Page 1

CS210

Kiln Shell Temperature

Monitoring System

Rev. B4 Feb 2015

58401

Page 2

Raytek Corporation

European Headquarters

France

United Kingdom

Fluke Service Center

© Raytek Corporation.

Raytek and the Raytek Logo are registered trademarks of Raytek Corporation.

All rights reserved.

Worldwide Headquarters

Santa Cruz, CA USA

Tel: +1 800 227 – 8074

+1 831 458 – 3900

Fax: +1 831 458 – 1239

solutions@raytek.com

(USA and Canada only)

CONTACTS

Berlin, Germany

Tel: +49 30 4 78 00 80

raytek@raytek.de

Beijing, China

Tel: +86 10 6438 4691

info@raytek.com.cn

Internet: http://www.raytek.com/

Thank you for purchasing this Raytek product. Register today at www.raytek.com/register to

receive the latest updates, enhancements and software upgrades!

info@raytek.fr

ukinfo@raytek.com

Specifications subject to change without notice.

Page 3

Every change of the standard system design must be acknowledged from Raytek;

WARRANTY

Raytek warrants this product to be free from defects in material and workmanship under normal use

and service for a period of two years from date of purchase except as hereinafter provided. This

warranty extends only to the original purchaser (a purchase from Raytek or Raytek’s licensed

distributors is an original purchase). This warranty shall not apply to fuses or batteries. Factory

calibration is warranted for a period of one year. The warranty shall not apply to any product which

has been subject to misuse, neglect, accident, or abnormal conditions of operation or storage. Should

Raytek be unable to repair or replace the product within a reasonable amount of time, purchaser’s

exclusive remedy shall be a refund of the purchase price upon return of the product.

In the event of failure of a product covered by this warranty, Raytek will repair the instrument when it

is returned by the purchaser, freight prepaid, to an authorize Service Facility within the applicable

warranty period, provided Raytek’s examination discloses to its satisfaction that the product was

defective. Raytek may, at its option, replace the product in lieu of repair. With regard to any covered

product returned within the applicable warranty period, repairs or replacement will be made without

charge and with return freight paid by Raytek, unless the failure was caused by misuse, neglect,

accident, or abnormal conditions of operation or storage, in which case repairs will be billed at a

reasonable cost. In such a case, an estimate will be submitted before work is started, if requested.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF

MERCHANTABILITY, FITNESS, OR ADEQUACY FOR ANY PARTICULAR PURPOSE OR USE.

RAYTEK SHALL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES, WHETHER IN CONTRACT, TORT, OR OTHERWISE.

otherwise the warranty of the complete system will be lost!

The device complies with the requirements of the European Directives.

EC – Directive 2004/108/EC (EMC)

Page 4

Content

Content .................................................................................................................................................................. 4

1. Safety Instructions ...................................................................................................................................... 8

2. Technical Data ............................................................................................................................................. 9

2.1 Specifications ............................................................................................................................................... 9

2.2 Scope of Delivery ........................................................................................................................................ 9

2.3 Weights and Dimensions ......................................................................................................................... 10

3. Description ................................................................................................................................................. 12

4. Pre-Installation .......................................................................................................................................... 13

4.1 Environment .............................................................................................................................................. 13

4.2 Scanner Distance to Kiln .......................................................................................................................... 13

4.3 Scanner Alignment ................................................................................................................................... 14

4.4 Trigger Bar ................................................................................................................................................. 14

4.5 Cable Requirements ................................................................................................................................. 14

4.6 PC Requirements ...................................................................................................................................... 17

5. Installation .................................................................................................................................................. 18

5.1 Mounting ................................................................................................................................................... 18

5.2 System Connection Box ........................................................................................................................... 20

5.2.1 Cable Entry System .............................................................................................................................. 21

5.3 Fibre Optic / RJ45 Ethernet Converter ................................................................................................... 22

5.4 Position Indicator ..................................................................................................................................... 23

5.5 Fibre Optic Converter Box ....................................................................................................................... 24

6. Configuration ............................................................................................................................................. 25

6.1 Software Installation ................................................................................................................................ 25

6.2 CS Configuration ...................................................................................................................................... 27

6.2.1 <General options>................................................................................................................................. 28

6.2.1.1 <General settings> Tab .................................................................................................................. 28

6.2.1.2 <Communications settings> Tab ................................................................................................... 29

6.2.1.3 <e-mail> Tab .................................................................................................................................. 32

6.2.2 <Colours and axes definition> .............................................................................................................. 33

6.2.2.1 <Colors> Tab ................................................................................................................................. 33

6.2.2.2 <Axes> Tab .................................................................................................................................... 33

6.2.3 <Kiln Settings> .................................................................................................................................... 34

6.2.4 <Position of Scanners / Pyrometers> .................................................................................................... 35

6.2.4.1 <Settings> for Scanner or Pyrometer ............................................................................................ 36

6.2.5 <Special Commands> ........................................................................................................................... 38

6.2.6 <Alarm zones> ...................................................................................................................................... 39

6.2.6.1 Repository of alarm zones configuration ....................................................................................... 39

6.2.6.2 Alarm Zone configuration detail ................................................................................................... 40

6.2.6.3 Alarm zone definition .................................................................................................................... 41

6.2.7 <Refractory> ......................................................................................................................................... 41

6.2.7.1 Repository of refractory configuration .......................................................................................... 41

6.2.7.2 Refractory configuration detail...................................................................................................... 42

6.2.7.3 Refractory zone definition ............................................................................................................. 43

Page 5

6.2.8 <Historical management> ..................................................................................................................... 43

6.2.8.1 <Images> Tab ................................................................................................................................. 43

6.2.8.2 <Others> Tab ................................................................................................................................. 44

6.2.9 <LRM Configuration> .......................................................................................................................... 44

6.2.10 <Digital Output Management> .......................................................................................................... 46

6.2.10.1 Repository of Digital Outputs ..................................................................................................... 46

6.2.10.2 Digital Output Management detail ............................................................................................. 46

6.2.11 <Daily Report> ................................................................................................................................... 47

6.2.12 <Management of Errors> .................................................................................................................... 48

6.2.12.1 Repository of errors ...................................................................................................................... 48

6.2.12.2 Error detail ................................................................................................................................... 48

6.2.12.3 Error list ...................................................................................................................................... 49

6.2.13 <Management of Alarms> .................................................................................................................. 50

6.2.13.1 Repository of alarms..................................................................................................................... 50

6.2.13.2 Alarms detail ................................................................................................................................ 51

6.2.13.3 Alarms list ................................................................................................................................... 51

6.2.14 <Users> ............................................................................................................................................... 52

6.2.14.1 Users Repository .......................................................................................................................... 52

6.2.14.2 User’s detail ................................................................................................................................. 53

6.2.15 <Update ReadScan> ............................................................................................................................ 56

7. Operation ..................................................................................................................................................... 57

7.1 ReadScan .................................................................................................................................................... 57

7.1.1 <Control> Tab ....................................................................................................................................... 58

7.1.2 <Scanners> Tab ..................................................................................................................................... 58

7.1.3 <Pyrometers> Tab ................................................................................................................................. 59

7.1.4 <LRM> Tab ........................................................................................................................................... 59

7.1.5 <OPC Server> Tab ................................................................................................................................ 60

7.1.6 <Log> Tab ............................................................................................................................................. 60

7.2 CS Runtime Software: Deneb .................................................................................................................. 61

7.2.1 <Main> <Real time> ............................................................................................................................. 61

7.2.2 <Main> <Historic time> <Short term> ................................................................................................. 64

7.2.3 <Main> <Historic time> <Long term> .................................................................................................. 66

7.2.4 <Main> <Reference image> ................................................................................................................... 66

7.2.5 <Secondary> <Internal temperatures> .................................................................................................. 66

7.2.6 <Secondary> <Burning zone graphic> .................................................................................................. 67

7.2.7 <Secondary> <LRM view> .................................................................................................................... 67

7.2.7.1 <Kiln view> Tab ............................................................................................................................. 67

7.2.7.2 <Vertical> Tab ................................................................................................................................ 68

7.2.7.3 <Horizontal> Tab ........................................................................................................................... 68

7.2.7.4 <Time trend> Tab ........................................................................................................................... 69

7.2.7.5 <Space trend> Tab .......................................................................................................................... 69

7.2.8 <Secondary> <Areas of Interest> .......................................................................................................... 70

7.2.9 <Secondary> <Errors> .......................................................................................................................... 70

7.2.10 <Secondary> <Alarms> ....................................................................................................................... 71

7.2.11 <Graphic> <Histogram> ..................................................................................................................... 73

7.2.12 <Graphic> <Trend> ............................................................................................................................. 74

7.2.13 <Graphic> <Difference between images> ............................................................................................ 75

7.2.14 <Reports> ............................................................................................................................................ 75

Page 6

7.2.14.1 Report Production History .......................................................................................................... 75

7.2.14.2 Daily Report ................................................................................................................................ 76

7.2.15 Command Line Options for Deneb ..................................................................................................... 77

8. Database ...................................................................................................................................................... 78

8.1 Concept ...................................................................................................................................................... 78

8.2 Historic Review......................................................................................................................................... 78

8.3 File Naming Convention ......................................................................................................................... 78

8.4 Backing Up all Data .................................................................................................................................. 79

8.5 Restoring THR Data ................................................................................................................................. 79

9. Options ........................................................................................................................................................ 80

9.1 Start-up-Service......................................................................................................................................... 80

10. Accessories .............................................................................................................................................. 81

10.1 Hardware ................................................................................................................................................. 81

10.2 Software ................................................................................................................................................... 81

10.3 Serial RS485 / RJ45 Ethernet Converter ............................................................................................... 82

10.3.1 Technical Data ................................................................................................................................... 82

10.3.2 LED Indicators ................................................................................................................................... 83

10.3.3 Driver Installation ............................................................................................................................. 83

10.4 Fan Control .............................................................................................................................................. 86

10.4.1 Technical Data ................................................................................................................................... 86

10.4.2 Installation ......................................................................................................................................... 86

10.5 LRM – Live Ring Migration .................................................................................................................. 87

10.5.1 Functionality ...................................................................................................................................... 87

10.5.2 LRM Remote Control ......................................................................................................................... 87

10.5.3 Position Indicator ............................................................................................................................... 88

10.5.4 Wiring ................................................................................................................................................ 89

10.6 Shadow Monitoring ............................................................................................................................... 90

10.7 Burning Zone Monitoring ..................................................................................................................... 92

10.8 Internal Heater ........................................................................................................................................ 94

11. Auxiliary Software ................................................................................................................................ 95

11.1 Managing the CS Database with DBCheck ......................................................................................... 95

11.1.1 Starting the DBCheck application ...................................................................................................... 95

11.1.2 Connecting to the database ................................................................................................................. 95

11.1.3 Migrating pre-existing CS100 data ................................................................................................... 96

11.1.4 Import and export CS configurations ................................................................................................. 97

11.1.5 Creating a backup file ......................................................................................................................... 98

11.1.6 Reset database ..................................................................................................................................... 99

11.2 Remote Access from a Client PC ........................................................................................................ 100

11.2.1 Enabling Remote Access to Readscan .............................................................................................. 100

11.2.2 Remote Access .................................................................................................................................. 100

11.3 Device Testing Programme: PComm ................................................................................................. 101

11.3.1 <Check operation> Window .............................................................................................................. 101

11.3.1.1 Scanner ...................................................................................................................................... 101

11.3.1.2 Pyrometer .................................................................................................................................. 102

11.3.1.3 Digital Output .......................................................................................................................... 103

11.3.1.4 LRM .......................................................................................................................................... 104

Page 7

11.4 Refractory Management ....................................................................................................................... 105

11.4.1 Configuration .................................................................................................................................... 105

11.4.1.1 Kiln State ................................................................................................................................... 105

11.4.1.2 Refractory Management ............................................................................................................ 106

11.4.1.3 Brick Manufacturers .................................................................................................................. 110

11.4.1.4 Brick Types ................................................................................................................................ 110

11.5 3D Real Time View ............................................................................................................................... 112

12. Troubleshooting ................................................................................................................................... 113

13. Drawings ............................................................................................................................................... 114

13.1 CS212 Installation without Accessories ............................................................................................. 114

13.2 CS212 Installation with Accessories ................................................................................................... 115

13.3 CS21x with Multiple Scanners............................................................................................................. 116

13.4 System Connection Box Wiring .......................................................................................................... 117

13.5 Fibre Optic Converter Box Wiring ...................................................................................................... 119

13.6 Position Indicator Wiring ..................................................................................................................... 120

13.7 Fan Control Wiring ............................................................................................................................... 121

13.8 LRM Wiring ........................................................................................................................................... 122

13.8.1 Terminal Wiring W8 ........................................................................................................................ 123

13.8.2 Terminal Wiring W9 ........................................................................................................................ 124

13.8.3 Internal Wiring for the Position Indicators 4, 5, 6 ........................................................................... 124

13.9 Shadow Monitoring Wiring ................................................................................................................. 125

13.10 Burning Zone Wiring .......................................................................................................................... 126

14. Appendix – Technical Data ................................................................................................................ 127

14.1 Protective Housing ............................................................................................................................... 127

14.2 Connection Box ..................................................................................................................................... 128

14.3 Fibre Optic / RJ45 Ethernet Converter ................................................................................................ 129

14.4 Connection Box for Accessories .......................................................................................................... 130

14.5 Position Indicator .................................................................................................................................. 131

14.6 Output Modules .................................................................................................................................... 132

14.6.1 Digital Output Module 7043 (16 channels) ..................................................................................... 132

14.6.2 Relay Output Module 7067 (7 channels) ......................................................................................... 132

15. Notes ....................................................................................................................................................... 133

Page 8

Safety Instructions

o to Fluke’s website for

The instrument is equipped with a Class 2 laser. Class 2 lasers shine only within the

mW. Looking directly into the laser beam can produce

, temporary blinding effect, but does not result in physical injury or damage to the

eyes, even when the beam is magnified by optical aids. At any rate, closing the eye lids is

reflections of the laser beam. The laser functions only to locate and mark surface

Incorrect use of 110 / 230 V electrical systems can result in electrical hazards and personal

All instrument parts supplied with electricity must be covered to prevent physical

1. Safety Instructions

This document contains important information, which should be kept at all times with the system

during its operational life. Other users of this instrument should be given these instructions with the

instrument. Updates to this information must be added to the original document. The instrument can

only be operated by trained personnel in accordance with these instructions and local safety

regulations.

Acceptable Operation

This instrument is intended only for temperature measurement and is appropriate for continuous use.

The instrument operates reliably in demanding conditions, such as in high environmental

temperatures, as long as the documented specifications are adhered to. Compliance with the operating

instructions is necessary to ensure the expected results.

Unacceptable Operation

The instrument should not be used for medical diagnosis.

Replacement Parts and Accessories

Use only original parts and accessories approved by the manufacturer. The use of other products can

compromise the operational safety and functionality of the instrument.

Instrument Disposal

Do not dispose of this product as unsorted municipal waste. G

recycling information.

Operating Instructions

The following symbols are used to highlight essential safety information in the operation instructions:

Helpful information regarding the optimal use of the instrument.

Warnings concerning operation to avoid instrument damage and personal injury.

visible spectrum at an intensity of 1

a slight

encouraged when eye contact is made with the laser beam. Pay attention to possible

measurement targets. Do not aim the laser at people or animals.

injury.

contact and other hazards at all times.

8 Rev. B4 Feb 2015 CS210

Page 9

Technical Data

2. Technical Data

2.1 Specifications

Linescanner

Type MP150HR linescanner

Temperature range: 100 to 650°C (212 to 1202°F)

1

Optical resolution (90% energy) 170 : 1 (IFOV = 5,9 mrad)

Spot detection (50% energy) 510 : 1 (IFOV = 2,0 mrad)

Spectral response: 3.5 to 4 µm

Scan angle (FOV): 90°

Accuracy: ± 0.5% of reading or ± 3°C (± 6°F)

at 0 - 50°C (32 - 122°F) ambient temperature for the scanner

Repeatability: ± 1°C (± 2°F),

Detector: HgCdTe

Sampling rate: 1024 pixel per scan line

Standard focal distance: infinity

Mechanical scanning system: MTBF: 40,000 hours

Power requirement: 100 to 240 VAC (for the system connection box in the field)

Protection rate: IP65 (NEMA4) protection for linescanner

Ambient temperature range:

(for scanner with housing)

- without cooling: -40 to 45°C (-40 to 113°F), no direct sunlight

Warm-up time: 20 minutes

System

Scan lines: 200

Min. kiln speed: 0.02 rpm (for synchronized measurement)

Max. kiln speed: 6 rpm @ 200 lines @ 20 Hz scan speed

Packaging: CS211: about 40 kg (88 lb)

CS212: about 80 kg (176 lb)

at 0 - 50°C (32 - 122°F) ambient temperature for the scanner

(for synchronized measurement)

2

whichever is greater,

2.2 Scope of Delivery

The standard CS211 package includes:

Scanner: Linescanner MP150HR

(CS212: 2 units, CS213: 3 units, CS214: 4 units)

7.5 m (24.6 ft) Ethernet cable

7.5 m (24.6 ft) power cable

1

at 20 Hz scan speed

2

at 20 Hz scan speed

CS210 Rev. B4 Feb 2015 9

Page 10

Technical Data

7.5 m (24.6 ft) alarm/trigger cable

7.5 m (24.6 ft) RS485 cable

Spare window

Protective Housing: XXXSYSPHSS, stainless steel box

(CS212: 2 units, CS213: 3 units, CS214: 4 units)

grommet kit

adjustable mounting bracket

Spare Window: for protective housing, XXXSYSPHSW

Position Indicator: High temperature inductive sensor with junction box

(XXXSYSSECPI)

System Connection Box (field) CS210CONBOX

(CS212: 2 units, CS213: 3 units, CS214: 4 units)

with:

Fibre Optic / RJ45 Ethernet Converter:

4x Ethernet, 2x fibre optic channels

and:

Power Supply 100/240 VAC to 24 VDC, 2.5 A

Fibre Optic patch cable with SC connector, 2 m (6.6 ft) - 2 pieces

Fibre Optic Converter Box XXXHSFICBOX (control room)

with:

Fibre Optic / RJ45 Ethernet Converter:

4x Ethernet, 2x fibre optic channels

and:

Power Supply 110/230 VAC to 24 VDC, 1.25 A

Ethernet patch cable, 2 m (6.6 ft)

Fibre Optic patch cable with SC connector, 2 m (6.6 ft) - 2 pieces

Tool Kit: Hex key wrench 2.5 mm

Hex key wrench 4 mm

Hex key wrench 5 mm

Wrench 7x8 and 10x13

Key for locking/unlocking enclosure doors

DVD: DataTemp CS Software (incl. manuals, presentations, tools)

Documentation: CS210 Manual,

MP150 Operating Instructions,

MP150 Protocol Manual (on DVD only)

2.3 Weights and Dimensions

Linescanner: Length: 180 mm (7.09 in)

Width: 120 mm (4.72 in)

Height: 200 mm (7.87 in)

Weight: 7 kg (15.4 lbs)

Protective Housing: Length: 300 mm (11.81 in)

Width: 300 mm (11.81 in)

Height: 300 mm (11.81 in)

Weight: 8 kg (17.6 lbs)

10 Rev. B4 Feb 2015 CS210

Page 11

Technical Data

Protective Housing: Length: 452 mm (17.79 in)

(with mounting bracket Width: 496 mm (19.53 in

and protective sighting channel) Height: 450 mm (17.72 in)

Weight: 13 kg (28.6 lbs)

Position indicator:

Sensor head: Length: 50 mm (1.97 in)

Diameter: 50 mm (M50 x 1,5) (1.97 in)

Weight: 0.3 kg (0.66 lbs)

Junction box: Length: 84 mm (3.31 in)

Length: 110 mm (4.33 in) with electronic tube

Width: 79 mm (3.11 in)

Height: 67 mm (2.64 in)

Weight: 0.7 kg (1.5 lbs)

System Connection Box: Width: 380 mm (15 in)

Height: 380 mm (15 in)

Deep: 210 mm (8.3 in)

Weight: 9.8 kg (22 lb) - netto

CS210 Rev. B4 Feb 2015 11

Page 12

Description

3. Description

The Raytek CS210 is a comprehensive temperature measurement system for the monitoring, control,

and analysis of rotating kiln shells used in cement and lime production, mineral processing,

hazardous waste incineration and other processes. This system is a unique combination of hardware

centered on the industry-leading MP150 linescanner and a powerful, industrial software package. The

system allows accurate monitoring of the kiln shell and early detection of hot spots indicating

damaged or missing refractory bricks, preventing costly kiln damage and

extending production runs.

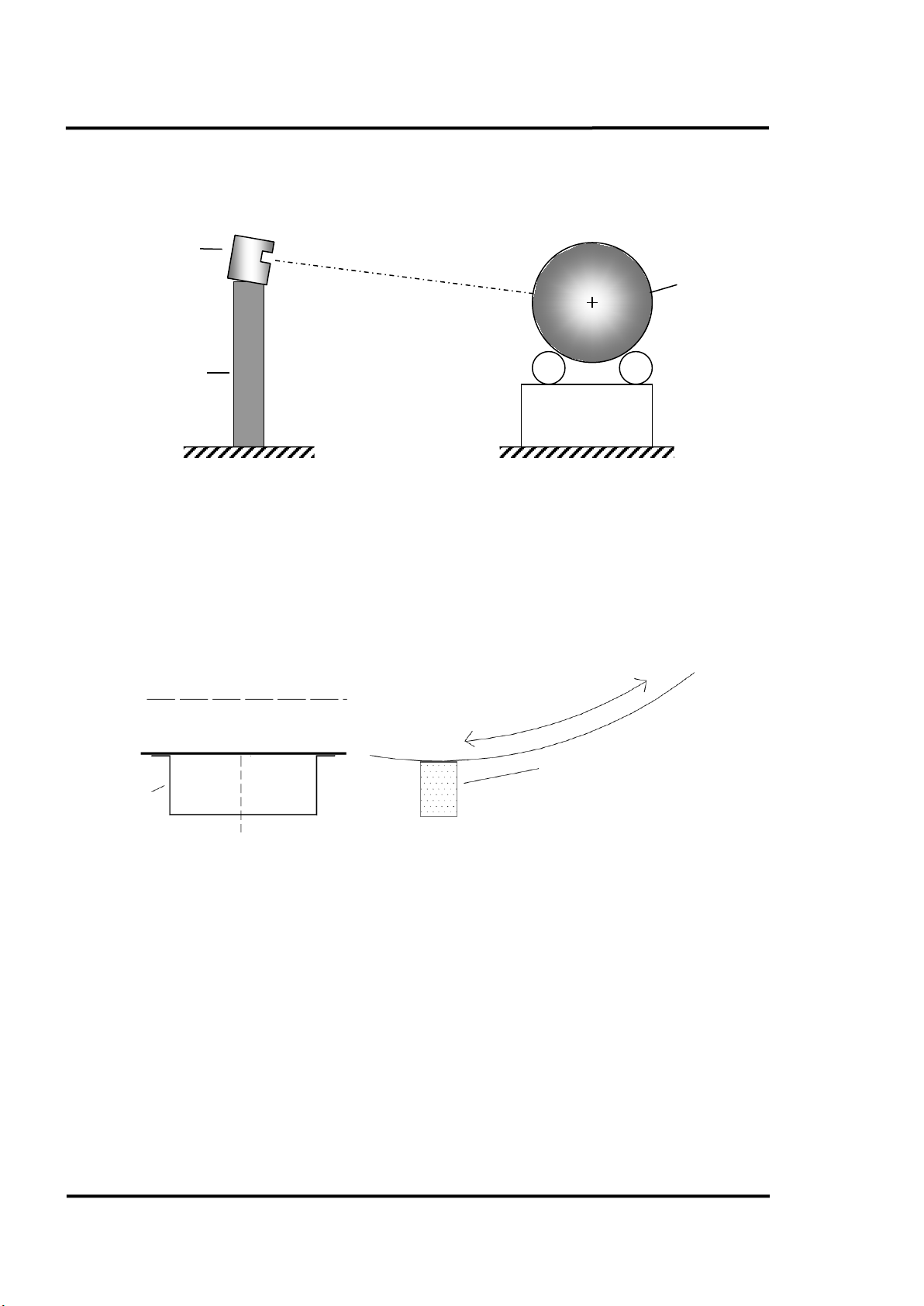

The key component of the CS210 system is an infrared linescanner (CS212

system: two linescanners). The linescanner collects infrared energy, emitted

from the kiln surface allowing the system to measure the temperature along the

length of the kiln.

The CS210 system provides many features, which include full-color

thermograms of the kiln surface, user defined alarms, automatic fan control and extensive historical

data analysis capability. The CS210 system also adds OPC server functionality, a powerful SQL server

for database applications, and full integration of all available accessories. Most notably, additional

point sensors can be installed and configured to monitor portions of the kiln “shadowed” from the

main sensor by physical obstructions and the results displayed as one homogenous thermogram.

Similarly, a separate sensor is available to monitor the burning zone of the kiln and again the data will

be seamlessly incorporated into one common display in the control room.

Using a optical fibre cable from the scanner in the field to the PC Ethernet interface in the control room

is a reliable way for connecting. Using fibre optics, you can prevent electrical interference from

corrupting the CS210 system. The optical fibre cable supports high speeds and long distance

transmissions (up to 2 km / 1.2 mi). One fibre optic communication line only from the field to the

control room minimizes the installation efforts on-site.

For a complete system overview see section 13.2 CS212 Installation with Accessories, page 115.

12 Rev. B4 Feb 2015 CS210

Page 13

Pre-Installation

L

2

1

D ≥

D

L

Scanner

Kiln

4. Pre-Installation

The customer is responsible for preparation of the sensor stand, installation of the position indicator

with the trigger bar and the complete field wiring as indicated in the appendix.

4.1 Environment

Please take note of the following:

• The maximum ambient temperature for the scanner within the protective housing is 45°C (113°F).

If necessary, add an additional shaded roof to protect the protective housing from direct sunlight

or provide water direct to the scanner.

• For details on grounding the sensor stand, please refer to the local building codes for lightning

protection.

• The housing of the linescanner and the system connection box must have the same potential.

(Check for good electrical contact at grounding wire connection).

4.2 Scanner Distance to Kiln

The standard system, CS211, is a one-scanner system and is suited for small to medium length kilns

up to 60 m (200 ft) in length. For longer kilns the CS212, a two-scanner system, will be required.

The linescanner has a 90° scan angle. The distance between the scanner and the kiln required for

complete coverage of the kiln length can be calculated as follows:

where:

D … Distance between scanner and kiln

L … kiln length (required scan width)

Figure 1: Distance between Scanner and Kiln

CS210 Rev. B4 Feb 2015 13

Page 14

Pre-Installation

Scanner stand

(dedicated tower or

roof of a building)

Scanner

Kiln

Kiln axis

Rotation

Kiln

Trigger bar

Trigger

bar

4.3 Scanner Alignment

The optimal scanner alignment is shown in the figure below.

Figure 2: Alignment of Scanner

4.4 Trigger Bar

A position indicator is mounted on the “colder” end of the kiln and generates a trigger pulse once per

revolution to supply the CS210 system with data on the rotational speed of the kiln. The installer must

mount a trigger bar onto the kiln shell as shown in the figure below.

The maximum ambient temperature for the position indicator is 230°C (446°F). For installing the

position indicator see section 5.4 Position Indicator, page 23.

4.5 Cable Requirements

The following cables are necessary for standard installations, see also system drawings given in

section 13.1 CS212 Installation without Accessories, page 114.

– W1 power supply cable for scanner (preinstalled with system connection box)

– W2 RS485 communication cable for scanner (preinstalled with system connection box)

– W3 trigger/alarm cable for linescanner (preinstalled with system connection box)

– W8 from the junction box of the position indicator to the system connection box (standard

– W9 from the LRM remote control box to the system connection box. This six-wire-cable is used for

14 Rev. B4 Feb 2015 CS210

Figure 3: Welding the Trigger Bar on the Kiln

installation) or to LRM remote control box (when used with accessory Live Ring Migration).

data communication, power supply, and trigger pulse.

Page 15

Pre-Installation

All copper cables must be shielded! The wires from W9, W10, W14, and W15 must be a

– W10 from the fan control output module to the system connection box. This four-wire-cable is

used for data communication and power supply to the output module.

– W14 from the MI connection box to the system connection box and between MI connection boxes

when more than one shadow sensor is installed. This four-wire cable is used for data

communication and power supply to the pyrometer.

– W15 from the MR connection box to the system connection box. This six-wire cable is used for

data communication and power supply to the pyrometer.

– W16 MI sensing head cable.

– W17 MR sensing head cable.

– W18 Ethernet communication cable for scanner (preinstalled with system connection box)

– W20 Fibre optic cable from system connection box to the control room and to the second scanner

(if used). Fibre optic cable to be provided by customer.

– W22 Ethernet cable from fibre optic converter (control room) to the PC.

– W23 from the position indicator head to the junction box.

– W24 Power supply cable 100 to 240 VAC.

– W25 Fibre optic cable from the first scanner to the second scanner (if used). Fibre optic cable to be

provided by customer.

twisted pair! Local building codes should be observed when selecting cables!

CS210 Rev. B4 Feb 2015 15

Page 16

Pre-Installation

Cable

Distance

Cable features

Supplied from …

Example / Remarks

W1, W2,

W3

7.5 m (25 ft.)

preinstalled

Raytek

W8

350 m (380 yd)

3 x 0.25 mm²,

24 AWG, 3 conductor, shielded

Customer

(N)YLHCY-J 3 × 0.25 mm²

Manhattan/CDT, P/N M13233

W9

350 m (380 yd)

3 x 2 x 0.25 mm²,

24 AWG, 3x twisted pair, shielded

Customer

LifYCY 3 × 2 × 0.25 mm²

W10

350 m

(380 yd)

2 x 2 x 0.25 mm²,

24 AWG, 2 x twisted pair, shielded

Customer

W14

350 m (380 yd)

2 x 2 x 0.5 mm²,

20 AWG, 2 x twisted pair, shielded

Customer

max. 5 pyrometers

350 m (380 yd)

2 x 2 x 1.5 mm²,

16 AWG, 2 x twisted pair, shielded

Customer

max. 14 pyrometers

W15

350 m (380 yd)

3 x 2 x 1.5 mm²,

16 AWG, 3x twisted pair, shielded

Customer

W16

8 m (26 ft)

preinstalled

Raytek

W17

15 m (49 ft.)

preinstalled

Raytek W18

7.5 m (25 ft.)

Raytek

W20

< 2 km (1.2 mi)

Fibre optic cable (outdoor),

connectors

Customer

Standard cable designation:

W22

2 m (6.5 ft.)

Ethernet patch cable (CAT5, RJ-45)

Raytek W23

5 m (15 ft.)

Raytek

W24

Power supply cable 100 to 240 VAC,

50 / 60 Hz, min. 3 x 1.5 mm² (16 AWG)

Customer

NYY

W25

< 2 km (1.2 mi)

Fibre optic cable (outdoor),

connectors

Customer

Standard cable designation:

The cable length causes a certain voltage drop on the power cable. In case of using

it must always be ensured, that the sensor will be supplied with the minimal voltage

Linescanner: min. 18 VDC

2 fibres, multi-mode, 62.5/125 µm or

50/125 µm, equipped with SC

2 fibres, multi-mode, 62.5/125 µm or

50/125 µm, equipped with SC

multiple sensors (MI shadow pyrometers via W14), longer cable lengths, or less gauges

power!

MR burning zone pyrometer: min. 20 VDC

MI shadow pyrometer: min. 12 VDC

A-DQ(ZN)B2Y…

A-DQ(ZN)B2Y…

16 Rev. B4 Feb 2015 CS210

Page 17

4.6 PC Requirements

software exclusively on the PC! Other

TCP/UDP Port

Server

Client

Remark

16500

CS Readscan

CS Deneb

1433

CS SQL database

CS Config, CS Readscan

25

CS Mail (SMTP)

CS Readscan

default

2727

Linescanner Communication

CS Readscan

default

5048, 5058

Serial RS485 / RJ45 Ethernet Converter

CS Readscan

as accessory only

23

Telnet

for service only

Minimum Hardware requirement for CS211 and CS212:

− Processor: Intel i5 quad core series CPU or comparable

− 8 GB RAM system memory

− 1280 x 1024 pixel graphic card and monitor

(for displaying one scanner with 1024 pixel per line)

2560 x 1600 pixel graphic card and monitor

(for displaying two scanners with 2048 pixel per line)

− OpenGL 2.1 graphics adapter (when using the 3D Real Time View)

− 50 GB hard disk

− DVD drive

− Ethernet, TCP/IP protocol, 100 Mbit/s

Minimum Software requirement:

− Windows

®

XP or Windows 7 3 with latest Service Pack

It is strongly recommended to run the CS

applications could affect function and performance.

Pre-Installation

For the CS system it is necessary to disable Windows' default power management

settings in order to avoid that the computer goes to sleep automatically.

Make sure that a possible firewall does not block the following ports:

3

Windows Vista should work but it is not guaranteed.

CS210 Rev. B4 Feb 2015 17

Page 18

Installation

Bottom view

Protective Housing

Bottom view

5. Installation

5.1 Mounting

The linescanner protective housing requires a solid vibration-free mounting stand. The protective

housing comes with a mounting bracket, adjustable 90° in all 3 axes. To mount the protective housing

onto the sensor stand, e.g. on a tower, make a mounting plate with two 8.5 mm (0.31 in.) diameter

mounting holes, as shown below. The mounting bracket is 150 mm (5.9 in) high.

Figure 4: Protective housing’s 3-axis mounting bracket

Preparing the protective housing to be mounted on the sensor stand

Open the protective housing from the back to access to the internal components. On the bottom of the

box, there is a rail/carrier system on which the linescanner will be mounted. Open the latches on both

sides of the rail, loosen the bolt on top of the carrier and take off the carrier. Mount the linescanner

onto the carrier using the 4 M6 x 12 screws provided. Connect the earth ground to the top of the

linescanner. To install the ground on the left mounting thread, use a M6 x 12 hex head screw with

washer and lock washer.

Mounting the protective channel and the window

Open the front door of the protective housing. Mount the protective field-of-view channel on the front

side by using 6 M4 x 12 bolts. The slotted side of the protection channel faces downwards. The bolts

must be inserted from inside the box (i.e. the nuts are outside).

Make sure that the drain hole for rain water in the protective channel faces downwards!

18 Rev. B4 Feb 2015 CS210

Page 19

Installation

Window holder

2 nuts – M6

Protective

housing

Protective

channel

Linescanner

Figure 5: Protective housing with protective channel

Installing the linescanner

Open the back door. Insert the linescanner (with the mounted carrier) into the rail/carrier system. Lock

in the linescanner in place with the latches and screw.

Electrical Installation

For best performance, the electrical installation of the CS210 System should correspond to one of the

recommended installation configurations illustrated in section 13.1 CS212 Installation without

Accessories, page 114.

Connecting the cables

The cables W1, W2, W3, and W18 (located between the linescanner and the system connection box) are

factory preinstalled and supplied along with the system connection box.

For running the cables through the protective housing: open one grommet plate (on the bottom of the

protective housing) by loosening the three Allen-bolts. Use an appropriate grommet by considering

the different cable outer diameters:

• Cable W1 (power supply): Ø 5 mm (0.2 in)

• Cable W18 (Ethernet): Ø 6 mm (0.24 in)

• Cable W2 (RS485) and W3 (Alarm/Trigger): Ø 7 mm (0.28 in)

Feed the cable through the grommets so that grommet is approximately 400 mm (15.7 in) away from

the linescanner connectors (round plugs). Place the grommet plate over the grommets as shown in the

figure below. Be careful to have the cable identification plates pointed toward the system connection

box (longer end of the cables). Close unused holes with the blind grommets then close the grommet

plate.

CS210 Rev. B4 Feb 2015 19

Page 20

Installation

cooling may be necessary.

Mains

Plug

Fuse

6 A

Power

Supply

Serial/Ethernet

Fibre Optic /

Heater

Grommet plate

Figure 6: Cable installation

Using the 4 M5x25 screws, mount the grommet plate on the outside of the protective housing. Plug

the cable connectors into the linescanner. Connect the socket and the plug for earth ground.

If installing the CS210 system in a warm environment, waterThe tubes used for water may be run through the second grommet plate!

5.2 System Connection Box

The system connection box connects all device field cables with the customer supplied optical fibre

cable. The system connection box includes the Fibre Optic / RJ45 Ethernet Converter, the 24 VDC

power supply and the Serial/Ethernet converter for supporting the accessories (if used).

The box is supplied with quick installation line-up terminals. For more technical data, see section

14.2 Connection Box, page 128.

RJ45 Ethernet

Converter

Converter

(Accessory)

(Accessory)

20 Rev. B4 Feb 2015 CS210

Figure 7: Opened System Connection Box

Page 21

Installation

Lay cable into appropriate grommet and provide strain relief

Use appropriate tool to punch through cover on base frame.

Pin 18

Pin 17

Installation

The system connection box can be mounted up to 7 meters (23 ft) away from the scanner. However to

simplify aiming the scanner at the kiln it is the best that the connection box is mounted as close to the

scanner as possible. The cables between the linescanner and the connection box needs to be protected

from mechanical damage.

Mount the connection box in a convenient location. The cables W1, W2, W3, and W18 are factory

preinstalled. Insert the cable W20 using the grommet plate taking care to select the correct grommet

size for the cable diameter.

Connect the cables for the accessories with the connectors of the line-up terminal as described in

section 13.4 System Connection Box Wiring, page 117.

After double-checking all connections, switch the power on. The 24V-LED indicates the ON/OFF

status (see terminal pin 8 in the system connection box). Check the trigger signal coming from the

position indicator (see terminal pin 40 in the system connection box).

Pins 17 and 18 of the terminal in the system connection box connect to the internal alarm relay of the

scanner. The contacts are potential free, the maximum load is 30 V / 1 A. To configure the alarm relay,

see section 6.2.4.1 <Settings> for Scanner or Pyrometer, page 36.

Figure 8: Connection to the internal Alarm Relay of the Scanner

5.2.1 Cable Entry System

The cable entry system is a split system that allows pre-assembled cables to be routed into the system

connection box without disassembling the connectors.

Snap-on mounting

4

where necessary using cable ties.

4

Illustrations: © Murrplastik

CS210 Rev. B4 Feb 2015 21

Page 22

Installation

Set catch hooks into the sides of the cut-out.

Insert rail completely.

Set the rail onto the catch hooks and press on.

Lock the catch hooks with the rail. Press gently on grommet one

The grommet must produce a continuous seal on the back side.

more time.

5.3 Fibre Optic / RJ45 Ethernet Converter

The Fibre Optic / RJ45 Ethernet Converter assures high reliability and

stability in harsh environments, making it a robust bridge between enterprise

fibre-optic backbones and Ethernet devices like the linescanner. Using fibre

optics, you prevent electrical interference from corrupting the CS210 system.

The Fibre Optic / RJ45 Ethernet Converter supports fast speed and high

distance transmissions. Copper based Ethernet communication is very

limited in length without using a repeater.

The Fibre Optic / RJ45 Ethernet Converter in the system connection box is

converting up to 4 Ethernet channels to support one or two scanners and the

CS210 accessories. The Fibre Optic / RJ45 Ethernet Converter in the control

room is converting the glass fibre signals back to TCP/IP Ethernet again. For further technical details

see appendix 14.3 Fibre Optic / RJ45 Ethernet Converter, page 129.

22 Rev. B4 Feb 2015 CS210

Page 23

Installation

In the case of a non-existing trigger signal, the system switches to the non-synchronized

software will blink

5.4 Position Indicator

The position indicator is a temperature resistant inductive proximity

switch used to synchronize the scanning system with the kiln rotation.

The position indicator consists of two parts, a high temperature sensor

head, and a junction box. Since the maximum ambient temperature

allowed is 230°C (446°F), the sensor may be mounted near the kiln’s

surface. For the junction box a maximum ambient temperature of 70°C (158°F) is allowed. For further

technical details see appendix 14.5 Position Indicator, page 131.

Both components, sensor and junction box, are connected via a high temperature cable (length: 5 m /

15 ft). Protecting the cable against mechanical stress is recommended. Since the position indicator is

necessary to generate a trigger pulse for the CS210 system, a trigger bar must be welded onto the

“colder“ end of the kiln and if possible close to the drive ring (see Figure 9).

The distance between the trigger bar and the position indicator is a very important parameter for

correct operation. If the distance is too small, the trigger bar can destroy the sensor head. On the other

hand, if the distance is too big, the position indicator will be unable to detect the trigger bar. Thus, it

will not be able to generate the trigger pulse for the system.

mode. In this mode, a yellow bar on the top area in the CS

continuously. Non-synchronized thermograms are not stored in the database!

In multi-scanner systems, the trigger signal may be associated with any scanner!

CS210 Rev. B4 Feb 2015 23

Page 24

Installation

Kiln axis

Rotation

Kiln

Trigger bar

steel St37

square (2.16

Trigger bar

Distance: max. 20 mm (0.79 in.)

Position indicator with

mounting pla

PTFE cable, 5 m (15 ft.)

Junction box

Cable W8 to system connection box

, sized 50 mm in

in. in square)

te

Figure 9: Mounting the Position Indicator

Adjustment of the position indicator:

1. Mount the trigger bar.

2. Mount the position indicator mounting plate .

3. Check the distance between position indicator and trigger bar.

4. Lock the position indicator in place and monitor its’ operation. With each revolution of the

kiln you should obtain a trigger pulse indicated by an LED in the junction box (field).

5.5 Fibre Optic Converter Box

The Fibre Optic Converter Box is located in the control room and connects the fibre optic cable from

the field to the Ethernet interface of the computer. For more technical data, see section 14.2 Connection

Box, page 128.

24 Rev. B4 Feb 2015 CS210

Figure 10: Fibre Optic Converter Box

Page 25

Configuration

The software installation requires the user as local administrator with full permission

It is strongly recommended to update the Windows operating system before installing

Make sure that the default SQL port 1433 is not in use; otherwise you will be not able to

c shutdown,

6. Configuration

The following sections of this manual describe the operation of the CS software. Complete

configuration requires the following steps:

1. Install the software.

2. Configure the system.

a. Provide detail of certain general options.

b. Define detail of visual appearance options.

c. Define temperature reading instruments (scanners and pyrometers).

d. List alarm zones and refractory details.

e. Need for controlling of fans

f. Provide detail of the LRM system installation.

g. Define preferences for storing historical data.

Before proceeding with the following sections please ensure that the physical installation

(communication and power wiring, air, water if necessary, etc.) is completed and working

satisfactorily.

6.1 Software Installation

whereby the administrator requires a dedicated password (network and non-password

accounts do not work).

the CS software!

install the software.

Disable all energy saving functions of the operating system like automati

energy saving modes, and hard drive spin down!

Insert the software DVD in the DVD drive and double click on the <Setup.exe> file. The install setup

application will start, showing the following steps in a screen window.

• When the install setup starts up, a welcome screen will show, letting you select the default

language for the application. Once you have selected the language, click on <Next> to

continue.

• Next, select the path where you want to install the application and the folder where you want

the database to be installed. When finished, click on <Next>.

CS210 Rev. B4 Feb 2015 25

Page 26

Configuration

Figure 11: Installation screen

• Once you have completed selecting your preferences, you can click on <Install> to proceed

with the installation.

• In one of the next screens, you have to give a valid <user name> and <password> for an

administrative user for a domain on the installation computer to allow the SQL database

server to be executed.

Figure 12: Administrative User for the Computer Domain

In case of installation problems uncheck the <Try to install SQL Server automatically>

item!

• On the last installation screen, you can activate the check box to import an old CS100

configuration and a CS100 database into CS software. After closing the install setup you will

be guided through the migration procedure.

26 Rev. B4 Feb 2015 CS210

Page 27

Configuration

In addition, you find also the check box to start automatically ReadScan when Windows

starts. It is strongly recommended to keep this check box enabled!

Figure 13: Installation finished

• If the installation is successful, all necessary shortcut icons will appear in your PC desktop

screen and in the Start-menu (Start\Programs\Raytek\DataTemp CS).

For Windows Vista and Windows 7 operating systems, the user data will be stored in

the dedicated <My Documents> folder separately from the program files!

6.2 CS Configuration

To configure the DataTemp CS software, select the start menu, activate the CS program group and

click on the icon <CS Config> (alternatively you can also find the icon on the desktop). You will be

prompted to enter a password.

Figure 14: Authentication screen

At this point, a valid user and password must be entered for the selected profile. If this is the first

login, a single profile will be seen, and that profile is normally <Raytek>.

Predetermined user for CS Config (valid also for the program components CS Deneb and ReadScan):

Username: <ADMIN>

Password: {empty}

CS210 Rev. B4 Feb 2015 27

Page 28

Configuration

When ReadScan is active, any changes made in the configuration settings won’t be

ctive until ReadScan restarts automatically later. For more information on this topic

uested physical units (distance and

The configured scanner data format <points per line> applies to all scanners and

database backups. The data format (256 pixel / 512 pixel / 1024 pixel, 1 byte / 2 byte and

200 lines) must not be mixed. The same resolution is used for every scanner

Once these 3 boxes are correctly filled, the user will proceed to a new screen and select the different

menu options.

effe

see section 7.1.1 <Control> Tab, page 58.

6.2.1 <General options>

6.2.1.1 <General settings> Tab

This tab allows the user to configure the general aspects of the system, such as description, language,

maximum and minimum temperature to be seen from Deneb, the amount of lines formed per

thermogram and metric or imperial units. In standard installations the scanner communicates via

Ethernet, there are no speed restrictions to consider.

Figure 15: General options: <General Settings> Tab

It is strongly recommended to select the req

temperature) before all others changes!

100 /

connected and all database backups loaded into the system!

28 Rev. B4 Feb 2015 CS210

Page 29

Configuration

The number of lines per thermogram is a parameter that can only be modified when the

western European languages (Turkish, Russian) it is strongly

Points per line

Bytes per point

Minimum serial speed

256 1 115 kBaud

512 1 115 kBaud

database is empty, (i.e. when the database does not contain any images)!

For running of nonrecommended to use a Windows Operating System in that desired language!

Non-western European languages can also be displayed by setting the Windows codepage

accordingly.

• Go to <Start> <Settings> <Control Panel> <Regional and Language Settings>

• Under <Regional Settings> select the desired language

• Under <Advanced> select the same desired language for programmes not supporting Unicode

fonts

For old systems only, running with RS485 communications:

The number of data points per line and the number of bytes per data point needs to be considered in case of running the

scanner via the serial RS485 communication line. The table below shows the recommended configurations.

<Points per line> defines the number of data points per line provided by one scanner.

<Bytes per point> defines the number of bytes per one data point.

Figure 16: Recommended Configurations for the Serial RS485 Communication

6.2.1.2 <Communications settings> Tab

On this tab the user can configure general communication settings for the serial devices.

The <command timeout> is the maximum time to wait after sending one command to a device. If the

device doesn’t answer in less than the time stipulated, the system will consider it as a communication

error.

The <communication timeout> is the time period between a communication error with a device and

the systems attempt to retry the communication.

<Retries for communication> defines the number of automatic trials to re-establish the communication

to a lost serial device.

By labeling the checkbox <OPC Server active>, the CS software runs as OPC server for one or more

OPC clients within a network. For interfacing to other control systems this option allows the remote

monitoring of the process.

OPC (OLE for Process Control) is an industrial standard for the data exchange between applications

based on the DCOM model from Microsoft. For further information see

http://www.opcfoundation.org/

The CS OPC server supports Data Access in version 2.0 only!

CS210 Rev. B4 Feb 2015 29

Page 30

Configuration

Figure 17: General Options: <Communication settings> Tab

<Send DTR signal with alarms> enables the output of a system alarm signal via the CS interface box

(for scanners communicating via COM) or a digital output module (for scanners communicating via

Ethernet).

30 Rev. B4 Feb 2015 CS210

Page 31

Configuration

Item

Type

Description

Synchronization

.System is synchronized

Bool

Flag for indicating that the system runs synchronized to the oven

Graphic

.Maximum temperatures

Integer array

Provides the Maximum Temperature Profile (temperature via pixel number)

.Minimum temperatures

Integer array

Provides the Minimum Temperature Profile (temperature via pixel number)

.Average temperatures

Integer array

Provides the Average Temperature Profile (temperature via pixel number)

Live Ring Migration system

.Rings

Integer

Number of rings currently used for Live Ring Migration

.Ring 1.Time

Integer

Revolution time for ring 1

.Ring 1.Offset

Integer

Offset time for ring 1 compared to kiln revolution time

.Ring 1.State

Bool

Status for ring 1

Alarm zones

.Zone 1.Maximum temperature limit

Integer

Upper alarm threshold for zone 1

.Zone 1.Hysteresis (low)

Integer

Hysteresis for zone 1 (reset threshold for an alarm)

.Zone 1.Maximum temperature

Integer

Maximum temperature for zone 1

.Zone 1.Alarm State

Bool

Alarm status for zone 1

Devices

.Kiln.Rotation velocity

Integer

Rotation velocity for the kiln given in rpm

.Kiln.Lap time

Integer

Rotation time for the kiln

.Kiln.Snapshot Counter

Integer

Snapshot counter, will be increased by 1 with each new stored image into the database, can be

used as live counter

.Kiln.Points of reading

Integer array

Provides the Length Profile of the kiln (location of each pixel)

.Scanner 1.State

Bool

Status for scanner 1

.Scanner 1.Internal temperature

Integer

Internal temperature for scanner 1

.Pyrometer 1.State

Bool

Status for pyrometer 1

.Pyrometer 1.Internal temperature

Integer

Internal temperature for pyrometer 1

.Pyrometer 1.Maximum temperature

Integer

Maximum temperature for pyrometer 1

.Pyrometer 1.Dirty lens alarm limit

Integer

Threshold for dirty lens alarm for pyrometer 1 (shadow pyrometer only)

.Pyrometer 1.Dirty lens alarm state

Bool

Dirty lens alarm status for pyrometer 1 (shadow pyrometer only)

.Pyrometer 1.Type

String

Pyrometer used for: <burningZone> or <shadowPyrometer>

.Pyrometer 2.Burning zone

Integer

Temperature of the burning zone for pyrometer 2 (burning zone pyrometer only)

The CS software provides the following data via OPC connections. All items listed below have read-only

access.

CS210 Rev. B4 Feb 2015 31

Page 32

Configuration

6.2.1.3 <e-mail> Tab

This tab lets you define the properties of the outgoing mail server to be used by the system. A typical

setting for the SMTP port is 25.

For your correct Email settings, ask your network administrator.

Figure 18: General options: <Mail setup> Tab – Configuring Outgoing Emails

To configure the email address for the recipient see section 6.2.14.2.1 <General> Tab, page 53.

To configure an email be sent in the event of an alarm see section 6.2.14.2.3 <Others> Tab, page 55,

under <Readscan>.

Figure 19: Example for an Outgoing Alarm Email

32 Rev. B4 Feb 2015 CS210

Page 33

Configuration

6.2.2 <Colours and axes definition>

6.2.2.1 <Colors> Tab

With this tabbed dialog box, the user can define their options for the thermogram colour palette. To

select colours, click on the RGB colours. <Scales> sets the number of colours to be included as the

palette colours. Blending is possible by selecting the <Color progression> option.

The <Range> value defines the temperature scale range of the temperature difference view in the CS

main software, see section 7.2.13 <Graphic> <Difference between images>, page 75.

Figure 20: Colours and axes definition: <Colours> Tab

6.2.2.2 <Axes> Tab

This tab lets you configure the appearance for the different axes shown in the graphical representation

of the thermogram, as well as the units representing the kiln diameter.

It also lets you configure the type font used for the axes in the graphical representation of the

thermogram.

CS210 Rev. B4 Feb 2015 33

Page 34

Configuration

The option <Inverse scale> only affects the labels of the screen ‘x’ axis. When this

option is selected, the actual optical parameters of the scanners and pyrometers will not

Figure 21: Colours and axes definition: <Axes> Tab

be affected!

6.2.3 <Kiln Settings>

Clicking the <Kiln settings> menu will open a screen where details about the kiln can be entered.

These specifications are the kiln size (length and diameter) and the longitudinal offset. The

longitudinal offset only affects the labels of the screen x-axis. The actual optical parameters of the

scanners and pyrometers are not affected.

Figure 22: Kiln settings

<Rotation velocity> is the parameter that defines the minimum kiln speed that the system expects

before launching a non-synchronized alarm. When not synchronized, the system will not save any

34 Rev. B4 Feb 2015 CS210

Page 35

Configuration

A kiln speed below <Rotation velocity> and a missing trigger pulse are the two main

images into the database. The <Real time> view shows scanned lines based on a simulated kiln speed

of <Rotation velocity>. The minimum kiln speed for synchronized measurements is 0.02 rpm.

reasons for a non-synchronized alarm!

6.2.4 <Position of Scanners / Pyrometers>

On this screen the user configures the characteristics of the several devices (scanners and pyrometers)

that will be used to monitor the kiln temperature. Up to four scanners can be arranged to cover the

whole kiln shell.

Figure 23: Scanners Position

The features for the different devices (scanners and pyrometers/shadow sensors) are displayed on the

screen on the basis of the type of device: the top-left area is assign to scanners, and the top-right one is

assign to pyrometers. The different devices and their positions are displayed on the centre of the

screen. However, there are few general parameters that must be modified from the screens shown

when clicking on the <Configuration> buttons.

Each pyrometer is only capable of triggering a single alarm zone. If the measurement spot of a

pyrometer is overlapping two alarm zones, only one will trigger. To avoid these kind of problems

ensure each pyrometer is aligned with a single alarm zone only.

The position of the scanners can be adapted very comfortable by using the mouse. For doing so, make

a right mouse click in the drawing area to open the context menu <Settings>. Being in that mode, the

left/right cursor keys can be used to change the Alpha angle dynamically.

CS210 Rev. B4 Feb 2015 35

Page 36

Configuration

Figure 24: Positioning the Scanner

For a multiple scanner system there is with <Overlapping points> an additional mode available to

determine the programs behaviour in the overlapping area:

<Automatic>: the program internal algorithm determines which pixels in the overlapping area

will be taken for the final merged thermal image either from one scanner or the

other scanner. The automatic mode is always useful if one scanner is being

hindered from monitoring the complete kiln by physical obstructions and also by

shadows from the tires but the other scanner is not.

<Manual>: Provides a scanner ranking to determine which scanner provides the pixel in the

overlapping area for the final merged thermal image.

6.2.4.1 <Settings> for Scanner or Pyrometer

From this screen you can configure the communication parameters and the device

emissivity/transmission setting. It is also possible to assign an output for the alarm in case the internal

temperature exceeds the maximum setting. The parameters that we are describing are applicable for

scanners and also for pyrometers.

36 Rev. B4 Feb 2015 CS210

Page 37

Figure 25: Definition of the Scanner device

Configuration

On scanners only, you can define these additional parameters:

• Communication parameters for the scanner:

Ethernet: <IP Address> for the scanner (default: 192.168.42.30 for the first scanner;

192.168.42.31 for a second scanner, and so on) and <Port> (default: 2727)

For further information to configure the Ethernet communication for scanner and PC network

adapter, see MP150 manual. Please note that all scanners in a multiple scanner system require

a different IP address!

COM: Port number and baud rate

Figure 26: Parameter for the Scanner Communication

• The execution of a template already defined in section 6.2.5 <Special Commands>, page 38.

This template contains scanner commands being executed when ReadScan is initialized.

• The triggering of the scanner <Fail Safe Hot Spot Alarm>. To increase the reliability of the

system it is necessary to guarantee fail-safe hot spot alarming even in the event of a PC or

software crash. For that reason the scanner provides an internal relay that will generate an

alarm if a hot spot that exceeds user-defined limits is detected within the 90° scanner field of

view. The relay contacts are available on the terminal line in the system connection box, see

Figure 8 Connection to the internal Alarm Relay , on page 21.

CS210 Rev. B4 Feb 2015 37

Page 38

Configuration

Figure 27: Definition for Pyrometer devices

For pyrometers you can define if it shares network with other pyrometers or not. When sharing the

network, it will be necessary to indicate the unit address.

Also, on this screen it is possible to set the dirty lens alarm and to configure one possible digital

output for it. With the dirty lens alarm, a temperature difference is being calculated for the

pyrometer’s reading and the temperature from the neighboured scanner pixel. If the difference

exceeds the maximal allowed threshold then an alarm is being triggered.

6.2.5 <Special Commands>

This library allows the user to execute commands either individually or as groups via the command

groups (templates) function.

38 Rev. B4 Feb 2015 CS210

Page 39

Configuration

Figure 28: Window of Raytek Commands

In order to create a template you must enter the name, the description, and the commands to be

executed, indicating if such commands are for Scanners or for Pyrometers.

You will also be able to delete and modify these templates.

To execute a command group you must first select the template, the port and the connection speed.

After that, click on the button to open the port. Once the connection with the device has been

established, the <Execute template> button will be active.

It is also possible to send a single command to a device. In such a case, you need only to select the type

of device, the port and the connection speed. Then you will have to open the port and introduce the

command to be executed. Afterwards, click on the button to run it.

Wrong set commands can suspend the whole CS210 system!

6.2.6 <Alarm zones>

6.2.6.1 Repository of alarm zones configuration

Within the CS software platform, several alarm zone configurations can be defined to accommodate