Page 1

Rev H

6/98

56700-1

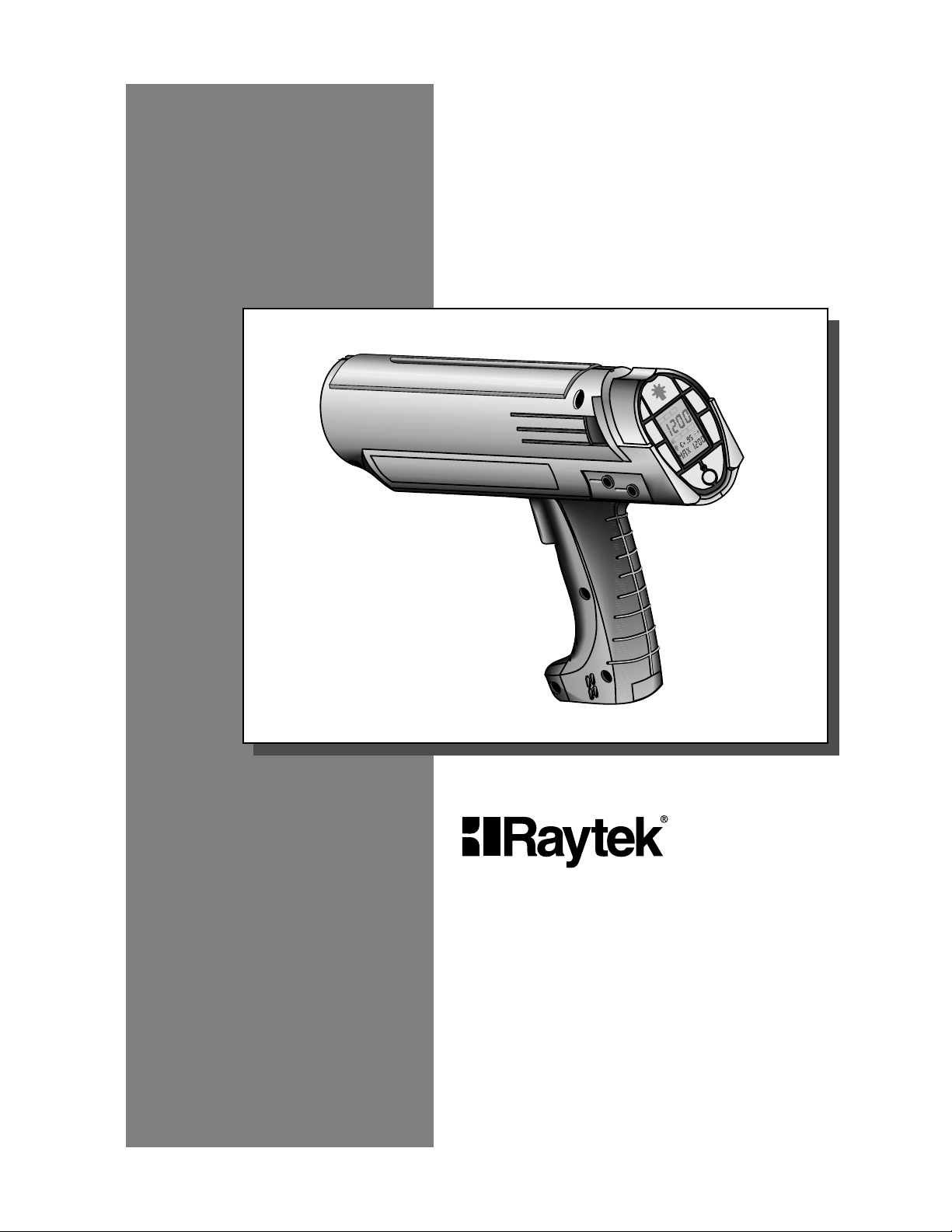

RAYNGER

®

3i

™

SERIES

OPERATOR’S MANUAL

▲

°F

°C

T

E

S

L

C

R

G

O

L

amb

T

RUN

▲

▼

LOG

DC

OUT

▼

( )

O

L

( )

I

H

RECALL

MODE

•

ACTIVATE

LOCK

•

R

E

S

A

L

SET

Page 2

Page 3

WARRANTY

Raytek warrants each instrument it manufactures to be free from defects in material and workmanship under normal use and service for the period of one year from date of purchase. This

warranty extends only to the original purchaser. This warranty shall not apply to fuses, batteries,

or any product which has been subject to misuse, neglect, accident, or abnormal conditions of

operation.

In the event of failure of a product covered by this warranty, Raytek will repair the instrument

when it is returned to an authorized Service Facility within one year of the original purchase,

provided the warrantor’s examination discloses to its satisfaction that the product was defective.

The warrantor may, at its option, replace the product in lieu of repair. With regard to any instrument returned within one year of the original purchase, said repairs or replacement will be made

without charge. If the failure has been caused by misuse, neglect, accident, or abnormal conditions of operation, repairs will be billed at nominal cost. In such cases, an estimate will be submitted before work is started, if requested.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS, OR ADEQUACY FOR ANY PARTICULAR PURPOSE OR USE.

RAYTEK SHALL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER IN CONTRACT, TORT, OR OTHERWISE.

WORLDWIDE HEADQUARTERS

Raytek Corporation

1201 Shaffer Road, PO Box 1820

Santa Cruz, CA 95061-1820 USA

Portable Products Division

800 866 5478

Phone 408 458 1110

Fax 408 425 4561

WORLD WIDE WEB

www.raytek.com

EUROPEAN HEADQUARTERS

Raytek GmbH

Arkonastrasse 45-49

D-13189 Berlin, Germany

Phone 49 30 478 0080

FAX 49 30 471 0251

Offices worldwide:

BRAZIL

Raytek do Brasil

Sorocaba, Brasil

Phone 55 152 276556

CHINA

Raytek China Company

Beijing, China

Phone 86 10 437 0284

JAPAN

Raytek Japan, Inc.

Tokyo, Japan

Phone 03 5976 1531

MEXICO

Raytek de Mexico

Puebla, Mexico

Phone 52 22 30 4380

UNITED KINGDOM

Raytek UK

Milton Keynes, UK

Phone 44 1 908 630800

® Raytek and Raynger are registered trademarks and 3i is a trademark of Raytek Corporation

© 1997 Copyright Raytek Corporation

Page 4

Page 5

Raynger 3i Series Operator's Manual Table of Contents

TABLE OF CONTENTS

SECTION PAGE

1.0 INTRODUCTION.............................................................................1-1

1.1 DESCRIPTION.......................................................................................................1-1

1.2 INVENTORY..........................................................................................................1-2

1.3 MODEL IDENTIFICATION.................................................................................1-3

2.0 OPERATION ......................................................................................2-1

2.1 QUICK START........................................................................................................2-2

2.2 PRINCIPLES OF OPERATION............................................................................2-3

2.3 YOUR PORTABLE INFRARED THERMOMETER...........................................2-4

2.4 OPERATION AND CONTROLS.........................................................................2-6

2.4.1 Battery/AC Adaptor Installation...................................................................2-6

2.4.2 Control Panel and Display..............................................................................2-7

2.4.3 Control System ...............................................................................................2-10

2.4.3.1 Control Loops ..............................................................................................2-10

2.4.3.2 General Information....................................................................................2-11

2.4.4 RUN Loop—To Measure Temperature .......................................................2-12

2.4.5 LOG Loop—To Measure and Store Temperature......................................2-14

2.4.6 RECALL Loop—To Recall Measured Temperature ..................................2-16

2.4.6.1 RECALL Values from RUN .......................................................................2-16

2.4.6.2 RECALL Values from LOG........................................................................2-17

2.4.7 SETUP Loop—To Setup and Activate Alarms and Features...................2-19

2.4.7.1 SETUP Values for RUN ..............................................................................2-19

2.4.7.2 SETUP Values for LOG...............................................................................2-21

2.5 USING A TRIPOD...............................................................................................2-22

2.6 DATA OUTPUTS .................................................................................................2-23

2.6.1 Digital Output.................................................................................................2-24

2.6.1.1 Data Output—RUN Loop..........................................................................2-24

2.6.1.2 Data Output—SET Loop............................................................................2-25

2.6.1.3 Data Output—LOG Run Loop..................................................................2-26

2.6.1.4 Data Output—LOG SETUP Loop.............................................................2-27

2.6.2 Analog Output................................................................................................2-28

SECTION PAGE

Page 6

Table of Contents Raynger 3i Series Operator's Manual

2.7 SIGHTING SYSTEMS..........................................................................................2-29

2.7.1 Single Laser Sighting .....................................................................................2-31

2.7.2 Dual Laser Sighting........................................................................................2-31

2.7.3 Crossed Laser Sighting..................................................................................2-32

2.7.4 Scope Sighting ................................................................................................2-32

3.0 SPECIFICATIONS ............................................................................3-1

3.1 THERMAL..............................................................................................................3-1

3.2 OPERATIONAL.....................................................................................................3-2

3.3 ELECTRICAL .........................................................................................................3-3

3.4 ENVIRONMENTAL..............................................................................................3-4

3.5 PHYSICAL..............................................................................................................3-4

3.6 DEFAULT VALUES ...............................................................................................3-5

3.7 REGULATORY.......................................................................................................3-6

4.0 MAINTENANCE...............................................................................4-1

4.1 BATTERY REPLACEMENT.................................................................................4-1

4.2 CLEANING ............................................................................................................4-1

4.2.1 Front Window Cleaning..................................................................................4-1

4.2.2 Cleaning the Housing......................................................................................4-2

4.3 LASER MAINTENANCE.....................................................................................4-2

SECTION PAGE

Page 7

Raynger 3i Series Operator's Manual Table of Contents

APPENDIX A: OPTICAL...........................................................................A-1

HOW TO READ THE OPTICAL CHARTS...................................................................A-1

OPTICAL CHARTS ..........................................................................................................A-2

APPENDIX B: OBJECT EMISSIVITY.......................................................B-1

HOW TO DETERMINE OBJECT EMISSIVITY.............................................................B-1

TYPICAL EMISSIVITY VALUES.....................................................................................B-2

APPENDIX C: TROUBLESHOOTING ....................................................C-1

APPENDIX D: OPTIONS AND ACCESSORIES...................................

D-1

APPENDIX E: TRACEABILITY OF

INSTRUMENT CALIBRATION...............................................................E-1

APPENDIX F: CE CONFORMITY FOR THE

EUROPEAN COMMUNITY......................................................................F-1

GLOSSARY OF TERMS

INDEX

Page 8

Table of Contents Raynger 3i Series Operator's Manual

Page 9

Raynger 3i Series Operator’s Manual 1-1

1.0 INTRODUCTION

1.1 DESCRIPTION

The Raynger

®3i™

series of instruments are portable infrared temperature measurement devices. Each model is rugged and easy to use for making fast, noncontact, nondestructive temperature measurements. They can measure operating temperatures of

mechanical, electrical, or production equipment without removing the equipment

from service. They can also measure product temperatures during manufacturing or

storage without contaminating or marring the product. Table 1-1 lists the standard

Raynger 3i models.

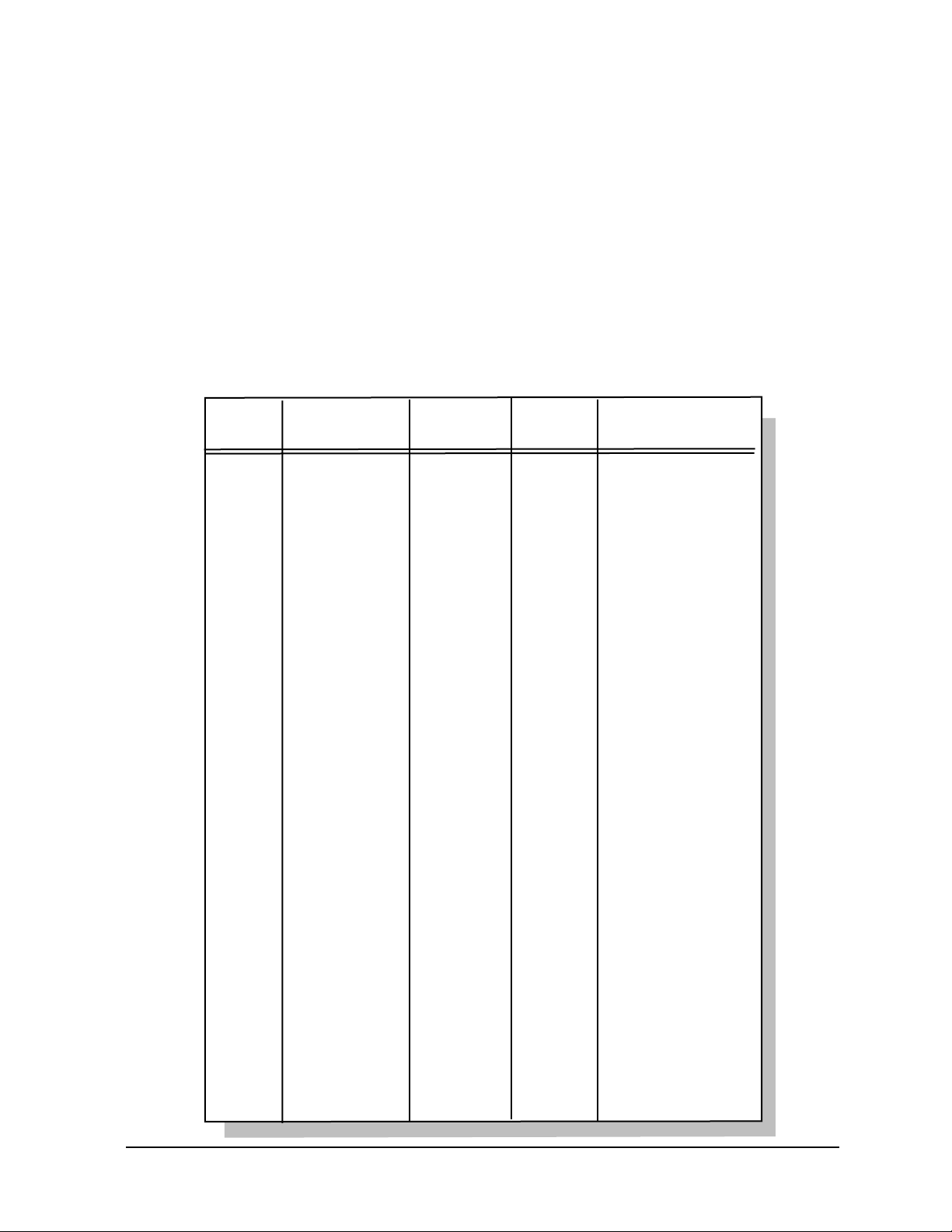

Table 1-1: Raynger 3i Models

TEMPERATURE OPTICAL SPECTRAL

MODEL RANGE RESOLUTION RANGE SIGHTING

LTDL2 &

LTDL3

LTSC

LTCL2 &

LTCL3

-30 to 1200°C

(-20 to 2200°F)

-30 to 1200°C

(-20 to 2200°F)

-30 to 1200°C

(-20 to 2200°F)

75:1

75:1

75:1

8-14 µ

8-14 µ

8-14 µ

dual laser

scope

crossed laser

LRSC

LRSCL2

LRL2 &

LRL3

P7DL2 &

P7DL3

G5SC

1MSC

1ML2 &

1ML3

2MSC

2ML2 &

2ML3

-30 to 1200°C

(-20 to 2200°F)

-30 to 1200°C

(-20 to 2200°F)

-30 to 1200°C

(-20 to 2200°F)

10 to 800°C

(50 to 1450°F)

150 to 1800°C

(300 to 3275°F)

600 to 3000°C

(1100 to 5400°F)

600 to 3000°C

(1100 to 5400°F)

200 to 1800°C

(400 to 3275°F)

200 to 1800°C

(400 to 3275°F)

120:1

105:1

120:1

25:1

50:1

180:1

180:1

90:1

90:1

8-14 µ

8-14 µ

8-14 µ

7.9 µ

5.0 µ

1.0 µ

1.0 µ

1.6 µ

1.6 µ

scope

single laser with scope

single laser

dual laser

scope

scope

single laser

scope

single laser

Page 10

1-2 Raynger 3i Series Operator’s Manual

Each model is molded from rugged, high-strength, solvent resistant plastic and is

actuated by a two-stage trigger (second stage is used for data logging only). Each

model has the following:

• High quality optical system

• Infrared detector

• Circuit board assembly with microprocessor

• LCD display with backlighting feature

• Touch-sensitive membrane switches for changing loops and modes

• Battery compartment for four AA batteries

• Power input jack for AC adaptor

• Signal output jack (analog 1mV per degree/digital RS232)

• A rugged, padded pouch for easy carrying

There are four types of laser sighting models:

• Single laser—shows the center of the measurement area.

• Dual laser—shows the spot diameter of the measurement area.

• Crossed laser—the point where the two laser beams cross is the location of the

minimum diameter measurement spot.

• Single laser with scope

1.2 INVENTORY

Your Raynger 3i package contains the following:

• Raynger 3i

• Carrying Case

• Operator’s Manual

• Four (4) AA batteries

• Warranty card

Page 11

Raynger 3i Series Operator’s Manual 1-3

1.3 MODEL IDENTIFICATION

Refer to Table 1-1 for a list of standard models along with their temperature ranges,

optical resolutions, spectral ranges, and sighting systems.

You can determine the exact model number of your unit by looking at the manufacturing label on the underside of the unit. On the label is an area for model designation. The model type is printed in the following format:

XXXYYYZZZZZ

where XXX is an abbreviation of the company name, YYY is the product (or abbreviation of the product name), and ZZZZZ is the model type. (Model type may be four or

five characters long. Refer to Table 1-1 to compare the label to model type.)

Page 12

1-4 Raynger 3i Series Operator’s Manual

Page 13

Raynger 3i Series Operator’s Manual 2-1

2.0 OPERATION

This portion of the manual contains the following sections:

• Quick Start—To use your unit right away, follow the brief instructions on basic

operating procedures in this section.

• Principles of Operation—A short introduction to infrared thermometry.

• Your Portable Infrared Thermometer—Describes and illustrates the thermome-

ter’s control panel, display, and features.

• How to Operate—A detailed user guide that describes each of the operating

modes. It includes descriptions of the RUN, RECALL, SETUP, and Data Logger

loops.

• Data Outputs—How to use the analog and digital (RS232) outputs to connect the

thermometer to a printer, chart recorder, or computer.

WARNING—LASER SAFETY

Models with laser sighting produce visible laser radiation that may be

harmful to the human eye. Be aware of the following:

• Avoid direct exposure of human eyes to laser light. Eye damage

can result.

• Use extreme caution when operating.

• Never point the unit at another person.

• Keep out of the reach of children.

• Refer to the FDA laser label on the unit for specific information.

IMPORTANT

1. If the unit is exposed to significant changes in ambient temperature

(hot to cold or cold to hot), allow 45 minutes for temperature stabilization before taking measurements.

2. Do not operate the unit near large electrical or magnetic fields such

as arc welders and induction heaters. These fields can cause measurement errors.

3. For the short wavelength units (e.g., 2 µm and below)—Avoid taking

temperature measurements in bright sunlight. High levels of ambient light may produce apparently valid high-temperature readings

when no target is in the thermometer’s field-of-view.

Page 14

2-2 Raynger 3i Series Operator’s Manual

RUN

LOG

SET

LOG

HI

RCL

( )

LO

SET

( )

°C °F

T

amb

Page 15

Raynger 3i Series Operator’s Manual 2-3

2.2 PRINCIPLES OF OPERATION

An infrared thermometer and the human eye are very similar. An infrared thermometer has a lens that focuses infrared radiation from an object onto a detector. The

eye focuses light onto the retina. The detector is stimulated by the incoming infrared

energy and produces a signal that is transmitted to the circuitry. The retina is stimulated by incoming light and sends a signal to the brain. The circuitry processes this

signal and computes the temperature of the object.

The intensity of an object’s emitted infrared energy increases or decreases in proportion to its temperature. The higher the temperature of the target, the greater the intensity of infrared radiation.

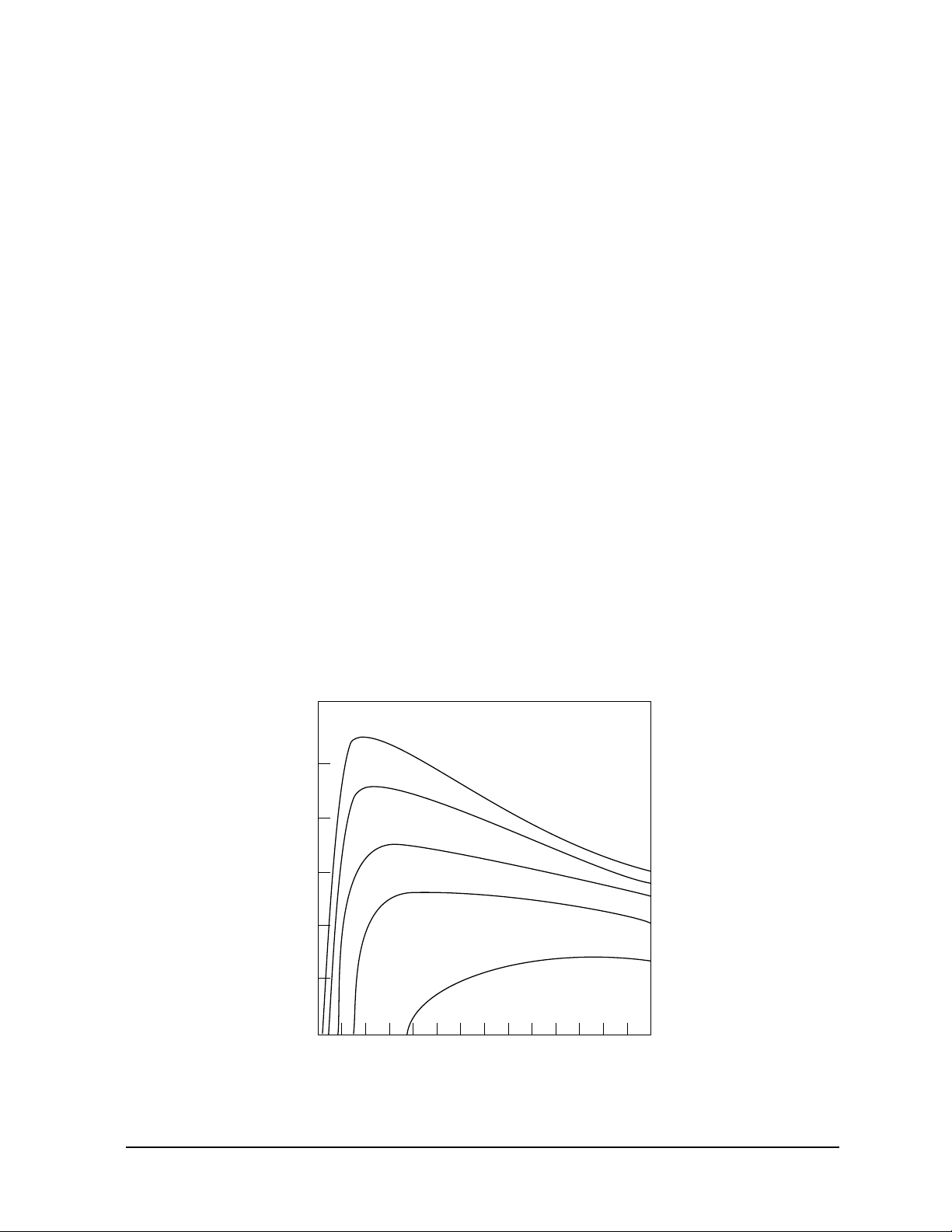

To calibrate a noncontact temperature measurement instrument, the manufacturer

uses a blackbody. A blackbody is a perfect emitter because it absorbs and emits all

radiant energy but reflects or transmits none. The emissivity value of a blackbody is

1.00. Figure 2-2 shows the radiant emittance values of a blackbody at various temperatures and wavelengths.

Most objects have emissivities that are less than 1.00 but are reasonably uniform at all

wavelengths of the infrared spectrum. These are called graybodies. The non-ideal

(less then 1.00) emissivity values of different materials can be compensated for, by the

emissivity controls, so that accurate temperature readings can be obtained. Emissivity

values for many common materials (both metals and non-metals) are listed in

Appendix B.

Figure 2-2: Blackbody Radiation Curves

2

10

2

1

10

1

-1

10

-2

10

-3

10

Blackbody Radiant Emittance (Watt/cm )

-4

10

12345678

0

Wavelength (Microns)

9 10111213

1500°C (2730°F)

1000°C (1830°F)

542°C (1000°F)

260°C (490°F)

20°C (70°F)

14

Page 16

2-4 Raynger 3i Series Operator’s Manual

2.3 YOUR PORTABLE INFRARED THERMOMETER

Portable infrared thermometers measure surface temperatures without touching the

surface. They collect the infrared energy radiated by a target and compute its surface

temperature. They also compute the running average, maximum, minimum, and differential temperatures and present them on a digital display in either degrees Celsius

or Fahrenheit. A digital/analog output allows data recording, instrumentation or

process control, and/or remote display of temperature and emissivity. The instru-6(. The instr)7.6contr is batmety powerared/ocan be powerared byionptatiitaAC adaprato7354.6(. he)]TJ0 -2.4158 Tg0 TwInmetiitamemoty cirart aum, anacs danalgnninfea-he

Page 17

Raynger 3i Series Operator’s Manual 2-5

Your portable thermometer has the following:

• Trigger—Two-stage trigger. The first stage activates the unit to take temperature

readings. The second stage is functional only in the datalog mode. To store a temperature reading, pull the trigger all the way in until you hear the tone (the tone

signals that the reading has been stored). When you release the trigger, the unit

goes to sleep.

• Control Panel and Display—All controls (except the trigger) are located on the

control panel. The display shows temperature and setup values, mode and loop

status, and operating information.

• Sighting System—Laser or scope sighting is provided with each model.

Note: Read the laser warning label before operating the laser.

• Analog Output—Connects the instrument to analog recording/printing devices

such as chart recorders and printers.

• Digital Output—An RS232 interface to connect the instrument to a computer or

directly to a printer’s RS232 port.

• DC In—AC adaptor connection.

Page 18

2-6 Raynger 3i Series Operator’s Manual

2.4 OPERATION AND CONTROLS

This section instructs you in the operation of the instrument. It describes battery

and/or AC adaptor installation and the controls and functions of the different control

loops and operating modes.

2.4.1 Battery/AC Adaptor Installation

The instrument may be powered by batteries or an AC adaptor. Battery power is supplied by 4 “AA” batteries. The batteries are located in the base of the handle. AC

power is supplied by an optional AC power adaptor (DIN VDE 0551 approved).

NiCad batteries can also be used, but battery life will be substantially reduced. Figure

2-3 shows the location of the battery compartment, battery orientation, and the location of the AC adaptor power connection.

Table 2-1 shows approximate battery life (for alkaline batteries) for various operating

conditions.

Notes: Battery types and brands vary in length of usable life. The values in Table 2-1 are

approximate for new alkaline batteries. The instrument will continue to read accurately up to 4 hours after the low battery icon displays if the laser and backlight are off.

Remove the batteries if the unit is not used for long periods of time.

220 VAC adaptors must have DIN VDE 0551 approval to be used with IEC Class 2

laser units.

Table 2-1: Battery Life (Alkaline)

CONDITION

Laser OFF Backlight OFF

Laser ON Backlight OFF

Laser OFF Backlight ON

Laser ON Backlight ON

"Sleep" mode (trigger off)

HOURS OF

CONTINUOUS USE

25

12.5

12.5

10

1 year

Page 19

Raynger 3i Series Operator’s Manual 2-7

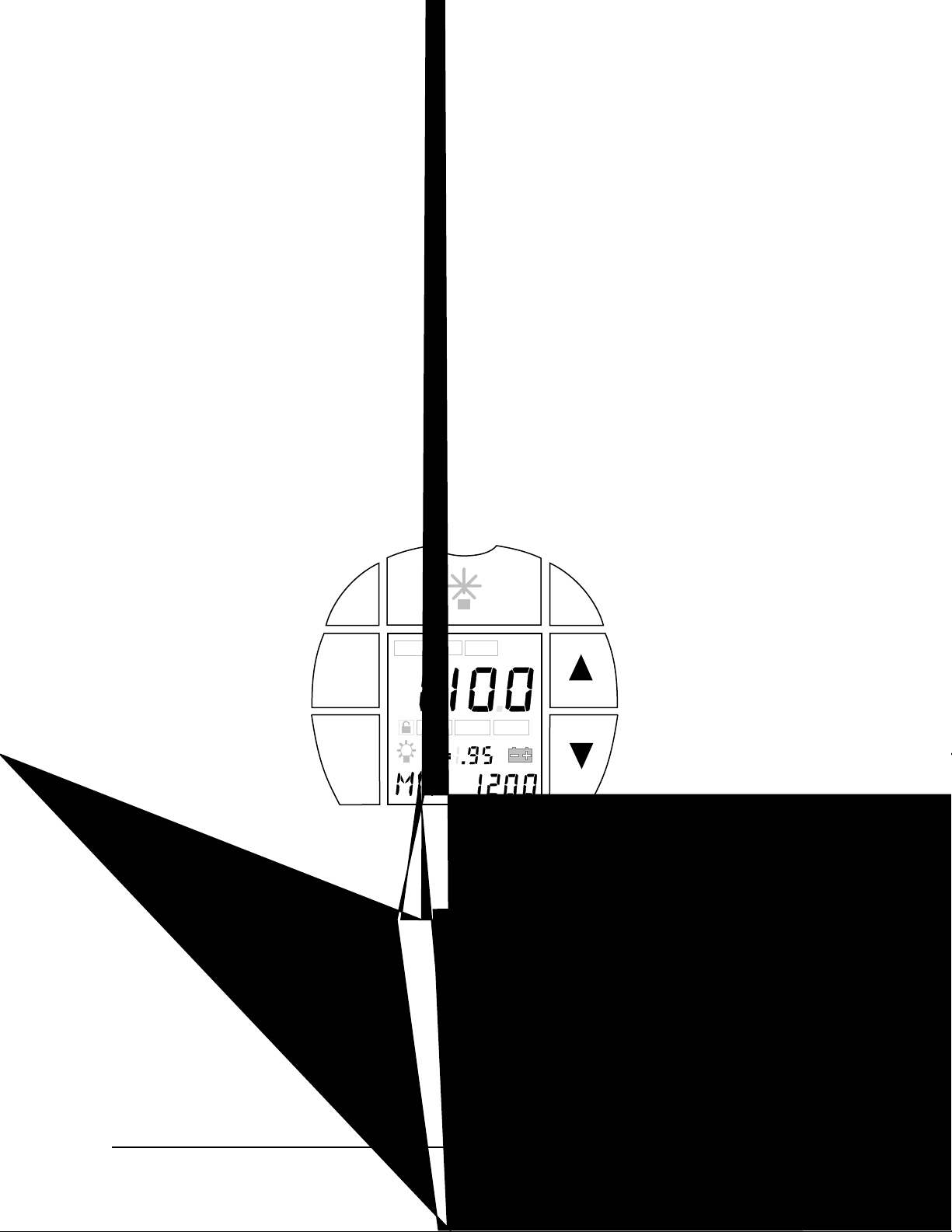

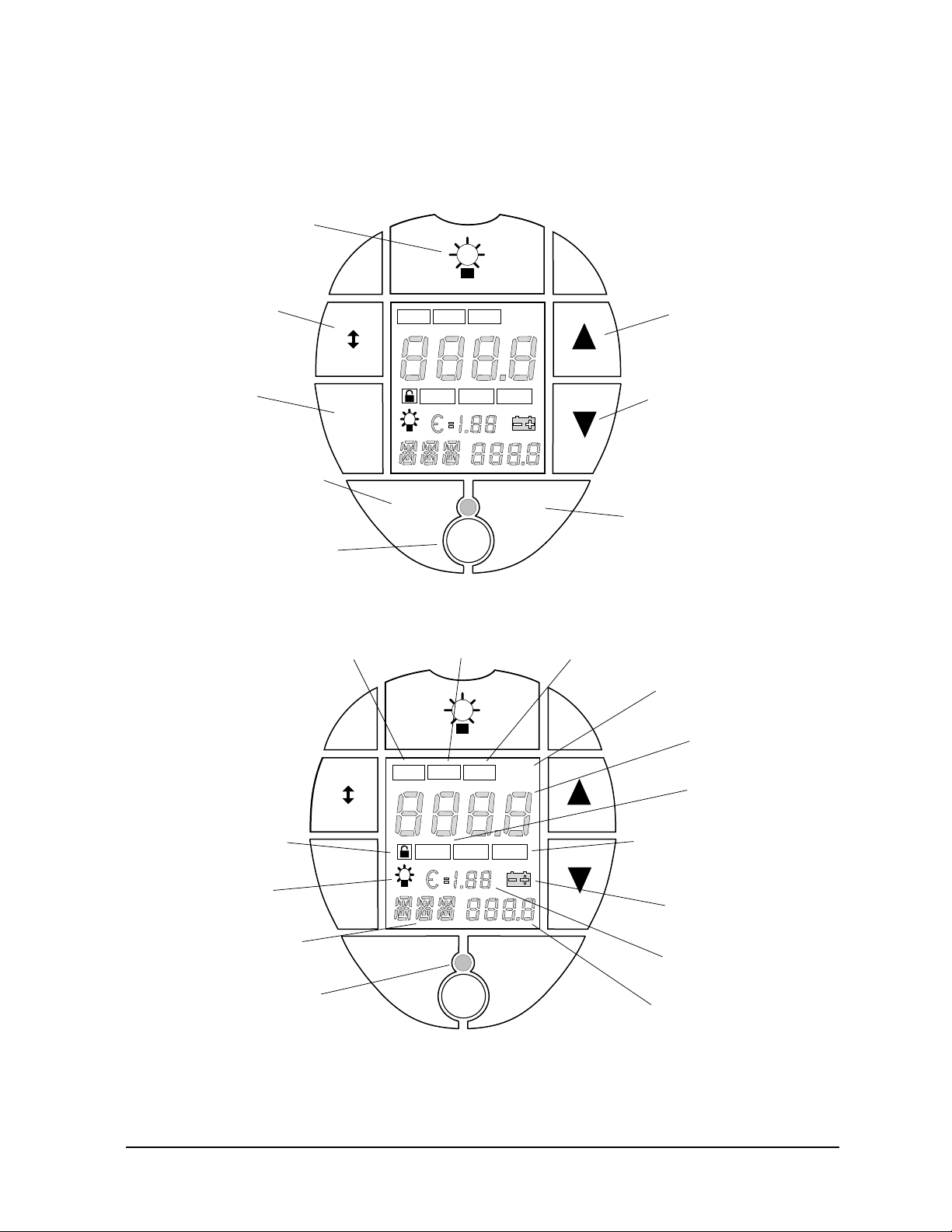

Figure 2-4: The Control Panel and Display

2.4.2 Control Panel and Display

Figure 2-4 shows the display and controls. Descriptions of these, in alphabetical

order, follow the illustration.

Backlight on/off

button

Run/Log

selector switch

Setup

button

Mode and Recall

button

Laser on/off button

Trigger lock

icon

Backlight

icon

RUN

RUN

LOG

LOG

SET

Data logger

icon

RUN

RUN

LOG

LOG

SET

LOG

HI

RECALL

MODE

•

•

MODE

RECALL

RCL

LOG

HI

RCL

SET

( )

LO

LASER

Recall

loop icon

SET

( )

( )

LO

°C °F

( )

T

amb

ACTIVATE

ACTIVATE

•

•

LOCK

LOCK

°C °F

T

amb

Increase/up

button

Decrease/down

button

Activate and trigger

lock button

Setup

loop icon

Celsius/Fahrenheit

icons

Temperature

display

High and low

alarm icons

Ambient temperature

compensation icon

Low battery icon

Mode display

Laser on/off LED

RECALL

MODE

•

•

MODE

RECALL

LASER

ACTIVATE

ACTIVATE

•

•

LOCK

LOCK

Emissivity display

Mode value display

Page 20

2-8 Raynger 3i Series Operator’s Manual

Activate button—Press the activate button to activate HAL, LAL, or TAM, or to toggle between DIG/ANA, or °C/°F, in the SET loop.

Backlight button and icon—The display has a backlight for working in low lighting

conditions. Press the backlight button to activate or deactivate the backlight. The

backlight icon is activated when the backlight is on. To save battery power, use the

backlight only when necessary. Note that if the battery voltage falls below 4.0 V, the

backlight will automatically turn off.

Low battery icon—The instrument is powered by four “AA” batteries. When the battery voltage falls below 4.6 V, the low battery icon is activated.

Note: Turning off the backlight and laser will extend the battery life (refer to Table 2-1 for

battery life under various conditions).

Celsius/Fahrenheit icons—The °C and °F icons indicate which temperature scale has

been selected.

LOG button and icon—Press the LOG/RUN button while you have the trigger

pulled to toggle between the LOG and RUN loops. The LOG icon is activated when

the instrument is in the LOG loop.

Emissivity display—The emissivity display shows the emissivity value selected in

either the RUN, RECALL, or LOG loops.

▲▲

and ▼▼buttons—▲ increases and ▼ decreases the emissivity settings, DOI rate,

HAL or LAL set-points, TAM, or the LOG location number.

High and Low alarm icons—These are activated when the corresponding alarms are

activated. The HAL icon flashes and the buzzer sounds when measured temperature

is greater than or equal to HAL and HAL is active. The LAL icon flashes and the

buzzer sounds when the measured temperature is less than or equal to LAL and LAL

is active. Note that when a high or low alarm condition is met and the unit is sending

out RS232 data while in the Digital Output mode, the buzzer will make two tones: a

normal tone followed by a higher pitched tone.

Laser on/off button and LED—Press the laser button to activate or deactivate the

laser (RUN and LOG loops only). The laser LED is activated when the laser is activated. (Not applicable for the scope sighting model.) Note that if the battery voltage

falls below 4.3 V, the laser will automatically turn off. Also, if the unit is in the LOCK

mode, the laser will go off when the trigger is released.

Temperature display—Shows the current temperature (while the trigger is pulled) or

the last temperature measured (when the RECALL button is pressed).

Page 21

Raynger 3i Series Operator’s Manual 2-9

Mode button—Press the mode button to change modes in any of the four loops.

Mode display and Mode value display—The Mode display shows the current mode

selected. The mode value display shows the temperature, set-point, or LOG location

value for the mode selected.

Recall button and icon—Press the RCL button to activate the RECALL loop. The

RECALL loop may be used to recall values from either the RUN or LOG loops. The

RCL icon is activated when the instrument is in the RECALL loop.

RUN button—Press the RUN/LOG button, when the trigger is pulled, to toggle

between the RUN and LOG loops.

Setup button and icon—Press the SET button to activate the SETUP loop. The

SETUP loop may be used to set values in either the RUN or LOG loops. The SET icon

is activated when the instrument is in the SET loop.

T

amb

icon—This is activated when the ambient temperature compensation function is

activated. This feature only affects readings in the RUN loop; readings in the LOG

loop are not affected.

Trigger lock icon—The small padlock is the trigger lock icon and is activated when

LOCK is pressed while the trigger is pulled. To unlock the trigger, simply press the

LOCK button again.

Page 22

2-10 Raynger 3i Series Operator’s Manual

2.4.3 Control System

The control system consists of four loops: SET, RUN, RECALL and LOG. The instrument may be cycled to any of the four loops by using the trigger or control panel buttons, as shown below.

RCL

LOG

SET

HI

( )

LASER

( )

LO

°C °F

T

amb

ACTIVATE

•

LOCK

RUN

LOG

SET

LOG

HI

MODE

•

RECALL

RCL

( )

LASER

SET

( )

LO

°C °F

T

amb

ACTIVATE

•

LOCK

RUN

LOG

SET

MODE

•

RECALL

RUN

LOG

SET

LOG

HI

MODE

•

RECALL

RCL

( )

LASER

SET

( )

LO

°C °F

T

amb

ACTIVATE

•

LOCK

Page 23

Raynger 3i Series Operator’s Manual 2-11

2.4.3.1 Control Loops

Each control loop has several modes, which are described in the following sections.

2.4.3.2 General Information

Before you begin using your portable instrument, you should be aware of the following general operating rules:

• The instrument goes to “sleep” (low power consumption, no display, no laser, no

backlight) after different times for each loop, as follows:

– SET Loop (after last button use): 10 seconds

– RUN Loop (after releasing the trigger): immediately

– RECALL Loop (after last button use): 10 seconds

_ LOG Loop (after releasing trigger): immediately

• The backlight can be turned on or off in any mode.

• The laser can be used only in the RUN and LOG loops.

• The trigger has two stages. The first stage is for measuring temperature. The second stage, when the trigger is pulled all the way in, is for storing temperature values in the LOG loop.

• The °C or °F icon flashes when the instrument is measuring temperature in the

RUN or LOG loops. It does not flash when values are recalled.

• You can lock the trigger in the RUN loop and the LOG loop.

• You must release the trigger to go into the SET or RECALL loops.

• When you simultaneously press the MODE and ACTIVATE buttons while in the

RUN loop, the instrument is reset to the RUN loop factory default settings (stored

data is unaffected). In the LOG loop, pressing the MODE and ACTIVATE buttons

not only resets the instrument to its LOG loop factory default settings, but also

clears all previously stored data. In both cases, the instrument will “beep” after

reinstalling the default settings. Section 3.6 lists default setting for each model as

well as non-model-specific default settings and range values.

IMPORTANT

For the short wavelength units (e.g., 2 µm and below)—Avoid taking

temperature measurements in bright sunlight. High levels of ambient

light may produce apparently valid high-temperature readings when

no target is in the thermometer’s field-of-view.

Page 24

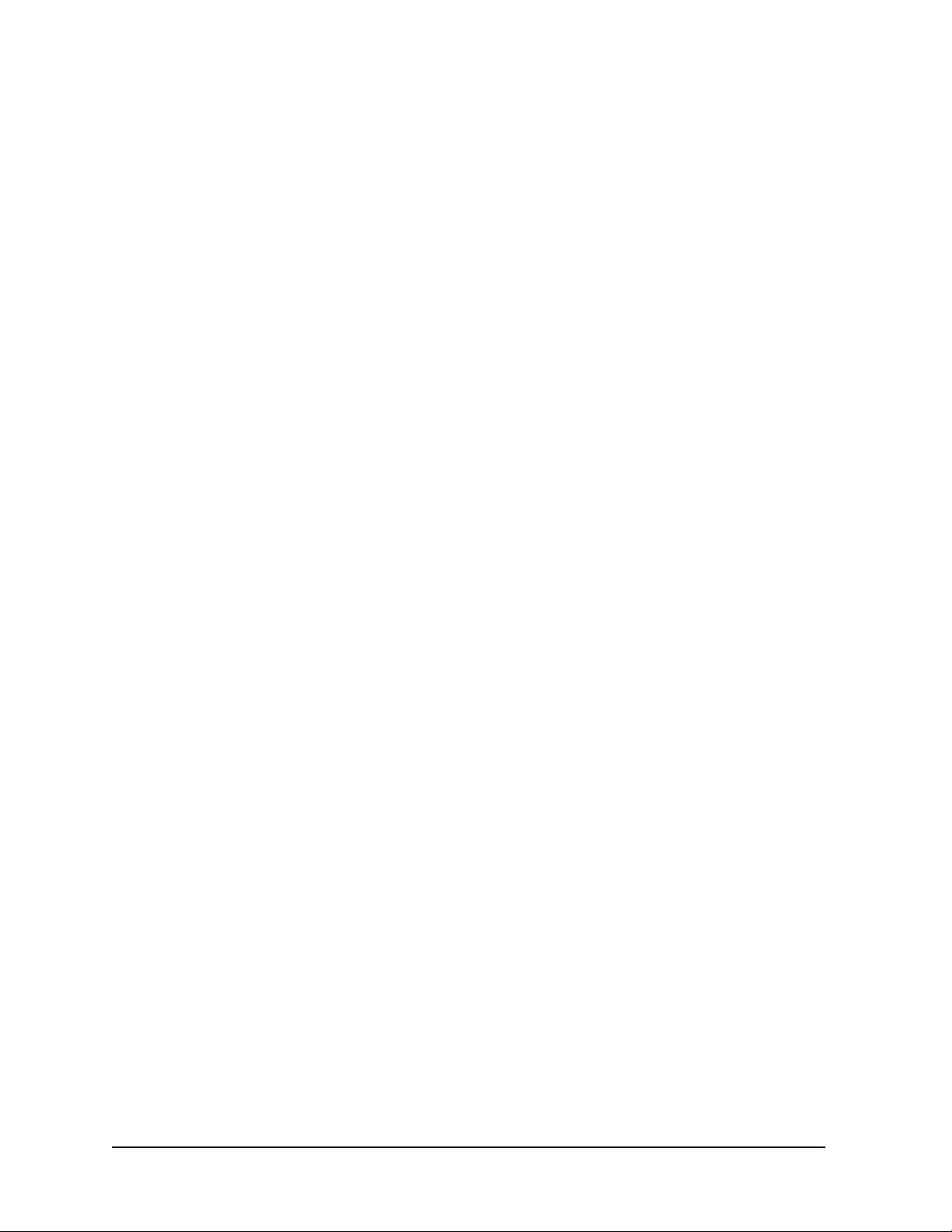

2.4.4 RUN Loop–To Measure Temperature

The RUN loop is for taking temperature measurements. Figure 2-6 illustrates the

RUN loop.

To take a measurement, do the following:

1. Point the instrument at the target.

2. Pull the trigger (press the RUN/LOG button, if necessary, so that the LOG icon is

not activated).

Figure 2-6: RUN Loop

2-12 Raynger 3i Series Operator’s Manual

RUN

RUN

LOG

LOG

SET

RUN

RUN

LOG

LOG

SET

MAX Mode

RCL

LOG

( )

HI

RECALL

MODE

•

•

MODE

RECALL

LASER

LASER

MODE

RCL

LOG

( )

HI

SET

( )

LO

ACTIVATE

SET

( )

LO

°C °F

T

amb

ACTIVATE

•

•

LOCK

LOCK

°C °F

T

amb

Current

temperature

MODE

Turn the trigger

lock ( ) on or off

with the Lock button

The °C (or °F) icon

flashes when the

trigger is pulled

MODE

RUN

RUN

LOG

LOG

SET

RUN

RUN

LOG

LOG

SET

MIN Mode

RCL

LOG

( )

HI

RECALL

MODE

•

•

MODE

RECALL

LASER

MODE

RCL

LOG

( )

HI

LO

LASER

LO

SET

°C °F

( )

T

amb

ACTIVATE

ACTIVATE

LOCK

LOCK

SET

°C °F

( )

T

amb

•

•

Change emissivity

RECALL

MODE

•

•

MODE

RECALL

LASER

LASER

ACTIVATE

ACTIVATE

•

•

LOCK

LOCK

with the ▲ and ▼

buttons in any mode

RECALL

MODE

•

•

MODE

RECALL

LASER

LASER

ACTIVATE

ACTIVATE

•

•

LOCK

LOCK

DIF ModeAVG Mode

TRIGGER

Pulled or Locked

BUTTON

RUN

LOOP ICON

None

Page 25

Raynger 3i Series Operator’s Manual 2-13

3. Press the laser button to activate the laser (if equipped with laser sighting).

4. Carefully aim using the laser or scope.

Note: The laser or scope indicate the target (see Sections 2.7.1 through 2.7.4). Make sure the

spot you are measuring fills the target.

5. Read the temperature from the display.

RUN contains 4 modes: MAX, MIN, DIF, and AVG (as shown in Figure 2-7). In RUN,

the current temperature and emissivity setting along with either the MAX, MIN, DIF,

or AVG temperature can be displayed. Note that AVG is a weighted average of all

readings taken since the trigger was pulled. The unit uses the following formula to

calculate the running average (while the trigger is pulled):

R

1

+ R2+ R3+ ...R

n

= AVG

n

where R = a reading and n = the total number of readings.

• Press the MODE button to change modes.

• Press the ▲ or ▼ buttons to change emissivity.

• Press the backlight button if a brighter display is necessary.

Note: When you simultaneously press the MODE and ACTIVATE buttons while in the

RUN loop, the instrument is reset to its RUN loop factory default settings (stored data

is unaffected). The instrument will “beep” after reinstalling the default settings.

Section 3.6 lists default setting for each model as well as non-model-specific default settings and range values.

Page 26

2-14 Raynger 3i Series Operator’s Manual

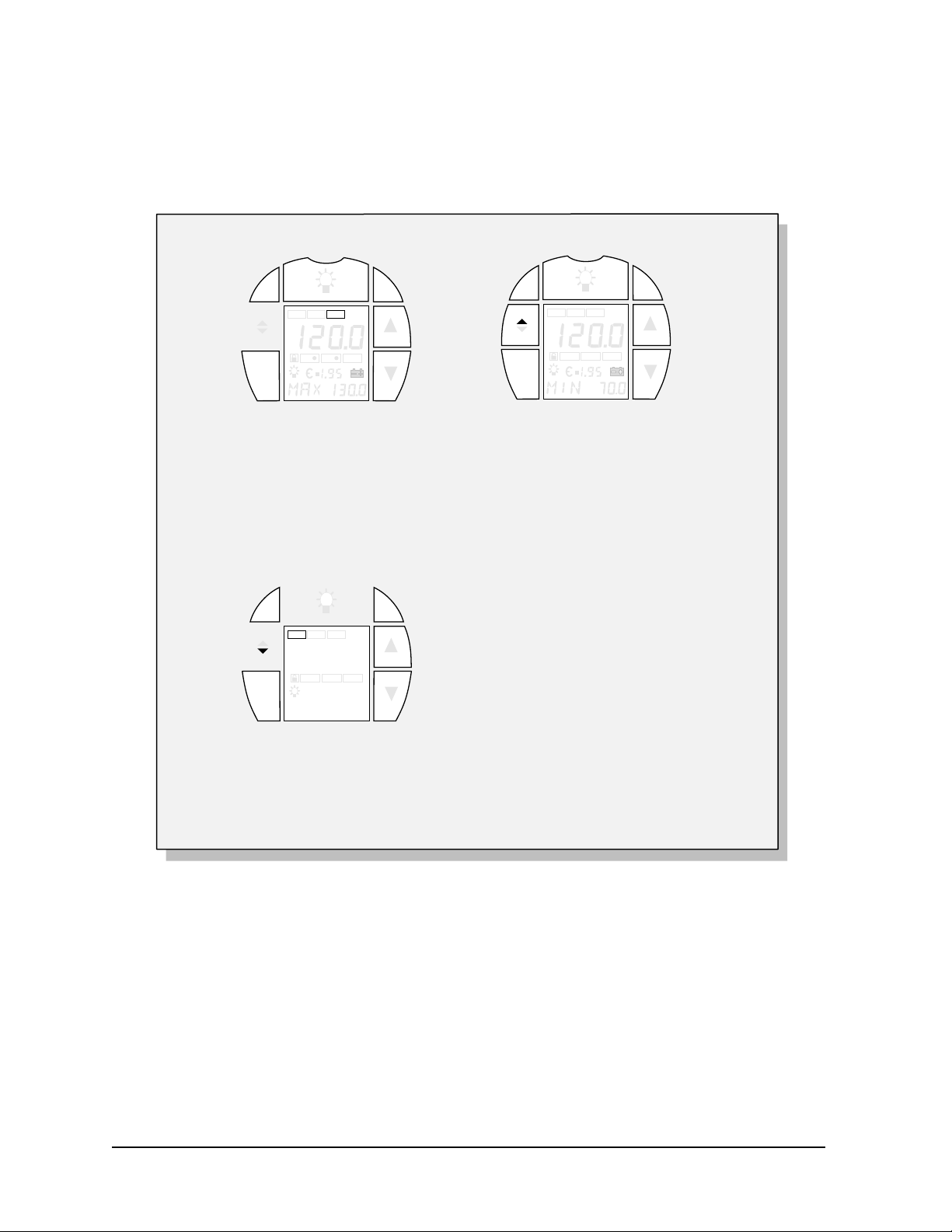

2.4.5 LOG Loop–To Measure and Store Temperature

The LOG loop is for making temperature measurements and storing them in the data

logger locations. Figure 2-7 illustrates the LOG loop.

To use the modes and functions of the LOG loop, do the following:

1. Point the instrument at the target.

2. Pull the trigger and press the RUN/LOG button, if necessary, so that the LOG icon

is activated.

3. Press the ▲ or ▼ buttons to select the LOG location number where you want to

store the measurement. To change the emissivity setting for that location, press

the MODE button and use the ▲ or ▼ buttons .

4. Press the laser button to activate the laser (if equipped with laser sighting).

5. Carefully aim using the laser or scope.

6. Read the temperature from the display.

Figure 2-7: LOG Loop

LOC Mode MAX Mode

RCL

RUN

RUN

LOG

LOG

SET

LOG

SET

°C °F

( )

( )

HI

LO

T

amb

MODE

RUN

RUN

LOG

LOG

SET

LOG

RCL

SET

°C °F

( )

( )

HI

LO

T

amb

Lock and unlock

the trigger with

the lock button

RECALL

MODE

•

•

RECALL

MODE

ACTIVATE

ACTIVATE

•

•

LOCK

LOCK

LASER

LASER

TRIGGER

Pulled or locked

Use the ▲ and ▼

buttons to change

the log location (LOC)

number

BUTTON

LOG

RECALL

MODE

•

•

RECALL

MODE

LASER

LASER

LOOP ICON

LOG

ACTIVATE

ACTIVATE

•

•

LOCK

LOCK

Use the ▲ and ▼

buttons to change

the emissivity

Page 27

Raynger 3i Series Operator’s Manual 2-15

7. Pull the trigger further until you hear the “beep” indicating that the measurement

has been stored. Both the current and MAX temperatures are stored in memory.

Notes: The instrument has a 2-stage trigger. The first stage is activated by pulling the trigger

a small amount. The second stage (operational in LOG only) is activated when the

trigger is pulled all the way.

To protect the data from being accidentally overwritten (trigger accidently pulled),

press the RUN/LOG button to exit the LOG loop (the LOG icon is off).

8. Release the trigger.

LOG contains two modes: LOC (location) and MAX (as shown in Figure 2-7). In

LOG, the current temperature and emissivity setting along with either the location

number or MAX temperature can be displayed. Note the following:

• Press the MODE button to change between LOC and MAX modes.

• Press the ▲ or ▼ buttons to change the location number or the emissivity set-

ting.

• Press the backlight button if a brighter display is needed.

Notes: If you change the emissivity after storing data, both the target temperature and MAX

temperature will reset to zero. The instrument will “beep” to indicate this.

IMPORTANT

When you simultaneously press the MODE and ACTIVATE buttons

while in the LOG loop, all previously stored data is cleared. The

instrument also resets to its LOG loop factory default settings. The

instrument will “beep” after reinstalling the default settings. Section

3.6 lists default setting for each model as well as non-model-specific

default settings and range values.

Page 28

2-16 Raynger 3i Series Operator’s Manual

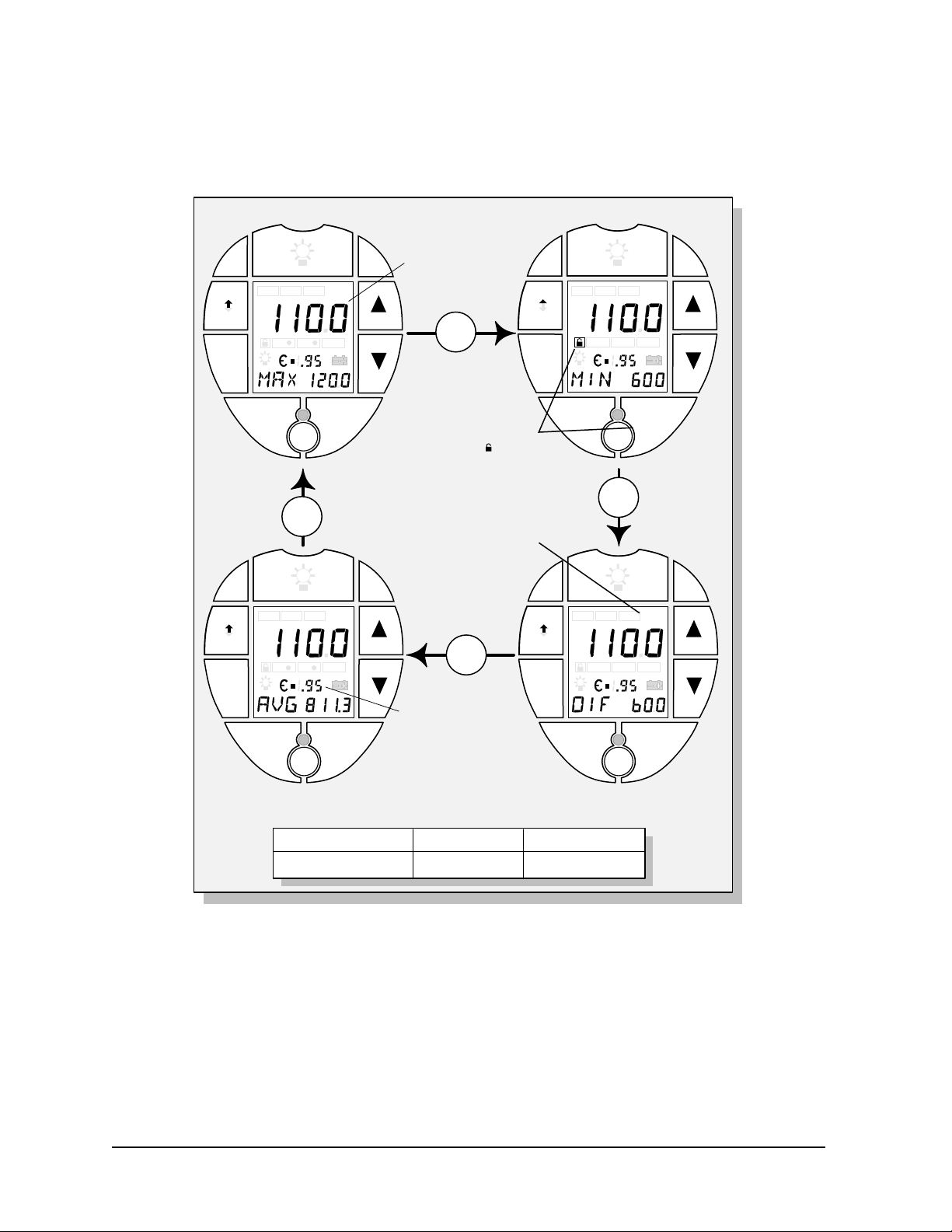

2.4.6 RECALL Loop–To Recall Measured Temperatures

The RECALL loop is for recalling values from either the RUN or LOG loops.

2.4.6.1 RECALL Values from RUN

Figure 2-8 illustrates RECALL for RUN values.

RUN

LOG

SET

RUN

LOG

SET

LOG

RCL

( )

HI

LASER

MODE

SET

LO

LASER

ACTIVATE

LOCK

°C °F

( )

T

amb

ACTIVATE

•

LOCK

MODE

•

MODE

If the display goes out,

press the Recall button again

to continue the Recall function

RUN

LOG

SET

RUN

LOG

SET

LOG

LOG

HI

HI

RCL

( )

LO

LASER

MODE

RCL

( )

LO

LASER

SET

°C °F

( )

T

amb

ACTIVATE

LOCK

SET

°C °F

( )

T

amb

ACTIVATE

LOCK

•

•

Page 29

Raynger 3i Series Operator’s Manual 2-17

To recall values from the RUN loop, do the following:

1. Release or unlock the trigger, if necessary.

2. Press the RECALL button. The RCL icon will be activated.

3. Press the RUN/LOG button, if necessary, so that the LOG icon is not activated.

4. Read the recalled temperature from the display.

RECALL contains four modes: MAX, MIN, DIF, and AVG (as shown in Figure 2-8).

In RECALL, the last temperature and emissivity setting along with either the MAX,

MIN, DIF, or AVG temperature can be displayed. Note the following:

• Press the MODE button to change modes.

• Press the ▲ or ▼ button to change emissivity. (This shows the effect that a dif-

ferent setting would have. Note that if the target’s temperature is known, you

can determine its emissivity by this method. MAX, MIN, DIF, or AVG are not

updated.)

• Press the backlight button if a brighter display is needed.

2.4.6.2 RECALL Values from LOG

Figure 2-9 illustrates RECALL for LOG values.

Figure 2-9: RECALL Loop–Recalling LOG Values

LOC Mode MAX Mode

RCL

RUN

RUN

LOG

LOG

SET

RECALL

Press the Recall button

again, if display goes out,

to continue Recall function

LOG

MODE

RECALL

MODE

SET

°C °F

( )

( )

HI

LO

T

amb

ACTIVATE

LASER

LASER

ACTIVATE

•

•

LOCK

LOCK

Use the ▲ and ▼

buttons to change

the log location (LOC)

number

•

•

TRIGGER

Released & Unlocked

MODE

Stored temperature.

If no temperature

is stored, the display

shows all zeros.

BUTTON

RECALL & LOG

RUN

RUN

LOG

LOG

SET

Press the Mode

button to toggle

between the LOC

and MAX modes.

LOOP ICONS

RCL

LOG

( )

HI

RECALL

MODE

•

•

RECALL

MODE

LASER

LASER

LOG RCL

SET

( )

LO

°C °F

T

amb

ACTIVATE

ACTIVATE

•

•

LOCK

LOCK

Stored temperatures.

If no temperatures

are stored, the

displays show

all zeros.

Page 30

To recall values from the LOG loop, do the following:

1. Release or unlock the trigger, if necessary.

2. Press the RECALL button. The RCL icon will be activated.

3. Press the RUN/LOG button, if necessary, so that the LOG icon is activated.

4. Read the recalled temperature from the display.

5. Press the ▲ or ▼ buttons (LOC mode) to recall values from other LOG locations.

RECALL contains two modes: LOC (location) and MAX (as shown in Figure 2-9). In

RECALL, the stored temperature and emissivity setting along with either the location

number or MAX temperature can be displayed for each of the 100 LOG locations.

2-18 Raynger 3i Series Operator’s Manual

Page 31

Raynger 3i Series Operator’s Manual 2-19

2.4.7 SETUP Loop–To Setup and Activate Alarms and Features

The SETUP loop is for setting up and activating alarms and features in either the RUN

or LOG loops.

2.4.7.1 SETUP Values for RUN

Figure 2-10 illustrates SETUP for the RUN loop.

Figure 2-10: SETUP Loop–RUN Values

The display changes

to show temperature

in °C or °F

ANA

Selected

RUN

RUN

LOG

LOG

SET

F/C Mode

LOG

HI

RECALL

MODE

•

•

MODE

RECALL

RUN

RUN

LOG

LOG

SET

RCL

( )

LASER

LASER

MODE

SET

( )

LO

RECALL

°C °F

T

amb

ACTIVATE

ACTIVATE

•

LOCK

LOCK

MODE

LOG

HI

MODE

•

•

MODE

RECALL

•

DOI Mode

RCL

SET

( )

( )

LO

ACTIVATE

LASER

LASER

DIG

Selected

MODE

Press the ACTIVATE

button to toggle

between °C or °F

°C °F

T

amb

ACTIVATE

•

•

LOCK

LOCK

Turn the High

Alarm (HAL) on

or off with the

ACTIVATE Button

Time (in seconds)

between data

transmissions

Press ▲ or ▼ to

change the interval

(from 1 to 9999 seconds)

RUN

RUN

LOG

LOG

SET

RUN

RUN

LOG

LOG

SET

HAL Mode

RCL

LOG

( )

HI

RECALL

MODE

•

•

MODE

RECALL

LASER

LASER

MODE

RCL

LOG

( )

HI

RECALL

MODE

•

•

MODE

RECALL

LASER

LASER

MODE

SET

( )

T

LO

ACTIVATE

ACTIVATE

LOCK

LAL Mode

SET

( )

LO

T

ACTIVATE

ACTIVATE

LOCK

°C °F

amb

•

LOCK

°C °F

amb

•

LOCK

•

•

Change the High

Alarm setpoint with

the ▲ and ▼ buttons

Turn the Low

Alarm (LAL) on

or off with the

ACTIVATE

Button

Change the Low

Alarm setpoint with

the ▲ and ▼ buttons

Last temperature

value changes if

is activated

T

amb

RCL

LOG

SET

( )

HI

LO

RECALL

MODE

•

•

MODE

RECALL

LASER

LASER

TAM Mode

LOOP ICON

SET

°C °F

( )

T

amb

ACTIVATE

ACTIVATE

LOCK

LOCK

•

•

Change the TAM

setpoint with the

▲ and ▼ buttons

Turn the Ambient

Temperature (T

on or off with the

ACTIVATE Button

amb

)

Press the ACTIVATE

button to toggle

between DIG or ANA

RCL

LOG

RUN

RUN

LOG

LOG

( )

HI

LO

SET

RECALL

MODE

•

•

MODE

RECALL

LASER

LASER

DIG/ANA Mode

Released & Unlocked

SET

°C °F

( )

T

amb

ACTIVATE

ACTIVATE

•

•

LOCK

LOCK

TRIGGER

MODE

BUTTON

SET & RUN

RUN

RUN

LOG

LOG

SET

Page 32

To setup values for the RUN modes and functions, do the following:

1. Release or unlock the trigger, if necessary.

2. Press the SET button. The SET icon will be activated.

3. Press the RUN/LOG button, if necessary, so that the LOG icon is not activated.

4. Press ACTIVATE to toggle between °C or °F for the display and data output.

5. Press the MODE button to switch between HAL, LAL, TAM, and DOI. Press the

▲ or ▼ buttons to change the HAL, LAL, TAM, and DOI settings.

6. Press ACTIVATE to activate the HAL, LAL, or TAM.

7. Press ACTIVATE to toggle between DIG (digital) or ANA (analog) outputs.

8. Press the ▲ or ▼ buttons to set DOI (Digital Output Interval) if DIG was selected.

SET contains six modes: °C/°F, HAL, LAL, TAM, DIG/ANA, and DOI (as shown in

Figure 2-10). In SET, the temperature scale can be set for °C or °F, the HAL, LAL, and

TAM setpoints can be displayed and set, the digital (DIG) or analog (ANA) output

can be selected, and the Digital Output Interval (DOI) can be set. Note the following:

• Press the MODE button to change modes.

• Press the backlight button if a brighter display is needed.

Notes on setting T

amb

(Ambient temperature compensation)—The T

amb

icon is

activated when the ambient temperature compensation function is active. Targets

that have low emissivities will reflect energy from nearby objects. This additional

reflected energy is added to the target’s own emitted energy and may result in inaccurate readings. In some situations objects near the target (machines, furnaces, or other

heat sources) have a temperature much higher than that of the target. In these situations it is necessary to compensate for the reflected energy from those objects. Note

that the T

amb

feature is disabled if the emissivity is set to 1.00.

To set or change the ambient temperature compensation, complete the following:

1. Go to the RUN loop (pull trigger, press RUN/LOG button, if necessary).

2. Set the emissivity value to 1.0.

3. Press the MODE button until the mode function indicator displays AVG (average

temperature).

4. Pull the trigger and scan across objects and surfaces that face the target. Read the

average temperature value in the MODE value display. This is the value to be

entered as the reflected ambient temperature in Step 7 below. Release the trigger.

5. Press the SET button (do not pull the trigger) to enter the Setup mode

6. Press the MODE button until TAM shows in the mode function indicator.

2-20 Raynger 3i Series Operator’s Manual

Page 33

Raynger 3i Series Operator’s Manual 2-21

7. Set the TAM value by pressing the ▲ and ▼ buttons.

8. Press the ACTIVATE button to turn on the ambient temperature compensation

function. The Tamb icon will be displayed indicating that it is active. (Pressing

ACTIVATE again turns off the function.)

9. Pull trigger and reset the emissivity to the proper value for the target. You can

now take the target’s temperature using normal procedures. The current temperature and all computed values, as well as the analog and digital outputs, will now

be based on the compensated measurement.

Note: TAM only affects readings in the RUN loop; LOG loop readings are not affected.

2.4.7.2 SETUP Values for LOG

Figure 2-11 illustrates SETUP for the LOG loop.

To setup values for the LOG modes and functions, do the following:

1. Release or unlock the trigger, if necessary.

2. Press the SET button. The SET icon will be activated.

3. Press the RUN/LOG button, if necessary, so that the LOG icon is activated.

4. Press the ▲ or ▼ buttons to select the LOG location number (LOC mode).

Figure 2-11: SETUP Loop–LOG Values

LOC Mode HAL Mode

RUN

RUN

LOG

LOG

SET

Press the Set button

again, if the display

goes out, to continue

the SETUP functions

LOG

RECALL

MODE

RECALL

MODE

SET

°C °F

( )

( )

HI

LO

T

amb

ACTIVATE

LASER

LASER

ACTIVATE

•

•

LOCK

LOCK

•

•

TRIGGER

Released & Unlocked

MODE

Press the ▲ and ▼

buttons to change the

Log Location (LOC)

number.

You can select and

log data in any location

number from 1 to 100.

BUTTON

SET & LOG

RUN

RUN

LOG

LOG

SET

Turn High Alarm

on or off with the

Activate button

RCL

LOG

( )

HI

RECALL

MODE

•

•

RECALL

MODE

LASER

LASER

LOOP ICON

LOG SET

SET

( )

LO

ACTIVATE

ACTIVATE

RCL

°C °F

T

amb

•

•

LOCK

LOCK

Change the High Alarm

temperature value with

the ▲ and ▼ buttons

Page 34

5. Press the MODE button.

6. Press the ▲ or ▼ buttons to change the HAL setting (HAL mode).

7. Press ACTIVATE to activate the HAL setting for the selected location.

SET contains two modes: LOC and HAL (as shown in Figure 2-11). In SET, the LOG

location can be selected and the high alarm value (HAL) can be set for each location

(independent of the setting for the RUN loop). Note the following:

• Press the MODE button to change modes.

• Press the backlight button if a brighter display is needed.

2.5 USING A TRIPOD

The instrument is equipped with a standard camera-type tripod mount fitting at the

base of the handle. You can set it up for continuous use by mounting it on a sturdy

tripod. This allows the instrument to be connected to a digital or analog recording or

controlling device (computer, printer, chart recorder, line or temperature controller) to

monitor temperatures over long periods of time.

Mounting the instrument is easy. Just attach it to the tripod by screwing the tripod’s

mounting screw into the fitting at the bottom of the handle.

You can also connect a digital or analog recording or controlling device to the digital/analog connector (labeled OUT) on the side of the instrument. For continuous

monitoring, pull the trigger and press the LOCK button.

Note that battery life is shortened by continuous use. If you plan to monitor temperatures over long intervals, you should connect an AC adaptor to the DC IN connector.

2-22 Raynger 3i Series Operator’s Manual

Page 35

Raynger 3i Series Operator’s Manual 2-23

2.6 DATA OUTPUTS

Data outputs from the instrument provide a direct interface to chart recorders, printers, and computers. All models are equipped with an output jack capable of providing analog and digital signals, which are user selectable in the SET loop. The format

of these signals are as follows:

• Digital: RS-232

Format: ASCII data

Baud Rate: 9600

Data Format: 8 bits, 1 stop bit, no parity

• Analog: 1 mV/° (°C or °F) for all models except the 1M

1 mV/°C or 0.5 mV/°F for the 1M

Figure 2-12: Data Outputs

F0072 E095 MAX 0080

F0072 E095 MAX 0080

F0072 E095 MAX 0080

F0072 E095 MAX 0080

F0072 E095 MAX 0080

F0072 E095 MAX 0080

F

0

0

7

2

E

0

F

9

0

5

0

7

M

2

A

X

E

0

0

F

9

0

0

5

8

0

0

7

M

2

A

X

E

0

0

9

0

5

8

F

0

0

M

0

A

7

X

2

0

E

0

0

8

9

F

0

5

0

0

M

7

A

2

X

E

0

0

0

9

8

F

5

0

0

0

M

7

A

2

X

E

0

0

0

F

9

8

0

5

0

0

7

M

2

A

X

E

0

0

9

0

F

5

8

0

0

0

M

7

A

2

X

E

0

0

0

F

9

8

0

5

0

0

7

M

2

A

X

E

0

0

9

0

5

8

0

M

A

X

0

0

8

0

RS232

RS232

Analog

Page 36

2.6.1 Digital Output

The following sections describe the digital data outputs for each mode.

2.6.1.1 Data Output—RUN Loop

In the RUN loop, the temperature scale, current temperature, emissivity, mode temperature (MAX, MIN, DIF, or AVG), HAL or LAL, a carriage return, and a line feed

are sent out at intervals determined by the DOI (set in the SET loop) when the trigger

is pulled. HAL or LAL is sent out if the temperature is above HAL or below LAL

(when they are activated). Three blank spaces replace HAL or LAL if they do not

meet this condition. There are 5 characters for the mode temperature. The fifth character is always a space for MAX, MIN, or DIF. For AVG, the fifth character is a space

if the average temperature is 1000° or above. Average temperatures up to 999.9° use

all 5 characters. A total of 29 characters are sent out.

Table 2-2 shows a sample output. The headings at the top of the table explain the contents of each column (these are not part of the output).

2-24 Raynger 3i Series Operator’s Manual

Table 2-2: RUN Mode Output Example

S

p

a

°C

c

e

or °F Temp Emissivity Value Mode Temperature 3 Blank Spaces Return Feed

S

p

a

Main E for Emissivity Mode HAL, LAL, or

c

e

S

p

a

c

e

S

p

a

c

e

S

p

a

c

e

S

p

a

c

e

Carriage Line

F 0072 E 0 . 95 MAX 0072 <CR> <LF>

F 0073 E 0 . 95 MAX 0073 <CR> <LF>

F 0090 E 0 . 95 MAX 0090 <CR> <LF>

F 0070 E 0 . 95 MAX 0090 <CR> <LF>

F 0071 E 0 . 95 MAX 0090 HAL <CR> <LF>

F 0081 E 0 . 95 MAX 0090 <CR> <LF>

F 0080 E 0 . 95 MAX 0090 <CR> <LF>

F 0070 E 0 . 95 MIN

F 0070 E 0 . 95 DIF

F 0081 E 0 . 95 AVG

F –018 E 0 . 95 AVG

F 0421 E 0 . 95 AVG

F 1480 E 0 . 95 AVG

0070 <CR> <LF>

0020 <CR> <LF>

088.4 <CR> <LF>

–11.5 <CR> <LF>

100.0 <CR> <LF>

999.9 <CR> <LF>

F 1900 E 0 . 95 AVG 1000 <CR> <LF>

F 0071 E 0 . 95 MAX 0090 <CR> <LF>

F 0081 E 0 . 95 MIN

F 0081 E 0 . 95 MIN

C

0027 E 0 . 95 MIN –028 <CR> <LF>

C

0027 E 1 . 00 MIN –028 <CR> <LF>

–018 LAL <CR> <LF>

–018 <CR> <LF>

Notes

(see below)

1

2

3

4

5

6

7

8

9

10

11

Page 37

Raynger 3i Series Operator’s Manual 2-25

Notes:

1. Indicates HAL is active and temperature HAL value.

2. Mode changed to MIN.

3. Mode changed to DIF.

4. Mode changed to AVG.

5. Main and Average temperatures went negative.

6. Average temperature goes positive and is 100°F.

7. Average temperature is up to 999.9°F.

8. Average temperature is now greater than 999.9°F so decimal point is no longer

displayed.

9. Indicates LAL is active and temperature LAL value.

10. Scale is changed from °F to °C.

11. Emissivity is changed to 1.00.

2.6.1.2 Data Output—SET Loop

After entering the SET loop (SET icon activated), setup parameters can be sent out by

pressing the SET button again. This information can be sent out at any time while still

in the SET loop. Unactivated setpoints are printed in lowercase (e.g., hal) and activated setpoints are printed in uppercase (e.g., HAL). Hi Alarm, Low Alarm, T. Ambient,

Temperature Scale, and DOI are sent out and terminated by a carriage return and line

feed. A total of 39 characters are sent out. The SET values will be printed any time

you press the SET button. Two examples follow:

hal 0085 lal 0065 tam 0100 F;DOI 3600<CR><LF>

(hal, lal, tam not activated)

HAL 0085 lal 0065 tam 0100 F;DOI 3600<CR><LF> (HAL activated)

The above lines indicate Hi Alarm = 85, Low Alarm = 65, T. Ambient = 100, the temperature scale is °F, and DOI = 3600 seconds. (The <CR> and <LF> do not print; these

denote the carriage return and line feed.)

Note: DOI does not apply to the SETUP mode.

Page 38

2.6.1.3 Data Output—LOG Run Loop

When you press the trigger (first stage only) in the LOG Loop, data will be sent out

only for those locations that have stored data. The temperature scale, stored main

temperature, stored emissivity, stored MAX temperature, location number, HAL, a

carriage return, and a line feed are sent out when the trigger is pressed. HAL is sent

out if the stored temperature is above or equal to the HAL value for that location, and

HAL is activated. Three spaces replace HAL if this condition is not satisfied. A total

of 32 characters are sent out.

Table 2-3 shows a sample output. The headings at the top of the table explain the contents of each column (these are not part of the output).

Notes:

1. Current and MAX temperature stored at Location 1.

2. Current and MAX temperature stored, and the emissivity changed to 1.00 at

Location 6.

3. Current and MAX temperature stored at Location 7, HAL is active, and the

stored temperature is HAL value. When the 2-stage trigger is pulled all the

way to store the current and maximum temperatures at Location 7, the current

temperature also exceeded the HAL value, which was activated. Therefore,

HAL was sent out at the end of the string.

Notes: Note that in the above example nothing was stored at locations 2, 3, 4, 5, and 8 through

99, so these locations were not sent out. There will be a pause in printing between

locations 1 and 6 and between locations 7 and 100 because the unit is searching

through the locations sequentially for stored data.

DOI does not apply to the LOG mode.

2-26 Raynger 3i Series Operator’s Manual

Table 2-3: LOG Run Mode Output Example

S

p

a

°C

c

e

or °F Temp Emissivity Value Mode Temperature Number HAL Return Feed

S

p

a

Main E for Emissivity Stored MAXMAX Location

c

e

S

p

a

c

e

S

p

a

c

e

S

p

a

c

e

S

p

a

c

e

F 0072 E 0 . 95 MAX 0090 001 <CR> <LF>

F 0095 E 1 . 00 MAX 0100 006 <CR> <LF>

F 0070 E 0 . 95 MAX

F 0090 E 0 . 97 MAX

0090 007 HAL <CR> <LF>

0100 100 <CR> <LF>

S

p

a

c

e

Carriage Line

Notes

(see below)

1

2

3

Page 39

2.6.1.4 Data Output—LOG SETUP Loop

After entering the LOG SETUP loop (both the LOG and SET icons are activated),

setup parameters are sent out when the SET button is pressed again. This information can be sent out at any time in the LOG SETUP mode. HAL, temperature scale,

and the location number are sent out and terminated by a carriage return and line

feed. A total of 16 characters are sent out. Go to the appropriate location number in

the LOG loop and press the SET button to send out the Hi Alarm value for that location. Activated Hi Alarm locations are uppercase (HAL), and unactivated Hi Alarm

locations are lowercase (hal). Only the HAL value at the present location is sent out.

For additional HAL values, go to the appropriate location and press SET again while

still in any of the two screens in the LOG SETUP mode. To get the LOG SETUP para-

meters for all 100 log locations, press the SET button for about 3 seconds.

Table 2-4 shows a sample output. The headings at the top of the table explain the contents of each column (these are not part of the output).

Notes:

1. For Location 1, HAL is not activated and is 1000°F.

2. For Location 2, HAL is activated and is 1000°F.

3. For Locations 3, 4, 5, 6, and 7, HAL is not activated and is 85°F.

4. For Location 8, HAL is activated and is 65°F.

Note: DOI does not apply to the LOG SETUP mode.

Raynger 3i Series Operator’s Manual 2-27

Table 2-4: LOG SETUP Mode Output Example

S

S

p

a

hal

c

e

or HAL Value or °F Number Return Feed

S

p

p

a

a

HAL °C Location

c

c

e

e

Carriage Line

Notes

(see below)

hal 1000 F 001 <CR> <LF>

HAL 1000 F 002 <CR> <LF>

hal 0085 F 003 <CR> <LF>

hal 0085 F 004 <CR> <LF>

hal 0085 F 005 <CR> <LF>

hal 0085 F 006 <CR> <LF>

hal 0085 F 007 <CR> <LF>

HAL 0065 F 008 <CR> <LF>

1

2

3

3

3

3

3

4

Page 40

2.6.2 Analog Output

The analog output is made up of the following:

• Output: 1 mV/° (°C or °F) for all models except 1M

1 mV/°C or 0.5 mV/°F for the 1M

• Output impedance: 1.3 K

W

Use the signal output jack accessory.

The analog output represents the current temperature of the object being measured,

regardless of the mode used. If T

amb

compensation is activated, the analog output

will be representative of the compensated temperature values.

2-28 Raynger 3i Series Operator’s Manual

Page 41

Raynger 3i Series Operator’s Manual 2-29

2.7 SIGHTING SYSTEMS

The aiming options for this instrument are laser(s), scope, or laser and scope combination. Laser sighting is available in single or dual spot models or in a crossed laser model.

Two different laser power levels are available for this product. Please refer to the label on

your unit and to the following label diagrams (Figure 2-13) to determine the one that you

have. The following table shows the specifications for both laser types.

CAUTION

Use of controls or adjustments, or performance of procedures other than

those specified herein, may result in hazardous laser radiation exposure.

WARNING—LASER SAFETY

Models with laser sighting produce visible laser radiation that may be

harmful to the human eye. Be aware of the following:

• Avoid direct exposure of human eyes to laser light. Eye damage can

result.

• Use extreme caution when operating.

• Never point the unit at another person.

• Keep out of the reach of children.

• Refer to the FDA laser label on the unit for specific information.

To operate the laser, do the following:

1. Point the instrument toward the spot being measured. (Do not point it at anyone.)

2. Pull the trigger.

3. Press the Laser button on the control panel.

4. Aim accordingly. (Refer to the following sections for laser aiming information.)

Note: The laser turns off automatically when the trigger is released. It cannot be locked on when

the trigger is locked. It cannot be turned on in the Recall and Setup loops.

Table 2-5: Laser Specifications

FDA Class IIIa FDA Class II and IEC Class 2

Type

Wavelength

Power

Operating Range

(depending on ambient

light level)

Gallium Arsenide

630-670 nm

<5 milliwatt

Up to 30 m (100 ft)

Gallium Arsenide

630-670 nm

<1 milliwatt

Up to 15 m (50 ft)

Page 42

2-30 Raynger 3i Series Operator’s Manual

FDA Class II

Figure 2-13: Laser Labels

AVOID EXPOSURE LASER RADIATION IS

EMITTED FROM THIS

APERTURE.

CAUTION

LASER RADIATION - DO

NOT STARE INTO BEAM

OUTPUT < 1mW

WAVELENGTH 630-670 nm

CLASS II LASER PRODUCT

COMPLIES WITH

FDA 21 CFR

SUBCHAPTER J

FDA Class IIIa

IEC Class 2

POR ESTA ABERTURA

SE EMITE RADIACION

LASER. EVITE

EXPONER LA VISTA.

AVOID EXPOSURE LASER RADIATION IS

EMITTED FROM THIS

APERATURE.

<1mW/630–670nm

IEC 825/93

PELIGRO

RADIACION LASER – EVITE

EXPONER LA VISTA

SALIDA < 5mW

`

LONGITUD DE ONDA 630-670 nm

PRODUCTO LASER CLASE IIIa

DANGER

LASER RADIATION - AVOID

DIRECT EYE EXPOSURE

OUTPUT < 5mW

WAVELENGTH 630-670 nm

CLASS IIIa LASER PRODUCT

LASER LIGHT

DO NOT STARE INTO BEAM

CLASS 2 LASER

RAYONNEMENT LASER

NE PAS EXPOSER L'OEIL

AU RAYON LASER

LASER DE CLASSE 2

CUMPLE CON LAS

NORMAS FDA 21 CFR

SUB CAPITULO J

COMPLIES WITH

FDA 21 CFR

SUBCHAPTER J

LASERLIGHT

NICHT IN DEN STRAHL

BLICKEN

LASER KLASSE 2

RAYO LASER

NO FIJAR LA VISTA

EN EL RAYO

LASER CLASE 2

Page 43

Raynger 3i Series Operator’s Manual 2-31

2.7.1 Single Laser Sighting

A single laser unit (see Figure 2-14) indicates the center of the area being measured,

not the diameter of the spot. (To find out the diameter of the spot being measured,

refer to the optical charts in Appendix A.)

2.7.2 Dual Laser Sighting

A dual laser unit indicates the diameter of the spot being measured. To take a measurement, aim the unit at the target and move closer or farther until the target is within the laser dots.

Note: The IR and laser spot diameters are not the same at close distances. The distance

between the laser beams is slightly greater than the spot being measured. Refer to

Figure 2-15 for a comparison of the IR spot and laser beam diameters.

Figure 2-15: Dual Laser and IR Spot Diameters

Figure 2-14: Single Laser Sighting

Dual Laser Focus Point D:S = 75:1 @ 15 m (50 ft) Far Field D:S = 68:1

DISTANCE: SENSOR TO OBJECT (ft)

0

SPOT DIA. (in)

SPOT DIA. (mm)

02

IR Spot Diameter at Lens = 23 mm (0.9 in)

Laser Diameter at Lens = 40 mm (1.6 in)

10 20 30 40 50

16

12

8

4

0

75

150

225

300

4 6 8 10 12 14 16

DISTANCE: SENSOR TO OBJECT (m)

IR

LASER

Page 44

2-32 Raynger 3i Series Operator’s Manual

2.7.3 Crossed Laser Sighting

The distance at which the two laser dots overlap is the point where the smallest area

is measured (Focus Point). To find this distance, aim the unit at the target and move

closer or farther until the laser beams overlap. Refer to Figure 2-16 for a comparison

of the IR spot and laser beam diameters.

2.7.4 Scope Sighting

Scope sighting models (Figure 2-17) have parallax-free sighting (at the focus distance).

Look through the scope. There are one or two circular reticles, depending on model.

The inner reticle indicates the area that is measured at the focus point (see Appendix

A for the focus point distance for your model). The outer reticle indicates an area

greater than or equal to the area that is measured at all other distances.

Figure 2-16: Crossed Laser and IR Spot Diameters

Figure 2-17: Scope Sighting

Crossed Laser Focus Point D:S = 75:1 Far Field D:S = 20:1

DISTANCE: SENSOR TO OBJECT (in)

0

24 36 60 120 180

12

Focus Point

0.3 in @ 24 in

SPOT DIA. (in)

Focus Point

8 mm @ 610 mm

SPOT DIA. (mm)

0 610

1000 1500 3000 5000

DISTANCE: SENSOR TO OBJECT (mm)

9

6

3

0

75

150

225

300

Page 45

Raynger 3i Series Operator’s Manual 2-33

2.7.5 Scope with Laser Sighting

The scope and single laser sighting model (Figure 2-18) combines the parallax-free sighting of the scope with the convenience of the laser. The combination unit has a single

class 2 laser. It indicates the center of the target being measured, not the diameter of the

spot being measured. See section 2.7.1 and Figure 2-14 for further details on the laser.

The scope has one reticle and it indicates the target area that is measured at the focus

point (see Appendix A for the focus point distance of your model). See section 2.7.4 and

Figure 2-17 for further details on the scope.

Figure 2-18: Scope with Laser Sighting

Page 46

2-34 Raynger 3i Series Operator’s Manual

Page 47

Raynger 3i Series Operator’s Manual 3-1

3.0 SPECIFICATIONS

This section covers the following specifications:

• Thermal

• Operational

• Electrical

• Environmental

• Physical

Also covered are factory default settings for each model as well as factory default settings and range values for all models.

3.1 THERMAL

Table 3-1 lists thermal specifications for each model.

Table 3-1: Thermal Specifications

* The instrument may measure temperature a few degrees below the minimum and

above the maximum specified temperature range.

Note: Hi Alarm, Lo Alarm, and T. Ambient ranges are the same as measurement ranges in

Table 3-1.

1M 2M G5 P7

600 to 3000°C

1.0 micron

Silicon diode

±0.5% of reading or ±1°C (±1°F), whichever is greater

200 to 1800°C

(400 to 3275°F)

1.6 micron

InGaAs diode

±3mV of display reading

150 to 1800°C

(300 to 3275°F)

5 micron

Thermopile

10 to 800°C

(50 to 1450°F)

7.9 micron

Thermopile

Measurement

Range

Spectral

Response

Detecting

Element

Display

Accuracy

Analog Output

Accuracy

Repeatability

Temperature

Coefficient

LT, LR, LRSCL2

-30 to 1200°C

(-20 to 2200°F)

8 to 14 micron

Thermopile

±1% of reading (±0.5% for 1M) or ±1°C (±1.5°F), whichever is greater, or ±2°C (±4°F)

for targets below 0°C (32°F), at 23°C ±5°C (73°F ±9°F) ambient operating temp.

(1100 to 5400°F)

±0.1°C (±0.1°F) change per 1°C (1°F) change in ambient temperature

Page 48

3-2 Raynger 3i Series Operator’s Manual

3.2 OPERATIONAL

Table 3-2 lists operational specifications for each model.

Table 3-2: Operational Specifications

Temperature

Display

Display and Digital

Output Resolution

Display Controls

Emissivity

DOI (Digital

Output Interval)

Analog Output

Resolution

LOG Locations

Response Time

(95% response)

LT, LR, LRSCL2

°C or °F (selectable), multifunctional 4-digit backlit LCD

1°C or 1°F (0.1°C or 0.1°F in AVG Mode for temperatures up to 999.9°)

Adjustable from 0.10 to 1.00 in 0.01 increments (default = 0.95)

700 msec 550 msec 700 msec 700 msec550 msec

1M 2M G5 P7

Membrane Switch Panel

1 to 9999 seconds

1°C or 1°F

1 to 100

Page 49

Raynger 3i Series Operator’s Manual 3-3

Table 3-3: Electrical Specifications

3.3 ELECTRICAL

Table 3-3 lists electrical specifications for each model.

LT, LR, LRSCL2 1M 2M G5 P7

Analog Output

Analog Output

Range

Analog Output

Impedance

Digital Output

Digital Output

Range

Power

Requirements

1mV/°C (1mV/°F) 1mV/°C (1mV/°F)

Four (4) AA alkaline or rechargeable batteries or 6 to 9 volt, 200 mA, DC power supply

1mV/°C (0.5mV/°F)

Same as Measurement Range in Table 3-1

1.3 KΩ

RS232, 9600 baud

Same as Measurement Range in Table 3-1

Page 50

3-4 Raynger 3i Series Operator’s Manual

3.4 ENVIRONMENTAL

Table 3-4 lists environmental specifications for each model.

Table 3-4: Environmental Specifications

3.5 PHYSICAL

Table 3-5 lists environmental specifications for each model.

Table 3-5: Physical Specifications

Note: The laser will turn off automatically if the instrument’s internal temperature exceeds

45° C (113° F).

LT, LR, LRSCL2

Relative

Humidity

Storage

Temperature

Ambient

Operating

Temperature

1M

10 to 95% at up to 30°C (86°F)

under non-condensing conditions

-20 to 50°C (-4 to 120°F)

0 to 50°C (32 to 120°F)

2M G5 P7

without battery

SCOPE & LASER

244 mm (9.6 in) H

257 mm (10.1 in) L

71 mm (2.8 in) W

1000 g (2.21 lbs)

Dimensions

Weight

SCOPE MODELSLASER MODELS

208 mm (8.2 in) H

257 mm (10.1 in) L

71 mm (2.8 in) W

794 g (1.75 lbs) 1000 g (2.21 lbs)

244 mm (9.6 in) H

257 mm (10.1 in) L

71 mm (2.8 in) W

Page 51

Raynger 3i Series Operator’s Manual 3-5

3.6 DEFAULT VALUES

Table 3-6 lists the factory default values for each model.

Table 3-6: Model Specific Factory Default Values

Table 3-7 lists factory default settings that are valid for all models.

Table 3-7: Non-Model Specific Factory Default Values

Hi Alarm Lo Alarm T. Ambient

LTDL, LTCL, LTSC,

LRSC, LRL, LRSCL2

1200°C

(2200°F)

0°C

(0°F)

23°C

(73°F)

1MSC, 1ML

P7DL

G5SC

2MSC, 2ML

3000°C

(5400°F)

800°C

(1450°F)

1800°C

(3275°F)

1800°C

(3275°F)

600°C

(1100°F)

10°C

(50°F)

150°C

(300°F)

200°C

(400°F)

600°C

(1100°F)

23°C

(73°F)

150°C

(300°F)

200°C

(400°F)

Function Default

Emissivity

DOI (Digital Output Interval)

Digital/Analog Output

Trigger LOCK

Laser

Backlight

HAL

LAL

TAM

Scale: U.S.

Scale: Outside U.S.

Loop

Setup Screen (RUN Loop)

Setup Screen (LOG Loop)

LOG Location

0.95

60 seconds

Analog Output

off

off

off

off

off

off

degrees F

degrees C

RUN Loop, MAX Mode

F/C

LOC (Location)

1

LOG Data–All Locations

Current Temperature

MAX Temperature

Hi Alarm Value

Hi Alarm State

Emissivity

0 degrees C, or 0 degrees F

0 degrees C, or 0 degrees F

See Table 3-6

off

0.95

Page 52

3-6 Raynger 3i Series Operator’s Manual

Note: When you simultaneously press the MODE and ACTIVATE buttons while in the

RUN loop, the instrument is reset to its RUN loop factory default settings (stored data

is unaffected). In the LOG loop, pressing the MODE and ACTIVATE buttons not only

resets the instrument to its LOG loop factory default settings, but also clears all previously stored data. In both cases, the instrument will “beep” after reinstalling the

default settings. Section 3.6 lists default setting for each model as well as non-modelspecific default settings and range values.

3.7 REGULATORY

The appropriate regulatory approvals and certificates have been issued as follows:

• FDA Class II Laser Certification

• FDA Class IIIa Laser Certification

• IEC Class 2 Laser Certification

• IEC801-3 (EN50082) for EMI susceptibility

Page 53

Raynger 3i Series Operator’s Manual 4-1

4.0 MAINTENANCE

4.1 BATTERY REPLACEMENT

When the battery icon comes on, you need to replace the batteries. To open the

battery compartment, press gently on the middle of the sliding panel (located on the

bottom of the handle) and slide it to the rear of the unit. Remove the batteries and

replace with four AA batteries. Be sure to insert the new batteries so they point in the

proper direction. (A symbol on the side of the handle shows the proper battery orientation.) Replace the battery compartment cover.

4.2 CLEANING

You should periodically clean the instrument’s front window and housing.

4.2.1 Front Window Cleaning

A dirty front window can cause temperature measurement errors. The window is

fragile, and care should be taken when cleaning it to prevent scratching. Use camera

lens or eye glass tissues to clean the window.

Periodic cleaning can be done by completing one or more of the following: