Page 1

Constant Running

Hydraulic Pump

Installation Guide

Drives covered:

M81125 Type CR1 (3 L) Constant Running Pump 12 V

M81127 Type CR1 (3 L) Constant Running Pump 24 V

M81126 Type CR2 (4.5 L) Constant Ru nning Pump 12 V

M81128 Type CR2 (4.5 L) Constant Ru nning Pump 24 V

Document number: 81179-3

March 2001

Page 2

2 Constant Running Hydraulic Pump - Installation Guide

Important information

Safety notices

WARNING: Product installation

This equipment must be installed and operated in accordance

with the instructions contained in this handbook. Failure to do so

could result in poor pr oduct performance, personal injury and/

or damage to your boat.

Because correct performance of the boat’s steering is critical for

safety , we STRONGLY RECOMME ND that an Authori zed

Raymarine Service Representative fits this product.

WARNING: Navigation aid

Although we have designed this pr oduct to be accurate and

reliable, many factors can affect its performance. As a result, it

should only be used as an aid to n avigation and should never

replace commons ense and navigational judgement. A lways

maintain a permanent watch so you can respond t o situations as

they develop.

EMC conformance

All Raymarine equipment and accessories are designed to the best

industry standards for use in the recreational marine environment.

The design and manufacture of Raymarine equipment and

accessories conform to the appropriate Electromagnetic

Compatibility (EMC) standards, but correct installation is required to

ensure that performance is not compromised.

Handbook information

T o the best of our knowledge, the information in this han dbook was

correct when it went to press. However, Raymarine cannot accept

liability for any inaccuracies or omissions it may contain. In addition,

our policy of continuous product improvement may change

specifications without notice. As a result, Raymarine cannot accept

liability for any differences between the product and the hand book.

© Raymarine Ltd 2001.

Page 3

Constant Running Hydraulic Pump - Installation Guide 3

Introduction

Product description

W elcome to the installation guide for the Raymarine constant running

(CR) hydraulic pump. This product is intended to operate the boat ’s

steering mechanism as part of a Raymarine autopilot system.

The pump provides an ideal drive system for large boats and heavy

duty steering applications. It is primarily designed for use on boats

with an existing hydraulic steering system. Alternatively , you can use

this pump on a boat with mechanical steering in conjunction with a

secondary steering ram and bypass valve.

The pump contains a built-in reservoir that holds hydraulic fl uid and

an integral solenoid valve that controls the flow of hydraulic fluid t o

the steering ram. The autopilot system steers the boat by using the

solenoid control valves to control the flow of h ydraulic fluid to the

steering ram.

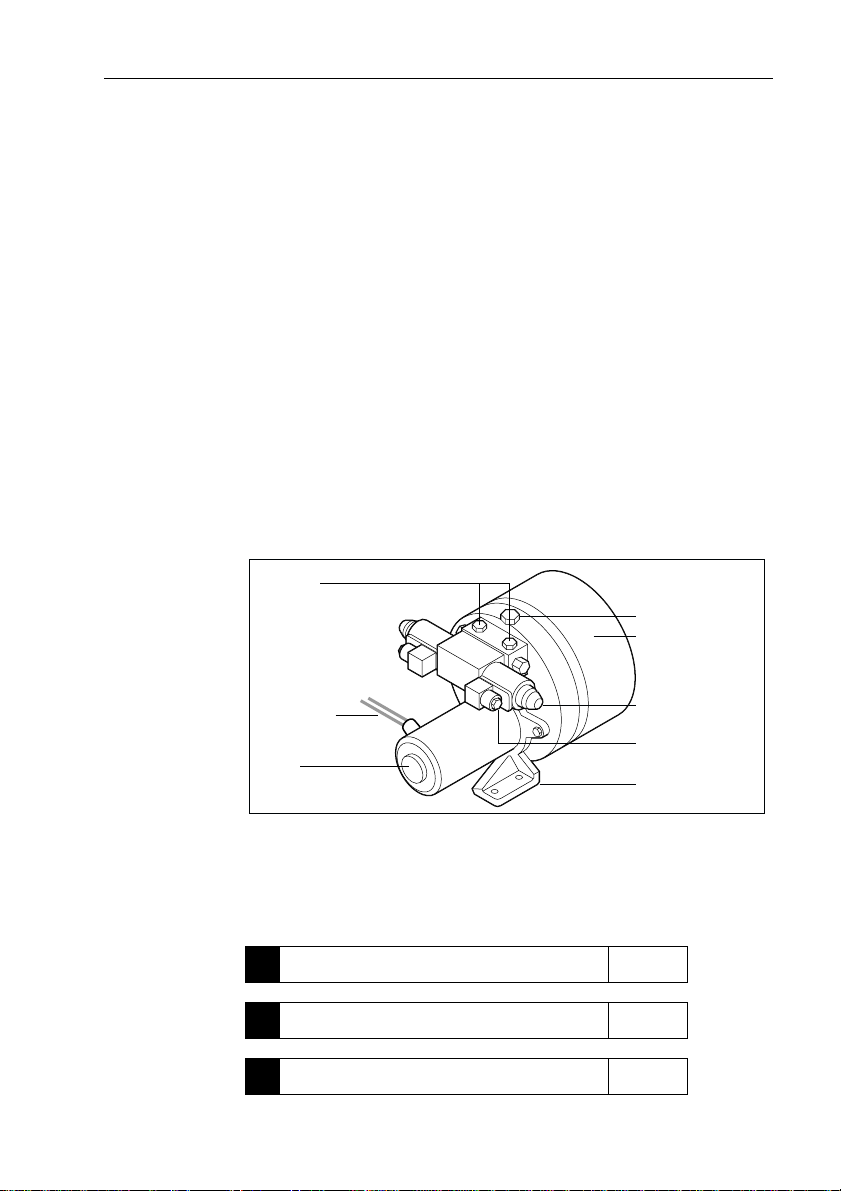

Ram ports

Reservoir port

Reservoir

Figure 1: Main parts of the CR pump

Contents

This guide contains:

Motor cables

Motor

Product specifications page 4

1

Installation instructions page 5

2

Maintenance information page 17

3

Solenoid

control valve x2

Power connector x2

(for solenoid control valve)

Mounting foot

D5176-1

Page 4

4 Constant Running Hydraulic Pump - Installation Guide

Specifications

Pump specifications

Table 1: Pump specifications

Performance

(at nominal voltage)

Ram capacity 350-500 cc

Ram single or double ended

Maximum stall

pressure (at 12 V)

Peak flo w rat e

(no load)

Other information (applies to Types CR1 and CR2)

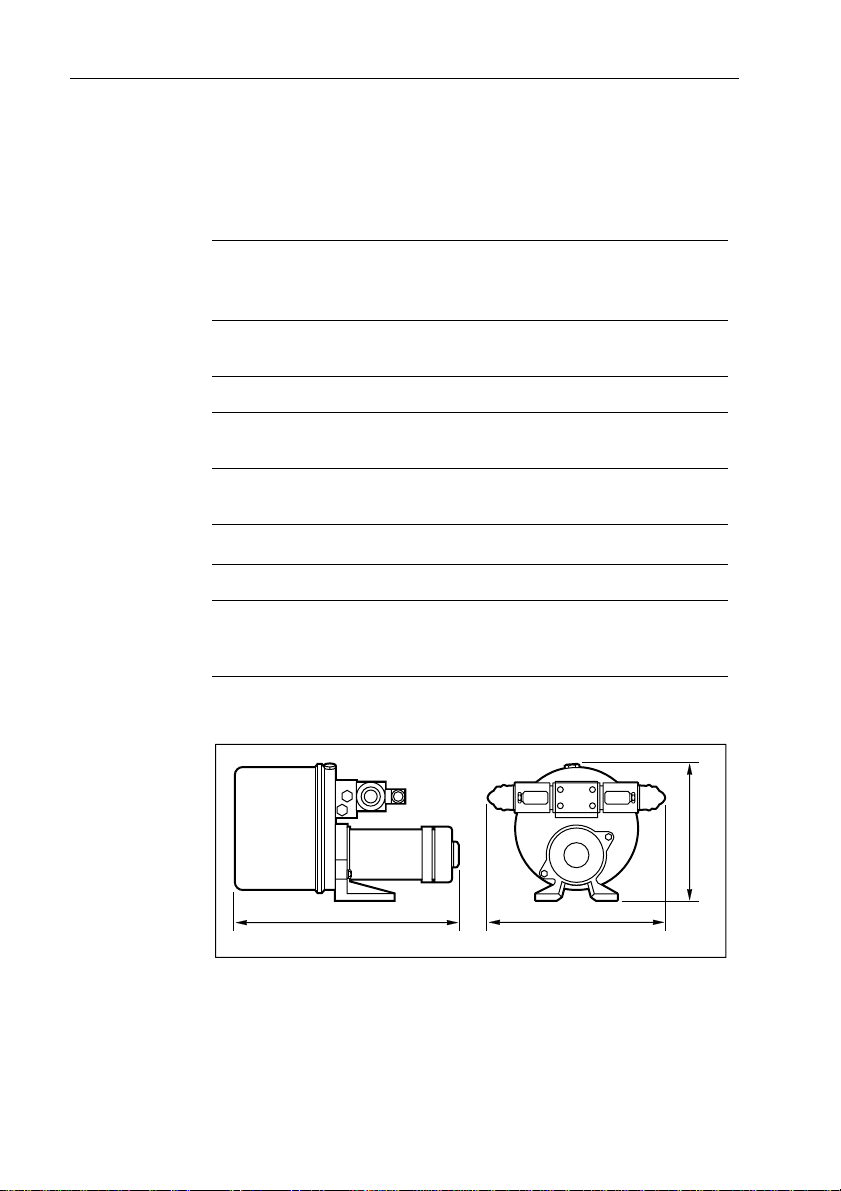

Pump dimensions

Typ e CR1

M81125 (12 V)

M81127 (24 V)

3

(21-30 in

)

50 bar

(750 psi)

3000 cc/min

3

/min)

(180 in

Type CR 2

M81126 (12 V)

M81128 (24 V)

500-1200 cc

(30-73 in3)

50 bar

(750 psi)

4500 cc/min

(270 in3/min)

protected for use in engine compartments

CE approvals - conforms to:

89/336/EC (EMC), EN60945:1997

94/25/EC (RCD), EN28846:1993

356 mm (14 in)

Figure 2: Pump dimensions

262 mm (10.3 in)

224 mm (8.8 in)

D5178-1

Page 5

Constant Running Hydraulic Pump - Installation Guide 5

Installation instructions

Parts required

T o install this drive you will need:

• Parts supplied:

• CR hydraulic pump

• if required: BSP to NP T adaptors (x3)

• Additional parts:

• suitable hydraulic pipes, hydraulic fluid, T -pieces, pipe

fittings and thread-sealing compound (see page8)

• suitable securing bolts, lock washers/lock nuts (see page 7)

• suitable cable and electrical connectors for the drive motor

and solenoid control valves (see page 13)

• CR interface (to connect to Ty pe 100/300 course computer)

• bypass valve (if connecting to a secondary steering ram)

Note: Obt ain these additional parts before you sta rt installation.

Installation steps

WARNING: Electrical safety

Make sure y ou have switched off the power su pply befor e you

start installing this product.

Follow these steps to install your CR pump:

Consult the EMC installation guidelines. page 6

1

Mount the pump. page 7

2

Connect to the hydraulic steering system. page 8

3

Connect to the course computer. page 13

4

Complete the post-installation checks. page 16

5

Ï

Ï

Ï

Ï

Page 6

6 Constant Running Hydraulic Pump - Installation Guide

1. EMC installation guidelines

All Raymarine equipment and accessories are designed to the best

industry standards for use in the recreational marine environment.

Their design and manufacture conforms to the appropriate

Electromagnetic Compatibility (EMC) standards, but correct

installation is required to ensure that performance is not

compromised. Although every effort has been ta ken to ensure that

they will perform under all conditions, it is importa nt to understand

what factors could affect the operation of the product.

The guidelines given here describe the conditions for opti mum EMC

performance, but it is recognized that it may not be possible to meet

all of these conditions in all situations. T o ensure the best possible

conditions for EMC performance within the constraints imposed by

any location, always ensure the maximum separation possible

between different items of electrical equipment.

For optimum EMC perform ance, it is recommended that wherever

possible:

• Raymarine equipment and cables connected to it are:

• At least 3 ft (1 m) from any equipment transmitting or cable s

carrying radio signals e.g. VHF radios, cables and antennas.

In the case of SSB radios, the distance should be increased to

7ft (2m).

• More than 7 ft (2 m) from the path of a radar beam. A radar

beam can normally be assumed to spread 20 degrees above

and below the radiating element.

• The equipment is supplied from a separate battery from that used

for engine start. Voltage drops below 10 V , and starter motor

transients, can cause the equipment to reset. This will not damage

the equipment, but may cause the loss of some information and

may change the operating mode.

• Raymarine specified cables are used. Cutting and rejoining these

cables can compromise EMC performance and must be avoided

unless doing so is detailed in the installation manu al.

• If a suppression ferrite is attached to a cable, this ferrite should no t

be removed. If the ferrite needs to be removed d uring installation

it must be reassembled in the same position.

Page 7

Constant Running Hydraulic Pump - Installation Guide 7

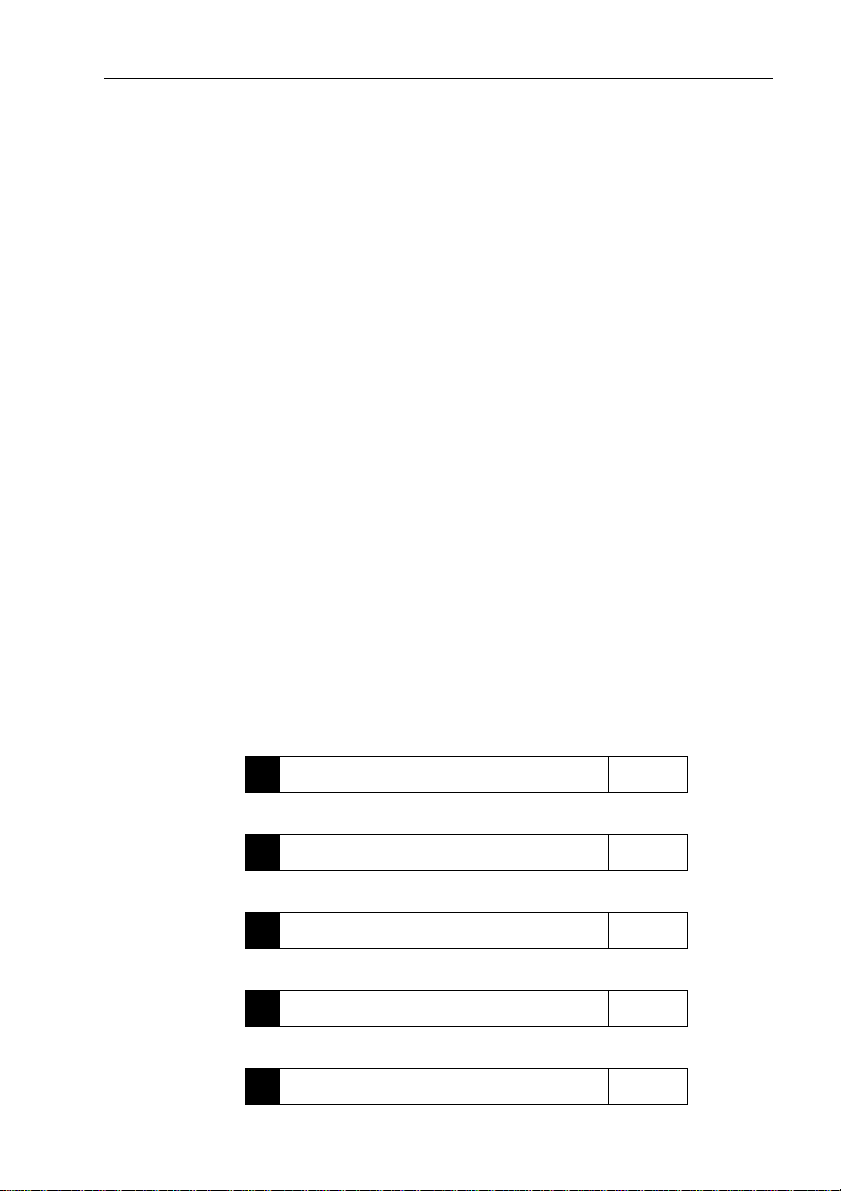

Suppression ferrites

This figure shows typical cable suppression ferrites us ed with

Raymarine equipment. Always use the ferrites suppl ied by

Raymarine.

D3548-2

Connections to other equipment

If your Raymarine equipment is to be connected to other equipment

using a cable not supplied by Raymarine, a suppression ferrite MUST

always be attached to the cable near to the Raymarine unit.

2. Pump mounting

CAUTION:

During installation, take care not to knock the CR pump’s

mounting feet on any solid structures as the impact may damage

the aluminium castings.

Mount the CR pump:

• on a substantial member to avoid vibration that could damage the

hydraulic pipes

• on a suitable horizontal surface clear of spray and possible water

immersion

• level or above the hydraulic steering ram to prevent air collecting

in the ram

• as close to the steering ram as possible

• using suitable bolts with lock nuts/lock washers

Note: As the pump can transmit noise to the boat’s st ructure, we

recommend placing rubber mounts between the pump and the boat’s

structure to reduce noise transfer.

CAUTION:

Locate the pump in a ventilated and soundpr oof enclosure.

Page 8

8 Constant Running Hydraulic Pump - Installation Guide

3. Hydraulic connections

CAUTION:

Before you connect the autopilot pump to your hydraulic system

we strong ly recomm end that you con sult the stee ring gear

manufacturer.

General guidelines

CAUTION:

Absolute cleanliness is essential when working with hydraulic

systems. Even the smallest particle of dirt could prevent the

steering system check valves fr om working properly .

• All pipes used to fit the pump should match, or exceed, the

specification of the existing steering system pipes. Contact the

steering system manufacturer if you need more information.

• Use flexible pipe to connect the pump to the boat’s steering

system - this avoids strain on the pipes .

• Try to keep hydraulic fluid loss to a minimum when installing the

pump. This will reduce the time and effort required to bleed the

system of trapped air after installation:

• non-pressurized systems: temporarily fit a non-ventin g plug

to the helm reservoir vent to minimize fluid loss

• pressurized systems:

WARNING:

Before disconnecting any pipes on pressurized systems, you

MUST release the pressure at the reservoir by following the

manufacturer’s instructions.

• The ram ports on the CR pump are tapped to

reservoir port is tapped to

3

/

in BSP. Three N P T adapto rs are

8

included for conversion to NPT where required.

• Follow the manufacturer’s instructions if you f it any T -pieces.

• Make sure all hydraulic pipes slope upwards towards the

reservoir.

• A set of bleed valves near the steering ram, fitted at the highest

point, will allow any air to escape upwards.

1

/

in BSP and the

4

Page 9

Constant Running Hydraulic Pump - Installation Guide 9

CAUTION:

Do not use P TFE tape on hydraulic pipe c onnections. If necessary

use a pipe-sealing compound t o ensure a leakpr oof joint.

CAUTION:

Before running the pump for the first time, make sure the system

contains suffi cient hydrauli c fluid. You will damage th e pump if

you let it run when ‘dry’.

Check valves

For single-steering position boats:

• Consult the steering gear manufacturer to determine whether the

helm pump is fitted with reversing check valves:

• without check valves, the autopilot pump will drive the helm

pump (sometimes referred to as ‘motoring the wheel’) instead

of moving the steering ram

• If the boat has a single helm pump system without check valves,

you must incorporate a double pilot check valve (part number:

M81166) as shown in Fi gure 3.

• A double pilot check valve may also be necessary on long pipe

runs - otherwise pipe expansion may cause poor autopilot

performance. Install the check valve as shown in Figure 3.

Note: If the boat has two steering positions, it will already have check

valves installed so the two wheels can operate independently.

Hydraulic steering systems

There are three basic types of hydraulic steering systems:

• two line system

• three line system

• two line pressurized system

On the following pages we describe each type of system and typical

connection points for the autopilot pump. For all of these systems you

will ne ed to connect a third hydraulic pipe as shown between the

autopilot pump and t he helm pump or d edicated system reservoir .

Page 10

10 Constant Running Hydraulic Pump - Installation Guide

Two line systems

Figure 3 shows a typical two line steering system. Hydraulic fluid

flows into the ram in either direction, depending on the direction the

helm pump rotates.

Connect the autopilot pump to the steering system as shown in

Figure 3.

Helm

pump

Check valve (if required)

Reservoir pipe

Ram pipes

Steering ram

CR pump

Figure 3: Autopilot pump location for two line systems

D

5168-1

Page 11

Constant Running Hydraulic Pump - Installation Guide 11

T wo line pressurized systems

T wo line pressurized systems have an external pressurized reservoir.

This reduces the possibility of introducing air i nto the system and

reduces any steering ‘sponginess’ caused by pipe expansion .

Connect the autopilot pump to the steering system as shown in

Figure 4.

Note: Refer to the manufacturer’s instructions for de-pr essurizing

and re-pressurizing the system.

Helm

pump

Reservoir pipe

Ram pipes

Steering ram

CR pump

5167-1

D

Figure 4: Autopilot pump location for two line pressurized systems

Page 12

12 Constant Running Hydraulic Pump - Installation Guide

Three line systems

In a three line system, the hydraulic fluid flows in only one direction:

• out of the helm pump to the ram

• returning from the other side of the ram to the reservoir via a

common return line

The system will include a check valve block to direct all returned

fluid from the ram back to the reservoir .

Connect the autopilot pump to the steering system as shown in

Figure 5.

Helm

pump

Check valve

CR pump

Reservoir

pipe

Ram pipes

Steering ram

Figure 5: Autopilot pump location for three line systems

D

5166-1

Page 13

Constant Running Hydraulic Pump - Installation Guide 13

4. Connecting to the course computer

WARNING: Electrical safety

Make sure the power su pply is swi tched off befo re you make any

electrical connections.

The CR pump has electrical connections for:

• motor supply: two single-core cables

• solenoid control valve supply: two plug-i n connectors (supplied)

Note: When routing cables, refer to the EMC installation guidelines.

Connecting to Type 150/400 course computer

Make the following connections:

1. CR pump motor supply:

• using appropriate cables (see Table 2) connect the CR pump

motor to the boat’s power supply , via an appropriate circuit

breaker and fuse (as specified in Figure 6)

2. Solenoid control val ves – using suitable cable (at least 16 AWG or

2

1.5 mm

• for the first valve: connect one core to the

for runs up to 16 m/52 ft):

and the other core to one of the

MOTOR A terminal

SOLENOID terminals at the

course computer (see Figure 6)

• for the second valve: connect one core to the

terminal and the other core to the other

SOLENOID terminal

MOTOR B

Note:

If installing the pump on a boat with mechanical steering, you

need to connect a bypass valve to the

Table 2: Recommended cable sizes

Pump motor cable length

(distribution panel to pump)

12 V CR pumps

24 V CR pumps

up to 3 m (10 ft)

up to 7 m (23 ft)

up to 16 m (52 ft)

up to 3 m (10 ft)

up to 5 m (16 ft)

up to 10 m (32 ft)

up to 16 m (52 ft)

CLUTCH

Cable gauge

(AWG)

10

8

6

12

10

8

6

terminals (see page 15).

Copper area

2

)

(mm

6

10

16

4

6

10

16

Page 14

14 Constant Running Hydraulic Pump - Installation Guide

Course computer

connections

O

SW

FF

To boat's battery

CR1 (12V) - 50A

CR1 (24V) - 30A

CR2 (12V) - 70A

CR2 (24V) - 40A

Circuit

breaker

ITCH

Fuse

Solenoid 'B' cable

Motor supply

Solenoid 'A' cable

CR pump

+–

A

MOTORPOWER

B

To bypass valve

(if required)

–

SO

–

LEN

O

–

ID

CLU

+

TCH

D5189-2

Figure 6: CR pump connections to a Type 150/400 course computer

Connecting to Type 100/300 course computer

When installing the CR pump with a T ype 100/ 300 course computer

we recommend using a Raymarine constant running (CR) inte rface

(part number: M81129).

Connecting the CR interface

Run cables from the main power supply to:

• the motor on the CR pump

• the CR interface and then onto the course computer power

connections

Install a suitable circuit breaker in the power supply to the co mplete

system (as specified in the core pack installation guide).

Note: It is important to use the correct cable size for the length of

cable run between the pump and the power supply (see Table 2).

The CR interface unit has connections for the solenoid valves (on the

CR pump) and a bypass valve (if fitting to a mechanical steering

system):

• connect the solenoid valves to the CR interface as shown in

Figure 7, using at least 16 A WG (1.5 mm

2

) cable.

Page 15

Constant Running Hydraulic Pump - Installation Guide 15

2

Circuit breaker

Fuse

Course computer

12 V - 25 A

24 V - 10 A

Supply

To bypass

valve (if

required)

CR1 (12 V) – 50 A

CR1 (24 V) – 30 A

CR2 (12 V) – 70 A

CR2 (24 V) – 40 A

1

3

Solenoid 'B' cable

Motor supply

5

1

2

4

Solenoid 'A' cable

+ –

BYPASS

VALVE

+ – + –

BATTERY

SOLENOIDS

3

4

5

A B

Type CR

interface unit

+ –

+

–

+

–

CLUTCH

SUPPLY

Course computer

connections:

CLUTCH

M1 M2

Figure 7: CR pump connections to a Type 100/300 course computer

Mechanical steering

If you are fitting the pump to a boat w ith mechanical steering you will

need to connect it to a secondary steering ram, along with a solenoidoperated bypass valve (part no. M81167 ). The bypass valve allows

you to switch between autopilot course control and manual steering.

T o fit to a mechanical steering system:

1. Use suitable hydraulic pipes to connect the pump to the secondary

steering ram and a suitable reservoir.

2. Install the solenoid-operated bypass valve across these pipes (as

shown in Figure8).

3. Connect the bypass valve to:

• the

CLUTCH terminals on the course computer (T ype 150/400

course computer), or

• the

BYPASS terminals on the CR interface (T ype 100/300

course computer

Note: Fo llow the manufacturer’s instructions for mounting the

hydraulic ram.

POWER

MOTOR

D5164-2

Page 16

16 Constant Running Hydraulic Pump - Installation Guide

Secondary steering ram

Bypass valve

Hydraulic pipes to

CR pump

Manual steering system Connect to:

CLUTCH terminal on 150/400 course computer

BYPASS on CR connector (100/300 course computer)

Figure 8: Connecting the bypass valve

5. Post-installation check

WARNING:

Keep clear of moving steering systems at all times. Protect

moving parts from access during normal use.

Check the following points after installing t he pump:

1. Is the pump installed as close to the steering ram as possible?

2. Is the pump secured to a substantial struct ure on the boat?

3. Have you connected a third hydraulic pipe between t he helm

pump and autopilot pump?

4. Have you fitted check valves where appropriate?

5. Are the hydraulic pipes made of a suitable flexible material (i.e.

rubber or nylon) with a suitable pressure rating?

6. Have you sealed all hydraulic connections and che cked for leakages?

7. Are power cables correctly routed and securely connected to the

course computer?

Y ou have now finished installing the pump. After installing the rest of

the autopilot you must bleed all air from the system (see below).

D5177-1

Note: W hen you have installed the entire autopilot system, you wil l

also need to complete an autopilot steering check. Refer to the control

unit handbook for more details.

Bleeding the system

Bleeding the hydraulic system correctly is one of the most important

steps when installing the autopilot hydraulic pump. If there is any air

Page 17

Constant Running Hydraulic Pump - Installation Guide 17

in the system the steering will feel spongy, particularl y when you turn

the wheel to hardover.

CAUTION:

Any air in the hydraulic system will greatly reduce the

performance of the autopilot and the overall steering system.

In addition to the manufacturer’s instruct ions for bleeding the

steering system, follow these steps to bleed the autopilot pump when

you have installed and set up the rest of the autopi lot system:

1. With the system in

• the autopi lot pump w ill try to d rive the r udder to po rt

• counter this rudder movement by turning the helm to

starboard to keep the rudder stationary

• you will be able to feel any air in the helm pump: any air in this

side of the pump will rise to the helm pump and exhaus t into

the reservoir

• continue until all of the air is out of this side of the pump

2. Clear any air on the other side of the pump:

• press the

• the autopilot will try to drive the rudder to starboard

• counter the rudder movement by turning the helm to port

• continue until all of the air is out of this side of the pump

3. Repeat in both directions until b oth sides of the help pump are

totally free of air.

auto mode, press the -10 button ten times:

+10 button te n times

Note: M onitor the reservoir at all tim es and top up with the

manufacturer’s recommended hydraulic fluid as required.

CAUTION:

After installation and bleeding, leave the system for 24 hours

then check for any air in the system or leaks at the joints and

around the pump.

Maintenance

On a regular basis:

• check all connections and mountings are secure

• check pipes and cables for any signs of wear or damage

• check hydraulic pipes and connections for leaks

Page 18

18 Constant Running Hydraulic Pump - Installation Guide

EMC servicing and safety guidelines

• Raymarine equipment should be serviced only by authorized

Raymarine service technicians. They will ensure that service

procedures/ replacement parts used will not affect performance.

There are no user serviceable parts in any Raymarine product.

• Some products generate high voltages, so never handle the cables

or connectors when power is being supplied to the equipment.

• When powered up, all electrical equipment produces

electromagnetic fields. These can cause adjacent pieces of

electrical equipment to interact with one another, with a

consequent adverse effect on operation. In order to minimize

these effects and enable you to get the best possible performance

from your Raymarine equipment, guidelines are given in the

installation instructions, to enable you to ens ure minimum

interaction between different items of equipment, i.e. ensure

optimum Electromagnetic Compatibility (EMC).

• Always report any EMC-related problem to your nearest Raymarin e

dealer. W e use such information to improve our quality standards.

• In some installations, it may not be possible to preven t the

equipment from being affected by ext ernal influences. In general

this will not damage the equipment but it can lead to spurious

resetting action, or momentarily may result in faulty operation.

Product support

Raymarine products are supported by a worldwide network of

distributors and Authorized Service Representa tives. If you

encounter any difficulties with thi s product, please contact either

your national distributor , service representative, or the Raymarine

T echnical Services Call Center.

Raymarine Ltd

Anchorage Park

Portsmouth, Hampshire

England PO3 5TD

Telephone +44 (0)23 9269 3611

Fax +44 (0)23 9269 4642

www.raymarine.com

Raymarine Technical Services Call Center

UK: +44 (0)23 9271 4713 or

+44 (0)23 9269 3611 ext. 1083

Raymarine Inc

22 Cotton Road, Suite 280

Nashua

NH 03063-4219, USA

Telephone +1 603 881 5200

Fax +1 603 864 4756

www.raymarine.com

USA: +1 603 881 5200 or

1-800-539-5539 ext. 2333

Loading...

Loading...