Page 1

Training Manual

Software

Water quality

Air supply Gas

Flue venting

Drain

Basics, Maintenance and Accessories

SelfCookingCenter® whitefciency® (SCC_WE)

CombiMaster Plus (CM_P)

Voltage

Installation

Accessories

Original components

Type of gas

V02 en, Basic_Maintenance_Accessories

Page 2

General hints:

Isolate the appliance from mains supply before opening the appliance

When working with chemicals, i.e. aggressive cleaning materials

always wear protective clothing, goggles and gloves!

After maintenance / repair the appliance must be checked for electrical

safety in accordance with your national, state and local requirements!

Whenever working on any gas component like:

Gas valve, gas blower and / or changing connected type of gas a detailed

ue gas analysis MUST be done using adequate CO and CO2

measuring equipment! This shall ONLY be done by trained technicians!

Always check appliance for possible gas leakages!

© 2011 Rational Technical Services. All rights reserved.

Please note that any technical information concerning Rational products

must NOT be forwarded to any third party.

V02 en, Basic_Maintenance_Accessories - 2 -

Page 3

List of content

Basic topics

Company history 4

History of the Combi Steamer 5

Structure of serial number 6

Unit history: Control panel Layout 7

Unit sizes 8

Basic principle 9

General information about water 10

Installation - Duties and responsibilities 12

Relationship: Installation - Components - Environment 13

Check list

Preinstallation checklist 14

Installation sheet - Electric / Gas units - Electrical connection 18

Installation sheet - Electric / Gas units - Water connection 19

Installation sheet - Electric / Gas units - Drain connection 20

Installation sheet - Gas units - Gas connection 21

Commissioning - Preventive maintenance

Installation/Commissioning Checklist 22

Preventive maintenance 27

Descaling - Cleaning

Instruction

for manual descaling 30

Additional information for manual descaling 33

User instruction electrical descaler pump 34

Daily care - Unit and Door Gasket 36

Instruction for manual cleaning 37

Accessories

Ultravent (UV) 38

CombiDuo, Thermo cabinet 41

Condensation breaker steam 42

Draft Diverter Gas units 42

Sicotronic 43

Ethernet Connection 43

Reporting forms

Product surveillance guideline 44

Registration form product surveillance 45

Registration form „dead on arrival“ 46

- 3 - V02 en, Basic_Maintenance_Accessories

Page 4

Company history

Milestone of an extraordinary company history

1973 Foundation of RATIONAL GmbH as a company for producing and selling of hot air ovens in

Germany

1976 Invention of the RATIONAL Combi-Steamer

1993 Opening of plant number 2

1993 Invention of the RATIONAL Clima Combi®

1997 Invention of the RATIONAL ClimaPlus Combi®

2000 Going public RATIONAL AG

2000 CleanJet® – World wide the rst full automatic self clean system

2004 Invention of the rst SelfCooking Center® of the world

2005 Invention of the rst VarioCooking Center® of the world by our daughter company

FRIMA. Cooking, roasting, frying, simply better, in one appliance, with double speed.

2008 Opening of the third and biggest plant in Landsberg

2008 CleanJet

+Care®

– cleaning intelligence for a maximum reliability

2011 Invention of SelfCooking Center whitefciency with Efcient Level Control

The following subsidiaries were founded:

UK, France, Japan, USA, Italy, Scandinavia, Switzerland, Canada, Spain,

Germany, Russia, Austria, Poland, China, Greece, Middle East and Brasil

V02 en, Basic_Maintenance_Accessories - 4 -

Page 5

History of the Combi Steamer

11C9103 1234 03-1991 05-1997

Low Temp Cook (LT)

Product line: Designation: Serial number Produced Produced

as of up to

Classic Line CD Steam, Hot air, Combi (S, HA, CS) 1018909 1234 1976 05-1997

CM (S, HA, CS) Vario-Steam (VS) 11M8610 1234 1986 11-1989

CM (S, HA, CS, VS), Reheating (R) 11M8904 1234 04-1989 04-1991

CC (S, HA, CS, VS, R)

CM S, HA, CS, VS, R 11M9104 1234 04-1991 05-1997

CM Gas (101) 14G9104 1234 04-1991 10-1997

CM Gas (201) 21G9301 1234 01-1993 10-1997

CM Gas (62) 62G9403 1234 03-1994 10-1997

C-Line

C-Line 61, 101 CCD – CCM - CCC CCM, CCC: humidity control C11D93101234 10-1993 05-1995

C-Line 201, 202 CCD – CCM - CCC C11M93101234 10-1993 05-1997

C-Line 61, 101 CCD – CCM - CCC C11C95051234 05-1995 05-1997

C-Line 102 CCD – CCM - CCC C12C95101234 10-1995 05-1997 CPC Line :

- 5 - V02 en, Basic_Maintenance_Accessories

ClimaPlus Combi® CD – CM - CPC CPC: ClimaPlus control E11CA97051234 05-1997 02-1999

CM Gas, CPC Gas G11CA97101234 10-1997 02-1999

CPC New humidity control E11CB99021234567 02-1999 03-2004

CPC IQT Sensor E11CB99101234567 10-1999 03-2003

CPC CleanJet®, CDS® E11CC00031234567 03-2000 03-2004

CM Gas, CPC Gas Electronic motor control, G11CD01011234567 01-2001 03-2004

230V burner control

CM, CPC Electric Electronic motor control E11CD01031234567 03-2001 03-2004

CD – CM - CPC Elimination of motor protector E11CD01121234567 12-2001 03-2004

SCC Line

SelfCooking Center® CM Electric / Gas E11ME04042345678 04-2004 01-2006

CM Electric / Gas New CPU pcb E11MF06022345678 02-2006 09-2008

CM Electric / Gas Extension of warranty E11MG08102355678 10-2008 09-2011

SCC Electric / Gas E11SE04042345678 04-2004 09-2008

SCC Electric / Gas CareControl / Extension of warranty E11SG08102445678 10-2008 09-2011

CM_P Electric / Gas Programmable and humidity control E11MH1109 09-2011

SCC_WE Electric / Gas Efcient Level Control E21SH1109 09-2011

Page 6

Structure of serial number

Classic Line - 05 / 1997 Serial number

Unit size Type

06 - 6x1/1GN Size Type Year Month Serial-#

11 - 10x1/1GN CD 006 94 07 1234

21 - 20x1/1GN CM 06 M 95 08 1235

20 - 20x2/2GN CC 20 C 96 10 1236

14G - CM 101 Gas (1x1/1GN) 21G - CM 201G (21x1/1GN) 62G - CM 62G (6x2/1GN)

C - Line - 10 /1993 - 05 /1997 Serial number

Unit size Type

61 - 6x1/1GN Family Size Type Year Month Serial-#

11 - 10x1/1GN

12 - 10x2/1GN CCD C 61 D 95 08 1234

21 - 20x1/1GN CCM C 11 M 95 11 1235

22 - 20x2/2GN CCC C 21 C 96 05 1236

CPC- Line - 06/1997 - 04/2004 Serial number

Unit size Type E - Elec.

G - Gas

61 - 6x1/1GN Family Size Type Version Year Month Serial-#

11 - 10x1/1GN A

12 - 10x2/1GN CD E 61 D B 98 12 1234

21 - 20x1/1GN CM E 12 M C 99 01 1234567

22 - 20x2/2GN CPC G 22 C D 96 05 1458967

SCC- Line - 04/2004 - Serial number

Unit size Type E - Elec.

G - Gas

61 - 6x1/1GN Family Size Type Version Year Month Serial-#

11 - 10x1/1GN

12 - 10x2/1GN E 21 S E 04 05 2345678

21 - 20x1/1GN CM E 06 M F ( CM) 06 02 2434567

22 - 20x2/2GN SCC G 11 S G 08 10 2534567

CM_P E 11 M H 11 09 2567892

SCC_WE G 21 S H 11 09 2569812

V02 en, Basic_Maintenance_Accessories - 6 -

Page 7

Unit history: Control panel Layout

Classic Line, CD, CM, CC

C-Line, CCD, CCM, CCC

CM SCC

CM_P SCC_WE

CPC Line, CD, CM, CPC

SCC Line, CM, SCC

Combi Master Plus , SCC_WE „whitefciency“

- 7 - V02 en, Basic_Maintenance_Accessories

Page 8

Unit sizes

Serial number

SelfCooking Center

6 x 1/1 GN

Thermo Cabinet

Serial number

®

SelfCooking Center

6 x 2/1 GN

Base stand

®

SelfCooking Center

®

10 x 1/1 GN

SelfCooking Center

10 x 2/1 GN

V02 en, Basic_Maintenance_Accessories - 8 -

®

SelfCooking Center

20 x 1/1 GN

®

SelfCooking Center

®

20 x 2/1 GN

Page 9

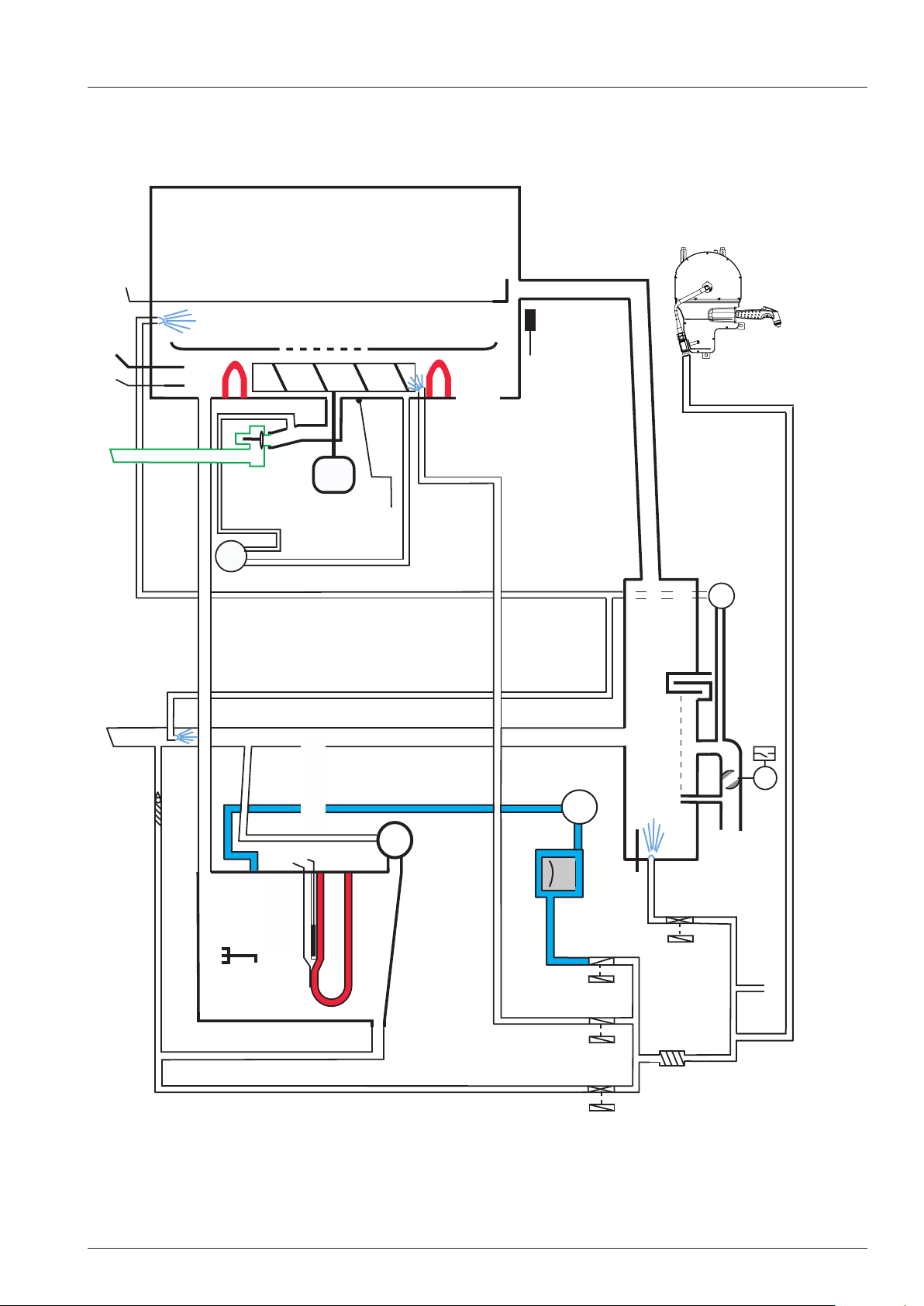

Basic principle

B1

Cabinet

B3.1 - 3.6

Core sensor (CT)

Safety thermostat STB

F4

Cabinet sensor

Diff. pressure sensor

Venting pipe

Y5

P1

Clima valve

Fan motor

M1

Humidity

Air bafe

B4

thermocouple

S3

Hot air heating

element

Door contact switch

Quenching box

M6

Emergency drain

Drain valve

S12

Hand shower roll guide

Check valve

Level electrode

S2

Safety

thermostat

F3

B5

generator

Sensor steam

M4

Self Clean (SC) pump

Steam heating element

Solenoid valve

Steam generator

Care

moistening

M12

Solenoid valve

llling

Quenching

B2

Solenoid valve

Care

Y4

Y3

Y1

sensor

Y2

Solenoid valve

quenching

S11

M7

Drain

Water supply

- 9 - V02 en, Basic_Maintenance_Accessories

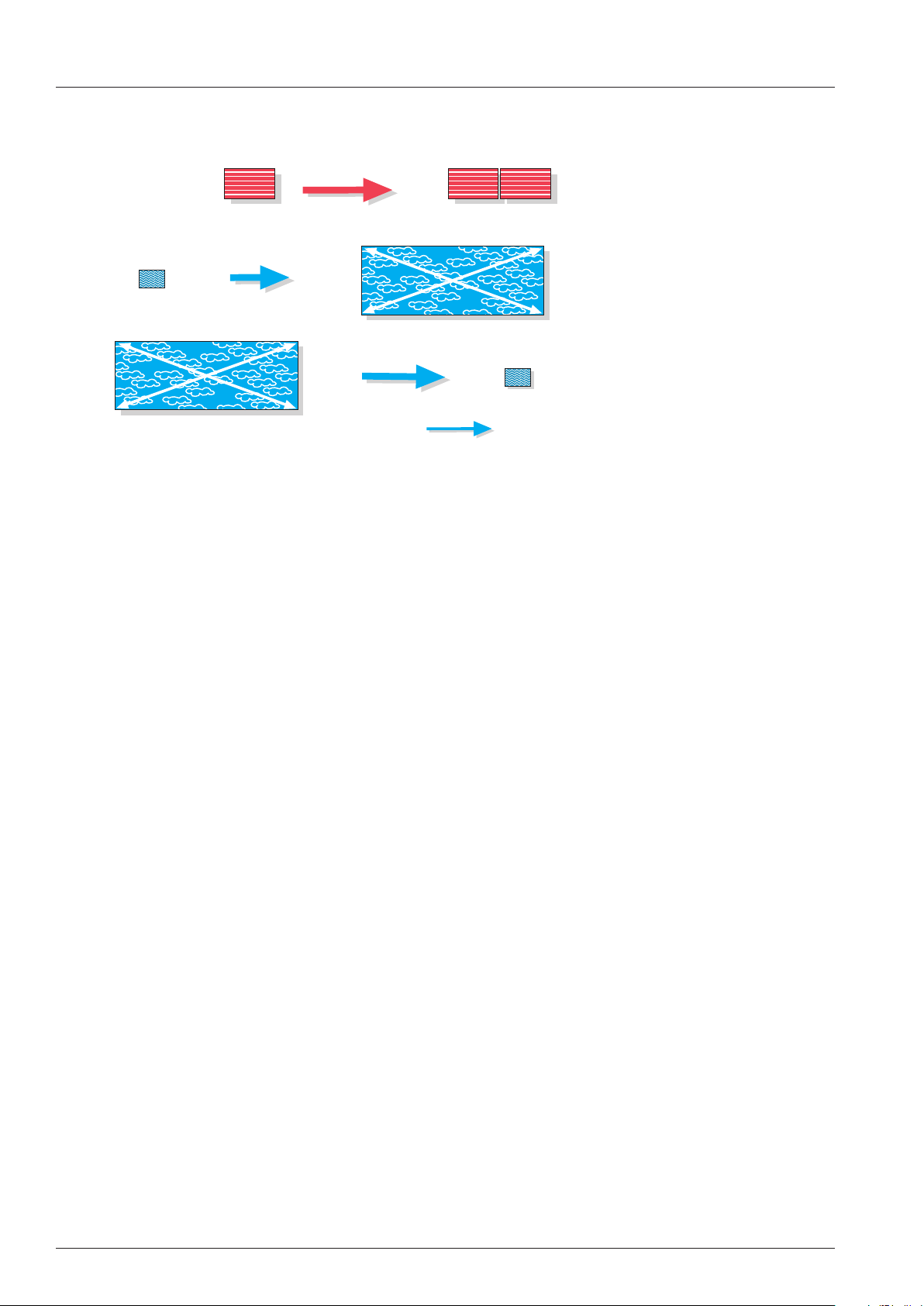

Page 10

1l

1700l Steam

approx.1700l Steam

1l

Water

Expansion through

heat energy

Volume reduction

through quenching

E+

E-

1dm

3

30°C

E+

300° C

2dm

3

Steam

Hot air

volume

Water

cold water

General information about water

Water- / Steam ratio

The conductivity of the connected water should be above 50µS/cm (micro Siemens).

The measured total hardness (TH) is normally higher than the measured amount of Carbonate hardness - calcium or magnesium carbonat (CaCO

Should the total hardness be less than the Carbonate hardness, most likely a water treatment system is

connected.

, MgCO3).

3

Common terms:

Total hardness TH is the measure of carbonate (CH) and non-carbonate

hardness (NCH) in the water

Carbonate hardness CH is the measure of bicarbonate (HCO3-) and carbonate

(CO3--) ions in the water;

Temporary water hardness; Forms sediments when

boiled;

Non-carbonate hardness NCH Calcium and Magnesum ions in the water;

permanent water hardness which can not be removed by

boiling

Water hardness e 1°dH = 1,25°e = 1,78°f = 17,8 ppm/l = 0,178 mmol/l

Chlorine Cl Gaseous, (used in swimming pools), limit 0,2mg/l

Chloride Cl-- chemical bond of chloride e.g. NaCl, limit 80mg/l

Water Analysis

Which values are required?

- Total hardness TH

- Carbonate hardness CH

- Conductivity in micro Siemens/cm

- Ideal: Water analysis with chloride content value

Possible reasons for corrosion

- excessive usage

- ferritic accessories

- rusting water pipes

- cleaning procedure (Unit is not dry over night)

- water

V02 en, Basic_Maintenance_Accessories - 10 -

Page 11

Water Info

Because of continuous examinations of systems for water treatment we would like to offer you some

information on different systems.

The given statements are only related to Rational units.

1. Recommended systems for water treatment

A) With pure scale problems in the steam generator we recommend hydrogen-(H+)-Ionic ex-

changer. This type of lter will extend the intervals between descales by approx. 5 to 8-times

of the normal descaling intervals. Please note that even with this type of lter it is still neces-

sary to descale the steam generator.

B) With a high chloride content above 80mg/l of water it is possible, that the interior cabinet will

start to corrode. To remedy this problem it is necessary to install a reverse osmosis lter.

C) With chlorine-contents above 0,2 mg/l of water an active carbon lter should be installed, to

avoid corrosive radicals when chlorine is heated up.

D) If the water is soiled with sand, iron particles or suspended matter a particle lter with

5-15 μm is recommended.

2. Limited recommended systems for water treatment

Physical systems for water treatment:

On some sites this type of water treatment showed satisfactory results. On other sites there was

no positive effect visible. Because of these circumstances we can not make a nal assessment of

this system.

3. Non recommended systems for water treatment

A) Sodium-Ionic exchanger:

With this lter system calcium is replaced by sodium. On chloride contents of the water above

50mg/l, sodium reacts with chloride to NaCl (=salt). This increase of salt in the water results in

a delay in boiling of the water. This delay in boiling can cause ”spitting” steam generators.

B) Silicate-dosing systems:

This kind of systems is problematic, as the adding of non conductive silicates, will inuence

the water level measurement.

- 11 - V02 en, Basic_Maintenance_Accessories

Page 12

Installation - Duties and responsibilities

Installation

Responsibilities

Designer / Architect

Make sure that during construction all dimensions needed are correct and sufcient

(Doors, corridors etc)

Make sure that all services (energy, water, drain and exhaust air) are available in

immediate vicinity of the unit

1. Drain

2. Water (Pressure, Water treatment)

3. Power supply and breaker specication

4. Gas connection (type of gas, dimension of supply pipe)

5. Vent hood (possible interconnection with gas supply)

6. Exhaust air for gas units (exhaust hood, ventilation ceiling, chimney, spacing

between top edge of unit to lower edge of fat lters / ceiling)

7. possible need for levelling device for trolley with sloped oor

Document: Pre Installation checklist

Designer Manual

Installer

Make sure the installation complies with the installation manual (part of starter kit) and

the local and / or national legislation / codes

1. Installed horizontally

2. Secured to the ground / stand secured from moving

3. Uneven oor levelled

4. Connected to cold water, possibly treated water, (water line rinsed)

5. Connected to power (equipotential bonding included - where required))

6. Connected to drain (steam temperature resistant pipe, permanent slope,

P-trap)

7. Connected to gas supply (correct type of gas), leakage test up to unit con-

nection point

8. Installation of accessories (Ultravent)

9. Testing of electrical safety

Document: Installation manual

RSP, Dealer

Commissioning and hand over to the customer

1. Conrm installation according to installation manual

2. Commissioning

3. Gas unit: Leakage test inside the unit

4. Gas unit: Flue gas analysis

5. Successful completion of Self Test

6. Function test of all components and cooking modes

7. Demonstration of cleaning mode for customer

8. Demonstration of preventive maintenance for customer (daily cleaning)

9. Download of Service Data

10. Photos of installation site

Document: Installation and commissioning checklist

Installation manual

Operator manual

V02 en, Basic_Maintenance_Accessories - 12 -

Page 13

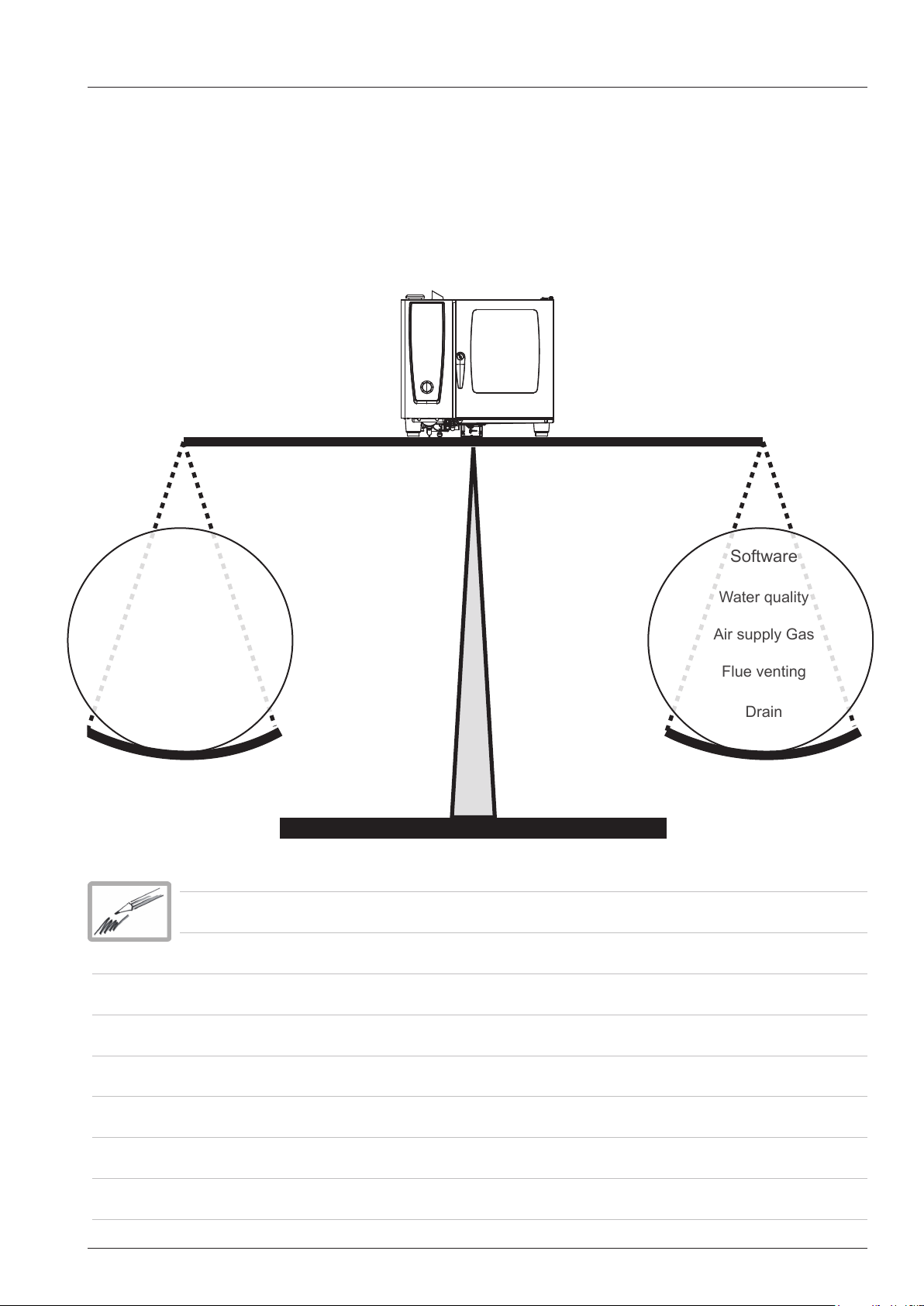

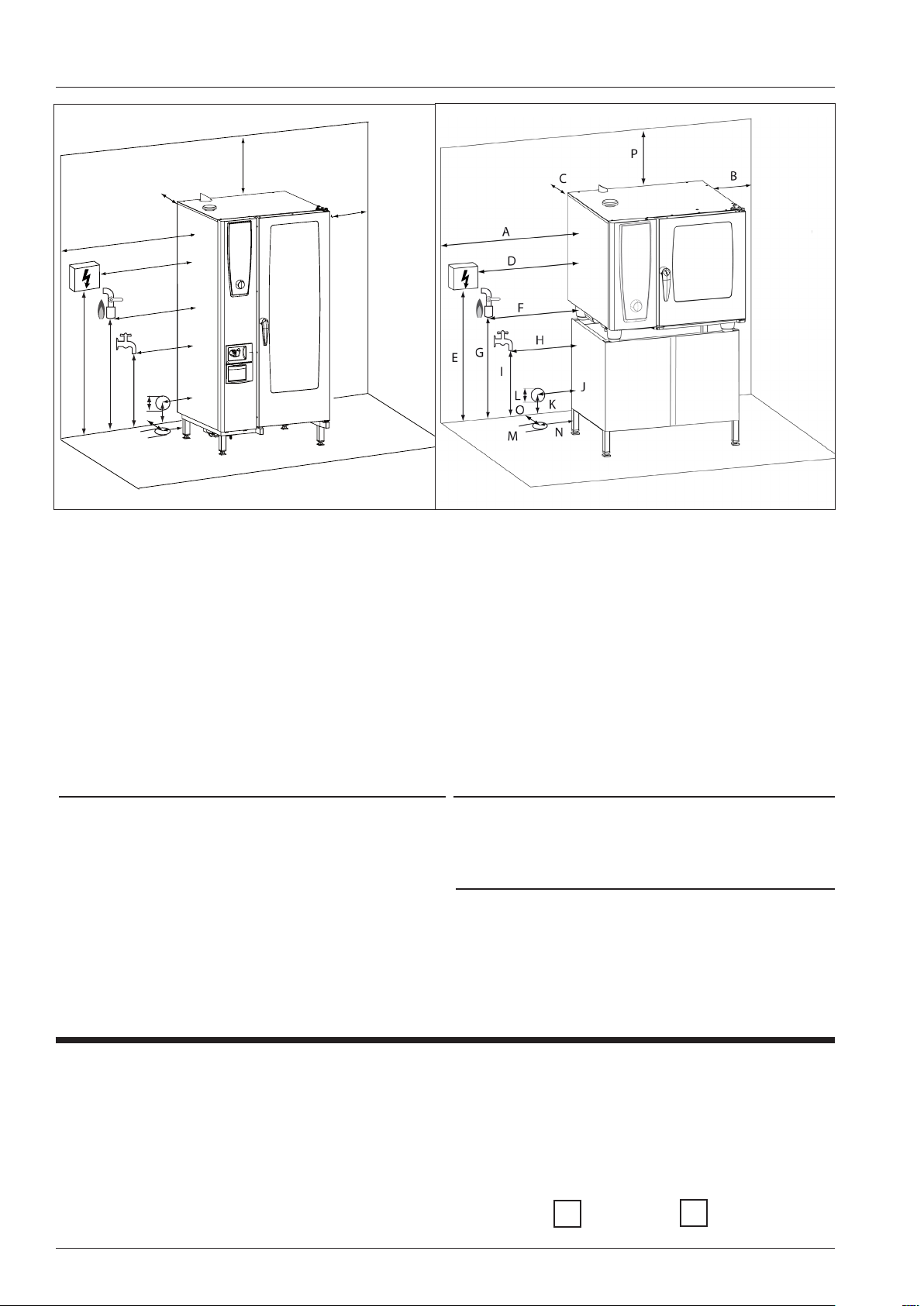

Relationship: Installation - Components - Environment

Software

Water quality

Air supply Gas

Flue venting

Drain

The unit will only function properly, when all components are designed correctly and the installation is

done according to the manufacturers instructions.

Therefore during maintenance and troubleshooting it is mandatory to observe all components together

with the connected services such as electricity, water etc. and the kitchen surrounding and venting.

Every deviation from the installation manual can cause different errors.

Voltage

Installation

Accessories

Original components

Type of gas

- 13 - V02 en, Basic_Maintenance_Accessories

Page 14

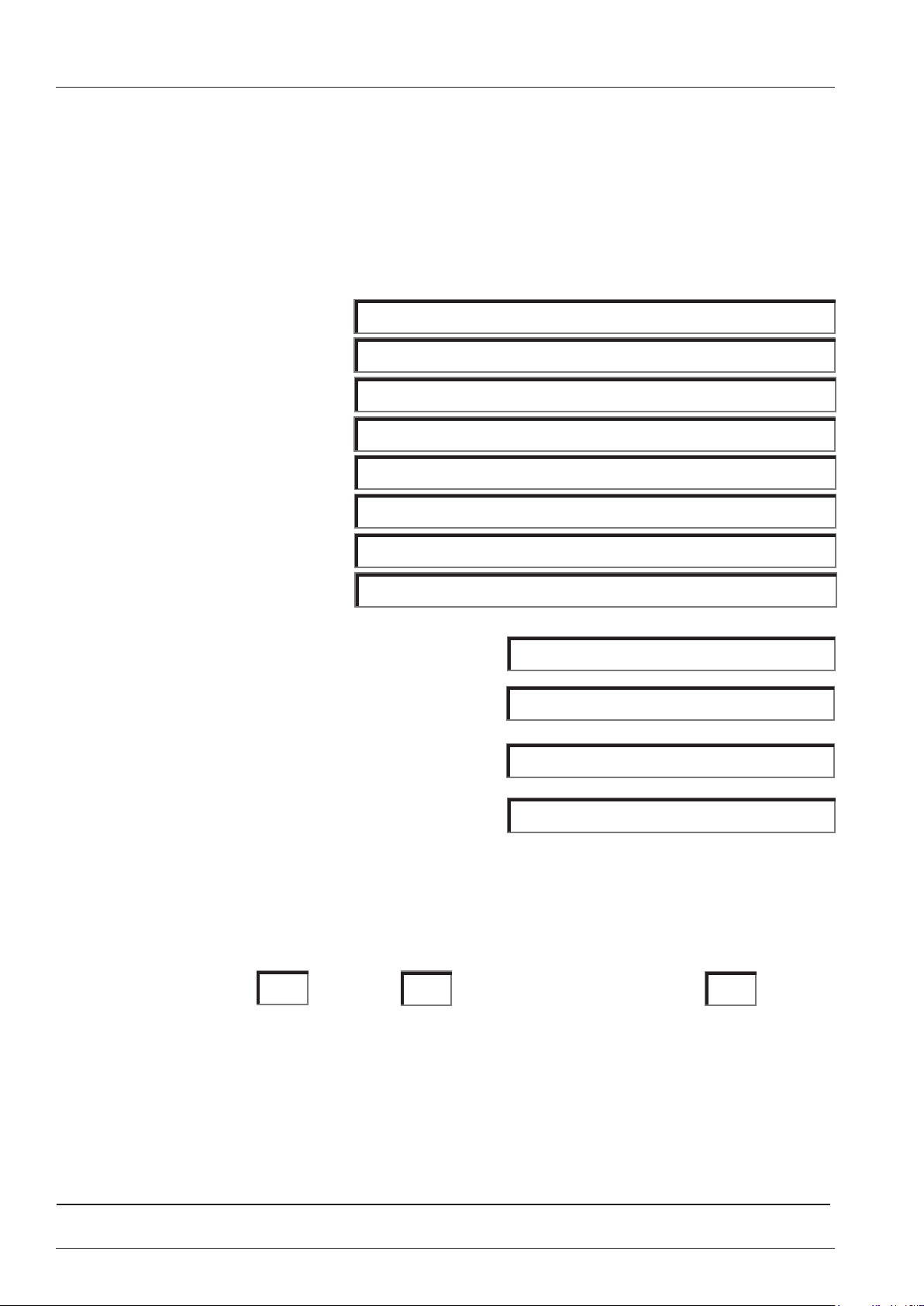

Preinstallation checklist

Preinstallation checklist

Company name:

Name of contact person:

Street:

City:

Country:

Telephone number:

Fax-Number:

E-Mail:

Number of RATIONAL units already installed:

Serial number of installed units:

How many units shall be installed?

What type of unit shall be installed?

Please fill in the form either by making a tick in the corresponding box or writing down the measured

values in the corresponding lines.

All measures, distances, services like electricity, water, drain and gas connection are properly

installed and complying with the list attached.

Yes No additional comments: Yes

Signature: Customer Sales Date

V02 en, Basic_Maintenance_Accessories - 14 -

Page 15

20x1/1 GN /

20x2/1 GN:

1900mm/75"

X (6x1/1 - 20x2/1GN)

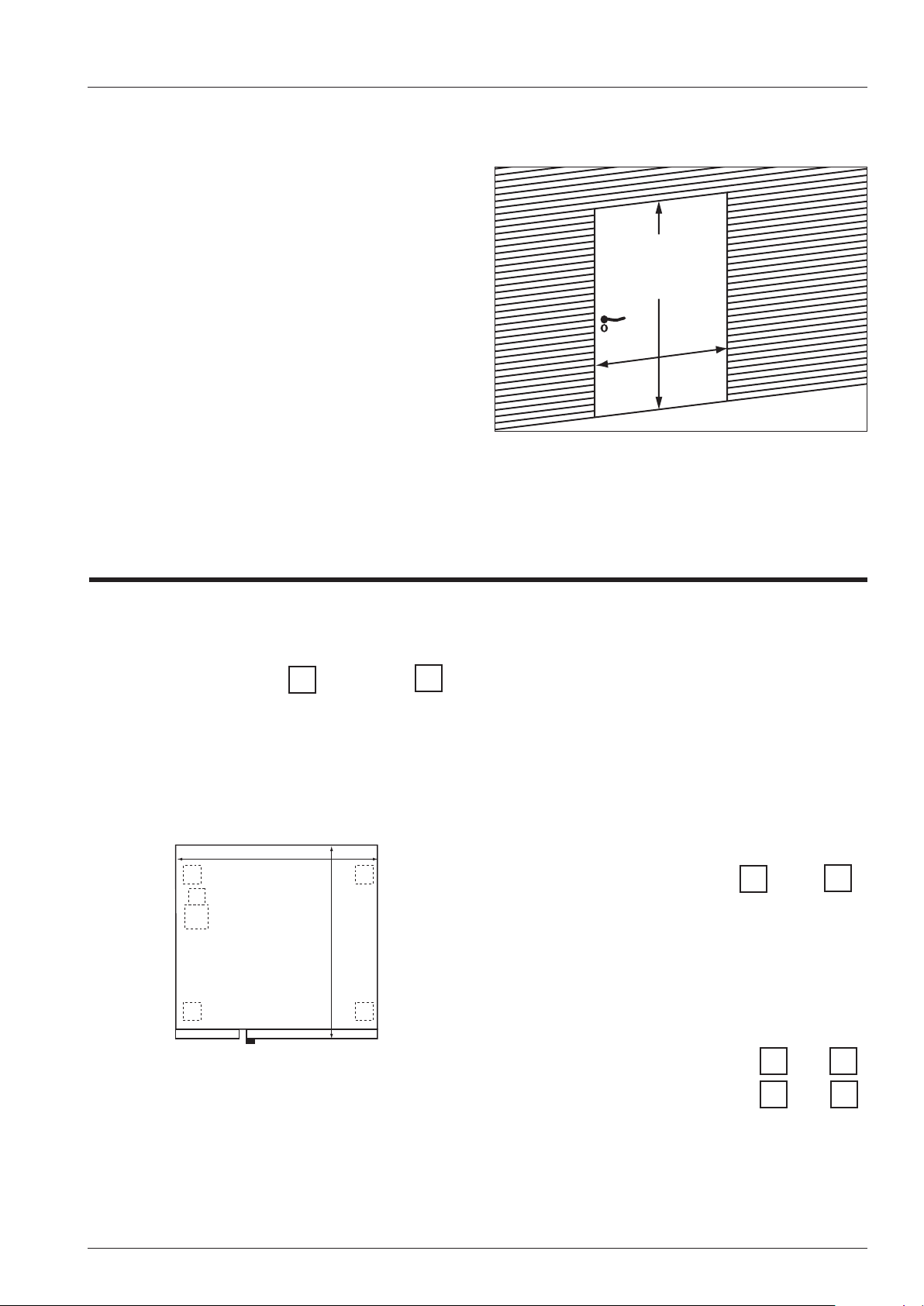

Preinstallation checklist

1. Check all doors and corridors for sufficient space

Required door width “X”:

Unit size without pallet with pallet

6x1/1GN 840 mm (33 1/8”) 920mm (36 1/4“)

6x2/1GN 1040 mm (41”) 1120mm (44 1/8“)

10x1/1GN 840 mm (33 1/8”) 920mm (36 1/4“)

10x2/1GN 1040 mm (41”) 1120mm (44 1/8“)

20x1/1GN 920 mm (36 1/4”) 950mm (37 1/2“)

20x2/1GN 1140mm (45“) 1150mm (45 1/4“)

Dimensions of doors Dimension of corridors

_____________mm ______________mm

_____________mm ______________mm

_____________mm ______________mm

2. Check site

yes no

a) Floor level?

if no, what is the approximate slope

(in case the slope is more than 3% use access

ramp)

b) Space left/right/rear

Write down distances on page 3

Breite

Tiefe

Hints:

- Dismounting door handle reduces depth minus

20 mm.

- Table models are with left hinged doors available.

Attention: No fryers at the left side of the unit Install

heat shield if necessary

c)

Other appliances left of the unit (seen from front

side) within 500 mm (20“)

Yes No

If yes, which appliance?

_______________________________

d) In case of floor models, is parking space for

trolleys available Yes No

Unit size depth: width

6x1/1GN 840 mm (33 1/8”) 847mm (33 3/8“)

6x2/1GN 1040 mm (41”) 1069 mm (42 1/8“)

10x1/1GN 840 mm (33 1/8”) 847 mm (33 3/8“)

10x2/1GN 1040 mm (41”) 1069 mm (42 1/8“)

20x1/1GN 920 mm (36 1/4”) 879 mm (34 5/8“)

20x2/1GN 1140mm (45“) 1084 mm (42 5/8“)

e) Is an extraction hood installed?

- 15 - V02 en, Basic_Maintenance_Accessories

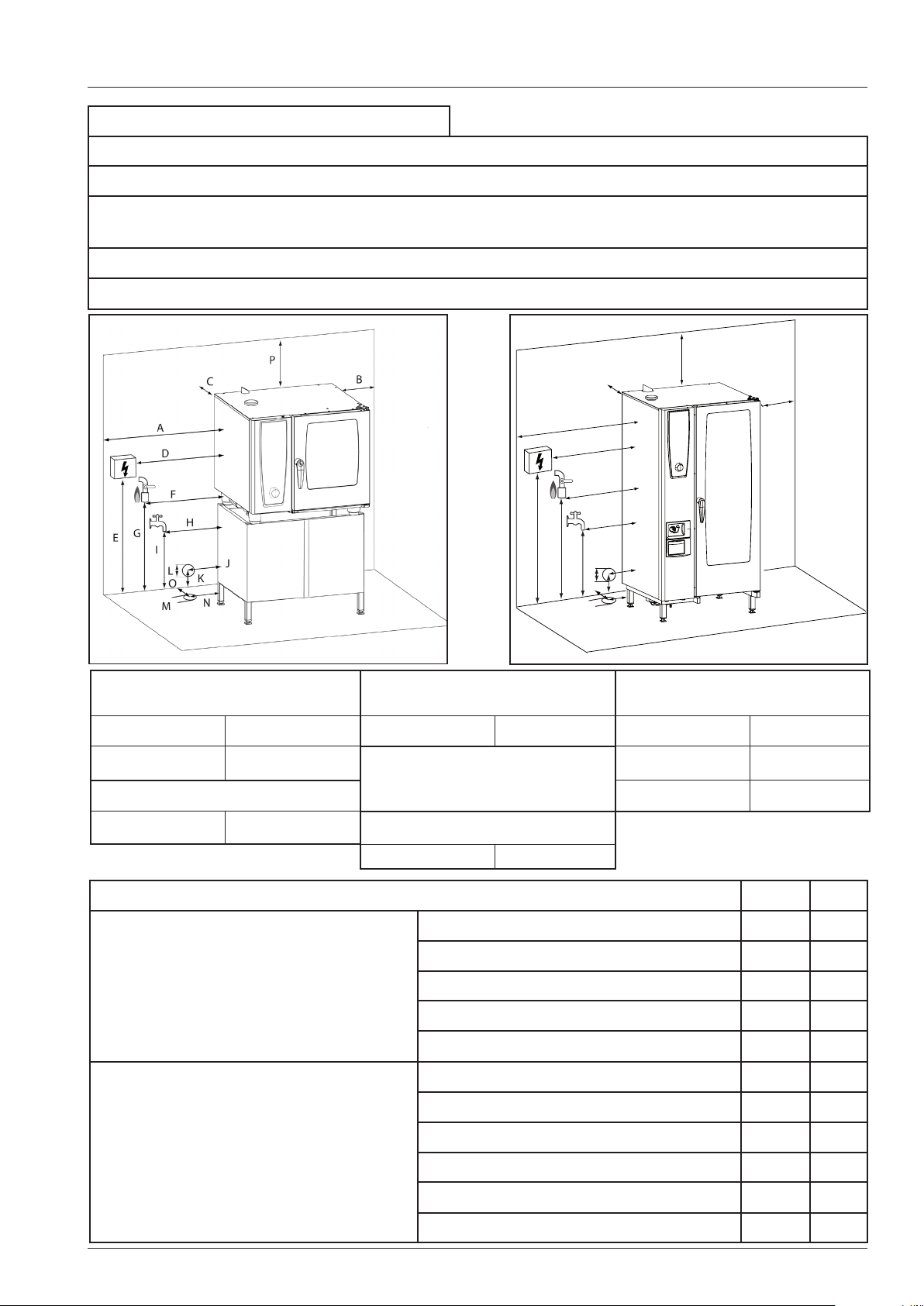

Page 16

Preinstallation checklist

P

C

A

D

F

G

E

H

I

L

M

J

K

O

B

Please fill in values measured at the site:

For calculating the distances see unit sizes on page 2.

If the connection points are at complete different position show the correct position in

the sketch

Side/top distances

A =

B =

C =

P =

Power supply

D =

E =

3. Elecrical connection

a) Which mains is available (fill in rest)?

1NAC...........

2AC..............

3NAC...........

3AC..............

Gas supply (in case of gas units)

F =

G =

Type of gas connection

Water supply

H =

I =

Drain:

Table model Floor model

J = M =

K = N =

L = O =

b) What fuses are installed in the mains

.................... A

ELCB / Residual current device (30mA) installed?

Yes No

V02 en, Basic_Maintenance_Accessories - 16 -

Page 17

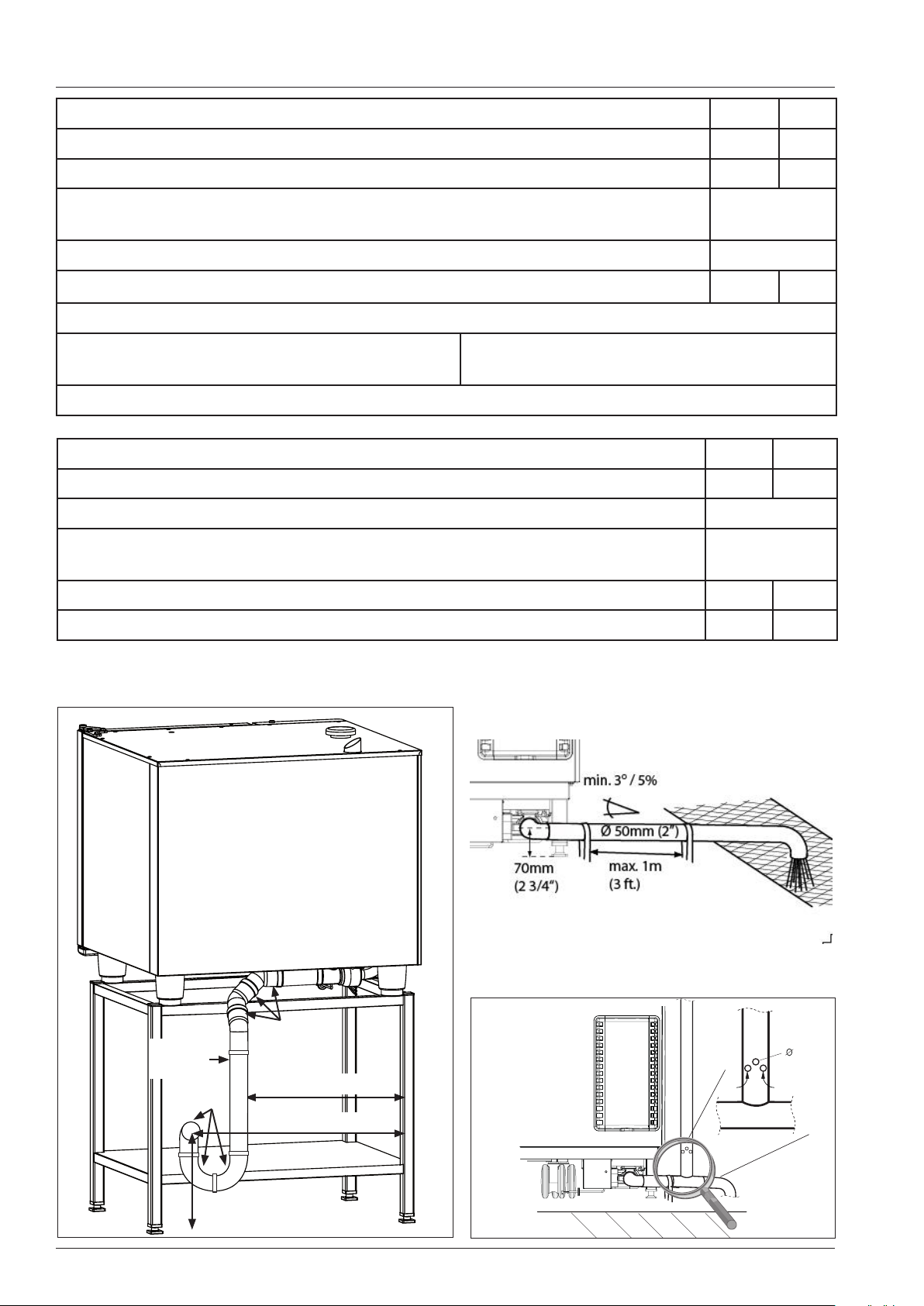

250-300mm

(10 - 12 “)

max. 1m

(3 ft.)

Ø 50mm (2”)

min. 3° / 5%

200-300mm

(8 - 12 “)

3x45°

Ø 50mm (2”)

70mm

(2 3/4“)

max. 1m

(3 ft.)

min. 3° / 5%

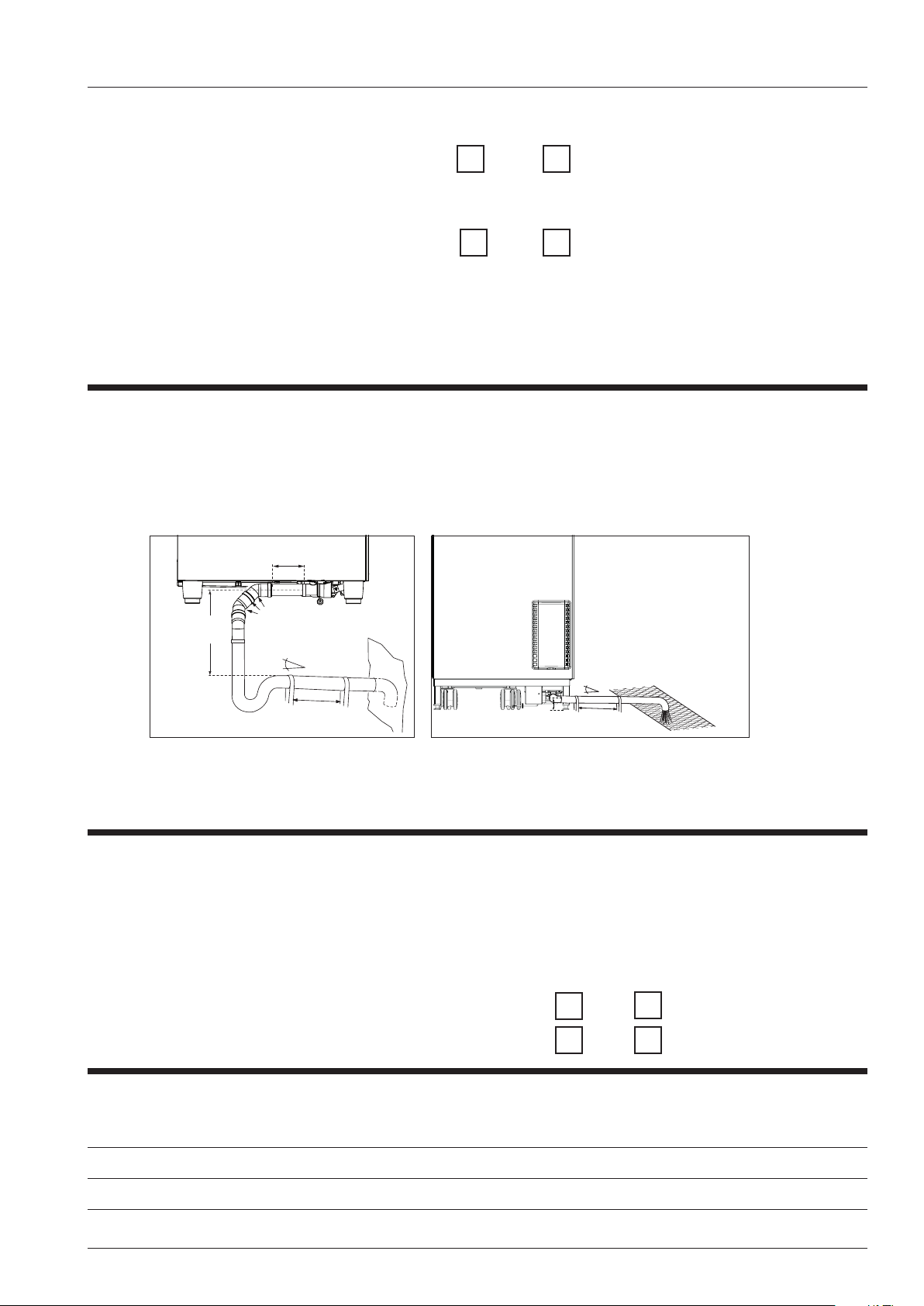

Preinstallation checklist

4. Water supply

Yes No

a) Water treatment system installed

If yes, which system_________________________________________

b) Separate water tap for every unit

(Attention: Unit has 3/4” connection)

c) Measured water pressure:_________________________________________________

d) Measured water temperature:______________________________________________

4. Drain

a) Location of drain (fill in page 3)?

b) Material of drain pipe______________

Suggestion for drain connection

Table units Floor units

NOTE:

Only use steam temperature resistant pipes for drain connection, no hoses!

5. Gas supply (in case of gas units)

a) Which gas type is foreseen?__________________________________________

b) Attention: Unit has 3/4” connection

c) Inform customer to discuss room size and flue gas system with local gas authority

yes no

6. Customer was informed about 2 years warranty?

7. Connection set complete (#60.70.464) required?

7. Comments / Notes

- 17 - V02 en, Basic_Maintenance_Accessories

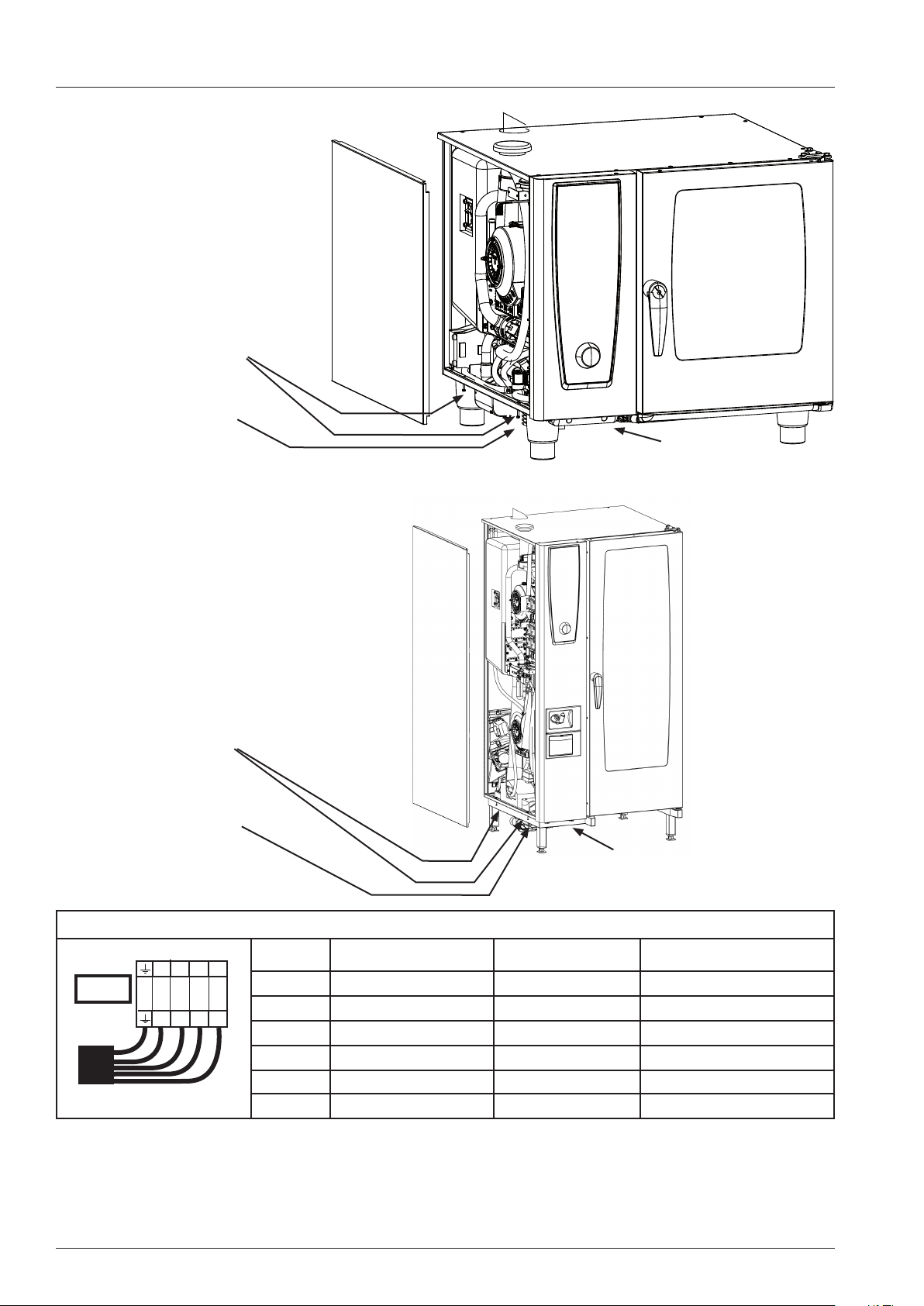

Page 18

Installation sheet - Electric / Gas units - Electrical connection

Electrical unit connection

61-102

Gas units:

Integrated cable

w/o plug top,

length approx. 2,5m,

Remove left side panel

Loosen 7 mm hex head screw

Opening for power cable

Ground

connection

Electrical unit connection

201-202

Gas units:

Integrated cable

w/o plug top,

length approx.. 2,5m

Remove left side panel

Loosen 7 mm hex head screw

Opening for power cable

Mains supply cable (Observe your local code for maximum cable length)

Terminal connection

L1

L1

L2

grey

L2

L3

grey

L3

Fig. 1

Ye/gn

N

blue

N

61 5x2,5mm² 4x2,5mm² 3x2,5mm²

grey

62 5x4mm² 4x4mm² 3x2,5mm²

101 5x4mm² 4x4mm² 3x2,5mm²

102 5x10mm² 4x10mm² 3x2,5mm²

3NAC400V 3AC440V Gas: 1NAC230V

Ground

connection

ELCB Breaker - residual current device 30 mA recommended

Electrical connection gas units: observe polarity!

All services must comply to local rules and regulations!

V02 en, Basic_Maintenance_Accessories - 18 -

.

Page 19

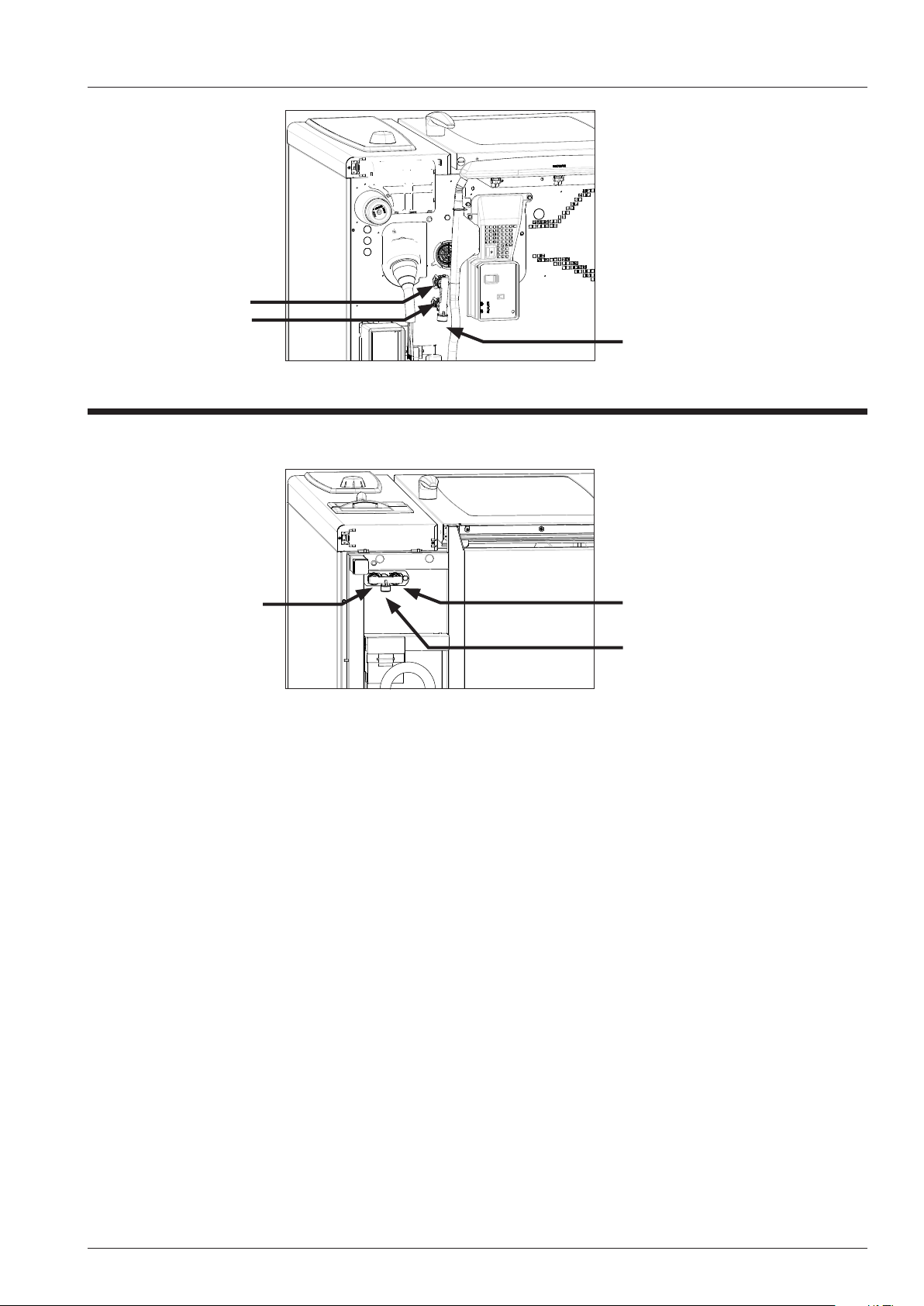

Installation sheet - Electric / Gas units - Water connection

Table units

61 - 102

Treated water

Fresh water

Fresh water

(common water supply)

Floor units

201 - 202

Treated water Fresh water

Fresh water

(common water supply)

Dimension water supply hose: 1/2“ pressure hose with 3/4” connection at the unti;

Water pressure:150-600 kPa with 20/25 l/min water quantity

Maximum water temperature for fresh and treated water: 30°C (87°F)

Note:

For selection of water lter please refer to installation manual!

Filter might be necessary in case of:

Cl2 >0,2 mg/l

Cl-- >80 mg/l

very hard water (details: Water info and Installation manual)

All services must comply to local rules and regulations!

- 19 - V02 en, Basic_Maintenance_Accessories

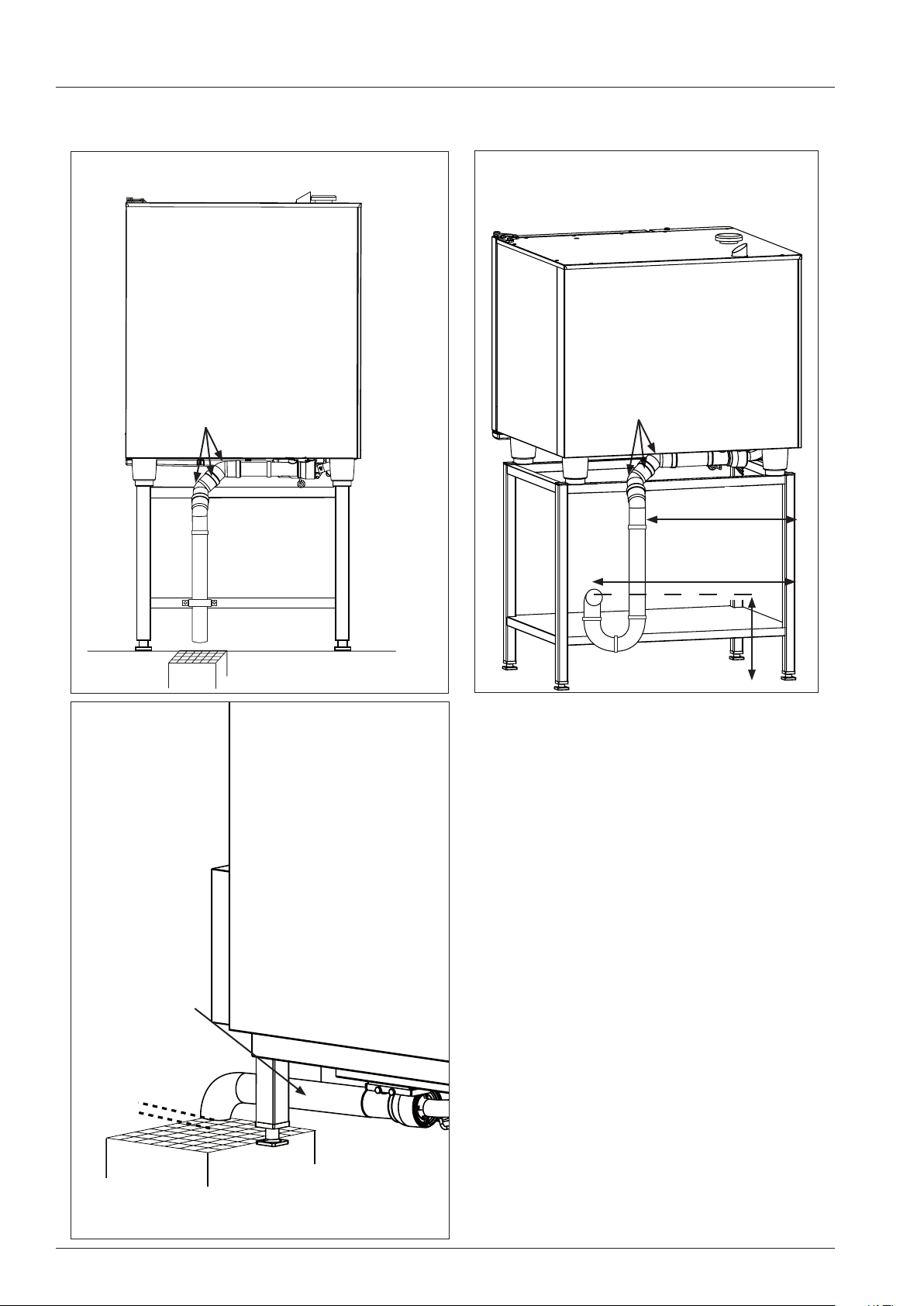

Page 20

Installation sheet - Electric / Gas units - Drain connection

Drain connection table model

Note: See install manual for leveling unit

Rear view

3x45°

DN 50 HT pipe

weight of piping not to be placed on

unit drain

Fixed to stand

Fixed drain connection table model

Note: See install manual for leveling unit

Rear view

3x45°

DN 50 HT pipe

approx. 550 mm

approx. 720 mm

Air gap per

local code

Floor drain sink with grease trap

Drain connection floor model

Note: See install manual for leveling unit

Side view left

Length approx.

250 mm

approx. 300 mm

Installation kit available # 60.70.464

(Water supply hose

Drain pipe set DN50 HT)

Drain connected

to unit leg

DN 50 HT pipe

All services must comply to local rules and

Floor drain sink with grease trap

V02 en, Basic_Maintenance_Accessories - 20 -

regulations!

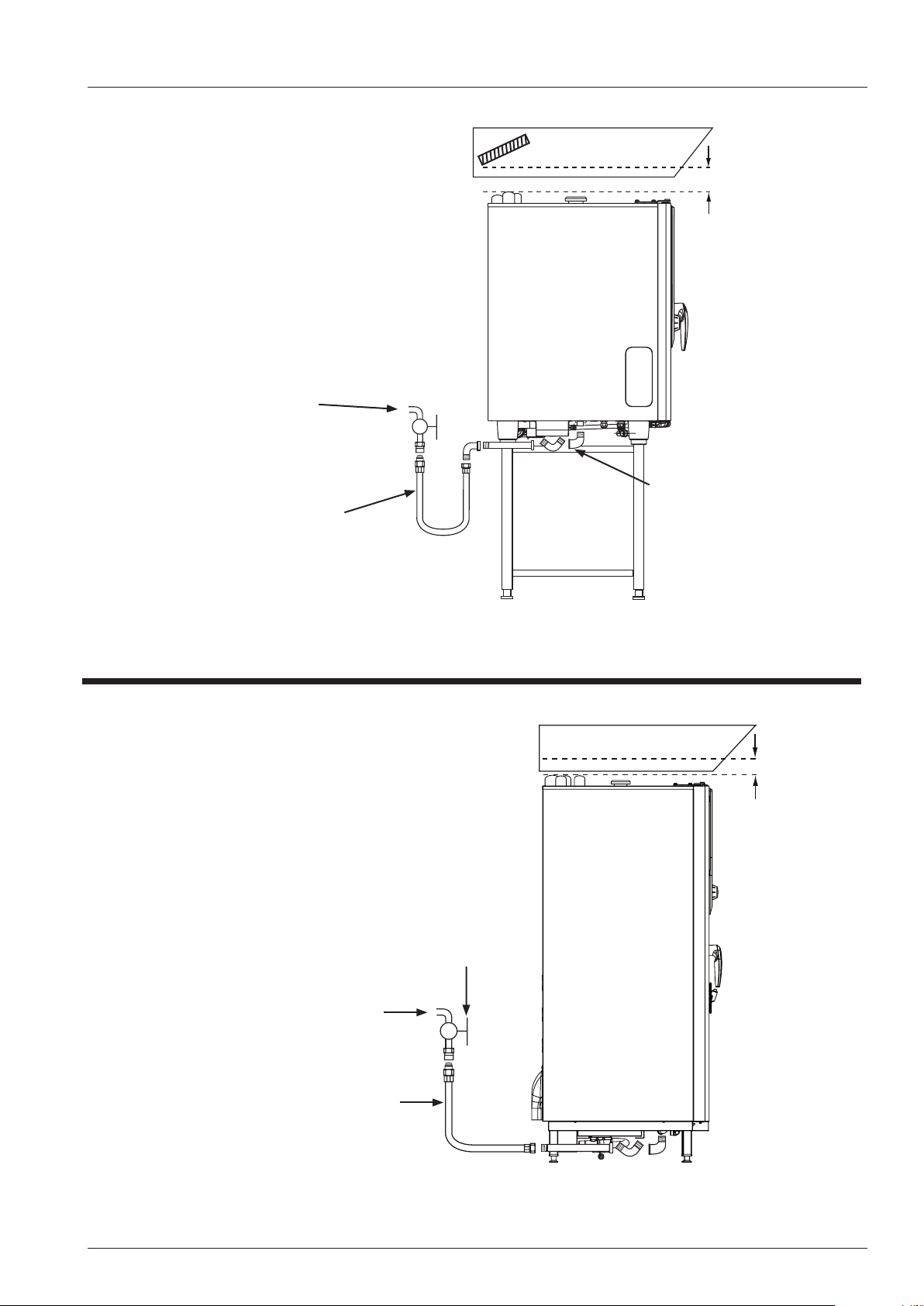

Page 21

Installation sheet - Gas units - Gas connection

Gas connection 61 - 102

Note: Observe local rules

and regulations

Gas supply

Gas quick

disconnect hose 1,5m

inner diameter ¾“

Unit under

extraction hood

Fat lter

min. 400mm

RATIONAL

Gas stop

valve

Gas connection

Natural gas 1,8 - 2,5 kPa

LPG 2,5 - 5,75 kPa

¾“ for 61 - 202

Gas connection 201 - 202

Note: Observe local rules

and regulations

Gas quick

disconnect hose 1,5m

inner diameter ¾“

Unit under

extraction hood

Fat lter

min. 400mm

Gas stop

valve

Gas supply

Gas connection

Natural gas 1,8 - 2,5 kPa

LPG 2,5 - 5,75 kPa

All services must comply to local rules

¾“ for 61 - 202

and regulations!

- 21 - V02 en, Basic_Maintenance_Accessories

Page 22

Installation/Commissioning Checklist

Installation and Commissioning Checklist

To be completed individually for each Rational Combi installation. This checklist is to be completed and

returned to your closest RATIONAL ofce (details are listed on the last page of the operation manual)

within 14 days of installation / commission to validate warranty.

Customer name:

Contact person:

Street:

Town:

Country:

Telephone number:

Fax-Number:

E-Mail:

Serial number of installed units:

Commissioned by company:

Date of installation:

Date of commissioning:

Installation complies does not comply with manufacturers specifications.

Please ll all information required into the embossed elds.

If the measured values do NOT comply with the values in the installation manual please inform the

customer and your Rational dealer.

We conrm the installation was done according to the attached installation checklist, the installation

manual and all national and local codes which ever may apply. The equipment was handed over free of

defects. Operation and maintenance of the equipment was explained.

---------------------------------------------- -------------------------------------

Signature / Date RSP / Dealer Signature / Date customer

V02 en, Basic_Maintenance_Accessories - 22 -

Page 23

Installation/Commissioning Checklist

1. Perimeter clearances

Left side all units (except 201/202 E) minimum:

Left side 201/202 electric units minimum

: 500mm

50mm

Left side recommended for all units for service

or with adjacent heat source: 500mm

Rear side all units minimum

Right side all units minimum

: 50mm

: 50mm

C

A

D

F

G

E

H

I

M

J

L

K

O

P

B

Perimeter clearances Gas supply (in case of gas

units)

Drain: Table models,

floor models

or Combi Duo

A: C: F: G: J: M:

B: P:

Type of gas supply:

K: N:

Power supply L: O:

D: E: Water supply

H: I:

2. Levelling and oor xing YES NO

Mounting surface / stand is level?

Unit is level?

Electric and gas 61, 62, 101, 102

Stand is xed to oor (Gas)?

Unit is secured to mounting surface (Gas)?

Transport trolley is level with unit and stand?

Unit is level?

Unit is xed to oor?

Electric and gas 201, 202

Mounting surface is level?

Trolley stands level inside the unit?

Access ramp is installed?

Unit and trolley extension installed?

- 23 - V02 en, Basic_Maintenance_Accessories

Page 24

Installation/Commissioning Checklist

3. Water connection YES NO

Water shut off valve available for each unit (also for each Combi Duo unit)?

Water shut off valve accessible by operator?

Measured water pressure at the water inlet of the unit

All units: minimum 150KPa (1,5 bar), maximum 600 KPa, (6 bar)

bar

Measured water temperature at the water inlet of the unit °C

Water ltration / treatment system installed?

Manufacturer and type of water lter / treatment system:

Measured water hardness

at lter inlet ____________ppm/l

Measured water hardness

at lter outlet ____________ppm/l

1°dH = 1,25°e = 1,78°f = 17,8 ppm/l = 0,178 mmol/l

4. Drain YES NO

Steam temperature resistant pipe, no exible hose? (I.e. drain kit # 8720.1031)?

Drain table units: P-trap or open drain? (please ll in)

Drain oor units: P-trap or open drain? (please ll in)

(open drain MUST NOT end underneath unit)

Separate drain for each unit (also Combi Duo units)?

Additional vent pipe installed

Example table units

Rear view

3x45°

DN 50

HT pipe

approx. 550 mm

3x90°

approx. 720 mm

Example oor models

Example additional vent pipe

8 mm

1/8"

approx. 300 mm

V02 en, Basic_Maintenance_Accessories - 24 -

Page 25

Installation/Commissioning Checklist

5. Electrical connection - Observe Local and National Codes! YES NO

Indicated voltage on data plate

Available voltage on site

Measured voltage L1- L2:_______V L1 - L3: _______V L2 - L3: _______V

L1 - N: _______V L2 - N: ________V L3 - N: _______V N - PE: ______V

Unit connected to equipotential bonding?

3 phase breaker installed?

Power switch / outlet accessible from front by operator?

Installed fuse rating?

Isolation/discharge current measurement carried out?

Amp draw at 100% steam heating L1:____A L2: ____A L3: ____A

Amp draw at 100% hot air heating L1:____A L2: ____A L3: ____A

Amp draw gas units A

6. Gas connection - Observe Local and National Codes! YES NO

Available diameter of gas line to each unit (all units 3/4“ minimum):

Flue gas and fresh air system sufciently dimensioned?

Gas pressure regulator installed?

Individual gas shut off valve installed for each unit?

Gas shut off valve accessible by operator?

Indicated gas type on data plate:

Available gas type on site:

Measured gas pressure with unit switched off (static gas pressure): mbar

Measured gas ow pressure with unit switched on,

when all other gas consumers in the kitchen are switched on (dynamic gas pressure):

mbar

Altitude above / below sea level? m

Flue gas analysis carried out (write down values in below list)?

Values at max. RPM Values at min. RPM

Burner

CO

2

CO

Flame current

CO

2

CO

Flame current

Steam ______% ______ppm ______μA ______% ______ppm ______μA

Hot air

top

Hot air

bottom

- 25 - V02 en, Basic_Maintenance_Accessories

______% ______ppm ______μA ______% ______ppm ______μA

______% ______ppm ______μA ______% ______ppm ______μA

Page 26

Installation/Commissioning Checklist

7. Exhaust / vent hood YES NO

Exhaust / vent hood installed?

Serial number of installed UltraVent or extraction hood

In case of gas units is hood interlocked with gas supply?

Free space between top edge of unit and lower edge of exhaust hood / ceiling cm

8. Function test / commissioning YES NO

All electrical connections and plugs tight and in accordance with local regulation?

All water and drain connections tight and not leaking?

All modes operational?

All additional functions / features operational?

Self test completed successfully?

Customer was informed about 2 years warranty?

Customer advised in basic operation?

Customer advised in daily cleaning routine incl. door gasket?

Customer advised in preventative maintenance

(changing air inlet lter, door gasket, etc)

9. Miscellaneous YES NO

Service data downloaded?

Photos of installation taken?

V02 en, Basic_Maintenance_Accessories - 26 -

Page 27

Preventive maintenance

Please ll in one form for every installed unit.

This checklist contains all works that have to be carried out during a maintenance.

Customer address Name

Company

Street

ZIP / Post code

City

Country

Telephone

Serial number of the unit

Software Version:

Checks / maintenance work scope Comment

Installation (conforms to install instruction) YES NO

All gas units and units 201-202 xed to oor

Water connection

Manufacturer of water treatment system

Drain

Gas connection

Electrical connection

Cabinet door (Functional)

Door lock

door catch

Door mounting / screws

Fastening of inner glass pane

Door gasket (steam tight in steam mode)

Door contact (door alignment and switch)

Trolley gasket (201-202)

Trolley castors (201-202)

Interior cabinet (Functional)

Interior cabinet light

Core temperature sensor

Cabinet sensor

Clima ap / valve tight

Air bafe

Moistening nozzle clean

Sieve installed correctly

Any corrosion on the unit or accessories

YES NO

Yes NO

- 27 - V02 en, Basic_Maintenance_Accessories

Page 28

Preventive maintenance

Checks / maintenance work scope Comment

Water supply - drain (Functional) YES NO

Dynamic water pressure KPa

All water joints leak tight

Function of hand shower and retraction system

Connection of drain conforms to install. instruct.

Quenching - quenching box clean

Function of drain valve (only SCC)

Steam generator

(Functional) YES NO

Steam generator leak tight

SC-Pump - ushing

Descale steam generator - if necessary

If descaled, was new lling volume evaluated?

Level electrode clean

Electric parts

(Functional) YES NO

Unit connected to earth bonding

Wire insulations undamaged

All electrical connections xed and tight

All contacts of main contactor free (not stuck)

Amp draw hot air (at 100%) electric units

Amp draw steam (at 100%) electric units

L1:___ A; L2:___ A; L3:___ A

L1:___ A; L2:___ A; L3:___ A

Max temperature of pcb °C

Gas components - Hint: Gas components must be maintained annually!

(Functional) YES NO

All gas connections leak tight

Cleaning of burner head (TI 03-2007) index E-G

Cleaning of ignition electrode

If necessary change all blower gaskets

Gas blower premix chamber free of fat and dust

Visual inspection of external ue gas venting

Dynamic ow pressure (all gas units in operation) mbar

CO

max steam - ame current - CO ppm % µA ppm

2

CO

min steam - ame current - CO ppm % µA ppm

2

CO

max HA top - ame current - CO ppm % µA ppm

2

CO

min HA top - ame current - CO ppm % µA ppm

2

CO

max HA bottom - ame current - CO ppm % µA ppm

2

CO

min HA bottom - ame current - CO ppm % µA ppm

2

Length of CO

screw of gas valve in mm

2

Steam HA top HA bottom

Make sure the gas compensation hose (hot air and steam) is not kinked and is properly xed in its

correct position.

V02 en, Basic_Maintenance_Accessories - 28 -

Page 29

Preventive maintenance

Checks / maintenance work scope

Control panel (functional)

Check closing mechanism

Control panel gasket and panel overlay

Plug for opening control panel in place

Dials

Mode switch (CM)

Temperature and time control

Core probe functional

LED indicators

PCB visual check (water marks etc)

Air lter clean and cooling fan ok

Exhaust hood / Ultravent

Exhaust hood or Ultravent installed

Hood and lighting operational

(Functional) YES NO

Comment

YES NO

Serial number of Rational exhaust hood

Free space between top edge of unit and

lower edge of exhaust hood / ceiling

Function test / commissioning

All electrical connections and plugs tight

All modes operational

All valid service error codes checked

All max. values of the sensors reset

Humidity control functional

Customer advised in basic operation and

programming

Customer advised in preventive maintenance

(Changing air lter, cleaning door gasket)

Service-telephone number entered

Chef Line-telephone number entered

Demonstration CleanJet

YES NO

cm

Service Data and HACCP Data copied to

USB stick.

Electrical safety

Electrical safety measures in accordance

with local standards

Name RSP Technician: Date and sign Customer: Date and sign

- 29 - V02 en, Basic_Maintenance_Accessories

Page 30

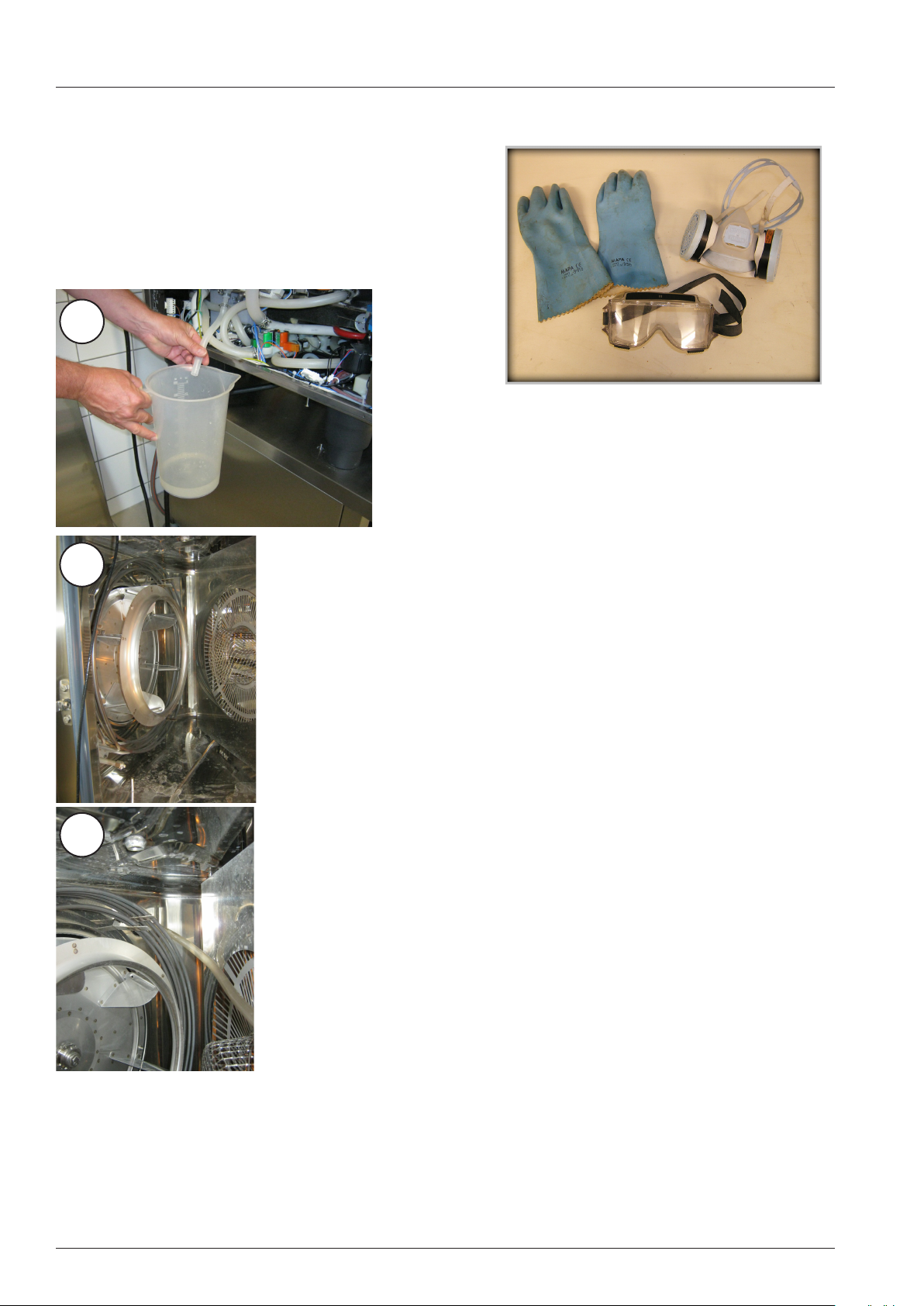

Instruction for manual descaling

Protective clothing and tools required:

- Protective clothing:

Goggles, gloves, apron

- Container with descaler

- Foot pump (6004.0203)

2

3

1. SCC or CM shall only be descaled when the cabinet temperature is below 40°C (104°F)

Start cool down if required.

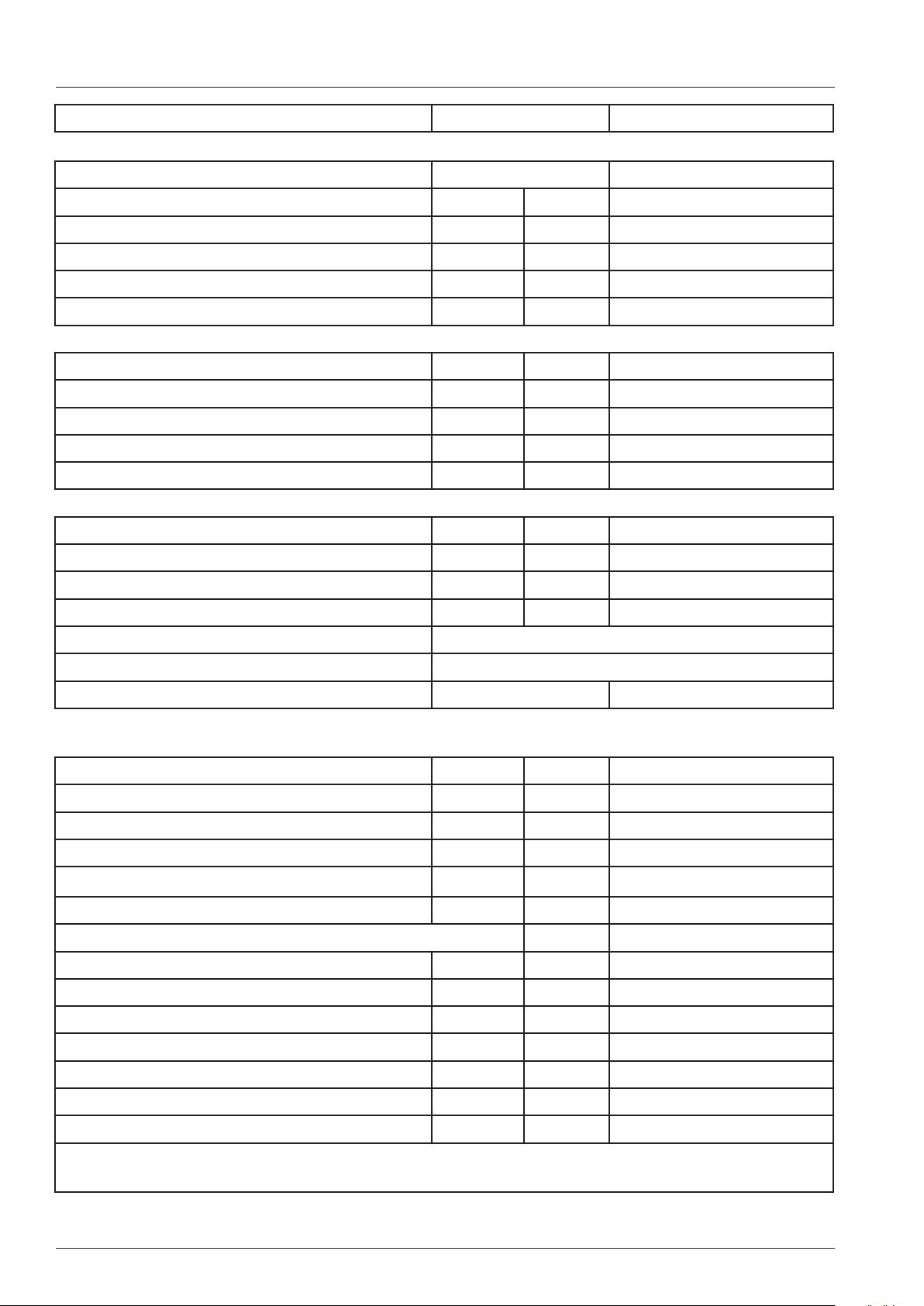

2. Empty and rell steam generator to cool it down.

Now empty steam generator manually into a

bucket and measure the volume of water drained

from the steam generator.

3. Descaler must ONLY be lled via the steam inlet

port found inside the interior cabinet!

Remove hinged rack (trolley) and swing air bafe

open.

4. Insert hose of descaler pump into steam inlet port

4

inside interior cabinet.

Do NOT ll through level electrode opening!

Damage to other components may occur!

5. Place descaler can into cabinet.

6. Insert the other hose end into can. Make sure the

red rubber plug rmly sits in the can opening

V02 en, Basic_Maintenance_Accessories - 30 -

Page 31

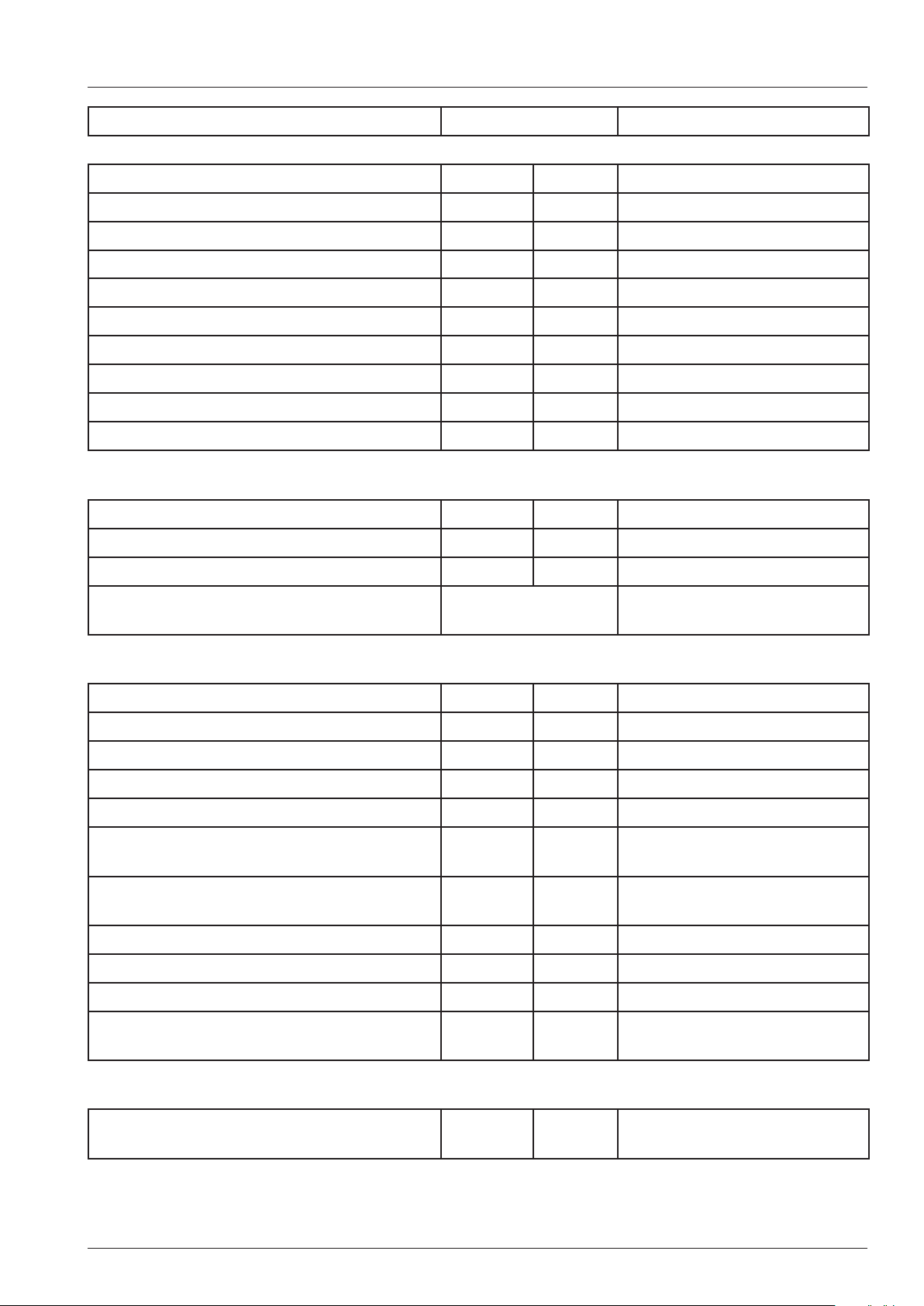

Instruction for manual descaling

5-7

7. Fill the recommended quantity SLOWLY into the

steam generator.

Caution:

Chemical may react violently with scale

and cause foaming back though steam

inlet port!

8. After lling remove pump and descaler can from

cabinet and rinse both cabinet and pump

thoroughly with fresh water.

8

10

9. Allow enough time for descaler to react

15 % concentration: ~ 1,5 hours,

30 % concentration: ~ 45 minutes

10. Carefully remove moistening nozzle and descale

in separate container with descaler liquid.

Isolate unit from power supply!

11. Open left side panel, remove quenching box cover

and remove any scale / deposits from quenching

box and cover.

After reassembly ensure no leaks are present.

12. Reconnect unit to power. After given time (pt.9)

use function test to drain liquid from steam

generator.

13. Let steam generator ll and drain 3 times.

11

14. Operate the unit for 15 min. in steam mode.

15. Rinse cabinet again with hand shower.

16. Isolate unit from power and drain steam genera-

tor manually to measure the new volume without

scale.

17. SCC only: In Basic Settings Pos. 9

press and hold for 5 seconds

“Reset after manual descaling”

Non compliance with this instruction can cause damages to the unit!

- 31 - V02 en, Basic_Maintenance_Accessories

Page 32

V02 en, Basic_Maintenance_Accessories - 32 -

Page 33

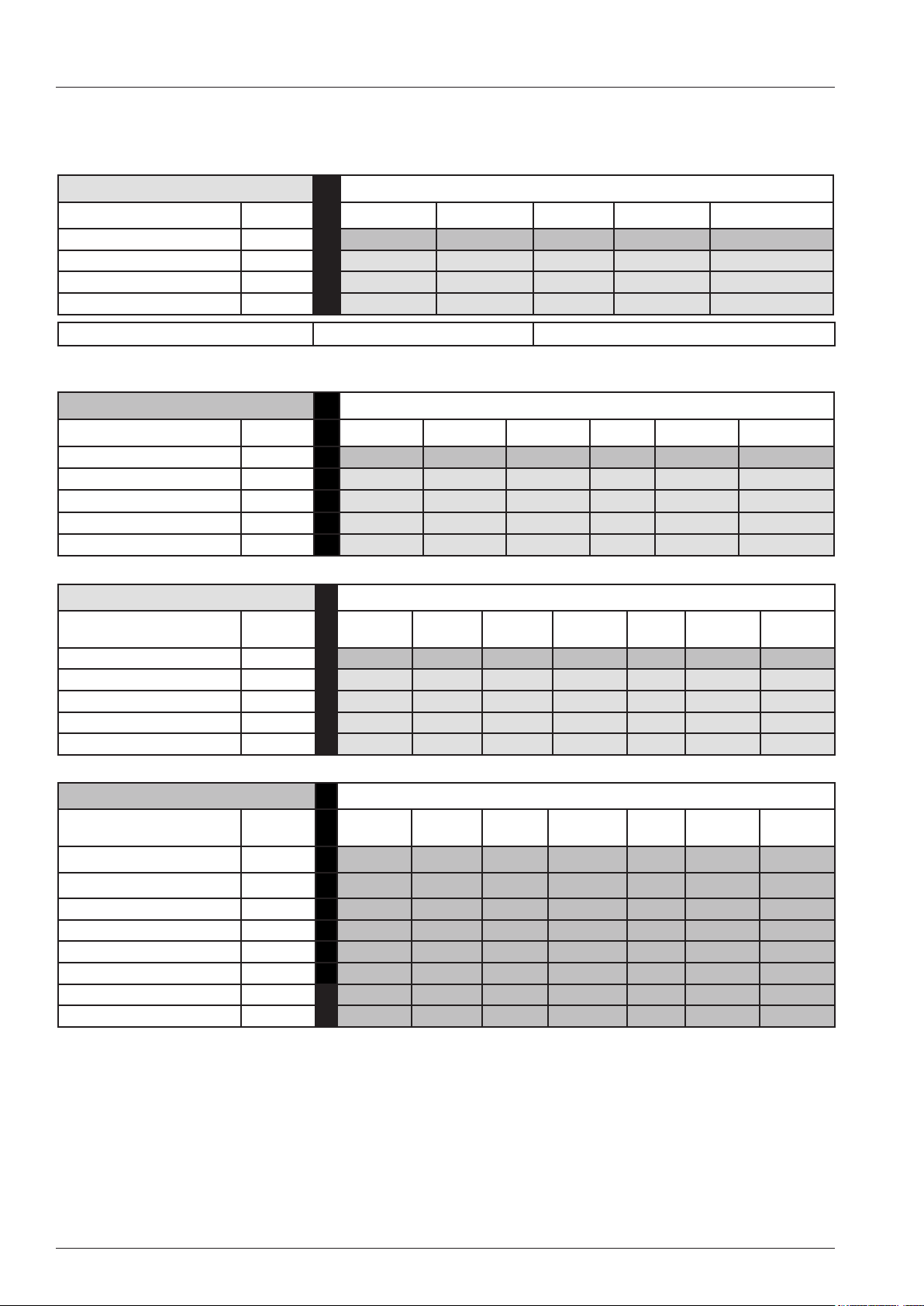

Additional information for manual descaling

In order to determine the amount of scale inside the steam generator manually drain and measure the

volume of water from the steam generator.

The steam generator should be descaled when less than the below listed volumes are drained from

the steam generator:

1 liter = 0.264gal (US); 1gal (US) = 3,78 liter; 4,5 liter = 4,5 x 0,264 = 1,19 gal(US)

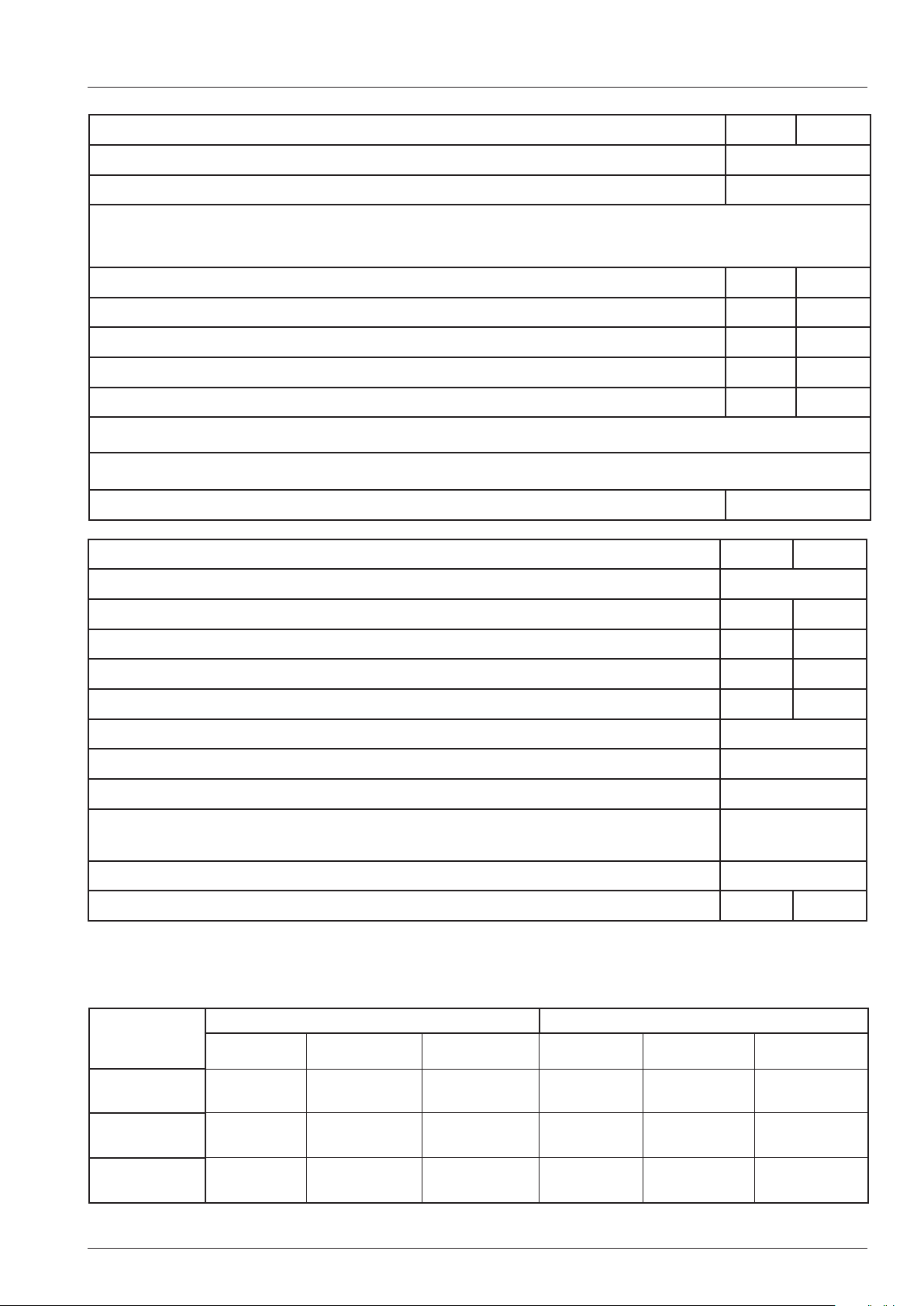

SCC/CM

Electric units

SCC/CM

Gas units

CPC/CM

Electric units

CPC/CM

Gas units

Line

Classic-

Gas units

Unit size Descale if less

than below volume

is drained

61 2,7 l 3,6 l 3,6 l

62 4,5 l 6,0 l 6,0 l

101 4,7 l 6,2 l 6,2 l

102 6,4 l 8,5 l 8,5 l

201 6,8 9,0 l 9,0 l

202 8,7 l 11,6 11,6

61 Gas 3,0 l 4,0 l 4,0 l

62 Gas 4,5 l 6,0 l 6,0 l

101 Gas 5,3 l 7,0 l 7,0 l

102 Gas 6,8 l 9,0 l 9,0 l

201 Gas 6,0 l 8,0 l 8,0 l

202 Gas 8,3 l 11,0 l 11,0 l

61 2,4 l 4,0 l 3,2 l

101 4,0 l 7,0 l 5,0 l

102 6,5 l 11,0 l 7,7 l

201 6,9 l 12,0 l 8,1 l

202 9,6 l 15,0 l 11,0 l

61 Gas 2,6 l 4,5 l 3,6 l

101 Gas 4,8 l 8,0 l 6,0 l

102 Gas 4,9 l 8,0 l 6,1 l

201 Gas 4,9 l 8,0 l 6,1 l

201 Gas 7,2 l 12,0 l 8,4 l

CM 62 Gas 3,5 l 6,0 l 5,5 l

CM 101 Gas 3,5 l 6,0 l 5,5 l

CM 201 Gas 7,0 l 12,0 l 11,0 l

CD/CM/CC 6 2,5 l

Required volume

of descaler

Volume of

clean steam

generator

CD/CM/CC 101 4,0 l

Line

Classic-

electric units

- 33 - V02 en, Basic_Maintenance_Accessories

CD/CM/CC 201 7,0 l

CD/CM/CC 20 10,0 l

Page 34

User instruction electrical descaler pump

The descaler pump 60.70.409 (230V) and 60.70.497 (110V) must

only be used to ll chemical part number: 6006.0110 into steam

generators of equipment bearing either of the following marks on the

data plate:

When working with chemicals, i.e. aggressive cleaning materials, always wear

protective clothing, goggles, face mask and gloves!

Please observe all information given on the Material Safety Data Sheet of your

descaling chemical!

Only personnel specially trained on handling hazardous materials shall follow

the instructions below!

Descaler shall ONLY be lled through steam inlet port inside cabinet!

1. Unlatch the left side hinged rack and the air bafe. Swivel them towards the right side.

2. Insert the pump hose marked with rings into the steam inlet port at the rear left top

corner of the interior cabinet.

The hose must be inserted at least to the following marking rings:

All electric heated units 3rd Ring 43cm (17“)

CM/SCC 61 and 62 Gas: 1st Ring 17cm (6,5“)

CM/SCC 101 and 102 Gas: 2nd Ring 31cm (12“)

CM/SCC 201 and 202 Gas: 3rd Ring 43cm (17“)

To prevent the hose from slipping out of the steam inlet port secure the hook

which is attached to the hose at 100cm (40”) from end of the hose onto the

air bafe cut out for the core probe as indicated.

3. Insert the suction hose of the pump into the descaling liquid bottle. Please observe the

below listed volume of descaler used for the different model sizes. Given volumes

are average and dependend on scale build up inside the steam generator.

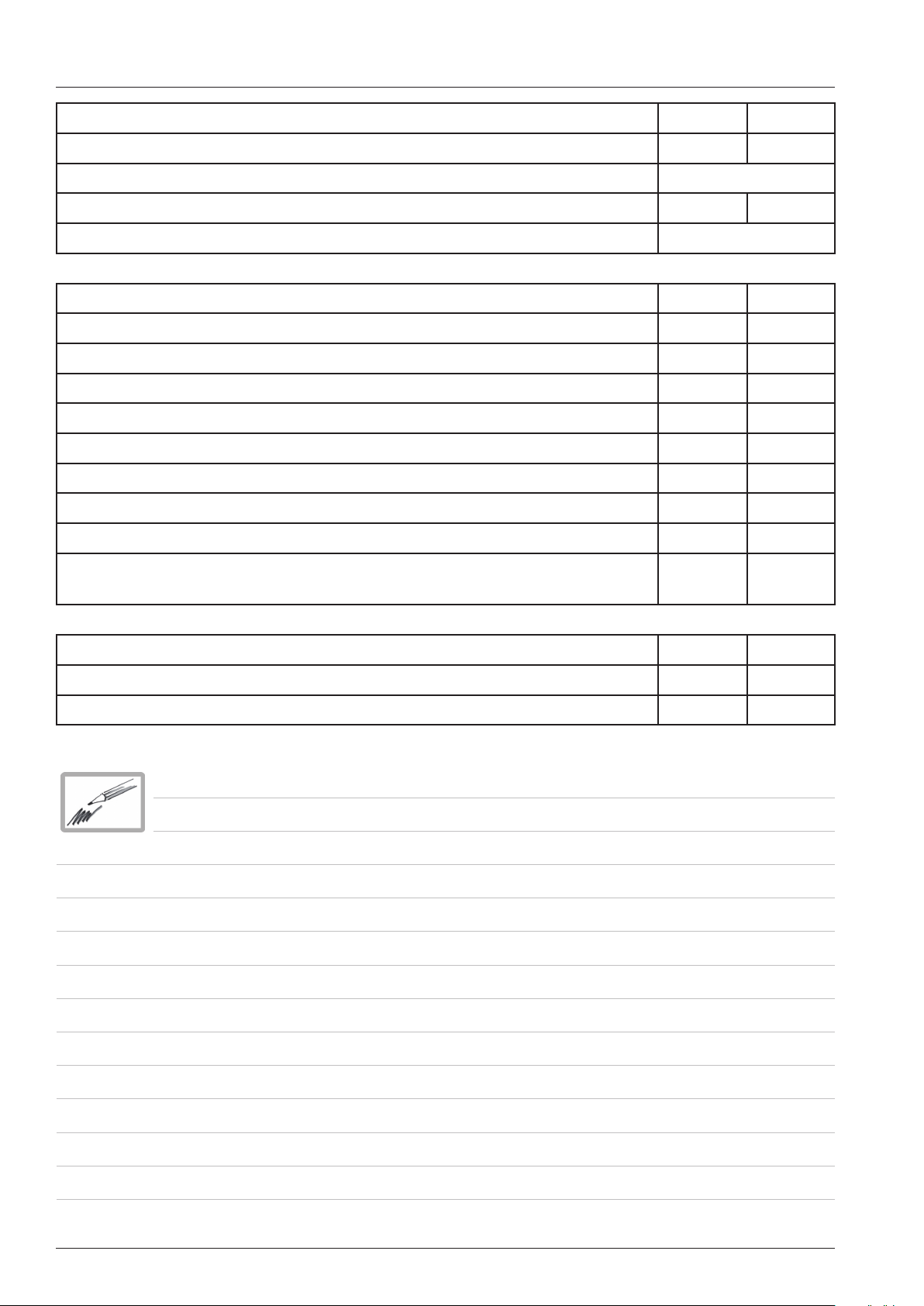

Descaler volume for electric units (volume in gal given as US gallons!)

SCC/CM 61 SCC/CM 62 SCC/CM 101 SCC/CM 102 SCC/CM 201 SCC/CM 202

3,6 L / 0,95gal 8 L / 2,1gal 8 L / 2,1gal 11,5 L / 3 gal 12 L / 3,1gal 14,6 L / 3,85gal

Descaler volume for gas units SCC and CM

SCC/CM 61G SCC/CM 62G SCC/CM 101G SCC/CM 102G SCC/CM 201G SCC/CM 202G

6 L / 1,6gal 8 L / 2,1gal 9 L / 2,4gal 11 L / 2,9gal 10 L / 2,6gal 14 L / 3,7gal

V02 en, Basic_Maintenance_Accessories - 34 -

Page 35

User instruction electrical descaler pump

4. Close cabinet door as far as possible and ll the above mentioned volume of descaler at 10 sec

intervals into the steam generator

NOTE: Descaling liquid can react very violently with the scale inside the steam generator!

Should any foam appear at the steam inlet port stop lling and wash the interior cabinet

with fresh water.

5. After lling the required volume remove the hose from the steam inlet port. Pump the remaining

liquid from inside the hose back into the descaler container bottle

6. Flush and rinse pump and pump hoses with fresh water.

Caution: not rinsing can cause internal corrosion of the pump.

7. Rinse the cabinet with fresh water.

8. Follow the additional instructions detailed in the users manual for completing the descaling proc-

ess.

Non compliance this instruction can cause damages to the unit!

- 35 - V02 en, Basic_Maintenance_Accessories

Page 36

Daily care - Unit and Door Gasket

Exterior surface of unit:

The exterior surface of the unit shall only be cleaned with a wet soft cloth. Aggressive or scouring

cleaning agents are not allowed.

Hosing down the unit with water jet or pressure cleaner is also not permitted.

Door glass:

The inner door glass can be opened by releasing the 2 spring clips. Use only a wet soft cloth for cleaning of this surface.

Aggressive or scouring cleaning agents are not allowed.

Door gasket:

Temperatures of 220°C or higher together with continued use of

grilling processes demand cleaning of the door gasket several times

per day, ideally after every loading.

Carefully wiping down the inner and outer side of the door gasket

will extend the life time of the gasket considerably.

Please do NOT use any aggressive, scouring or vinegar-based

cleaning agents for this purpose.

Please do NOT run the unit idle at high temperatures for stand by

purposes.

Drain of door drip pan

Please make sure the drain of the door drip pan is not blocked by fat or other foreign matter.

Rinse daily with water from the hand shower.

Air lter:

Depending on the kitchen environment the air lter should be

changed every 3-12 months.

The air lter can be cleaned in a commercial dish washer too.

The air lter for unit sizes 61 - 102 is located under the front panel

and can be removed by simply pushing the lter frame backwards.

The air lters of units 201 - 202 are located at the rear left side of

the unit and can only be accessed by unlocking the covering frame

using e.g. a screw driver. This must not be done by the customer!

Make sure the air lter is properly engaged again after replacing.

V02 en, Basic_Maintenance_Accessories - 36 -

Page 37

Instruction for manual cleaning

For manual cleaning observe the following:

• Follow the safety instructions on the spray bottle and cleaner canister.

• Use only genuine cleaning agents and the genuine hand spray gun (article no.: 6004.0100)

from the unit manufacturer.

• Never leave hand spray guns pressurised.

• Never spray other people, animals or objects

Cleaning steps:

1. In case of a high degree of soil inside the cooking cabinet rst select steam mode at 90°C and run

unit for 10 minutes. Afterwards ush the cabinet with the hand shower.

2. Check cooking cabinet temperature

Should temperature inside the cooking cabinet exceed 60°C, then cooking cabinet must be cooled

down below 60°C. To cool down the unit use the function “cool down”.

Hint:

If cleaner is sprayed into a hot cooking cabinet (temperature above 60°C), this will cause permanent

staining. To remove staining aggressive chemicals are necessary.

3. Spray cleaner into cooking cabinet

Swivel hinging rack and air baffle to the middle of the cooking cabinet.

Spray cleaner to the space behind the air baffle, into the cooking cabinet, the inner side of the door

and the door gasket.

Once complete bring air baffle and hinging rack to original position and lock them.

Warning:

Aggressive chemical fluid – risk of chemical burns.

It is essential that you use: protective clothing, safety goggles, gloves, face mask and the unit manufacturer‘s hand spray gun.

4. Allow cleaner to react for 20 minutes.

5. Select steam mode. Cooking cabinet temperature 90°C, running time 20 minutes.

6. After the running time has elapsed, spray the cooking cabinet thoroughly with the hand shower.

Check cleaning result, if necessary repeat steps 3 to 6.

7. Wipe door gasket inside and outside with a wet cloth.

8. Select hot air mode, cooking cabinet temperature 160°C running time 15 minutes.

9. If unit will not be used after cleaning switch off unit and leave cooking cabinet door ajar.

- 37 - V02 en, Basic_Maintenance_Accessories

Page 38

Ultravent (UV)

Ultravent Ultravent Plus

Serial number:

ET1UVA11095000126

ET2PA11095000133

old:

6606 2 0111 2120

from 09-2011

Energy, Duo unit size model Version Year Month Serial number

E = Electric T1 - 61 / 101

G = Gas T2 - 62 / 102

D = Combi Duo

only electric

F1 = 201

F2 = 202

U = UV

P = UVPlus

D = Extraction hood

A- Basis Version 11 09 5000126

until 09-2011 - Type Year Revision Day Month number

Ultravent (UV) 11 1 01 11 2120

66 61/101 Electric 1= contactor control

68 61/101 Electric, Combi-Duo 2= BUS control

70 61/101 Gas

72 62/102 Electric

73 201 Electric

74 61/101 Elektro Version US/Can 1= contactor control inside UV

77 62 Elektro Version US/Can 2= contactor control outside UV

Venting hood (EH):

60 61/101 Electric

62 61/101 Electric, Combi-Duo

64 61/101 Gas

08 62/102 Electric,

Air circulation Ultravent:

V02 en, Basic_Maintenance_Accessories - 38 -

Page 39

Ultravent

Ultravent / Ultravent Plus

The Ultravent has to be connected to a separate power supply.

The Ultravent will be started by the BUS signal. (Combi Duo: The Ultravent is connected to the BUS

system of both units.)

The PCB Service part is always equipped with 2 Minit BUS connections and 2 RJ45 BUS connec-

tions.

In case the power supply to the Ultravent or the BUS connection is faulty, Service 35 (SCC_WE) or

E35 (CM_P) will be indicated.

If the Ultravent is nally disconnected, it must be deactivated in “Basic Settings”.

Ultravent

As soon as the BUS sends the signal „unit is running“ the Ultravent is running on low speed. When

the cabinet door is opened, it will switch to high speed. 1 minute after ending of cooking program the

Ultravent will switch off.

A Ultravent for Combi Duo and Ultravent Plus has 2 fan motors (ref. to circuit diagram below)

Ultravent und SCC / CM Index E-G

The BUS controlled UV is only supported starting with software version 01-07-11 (SCC)

and C1.07.01 (CM) accordingly

Ultravent Plus

The UV Plus is equipped with 2 lters. The state of the lter is monitored by differential pressure

switches and positioning switches and indicated by 1 LED each.

Filter 1 (pre lter) is located directly behing the front grease lters. In order to extend the life of the

main lter (2) and should be changed when the middle LED (LED1) is activ.

Filter 2 (main lter) is located on top of the Ultravent. This lter should be changed when the right LED

(LED2) is activ.

Should any of the positioning switches remain open (lter not inserted) the left LED „ERROR“ will show

red.

Circuit diagram Ultravent Combi Duo (2 fan motors):

- 39 - V02 en, Basic_Maintenance_Accessories

Page 40

4

--

Circuit diagram Ultravent Plus:

Circuit diagram Ultravent Version USA:

F1

6,3A

S1

3

4

F3

115V

315mA

F2

315mA

115V

T1

24V

K3

-

1

2

-

-

K1

A1

A2

H1

K5

A1

B1A1A2

A2

S6

K3

-

-

-

115V 0V

T2

-

AC

-

AC

- +

K5

K4

-

X0

+

-

A1

A2

-

- 0V

-

+24V DC

-

161518

Magnet

Y1

K4

X23

1

2

L1

W26

N

PE

-

S4

-

5

K1

12 14

-

M

~

M1

215W

11

-

K3

11

12

1

2

K1

F2

161518

-

3

-

F1

3

N

N

K2

A1

A2

A1

A2

-

-

PE

PE

S5

11

K2

14

-

F1 Fuse 6,3 A

F2 Fuse 315 mA

F3 Fuse 315mA

K1 Fan relay

K2 Mode relay

K3 Warning relay

K4 Magnet relay

K5 Timing relay

M1 Fan motor

S1 Mode switch

S4 Charcoal filter switch 1

S5 Charcoal filter switch 2

S6 Pressure sensor filter

T1 Transformer 115V/24V

T2 Transformer 115V/24V

Y1 Magnet

V02 en, Basic_Maintenance_Accessories - 40 -

Page 41

CombiDuo, Thermo cabinet

The following units (manufactured after 04-2004) can be combined

as a CombiDuo:

• 61 (top) on top of 61, 101, 62 or 102

• 62 (top) on top of 62 or 102

• 101 (top) on top of 62

To order a mounting kit for Combi Duo you must select the energy of

the lower unit (electric or gas) and one of the following base options:

1. Movable (front - back) on 40mm rollers

2. On castors (2 xed - 2 swivel)

3. On 150mm legs

The combination 101 on top of 61 shall not be assembled. Reason is the unfavourable center of gravity.

Only the combination 61 on 61, 61 on 101 and 62 on 102 in the base

option “movable” have the top GN runner not higher than 1600mm

under the condition the lower unit is an electric version unit.

Installation instruction you can nd on the Service DVD 7007.3080 or

on the Service Web site.

Thermo cabinet

The Thermo cabinet is available for unit sizes 61/101 and 62/102.

The heating elements are located inside the middle dividing wall.

This appliance must only be used in catering

establishments to keep plates and GN containers

warm!

Due to hygienic regulations the storing of food is

not allowed!

- 41 - V02 en, Basic_Maintenance_Accessories

Page 42

Condensation breaker steam

In order to guide the steam from the vent pipe of the quenching box

into a ventilation hood without affecting the humidity control we have

created 3 new condensation breaker as an accessory.

SCC_WE and CM_P 61, 62 and 101: 60.72.591

SCC_WE and CM_P 102: 60.72.592

SCC_WE and CM_P 201 and 202: 60.72.593

All pipes of the condensation breaker are made of stainless steel

for use also on gas units.

These condensation breaker can no be used on older units

of the SCC line

Draft Diverter Gas units

When discharging the ue gases of a gas unit into a chimney, a draft diverter type B13 must be used.

This draft diverter is equipped with a safety thermostat, which will interrupt the power supply to the

ignition box and stop the operation of the unit when the temperature in the draft diverter is above the

maximum allowable temperature.

8 different draft diverter and draft diverter with silencer are available:

Draft diverter Gas units 61 type B13 70.00.737

Draft diverter Gas units 101 type B13 70.00.757

Draft diverter Ultravent Gas units 61 type B13 70.00.759

Draft diverter Ultravent Gas units 101 type B13 70.00.793

Draft diverter with silencer:

Draft diverter with silencer Gas units 62 Typ B13 70.00.768

Draft diverter with silencer Gas units 102 Typ B13 70.00.769

Draft diverter with silencer Gas units 201 Typ B13 70.00.770

Draft diverter with silencer Gas units 202 Typ B13 70.00.771

V02 en, Basic_Maintenance_Accessories - 42 -

Page 43

Sicotronic

Sicotronic stands for energy management systems and energy optimization plants for electro-thermal

and general electrical devices in a large-scale catering establishment.

Industrial customers pay electricity rate according to a maximum of Power consumption. Should the

amp draw exceed a set maximum the power supply company will charge a higher premium per KWh.

In order to avoid this current peak a surveillance system like Sicotronic is connected to the Power

meter which will disconnect individual consumers for a certain time according to a preset priority list.

For this purpose these consumers are connected to this system with a signal “energy demand ON”.

The feed back signal will be interrupted if needed.

The Sicotronic option must be ordered separately.

When retrotting Sicotronic, a new service part PCB is needed for SCC_WE and CM_P.

Ethernet Connection

SCC_WE:

Ethernet connectivity is a standard feature of all SCC_WE units. The PCB is equipped with an ethernet

interface which is supported with the standard software.

When ordering an unit with option Ethernet, the interface will be wired from the PCB to a position close

top the main power terminals.

SCC_WE oor units 201 and 202

To connect the Ethernet Interface to the PCB without having ordered the option “Ethernet” ex works a

special network cable with an angled plug must be used.

CM_P:

When ordering an CM_P unit with option Ethernet, a second PCB will mounted on top of the main PCB.

- 43 - V02 en, Basic_Maintenance_Accessories

Page 44

Product surveillance guideline

According to the European product liability law, RATIONAL AG is required by law to observe RATIONAL products in the markets and to react as soon as any deviation occurs. This product observance

liability is being extended to the RATIONAL partners for RATIONAL products sold by the partners.

The liability is described in detail below and consists mainly of the notication duty in case of safety

related incidents.

1. Objective

The purpose of this guideline is to advise you of the extension of the “duty of notication” to the

Service Manager RATIONAL AG.

2. Denitions

Duty of notication

It is mandatory to report on safety-related market incidents and on other safety-related incidents

which have or may have some connection with RATIONAL products.

Safety-related market incidents

- An accident with injury to a person or property damage which occurs after installing a RATIONAL

product or

- Factors, which could either directly or indirectly endanger the health or life of a person or damage

property. Such dangers could arise in following situations:

a) Installation (e.g. insufcient electrical coverage, gas point contrary to regulations)

b) The methods applied by the user of the appliance (e.g. blockage of the necessary air ow con-

trary to instructions)

c) A combination of RATIONAL products with products from other companies (e.g. incompatible

air/exhaust circulation)

d) Manipulation of RATIONAL products (e.g. through manipulation of internal wiring, by-passing

safety mechanisms such as the safety temperature regulator)

e) RATIONAL products which do not have the permitted standards required at the place of

installation (e.g. re-imported appliances)

Other safety-related incidents

Accidents or factors as mentioned in the above denition which occur before installing RATIONAL

products.

RATIONAL products

RATIONAL products include both appliances and accessories (the entire product range).

Every technician trained on RATIONAL products is obliged to conrm his attendance on the “product

surveillance training” with his signature annually.

To report on safety-related market incidents and on other safety-related incidents please use the

RATIONAL form “product surveillance” (see next page).

V02 en, Basic_Maintenance_Accessories - 44 -

Page 45

Registration form product surveillance

To Service Reg.No.

Email: Service@RATIONAL-online.de (

to be filled in by Service in Landsberg)

Registration form for product surveillance

From subsidiary/

dealer:

Where installed (address): Installed by:

Combi-Steamer/Accessories

(Type, Serial no, other markings)

Description of fault: (if nec. diagrams, surrounding conditions, installation room, photos, in the case of

serious injury please provide info in advance to tel.

Reported by, Name:

P = injury to a person (Please fill in letter)

G = danger to a person

S = property damage with danger to a person

V = insurance case

P+S = accident with injury to a person and property damage

*with an insurance case,

include insurance form and add ”V” above

Date/time when fault occurred:

Installation date: Date fault settled:

+49 8191/ 327 208)

Other remarks: (measures carried out or arranged; whereabouts of appliance/parts; info to specialist dealer,

chimney sweep, end-user etc.; informed authority, expert, police etc.)

Report on findings required? yes / no

If you exchanged service parts, pls return to RATIONAL

Landsberg, QM-R, as soon as possible!

Include a copy of this registration form!

Sent out (date):

Which parcel service:

Version 09/2006

Parcel number / Tracking number:

- 45 - V02 en, Basic_Maintenance_Accessories

Page 46

Registration form „dead on arrival“

Return as .doc file / Als Worddokument senden an:

Service@RATIONAL-online.de

Registration form for units “dead on arrival” (DOA)

Meldebogen für “Keine Funktion“ nach Geräteinstallation (DOA)

Reported by subsidiary: / Gemeldet durch (Tochter): Reported by (Name): / Gemeldet durch (Name):

Reg. No.:

Installation date: / Installationsdatum:Serial No of the unit: / Geräte-Nummer:

Was the “Seal tested“ intact ?/

War das „Siegel geprüft“ unverletzt?:

Date when fault occurred: /

Datum der Fehlererkennung:

Yes/ja No/nein

Customers Address: / Kundenadresse: Service Company / Name of Technician who

reported the fault: /

/ Name des Technikers, der die Meldung gemacht hat:

Adresse des Rational Service Partners

Fault description: / Fehlerbeschreibung:

Fault remedy (if repaired) + service parts used/exchanged: / Fehlerbehebung (falls erfolgreich) u. dazu benötigte Service

Teile:

If you have exchanged service parts, pls return as soon as possible to:

Sollten Serviceteile ausgewechselt worden sein, bitte umgehend senden an:

Which parcel service: /

Mit Paketdienst:

RATIONAL AG

Qualitätsmanagement

TOR 110, z.Hd. Hr. Macenka

Iglinger Strasse 62

D-86899 Landsberg/Lech

Sent out (date): /

Verschickt am (Datum):

Answer from Landsberg (QM): / Kommentar von Landsberg (QM):

Reason for the fault: / Ursache des Fehlers:

Actions taken: / Maßnahme:

Other comments: / Kommentar:

Copies see mail distribution:

Answered by QM:

Parcel number / Tracking number: /

Paketnummer / Tracking Nr.:

Dead on Arrival Version 12/2008

V02 en, Basic_Maintenance_Accessories - 46 -

Page 47

- 47 - V02 en, Basic_Maintenance_Accessories

Page 48

RTS Contact Germany

Fax: +49 (0)8191-327397

e-mail: service@rational-online.com

web: https://portal.rational-online.com

Service Parts:

Fax: +49 (0)8191-327408

e-mail: rational.ersatzteile@rational-online.com

Chef Line:

Phone: +49 (0)8191-327300

© 2011 Rational Technical Services. All rights reserved.

Please note that any technical information concerning Rational products

must NOT be forwarded to any third party.

80.51.111 - V02 en - RTS/Sc 03/2012

Page 49

Training Manual

CombiMaster Plus (CM_P)

V02 en, CM_P

Page 50

General hints:

Isolate the appliance from mains supply before opening the appliance

When working with chemicals, i.e. aggressive cleaning materials

always wear protective clothing, goggles and gloves!

After maintenance / repair the appliance must be checked for electrical

safety in accordance with your national, state and local requirements!

Whenever working on any gas component like:

Gas valve, gas blower and / or changing connected type of gas a detailed

ue gas analysis MUST be done using adequate CO and CO2

measuring equipment! This shall ONLY be done by trained technicians!

Always check appliance for possible gas leakages!

© 2011 Rational Technical Services. All rights reserved.

Please note that any technical information concerning Rational products

must NOT be forwarded to any third party.

List of content

General

CM Control 4

New Features - Additional functions 5

Additional function - Program description 6

Additional function 7

Water level control steam generator CM_P 8

SC (Self Clean) Automatic CM_P 9

Basic principle CM_P electric 10

Manual operation modes

Manual Operating modes CM_P - Boiling point recognition 11

ClimaPlus: Humidity control CM_P 12

V02 en, CM_P - 2 -

Page 51

List of Content

Control

Self test 14

Fan motor CM_P / SCC_WE 16

Bus connection 17

PCB CM_P 18

SolidStateRelay (SSR) internal design / Test 19

SSR 100% - 50% power at 3NAC/400V 20

SSR 100% - 50% power at 3AC 200-240V 21

Control of cooling fan 22

PCB - Service package

Activation Service Level 24

dP -- Diagnostic 25

Er -- Error messages, Blink code fan motor 27

rt -- Running times 29

SE -- Basic settings 30

F -- Function test 32

Calibration humidity 34

Calibration: Steps 35

Software

Software update - CM 36

HACCP Protocol 37

Changing pcb / changing EEPROM / Error „E16” 38

Circuit diagram

Circuit diagram CM 101 - Power - 3NAC 400-415V 40

Circuit diagram CM 101 - Heating CM 101 - 3NAC 400V 41

Circuit diagram CM 101 - Sensor - 3NAC 400V 42

Bill of material 43

Circuit diagram CM 202 - Power - 3NAC 400-415V 45

Circuit diagram CM 202 - Heating CM 101 - 3NAC 400V 46

Circuit diagram CM 202 - Sensor - 3NAC 400V 47

Bill of material 48

- 3 - V02 en, CM_P

Page 52

CM Control

Steam (30° - 130°C)

Hot Air (30°C - 300°C)

Combination (30°C - 300°C)

Finishing (30°C - 300°C)

Cool Down

Programming (50 Prog. with 6 steps each)

Humidity reducing

Humidity increasing

Humidity indication

Temperature display

Actual temperature

Temperature setting

Fan speed setting

Time selection

Core probe selection

Time - Core probe display

Preheating

Time - Core probe setting

V02 en, CM_P - 4 -

Continuous run

Page 53

New Features - Additional functions

Differences from Combi Master Plus (Index H) compared with Combi Master Index G

• Unit self test after installation (all components are tested for function and boiling point is determined)

• Steam preset to boiling point temperature, adjustable 30-130°C (86 - 266°F)

• Unit is programmable with 50 programs with 6 steps each

• Humidity control in steps 0% - 20% - 40% - 60% - 80% - 100%

• Self written cooking programs can be downloaded and uploaded from USB stick

• Service data can be downloaded to USB stick

• New fan motor turns left - right

• New PCB (optional ethernet add-on card availble)

• Cooling fan is temperature controlled

Additional functions:

1. Select Prog / Start

2. Select additional program with temperature dial

Pin - upload program from stick

Pout - download program to stick

Hout - download HACCP to stick

Sout - download Service Data to stick

ESG - Empty steam generator

CALC - Descale steam generator

°C°F - set temperature from °C - °F

rtc - Setting of date and time (real time clock)

Ethernet connection

CLE - Cleaning program

3. Start selected Programm by pressing buttom

- 5 - V02 en, CM_P

Page 54

Additional function - Program description

CLE - Cleaning Program

Reinigung - Cleaning Puhdistus - Rengjøring - Rengøring - cisteni - cistenie - ciscenje - Tisztitas - Zyszczeni

1.

T

2.

3.

Nettoyage - Limpieza - Pulitura - Reiniging - Limpeza - Tvätt

-

60°C (140°F)

-

4.

T

T

5.

6.

40 min

10 sec

-

7.

1X

9.

10.

8.

10 min

10.00.381

Cool down unit below 60°C (140°F)

Spray cabinet and area behind air bafe with Rational Cleaner

(6006.0101), Protective clothing must be used.

Close cabinet door;

After 40 minutes (reaction time for cleaner) the buzzer will sound;

Rinse cabinet with fresh water;

Close cabinet door;

After another 10 minutes (Hot Air phase) the unit is ready for use.

NOTE: The cabinet is 130°C (266°F) hot!

ESG - Empty Steam Generator manually

Close water tap

Press Start - SC pump runs for 45 seconds

CALC - Descaling steam generator

Caution:

Descaler shall ONLY be lled through the steam inlet port inside the interior cabinet!

Protective clothing must be worn.

1. Interior cabinet temperature must be below 40°C (104°F);

2. Steam generator will be emptied, relled and emptied again;

3. „CALC“ „FILL“: prompt to ll descaler into the steam generator;

4. 30 second waiting time (to rinse cabinet with water);

5. “door”: prompt to close cabinet door;

6. 45 minutes reaction time for the chemical,

7. “CALC”: Steam generator will be rinsed twice and relled again;

8. Steam mode for 15 minutes;

9. “END” and buzzer for 20 seconds

°C°F - Setting °C >=< °F

Press Start - display changes from °C to °F or vice versa

rtc - (real time clock) Setting of date and time for HACCP protocol

V02 en, CM_P - 6 -

Page 55

Additional function

PIn - Load programs from USB Stick onto unit (Program In)

Pout - Load programs from unit onto USB Stick (Program out)

Programs can not be interchanged from SCC or SCC_WE to CM_P and vice versa.

Now set mode switch to Prog/Start and select desired additional program with temperature dial.

- Import (Pin):

Should no „progs.xml“ le exist on the USB stick, Pin is blinking (Import not possible, Start

key without function).

Should a „progs.xml“ le exist on the USB stick, Pin is showing steady. Import of programs

is started by pressing Start/Prog key. During the import time the Prog/Start-LED is blinking.

- Export (Pout):

In case a „progs.xml“ le already exists on the USB stick, Pout is blinking;

Note: Pressing Start key now would overwrite the existing program le!

If Pout is showing steady the programs can be downloaded by pressing Start key. During

the download process the Prog/Start-LED is blinking.

Sout - Copy Service Data to stick

Hout - Copy HACCP Data to stick

As soon as the Start key is pressed, download starts and a LED is circling in the display.

rtc - Conrm the individual settings of hour, minute etc by pressing the START key.

Ethernet connection

Setting IP address:

Select IP 1 for rst block. Set block number with timer pot. Press Prog/Start to conrm. Display

will switch automatically to IP2 etc

Setting Gateway Address:

After entering IP 4 the display will switch over to GAt 1 automatically. Set block number with timer

pot. Press Prog/Start to conrm. Display will switch automatically to GAt 2 etc.

Setting Subnet address:

After entering GAt 4 the display will switch over to Sub 1 automatically. Set block number with

timer pot. Press Prog/Start to conrm. Display will switch automatically to Sub 2 etc.

- 7 - V02 en, CM_P

Page 56

Water level control steam generator CM_P

V

Center level electrode S2 => Ground: 2 - 6V AC:

S2

B5

F3

water level too low

steam heating must switch OFF

solenoid valve lling Y1 ON

M4

Y1

Center level electrode S2 => Ground: 0V AC:

water level reached

steam heating can switch ON

PCB

S2

AC

solenoid valve lling Y1 switched OFF

Level electrode measurement: X12, 1-4

The level electrode is equipped with two side elec-

trodes to ensure safe water level recognition even

when the center level electrode is scaled. These

side electrodes compensate for the build up of

scale.

Permanent water level control;

Maximum continuous steam time: 2 Minutes,

Property of connected water:

Conductivity must be above 50µS/cm;

St.Gen. empty: ca. 2 - 6V AC

St.Gen. full: 0V

SV Filling on 230V

SV Filling off 0V

Heating on 230V

Heating off 0V

Filling SG Max. heating 2 Min. Control Steam heating

V02 en, CM_P - 8 -

Page 57

SC (Self Clean) Automatic CM_P

During the production of steam, the concentration of minerals inside the steam generator will

increase over time. These minerals settle on the heating elements and heat exchanger as

well as the interior steam generator walls.

In order to reduce this effect the steam generator will be pumped off and ushed regularly depending

on the duration of steam production. This process needs approximately 45 seconds.

After emptying the steam generator it will be lled automatically with fresh water.

There are 4 conditions to start this SC Automatic:

1. Heating time of the steam generator must exceed 60 min.* and

2. the temperature of the thermocouple steam generator must be below 65°C (149°F) and

3. the temperature of the thermocouple interior cabinet must be below 70°C (158°F) and

4. the unit is switched ON.

In case the unit is used permanently the above mentioned temperature conditions

can not be met.

In this case the „forced SC Automatic“ applies as follows:

1. The heating time of the steam generator reaches twice the set duration*, e.g. 120 min. and

2. the unit door is open for longer than 30 seconds

* The marked values can be changed in unit specic ranges using the diagnostic program.

After completion of the SC-Automatic the accumulated steam heating time is re-set to zero.

SC-Automatic does not replace the need for descaling and/or installing water treatment lter

- 9 - V02 en, CM_P

Page 58

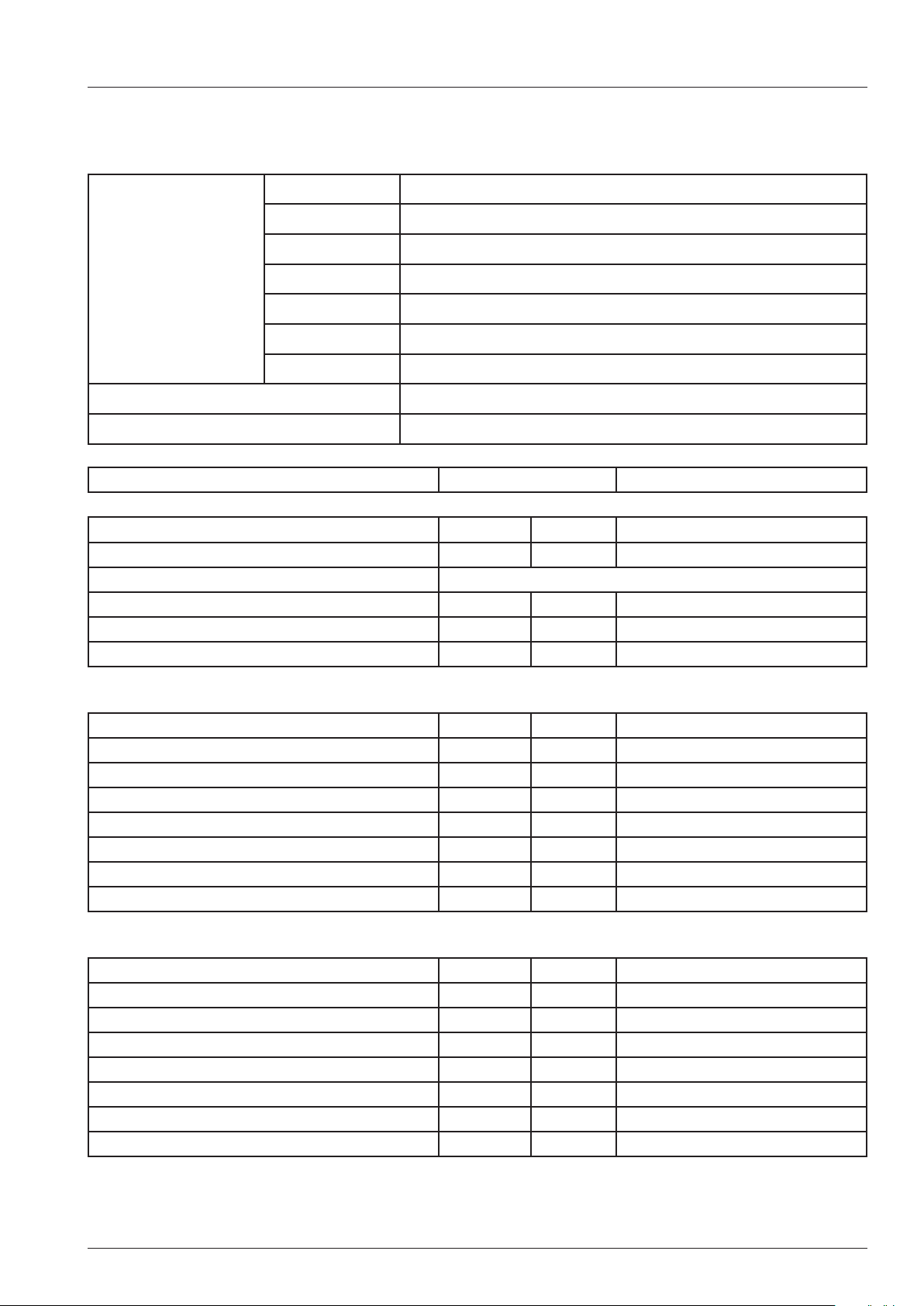

Basic principle CM_P electric

B1

B3

F4

P1

M4

Y1

Y2

B2

M1

S2

B4

B5

F3

S3

Y5

B1 Thermocouple cabinet

B2 Thermocouple quenching

B3 Thermocouple core temperature

B4 Thermocouple humidity

B5 Thermocouple steam generator (preheating, 180°C (356°F) max)

F3 Safety temperature limiter steam generator 160°C / 320°F

F4 Safety temperature limiter cabinet 360°C / 680°F

Y1 Solenoid valve lling

Y2 Solenoid valve quenching

Y5 Solenoid valve humidity

M1 Fan motor (without jumper)

M4 Pump SC-Automatic

P1 Differential pressure sensor

S2 Level electrode

S3 Door contact switch

CM_P 201/202 only:

M2 Fan motor bottom (with jumper)

V02 en, CM_P - 10 -

Page 59

Manual Operating modes CM_P - Boiling point recognition

Steam mode in relation to boiling point recognition

During self test (after initial installation) the unit will determine the installation altitude by water boiling

point recognition.

As the boiling temperature declines with increasing altitude above sea level, the water boiling point

determines the installation altitude.

During self test the steam production will be active until the quenching sensor B2 reaches 70°C

(158°F). At this time the pcb will memorise the temperature measured by the interior cabinet sensor B1

as the boiling point temperature at the actual point of installation.

To run a manual cooking mode the following steps must be valid:

1. Cooking mode is selected.

2. Time or core temperature is selected.

3. Cabinet door is closed (door contact).

4. Fan motor is running (speed signal via bus).

5. In wet modes (Steam, Combination, Finishing) the steam generator must be lled with water (level

electrode)

6. In wet modes (Steam, Combination, Finishing) the steam generator will be preheated

(thermocouple steam generator)

Mode

Temperature

range

below

boiling point

at

boiling point

e.g. 97°C (206°F)

above

boiling point up to

130°C (266°F)

30° (87°) up to

boiling point

above boil-

ing point up to

300°(572°)

30 - 300°C

(86 - 572°F

30- 300°C

Responsible sensor

Cabinet sensor B1 controls steam heating

- Humidity setting not possible

Cabinet sensor B1 controls steam heating

- Humidity setting not possible