Optical Resolution 50:1( 6mm spot size at 0.3 M.)

(Close Focus) (0.24in. spot size at 0.98 feet)

Accuracy ± 2K or ± 0.75%,

(Thermocouple K & J) whichever is greater

Accuracy

(Thermistor)

-30 to 0°C (-22 to 32°F) ± 0.6K

0 to 70°C (32 to 158°F) ± 0.4K

70 to 100°C (158 to 212°F) ± 1K

100 to 120°C (212 to 248°F) ± 1.5K

Repeatability ± 0.5% of reading or ± 0.5°C (1°F),

(Infrared) whichever is greater,

± 1°C (± 2°F) for targets

below -5°C (23°F)

Response Time (95%) 250 mSec

Hot Spot Detection (30%) 85 mSec

Spectral Range 8 to 14 µm

Ambient Operating Range 0 to 50°C (32 to 122°F)

Storage Temperature -20 to 50°C (-4 to 122°F)

(without batteries)

Analog output 1 mV/°C(°F)

Digital Output RS232

30

Page 35

english

31

FACTORY DEFAULTS

Default Range

Emissivity/Gain 0.95 0.10 to 1.50

in steps of 0.01

Emissivity Table Free 30 materials

Mode normal

Hi Alarm 50°C (100°F) -30 to 900°C

(-25 to 1600°F)

Lo Alarm 0°C (32°F) -30 to 900°C

(-25 to 1600°F)

Offset Adjust 0°C (0°F) -10 to 10°C

(-18 to 18°F)

Graphic Display Auto Range Auto Range

/ Man Range

Cycle Time 0.2 sec 0.1 sec to 300 sec

Printer Mode Data Recording 3 modes,

selectable

via software

Printer output ASCII

8 bits

1 Stop bit

No Parity

Baud Rate 9600

Data logger 100 points

pre-set with emissivity 0.95

Lo-Al: 0°C

Hi-Al: 50°C

adjustable only via Software

Accessory

SPECIFICATIONS (Cont.)

Power 2 x 1.5 V Alkaline Type AA

Battery Life 13 hrs. (50% laser and 50% backlight on)

Power supply 7.5 V

>

200 mA (Using the power supply

(External) the display automatically switches on)

Dimensions 200 x 170 x 50 mm (7.9 x 6.7 x 2 inches)

Tripod Mount 1/4”-20 UNC

Page 36

32

This instrument conforms to the following

standards:

EMC: - EN 61326-1

Safety: - EN 61010-1:1993 / A2:1995

- EN 60825-1:1994

This product herewith complies with the

requirements of the EMC Directive

89/336/EEC and the Low Voltage

Directive 73/23/EEC.

This instrument conforms to the Standards

of the European Community.

CE CONFORMITY

NIST/DKD

CERTIFICATION

The temperature sources used to calibrate this

instrument are traceable to the U.S. National

Institute of Standards and Technology (NIST)

and the Deutscher Kalibrierdienst (DKD). NIST

and DKD certificates are available as an option

from the manufacturer.

Page 37

Infrared Thermometer with LinTech* Bluetooth module

This infrared thermometer allows wireless data transfer with the aid of Bluetooth technology.

System requirements:

- Windows-compatible computer (operating system 98, ME, 2000, XP or higher)

- Bluetooth system fully installed on the computer (not included)

- BlueTool configuration software (included)

After the Bluetooth system has been installed as required on the computer, the thermometer can be operated in two

different modes:

1. Passive mode

In this mode, the thermometer is constantly activated

and is searched for by the computer. This is advantageous when continuous temperature monitoring

should take place.

Attention: As a result of continuous operation, the thermometer‘s

batteries are discharged much faster then during intermittent use.

Proceed as follows:

1. Switch on the thermometer with the measurement

button.

2. Press the Setup

button on the display.

The words “Bluetooth on-up,

off-down“ appear. Activate

Bluetooth with the Up button

below the display. A lightning

symbol in the display

indicates that the Bluetooth

module is ready

- the lock symbol signals continuous operation.

Note: If the automatic battery test finds that the battery is too weak

here (display: “LowBat - no BT“), the Bluetooth application is not

started.

* Please refer to the LinTech specifications overview for the exact specification of the Bluetooth module used.

3. Now start the Bluetooth software on your computer

and allow it to search for and

connect the Bluetooth devices.

(Please refer to the relevant operating

instructions for how this happens in the

case of your Bluetooth application)

4. The thermometer is reco-

gnized as “IR Therm....“. The

requested PIN is “1234“ when

the unit is delivered. With the

right mouse button, click on the

symbol for the device and select

“Eigenschaften/Properties“ in

the submenu. Make a note of

the ComPort‘s number. The

green LED on the left above the

thermometer‘s display signals

the existing connection.

5. If you have not already done

so, now start the relevant

application software for the

thermometer. Before you can exchange data between

the thermometer and computer, you must set in this

software the number of the ComPort found under Point 4.

6. Press the Setup button

and then the Down button

below the display to end the

Bluetooth connection.

If data is being

transferred at this time,

you cannot deactivate

the Bluetooth module.

Important note: The above refers to the thermo

meter as delivered. It can be programmed on a

user-defined basis with the aid of the “BlueTool“

software. For details, see the section “User-defined

configuration“.

2. Active mode

After switching on, the thermometer automatically

establishes contact with the computer, the address of

which has been programmed for the thermometer.

This is done by the supplied BlueTool software

details, see the section “User-defined configuration“). The active mode is particularly suitable for

intermittent operation of the infrared thermometer. The

thermometer‘s power consumption is significantly less

than in passive mode.

Making contact with the computer and

data transfer

Open the thermometer‘s handle and switch the DIL

switch 9 to ON (Master). Switch on the thermometer

with the measurement button.

(for

In the display, a framed lightning

symbol points to the Bluetooth

module in active mode and the

thermometer starts to search

for the associated computer.

When the connection has been

made, a green LED lights up

on the left above the display

and the color of the Bluetooth symbol changes on the

connected computer. You can now transfer data to the

thermometer‘s user software.

The thermometer automatically switches itself off after

approximately 7 seconds if the measurement button is

not pressed and if there is no data transfer.

3. User-defined configuration

Preparing the thermometer

Open the device‘s handle and set the DIL switch 5 to

ON (Set Default). “Default ?“

appears in the display. At this

point in time, it is essential

for the DIL switch 9 to be set

to OFF (Slave). Now start the

Bluetooth module as described under “Passive mode“.

Programming the thermometer with the aid of

BlueTool

Start the Bluetooth software

on your computer and start

the device search. Make the

connection by double clicking on the symbol for the

in-frared thermometer (signaling by the green LED on

the left above the display and the color of the Bluetooth

symbol changes on the computer). The properties can

be displayed by right-clicking on the service under

Page 38

Serial Ports. Note the number of the

connected ComPort.

Now start the BlueTool

application, enter the

ComPort number just

found and then click on

Connect.

A configuration window

opens.

It shows various details of

the device and several fields for calling up additional setting

possibilities.

First open ”Device settings“.

Here you can give the thermometer a name and change

the PIN.

Attention: Be sure to make a note of this PIN, because

you will be asked to provide it for encrypted transmissions

and connections with the aid of the BlueTool software. SPP

must be selected as the ComHardware mode and the connection indicator must be deactivated. Confirm the settings

with OK. Now open ”Master settings“.

Here, place a tick in front

of both “Master - automatic connection attempt“

and “Master attempts to

establish connection when

starting“. The address of the

current computer is in the

Remote BTA field

Note: Only if you wish to address another computer

(e.g. PDA or notebook) with the thermometer later must

you enter the Bluetooth address of the other computer

here. The same applies to the PIN in this window. It is

then binding for the connection with the other computer.

It is therefore essential to note it.

Click on OK. In the main window, first

settings“ - the data is transferred to the thermometer.

With “Update“, you can call up the current settings to

check them.

Then end the program. Now switch the DIL switch 5 in

the thermometer‘s handle back to OFF. Press the DOWN

button under the display. Now wait until the device

switches itself off automatically (approximately 7 s).

click on “Save

FCC NOTICE

This device complies with Part 15 of the FCC Rules.

Operation issubject to the following two conditions:

(1) this device may not cause harmful interference,

and

(2) this device must accept any interference received, including interference that may cause undesired

operation.

NOTE: This equipment has been tested and found

to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against

harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference

in which case the user will be required to correct the

interference at his own expense.

WARNING: Modifications not expressly approved by

this company could void the user‘s authority to operate the equipment.

FCC ID: STG-DFQMX4.

Loading...

Loading...