Page 1

DSM300

Digital Sounder

Module

Installation Manual

Document number: 87048-1

Date: November 2004

Page 2

Trademarks and registered trademarks

HSB, Raymarine and SeaTalk are registered trademarks of Raymarine Limited.

All other product names are trademarks or registered trademarks of their

respective owners.

Contents of this handbook ©Raymarine 2004

Page 3

3

Contents

Preface .....................................................................................................................5

Purpose .................................................................................................. 5

SAFETY NOTICE ...................................................................................... 5

EMC Conformance ................................................................................. 6

Conventions ........................................................................................... 6

Technical Accuracy ................................................................................. 6

Warranty ................................................................................................ 6

Chapter 1: DSM300 Installation ..........................................................................7

1.1 Introduction ........................................................................................... 7

Planning the Installation ........................................................................ 7

EMC Installation Guidelines ................................................................... 7

1.2 Unpacking and Inspecting the Components ........................................... 9

1.3 Selecting Sounder Module Mounting Location .................................... 10

1.4 Mounting the Sounder Module ............................................................ 11

1.5 Cable Runs ........................................................................................... 14

1.6 System Connections ............................................................................. 15

DC Power Connection .......................................................................... 15

Transducer Connection ........................................................................ 17

Ground Connection .............................................................................. 17

1.7 Configuration ....................................................................................... 20

Chapter 2: Transducer Installation ...................................................................23

2.1 Selecting the Correct Type of Transducer .............................................. 23

Applications ......................................................................................... 23

Accessories .......................................................................................... 25

2.2 Transducer Cable .................................................................................. 26

Transducer Cable Connections ............................................................. 26

2.3 Selecting the Equipment Location ........................................................ 29

Transducer Mounting Location ............................................................. 29

Transom Mount Transducer .................................................................. 30

2.4 Installing the Transom Mount Transducer ............................................ 35

Preparation .......................................................................................... 35

Installation ........................................................................................... 36

2.5 Installing the Thru-hull Transducer ....................................................... 36

Tools and Material Needed .................................................................. 36

Preparation .......................................................................................... 37

Installation ........................................................................................... 41

Drilling Holes ........................................................................................ 41

Installation in a Cored Fiberglass Hull .................................................. 48

2.6 Installing the In-hull Transducer ........................................................... 50

Tools and Material Needed .................................................................. 50

Page 4

4 DSM300 Installation Manual

Testing the Selected Mounting Location ...............................................50

Installation ...........................................................................................52

Installation in a Cored Fiberglass Hull ...................................................55

Chapter 3: Maintenance and Problem Solving ...............................................57

3.1 Maintenance ........................................................................................57

Routine Checks .....................................................................................57

Cleaning Instructions ............................................................................ 57

EMC Servicing and Safety Guidelines ...................................................58

3.2 Resetting the System ............................................................................59

3.3 Problem Solving ...................................................................................61

Common Problems and Their Solutions ................................................61

Status LED ............................................................................................ 62

3.4 How to Contact Raymarine ................................................................... 64

On the Internet .....................................................................................64

In the US ............................................................................................... 64

In Europe ..............................................................................................66

Worldwide Support ..............................................................................66

Appendix A: Specifications...............................................................................67

General ................................................................................................. 67

Sounder Features ..................................................................................67

Index ......................................................................................... 69

Page 5

Preface

Purpose

Raymarine DSM300 Digital So under Modules provide echo sounder data that ca n

be displayed on Raymarine E Series, C Series, and hsb

display units.

DSM300 Digital Sounder Modules are intended for recreational depth finding and

fishfinding purposes. Echo sounder systems require an appropriate Raymarine

transducer unit and inter-connecting cable.

This manual contains very important information for installing your DSM300 and

transducer. To obtain the best results in operation and performance, please read

this handbook thoroug hly. Raymarine’s Technical Services representatives or your

local dealer will be available to answer any questions you may have.

SAFETY NOTICE

This equipment must be installed and operated in accordance with the

instructions contained in this manual. Failure to do so can result in personal injury

and/or navigational inaccuracies. In particular:

CAUTION: High Voltage

The DSM300 contains high voltages. Adjustments require specialized service

procedures and tools only available to qualified service technicians – there are no

user serviceable parts or adjustments. The operator should never remove the

cover or attempt to service the equipment.

2

PLUS (Pathfinder) Series

5

CAUTION: Transducer Cable

Removing the transducer cable from the rear of the DSM300 while the sounder

module is powered on can cause sparks. Only remove the transducer cable after

power has been removed from the DSM300. As with any electronic device, be

sure the sounder module is mounted where it is well ventilated and free from

gasoline fumes.

If the transducer cable is accidentally removed while the DSM300 is powered on,

remove power from the sounder module, replace the transducer cable, and then

return power to the module. As a safety feature, the DSM300 only recognizes that

the transducer is connected at power-up.

Page 6

6 DSM300 Installation Manual

EMC Conformance

All Raymarine equipment and accessories are designed to the best industry

standards for use in the recreational marine environment.

The design and manufacture of Raymarine equipment and accessories confor m to

the appropriate Electromagnetic Compatibility (EMC) standards, but correct

installation is required to ensure that performance is not compromised.

Conventions

Throughout this handbook, the dedicated (labelled) keys are shown in bold

capitals; for example, ENTER. The soft key functions, menu names and options

are shown in normal capitals; for example, SCREEN.

Operating procedures, which may consist of a single key-press or a sequence of

numbered steps, are indicated by a ➤ symbol in the margin. When the procedure

requires you to press a soft key, the soft key icon is shown in the margin.

Technical Accuracy

To the best of our knowledge, the technical and graphical information contained

in this handbook was correct as it went to press. However, the Raymarine policy of

continuous improvement and updating may change product specifications

without prior notice. As a result, unavoidable differences between the product

and handbook may occur from time to time, for which liability cannot be accepted

by Raymarine.

Warranty

To register your DSM300 Digital Sounder Module ownership, please take a few

minutes to fill out the warranty registration card found at the end of this

handbook. It is very important that you complete the owner information and

return the card to the factory in order to receive full warranty benefits.

Page 7

Chapter 1: DSM300 Installation

1.1 Introduction

This chapter provides details for mounting the DSM300 and connecting to the

display.

For the system to display depth, water temperature and speed, you must install

the transducer type(s) capable of transmitting the appropriate data. Transducer

information is provided in Chapter 2.

Planning the Installation

Before you install your system, plan the installation, considering:

• Correct transducer for your application, as described in Section 2.1

• Location of the sounder module, as described in Section 1.3

• Cable Runs, as described in Section 1.5

EMC Installation Guidelines

All Raymarine equipment and accessories are designed to the best industry

standards for use in the recreational marine environment.

7

Their design and manufacture conforms to the appropriate Electromagnetic

Compatibility (EMC) standards, but correct installation is required to ensure that

performance is not compromised. Although every effort has been taken to ensure

that they will perform under all conditions, it is important to understand what

factors could affect the operation of the product.

The guidelines given here descri be the conditions for optimum EMC performa nce,

b ut it i s r ec o gn iz e d t ha t it ma y n ot b e p os si bl e t o m ee t a ll o f t he s e c on di ti o ns in a ll

situations. To ensure the best possible conditions for EMC performance within the

constraints imposed by any location, always ensure the maximum separation

possible between different items of electrical equipment.

For optimum EMC performance, it is recommended that wherever possible:

• Raymarine equipment and cables connected to it are:

• At least 5 ft (1.5 m) from any equipment transmitting or cables carrying

radio signals, e.g., VHF radios, cables and antennas. In the case of SSB

radios, the distance should be increased to 7 ft (2 m).

Page 8

8 DSM300 Installation Manual

• More than 7 ft (2 m) from the path of a radar beam. A radar beam can normally be assumed to spread 20 degrees above and below the radiating

element.

• The equipment is supplied from a separate battery from that used for engine

start. Voltage drops below 10 V and starter motor transients can cause the

equipment to reset.

This will not damage the equipment, but may cause the loss of some information and may change the operating mode.

• Raymarine specified cables are used. Cutting and rejoining these cables can

compromise EMC performance and must be avoided unless doing so is

detailed in the installation manual.

• If a suppression ferrite is attached to a cable, this ferrite should not be

removed. If the ferrite needs to be removed during installation it must be reassembled in the same position.

Suppression Ferrites

The following illustration shows typical cable suppression ferrites used with

Raymarine equipment. Always use the ferrites supplied by Raymarine.

D3548-3

Figure 1-1: Typical Suppression Ferrites

Connections to Other Equipment

If your Raymarine equipment is to be connected to other equipment using a cable

not supplied by Raymarine, a suppression ferrite must always be attached to the

cable that is closest to the Raymarine unit.

Page 9

Chapter 1: DSM300 Installation 9

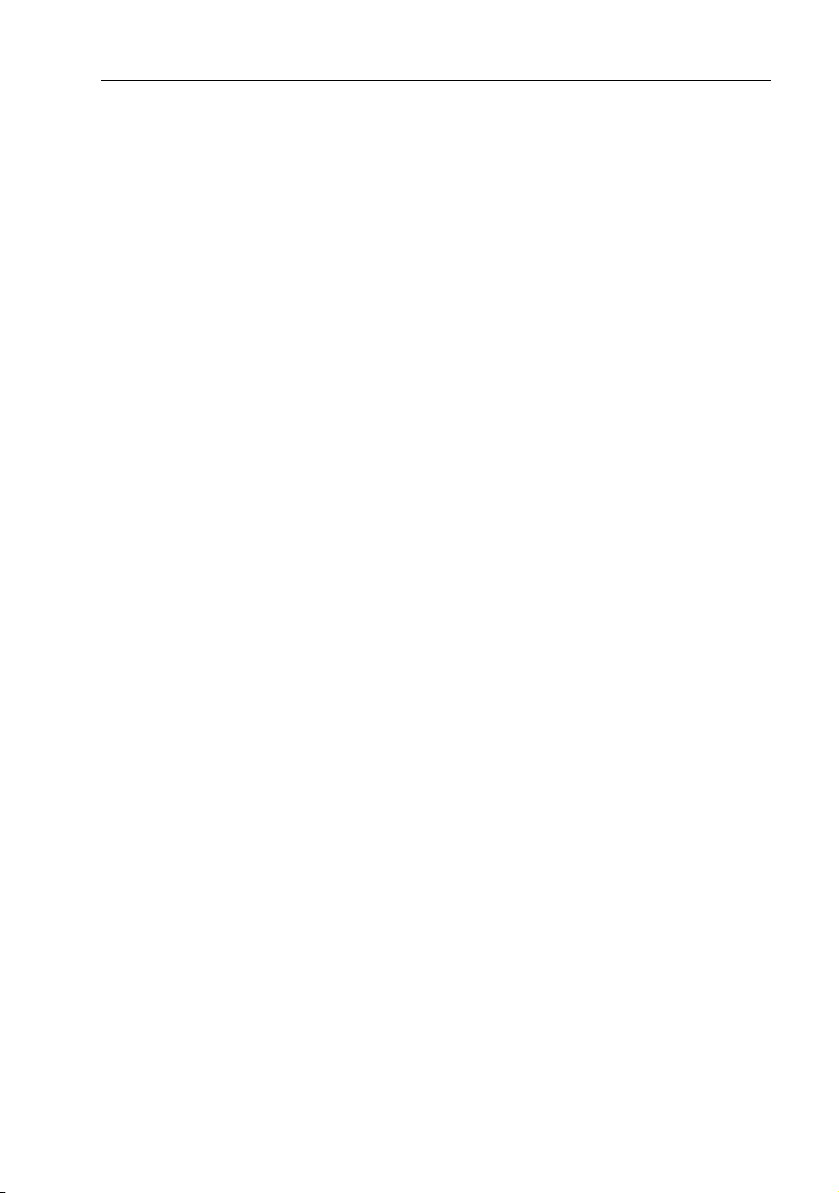

1.2 Unpacking and Inspecting the Components

Unpack your system carefully, to prevent damage to the equipment. Save the

carton and packing, in case you need to return the unit for service.

Check that you have all the correct system components:

Power Cable, 3m

part no. R69053

C Series Network Cable, 3m

Digital Sounder Module,

part no. E63069

DSM300

Installation

Manual

D7481-1

Installation Manual,

part no. 87048

DSM300

Operation

Manual

Operation Manual for PLUS

Displays, part no. 81249

part no. E65010

2

adapter, 4-pin to 3-pin

hsb

part no. R69081

Mounting Screws,

No.8 (x4)

A 3m-long cable is included for connecting your DSM300 to a C Series display.

Longer cables and connection cables for other types of systems must be

purchased separately. Select from the following:

Table 1-1: Cable Options

System Item Part No.

E Series

SeaTalkhs Network Cable, RJ-45, 1.5m

SeaTalkhs Network Cable, RJ-45, 5m

hs

SeaTalk

Network Cable, RJ-45, 10m

SeaTalkhs Network Cable, RJ-45, 20m

C Series C Series Network Cable, 4-pin-to-4-pin, 10m

DSM Cable, 4-pin-to-3-pin, 3m

DSM Cable, 4-pin-to-3-pin, 10m

2

hsb

PLUS Series

(Pathfinder)

hsb2 In Line Terminator

hsb2 Splitter Cable

E55049

E55050

E55051

E55052

E65011

E65009

E05016

R58117

E55040

Page 10

10 DSM300 Installation Manual

1.3 Selecting Sounder Module Mounting Location

The DSM300 is waterproof to IPX-7 is and is designed to be mounted either above

or below deck.

Mount the DSM300 where it is:

• protected from physical damage and excessive vibration

• protected from prolonged exposure to rain, salt spray and direct sunlight

• well ventilated

• as close to the transducer as possible

Do not locate the DSM300:

• in the engine compartment

• on the main console

When planning the installation, the following should be considered to ensure

reliable and trouble free operation:

•

Access: There must be sufficient space below the unit to enable cable con-

nections to the panel connectors, avoiding tight bends in the cable.

Interference: The selected location should be far enough away from

•

devices that may cause interference, such as motors, generators, and radio

transmitter/receivers. (See the EMC guidelines earlier in this chapter.)

•

Magnetic compass: Moun t the unit at least 3 ft (1 m) away from a magn etic

compass.

•

Cable runs: The unit must be located near a DC power source. The power

cable supplied is 10 ft (3 m).

•

Environment: Good ventilation is required to prevent the unit from over-

heating.

CAUTION: Do Not Remove the Transducer Cable

Removing the transducer cable from the DSM300 while power is

turned on can cause sparks. As with any electronic device, be sure

the sounder module is mounted where it is well ventilated and

free from gasoline fumes.

Page 11

Chapter 1: DSM300 Installation 11

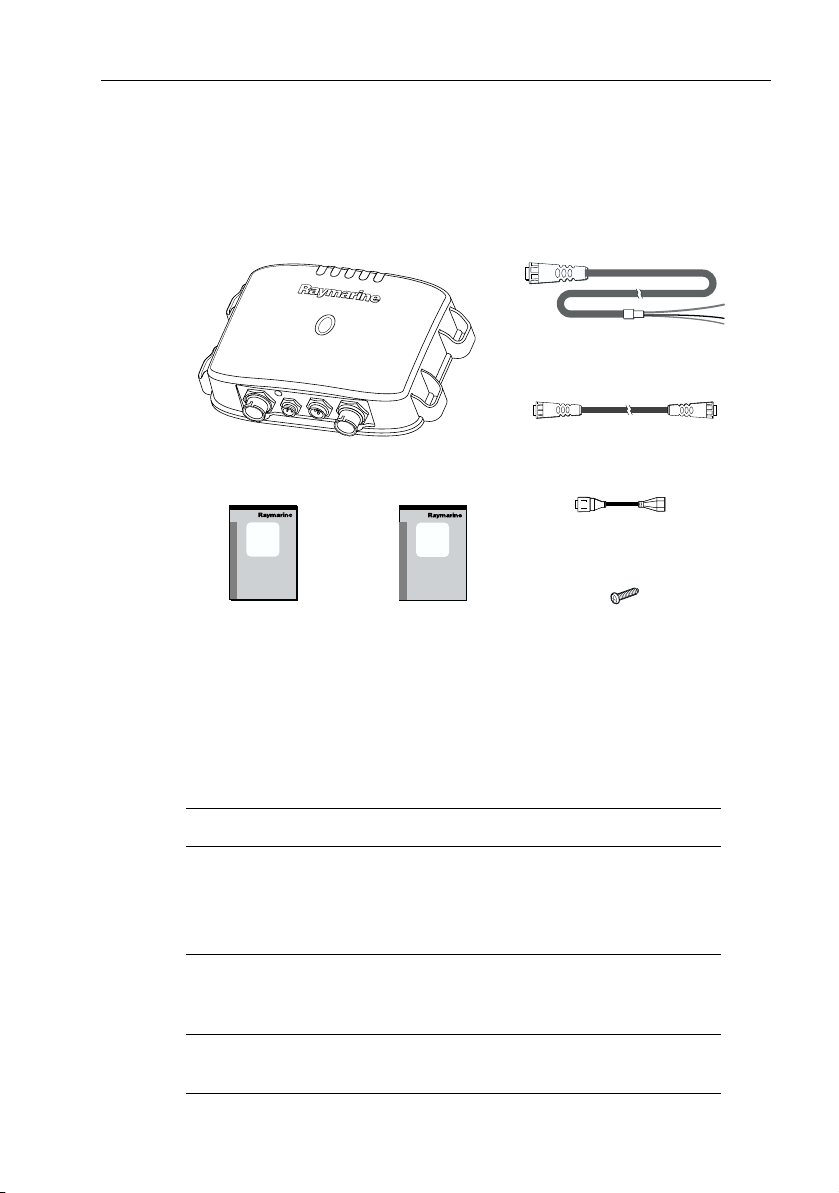

1.4 Mounting the Sounder Module

The DSM300 can be mounted either above or below deck using the supplied

hardware. To allow for ease of cable connection, mount the sounder module so

that the cables hang below the unit.

1.65 in

(41.8 mm)

3.46 in

(88 mm)

Weight: 2.2 lbs (1.0 Kg)

9.96 in (252.9 mm)

9.51 in (241.6 mm)

10.76 in (273.3 mm)

Figure 1-2: DSM300 Dimensions

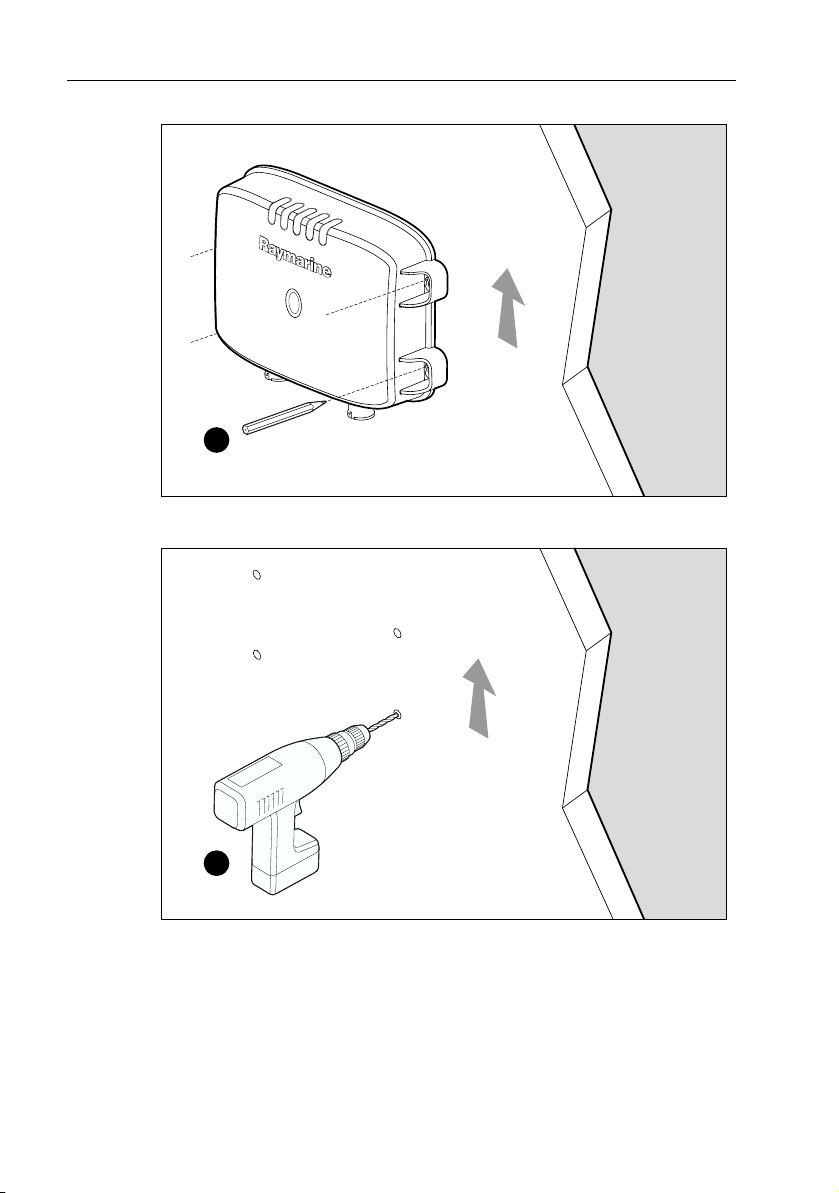

➤ To mount the DSM300:

1. Hold the module in the location where you want to mount it, making sure it is

perpendicular to the deck.

2. Mark the location of the four key holes onto the mounting surface.

Compass Safe Distance: 39 in (1 m)

D7468-1

7.37 in (187.2 mm)

2.43 in

(61.7 mm)

Page 12

12 DSM300 Installation Manual

Vertical

x4

D7479-1

3. Drill a 9/64" pilot hole at each of the marked locations.

Vertical

x4

D7538-1

Note:

For fiberglass wi th a gelcoat surface, you should overdrill the surface to prev ent the

gelcoat from chipping when driving in the screw. Before drilling the pilot hole, hand drill

the marked location with an oversized bit and countersink to approximately 3/8" diameter.

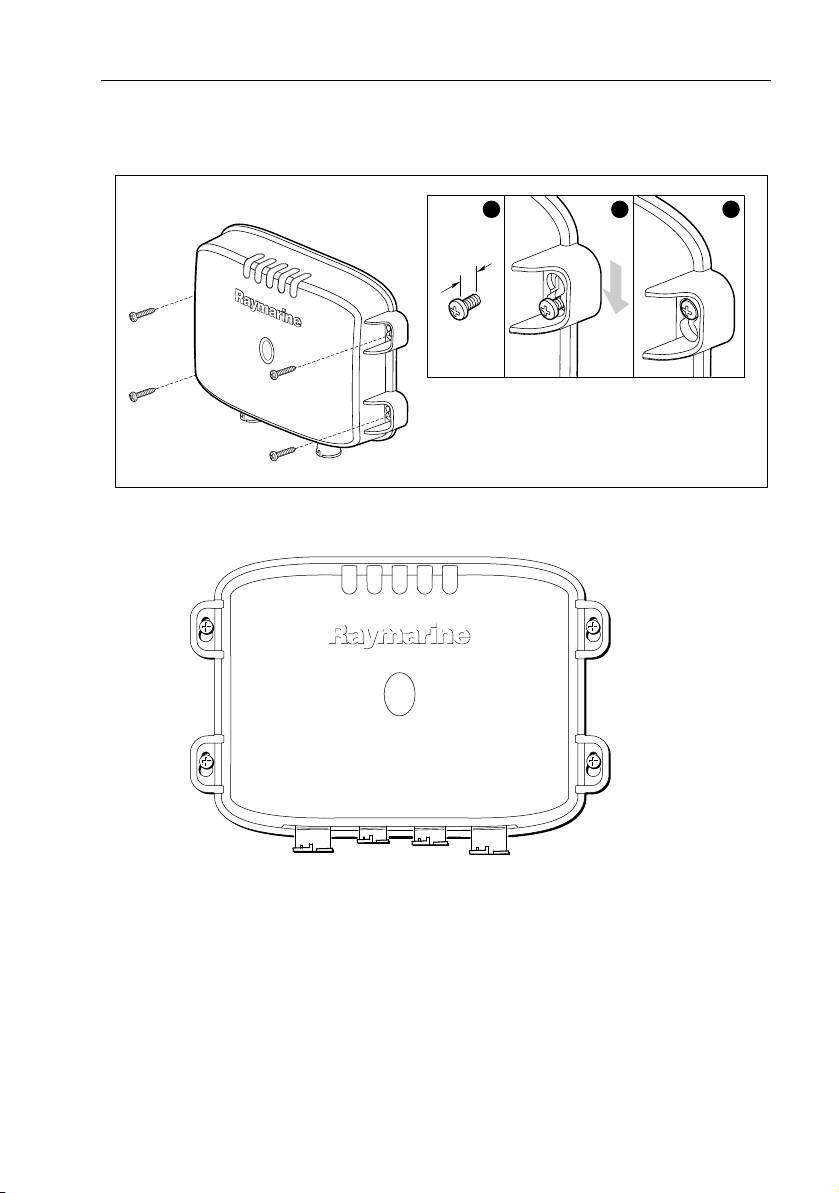

4. Drive the supplied #8 screws into the pilot holes. Screw them in about half way.

5. Mount the module to the surface, slipping the screw heads through the four

key holes.

Page 13

Chapter 1: DSM300 Installation 13

6. Press the module downward so the screws align with the narrow end of the

keyholes.

6 mm

minimum

7. Tighten the screws. Do not overtighten.

1

2

3

D7480-1

Figure 1-3: Properly Mounted DSM300

7469-1

Page 14

14 DSM300 Installation Manual

1.5 Cable Runs

Consider the following before installing the system cables:

• You will need to attach power, transducer, and display cables.

• All cables should be adequately secured, protected from physical damage,

and protected from exposure to heat.

• Avoid running cables through bilges or doorways, or close to moving or hot

objects.

• Avoid sharp bends.

• Use a watertight feed-through wherever a cable passes through an exposed

bulkhead or deckhead.

• Secure cables in place using tie-wraps or lacing twine. Coil any extra cable

and tie it out of the way.

You will need to run the following cables:

•

Power cable, supplied with the unit. This 10 ft (3 m) cable has a connector

plug at one end for connecting to the sounder module, and 3 wires at the other

end for connecting the power supply. The power cable may be extended by up

to 60 ft (20 m) using a wire gauge of AWG 12 or greater. The DSM300 is

intended for use on boat’s DC power systems rated from 10.7 V to 32 V.

•

Display cable, used to connect the DSM300 to a display unit. A 3m-long

cable is included for connecting to a C Series display. Connection cables for E

Series or hsb

be purchased separately. See Table 1-1 “Cable Options“ on page 9 for a list of

available display cables.

•

Trans ducer c able, supplied with the transducer. This 30 ft (10 m) cable has

a connector plug (with an outer nut that you must attach) at one end for the

sounder module or extension cable. Optional extension cables are listed in

Table 2-1 “Accessories“ on page 25.

2

PLUS (Pathfinder) Series displays, or longer C Series cables, must

CAUTION: Do Not Cut or Splice the Transducer Cable

• There is high voltage on the transducer cable. Splicing could

create a safety hazard.

• Cutting the transducer cable severely reduces sonar

performance. If the cable is cut, it must be replaced—it cannot

be repaired.

• Cutting the transducer cable will void the warranty and

invalidate the European CE mark.

Page 15

Chapter 1: DSM300 Installation 15

1.6 System Connections

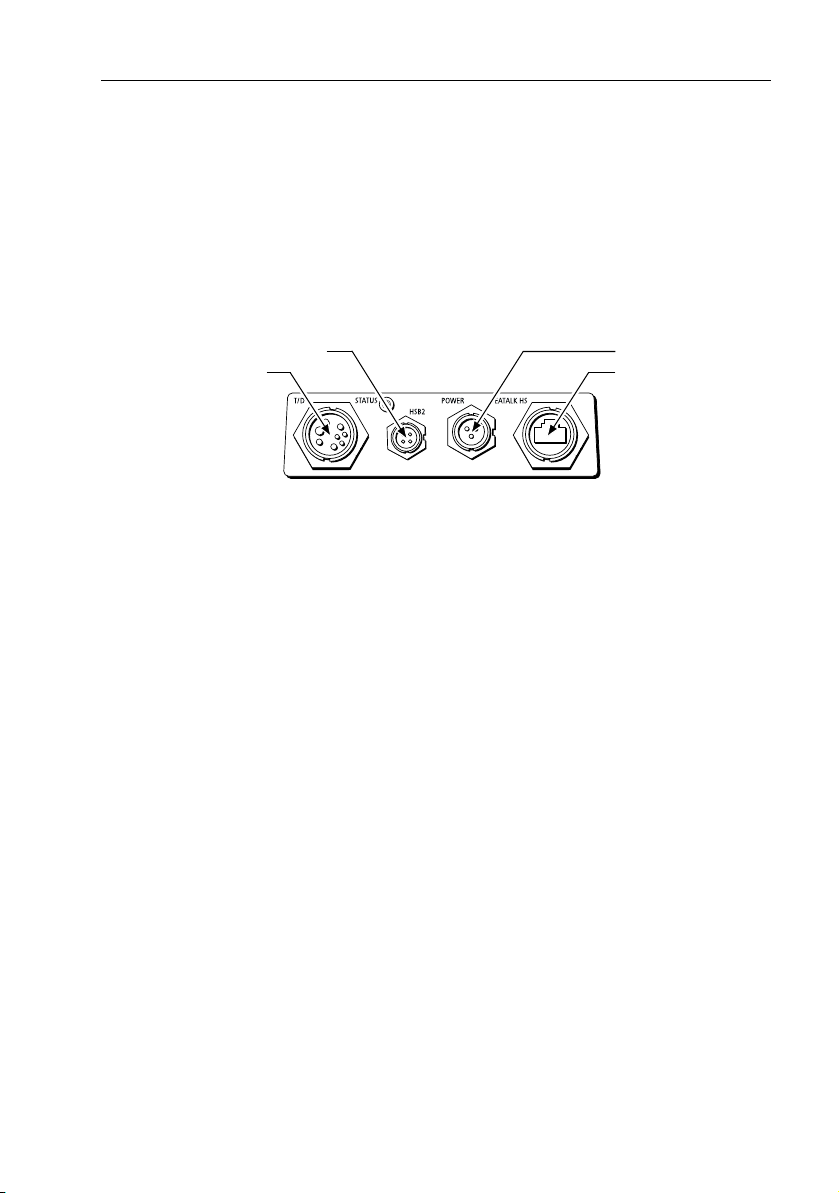

The connector panel provides the following connection sockets:

T/D, 7-pin socket for connecting to the transducer

•

•

HSB2, 4-pin socket for connecting to a C Series or hsb

•

POWER, 3-pin socket for connecting to boat’s DC power systems rated from

10.7 V to 32 V and one RF ground (screen) connection

•

SEATALK HS, RJ-45 socket for connecting to an E Series display

C Series or hsb PLUS

Transducer

2

Figure 1-4: DSM300 Connector Panel

CAUTION:

To protect exposed pins, please place the attached dust cover

over the socket (4-pin or RJ-45) to which you are not connecting a

cable.

2

PLUS Series display

10.7 to 32 VDC

E Series Display

D7464-1

The following sections detail the connectors used when installing the DSM300.

DC Power Connection

The DSM300 is intended for use on boat’s DC power systems rated from 10.7 V to

32 V.

The power connection to the unit should be made at either the output of the

battery isolator switch or at a DC power distribution panel. Power should be fed

directly to the DSM300 via its own dedicated cable system and protected by a

thermal circuit breaker or fuse on the red (positive) wire that is installed close to

the power connection.

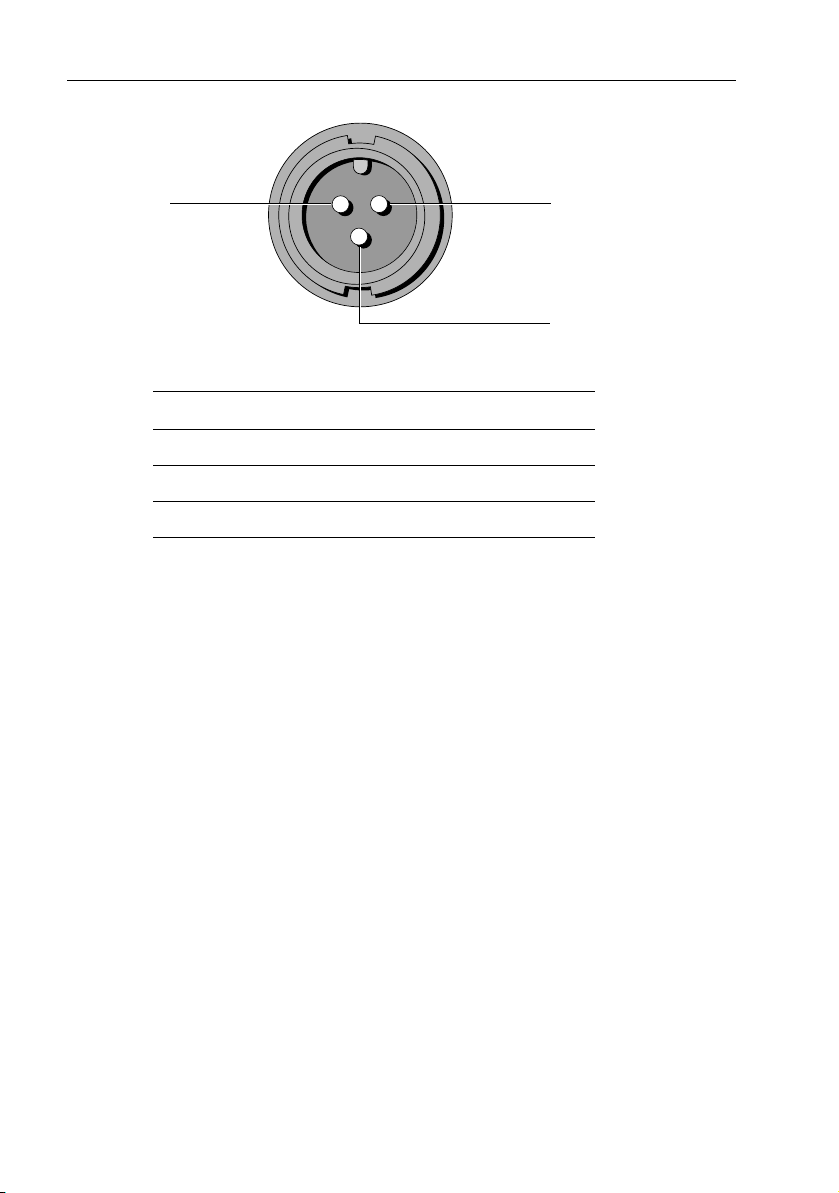

DC power is connected at the 3-pin POWER connector on the unit’s connector

panel. The connector (viewed from the outside) and pin functions are shown in

the following diagram and table.

Page 16

16 DSM300 Installation Manual

1

D6162-1

2

3

Figure 1-6: Power Connector

Pin No. Function Color

1 Battery positive (12/24/32 V systems) Red

2 Battery negative Black

3 Shield (drain wire) No insulation

The RED wire must be connected to the feed from the positive (+) battery terminal

and the BLACK wire to the feed from the negative (–) battery terminal. The shield

wire (drain) should be connected to the boat’s RF ground. See “Ground

Connection” on page 17.

Install a quick blow 8 amp fuse on the red (positive) wire.

CAUTION:

If the power connections are accidentally reversed the system

will not work. Use a multimeter to ensure that the input power

leads are connected for correct polarity.

There is no power switch on the DSM300. The unit turns on when the power cord

is attached to boat’s power and plugged into the POWER connector on the

connector panel.

Note:

You should locate the DSM300 so that the power cord can be easily removed, if

necessary. If the sounder is placed in a difficult-to-reach location, Raymarine strongly

suggests installing an on/off switch on the DSM300 power cord at a point where it is easily

accessible.

Page 17

Chapter 1: DSM300 Installation 17

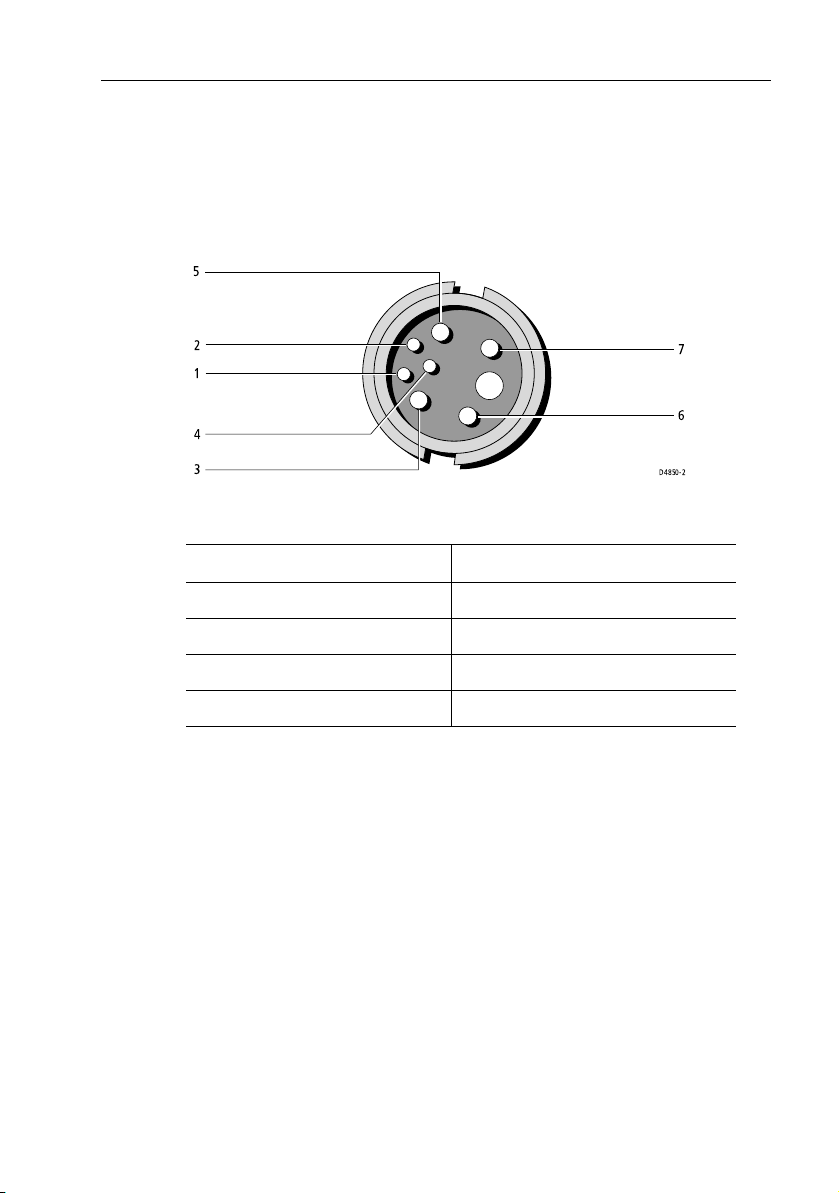

Transducer Connection

A 30 ft (10m) cable is supplied with the transducer. For details see “Tra ns du ce r

Cable” on page 26. The connector pins are shown in the following diagram,

together with the connections and wire colors; this is information is provided as

an aid to fault diagnosis.

5

2

1

4

3

7

6

D4850-2

Figure 1-7: DSM300 Transducer Connector

Pin No Function Color Pin No Function Color

1 Speed Red 5 Speed/Temp Ground Brown

2TempWhite 6+ Depth Blue

3ShieldDrain 7– Depth Black

4 Sense Green

Ground Connection

It is important that an effective RF ground is connected to the system. A single

ground point should be used for all equipment. You can ground the DSM300 by

connecting the drain wire (shield) of the Power Input cable to the boat’s RF

ground. If you need to extend the wire, the extension wire should be an 8 mm

braid or AWG 10 multi-stranded cable.

If your boat has a dedicated ground strap available, you can alternatively attach it

to the ground wing nu t on the rear panel of the module. If your boat do es not have

an RF system, connect the drain wire to the negative battery terminal.

The DC system should be either:

• Negative grounded, with the negative battery terminal connected to the

boat’s ground.

• Floating, with neither battery terminal connected to the boat’s ground.

Page 18

18 DSM300 Installation Manual

This system is not intended for use on “positive” ground vessels.

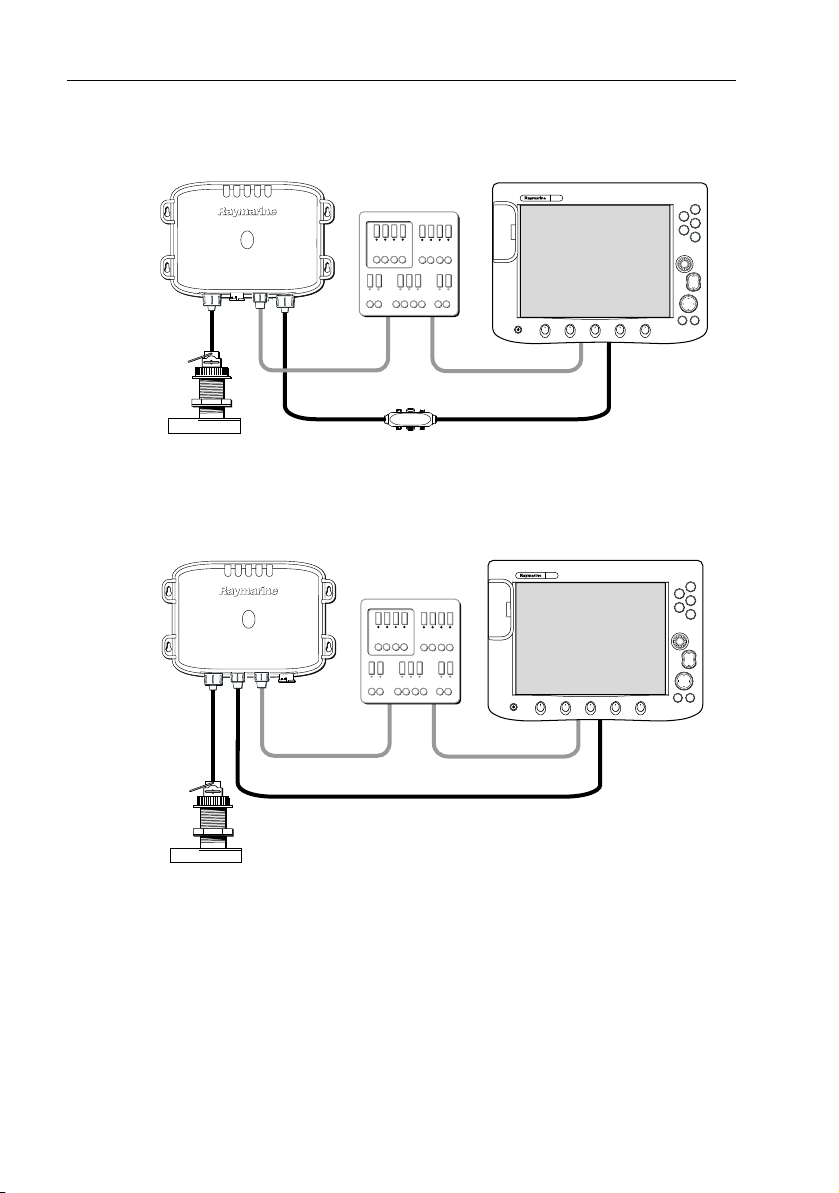

DSM300

not

used

Power Supply

E Series Display Unit

PAGE

ACTIVE

WPTS/

MOB

DATA

MENU

OUT

RANGE

IN

CANCELOK

D7467-1

Transducer

Crossover Coupler

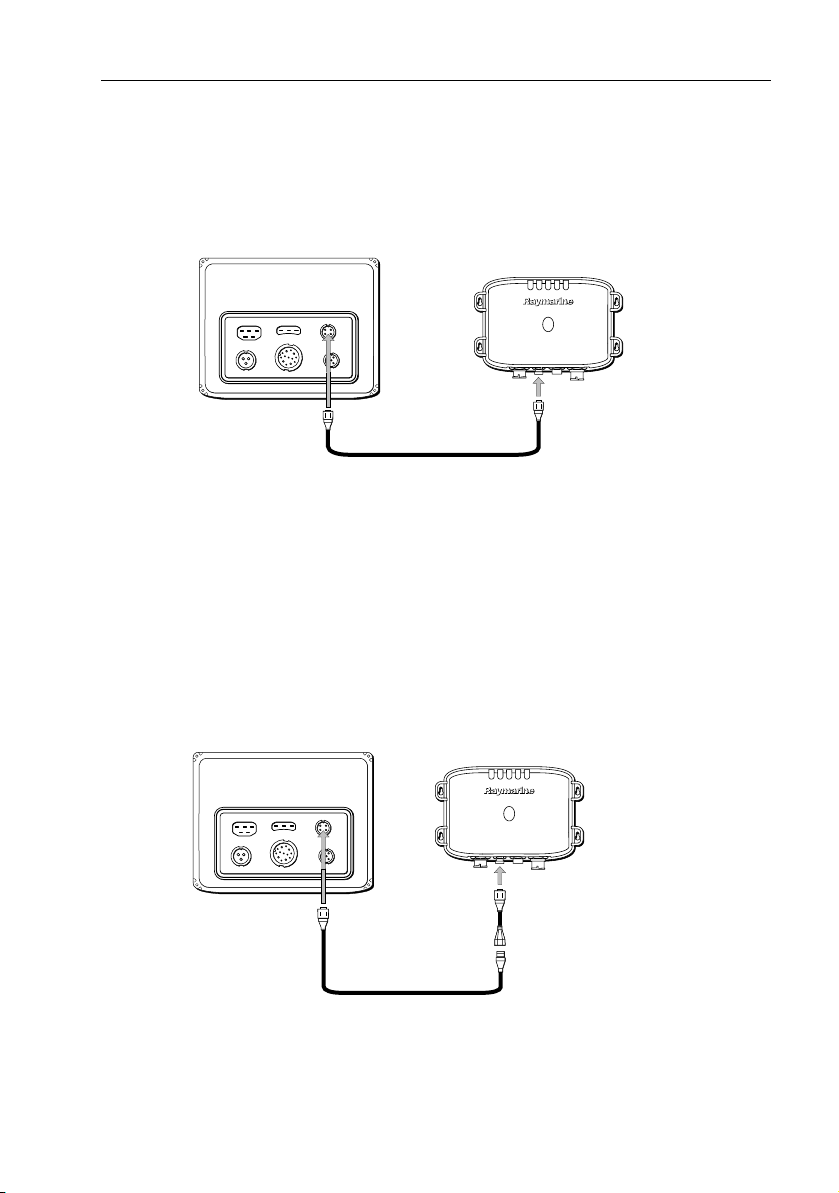

Figure 1-8: Using the DSM300 with an E Series Display

Transducer

DSM300

not

used

Power Supply

Figure 1-9: Using the DSM300 with a C Series Display

C Series Display Unit

PAGE

ACTIVE

WPTS/

MOB

DATA

MENU

OUT

RANGE

IN

CANCELOK

D7466-1

Page 19

Chapter 1: DSM300 Installation 19

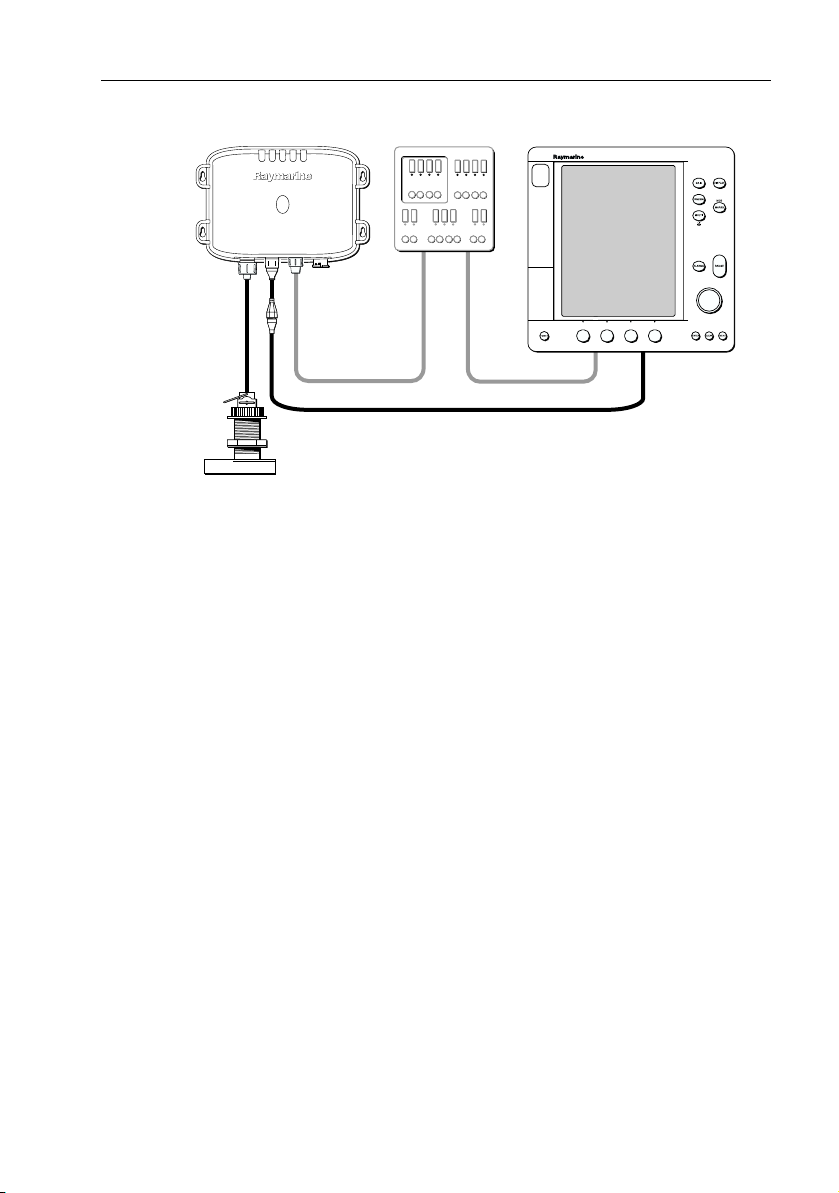

DSM300 hsb PLUS Series Display Unit

not

used

Power Supply

2

Transducer

Figure 1-10: Using the DSM300 with an hsb2 PLUS Series Display

D7606-1

Page 20

20 DSM300 Installation Manual

1.7 Configuration

How you configure your DNT300 depends on the type of display to which you will

be connecting it.

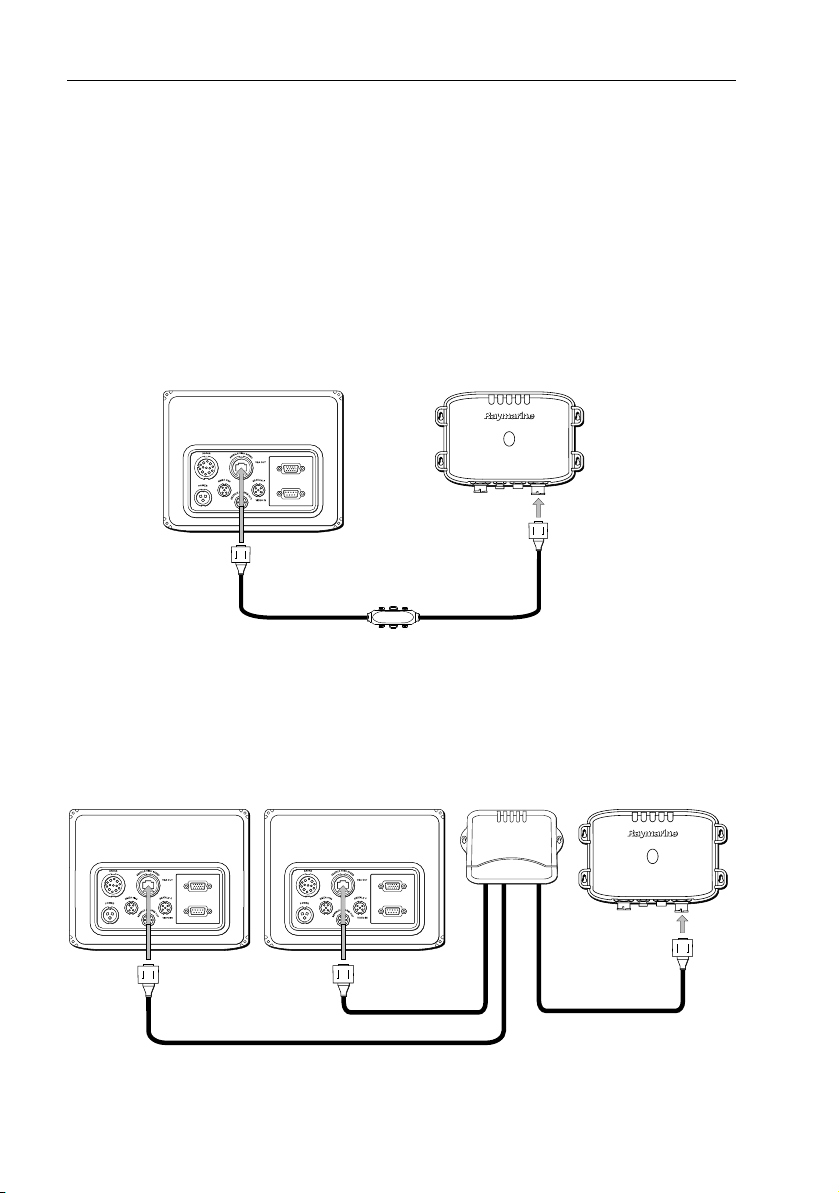

Configuring the DSM300 with E Series Displays

The E Series system operates on the SeaTalk

hs

network, which uses cables with an

RJ-45 modular connector. See Table 1-1 for a list of available E Series cables. When

the DSM300 is used with a single display, connection is made via a SeaTalk

Crossover Coupler.

E Series Display

SeaTalk

Crossover Coupler

hs

Cable

E55060

SeaTalk

DSM300

hs

Cable

D7593-1

Figure 1-11: Configuring an E Series System - Single Display

When used in a multiple display system, connect the DSM300 to the SeaTalk

Network Switch.

E Series Display

E Series Display

SeaTalk

hs

Network Switch

E55058

DSM300

hs

hs

SeaTalk

hs

Cable

SeaTalk

hs

Cable

SeaTalk

Figure 1-12: Configuring an E Series System - Multiple Displays

hs

D7602-1

Cable

Page 21

Chapter 1: DSM300 Installation 21

Configuring the DSM300 with C Series Displays

The C Series system uses cables with a round 4-pin twist-lock network connector.

A 3m-long C Series cable is included with your DSM300. If a longer cable is

required, an optional 10m C Series cable (part number E65011) is available from

Raymarine.

C Series Display

G

Y

R

K

2

L

K

A

L

T

A

A

T

E

A

S

E

S

R

R

A

E

D

A

W

R

O

P

M

S

D

T

A

U

E

/ O

M

IN

N

4-pin to 4-pin C Series Cable

DSM300

D7592-1

Figure 1-13: Configuring a New C Series System

The product that the DSM300 replaces—the DSM250 sounder module—has a

triangular 3-pin network connector. If you are replacing an old DSM250 with a

new DSM300 in an existing C Series network, you will need to install the supplied

4-pin to 3-pin hsb

2

adapter. Connect the 4-pin end of the adapter to the DSM300

and then connect the 3-pin end of the DSM cable to the DSM300.

Unlike the DSM250, however, the DSM300 network connection is internally

terminated. When replacing a DSM250 with a DSM300, DO NOT USE

the hsb

2

Inline Terminator that was connected to the DSM250.

DSM300

C Series Display

G

Y

R

2

LK

K

A

L

A

T

A

E

S

R

E

W

O

P

M

T

S

A

D

E

S

R

A

T

A

U

D

E

A

/ O

M

R

IN

N

R69081

4-pin to 3-pin hsb

adapter (supplied)

D7603-1

2

4-pin to 3-pin DSM cable

Figure 1-14: Replacing a DSM250 in an Existing C Series System

Page 22

22 DSM300 Installation Manual

Configuring the DSM300 with hsb2 (Pathfinder) Series Displays

2

hsb

PLUS network cables have a triangular 3-pin connector on both ends. When

using the DSM300 with an hsb

3-pin hsb

The hsb

2

adapter between the DSM300 and the network cable.

2

system must be terminated at both ends of the network. If a PLUS Series

2

PLUS Series display, connect the supplied 4-pin to

display is the last device on the network, an inline terminator is installed on the

cable where it connects to the display. The network connection in the DSM300,

however, is internally terminated; it does not require an inline terminator.

Because the DSM300 is internally terminated, it must be installed

at the end of the hsb

terminator on the DSM300 end of the network. If an hsb

2

network. You must NOT use an inline

2

splitter is

used, you must connect it to a display and not to the DSM300.

R58117

2

PLUS Series Display

hsb

NMEA OUT

POWER/NMEA

HSB

2

hsb

Terminator

GRY

SeaTalk

TRANSDUCER

Inline

3-pin to 3-pin hsb2 cable

R69081

DSM300

4-pin to 3-pin hsb

adapter (supplied)

D7594-1

2

Figure 1-15: Installing a DSM300 in the hsb2 PLUS System - Single Display

2

hsb

PLUS Series Display

NMEA OUT

POWER/NMEA

HSB

TRANSDUCER

2

hsb

PLUS Series Display

GRY

SeaTalk

NMEA OUT

HSB

POWER/NMEA

TRANSDUCER

GRY

SeaTalk

DSM300

D7604-1

R58117

hsb

Terminator

3-pin hsb

2

cable

R55040

2

hsb

Splitter

3-pin hsb

2

cable

R69081

2

Inline

Figure 1-16: Installing a DSM300 in the hsb2 PLUS System - Multiple Displays

4-pin to 3-pin hsb

adapter (supplied)

2

Page 23

Chapter 2: Transducer Installation 23

Chapter 2: Transducer Installation

Transducers enable fishfinder systems to display depth, water temperature and/or

speed information, depending on the type of transducer(s) installed. This chapter

describes the transducers that are available for use with the DSM300.

This chapter also provides general information for installing the three main types

of transducers: transom mount, thru-hull and in-hull. Specific instructions for

installing your particular model are included with your transducer.

2.1 Selecting the Correct Type of Transducer

Before you start the installation, check that you have the correct transducer for

your application.

Applications

Transom Mount Transducers are recommended for personal watercraft and

powerboats with outboard, inboard-outboard and jet drives. They are NOT

recommended for large or twin screw inboard boats.

• Adjusts to transom angles from 3

tapered plastic, wood or metal shim will be needed.

• Designed for operation from 5 – 58 m.p.h. (4 – 50 knots).

Thru-Hull Transducers are recommended for boats with straight-shaft inboard

engines.

In-Hull Transducers are recommended for fiberglass hulls, especially in high

speed power boats and racing sailboats.

° – 16°. For angles greater than 16°, a

Materials

Plastic housings are recommended for fiberglass or metal hulls.

Bronze housings are recommended for wood or fiberglass hulls.

Stainless Steel housings are recommended for steel or aluminum hulls.

Notes: (1)

Installation of a bronze housing in a metal hull requires using of a fairing,

available from your Raymarine dealer.

(2)

Never install a metal housing in a vessel with a positive ground system.

Page 24

24 DSM300 Installation Manual

The DSM300 can be used with any of the following transducers:

Mounting

Method

Tra ns om

Part No.

(Model)

E66049

(M260)

E66078

(M256)

1, 2

3

Sensor

Type Material

Max.

Power

Depth Cast Urethane 1000W

Depth Cast Urethane 1000W

E66019

(ST69)

E66054

(P66)

Thru-Hull E66013

(P319)

E66014

(B117)

E66015

(SS555)

E66076

(R99)

E66024

(B256)

E66033

(B260)

E66053

(SS560)

E66018

(ST600/B120)

Speed,

Plastic 600 W

Temp

Depth,

Plastic 600W

Speed,

Temp

Depth Plastic 600 W

Depth Bronze 600 W

Depth Stainless Steel 600 W

4

5

5

4

Depth Cast Urethane 2000W

Depth,

Temp

Depth,

Temp

Depth,

Bronze 600 W or

1000 W

Bronze 600 W or

1000 W

Stainless Steel 1000W

Temp

Speed,

Bronze 600 W

Temp

E66030

(ST600/P120)

4

E66056

(B744V)

Speed,

Temp

Depth,

Speed,

Temp

Plastic 600 W

Bronze 600 W

Page 25

Chapter 2: Transducer Installation 25

Mounting

Method

Part No.

(Model)

E66057

(B744VL)

Sensor

Type Material

4

Depth,

Bronze 600 W

Max.

Power

Speed,

Tem p

In-Hull E66008

Depth Plastic 600 W

(P79)

E66049

1

Depth Cast Urethane 1000W

(M260)

E66075

Depth Cast Urethane 2000W

(R199)

1

Can be used In-Hull or Transom mounted

2

Requires E66047 kit to complete transom mount installation

3

Includes transom mounting kit

4

Includes high-speed fairing

5

Must be installed with a high-speed fairing (sold separately)

Accessories

The following optional equipment is also available from Raymarine for your

transducer:

Table 2-1: Accessories

Item Part No. For Use With

Transducer Extension Cable, 10 ft (3 m)

Transducer Extension Cable, 18 ft (5 m)

Trans du cer Y-C ab le

High Speed Fairing E66023

E66009

E66010

E66022

E66025

E66034

Depth Transducers

Depth Transducers

Spe ed /Temp Tra ns ducers

E66056(B744V), E66057(B744VL)

E66024 (B256)

E66033 (B260)

In-Hull Mounting Kit

Transom Mounting Kit

Notes: (1)

To ensure proper alignment and a secure fit, many thru-hull transducers

require a fairing for installation. In addition to improving sounder performance at all speeds, the fairing allows better fitting to the hull and dramatically increases the sealing surface.

(2)

This information was current as of the date this handbook was printed.

New transducer models are constantly becoming available. Check with

your dealer for the most current list.

E66050

E66047

E66049 (M260)

E66049 (M260), E66046 (M256)

Page 26

26 DSM300 Installation Manual

2.2 Transducer Cable

A 30 ft (10m) cable is supplied with the transducer. The transducer cable may be

extended up to a maximum of 60 ft (20 m) using optional extension cables.

The transducer cable connector has a nut that has been removed to aid

installation. To allow you to complete the installation without cutting the cable,

ensure that any holes you drill are large enough to accept the connector, with the

nut removed.

After the cable has been run through the holes, this nut must be attached before

the cable can be connected, as described in

CAUTION: Do Not Splice the Cable

Do not cut the transducer cable or remove the connector. Do not

try to shorten or splice the cable. If the cable is cut, it cannot be

repaired. Cutting the cable will also void the warranty.

• For a Transom mount installation – route the cable up and over the top edge

of the transom as shown in Figure 2-2 . Secure the cable using cable clamps

(available from your local marine equipment supplier).

If you do not want to expose the cable on deck, you may drill a hole 13/16"

(21 mm) through the transom for the cable (with connector attached). To

seal the opening, use a feed-thru cap where the cable passes through the

transom.

• For either type of installation – run the cable through the interior of the boat.

• If the 30 ft (10 m) cable is not long enough, extension cables are available

from your Raymarine dealer. See Table 2-1 on page 25. Total cable length from

the transducer to the DSM must not exceed 60 ft (20 m). When you attach the

extension cable, be sure that the connections are watertight. Use Dow Corning DC-4 or an equivalent sealing compound to protect the connector assemblies.

CAUTION:

Do not pull on the cable as this can damage the transducer wires.

Transducer Cable Connections

.

Transducer Cable Connections

The transducer cable connector (and Y-connector, if supplied) has a nut that has

been removed to aid installation. To allow you to complete the installation

without cutting the cable, ensure that any holes you drill are large enough to

accept the connector, with the nut removed (approximately 13/16" or 21mm).

Page 27

Chapter 2: Transducer Installation 27

Before attaching the transducer cable, you will need to attach the connector nut

and split ring. These items, plus a wedge tool, are included in the transducer

packaging.

Connector/cable

Protrusion

Mounting groove

Nut

Split

Split ring

Wedge tool

D5256-1

Figure 2-1: Assembling the Transducer Connector

➤ To attach the transducer cable connector:

1. Slip the nut over the connector cable end. Push it past the connector and over

the cable.

2. Insert the wedge tool into the groove in the split of the split ring and slide the

wedge tool until its squared end is flush with the larger edge of the split ring.

3. Slip the split ring and wedge tool over the connector body until aligned with

the mounting groove on the connector.

4. Remove the wedge tool and seat the split ring in the mounting groove, making sure the connector protrusion falls into the split.

5. Slip the nut forward until it stops. Twist until the protrusions on the inside of

the nut align with the grooves on the split ring.

6. Slip the nut forward and snap into place.

Page 28

28 DSM300 Installation Manual

The transducer cable is attached to the 7 pin male connector on the DSM. How

you connect the cable to the unit depends on the type of transducer you have

installed:

•

Combined depth/speed/temp transducers have a 7 pin female connec-

tor. Attach the transducer cable connector directly to the sounder module.

•

Combined speed/temperature transducers have a 3 pin female con-

nector that requires the use of an additional Y-shaped cable (Raymarine part

number E66022) to attach to the 7 pin connector on the DSM300. This Y-cable

is included with your speed/temperature transducer.

Attach the 7 pin female connector on the Y-cable to the sounder module, and

then attach the transducer cable to the 3 pin male connector on the Y-cable.

•

Depth-only transducers have a 7 pin female connector.

Attach the transducer cable connector directly to the sounder module.

If being installed in conjunction with a speed/temperature transducer, attach

the Y-cable’s 7 pin female connector to the sounder module, and then attach

the transducer cable to the 7 pin male connector on the Y-cable.

Note:

If your syste m requires both a Y-cab le and a transducer extens ion cable, ensure that

you connect the Y-cable to the sounder module and the extension cable to the transducer.

CAUTION: Do not cut or splice the transducer cable:

• There is high voltage on the transducer cable. Splicing could

create a safety hazard.

• Cutting the transducer cable severely reduces sonar performance. If the cable is cut it must be replaced, not repaired.

• Cutting the transducer cable will void the warranty and invalidate the CE mark.

CAUTION: Removing the Transducer Cable

Removing the transducer cable from the rear of the DSM300 while the sounder

module is powered on can cause sparks. Only remove the transducer cable after

power has been removed from the DSM300.

If the transducer cable is accidentally removed while the DSM300 is powered on,

remove power from the sounder module, replace the transducer cable, and then

return power to the module. As a safety feature, the DSM300 only recognizes that

the transducer is connected at power-up.

Page 29

Chapter 2: Transducer Installation 29

Cable cover

Cable clamps

2 in (50 mm)

D5033-2

Figure 2-2: Installing the Cable on a Transom Mount Transducer

2.3 Selecting the Equipment Location

Transducer Mounting Location

It is very important that you mount the transducer correctly. The transducer

provides the most reliable readings if it looks into water that is smooth and

undisturbed.

Acoustic noise is always present and these sound waves can interfere with the

operation of the transducer. Ambient (background) noise from sources such as

waves, fish, rain and other vessels cannot be controlled. Carefully selecting the

transducer’s mounting location can minimize noise generated by the vessel’s

propeller(s), shaft(s), machinery, and other echo sounders. The lower the noise

level, the higher the echo sounder gain that can be used, and the better the

sounder’s performance.

Page 30

30 DSM300 Installation Manual

To ensure accurate readings, DO NOT mount the transducer in an

area of turbulence or bubbles:

• near water intake or discharge openings

• behind strakes, fittings or hull irregularities

• behind eroding paint (an indication of turbulence)

Choose a location where:

• The water flowing across the hull is smoothest with a minimum of turbulence

and bubbles (especially at high speeds).

• The transducer will be continuously covered by water when the boat is moving. If the transducer is mounted near the side of the boat, it may be exposed

when the boat is turning.

• The transducer beam is unobstructed by the keel or propeller shaft.

• There is a minimum deadrise angle.

• There is adequate headroom inside the vessel for the height of the thru-hull

housing, tightening the nuts, and removing the valve assembly insert.

Transom Mount Transducer

• Single drive boat – Refer to Figure 2-3 . If your boat has one propeller (out-

board or inboard), mount the transducer about 18" (455 mm) to the side of

the boat’s centerline. To reduce any interference caused by air bubbles,

choose the side on the downstroke of the propeller (usually the starboard

side).

• Twin drive boat – If your boat has twin propellers (outboard or inboard-out-

board), mount the transducer between the drives near the centerline of the

boat. If the boat will be operated at high speeds, the transducer may be

mounted closer to the centerline of the hull.

• If the propeller can be turned to steer the boat, allow at least 2" (50 mm)

beyond the swing radius of the propeller. This will prevent the propeller from

damaging the transducer when it is turned.

Page 31

Chapter 2: Transducer Installation 31

Approximately 18 in (457 mm) clearance

Be sure to allow at

least 2 in (50 mm)

beyond the swing radius

of the propeller

D4871-2

Figure 2-3: Transom Mount Transducer Location

• Do not mount the transducer behind any hull fittings, intakes or other parts

extending from the hull that may cause turbulence or air bubbles.

• The bracket has a quick-release mechanism, shown Figure 2-4 . This allows

the transducer to flip up if it hits any debris or the bottom. Allow enough clearance above the transducer for it to swing upwards completely – this is about

10" (254 mm), measured from the bottom of the transom.

Allow a clearance of

at least 254 mm (10 in)

Figure 2-4: Transom Mount Transducer - Quick-release Bracket

Transducer in

released position

D4872-2

Page 32

32 DSM300 Installation Manual

• On a boat with a fiberglass hull, the leading edge of the transducer should

extend 1/8" (3.2 mm) to 1/4" (6 mm) below the bottom edge of the hull as

shown in Figure 2-5 . On an aluminum hull, the transduce r should extend a bit

more – 1/4" (6 mm) to 3/8" (9 mm)

• If the boat will be trailered, be sure the transducer will not hit any rollers,

bunks or fittings on the trailer.

Average transom angle -

no wedge necessary

Vertical transom -

place wedge this way

Sloping transom -

place wedge this way

2° to 5°

The bow of the transducer

is above the bottom of the

transom, creating cavitation.

For fibreglass hull 1/8 to 1/4 in (3.2 to 6 mm)

For aluminium hull 1/4 to 3/8 in (6 to 9 mm)

2° to 5°

Rivets on the hull are

creating bubbles. Lower

the transducer a bit.

Figure 2-5: Transom Mount Transducer - Vertical Position

Thru-hull Transducer and In-hull Transducer

Similar consideration should be given to the location of thru-hull and in-hull

transducers. Figure 2-6 shows the best transducer location for different hull types.

• Displacement hull powerboat – Locate at 1/3 aft load waterline length (LWL)

and 6 - 12" (150-300 mm) off the centerline on the side of the hull where the

propeller is moving downward.

• Planing hull powerboat – Mount well aft, on or near the centerline, and well

inboard of the first set of lifting strakes to ensure that it is in contact with the

water at high speeds. Mount on the side of the hull where the propeller is

moving downward.

2° to 5°

No!No!No!

The rear of the transducer

is too high, creating

cavitation.

D4873-2

Page 33

Chapter 2: Transducer Installation 33

Outboard and I/O – Mount just forward of the engine(s).

Inboard – mount well forward of the propeller(s) and shaft(s).

Step-hull – Mount just ahead of the first step.

Boats capable of speeds above 25 kn (29 m.p.h.) – Review transducer location

and operating results of similar boats before proceeding.

• Fin keel sailboats – Mount to the side of the centerline and forward of the fin

keel 1 - 2 ft (300-600 mm).

• Full keel sailboats – Locate amidships and away from the keel at the point of

minimum deadrise angle.

• Fiberglass Hulls – Since the hull absorbs acoustic energy, transmitting through

the hull reduces the sensor’s performance. Fiberglass hulls are often reinforced in places for added strength. These cored areas contain balsa wood or

structural foam, which are poor sound conductors. If you cannot avoid locating the sensor over coring, follow the instructions for “Installation in a Cored

Fiberglass Hull” on page 55.

• Thru-hull Transducer Headroom– Allow adequate headroom inside the vessel

for the height of the thru-hull housing, tightening the nuts and removing the

insert. The minimum headrooms are:

With fairing: 10" (254 mm)

Without fairing: 12" (305 mm)

• In-hull Transducer – Find a location where the fiberglass is solid:

There are no air bubbles trapped in the fiberglass resin.

There is no coring, flotation material, or dead air space sandwiched between

the inside skin and the outer skin of the hull.

Page 34

34 DSM300 Installation Manual

Displacement hull

Pressure waves

1/3 Aft

Load waterline length (LWL)

Planning hulls

Outboard and I/O

Full keel sailboat

Step hull Fin keel sailboat

Inboard

6--12in

(150 -- 300 mm)

D4857-2

Figure 2-6: Best Location for Thru Hull Transducer

Page 35

Chapter 2: Transducer Installation 35

2.4 Installing the Transom Mount Transducer

Preparation

Transducer Mounting Bracket

When installed, the lower surface of the transducer should tilt down toward the

rear at a slight angle (2° to 5°). The mounting bracket includes a wedge;

depending on the angle of the transom on your boat, you may need to install this

wedge to get the correct transducer angle.

1. To attach the transducer to the bracket, insert the transducer mounting lugs

into the slot in the bracket as shown in Figure 2-7 .

Correct Incorrect

Attach the two parts Bracket is installed

Lower the transducer and

snap in the release clip

upside down

D4874-2

Figure 2-7: Fitting the Transducer to the Bracket

2. Looking at the rear of the boat, be sure the bracket is vertical (perpendicular

to the water line) and hold the bracket (plus the wedge, if used) against the

transom.

Trace the position of the screw slots, then mark the screw positions as shown

in Figure 2-8 . The outer two screws should be placed about 1/4" (6 mm) up

from the bottom of each slot, the center screw should be placed about 1/4" (6

mm) down from the top. This will allow the bracket to be adjusted up or down.

Remove the bracket.

Page 36

36 DSM300 Installation Manual

Correct alignment

Insert screws 1 and 3, 6.4 mm (1/4 in)

from the bottom of the slots, and

screw 2, 6.4 mm (1/4 in) from the top

the slot to allow room for adjustment.

Incorrect alignment

If screws are inserted this way it

won't be possible to make the

height adjustment.

1

23

123

D4875-2

Figure 2-8: Position of Screws in Mounting Bracket

Installation

1. On a fiberglass hull, to minimize surface cracking of the gel coat: Before drilling the pilot holes, use a 1/4" (6 mm) drill bit to drill a shallow hole (chamfer)

at each location about 1/16" (1.5 mm) deep.

Drill pilot holes 3/4" (19 mm) deep using a 9/64" (3.6 mm) drill bit.

To prevent drilling too deeply, wrap masking tape around the drill bit about

7/8" (22 mm) from the tip. Drill in only as far as the tape.

2. Apply a good quality marine sealant to the pilot holes to protect the hull from

water penetration.

3. Attach the bracket to the hull using the panhead screws with flat washers. Do

not completely tighten the screws yet.

4. Move the bracket up or down so the leading edge of the transducer has the

clearance shown in Figure 2-5 .

5. Once the bracket is in the correct position tighten the screws.

2.5 Installing the Thru-hull Transducer

Tools and Material Needed

Water-based antifouling paint (mandatory for boats kept in salt water)

Safety goggles

Dust mask

Electric drill

Drill bit: 1/8" (3 mm)

Page 37

Chapter 2: Transducer Installation 37

Hole saw:

Fiberglass or wood Drill 2" (51 mm)

Aluminium or steel hull Drill 2-1/8" (54 mm)

Sandpaper

File (for installation in a metal hull)

Mild household detergent or weak solvent (alcohol)

Marine sealant

Slip-joint pliers

Silicone grease or petroleum jelly

Tie-wraps

Cored fiberglass hull installation:

Hole saw for hull interior 2-3/8" (60 mm)

Cylinder, wax, tape and casting epoxy

Fairing;

Level and protractor (installation with a fairing)

Rasp (installation with a fairing)

Preparation

Fairing

Most vessels have a deadrise angle at the transducer’s mounting location. If the

transducer is mounted directly to the hull, the sonar beam will be tilted off-vertical

at the same angle as the deadrise. To offset this deadrise angle, you can install a

transducer fairing. Different fairings are available to fit various transducers.

CAUTION: Using a Fairing

If thru-hull transducers are not carefully installed and fitted to the

shape of the hull, the vessel may take on water. To ensure proper

alignment and a secure fit, these transducer models MUST be

installed with a fairing. In addition to improving sounder

performance at all speeds, the fairing allows better fitting to the

hull and dramatically increases the sealing surface.

Fairings are also strongly recommended for use with other high performance

transducers. See the table that follows.

The fairing is used to:

• Vertically orient the sound beam by mounting the transducer parallel to the

water surface

• Minimize aerated water flowing over the transducer’s face by mounting it in

deeper water

• Reduce drag by directing the water around the multisensor

Page 38

38 DSM300 Installation Manual

The fairing is made of high impact urethane with an integrated cutting guide. It

can be shaped to accommodate a deadrise angle of up to 25° and a range of hull

thicknesses as follows:

Fairing

No.

Used with Transducer

No. (model)

Max. Hull Thickness

with Fairing

E66023 E66056 (B744V)

E66023 E66057 (B744VL)

E66025 E66024 (B256)

E66034 E66033 (B260)

" (26mm)

1

" (87mm)

3-3/4

" (45mm)

1-3/4

" (45mm)

1-3/4

Aft View

Backing block

minimum fairing

thickness

D5568-1

Hull

Slope of hull

Deadrise angle

Parallel to

water surface

Fairing

Isolation sleeve

Figure 2-9: Deadrise Angle and Fairing Thickness

Backing Block

A backing block is used inside the hull to provide a level surface for the hull nut to

seat against (see Figure 2-9 ). After cutting the fairing, use the remaining section

with the cutting guide as the backing block (see Figure 2-10 ).

Page 39

Chapter 2: Transducer Installation 39

⇐

BOW

Cutting guide

Triangular recess

for anti-rotation bolt

D5567-1

Figure 2-10: Transducer Fairing

Cutting the Fairing

1. Measure the deadrise angle of the hull at the selected location using a digital

level, or bubble level and protractor (see Figure 2-9 ).

2. Tilt the band saw table to the measured angle and secure the cutting fence

(see Figure 2-11 ).

Band saw table

Cutting guide

Deadrise

angle

Bow end for

installation

on port side

Figure 2-11: Cutting the Fairing

Fence

D4860-2

Page 40

40 DSM300 Installation Manual

CAUTION:

The arrow on the fairing always points forward towards the bow.

Be sure to orient the fairing on the band saw so the angle cut

matches the intended side of the hull.

3. Place the fairing on the table so the cutting guide rests against the fence. The

arrow/blunt end will point toward you for installation on the port side and

away from you for installation on the starboard side of the boat.

CAUTION:

Always wear safety goggles and a dust mask when drilling.

4. Recheck steps 1 through 3, then cut the fairing.

5. Shape the fairing to the hull as precisely as possible with a rasp or power tool.

Antifouling Paint

Marine growth can accumulate rapidly on the transducer’s surface, reducing

performance in weeks. Surfaces exposed to salt water must be coated with

antifouling paint.

Use water-based antifouling paint only.

Never use ketone-based paint since ketones can attack many

plastics, possibly damaging the transducer.

Reapply paint every six months or at the beginning of each boating season.

It is easier to apply antifouling paint before installation, but allow sufficient drying

time. As illustrated in Figure 2-12 , paint the following surfaces:

Exposed area of the housing, including the acoustic window

Bore of the housing up to 1-1/4" (30 mm)

Outside wall below lower O-ring

Exposed end of the paddle wheel insert

Paddle wheel cavity

Paddle wheel

Blanking plug below the lower O-ring and the exposed end

Page 41

Chapter 2: Transducer Installation 41

Housing Paddlewheel

Paint exposed housing

and bore up to 1.1/4" (30 mm)

Paint outside wall below the lower 'O' ring including

exposed end, paddlewheel cavity and paddlewheel

insert

Lower

'O' ring

D4859-2

Figure 2-12: Applying Antifouling Paint

Installation

Note:

To install the thru-hull transducer in a cored fiberglass hull, follow the instructions

in Installation in a Cored Fiberglass Hull on page 48.

Drilling Holes

CAUTION:

Always wear safety goggles and a dust mask when drilling.

1. Drill a 1/8" (3 mm) pilot hole perpendicular to the water line from inside the

hull (see Figure 2-9 ).

If there is a rib or strut near the mounting location, drill from the outside.

If the pilot hole is drilled in the wrong location, drill a second hole in a better

location. Apply masking tape to the outside of the hull over the incorrect hole

and fill it with epoxy.

Page 42

42 DSM300 Installation Manual

2. Cut a hole from outside the hull:

Fiberglass or wood hull – Use a 2" (51 mm) hole saw.

Aluminium or steel hull – Use a 2-1/8" (54 mm) hole saw to accommodate the

isolation sleeve used to prevent contact between the stainless steel housing

and the metal hull.

3. Sand and clean the area around the hole, inside and outside, to ensure that

the sealant will adhere properly to the hull. If there is any petroleum residue

inside the hull, remove it with either a mild household detergent or a weak

solvent (alcohol) before sanding.

4. Remove one safety ring, the retaining pin, the cap nut, and the hull nut from

the transducer (see Figure 2-13 ).

Retaining pin

Safety ring

Cap nut

Stem

Hull nut

Backing

block

Hull

Fairing

Marine

sealant

D5566-1

Figure 2-13: Seating

Dry Fit for Fairing

CAUTION:

If a fairing is used, the anti-rotation bolt must be installed to

prevent the fairing from rotating when the boat is underway.

1. Dry fit the transducer to locate the hole for the anti-rotation bolt.

2. Thread the transducer cable through the large hole in the fairing and through

the mounting hole in the hull. Seat the transducer firmly in the recess in the

fairing.

Note:

The transducer must be flush with the fairing. If it is recessed more than 1/64"

(0.5mm) inside the fairing, you may carefully file or sand the fairing flush with the transducer.

Page 43

Chapter 2: Transducer Installation 43

CAUTION:

Always wear safety goggles and a dust mask.

3. Attach the drill bit to your drill appropriate for your fairing:

Fairing Used with Transducer Drill Size

E66023 E66056 (B744V),

3/8

" (10mm)

E66057 (B744VL)

E66025 E66024 (B256)

E66034 E66033 (B260)

" (13mm)

1/2

" (13mm)

1/2

4. Slide the transducer’s stem with the fairing in place into the mounting hole. Be

sure the triangular recess in the fairing is pointing forward toward the bow.

5. While holding the assembly in place and using the bolt hole in the fairing as

your guide, drill a hole through the hull for the anti-rotation bolt.

6. Remove the assembly and cable from the mounting hole.

7. Sand and clean the area around the hole, inside and outside, to ensure that

the sealant will adhere properly to the hull.

Metal hull - Remove any burrs around both holes with a file and sandpaper.

BOW

Anti-rotation

bolt

⇐

Nut and

washer

Triangular plug

with curved surface

facing outward

Backing

block

D5565-1

Fairing

Figure 2-14: Using a Fairing and Backing Block

Seating

1. Remove the transducer from the fairing, if used.

2. Stainless steel transducer in metal hull - Slide the appropriate size isolation

sleeve over the cable and onto the stem of the transducer as far down as possible (see Figure 2-9 ).

Page 44

44 DSM300 Installation Manual

Be sure the top of the isolation sleeve will be below the top of the backing

block to prevent the sleeving from interfering with tightening the hull nut.

CAUTION:

To prevent electrolytic corrosion, never allow direct contact

between a stainless steel transducer and a metal hull.

3. Apply a 1/16" (2mm) thick layer of marine sealant to the sides of the transducer that will contact the fairing, if used, and up the stem 1/4" (6mm) higher

than the combined thickness of the fairing, hull, backing block, and hull nut.

This will ensure there is marine sealant in the threads to seal the hull and hold

the hull nut securely in place (see Figure 2-13 ).

Stainless steel transducer in metal hull - Apply the marine sealant to the outside of the sleeving instead of the stem itself.

4. If a fairing is used, thread the transducer cable through the fairing and seat

the transducer firmly within the recess in the fairing.

5. Apply a 1/16" (2mm) thick layer of marine sealant to the surface of the fairing

that will contact the hull, if used.

Attaching the Transducer

1. From outside the hull, thread the cable through the mounting hole.

2. Push the stem of the transducer (with the fairing in place) into the mounting

hole using a twisting motion to squeeze out excess sealant.

3. From inside the hull, slide the backing block onto the transducer cable and

stem, seating it firmly against the hull (Figure 2-15 ).

CAUTION:

Be careful to avoid cross threading the cap nut.

4. Screw the hull nut in place and tighten it with slip-joint pliers.

Stainless steel transducer in metal hull - Be sure the top of the isolation sleeve

is below the top of the backing block to prevent the sleeving from interfering

with tightening the hull nut.

5. Apply a 1/16" (2mm) thick layer of marine sealant to the anti- rotation bolt,

1/4" (6mm) higher than the combined thickness of the fairing, hull, backing

block, washer, and nut. This will ensure that there is marine sealant on the

threads to seal the hull and hold the nut securely in place (see Figure 2-14 ).

6. Push the bolt through the fairing, if used, and into the hull.

7. From inside the hull, slide the washer and nut onto the bolt. Screw the nut in

place and tighten it with slip-joint pliers.

Wood hull - Allow for the wood to swell.

Page 45

Chapter 2: Transducer Installation 45

Cable

Safety chain

Pull ring

Safety ring

Cap nut

Stem

Backing block

D4863-2

Retaining pin

Safety wire

Hull nut

Hull

Fairing

Transducer

Figure 2-15: Fore View of Transducer Installation

8. If a fairing is used, apply marine sealant to the flat side of the triangular plug.

Push the plug into the triangular recess in the fairing. The triangular plug fits

one way only. Be sure the curved side of the plug is exposed, matching the

curve on the outside of the fairing. Tap it into place with a mallet.

CAUTION:

For smooth water flow over the transducer’s sensor, be sure that

the external surface of the installed triangular plug is FLUSH with

the external curved surface of the fairing.

9. Being sure the valve assembly is seated firmly in the housing, carefully screw

the cap nut in place. Hand tighten it only;

do not over tighten

.

10. Remove any excess sealant on the outside of the hull to ensure smooth water

flow over the transducer.

Page 46

46 DSM300 Installation Manual

11. After the sealant cures, inspect and lubricate the O-rings on the paddle wheel

insert with silicone grease or petroleum jelly (see Figure 2-16 ).

12. Slide the paddle wheel insert into the valve assembly with the arrow on the

top pointing forward until it is fully seated (the insert fits one way only).

Take care not to rotate the outer housing and disturb the sealant.

13. Slide the center ring of the safety chain onto the cable. Slide the retaining pin

in place and reattach the safety ring (Figure 2-15 ).

CAUTION:

Always attach the safety wire to prevent the insert from backing

out in the unlikely event that the cap nut fails or is screwed on

incorrectly.

14. Wrap one end of the safety wire tightly around the stem of the housing and

twist it together with the long end. Lead the wire straight up and through one

eye in the cap nut, then through one of the safety rings. Loop the wire through

the pull ring and twist it securely to itself.

15. Route the cable to the transducer, being careful not to tear the cable jacket

when passing it through the bulkhead(s) and other parts of the boat.

16. Attach the connector nut to the cable per instructions in

Connections

17. Attach the assembled connector cable to the transducer.

18. Route the other end of the cable to the DSM, being careful not to tear the

cable jacket when passing it through the bulkhead(s) and other parts of the

boat. To reduce electrical interference, separate the transducer cable from

other electrical wiring and the engine.

19. Coil any excess cable and secure it in place using tie-wraps to prevent

damage.

on

page 26

.

Transducer Cable

Page 47

Chapter 2: Transducer Installation 47

Top view of

paddlewheel

insert

Paddlewheel

insert

BOW

Notches

Pull ring

Flat side of

paddlewheel

blade faces bow

Paddlewheel detail

'O' rings

Housing

and valve

assembly

Cable

Key (2)

Valve assembly

Cap nut

Housing

D4864-2

Figure 2-16: Servicing the Paddle Wheel Insert and Valve Assembly

Page 48

48 DSM300 Installation Manual

Installation in a Cored Fiberglass Hull

The core (wood or foam) must be cut and sealed carefully. The core must be

protected from water seepage and the hull must be reinforced to prevent it from

crushing under the hull nut, allowing the housing to become loose.

CAUTION:

Always wear safety goggles and a dust mask when drilling.

1. Drill a 1/8" (3 mm) pilot hole perpendicular to the waterline from inside the

hull. If there is a rib or strut near the selected mounting location, drill from the

outside (see Figure 2-16 ). If the hole is drilled in the wrong location, drill a second hole in a better location. Apply masking tape to the outside of the hull

over the incorrect hole and fill it with epoxy.

2. Using a 2" (51 mm) hole saw, cut a hole from outside the hull through the

outer skin only.

3. Using the 2 3/8" (60 mm) hole saw, cut through the inner skin and most of the

core from inside the hull. The core material can be very soft. Apply only light

pressure to the hole saw after cutting through the inner skin to avoid accidentally cutting the outer skin

Note:

The optimal interior hole diameter is affected by the hull’s thickness and deadrise

an gle . It mus t be large e nou gh i n diamet er t o allow the cor e to be c omp let ely sealed.

4. Remove the plug of core material so the inside of the outer skin and inner core

of the hull is fully exposed. Clean and/or sand the inner skin, core, and the

outer skin around the hole.

CAUTION:

Completely seal the hull to prevent water seepage into the core.

5. Coat a hollow or solid cylinder of the correct diameter with wax and tape it in

place. Fill the gap between the cylinder and hull with casting epoxy. After the

epoxy has set, remove the cylinder (see Figure 2-17 ).

Page 49

Chapter 2: Transducer Installation 49

Dimension equal to the thickness of the hull's

outer skin to ensure adequate clearance

Casting epoxy

Hull

D4865-2

Inner skin

Core

Outer skin

Solid or

hollow

cylinder

Figure 2-17: Preparing a Cored Fiberglass Hull

6. Sand and clean the area around the hole, inside and outside, to ensure that

the sealant will adhere properly to the hull. If there is any petroleum residue

inside the hull, remove it with either mild household detergent or a weak solvent (alcohol) before sanding.

7. Proceed with

Seating

on

page 43

and

Attaching the Transducer

on

page 44

Check for Leaks

CAUTION:

Never install a thru-hull transducer and leave the boat unchecked

for several days.

1. When the boat is placed in the water, immediately check around the thru-hull

transducer for leaks. Note that very small leaks may not be readily observed.

Do not to leave the boat in the water for more than 3 hours before checking it

again. If there is a small leak, there may be considerable bilge water accumulation after 24 hours (probably not enough to cause water damage). If a leak

is observed, repeat

page 44

immediately.

Seating

on

page 43

and

Attaching the Transducer

.

on

Page 50

50 DSM300 Installation Manual

2.6 Installing the In-hull Transducer

Tools and Material Needed

Ta pe

Pole

Detergent

Weak solvent (alcohol)

Safety goggles

Dust mask

Disc sander

Thin, sealable plastic bag (optional)

Twist-tie

Petroleum jelly (Vaseline®)

Level and protractor

Carpenter’s square

Pencil

Adhesive (Loctite #5699 or 3M #4200)

Screwdriver

Silicone grease (optional)

Mineral oil 2.4 fl oz. (71 mil)

Cored fiberglass hull installation:

Drill

Hole saw for hull interior 4" (100 mm)

Miniature disk sander

Casting epoxy (polyproxy #7035/7040) or resin

Pap er cu p

Stirrer

Testing the Selected Mounting Location

Establishing a Performance Baseline

The results of this test are used to determine the best in-hull location for a

transducer.

1. Take the boat to the maximum depth for which your instrument is rated, or the

maximum depth in which you will operate the sounder.

2. Connect the transducer to the DSM. Refer to

on

page 26

.

Transducer Cable Connections

Page 51

Chapter 2: Transducer Installation 51

3 . T ap e t he t r an s d uc e r to a p ol e w it h t he c a bl e s id e up . Ho l d it o v er t h e s i d e o f t he

boat with the active face submerged in the water (see Figure 2-18 ). Keep the

active face of the transducer parallel to the surface of the water.

4. Observe the sounder’s performance and depth reading.

D5000-2

Figure 2-18: Establishing a Performance Baseline

Testing the Mounting Location

While the boat is moving around the same site (and depth of water), test the

transducer at your selected mounting location inside the hull. Use one of the

methods below:

1. This method is recommended if the sensor will be located near the stern and

the boat has a minimum deadrise angle.

i. Clean away any large build-up of dirt and/or grease using detergent or a

weak solvent such as alcohol.

ii. Place the sensor against the hull and allow bilge water to cover the sur-

face where they touch (see Figure 2-19 A).

CAUTION:

Always wear safety goggles and a dust mask.

2. This method can be used at all hull locations.

i. If the hull surface is not smooth, grind it with a disc sander.

ii. Partially fill a thin plastic bag with water, place the sensor inside the bag

and close it tightly with a twist-tie.

iii. Wet the surface of the hu ll and press the sensor face against it through the

bag (see Figure 2-19 B).

3. This is the least desirable testing method, as it may be difficult to remove all

traces of the petroleum jelly before bonding the base to the hull.

i. If the hull surface is not smooth, grind it with a disc sander.

ii. Coat the face of the sensor with petroleum jelly.

Page 52

52 DSM300 Installation Manual

iii. Press it against the hull with a twisting motion (see Figure 2-19 C).

ABC

D5001-2

Figure 2-19: Testing the Transducer at the Selected Location

Observe the sounder’s performance and compare it to the baseline. Look for a

stable depth reading that is similar to the baseline, compare the thickness and

intensity of the bottom trace.

If the performance is close to the baseline, this is a good mounting location.

Remember, some energy is lost transmitting through the hull.

If the test reading differs markedly from the baseline, you need to find another

location to install the transducer.

If there is no reading or it is erratic, the sensor may be positioned over coring

which is absorbing the acoustic energy. Choose another location. If no other spot

is available, check with the boat manufacturer to be certain coring is present

before proceeding with

Installation in a Cored Fiberglass Hull

on

page 55

.

Installation

1. Measure the deadrise angle of the hull at the selected location using a level

and protractor (see Figure 2-20 ). Measure carefully, since the installed transducer must be within 5 ° of vertical.

CAUTION:

Always wear safety goggles and a dust mask.

2. The hull surface to be bonded must be smooth and free of paint or any other

finish. If the surface is rough, use a disc sander to smooth an area 4"

(100 mm) in diameter.

3 . R e m ov e a ny d u st , g re a s e o r o il w i th a w ea k s ol v e nt , s uc h a s a l c oh o l, t o en s u r e

a good bond. Clean and dry both the selected area and the underside of the

base.

Page 53

Chapter 2: Transducer Installation 53

4. Using a carpenter’s square, draw a line on the hull perpendicular to the keel

through the center of the mounting location. This will be used as a guideline

to orient the base.

Guideline

perpendicular

to keel

Base

Hull

Flange

Parallel to waterline

Deadrise angle

D5002-2

Figure 2-20: Deadrise Angle

5. The numbers on the flange of the base represent deadrise angles. Identify the

number that most closely corresponds to the deadrise angle of your hull. Find

its match on the opposite side of the flange. Keeping the keel direction arrows

on the side of the base nearest the keel, align the two raised marks indicating

your deadrise angle with the guideline drawn on the hull (see Figure 2-21 ).

CAUTION:

The base must be liquid-tight.

6. When you are satisfied that the location of the transducer is optimal and the

orientation of the base corresponds to the deadrise angle of your boat, apply

a bead of adhesive to the bottom of the base flange. (Follow the adhesive

manufacturer’s instructions for use).