Page 1

Training Manual

SCC Line

SelfCooking Center - Combi Master

Edition 09-2007

Page 2

Training Manual

SCC Line

Edition 09 - 2007

General hints:

Isolate the appliance from mains supply before opening the appliance

When working with chemicals, i.e. aggressive cleaning materials

always wear protective clothing, goggles and gloves!

After maintenance / repair the appliance must be checked for electric

safety in accordance with your national, state and local requirements!

Whenever working on any gas component like:

Gas valve, gas blower and / or changing connected type of gas a detailed

ue gas analysis MUST be done using adequate CO and CO2

measuring equipment! This shall ONLY be done by trained technicians!

Always check appliance for possible gas leakages!

Part1: CM Technology

CM Technique from 04 - 2004 4

Water level control Steam Generator 6

RATIONAL SC Automatic 7

Steam Control CM 8

Additionaly functions CM from 04 - 2004 10

CM PCB (42.00.004) 12

Motor for CM 40.00.274 13

CM - Sequence of events 14

Service level CM from 04 - 2004 19

Service level: dP -- Diagnostic Program 20

Service Level: ER -- Error code history 21

Failure Codes CM „ER“ 22

Service Level: rt -- Running Time 23

Service level: SE -- Basic settings 24

Service level: SE -- Function test 26

CM Gas from 04 - 2004 28

Identification of the different gas burners / Gas blowers: 29

Sequence of events of Burner and Ignition control 30

Changing installation altitude: CM gas 32

Checking of dyn. input gas flow pressure 33

Flue gas analysis 34

Changing Gas blower speed 37

Burner adjustment 38

Page 3

Part2: SCC Technology

SCC Control Panel 39

Display up to Software version SCC 01-07-12 40

Display since Software version SCC 02-01-01 42

Display Programming / CleanJet SCC 02-01-01 44

SCC Electric from 04-2004 46

SCC Operator pcb (42.00.002) 48

I/O PCB SCC (40.00.049) 49

Motor for CM 40.00.274 50

Humidity control SCC 51

Service level SCC 60

SCC Diagnostic Mode 61

SCC Running Times 65

Basic Settings 69

RESET 73

Function test 74

Download of unit service data 78

HACCP 82

Service messages 84

Calibration SCC 88

Control Drain Valve 54.00.357 90

SCC Gas

SCC Gas from 04-2004 92

Identification of the different gas burners / Gas blowers: 94

Sequence of events of Burner and ignition control 95

Gas conversion : SCC Gas 96

Adjustment of installation altitude above sea level 97

Flue gas analysis: SCC gas 98

Burner adjustment 100

Changing gas blower speed SCC Gas 101

Part3: Common information

Flash SCC Software 102

Software update CM units 104

User instruction electrical descaler pump 108

RATIONAL Commissioning SCC-CM 110

Preventative maintenance SCC / CM 114

Water info 118

Part4: Fault list SCC - CM 120

Part5: Circuit diagram (Training version 3NAC 400V 138

SCC Service reference 192

Page 4

S

C

M

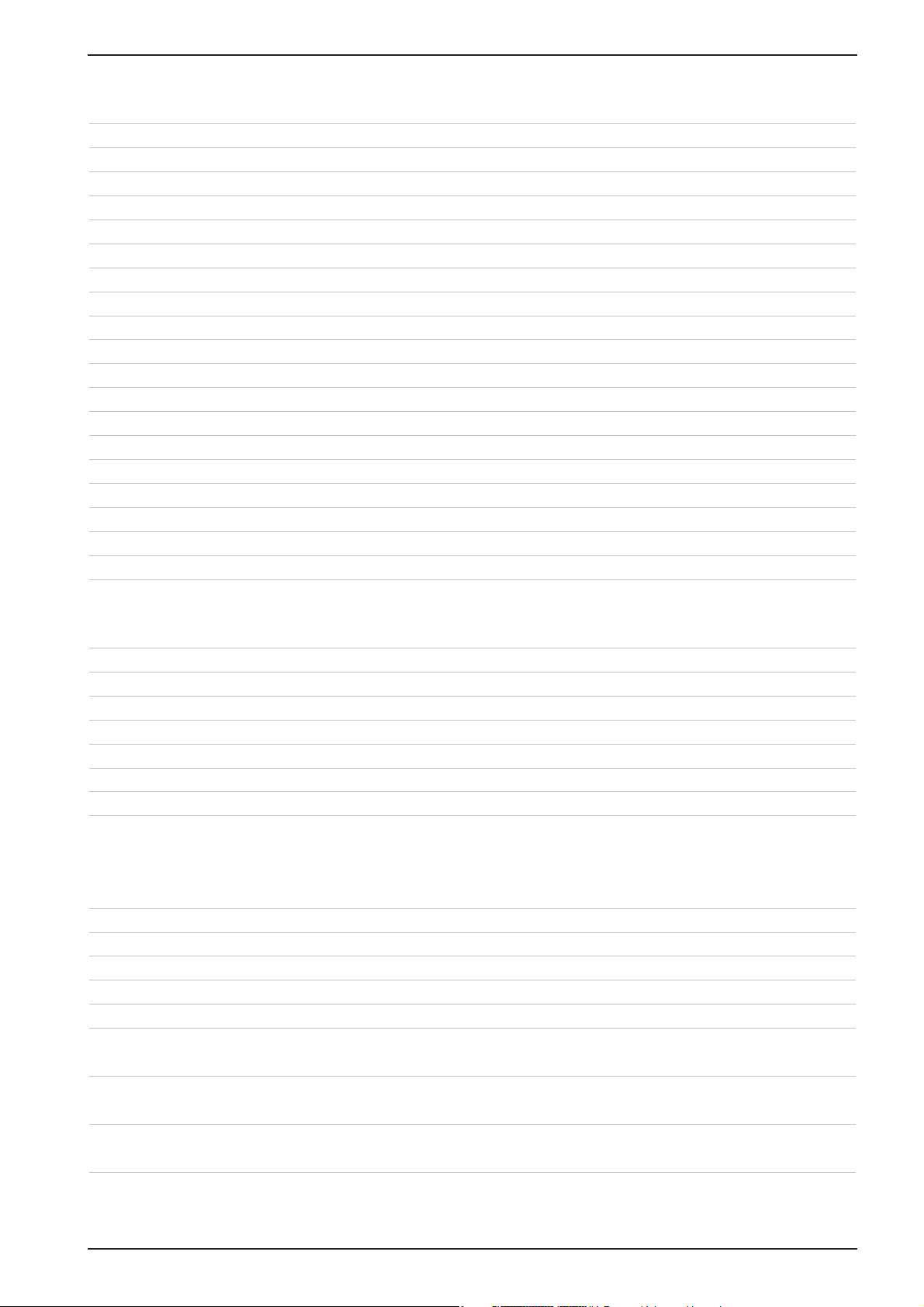

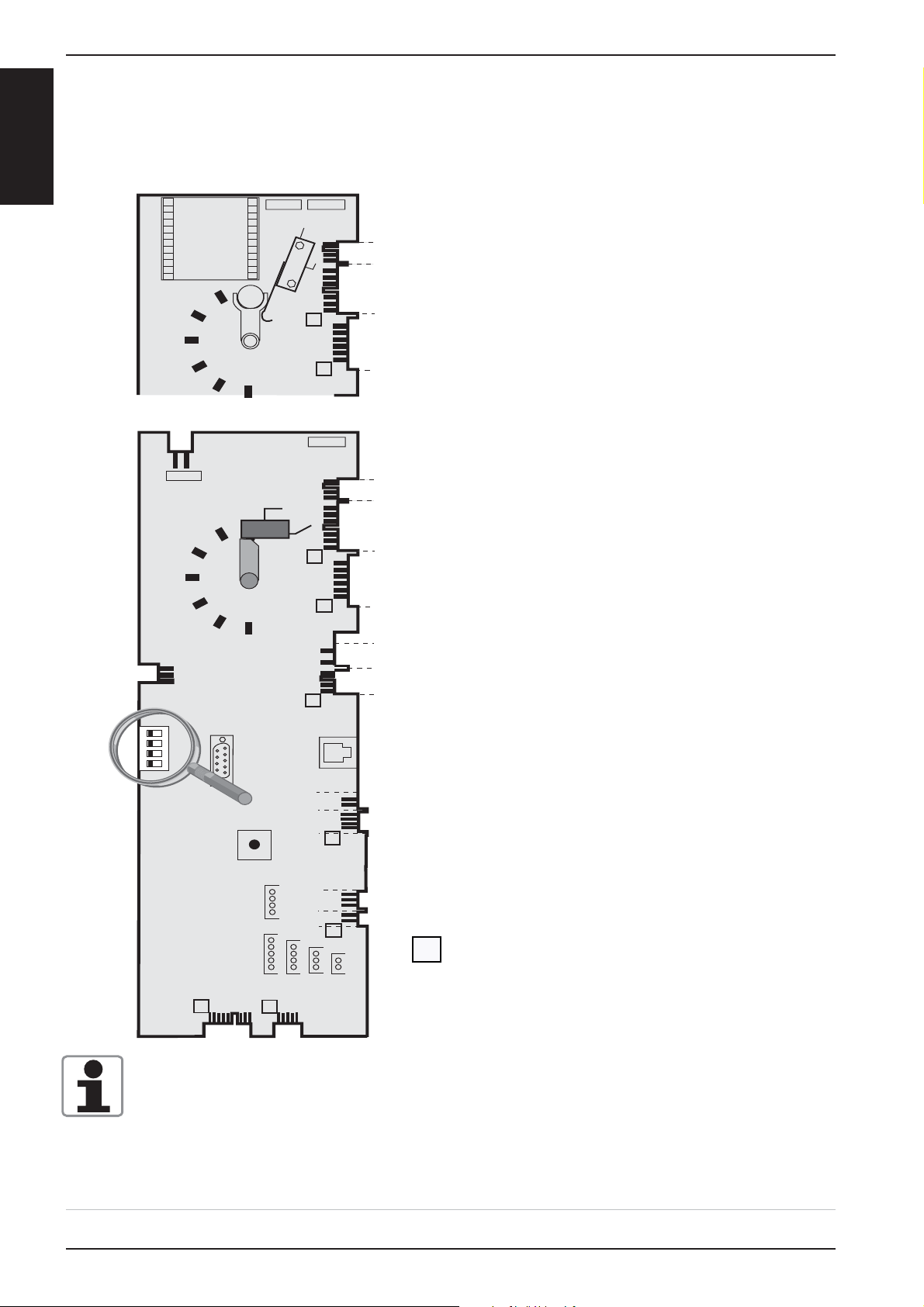

CM Technique from 04 - 2004

Steam

Hot Air

Combi Steam

Low Temperature Steam

Finishing

Cool Down

Cabinet temperature display

Cabinet temperature setting

Timer

Core temperature

Time - Core temperature display

Time - Core temperature setting

-4-

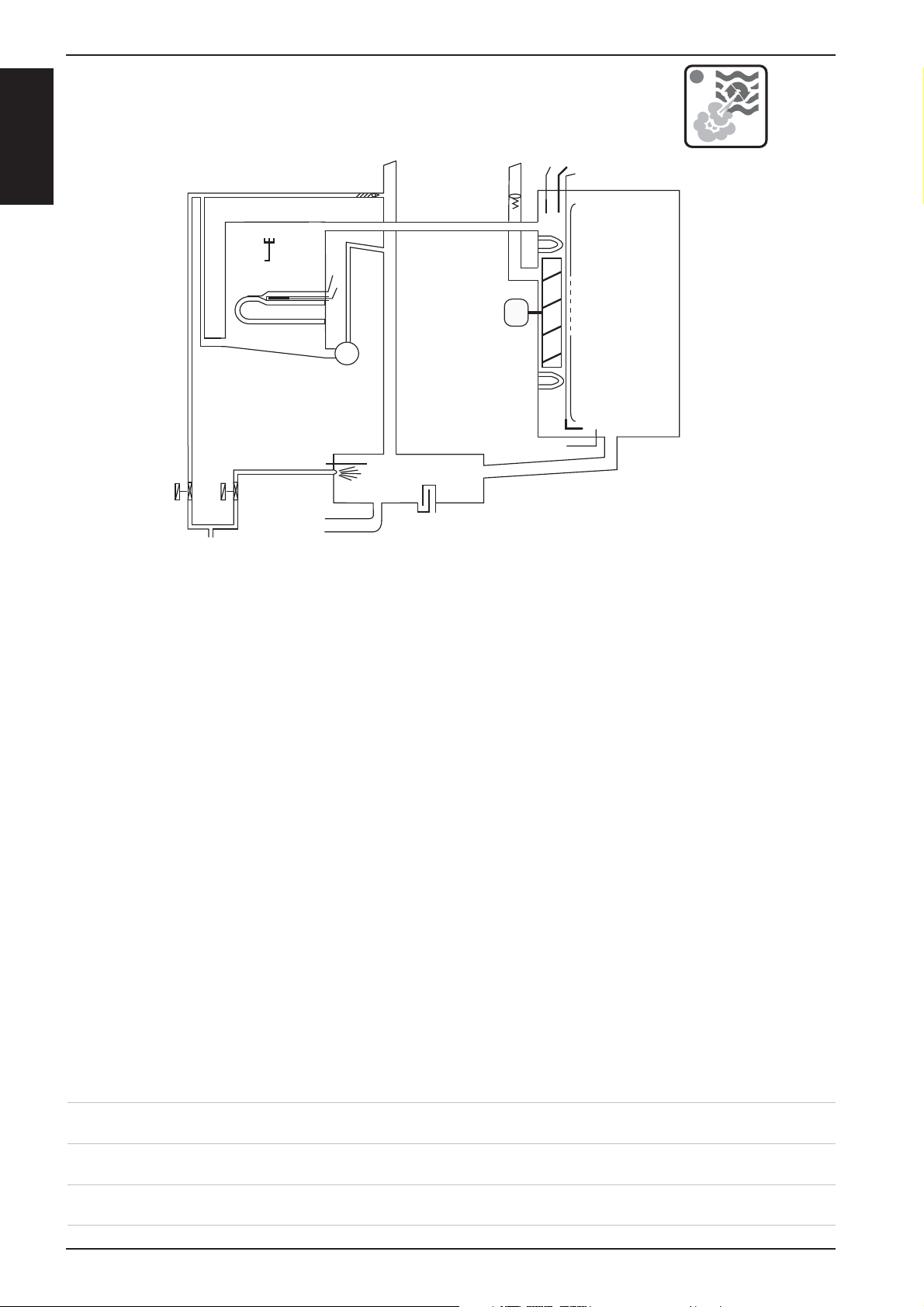

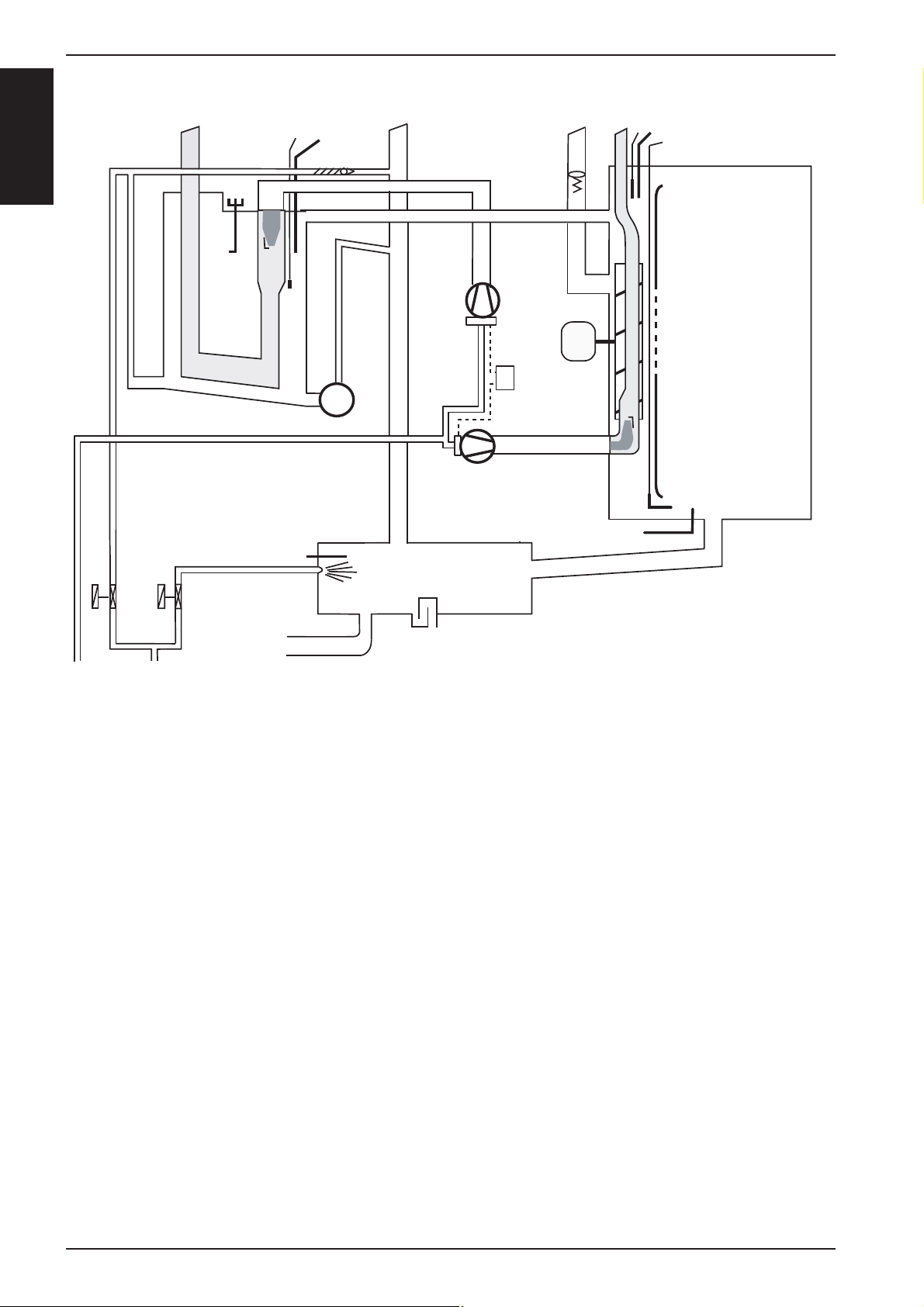

Page 5

S

S2

CM Technique from 04 - 2004

B5

F3

M1

M4

B1

F4

C

M

B3

S3

B2

Y1

Y2

B1 Thermocouple cabinet

B2 Thermocouple quenching / Steam control

B3 Thermocouple core temperature

B5 Thermocouple steam generator (preheating, 180°C (356°F) max)

F3 Safety temperature limiter steam generator 160°C

F4 Safety temperature limiter cabinet 360°C

Y1 Solenoid valve lling

Y2 Solenoid valve quenching

M1 Fan motor (without jumper)

M4 Pump SC-Automatic

S2 Level electrode

CM 201/202 only:

M2 Fan motor top (with jumper)

-5-

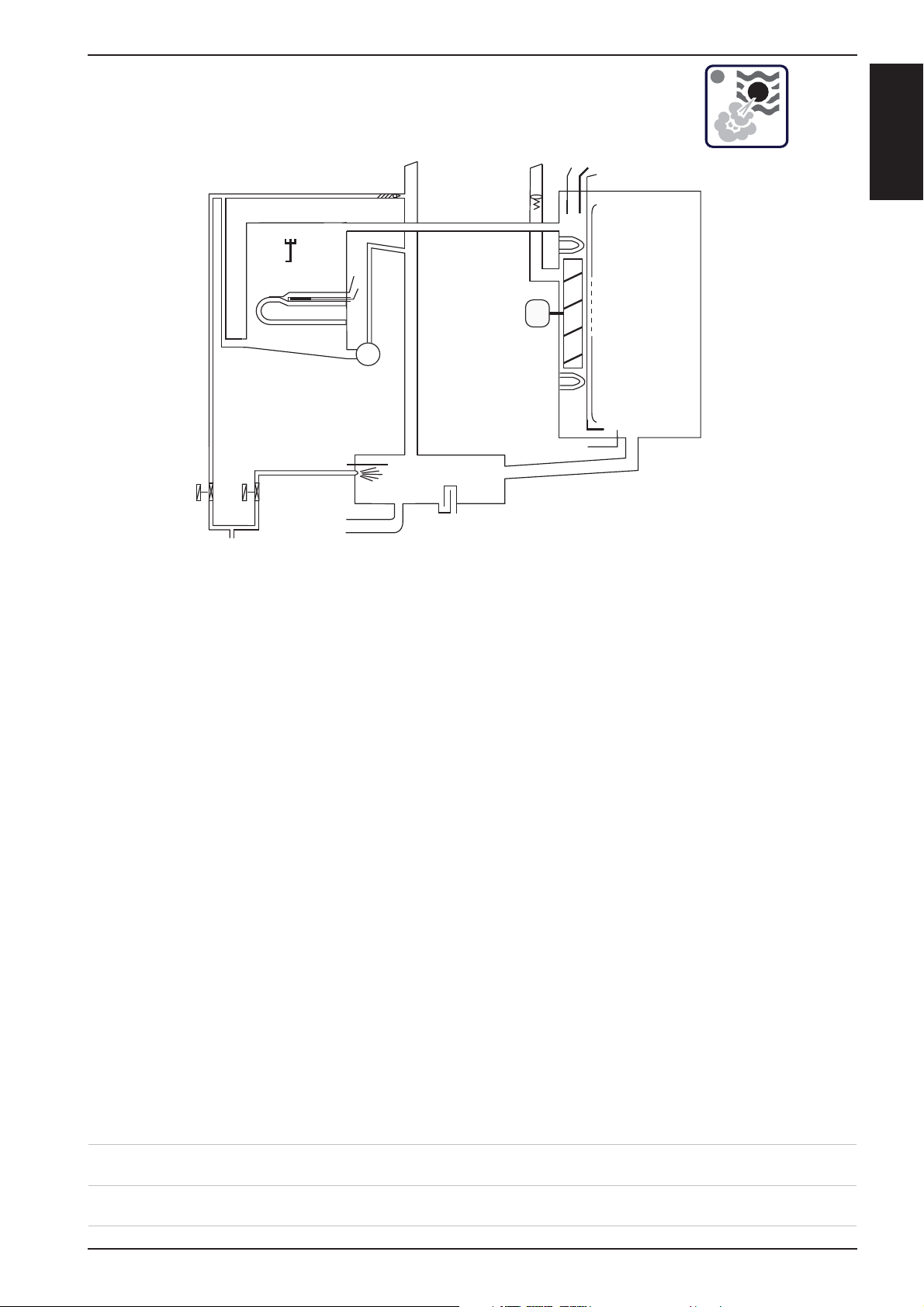

Page 6

S

C

M

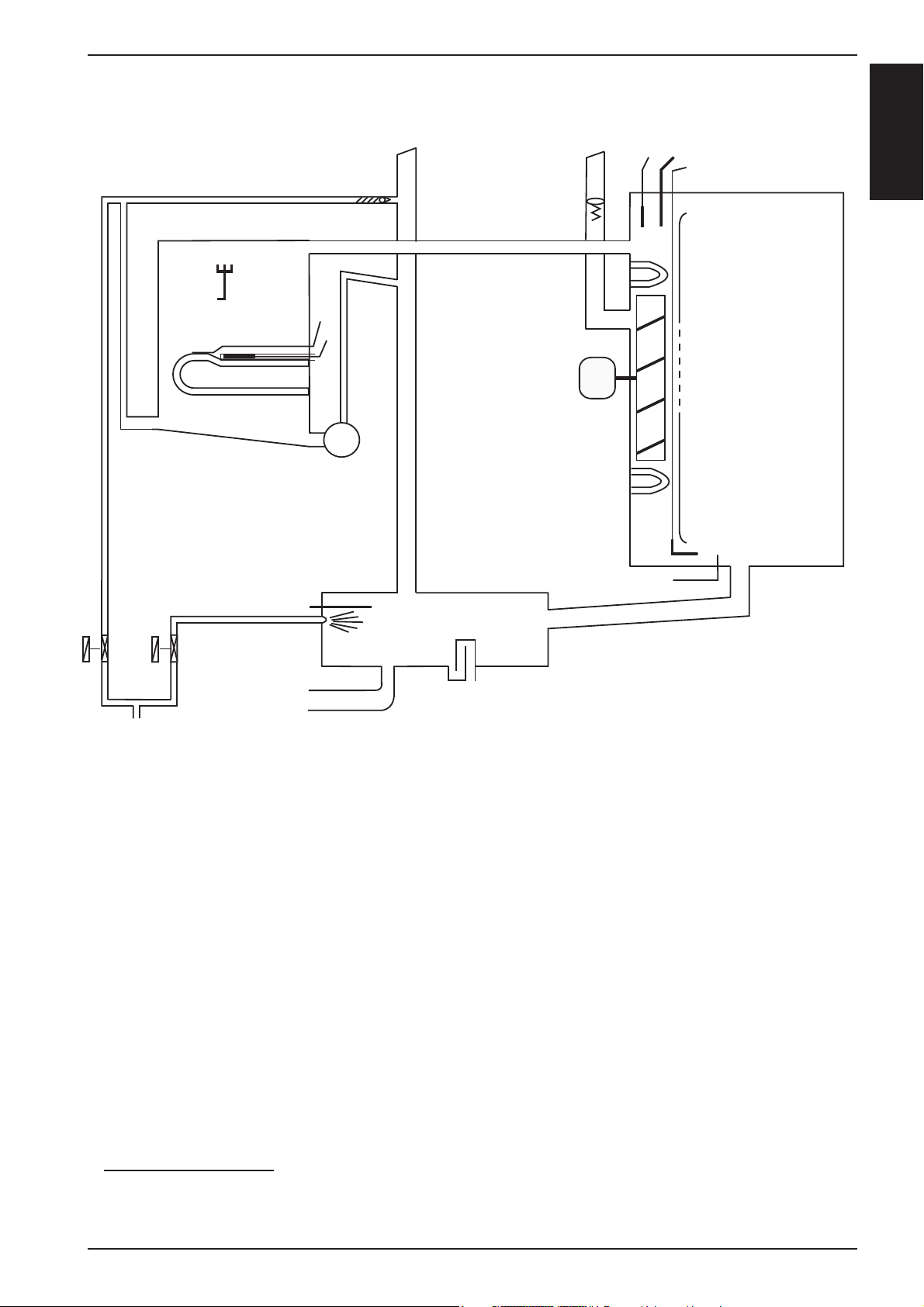

Water level control Steam Generator

S2

B5

F3

S2

M4

B2

Y1

Center S2 ==> Ground: 2 - 6V AC: water level too low

steam heating must switch OFF

solenoid valve lling Y1 ON

Y2

V

AC

Center S2 ==> Ground: 0V AC: water level reached

steam heating can switch ON

solenoid valve lling Y1 switched OFF

Every 2 minutes steam elements will switch off for water level control

Notes:

X12

-6-

Page 7

S

RATIONAL SC Automatic

During the production of steam, the concentration of minerals inside the steam generator

will increase over time. These minerals settle on the heating elements and heat exchanger

as well as the interior steam generator walls.

In order to reduce this effect the steam generator will be pumped off and ushed regularly

depending on the duration of steam production. This process needs approximately 45 seconds.

After emptying the steam generator it will be lled automatically with fresh water.

There are 4 conditions to start this SC Automatic:

1. Heating time of the steam generator must exceed 60 min. (CM - 45 min.)*

and

2. the temperature of the thermocouple inside steam generator (B5) must be below 65°C (149°F)

and

3. the temperature of the thermocouple inside interior cabinet (B1) must be below 70°C (158°F)

and

C

M

4. the unit is switched ON.

* - can be adjusted from 20-120min

In case the unit is used permanently the above mentioned temperature conditions

can not be met.

In this case the following 2 conditions apply:

1. The heating time of the steam generator reaches the twice the set duration*,

i.e. 120 min. (CM - 90 min.) and

2. the unit door is open for longer than 30 seconds

After completion of the SC-Automatic the timer accumulating the steam heating time is re-set to zero.

-7-

Page 8

S

Y1

Y2

B2

B1

C

M

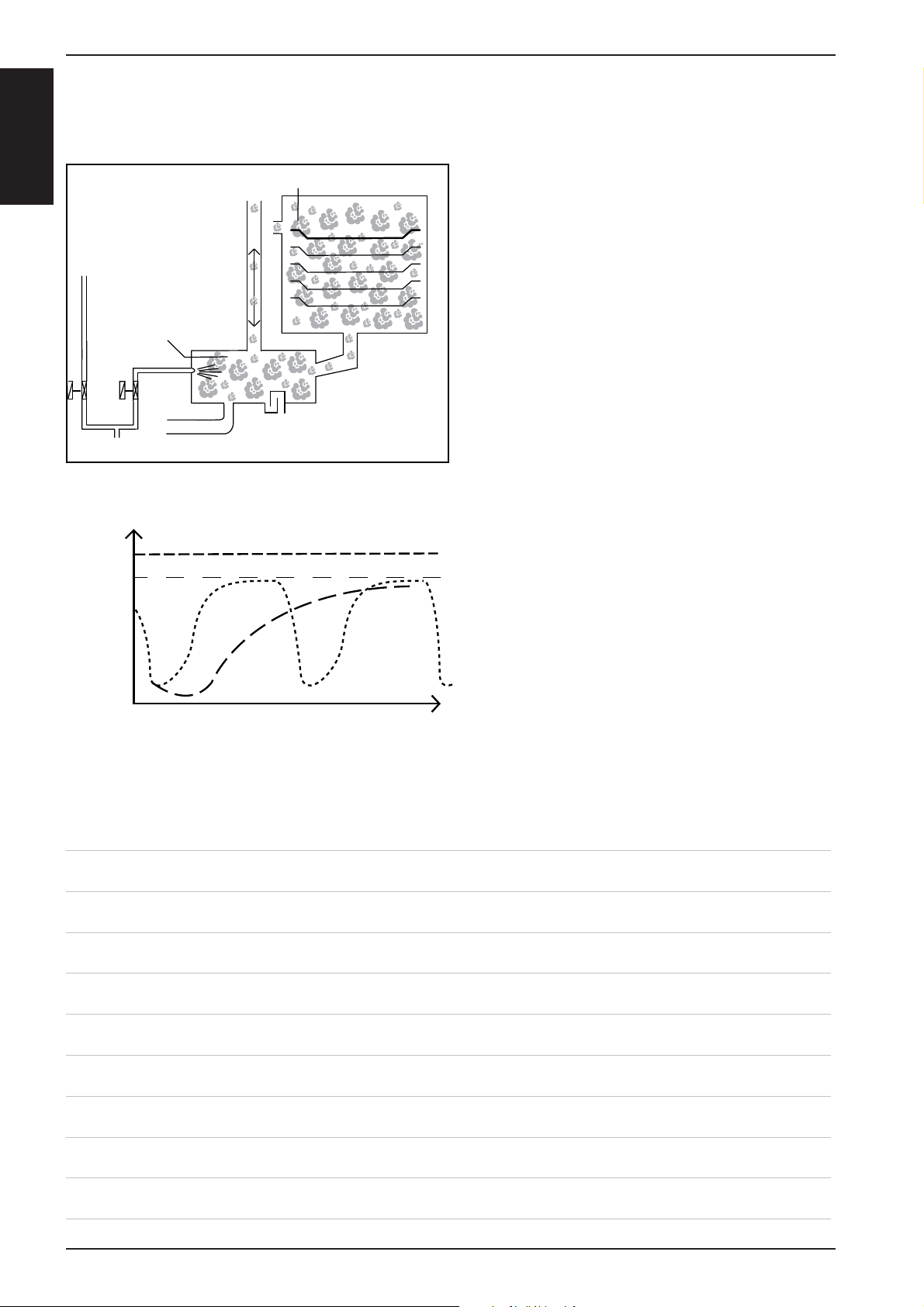

Steam Control CM

Intelligent steam control via quenching sensor

1. Filling of interior cabinet based on time and

temperature control of B2 quenching sensor

2. After steam saturation inside cabinet steam

will also ll quenching chamber

°C / °F

70°C

(158°F)

Notes:

B1 - 100°C(212°F)

B2 - 1

B2 - 2

t (sec)

3. Depending on the frequency of temperature

raise of the quenching sensor B2 the

duration of the next steam supply is

calculated.

B2-1: B2 temperature with partial load

B2-2: B2 temperature with full load

4. The amount of steam inside the cabinet is

directly depending on the temperature

variation of quenching sensor B2.

-8-

Page 9

S

Notes:

C

M

-9-

Page 10

S

Additionaly functions CM from 04 - 2004

C

M

Below are listed the additionaly functions for the user / operator:

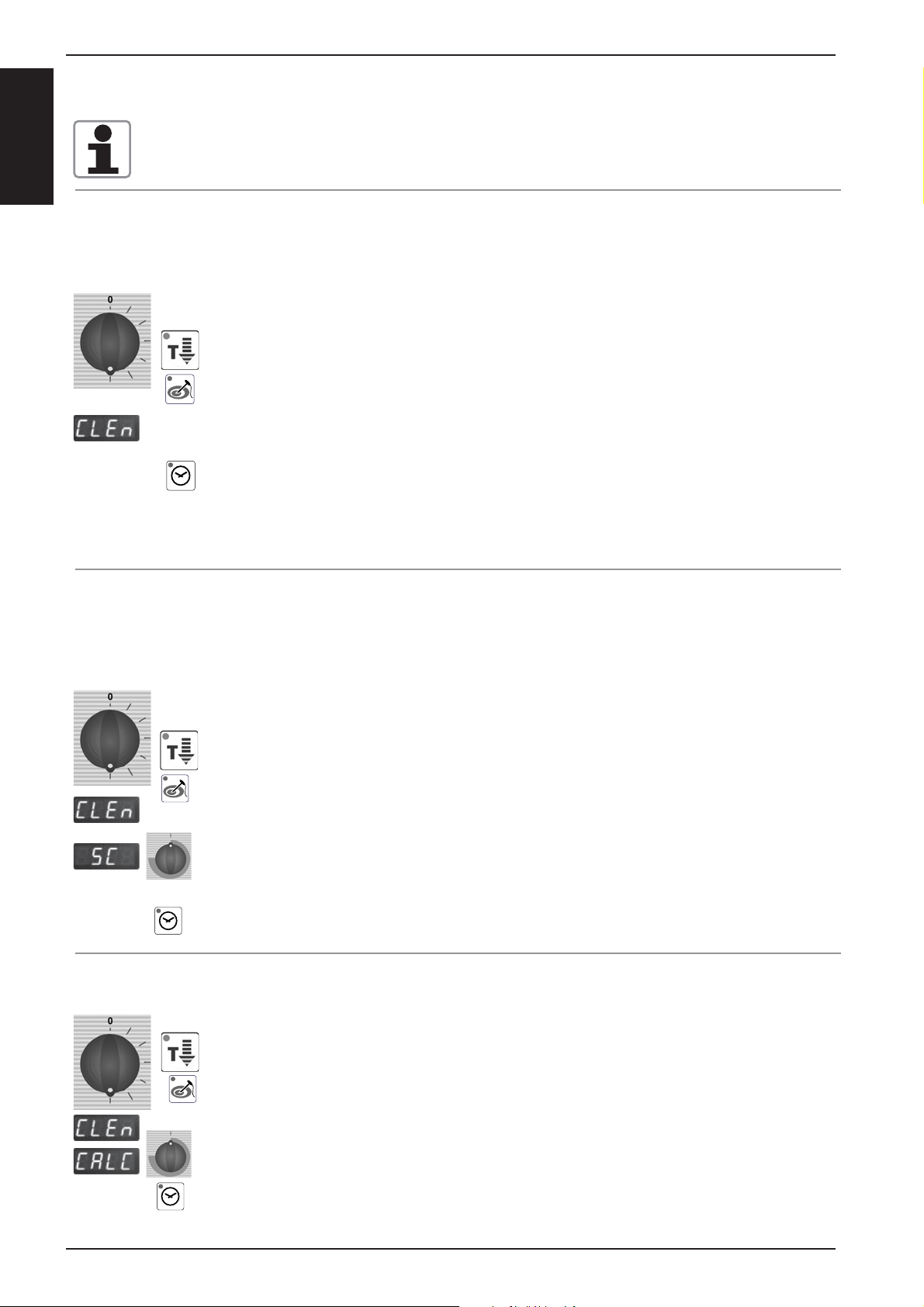

1. Cleaning program

1) Cool down cabinet below 60°C

2) Spray inside cabinet with Rational cleaner

3) Close cabinet door

4) Select „Cool Down

5) Press core temperature key for 10 sec.

6) „CLEn“ will show in cabinet temperature display

7) Press timer key 1x; Cleaning program starts automatically (open cabinet door

and rinse interior cabinet after 40 min.) Close door again. Since Software version C1-06-05 a 10 min step hot air will follow to dry the interior cabinet.)

8) After end of program, leave cabinet door open over night.

2. Empty steam generator

This should be done after each installation to verify free drain connection and prior to disconnection

the unit for storage.

1) Open cabinet door

2) Select „Cool Down“

3) Press core temperature key for 10 sec.

4) „CLEn“ will be shown in cabinet temperature display

5) Select „SC“ with temperature dial

6) Close water tap

7) Press timer key 1x and remain on „Cool Down“ position for about 45 sec.

3. Descaling program

1) Open cabinet door

2) Select „Cool Down“

3) Press core temperature key for 10 sec.

4) „CLEn“ will be shown in cabinet temperature display

5) Select „CALC“ with temperature dial

6) Press timer key 1x and follow procedure of the decalci cation instruction. (See

user manual CM).

-10-

Page 11

Notes:

Additionaly functions CM from 04 - 2004

S

C

M

4. Changing temperature display from °C to °F

1) Select any mode

2) Press timer and core temperature key simultaneously for 10 sec. until Display

changes from °C to °F or vice versa

3) Release both keys

-11-

Page 12

S

F6.1

2 AT

X16

F6

C

CM PCB (42.00.004)

M

CM PCB (42.00.047) from 02-2006 (without transformer)

42.00.004

X2 B3 Core temperature

X3 B1 Interior cabinet

X4 B2 Quenching / Steam control

X6 B5 Steam generator

X7 ON - OFF switch

X8 Buzzer

X12 Level electrode

X 16 power supply from transformer (42.00.047)

X18 SC - pump

X19 Solenoid valves

X20 Energy optimising / Sicotronic

X23 Vent hood (signal door open / closed)

Transformer

42.00.047

X16

2 AT

F6.1

0,1 AT

F1 F2

1

1

2 AT

1

2 AT

F6

1

X7

X19

X20

X7

X19

X20

X24 SSR

X26 SSR pulsing (USA version only)

X27 Door contact switch

X30 Serial interface (RS232)

X31 BUS interface

X32 Timer / Core Temp. Potentiometer

X50 external EEPROM

X63 Not used

Counting sequence

1

X63

1

2

on

off

3

4

Temperature

potentiometer

1

X30

RS 232

X50

X2

1

X18

X23

1

X31

RS 485

X8

X12

1

X26

X27

1

X3X4X6

X32X24

Since February 2006 PCB 42.00.004 is replaced by 42.00.047.

(Conversion kit: 87.00.139, pls. see Technical info 04-06)

The transformer on the new PCB 42.00.047 is no more existing and replaced by external transformer

40.00.227

-12-

Page 13

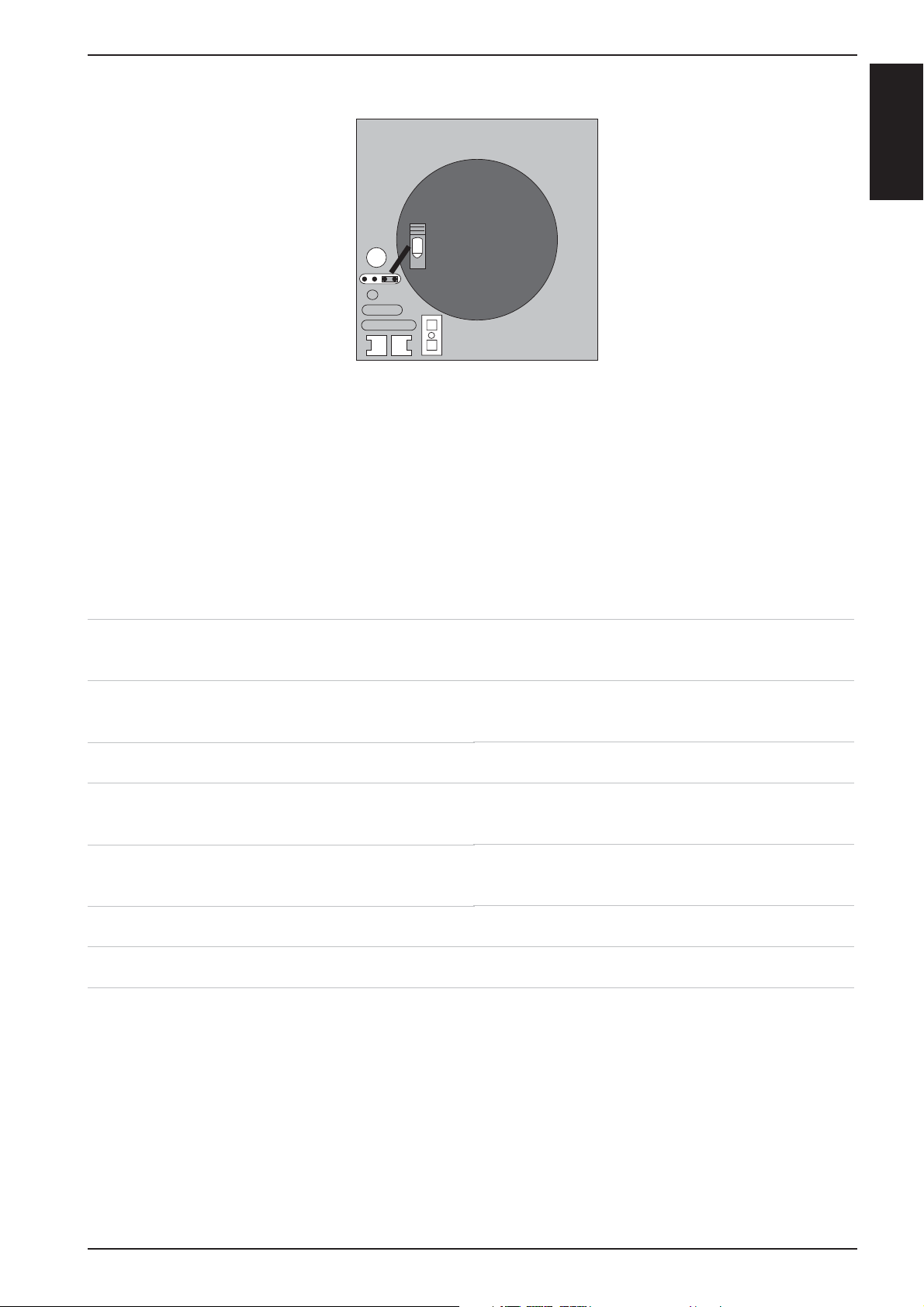

Motor for CM 40.00.274

S

C

M

LED

Jumper

Jumper 40.01.581 is used on oor model 201 and 202 for top position motor only!

Jumper is not used on models 61 - 102 with one motor only! (Service 34 will be shown!)

LED code fan motor SCC and CM from 04/2004

Reason

1x Motor doesn’t start, no changing

signal from hallsensor

2x Voltage too low on motor pcb

Check for motor blockage or change motor.

Check supply voltage or

change motor.

3x Voltage too high on motor pcb

4x rpm measurement defective

5x Motor pcb temperature >105°C

6x Supply voltage <80V

7x Motor pcb defective

8x Motor pcb defective

Remedy

Check supply voltage or

change motor.

Change motor.

Check cooling system (cooling fan, air intake

filter), otherwise change motor

Check power supply

(F1-F2)

Change motor.

Change motor.

-13-

Page 14

S

CM - Sequence of events

C

M

Mode: Steam 100°C (212°F)

Temp. preset, not adjustable

S2

Y2

Y1

B1

F4

B3

B5

F3

M1

M4

S3

B2

Function Step Responsible sensor

1. Select Steam mode

2. Select time or core temperature

3. Close cabinet door Reed switch S3

4. Check water level inside steam generator Level electrode S2 inside Steam Generatorr

5. Preheat steam generator, Thermocouple B5 inside Steam Generator

if B5 is below 85°C (185°F);

6. Timer starts after successful preheating Logic on PCB

(blinking dot in Display)

7. Steam supply up to steam saturation Quenching sensor B2

inside cabinet (Steam control)

8. Hot Air supply (only 50%) when set Cabinet sensor B1

temperature (100°C/212°F) can not be

reached in time by Steam alone

9. Quenching (set to 70°C/158°F) Quenching sensor B2

-14-

Page 15

CM - Sequence of events

S

Mode: Low temperature steam

Temp. range 30-99°C (86-210°F)

S2

Y2

Y1

C

M

B1

F4

B3

B5

F3

M1

M4

S3

B2

Function Step Responsible sensor

1. Select Low temperature steam mode

Set temperature 30-99°C (86-210°F)

2. Select time or core temperature

3. Close cabinet door Reed switch S3

4. Check water level inside steam generator Level electrode S2 inside Steam Generatorr

5. Preheat steam generator, Thermocouple B5 inside Steam Generator

if B5 is below 85°C (185°F);

6. Timer starts after successful preheating Logic on PCB

(blinking dot in Display)

7. Steam supply until set temperature Cabinet sensor B1

inside cabinet is reached

8. Hot Air supply (only 50%) when set Cabinet sensor B1

temperature can not be reached in time

by Steam alone

9. Quenching (set to 70°C/158°F) Quenching sensor B2

Note: Reduction of fan motor speed

In case the actual temperature is higher than the set temperature for longer than 2 minutes,

the fan speed will be reduced automatically.

-15-

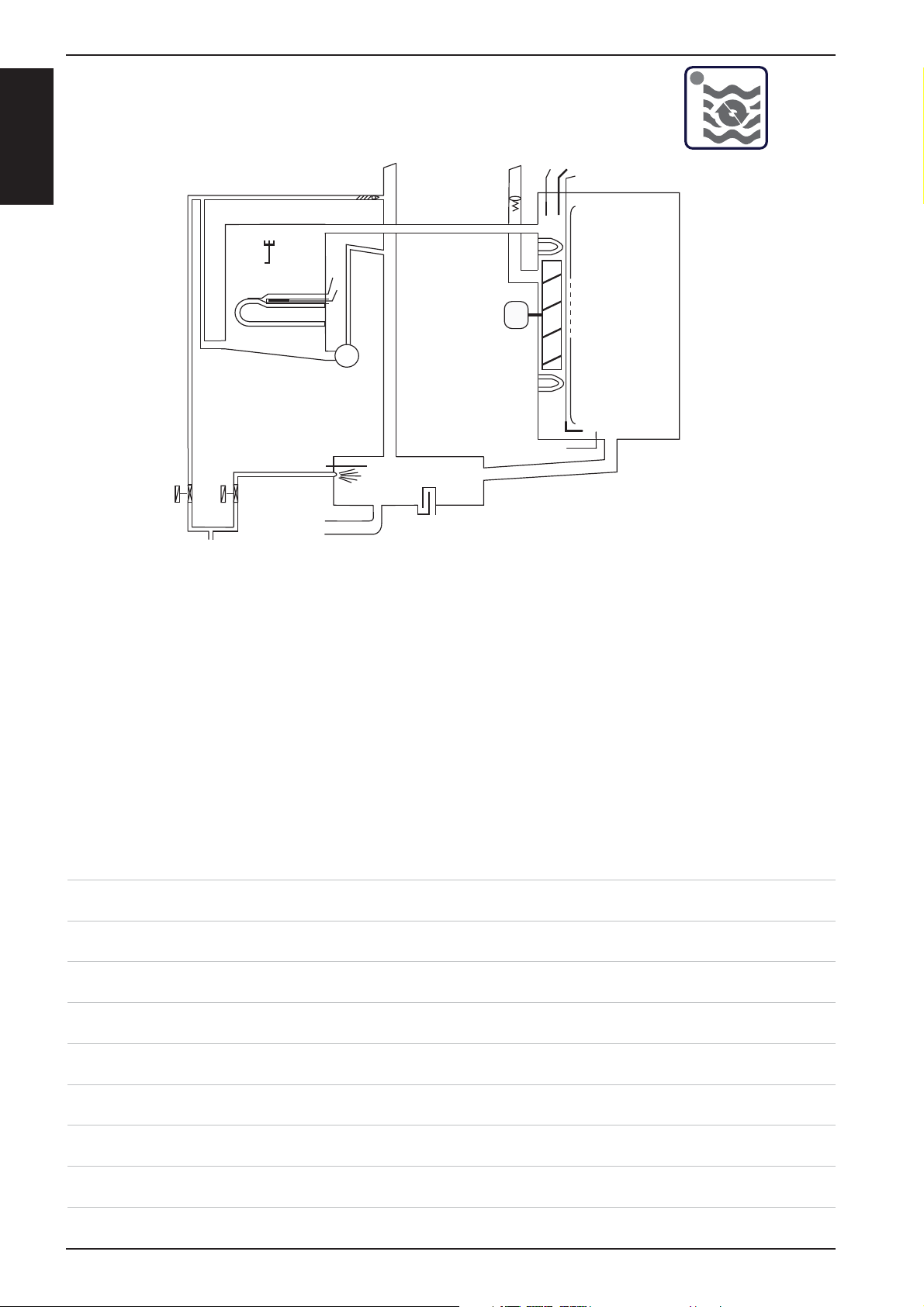

Page 16

S

C

Mode: Combination

Temp. range 30-300°C (86-572°F)

M

Y2

Y1

CM - Sequence of events

S2

B5

F3

M4

B2

B1

F4

B3

M1

S3

Function Step Responsible sensor

1. Select Combi mode

Set temperature 30-300°C (86-572°F)

2. Select time or core temperature

3. Close cabinet door Reed switch S3

4. Check water level inside steam generator Level electrode S2 inside Steam Generatorr

5. Preheat steam generator, Thermocouple B5 inside Steam Generator

if B5 is below 85°C (185°F);

6. Timer starts after successful preheating Logic on PCB

(blinking dot in Display)

7. Hot Air supply until set temperature Cabinet sensor B1

inside cabinet. Hot air has priority

8. Steam supply up to steam saturation Quenching sensor B2

inside cabinet (Steam Control)

9. Quenching (set to 70°C/158°F) Quenching sensor B2

Note: Reduction of fan motor speed

In case the actual temperature in the range of 30-99°C (37-210°F) is higher than the set temperature for longer than 2 minutes, the fan speed will be reduced automatically.

-16-

Page 17

F

CM - Sequence of events

Mode: Finishing

Temp. range 30-300°C (86-572°F)

S2

B2

Y2

Y1

S

C

M

B1

F4

B3

B5

F3

M1

M4

S3

Function Step Responsible sensor

1. Select Finishing mode

Recommended temperature 100-140°C (212-284°F)

2. Select time or core temperature

3. Close cabinet door Reed switch S3

4. Check water level inside steam generator Level electrode S2 inside Steam Generatorr

5. Preheat steam generator, Thermocouple B5 inside Steam Generator

if B5 is below 85°C (185°F);

6. Timer starts after successful preheating Logic on PCB

(blinking dot in Display)

7. Hot Air supply Cabinet sensor B1

Electric units: 12 sec on - 6 sec off

Gas units: 30 sec on - 15 sec off

8. Steam supply Quenching sensor B2

Electric units: 6 sec on - 12 sec off (Steam Control)

Gas units: 15 sec on - 30 sec off

9. Quenching (set to 70°C/158°F) Quenching sensor B2

Note: Reduction of fan motor speed

In case the actual temperature in the range of 30-99°C (37-210°F) is higher than the set temperature for longer than 2 minutes, the fan speed will be reduced automatically.

-17-

Page 18

S

C

Mode: Hot Air

M

Temp. range 30-300°C (86-572°F)

Y2

Y1

CM - Sequence of events

S2

B5

F3

M4

B2

B1

F4

B3

M1

S3

Function Step Responsible sensor

1. Select Hot Air mode

Set temperature 30-300°C (86-572°F)

2. Select time or core temperature

3. Close cabinet door Reed switch S3

4. Hot Air supply unitl set temperature Cabinet sensor B1

is reached

8. Quenching (set to 90°C/194°F) Quenching sensor B2

Note: Reduction of fan motor speed

In case the actual temperature in the range of 30-99°C (37-210°F) is higher than the set temperature for longer than 2 minutes, the fan speed will be reduced automatically.

-18-

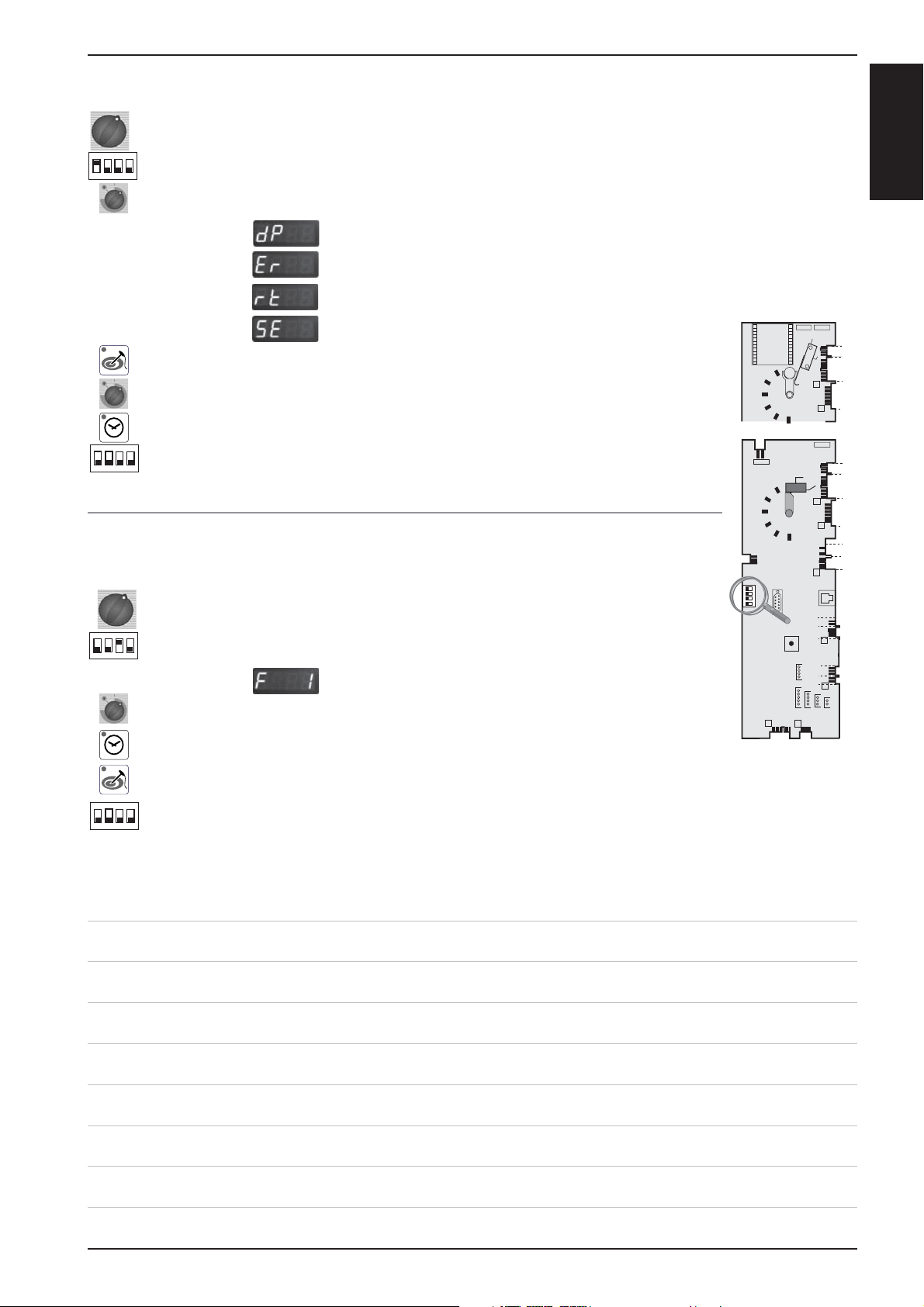

Page 19

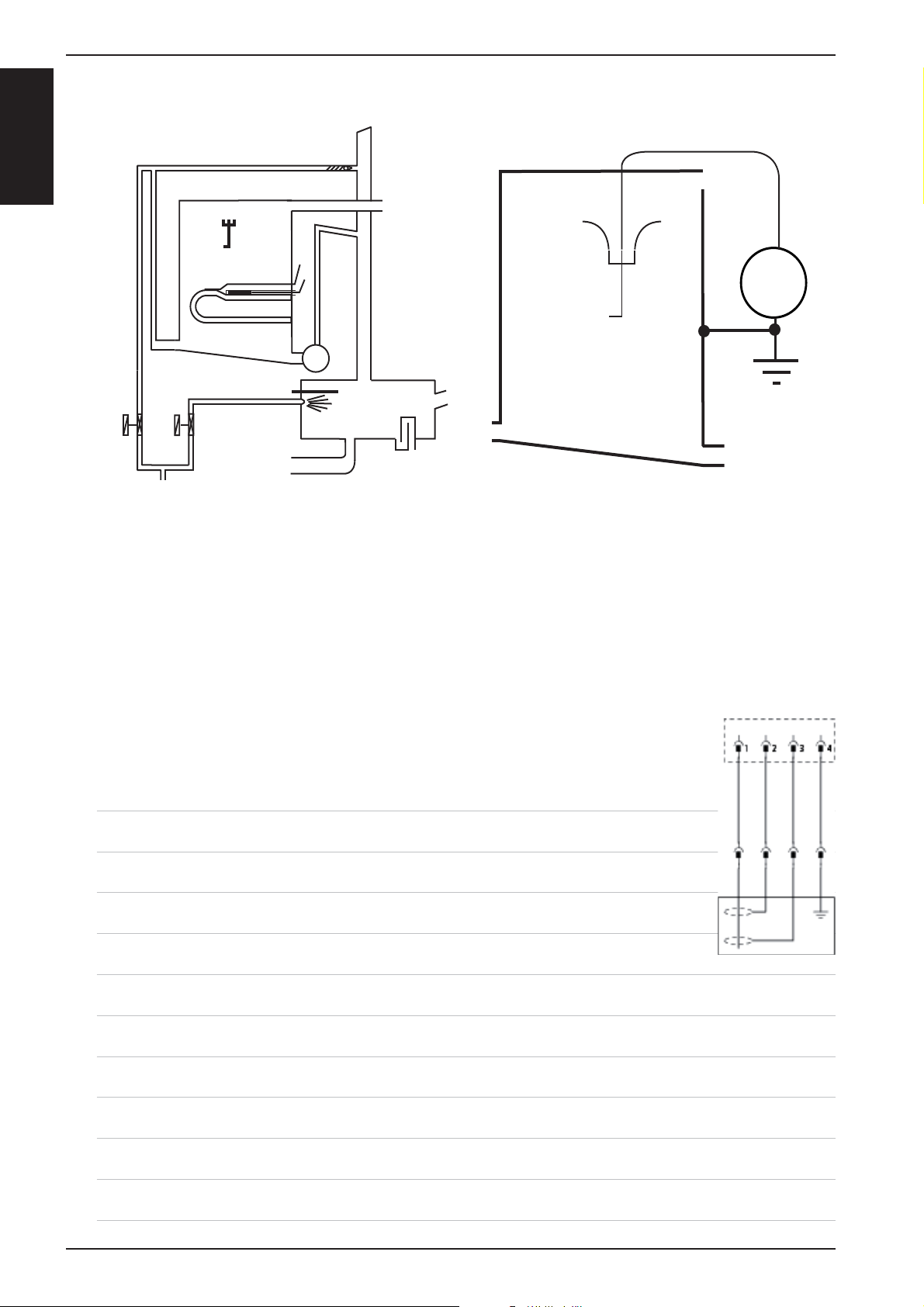

Service level CM from 04 - 2004

F6.1

2 AT

X16

F6

S

C

on

on

1

on

1

1

234

234

234

1) Switch unit ON

2) On operator PCB set DIP switch 1 to „ON“ position

3) Select service package with timer dial:

Diagnostic Program

Error code history

Running times

Basic settings

4)

Activate with core temperature key the desired service package

5) Select with timer dial the desired step

6) Activate selected step by pressing timer key

7)

To de-activate service package set DIP switch 1 to „OFF“ position

Function Test

.

X63

off

1) Switch unit ON

2) Auf Bedienplatine DIP Schalter 3 auf „ON“ Stellen

First step of function test is displayed.

3) Select desired step of function test with timer dial

4) Activate selected step by pressing timer key

42.00.004

Transformer

42.00.047

X16

2 AT

F6.1

1

2

on

3

4

1

X30

RS 232

0,1 AT

X50

X2

1

F1 F2

X32X24

M

2 AT

X7

X19

1

X20

1

2 AT

F6

X7

X19

1

X20

1

X18

X23

1

X31

RS 485

X8

X12

1

X26

X27

1

X3X4X6

on

234

1

Notes:

5) Activate selected step with core temperature key

6)

To de-activate function test set DIP switch 3 to „OFF“ position

.

-19-

Page 20

S

C

M

dP #

dP 1

Service level: dP -- Diagnostic Program

Description

Software Version

Connector

Cabinet display

Software

version: C - 1 -

Timer display

Software

Version:06.05

Comment

dP 2

dP 3

dP 4

dP 5

dP 6

dP 7

dP 8

dP 9

dP 10

dP 11

dP 12

dP 13

dP 14

dP 15

dP 16

dP 17

B1 Cabinet sensor

B2 Quenching sensor

B3 Core sensor

B5 Steam generator sensor

PCB temperature

S3 Door contact

S2 Water level steam

generator

Steam elements

0 - off; 1 - 50%; 2 - 100%

Hot Air elements

0 - off; 1 - 50%; 2 - 100%

Speed fan motor top

Speed fan motor bottom

Energy optimising

(Sicotronic)

SSR pulsing (US version)

Unit size and type

Flame Current Steam

Flame Current Hot Air top

X 3

X 4

X 2

X 6

X27:(1-2)

X12:(1-4) S2

X19:(1-3) Y1

BUS

BUS

X 20

X 26

actual value

actual value

actual valuet

actual value

actual value

S3: 1 - 0

Temp. B5

Temp. B1

Set rpm

Set rpm

61 - 202

max value

max value

max value

max value

max value

1 - 0

Y1: 1 - 0

0 - 1 - 2

0 - 1 - 2

actual rpm

actual rpm

1 - 0

1 - 0

ELE - GAS

x.x A

x.x A*

Reset by pressing

for 5 sec.

Reset by pressing

for 5 sec.

Reset by pressing

for 5 sec.

Reset by pressing

for 5 sec.

Reset by pressing

for 5 sec.

USA version only

since SW Version:

*

C1-06-05 ( ame current)

since SW Version:

C1-06-05 ( ame current)

+

+

+

+

+

x.x A*

dP 18

*

(This value must be divided by 4 to get the correct ame current e. g. 22:4 = 5,5A.)

Flame Current Hot Air bottom

With SW Version C1-06-05 the ame current will show as 20-24A

since SW Version:

C1-06-05 ( ame current)

Starting with SW version C1-07-01 the actual ame current is shown .

-20-

Page 21

Service Level: ER -- Error code history

S

Since software version C1-07-01 the last 10 general error messages are

shown

Er When timer key is pressed the error code will be displayed. i.e.:

Er1 3 B1 Cabinet sensor defective

Er2 14 Y1 Filling solenoid defective

Er3

---ER10

Note: Er1 - Er10 is a consecutive counting

Number 1-24 are error codes which are generated by the pcb

Gas error GE: (gas units only!)

Since software version C1-07-01 the last 16 gas error messages are shown in addition to the

general error messages

GE11 20 No rpm signal

GE12 32 No ame after 5 ignition sequences

GE13

--GE25

Note: GE11 - 25 is a consecutive counting

(applies for electric and gas models)

C

M

Number 1-43 are internal error codes which are generated by the ignition box

Indication of ignition box error messages (1-32 is shown to the operator as „rES“):

1 Hot air or Steam no gas, gas valve or electrode defective

14 Hot air gas valve controll, change ignition box

19 Hot air no ame because ame current is too low

check burner setting, ame current, ignition cable and plug

20 Hot air wrong or no rpm signal from gas blower

check gas blower, power supply gas blower and control harness of gas blower

22 Hot air no ame after 5 ignition sequences

no gas, gas valve or electrode defective

24 Steam gas valve controll, change ignition box

29 Steam no ame because ame current is too low

check burner setting, ame current, ignition cable and plug

30 Steam wrong or no rpm signal from gas blower

check gas blower, power supply gas blower and control harness of gas blower

32 Steam no ame after 5 ignition sequences

no gas, gas valve or electrode defective

Possible failure in case of „E21“

33, 36 Change ignition box

35 Check frequency of main

39 Hot air Check burner setting, ignition electrode and distance,and ame current

40 Hot air Check ignition cable

42 Steam Check burner setting, ignition electrode and distance,and ame current

43 Steam Check ignition cable

Is shown on display „CHnG PoL“

34 Change polarity of mains

All other numbers (2-13, 15-18, 21, 23, 25-28, 31): change ignition box

-21-

Page 22

S

C

M

Int. cab.

display

H2o

CHnG

Timer

display

OPEn

PoL

Failure Codes CM „ER“

Failure explanation

H2O open

Change Polarity

Description

Lack of water / open water tap

Phase / Neutral (only gas units)

Timer

display

E1

E2

E3

E4

E5

E6

E7

E8

E9

E10

E11

E12

E 12

E13

E14

E15

E16

E17

E18

E19

E20

E20

E21

E21

E21

E22

E22

E22

E23

E24

Int. cab.

display

(E -press

core temp.

key)

1 St

1 Co

2 St

2 Co

1_

2_

1xx

2xx

3xx

1xx

2xx

3xx

Part concerned

external EEPROM

Timeout of external

power optimising system

(Sicotronic)

B1 Interior cabinet sensor

B2 Quenching sensor

B3 Core sensor

B5 Sensor steam generator

Thermocouple on PCB

Poti interior cabinet

Poti timer/core temperature

External EEPROM

Mode switch

Fan motor 1 (bottom)

Fan motor 1 (bottom)

Fan motor 2 (top)

Fan motor 2 (top)

M4 SC-pump

Solenoid valve lling Y1

PCB temperature

Steam generator

Steam generator

Interior cabinet temp.

free

Ignition box 1

Ignition box 2

Ignition box 1 Steam

Ignition box 1 Hot air

Ignition box 2 Hot air

Ignition box 1 Steam

Ignition box 1 Hot air

Ignition box 2 Hot air

free

EEPROM

Description

Not initialised

Heating blocked by the extern. energyoptimising system for longer 2 min.

Sensor broken

Sensor broken

Sensor broken

Sensor broken

Sensor broken

Defective

Defective

Defective

After 5 sec switching on the unit, a cooking

mode couldn‘t be identi ed

St = Status (probably Motor defect)

Co = Communication,(Bus failure)

St = Status (probably Motor defect)

Co = Communication,(Bus failure)

Mal function

Mal function

above 85°C (185°F)

Temperature B5 above

180°C (356°F)

Temperature B5 below -5°C (23°F)

Temperature B1 above 340°C (644°F)

Ignition box does not reply, Bus failure

Ignition box does not reply, Bus failure

Ignition box defective (change box)

Ignition box defective (change box)

Ignition box defective (change box)

Testing of ignition and monitoring

necessary

Testing of ignition and monitoring

necessary

Testing of ignition and monitoring

necessary

Actual data structure of the EEPROM does

not match with the software; flash pcb first

-22-

Page 23

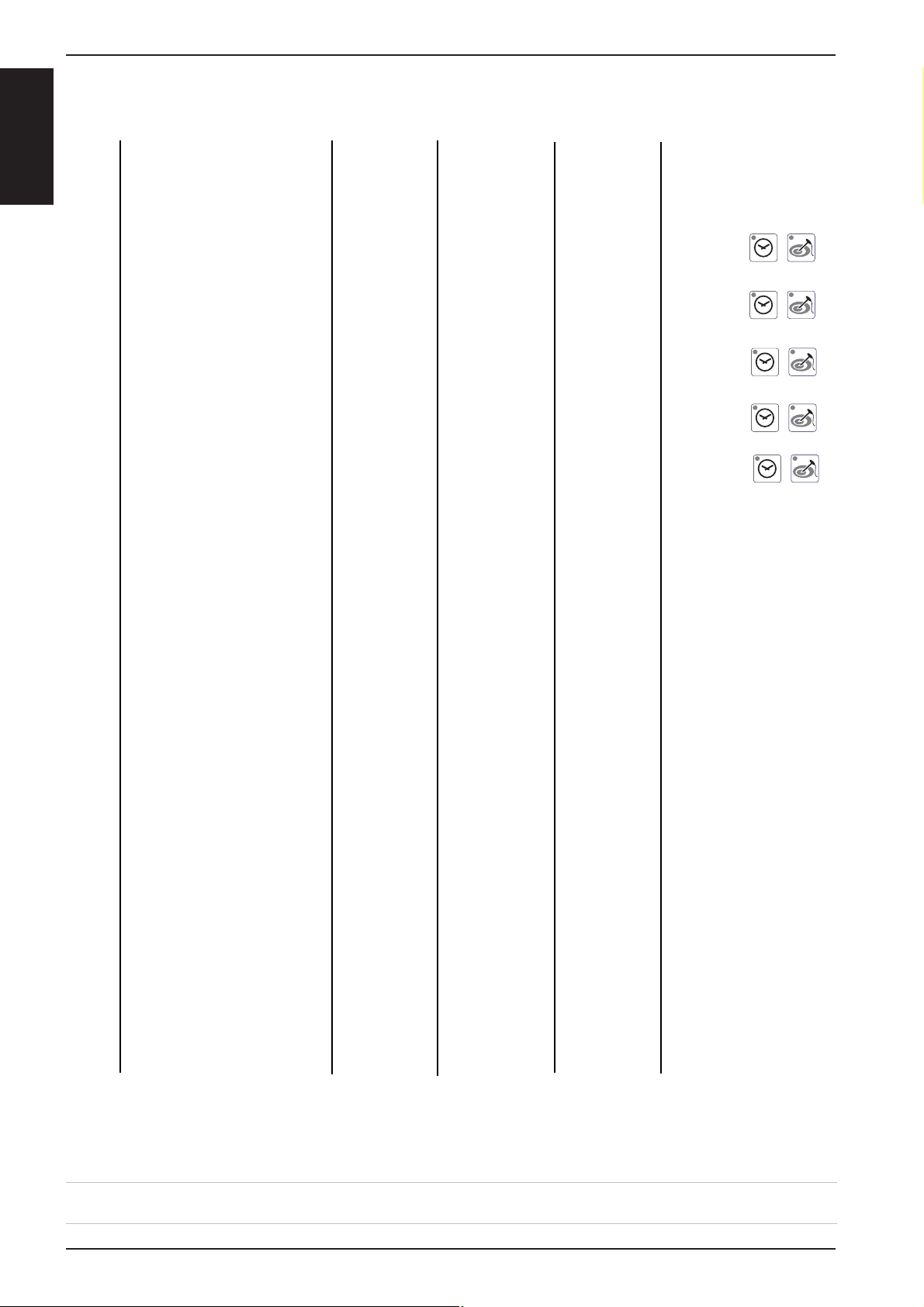

Service Level: rt -- Running Time

S

C

rt #

rt 1

rt 2

rt 3

rt 4

rt 5

rt 6

rt 7

rt 8

rt 9

Description

Total S3 door openings

Total time Y1 valve lling

Total time Y2 valve quenching

Total time M4 SC-pump

Total time steam heating time

Total time hot air heating time

Total time steam mode

Total time hot air mode

Total time combination mode

Timer display: 1-999

Temp. display: >1000

number

min

min

min

hrs

hrs

hrs

hrs

hrs

Comment

Reset by pressing

for 5 sec.

Reset by pressing

for 5 sec.

Reset by pressing

for 5 sec.

Reset by pressing

for 5 sec.

Reset by pressing

for 5 sec.

Reset by pressing

for 5 sec.

Can not be reset

Can not be reset

Can not be reset

M

+

+

+

+

+

+

rt 10

rt 11

rt 12

rt 13

Notes:

Total time vario steam mode

Total time nishing mode

Total time cleaning program

Total running time unit

hrs

hrs

hrs

hrs

Can not be reset

Can not be reset

Can not be reset

Can not be reset

-23-

Page 24

S

C

M

+

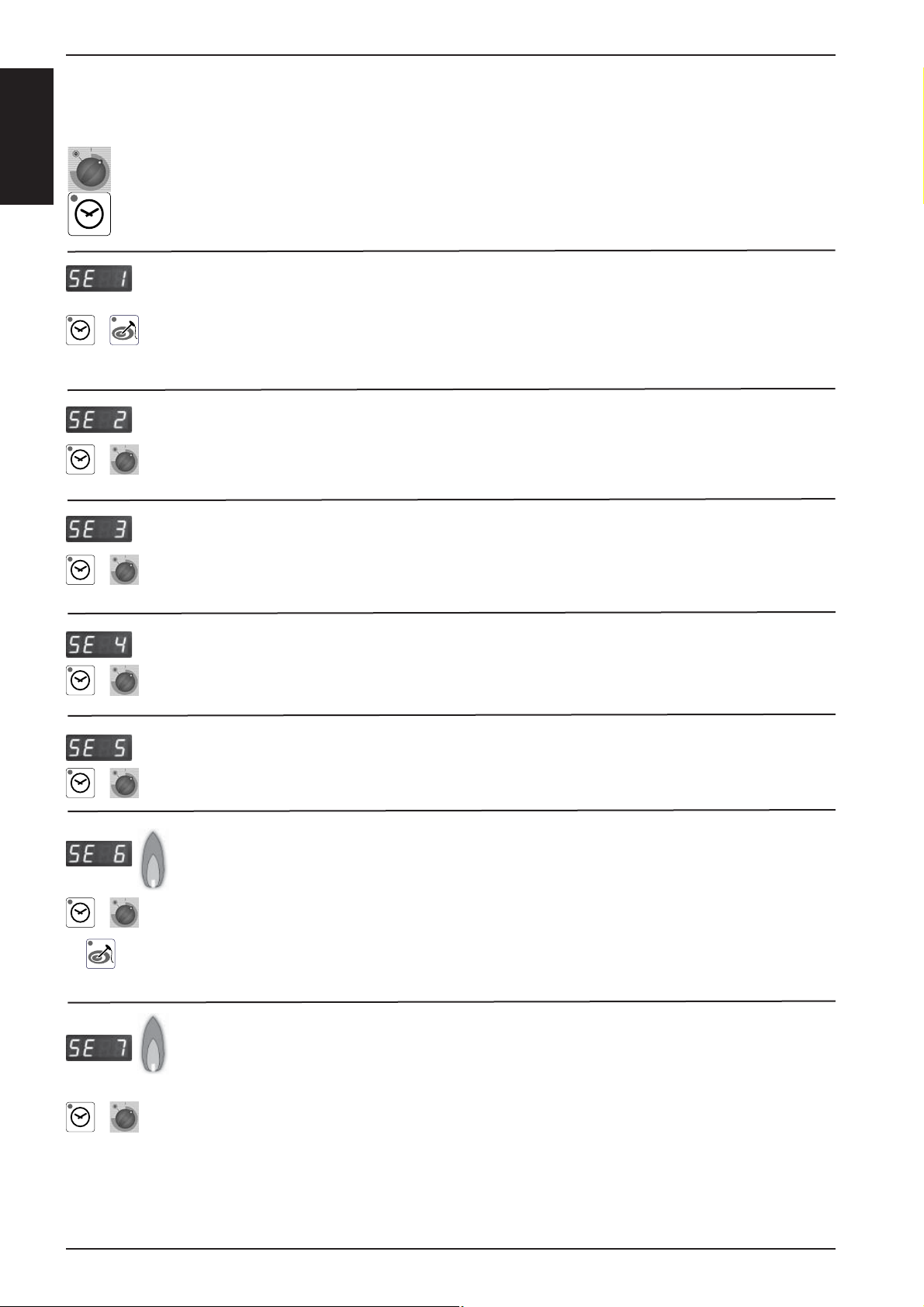

Service level: SE -- Basic settings

Select desired step with timer dial

(fan motor and heating elements are automatically OFF)

Activate selected step with timer key

Steam heating time since last SC-Automatic

Press time and core key simultaneously for 5 seconds to set steam heating time

(SE2) to preset steam heating time plus 1 minute (default 45+1min) => test function

for SC-Automatic

Preset Steam heating time until SC-Automatic (default 45min)

+

+

+

+

Press time key and adjust preset steam heating time from 20 - 120 minutes with timer

dial

Flushing time SC-Automatik (default 45 seconds)

Press time key and adjust ushing time of SC-automatik from 30 - 90 seconds with

timer dial

Operation steam generator pump (oFF - continous or on - pulsing)

Press time key and select „on“ or „oFF“ with timer dial

Show mode (on - oFF) SHO

Press time key and select „on“ or „oFF“ with timer dial

Setting new gas type (G20, G25, G30, G31, 13A)

Press time key, keep it pressed and select new gas type with timer dial

+

+

Con rm new gas type by pressing core temperature key once.

Corresponding gasblower speed is automatically adjusted

NOTE: After changing gas type a waste gas analysis must be carried out in the function test.

Presetting of CO2 screw in mm on gas valve after gas type modi cation / changing

gas valve

Press time key, keep it pressed and select with timer dial “ST“ for steam, “HA1“ for

hot air top or “HA2“ for hot air bottom (only 201/202) with timer dial;

Average lenght in mm of CO

screw on gas valve is shown on timer display

2

-24-

Page 25

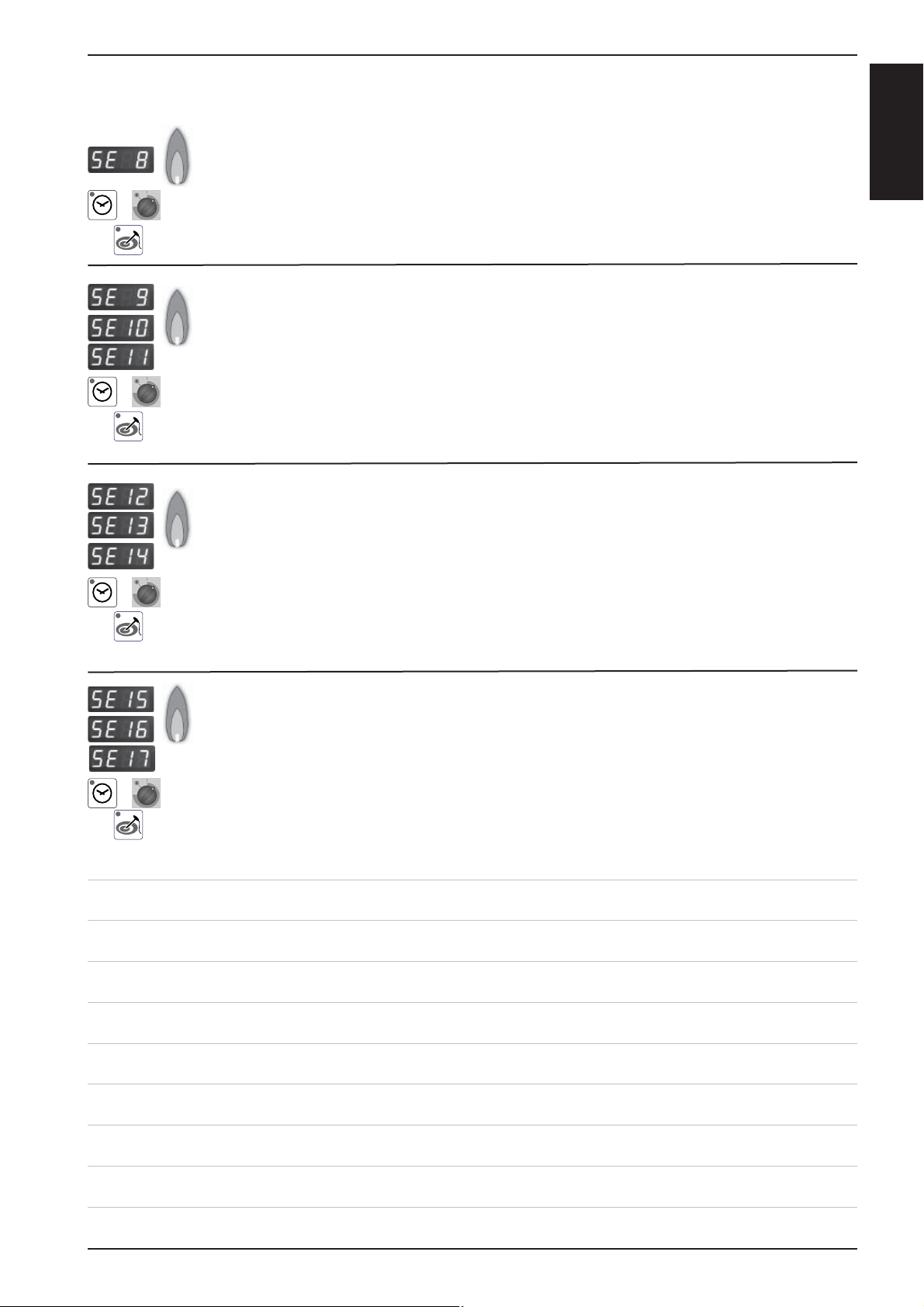

Service level: SE -- Basic settings

Adjustment of installation altitude above sea level (since SW C1-06-05)-500m 4500m

S

C

M

+

+

+

Press time key, keep it pressed and select installaton altitude in 500m steps by timer

dial. Con rm altitude setting by pressing simultaneously core temperature key once

Adjusting speed of blower motor steam (+/ -10%)

(After blower speed adjustment the original rpm is shown in the temp. display, the

changed rpm is shown in the time display)

Press time key, keep it pressed and adjust displayed rpm with timer dial

SE9 = MIN rpm; SE10 = Start rpm; SE11 = MAX rpm

NOTE: After changing speed of blower motor a waste gas analysis MUST be carried

out in the function test.

Adjusting speed of blower motor hot air top (+/ -10%)

(After blower speed adjustment the original rpm is shown in the temp. display, the

changed rpm is shown in the time display)

Press time key, keep it pressed and adjust displayed rpm with timer dial

SE12 = MIN rpm; SE13 = Start rpm; SE14 = MAX rpm

NOTE: After changing speed of blower motor a waste gas analysis MUST be carried

out in the function test.

+

Notes:

Adjusting speed of blower motor hot air bottom (+/ -10%)

(After blower speed adjustment the original rpm is shown in the temp. display, the

changed rpm is shown in the time display)

Press time key, keep it pressed and adjust displayed rpm with timer dial

SE15 = MIN rpm; SE16 = Start rpm; SE17 = MAX rpm

NOTE: After changing speed of blower motor a waste gas analysis MUST be carried

out in the function test.

-25-

Page 26

S

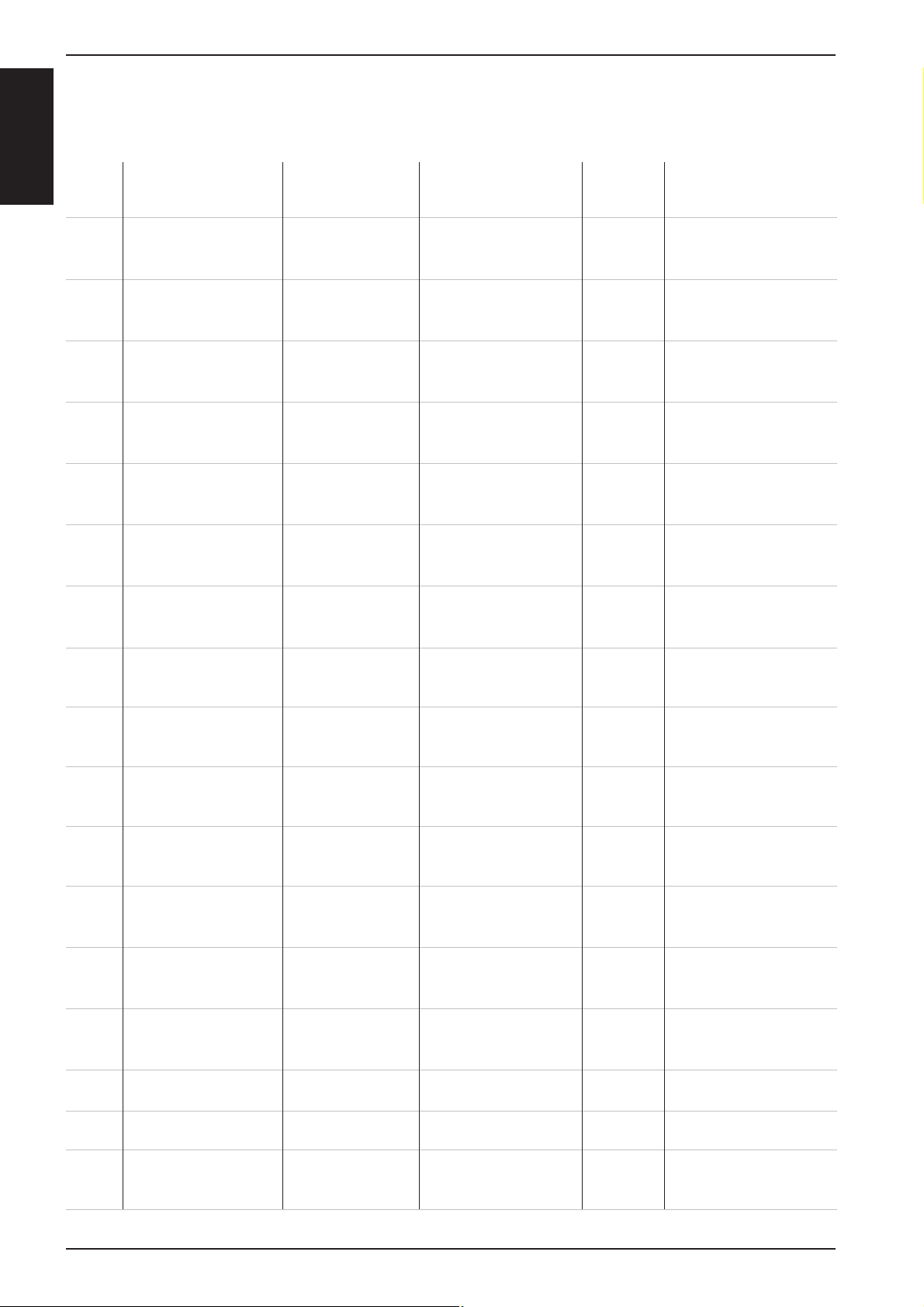

Service level: SE -- Function test

C

NOTE: In Function test components are NOT protected against overload!

M

Function Connection Cabinet Time Comment

I/O PCB Display Display

F1 Steam 50%, X24:(1-2) actual temp.B5 1 / 0 Gas: no function

Electric unit steam generator

F2 Steam 100% X24:(1-2)+(5-6 actual temp.B5 1 / 0 Gas: no function

Electric unit steam generator

F3 Hot Air 50% X24:(7-8) actual temp. B1 1 / 0 Gas: no function

Electric unit cabinet

F4 Hot Air 100% X24:(7-8)+(3-4) actual temp. B1 1 / 0 Gas: no function

Electric unit cabinet

F5 Steam BUS actual temp.B5 1 / 0 Electric: no function

Gas unit steam generator

F6 Hot air top BUS actual temp.B1 1 / 0 Electric: no function

Gas unit cabinet

F/ Hot air bottom BUS actual temp.B1 1 / 0 Electric: no function

Gas unit cabinet

F8 Bottom Motor BUS Set rpm Act. rpm

MAX speed

F9 Bottom Motor BUS Set rpm Act. rpm

MIN speed

F10 Top Motor BUS Set rpm Act. rpm

MAX speed

F11 Top Motor BUS Set rpm Act. rpm

MIN speed

F12 Solenoid valve X19:(2-4) actual temp. Y2, 1 / 0

quenching B2 quenching

F13 Solenoid valve X19:(2-4) Level electrode Y1, 1 / 0

lling S2, 1 / 0

F14 Steam generator X18:(1-2) M4 Level electrode M4,1 / 0

pump X12:(1-4) S2 S2, 1 / 0

F15 Buzzer 1 / 0

F16 All Displays / LED

F17 Relais Vent hood X 23: (1-2-3) 1 / 0

(door open/close)

-26-

Page 27

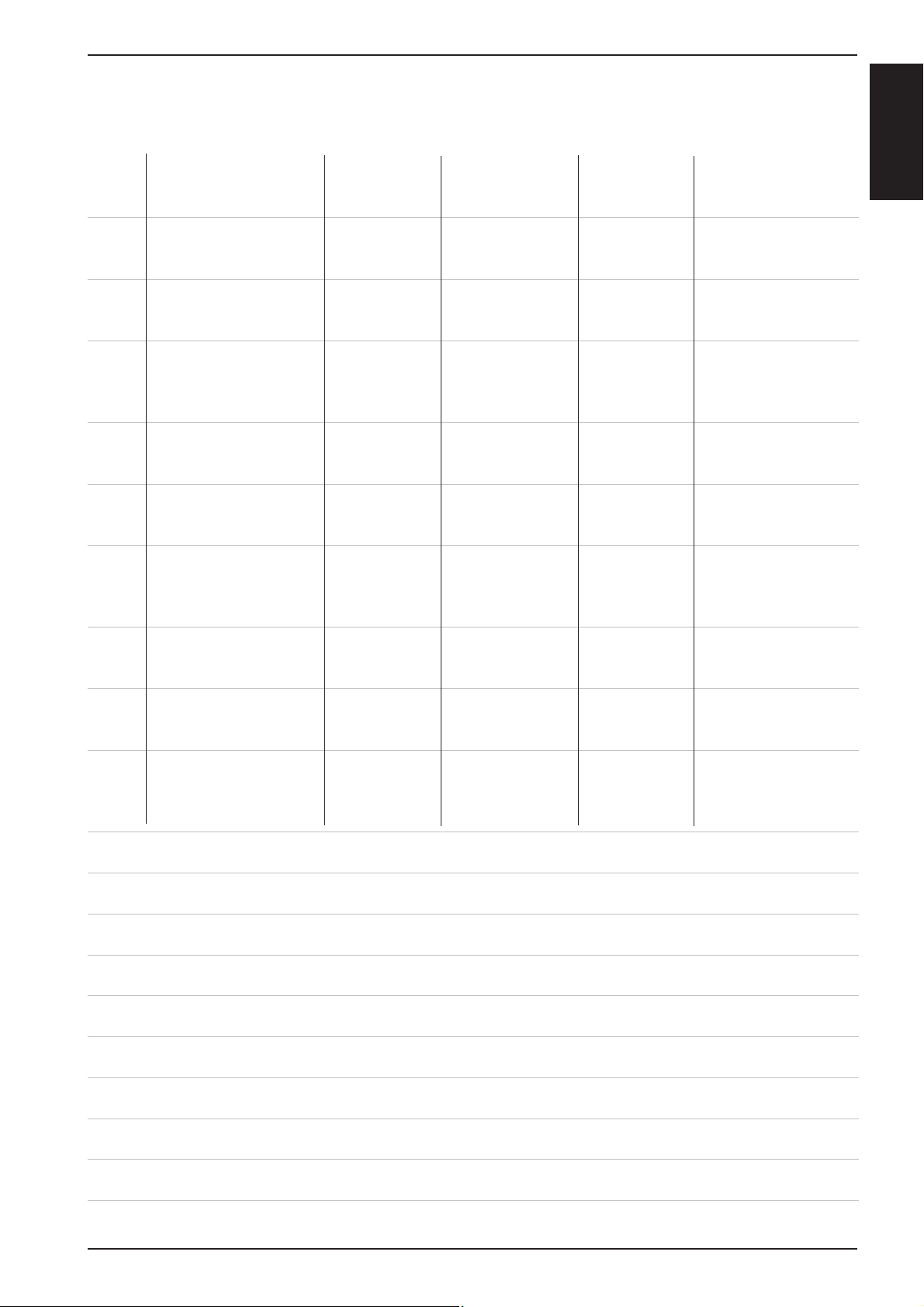

Function test

NOTE: In Function test components are NOT protected against overload!

Function Connection Cabinet Time Comment

I/O PCB Display Display

F19 Steam blower motor BUS Actual blower Set CO

MIN rpm rpm value value only

F20 Steam blower motor BUS Actual blower

START rpm rpm

F21 Steam blower motor BUS Actual blower Set CO

MAX rpm rpm value with C02 screw

on gas valve

F22 Hot Air blower motor BUS Actual blower Set CO

TOP, MIN rpm rpm value value value only

F23 Hot Air blower motor BUS Actual blower

TOP, START rpm rpm

F24 Hot Air blower motor BUS Actual blower Set CO

TOP, MAX rpm rpm value with C02 screw

on gas valve

F25 Hot Air blower motor BUS Actual blower Set CO

TOP, MIN rpm rpm value value value only

F26 Hot Air blower motor BUS Actual blower

TOP, START rpm rpm

F27 Hot Air blower motor BUS Actual blower Set CO

TOP, MAX rpm rpm value with C02 screw

on gas valve

Check CO2

2

Adjust CO2 value

2

Check CO2

2

Adjust CO2 value

2

Check CO2

2

Adjust CO2 value

2

S

C

M

Notes:

-27-

Page 28

S

C

M

S2

B11

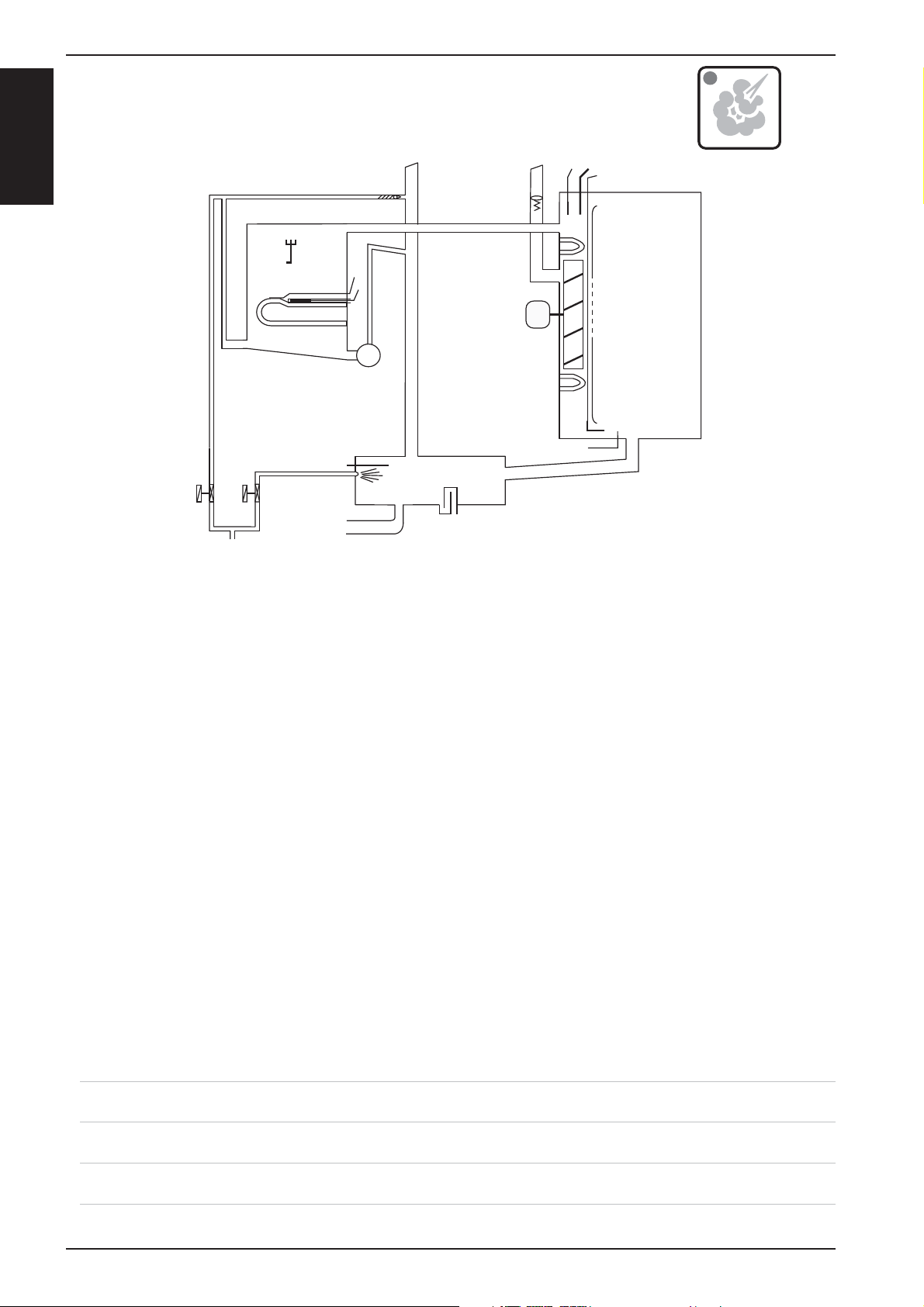

CM Gas from 04 - 2004

B5

F3

M4

Y12

M8

M9

Y11

A5

M1

B12

B1

F4

B3

B2

Y1

Y2

A5 Ignition module (Steam and Hot Air) (without jumper)

B1 Thermocouple interior cabinet

B2 Thermocouple quenching / Steam control

B3 Thermocouple core temperature

B5 Thermocouple steam generator

B11 Ignition/monitoring electrode steam

B12 Ignition/monitoring electrode hot air

F3 Safety thermostat steam generator 135°C

F4 Safety thermostat interior cabinet 360°C

M1 Fan motor

M4 SC-pump

M8 Gas blower motor hot air

M9 Gas blower motor steam

Y1 Solenoid valve lling

Y2 Solenoid valve quenching

Y11 Gas valve steam

Y12 Gas valve hot air

S2 Level electrode

S3 Door reed switch

S3

Only oor units 201 - 202

A6 Ignition module hot air bottom (with jumper)

M2 Fan motor top (with jumper)

M10 Gas blower motor hot air bottom

Y13 Gas valve hot air bottom

B13 Ignition/monitoring electrode hot air bottom

-28-

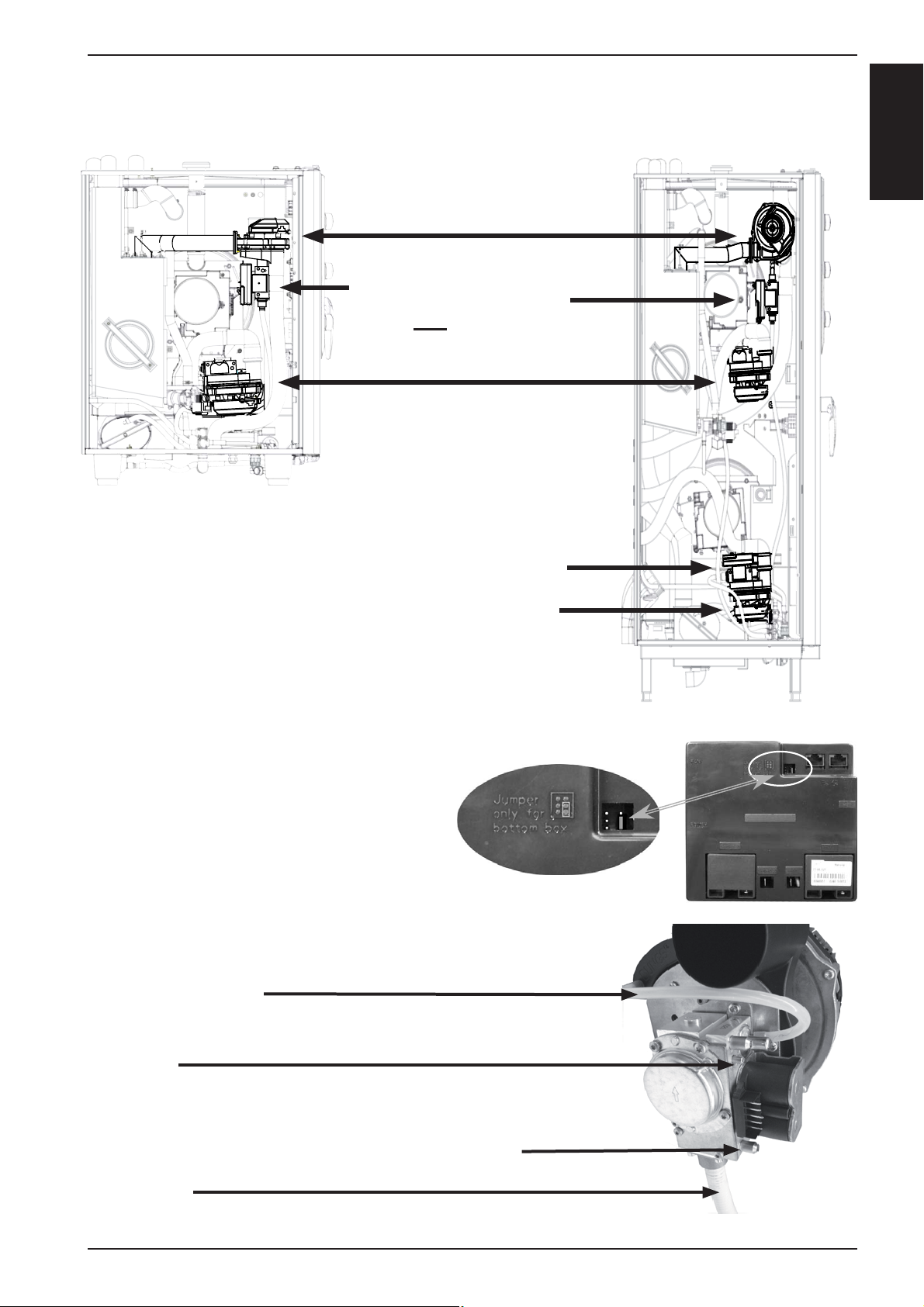

Page 29

S

Identification of the different gas burners / Gas blowers:

CM 61 - 62 - 101 - 102 CM 201 - 202

Steam Blower

Steam Gas valve with

common ignition box for

Steam and Hot Air (top) tted

Hot Air blower (top)

Hot Air (bottom) Gas valve with

second ignition box tted

C

M

Hot Air blower bottom

(ignition box tted)

Ignition box of Hot Air Blower, Bottom (201-202):

Jumper must ONLY be set

on Ignition Box for

Hot Air Blower Bottom (201 - 202)

Gas valve components

Compensation hose

Srew

CO

2

Ignition box

Measuring test point for dynamic gas ow pressure

Gas supply

-29-

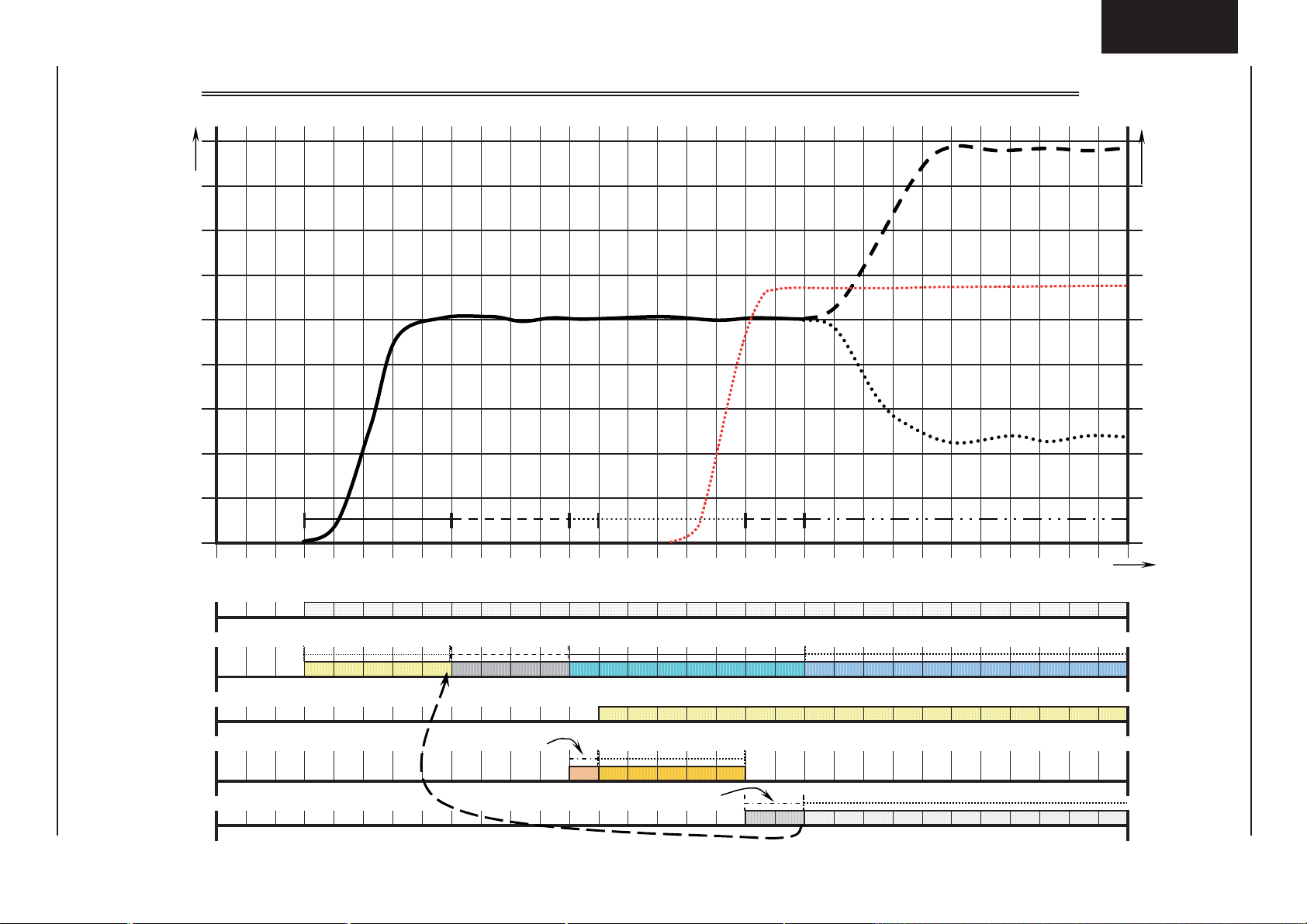

Page 30

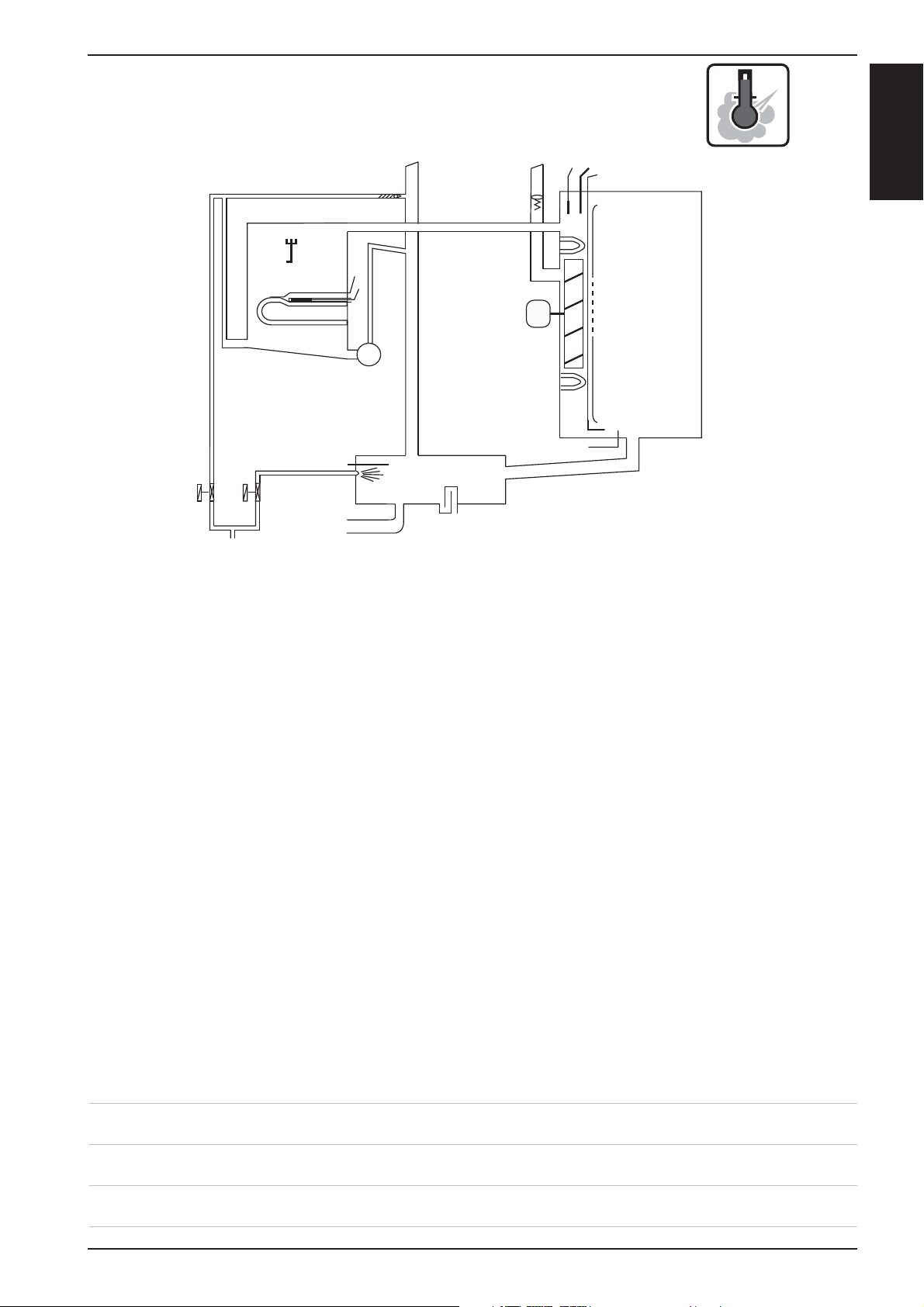

Sequence of events of Steam / Hot Air Burner (SCC as well as CM)

C

Igniti

μA

M

C

-30-

Max RPM

RPM

8

Speed of burner blower motor in U/min

7

Sequence of events of Burner and Ignition control

6

Start RPM

Flame current

5

4

3

Min RPM

F l a m e c u r r e n t in μA

2

1

Time 2 3

Start up Pre purge

Pre ignition

Flame

Ignition Burner running

control

16 2419 2017 1810 11 14 15

21 22 23 26 27678901 45

2512 13

sec

Heat demand

Burner blower motor

Gas valve

Ignition, ca 20KV

Flame monitoring

Ignition box gets heat demand over the BUS cable

Start - pre purge

about. 4-5 sec

If no flame detected => new ignition sequence. After 5th ignition without success => RESET

Pre purge, 4 sec

RPM monitored

Flame monitoring within. 2 sec

Blower runs with Start RPM

RPM monitoring by ignition box

Energise Solenoids: Black coils ca 205V DC / orange coils ca 108V DC

on,5 secPre ignition, 1sec

Blower runs with Max or Min RPM

RPM monitoring by ignition box

continuous flame control

Page 31

Check Gas Type / Gas Conversion: CM Gas from 04-2004

on

234

1

Whenever

Changing the gas setting only by adjusting the CO

Clean Burner head, Electrode and interior blower housing from fats and dust! (TI03-2007)

1) Select any mode and cooking time

2) Open control panel

3) Set DIP switch 1 on PCB to „ON“ position

4) With timer dial select: „SE“ = Settings:

5) Activate „Settings“ by pressing core temperature key; display changes to „SE1“

changing connected type of gas a detailed ue gas analysis

adequate CO and CO

measuring equipment!

2

This shall ONLY be done by trained technicians!

screw will result in an unsafe ue gas

2

condition, is dangerous to life and will damage the equipment

Note: Yearly maintenance of Gas components is needed:

MUST be done using

!

S

C

M

6) With timer dial select: SE6

7) Activate position SE6 with timer key (keep key pressed)

8) Select new gas type with timer dial:

G20=Nat Gas H, G25=Nat Gas L, G30=3BP, G31=3P, 13A=Nat. Gas Japan

9) Con rm new gas type with core temperature key (now timer key can be released)

10) With timer dial select: SE7

11) Activate position SE7 with timer key (keep key pressed)

12) Keeping the timer key pressed the average length of the CO

screw is indicated. „St“

2

Steam, „HA1“ Hot air top, HA2“ Hot air bottom. Select the corresponding value with the

timer dial (keep timer key pressed)

13) Set the CO

screw according the values of timer display or according

2

the table “Values for burner adjustments“ Setting this screw to the given length shall

ONLY bring the unit into working condition with the newly supplied gas. (! ! ! Set all CO

screws ! ! !). If the mm setting of CO

screw is too high, turn CO

2

screw rst 2 turns

2

clockwise and then to the requested length (Screw adjustment tolerance).

2

xx mm

This does NOT replace ue gas analysis or make the ue gas analysis obsolete!

14) De-activate selected package “SE“ by pressing core temperature key

on

1

15) To exit service program set DIP switch 1 to „OFF“ position

234

16) To store the new gas type the unit must be switched OFF and ON again

!

17) Check / Set Installation Altitude in Basic settings. Perform ue gas analysis in

function test at F21, F24, F27 as well as the check of CO

values at F19, F22, F25.

2

-31-

Page 32

S

Changing installation altitude: CM gas

C

M

Adjusting the installation altitude compensates for the

different concentration of oxygen in the air at different height above sea level

by adjusting the blower speed accordingly.

Note: The altitude settings of 0-499 and 500-999m are identical.

Therefore resetting of installation altitude needs to be done only

when installing above 1000m (3280ft) or below sea level.

1) Select any mode and cooking time

2) Open control panel

on

1

3) Set DIP switch 1 on PCB to „ON“ position

234

4) With timer dial select: „SE“ = Settings

5) Activate „Settings“ by pressing core temperature key; display changes to „SE1“.

6) With timer dial select: SE8

7) Activate position SE8 with timer key and keep it pressed.

8) While pressing timer key corresponding installation altitude above sea level can be

selected with the timer dial.

on

1

Possible altitude selection:

-500 m - - 1 m

0 m - 499 m

500 m - 999 m

1000 m - 1499 m

1500 m - 1999 m

2000 m - 2499 m

2500 m - 2999 m

3000 m - 3499 m

3500 m - 3999 m

4000 m - 4499 m

4500 m - 4999 m

9) Con rm new altitude setting with core temperature key (Keep timer key pressed)

10) Release timer and core temperature key

11) De-activate selected package by pressing core temperature key

12) To exit service program set DIP switch 1 to „OFF“ position

234

13) To store the new altitude setting the unit must be switched OFF and ON again

14) Perform ue gas analysis in function test at F21, F24, F27

as well as the check of CO

values at F19, F22, F25.

2

!

-32-

Page 33

S

Checking of dyn. input gas flow pressure

• Before you carry out a ue gas analysis check input gas ow pressure when burner is

running

• Check input gas ow pressure

• See correct values of input ow pressure on data plate

• If necessary adjust gas input pressure

C

M

Necessary input gas ow pressure:

- Natural gas 18 - 25 mbar

- LPG 30 - 57 mbar.

Note: All gas units in the kitchen must operate on high ame.

NOTES:

-33-

Page 34

S

C

M

Flue gas analysis

Steam (F21) at MAX rpm and Checking CO

1) Select any mode and cooking time

2) Open control panel

on

1

3) Set DIP switch 3 on PCB to „ON“ position

234

4) „F1“ is shown on timer display. With timer dial select position F21

5) Enter position F21 „Steam MAX“ with timer key

6) Activate position F21 with core temperature key;

NOTE: In this position core temp. key is used as a switch and will automatically deactivate after 4 minutes. Gas blower rpm is shown in cabinet temp. display.

Speci c CO

value is shown on timer display, i.e. 9,5

2

7) Place ue gas testing nozzle in correct ue outlet.

Adjust CO

to given value by turning CO2 screw on gas valve.

2

You also can nd that value on table “Values for burner adjustments.

• If CO

• If CO

value is too low => turn CO2 screw anti clockwise (+ direction),

2

value is too high => turn CO2 screw rst 2 turns clockwise (- direction), and

2

than slowly anti clockwise (+ direction) till you get the indicated CO

adjustment tolerance).

• CO value must be below 300ppmn

(F19) at MIN rpm

2

value. (Screw

2

on

1

8) Press core temperature key. Burner will stop.

9) Leave position F21 „Steam MAX“ with timer key.

10) Select position F19 with timer dial.

11) Enter „Steam MIN“ with timer key.

12) Activate position F19 with core temperature key.

NOTE: in this position core temp. key is used as a switch and will automatically deactivate after 4 minutes. Speci c CO

13) Carry out a CO

value must be equivalent to the values mentioned in table “Values for burner adjust-

CO

2

measurement to cross-check CO2 value only.

2

ments“

14) If CO

value is out of allowed tolerance => Change gas valve

2

15) Press core temperature key. Burner will stop.

16) Leave position F19 „Steam MIN“ with timer key.

17) To exit service program set DIP switch 3 to „OFF“ position

234

value is shown on timer display, i.e 8,8

2

-34-

Page 35

Flue gas analysis

Steam (F21) at MAX rpm and Checking CO

1) Select any mode and cooking time

2) Open control panel

on

3) Set DIP switch 3 on PCB to „ON“ position

234

1

4) „F1“ is shown on timer display. With timer dial select position F21

5) Enter position F21 „Steam MAX“ with timer key

6) Activate position F21 with core temperature key;

NOTE: In this position core temp. key is used as a switch and will automatically deactivate after 4 minutes. Gas blower rpm is shown in cabinet temp. display.

Speci c CO

7) Place ue gas testing nozzle in correct ue outlet.

Adjust CO

You also can nd that value on table “Values for burner adjustments.

• If CO

• If CO

than slowly anti clockwise (+ direction) till you get the indicated CO

adjustment tolerance).

• CO value must be below 300ppmn

value is shown on timer display, i.e. 9,5

2

to given value by turning CO2 screw on gas valve.

2

value is too low => turn CO2 screw anti clockwise (+ direction),

2

value is too high => turn CO2 screw rst 2 turns clockwise (- direction), and

2

(F19) at MIN rpm

2

value. (Screw

2

S

C

M

8) Press core temperature key. Burner will stop.

9) Leave position F21 „Steam MAX“ with timer key.

10) Select position F19 with timer dial.

11) Enter „Steam MIN“ with timer key.

12) Activate position F19 with core temperature key.

NOTE: in this position core temp. key is used as a switch and will automatically deactivate after 4 minutes. Speci c CO

13) Carry out a CO

value must be equivalent to the values mentioned in table “Values for burner adjust-

CO

2

measurement to cross-check CO2 value only.

2

ments“

14) If CO

value is out of allowed tolerance => Change gas valve

2

15) Press core temperature key. Burner will stop.

16) Leave position F19 „Steam MIN“ with timer key.

on

1

17) To exit service program set DIP switch 3 to „OFF“ position

234

value is shown on timer display, i.e 8,8

2

-35-

Page 36

S

C

M

Flue gas analysis Hot air bottom (F27)

at MAX rpm and Checking CO

1) Select any mode and cooking time

2) Open control panel

on

3) Set DIP switch 3 on PCB to „ON“ position

234

1

4) „F1“ is shown on timer display. With timer dial select position F27

5) Enter position F27 Hot air bottom MAX“ with timer key

6) Activate position F27 with core temperature key;

NOTE: In this position core temp. key is used as a switch and will automatically deactivate

after 4 minutes. Gas blower rpm is shown in cabinet temp. display.

Speci c CO

7) Place ue gas testing nozzle in correct ue outlet.

Adjust CO

You also can nd that value on table “Values for burner adjustments.

• If CO

• If CO

than slowly anti clockwise (+ direction) till you get the indicated CO

adjustment tolerance).

• CO value must be below 300ppmn

value is shown on timer display, i.e. 9,4

2

to given value by turning CO2 screw on gas valve.

2

value is too low => turn CO2 screw anti clockwise (+ direction),

2

value is too high => turn CO2 screw rst 2 turns clockwise (- direction), and

2

(F25) at MIN rpm only (201/202)

2

value. (Screw

2

8) Press core temperature key. Burner will stop.

9) Leave position F27 Hot air bottom MAX“ with timer key.

10) Select position F25 with timer dial.

11) Enter Hot air bottom MIN“ with timer key.

12) Activate position F25 with core temperature key.

NOTE: in this position core temp. key is used as a switch and will automatically deactivate

after 4 minutes. Speci c CO

13) Carry out a CO

CO

value must be equivalent to the values mentioned in table “Values for burner adjust-

2

measurement to cross-check CO2 value only.

2

ments“

14) If CO

value is out of allowed tolerance => Change gas valve

2

15) Press core temperature key. Burner will stop.

16) Leave position F25 Hot air bottom MIN“ with timer key.

on

1

17) To exit service program set DIP switch 3 to „OFF“ position

234

value is shown on timer display, i.e 8,7

2

-36-

Page 37

Changing Gas blower speed

CM Gas from 04 - 2004 (ab Software C-06-03) par example Steam, MIN SE9

This setting shall ONLY be done by specially trained and

RATIONAL approved technicians!

1) Select any mode and cooking time

2) Open control panel

on

1

3) Set DIP switch 1 on PCB to „ON“ position

234

4) With timer dial select: „SE“ = Settings:

5) Activate „Settings“ by pressing core temperature key; display changes to „SE1“

6) With timer dial select: SE9

7) Activate position SE9 „blower motor steam MIN“ rpm with timer.Timer display shows

stored value from EEPROM, i.e. 6250.

S

C

M

8) While pressing timer key blower speed can be adjusted with timer dial by + / -10%.

Note: Adjust steps in increments of 30rpm only! Changed rpm will be shown in timer

display

9) Con rm new rpm setting with core temperature key (keep timer key pressed).

10) Release timer key.

11) De-activate selected package by pressing core temperature key

on

1

12) To exit service program set DIP switch 1 to „OFF“ position

234

13) To store the new blower speed setting the unit must be switched OFF and ON again!

14) Perform ue gas analysis in function test at F21, F24, F27 as well as the check of CO

values at F19, F22, F25.

With this procedure you can change gas blower speed (MAX, Start, MIN rpm)

for steam, hot air top and hot air bottom.

Changing blower speed must be followed by ue gas analysis!:

2

Steam Hot air top Hot air bottom

MIN

Start

MAX

-37-

Page 38

M

)

y

C

-38-

Type of gas

Natural Gas

High

(G20)

Natural Gas

Low

(G25)

LPG

3BP

(G30)

LPG

3P

(G31)

Natural gas

Japan

(13A)

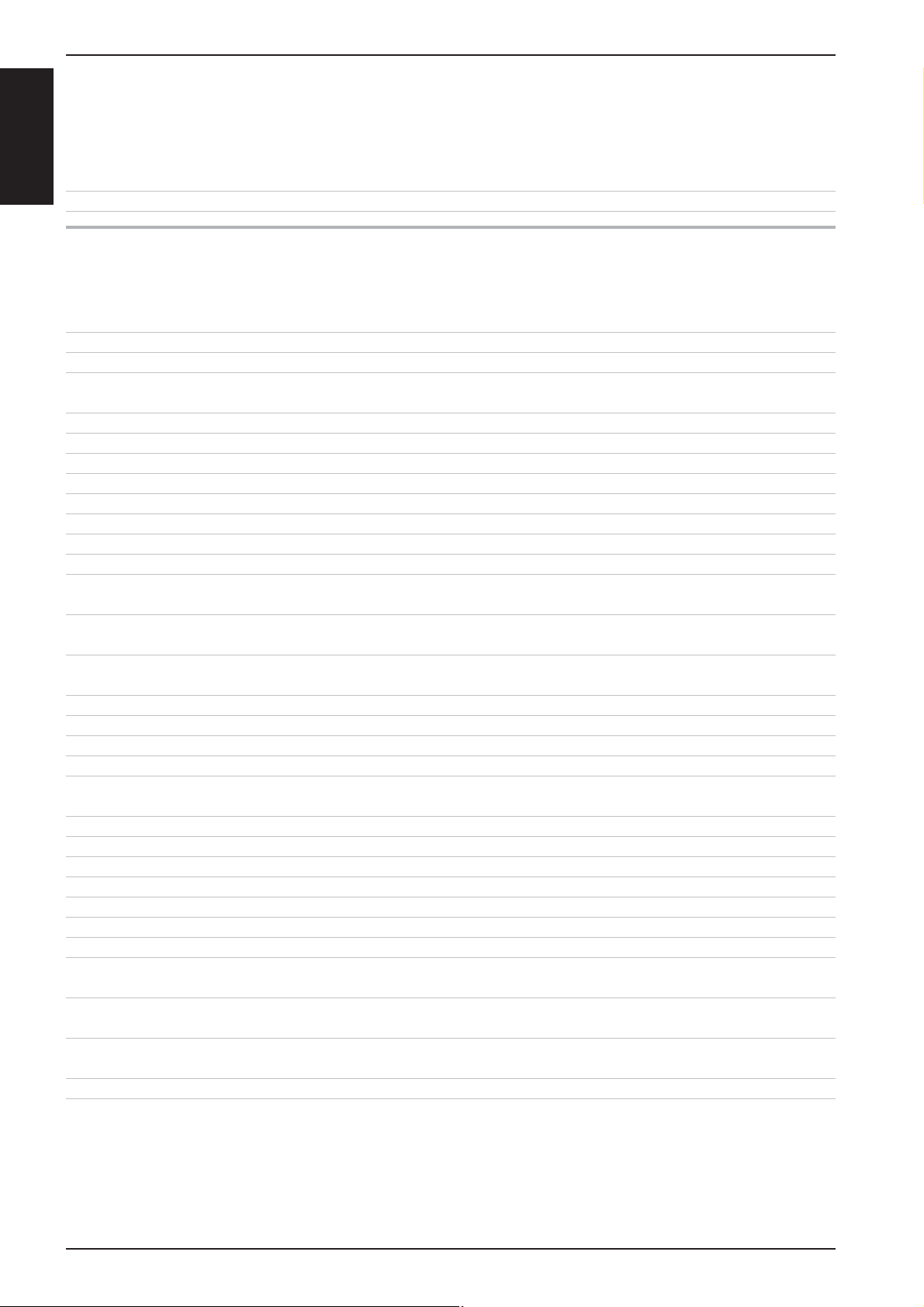

Values for burner adjustments of gas units SCC / CM

(valid since January, 2007), entry in "red" => new

Hot Air Burner - Bottom Side (only at 201-202)Steam Burner Hot Air Burner - Top Side

CO

CO

Input gas flow

pressure

SCC - CM

61 18 - 25 mbar

62 18 - 25 mbar 3,4 mm 18 - 25 mbar 3,5 mm

101 18 - 25 mbar 3,2 mm 18 - 25 mbar 3,3 mm

102 18 - 25 mbar 3,6 mm 18 - 25 mbar 3,1 mm

201 18 - 25 mbar 3,7 mm 18 - 25 mbar 3,3 mm 18 - 25 mbar 3,2 mm

202 18 - 25 mbar

61 18 - 25 mbar

62 18 - 25 mbar 4,1 mm 18 - 25 mbar 4,3 mm

101 18 - 25 mbar 3,8 mm 18 - 25 mbar 3,8 mm

102 18 - 25 mbar 5,5 mm 18 - 25 mbar 3,8

201 18 - 25 mbar

202 18 - 25 mbar 4,8 mm 18 - 25 mbar 3,8 mm 18 - 25 mbar 3,8 mm

61 30 - 57 mbar

62 30 - 57

101 30 - 57 mbar 2,4 mm 10,4% 11,6% 8.4% 9,2% 30 - 57 mbar 2,3 mm 10,4% 11,6% 8,2% 9,6%

102 30 - 57 mbar 2,5 mm 10,4% 11,6% 8.9% 10,1% 30 - 57 mbar 2,4 mm 10,4% 11,6% 9,4% 10,3%

201

30 - 57 mbar

202 30 - 57 mbar 2,5 mm 10,4% 11,6% 9.7% 11,0% 30 - 57 mbar 2,3 mm 10,4% 11,6% 9.7% 10,1%

61 30 - 57 mbar

62 30 - 57 mbar

101 30 - 57 mbar 2,4 mm 30 - 57 mbar 2,7 mm

102 30 - 57 mbar 2,6 mm 30 - 57 mbar 2,5 mm

201

30 - 57 mbar

202 30 - 57 mbar

61 18 - 25 mbar 4,2 mm 18 - 25 mbar 3,5 mm

62 18 - 25 mbar 3,7 mm 18 - 25 mbar 3,4 mm

101 18 - 25 mbar 3,1 mm 18 - 25 mbar 3,0 mm

102 18 - 25 mbar 3,3 mm 18

201 18 - 25 mbar

202 18 - 25 mbar 3,5 mm 18 - 25 mbar 3,1 mm

Adjustment of

2

- Screw

CO

4,2 mm

3,7 mm 18 - 25 mbar 3,2 mm 18 - 25 mbar 3,2 mm

4,8 mm

5,1 mm 18 - 25 mbar 3,9 mm 18 - 25 mbar 3,9 mm

mbar 2,4 mm 10,4% 11,6% 8.5% 9,2% 30 - 57 mbar

2,5 mm

2,5 mm 10,4% 11,6% 8.8% 9,8% 30 - 57 mbar 2,4 mm 10,4% 11,6% 8,8% 9,6%

2,9 mm

2,5 mm 30 - 57 mbar 2,5 mm

2,6 mm 30 - 57 mbar 2,4 mm

2,5 mm 30 - 57 mbar 2,3 mm

3,4 mm

2

at "MAX" rpm

± 0,2%

9,4%

9,4%

9,4%

9,4%

9,4%

9,5%

9,3%

9,3%

9,3%

9,3%

9,3%

9,4%

3B/P

10,4% 11,6% 9.3% 10,6% 30 - 57 mbar

100%

Butane

11,1%

11,1%

11,1%

11,1%

11,1%

11,1%

9,5%

9,5%

9,5%

9,5%

9,5%

9,5%

CO2

at "Min" rpm

- 0,2% / + 0,5%

8,0%

7,9%

7,7%

8,4%

8,2%

8,8%

8,2%

7,8%

7,8%

8,0%

9,0%

8,9%

3B/P

100%

Butane

9,4%

8,9%

9,3%

9,7%

9,6%

10,7%

8,6%

7,8%

8,0%

8,5%

8,4%

9,1%

Input gas flow

pressure

18 - 25 mbar

18 - 25 mbar

30 - 57 mbar

- 25 mbar 3,1 mm

18 - 25 mbar

Adjustment of

CO

2

- Screw

3,6 mm

4,6 mm

mm

2,3 mm

2,4 mm 10,4% 11,6% 8,1% 9,6%

2,5 mm

3,1 mm 18 - 25 mbar 3,1 mm

2

at "MAX" rpm

± 0,2%

9,4%

9,4%

9,4%

9,4%

9,4%

9,4%

9,3%

9,3%

9,3%

9,3%

9,3%

9,3%

3B/P

10,4% 11,6% 9,4% 10,4%

100%

Butane

11,1%

11,1%

11,1%

11,1%

11,1%

11,1%

9,5%

9,5%

9,5%

9,5%

9,5%

9,5%

CO2

at "Min" rpm

- 0,2% / + 0,5%

8,3%

8,0%

7,7%

8,6%

7,8%

8,7%

8,0%

7,7%

7,8%

8,3%

7,8%

8,6%

3B/P

100%

Butane

9,8%

9,2%

9,7%

9,9%

9,1%

10,0%

8,4%

8,0%

8,2%

8,5%

8,2%

8,8%

Input gas flow

pressure

30 - 57 mbar

30 - 57

mbar

30

- 57 mbar

30 - 57 mbar

18 - 25 mbar

Adjustment of

2

- Screw

CO

2,4 mm 10,4% 11,6% 8,8% 9,6%

2,3 mm 10,4% 11,6% 9.7% 10,1%

2,4 mm

2,3 mm

3,1 mm

CO

2

at "MAX" rpm

± 0,2%

9,4%

9,4%

9,3%

9,3%

3B/P

100%

Butane

11,1%

11,1%

9,5%

9,5%

CO2

at "Min" rpm

- 0,2% / + 0,5%

7,8%

8,7%

7,8%

8,6%

3B/P

100%

Butane

9,0%

10,1%

8,2%

8,8%

Burner adjustment

Check the gas type adjustment at "Basic Settings".

How to carry

out a burner

adjustment:

1.

2.) Check the given length of the CO2 screw. See correct values from table above.

3.) Check gas input flow pressure. See correct values from table above.

4.) Select "Gas Steam Blower" at "Function Test". Exhaust temperature should be during the "gas flow analysis" above 200°C.

out first a CO2"Max" adjustment.

Carr

Setting of exhaust values only by CO

Carry out the CO

2

"Min" measurement. At CO2"Min" measurement no adjustment necessary on the CO2 screw => ! ! ! Check only the CO2 values ! ! ! !

2

screw adjustment. CO2 = see table above, CO = below 300ppm, if possible below 100ppm.

Repeat same measurements at "Gas Hot Air Blower Top" and "Gas Hot Air Blower Bottom (201-202)".

2

5.) Recommendation: Note down all actual values (mm, CO

, CO) inside the unit. This will help your fellow technician in fault finding!

Page 39

SCC Control Panel

Notes:

S

S

C

C

-39-

Page 40

1

2

3

4

1

2

3

4

1

2

3

4

Display up to Software version SCC 01-07-12

S

SelfCooking Control

Mode - Level 1

SelfCooking Control

Mode - Level 2

SelfCooking Control

Mode - Level 3

S

C

C

Universal

roasting

Soft

roasting

Overnight

roasting

Back to previous level help guide line for selected setting

CleanJet, HACCP, Delta T, E1/2 Store selected setting

Start time, CDS, Descaling, Settings

Selection of core temperature Searing

Roasting with

crackling

Soft

cooking

Overnight

cooking

Overnight

roasting

Low

rare

preheat

High

well

done

Notes:

-40-

Page 41

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

Display up to Software version SCC 01-07-12

Combi Steamer Mode Functions Settings

am/pm

24 h

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

200°C

CleanJet

HACCP

Start time

10:24

08/22/03

22.08.03

h:m

m:s

°C / °F

S

S

C

C

Duration

Setting of Humidity

Setting of cabinet

temperature

Setting of time

Setting of

core temperature

Moistening

Setting of

fan speed

Cool Down

CDS

Settings

Setting of : time, Date,

time format, °C/°F etc.

Delta -T cooking

1/2 Energy

HACCP Protokol

HACCP

Telephone Chef-Line

Service

english

Prog

am/pm

Setting of time format

24 h

h:m

Setting of time laps

m:s

08/22/03

Setting of date format

22.08.03

Setting of °C/°F

°C / °F

Setting of language

english

default 12345, SU: ttreu

Prog

Setting of buzzer sound

Setting of display intensity

Setting of CleanJet prompting

(only active when frame is red)

Service Typ

Service Info No: E11SE0503200......... Service Info: Display of

pending service faults

Descaling SW: SCC - 01 - 07 - 08

Info

Mod: SCC_101

English

Typ

empty steam generator humidity emergency control active

(Door must be open!)

humidity emergency control was active since last switch ON

Typ

Display Software version (will not be displayed when in „dry heat mode“)

Download of service data to stick.Set DIP-switch 1 to “on” (=activation of diagnostic program).

Info

Afterwards touch function key and then service key.

-41-

Page 42

1

2

3

4

1

2

3

4

1

2

3

4

Display since Software version SCC 02-01-01

S

SelfCooking Control

Mode - Level 1

SelfCooking Control

Mode - Level 2

S

C

C

roast braise

roast with

crackling

overnight

roasting

13:45

Large roast Potato product

13:45

gentle

roasting

gentle

cooking

SelfCooking Control

Mode - Level 3

overnight

roasting

medium

close

door

62°C

Pan fries Egg dishes/Desserts

Poultry Bakery products

Fish Finishing

Side dishes Help: guide line for selected set

ting;practical hints for product to be used in the respective

SCC cooking process

Back to previous level

CleanJet, HACCP, Delta T, E1/2 Store selected setting

Start time, CDS, Descaling, Settings

Selection of core temperature Searing

Notes:

-42-

Page 43

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

Display since Software version SCC 02-01-01

Combi Steamer Mode Functions Settings

am/pm

24 h

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

CleanJet

10:24

h:m

m:s

S

S

C

200°C

Duration

Setting of Humidity

Setting of cabinet

temperature

Setting of time

Setting of

core temperature

Moistening

Setting of fan speed

(lowest level=intermittent)

Cool Down

Service key

(after setting dip switch #1)

settings

CleanJet

start time

CleanJet programs

Function level

Delta -T cooking

1/2 Energy

Telephone Chef-Line

delete all programs, program lock, buzzer setting,

time setting

Data download (upload):

Customer programs

HACCP

Service data

10/22/06

22.10.06

english

°C / °F

IP

am/pm

Setting of time format

24 h

h:m

Setting of time laps

m:s

08/22/03

Setting of date format

22.08.03

Setting of °C/°F

°C /

°F

english

Setting of language

reset to factory setting

english, °C, buzzer perm.,

buzzer,

Setting of buzzer sound

Setting of display intensity

C

Service Typ

Service Info No: E11SE0503200......... Service Info: Display of

pending service faults

Descaling SW: SCC - 01 - 07 - 08 Scale level of steam gen.

Mod: SCC_101

CDS

English

Typ

empty steam generator humidity emergency control active

(Door must be open!)

humidity emergency control was active since last switch ON

Typ

Display Software version (will not be displayed when in „dry heat mode“)

Download of service data to stick.

Info

-43-

CDS

Page 44

S

1

2

3

4

1

2

3

4

Display Programming / CleanJet SCC 02-01-01

Prog

select program name with central dial

S

C

C

new

copy

delete

Clean manual

level

control

change

new

copy

change

delete

level

control

give program name

(blank - between _ and @

existing SCC process or program can be

copied and get an index number, i.e. 1;

name can be edited and changed;

Change parameter and / or cooking mode of

program in a non-active program;

con rm change by:

selected program ashes; con rm delete by

pressing again

1. Give program name

2. Store

3. select mode, temperature, time (in minutes

and seconds) or core temperature,

4. Second program with identical mode and

temperature, but different time can be stored

and selected alternating after pre-heating;

rinse

without tabs

Rinse with water only; cabinet will be dried out;

CleanJet

rinse

interim

cleaning

rinse

without tabs

interim

cleaning

medium

CleanJet

rinse

light

strong

light

medium

strong

Rinse with 1 rinse tab for cleaning after steaming

Rinse with 1 cleaner tab for cleaning in between

cooking cycles; no drying of cabinet;

Cleaning of light soiling with drying of cabinet

Cleaning of medium soiling with drying of cabinet

Cleaning of strong soiling with drying of cabinet

Note:

Reduce number of detergent tabs when too much

foam is visible;

Check direction of water jet inside cabinet when

timer is counting up;

-44-

Page 45

Notes:

S

S

C

C

-45-

Page 46

S

Y

S

S2

SCC Electric from 04-2004

M3

S4

B1

F4

B6

C

C

B5

F3

M4

S11

1

Y3

Y2

B2

M7

S12

P1

M1

B4

S3

M6

B1 Thermocouple interior cabinet

B2 Thermocouple quenching

B4 Thermocouple humidity

B5 Thermocouple steam generator (preheat, 180°C (356°F) max)

B6-B11 Thermocouples core temperature

F3 Safety thermostat steam generator 160°C (320°F)

F4 Safety thermostat interior cabinet 360°C (680°F)

Y1 Solenoid valve lling

Y2 Solenoid valve quenching

Y3 Solenoid valve moistening

M1 Fan motor bottom

M3 Humidity ap motor

M4 SC-pump

M6 CleanJet pump

M7 Motor drain valve / ball valve

S2 Level electrode

S4 Micro switch humidity motor

S11 CDS sensor

S12 Micro switch drain valve

P1 Pressure sensor humidity

SCC 201/202 only:

M2 Fan motor top with jumper ( oor units only)

-46-

Page 47

Notes:

S

S

C

C

-47-

Page 48

S

S

C

C

X 7X 8

A2 SCC pcb

X 12

X 11

X 5X 2X 6X 4

A3 Add On pcb

Battery

3V

SCC Operator pcb (42.00.002)

X7 200 - 240V input to I/0 Switch

11

1

1

X 3

X 1

1

X 50

ON

X8 Buzzer

X12 Level electrode

X11 Humidity ap motor / Micro switch

Add on X1 P1 pressure sensor

Add on X2 B6-11 thermocouples

core temperature

Add on X3 B1 thermocouple interior cabinet

Add on X4 B2 thermocouple quenching

Add on X5 B4 thermocouple humidity

Add on X6 B5 thermocouple steam generator

Add on X50 External EEPROM

Add on X51 BUS interface

and power supply for cpu from I/O pcb

Add on X52 RS232 interface

Add on X53 USB interface (only until 11/2005)

Add on X54 USB interface

Add on X09 Central dial

LED

1 2 3

X 51

X 53

X 54

X 52

RS 232

X 2

Note: LED code: SCC PCB

Green LED on - ok;

Red LED blinks 1x during re-booting when switching on - ok

Green LED - off: Bus cable defective; CPU defective; I/O pcb or transformer defective

Red LED on: CPU defective

X 09

X 10

1

(X10 indicated as X1 on pcb layout)

X2 Free

1

Counting sequence

X10 Power suply for display 2,5 - 0 - 2,5V

Red LED doesn‘t blink during re-booting when switching on - CPU defective

-48-

Page 49

I/O PCB SCC (40.00.049)

Wires of pcb edge connectors are pointing to component side of pcb!

X6.1

X 24.1

6

X 23.1

5

2A T

X 21.1

4

K1:L1

F2: N

X 20.1

2A T

230 V

3

X 19.1

N

2

X 18.1

230 V

1

230 V

A1

A1

A1

M4

M

~

M6

M

~

SSR2: B-

SSR2: A-

SSR1: B-

SSR1: A-

+ 12V

N

A2

Y1

Y1

230 V

A2

Y2

Y2

230 V

A2

Y3

Y3

230 V

LED 1

LED 2

12 V DC

BUS

12 V DC

+

M7

M

H1

BUS

_

OUT

12 V AC

11,5 V AC

GND

CDS-HALL

11,5 V

AC

34

16 V DC

S12

S3

IN

2

X 25.1

12 V DC

1

ON

12 V DC

X 14.1

X 13.1

X 26.1

X 27.1

X 15.1

X 17.1

X 16.1

T1

S

S

C

C

10

11

12

13

14

15

16 16

7 8 9

1: SC-pump M4, Cleanjet pump M6

2: Solenoid vales Y1-filling, Y2 - quenching, Y3 - moistening

3. Energy optimizing plug with link on 5-6 used only on I/O pcb with 6 relais card!

Please refer to Technical Info 16-2005

4. 230V input

5 Connection to Ultravent (used for Ultravent without BUS connection only)

6. free

7. Output 12VDC to SSR

8. Output 12VDC to M7 drain valve, S12 micro switch drain valve

9. SSR pulsing (US-CAN version only)

10. Output 12VDC to door contact

11. Input from Control transformer T1, 11.5V interior light, 12V CPU,

12. Output 11.5VAC to interior cabinet light

13. Output 12VDC to CDS sensor

14. free

15. free

16. BUS connection

LED code: I/O PCB

Green LED on - ok;

Yellow LED blinks during re-booting but is off during operation - ok

Yellow LED blinks always: Set DIP switches to OFF position; Bus cable defective;

Green LED off: I/O pcb defective; transformer defective

-49-

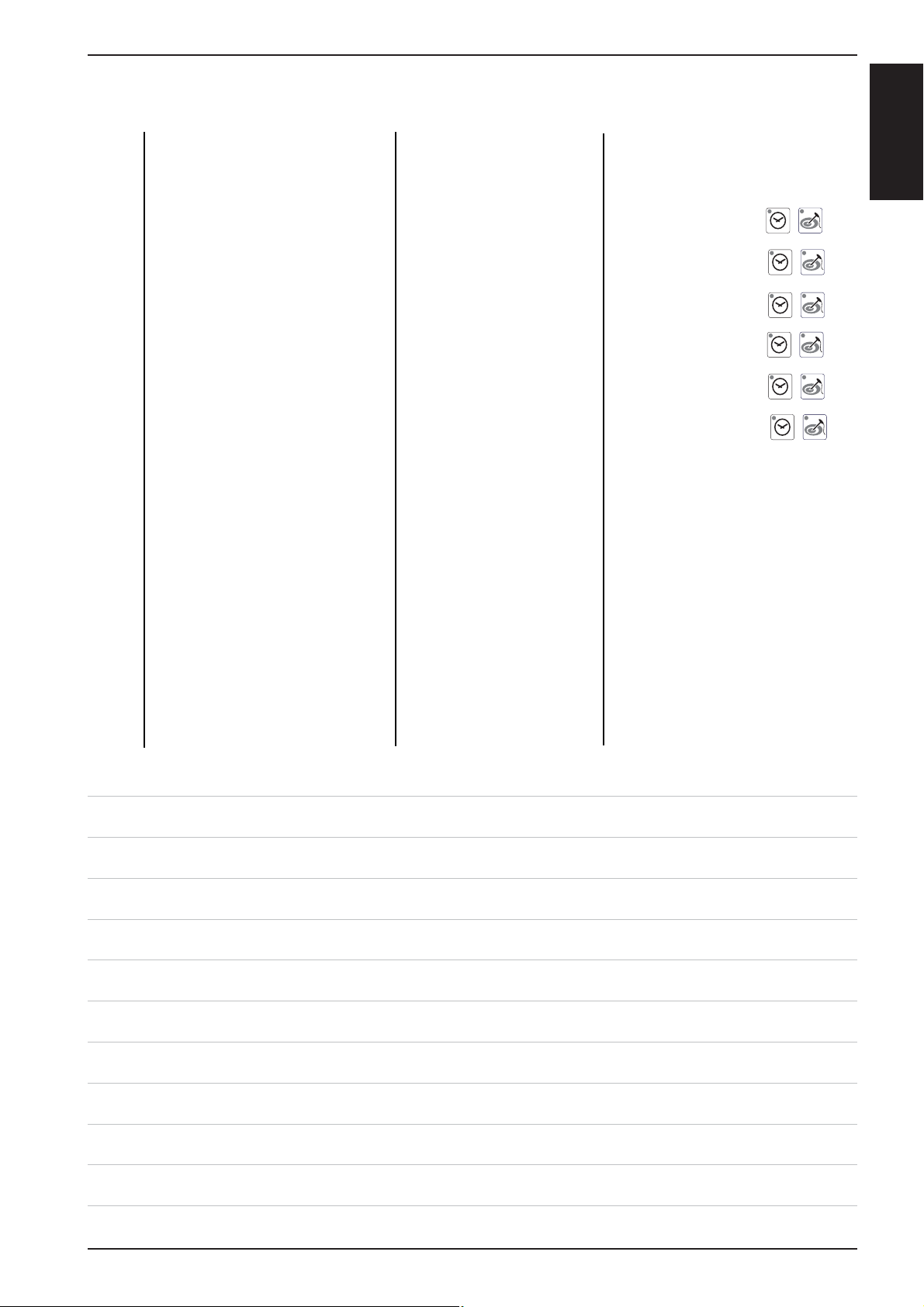

Page 50

S

Motor for CM 40.00.274

S

LED

Jumper

C

C

Jumper 40.01.581 is used on oor model 201 and 202 for top position motor only!

Jumper is not used on models 61 - 102 with one motor only! (Service 34 will be shown!)

LED code fan motor SCC and CM from 04/2004

Reason

1x Motor doesn’t start, no changing

signal from hallsensor

2x Voltage too low on motor pcb

Remedy

Check for motor blockage or change motor.

Check supply voltage or

change motor.

3x Voltage too high on motor pcb

4x rpm measurement defective

5x Motor pcb temperature >105°C

6x Supply voltage <80V

7x Motor pcb defective

8x Motor pcb defective

Check supply voltage or

change motor.

Change motor.

Check cooling system (cooling fan, air intake

filter), otherwise change motor

Check power supply

(F1-F2)

Change motor.

Change motor.

-50-

Page 51

Humidity control SCC

The calculated humidity inside the cabinet is based on:

1. RPM signal of the fan motor (via BUS signal)

2. Temperature B4 (thermocouple behind motor mounting plate)

3. Voltage output signal P1 (depending on fan motor speed and humidity)

Die Offsetspannung P1 (Motor im Stillstand) liegt bei ca. 0.45 - 0.55V

RPM

Bus

B4

Humidity triangle

P1

S

S

C

C

B4

Basic rule:

Voltage output of P1 is high when cabinet clima is dry;

Voltage output of P1 is high when main fan speed is high;

Example: SCC 101 E

RPM P1 (ca Volt) Clima FA (ca value in Pascal)

(given values only as example)

Dry 1,1 102099

Calibration speed 500rpm Wet 0,7 106344

Combi 0,6 118160

Dry 2.3 102174

Calibration speed 1250rpm Wet 1.7 102131

Combi 1.5 108239

Dry 2.9 102679

Calibration speed 1800rpm Wet 2.4 103263

Combi 1.9 106705

P1

Dry 3,1 103077

Calibration speed 1900rpm Wet 2.5 102907

Combi 2.2 106222

-51-

Page 52

Notes:

S

S

C

C

-52-

Page 53

Y

SCC - Sequence of events

SCC mode: Wet Heat

98-103°C (208-218°F)

S2

set temperature

M3

S4

B1

F4

B6

S

S

C

B5

F3

M4

S11

Y3

1

B2

Y2

S12

M7

P1

M1

B4

S3

M6

Function step Responsible sensor

1. Select Wet heat (Temp 98-103°C (208-218°F))

2. Select time or core temperature

3. Close cabinet door Reed switch S3

C

4. Check water level inside steam generator Level electrode S2 inside Steam Gen.

5. Preheat steam generator,; Thermocouple B5 inside Steam Gen.

if B5 is below 85°C (185°F)

6. Timer starts after successful preheating Logic on PCB

7. Steam production up to saturation in cabinet Pressure sensor P1, Thermocouple B4

rpm motor via BUS

8. Adding of Hot Air from 70°C (158°F) Cabinet sensor B1

possible, if 70% humidity reached

9. Quenching (set to 70°C/158°F) Thermocouple B2

Additional functions possible: 4 Fan speeds (Standard = Level 4), pulsed fan wheel, ½ Energy,

HACCP output, ¨T

Note:

Steam heating only active when humidity ap (S4) is in closed position!

Steam saturation means: temperature of B2 ~ B1

-53-

Page 54

S

Y

SCC - Sequence of events

SCC mode: Low temperature steam;

(30-97°C (85-207°F), set temperature)

S

C

C

B1

F4

B6

M3

S4

S2

B5

F3

P1

M1

M4

S11

Y3

1

B2

Y2

S12

M7

B4

S3

M6

Function step Responsible sensor

1. Select Wet heat (Temp 30-97°C (85-207°F))

2. Select time or core temperature

3. Close cabinet door Reed switch S3

4. Check water level inside steam generator Level electrode S2 inside Steam Gen.

5. Preheat steam generator,; Thermocouple B5 inside Steam Gen.

if B5 is below 85°C (185°F)

6. Timer starts after successful preheating Logic on PCB

7. Steam supply until set temperature inside Cabinet sensor B1

cabinet is reached

8. Adding of Hot Air from 93°C (200°F) Cabinet sensor B1

possible (only 50%)

9. Quenching (set to 70°C/158°F) Thermocouple B2

Additional functions possible: 4 Fan speeds (Standard = Level 4), pulsed fan wheel, ½ Energy,

HACCP output, ¨T

Note:

Steam heating only active when humidity ap (S4) is in closed position!

Below 98°C fan at lowest speed when no energy required for longer than 2 minutes.

-54-

Page 55

Y

SCC - Sequence of events

SCC mode: Forced Steam

104-130°C (219-266°F), set temperature

S2

B1

F4

B6

M3

S4

S

S

C

B5

F3

P1

M1

C

M4

S11

Y3

1

B2

Y2

S12

M7

B4

S3

M6

Function step Responsible sensor

1. Select Wet heat

(Temp 104-130°C (219-266°F))

2. Select time or core temperature

3. Close cabinet door Reed switch S3

4. Check water level inside steam generator Level electrode S2 inside Steam Gen.

5. Preheat steam generator,; Thermocouple B5 inside Steam Gen.

if B5 is below 85°C (185°F)

6. Timer starts after successful preheating Logic on PCB

7. Steam supply until set temperature inside Pressure sensor P1, Thermocouple B4

cabinet is reached rpm motor via BUS

8. Adding of Hot Air if 85% humidity reached Cabinet sensor B1

9. Quenching (set to 70°C/158°F) Thermocouple B2

Additional functions possible: 4 Fan speeds (Standard = Level 4), pulsed fan wheel, ½ Energy,

HACCP output, ¨T

Note:

Steam heating only active when humidity ap (S4) is in closed position!

-55-

Page 56

S

Y

SCC - Sequence of events

SCC mode: Mode: Combi Steam

141-300°C (286-572°F), set temperature

S

C

C

B1

F4

B6

M3

S4

S2

B5

F3

P1

M1

M4

S11

Y3

1

B2

Y2

S12

M7

B4

S3

M6

Function step Responsible sensor

1. Select Wet heat and Dry heat

141-300°C (286-572°F), set temperature

2. Select time or core temperature

3. Close cabinet door Reed switch S3

4. Check water level inside steam generator Level electrode S2 inside Steam Gen.

5. Preheat steam generator,; Thermocouple B5 inside Steam Gen.

if B5 is below 85°C (185°F)

6. Timer starts after successful preheating Logic on PCB

7. Heat up cabinet with Hot Air until set temperature. Cabinet sensor B1

is reached

Priority Hot Air

8. Adding of steam up to set steam saturation Pressure sensor P1, Thermocouple B4

rpm motor via BUS

9. Quenching (set to 70°C/158°F) Thermocouple B2

Additional functions possible: 4 Fan speeds (Standard = Level 4), pulsed fan wheel, ½ Energy,

HACCP output, ¨T

Note:

Steam heating only active when humidity ap (S4) is in closed position!

-56-

Page 57

Y

SCC - Sequence of events

SCC mode: Finishing

(30°-140°C (85-284°F)

S2

, set temperature

B1

F4

B6

M3

S4

S

S

C

B5

F3

P1

M1

C

M4

S11

Y3

1

B2

Y2

S12

M7

B4

S3

M6

Function step Responsible sensor

1. Select Wet and Dry heat

(Temp. 30-140°C, 85-284°F)

2. Select time or core temperature

3. Close cabinet door Reed switch S3

4. Check water level inside steam generator Level electrode S2 inside Steam Gen.

5. Preheat steam generator,; Thermocouple B5 inside Steam Gen.

if B5 is below 85°C (185°F)

6. Timer starts after successful preheating Logic on PCB

7. Steam supply up to set humidity Pressure sensor P1, Thermocouple B4

Electric: 8sec on / off rpm motor via BUS

Gas: 20 sec on / off

8. Hot air supply up to set temperature Cabinet sensor B1

Electric: 8sec on / off

Gas: 20 sec on / off

9. Quenching (set to 70°C/158°F) Thermocouple B2