Rational SCC Line Training Manual

-1-

Training Manual

Diagnostic and Troubleshooting

SCC Line

SelfCooking Center - Combi Master

Edition 11-2006

-2-

Training Manual

Diagnostic and Troubleshooting

SCC Line

Edition 11-2006

General hints:

Isolate the appliance from mains supply

before opening the appliance

When working with chemicals, i.e. aggressive cleaning materials

always wear protective clothing, goggles and gloves!

After maintenance / repair the appliance must be checked for electric safety

in accordance with your national, state and local requirements!

Whenever working on any gas component like:Gas valve, gas blower

and / or changing connected type of gas a detailed

fl ue gas analysis MUST be done using adequate

CO and CO2 measuring equipment!

This shall ONLY be done by trained technicians!

Always check appliance for possible gas leakages!

Part 1: Topic: CM technique Page:

1. CM Overlay

2. CM Principle

3. CM Water level control

4. CM Steam control

5. CM Key code

6. CM PCB

7. CM Main fan Motor

8. CM Sequence of events

9. CM Service level

10. CM Diagnostic

11. CM Running times

12. CM Basic settings

13. CM Function test

14. CM Error history

15. CM Failure code

16. CM Gas principle

17. CM Gas components

18. CM Burner sequence of events

19. CM Gas Conversion

20. CM Gas changing installation altitude

21. CM Gas Flue gas analysis

22. CM Gas adjustment table

23. CM Gas Changing gas blower speed

04

05

06

07

08 - 09

10

11

12 - 16

17

18

19

20 - 21

22 - 23

24

25

26

27

28

29

30

31 - 32

33

34

-3-

Part 2: Topic: SCC Technique Page:

1. SCC Overlay

2. SCC Self Cooking Control until software 01-07-12

3. SCC Combi Steamer mode until software 01-07-12

4. SCC Self Cooking Control since software 02-01-01

5. SCC Combi Steamer mode since software 02-01-01

6. SCC Programming, CleanJet

4. SCC Principle

5. SCC Operator PCB; LED code;

6. SCC I/O PCB; LED Code

7. SCC Main fan Motor; LED code

7. SCC Sequence of events (cooking modes)

8. SCC Service level

9. SCC Diagnostic mode overview

10. SCC Diagnostic mode

11. SCC Running times overview

12. SCC Running times

13. SCC Basic settings overview

14. SCC Basic settings

15. SCC Function test overview

16. SCC Function test

17. SCC Overview Service messages / intermittent buzzer code

17. SCC Service messages

18. SCC Calibration

19. SCC Drain valve

20. SCC Gas principle

21. SCC Gas technique

22. SCC Burner sequence of events

23. SCC Gas conversion

24. SCC Gas adjustment of installation altitude

25. SCC Flue gas analysis

26. SCC Gas adjustment table

27. SCC Gas changing gas blower speed

Part 3: Topic: Common topics SCC and CM Page:

1. Software fl ashing SCC

2.

SCC Fault tree „pcb/EEPROM changing; software update“

3. Software fl ashing CM

5. CM Fault tree „Changing pcb/EEPROM, Fault E1“

6.

CM fl ashing via PC

7. Electrical descaling pump

8. Installation Checklist

9. Preventative maintenance list

10. Water Info

Part 4: Fault list SCC and CM

1. Index

2. Fault list SCC

3. Fault list CM

Part 5: Circuit diagram (Training version 3NAC 400V)

SCC - CM Reference sheet

35

36

37

38

39

40

42

44

45

46

48 - 53

54

56

57 - 59

60

61 - 62

64

65 - 67

68

69 - 70

72

73 - 74

76 - 77

78

80

82

83

84

85

86 - 87

88

89

91

92

93 - 94

95

96

98 - 99

100 - 103

104 - 106

108

110

111 - 121

122 - 127

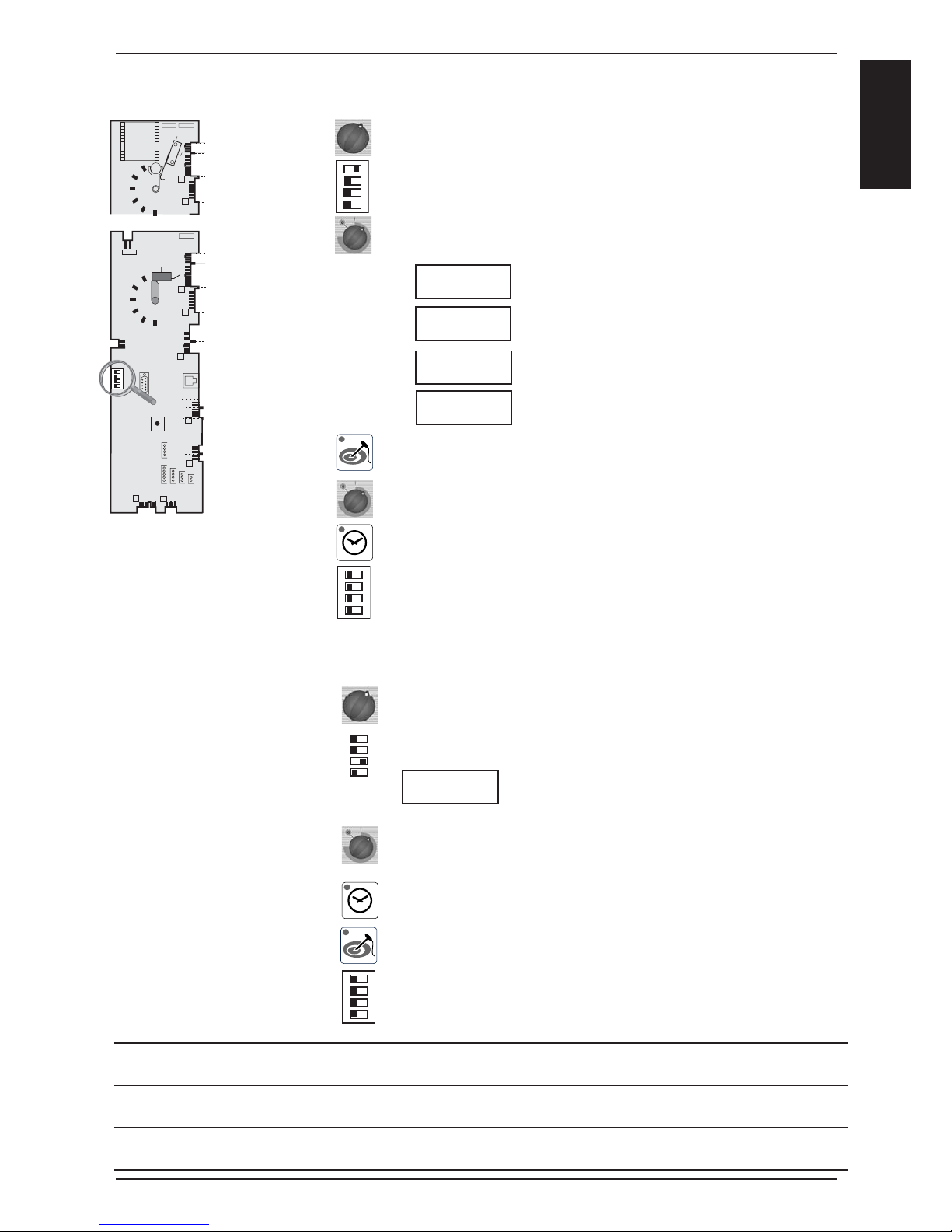

-4-

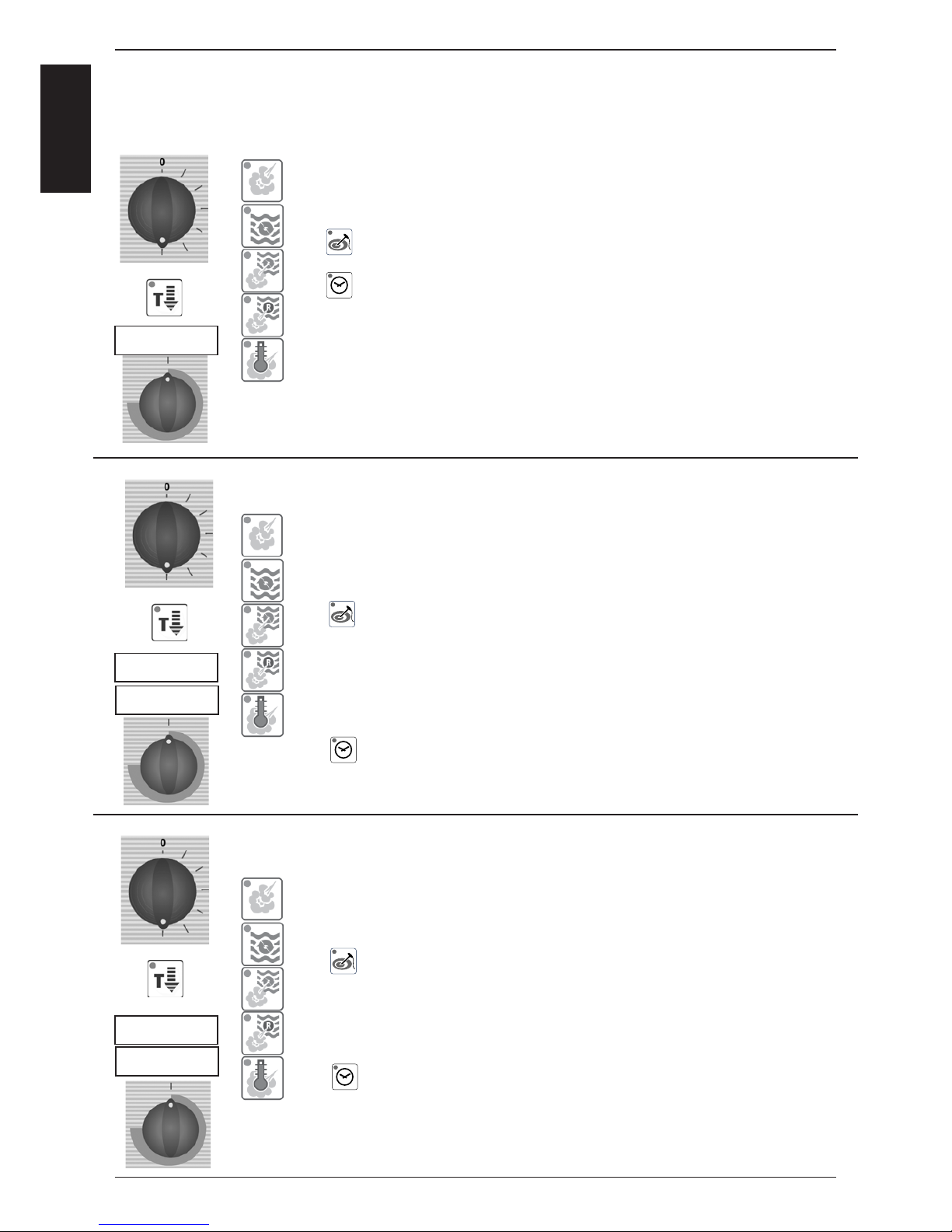

S

C

M

Steam

Hot Air

Combi Steam

Low Temperature Steam

Finishing

Cool Down

Cabinet temperature display

Cabinet temperature setting

Timer

Core temperature

Time - Core temperature display

Time - Core temperature setting

CM Technique from 04 - 2004

-5-

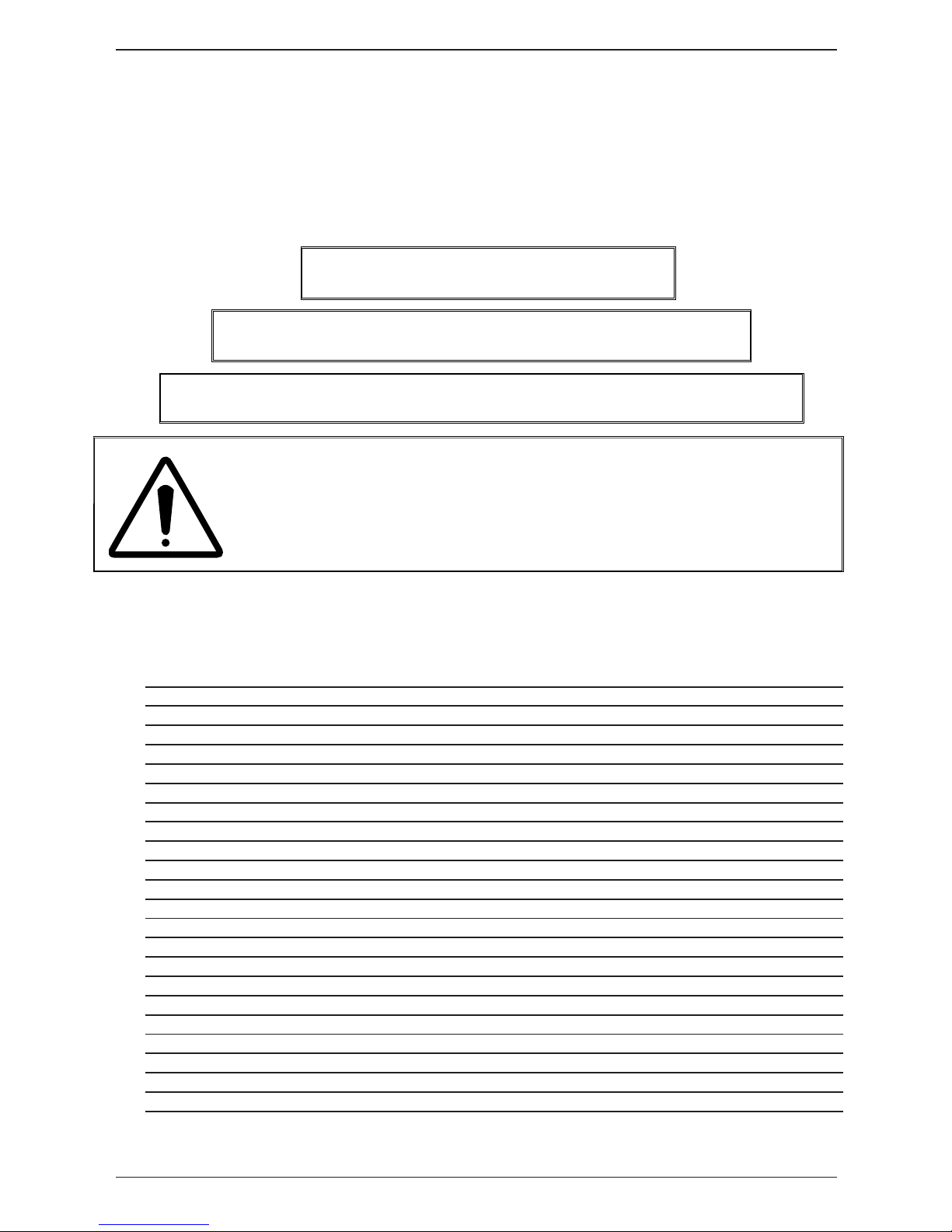

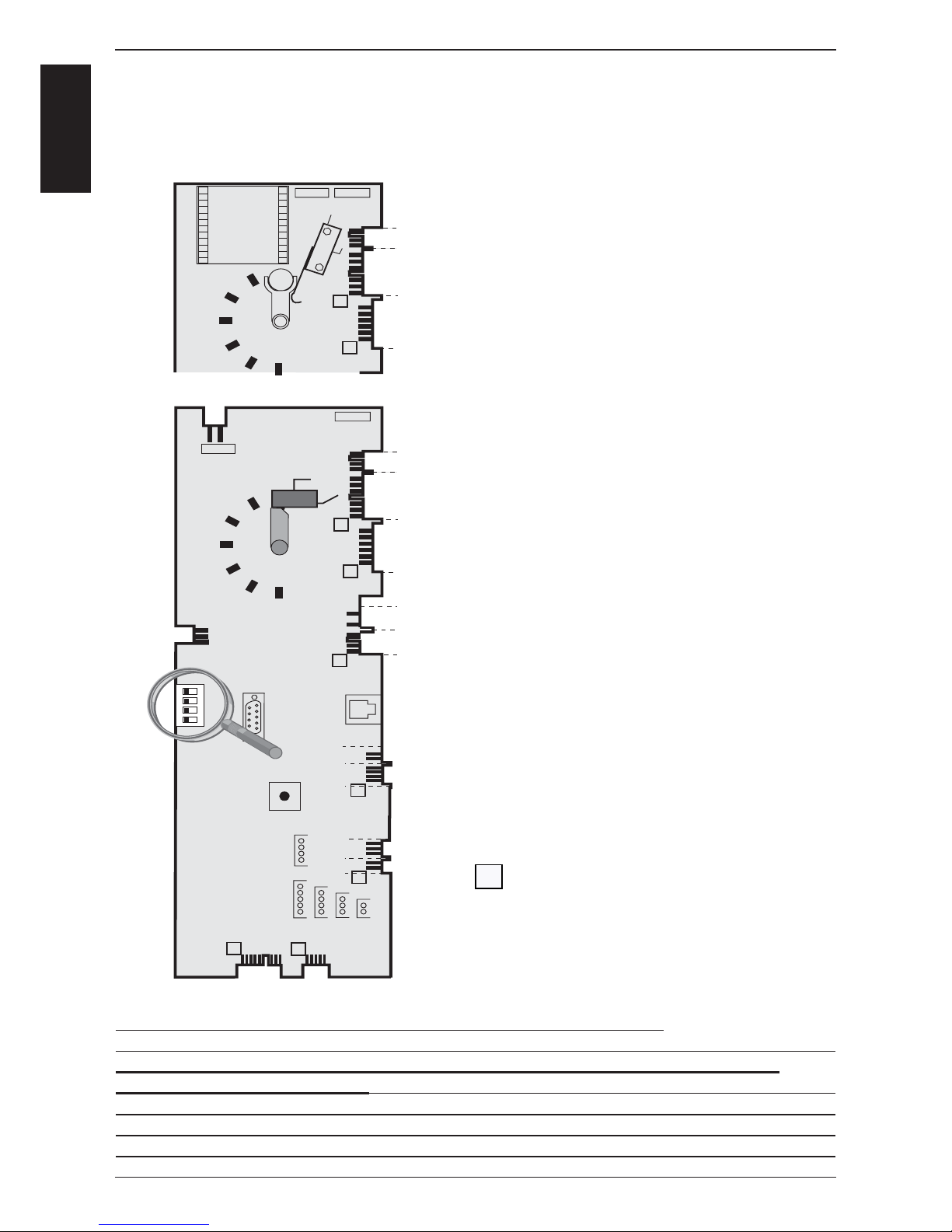

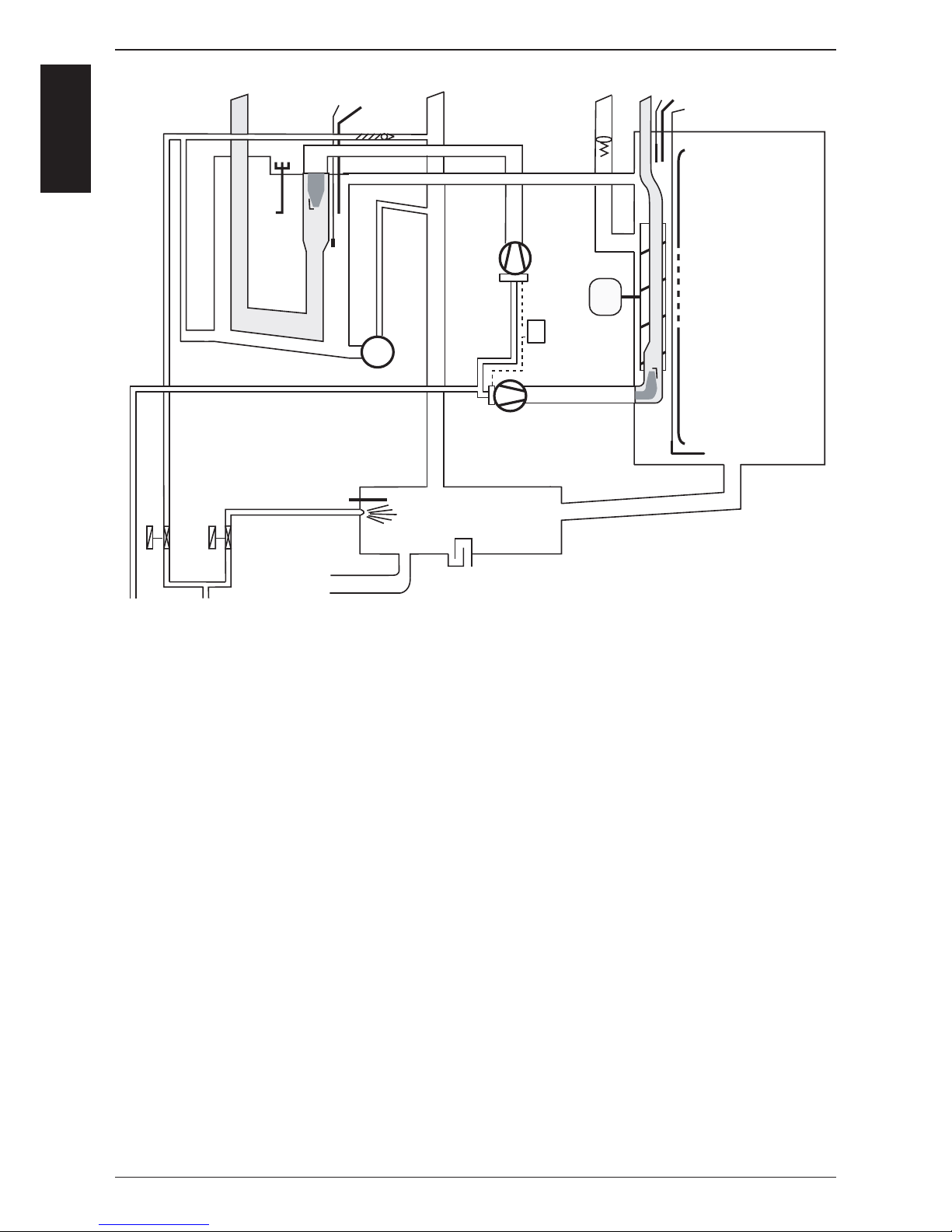

S

C

M

B1

B3

F4

M4

Y1

Y2

B2

M1

S2

B5

F3

CM Technique from 04 - 2004

B1 Thermocouple cabinet

B2 Thermocouple quenching / Steam control

B3 Thermocouple core temperature

B5 Thermocouple steam generator (preheating, 180°C (356°F) max)

F3 Safety temperature limiter steam generator 160°C

F4 Safety temperature limiter cabinet 360°C

Y1 Solenoid valve fi lling

Y2 Solenoid valve quenching

M1 Fan motor (without jumper)

M4 SC-pump

S2 Level electrode

CM 201/202 only:

M2 Fan motor top (with jumper)

-6-

S

C

M

Water level control Steam Generator

V

AC

S2

M4

Y1

Y2

B2

S2

B5

F3

Center S2 ==> Ground: 2 - 6V AC: water level too low

steam heating must switch OFF

solenoid valve fi lling Y1 ON

Center S2 ==> Ground: 0V AC: water level reached

steam heating can switch ON

solenoid valve fi lling Y1 switched OFF

Every 2 minutes steam elements will switch off for water level control

Notes:

X12

-7-

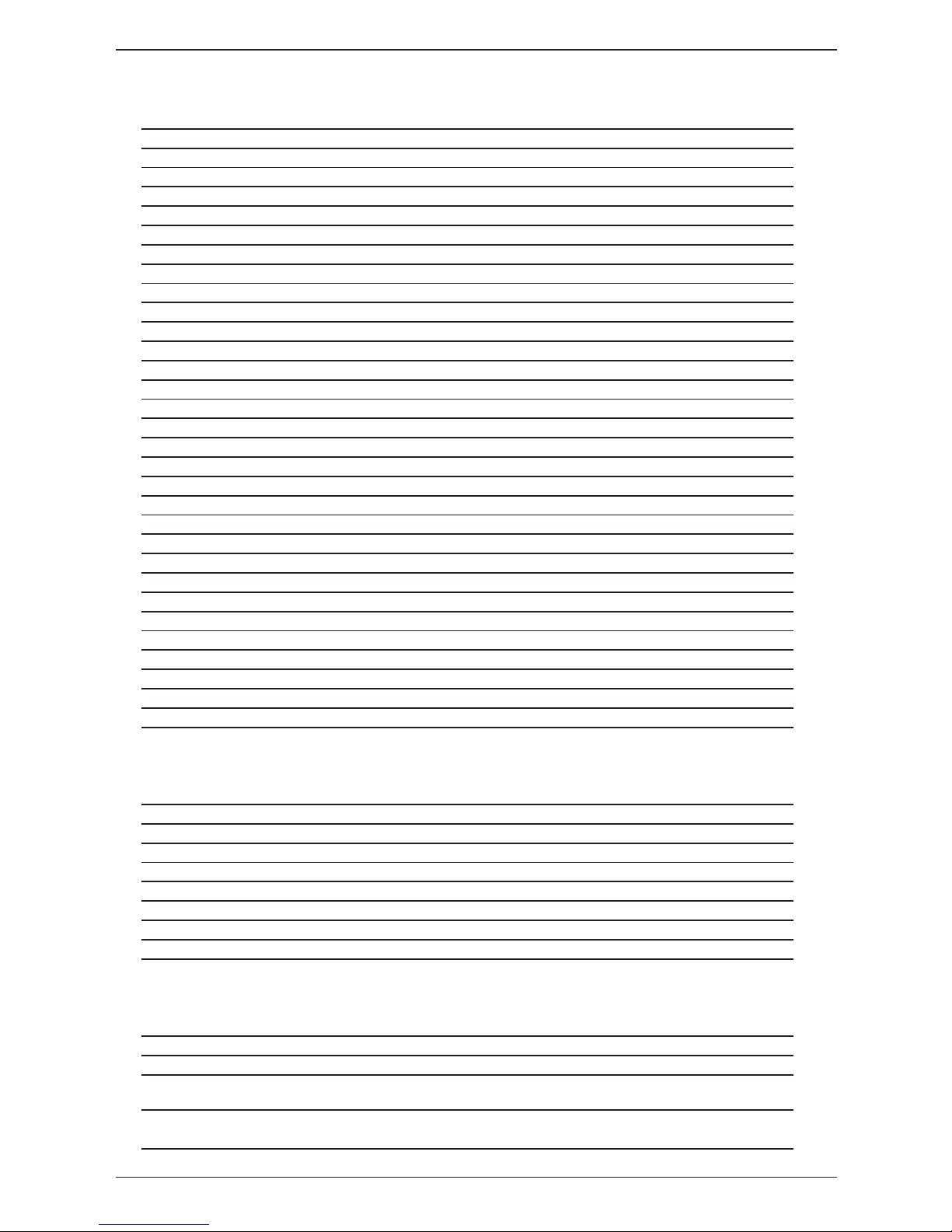

S

C

M

Y1

Y2

B2

B1

°C / °F

t (sec)

B2 - 2

B2 - 1

B1 - 100°C(212°F)

70°C

(158°F)

1. Filling of interior cabinet based on time

and temperature control of B1 cabinet sensor

2. After steam saturation inside cabinet

steam will also fi ll quenching chamber

3. Depending on the frequency of temperature raise of the quenching sensor B2 the

duration of the next steam supply is

calculated.

B2-1: B2 temperature with partial load

B2-2: B2 temperature with full load

4. The amount of steam inside the cabinet is

directly depending on the temperature

variation of quenching sensor B2.

Steam Control CM from 04 - 2004

Intelligent steam control via quenching sensor

Notes:

-8-

S

C

M

Key code CM from 04 - 2004

CLEn

CLEn

CLEn

SC

CALC

A) Cool down cabinet below 60°C

B) Spray inside cabinet with Rational cleaner

C) Close cabinet door

D) Select „Cool Down

E) Press core temperature key for 10 sec.

F) „CLEn“ will show in cabinet temperature display

G) Press timer key 1x; Cleaning program starts automatically

(open cabinet door and rinse interior cabinet after

40 min.)

Close door again. Since Software version C1-06-05

a 10 min step hot air will follow to dry the interior cabinet.)

H) After end of program, leave cabinet door open over night.

This should be done after each installation to verify free drain connection and before disconnection the unit for storage.

A) Open cabinet door

B) Select „Cool Down“

C) Press core temperature key for 10 sec.

D) „CLEn“ will be shown in cabinet temperature display

E) Select „SC“ with temperature dial

F) Close water tap

G) Press timer key 1x and remain on „Cool Down“ position for

about 45 sec.

A) Open cabinet door

B) Select „Cool Down“

C) Press core temperature key for 10 sec.

D) „CLEn“ will be shown in cabinet temperature display

E) Select „CALC“ with temperature dial

F) Press timer key 1x and follow procedure of the

decalcifi cation instruction. (See user manual CM).

1. Cleaning program

2. Empty steam generator

3. Select descaling program

-9-

S

C

M

100°C

212°F

A) Select any mode

C) Press timer and core temperature key

simultaneously for 10 sec. until ==>

D) Display changes from °C to °F or vice versa

E) Release both keys

Key code CM from 04 - 2004

Notes:

4. Changing temperature display from °C to °F

-10-

S

C

M

X7

X19

X20

F1 F2

Transformer

0,1 AT

2 AT

1

1

X7

X19

X20

X18

X23

X31

RS 485

X8

X12

X26

X27

X32X24

X30

RS 232

X63

X3X4X6

X2

X50

2 AT

1

2

3

4

on

off

1

1

1

1

1

1

1

F6.1

F6.1

2 AT

2 AT

X16

X16

F6

F6

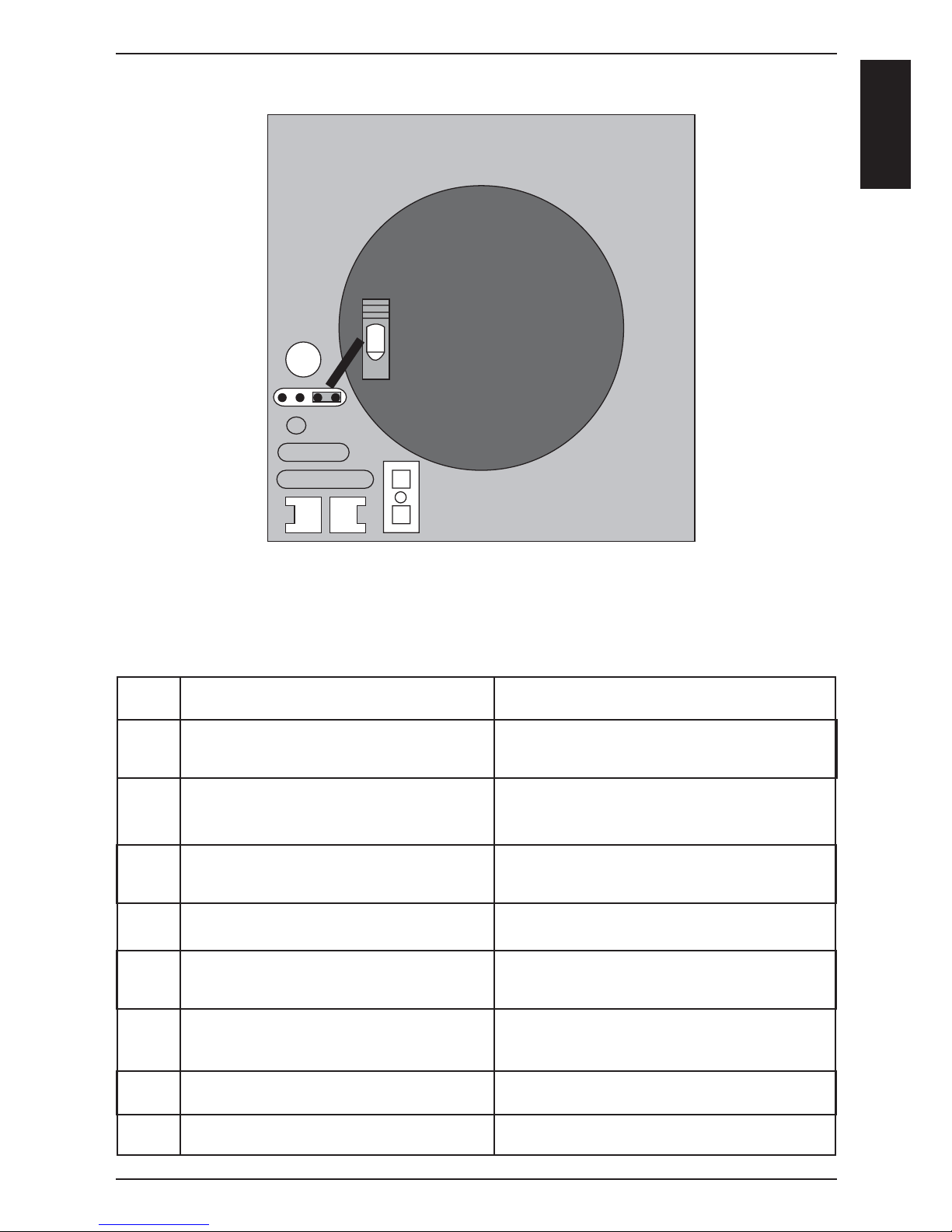

42.00.004

42.00.047

X2 B3 Core temperature

X3 B1 Interior cabinet

X4 B2 Quenching / Steam control

X6 B5 Steam generator

X7 ON - OFF switch

X8 Buzzer

X12 Level electrode

X 16 power supply from transformer (42.00.047)

X18 SC - pump

X19 Solenoid valves

X20 Energy optimising / Sicotronic

X23 Vent hood (signal door open / closed)

X24 SSR

X26 SSR pulsing (USA version only)

X27 Door contact switch

X30 Serial interface (RS232)

X31 BUS interface

X32 Timer / Core Temp. Potentiometer

X50 external EEPROM

X63 Not used

Counting sequence

Notes: Since February 2006 PCB 42.00.004 is replaced by 42.00.047.

(Conversion kit: 87.00.139, pls. see Technical info 04-06)

The transformer on the new PCB 42.00.047 is no more existing and replaced by

external transformer 40.00.227

CM PCB (42.00.004) from 04-2004

1

CM PCB (42.00.047) from 02-2006 (without transformer)

Temperature

potentiometer

-11-

S

C

M

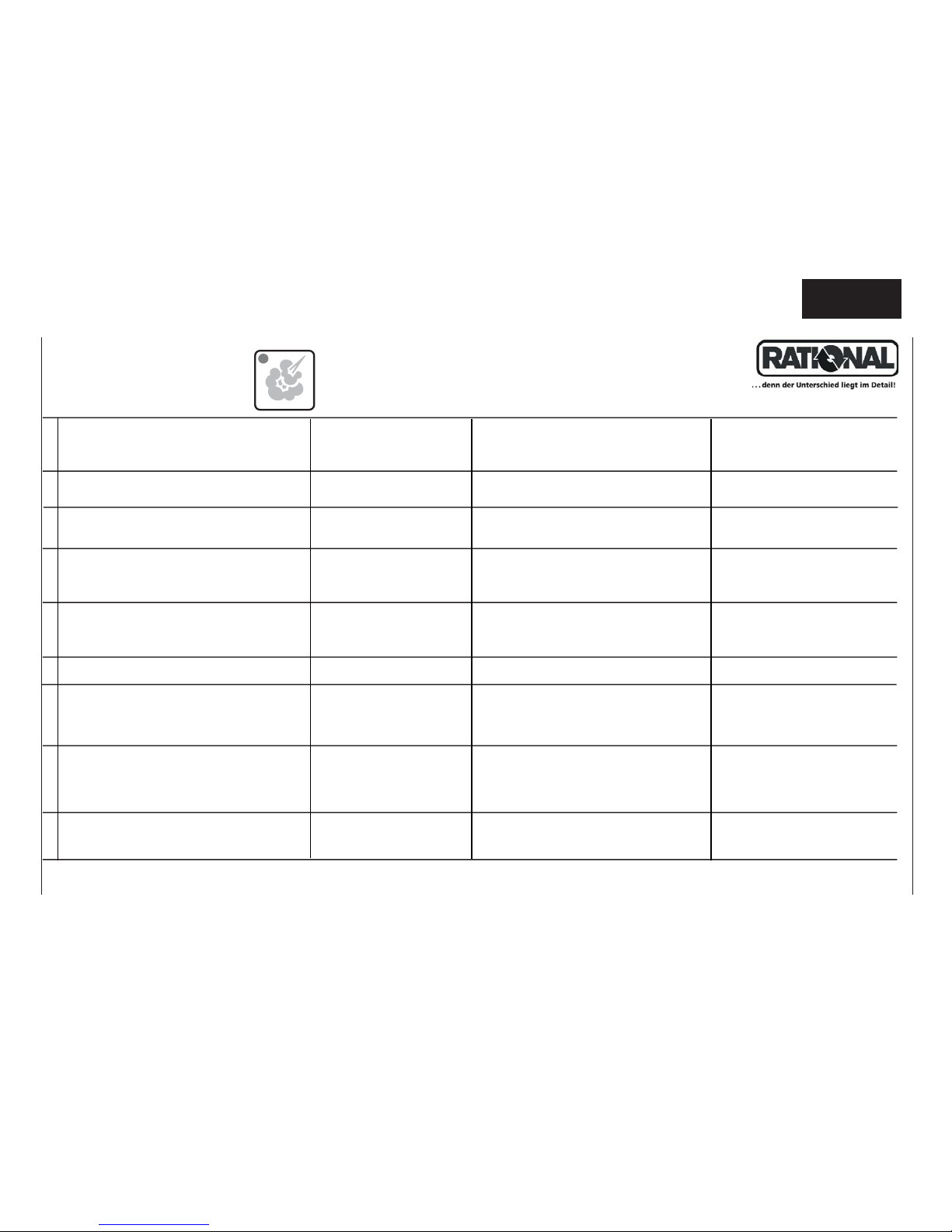

Motor for CM 40.00.274

Jumper 40.01.581 is used on fl oor model 201 and 202 for top position motor only!

Jumper is not used on models 61 - 102 with one motor only! (Service 34 will be shown!)

LED

Jumper

Reason

1x Motor doesn’t start, no changing

signal from hallsensor

2x Voltage too low on motor pcb

3x Voltage too high on motor pcb

4x rpm measurement defective

5x Motor pcb temperature >105°C

6x Supply voltage <80V

7x Motor pcb defective

8x Motor pcb defective

LED code fan motor SCC and CM from 04/2004

Remedy

Check for motor blockage or change motor.

Check supply voltage or

change motor.

Check supply voltage or

change motor.

Change motor.

Check cooling system (cooling fan, air

intake fi lter), otherwise change motor

Check power supply

(F1-F2)

Change motor.

Change motor.

-12-

S

C

M

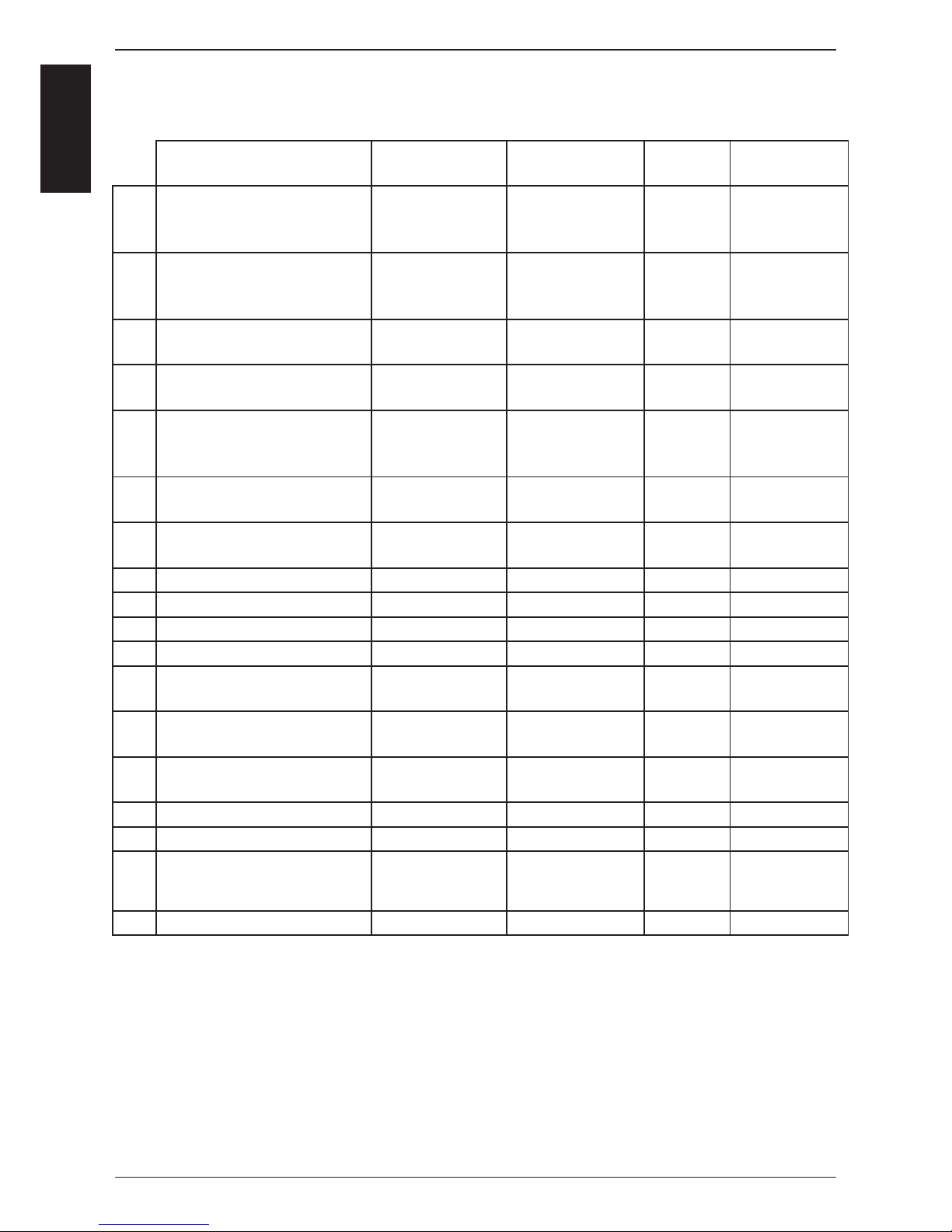

Mode: Steam 100°C (212°F)

Temp. preset, not adjustable

Function Step

Select Steam mode

Select time or core temperature

Close cabinet door

Check water level inside

steam generator

Preheat steam generator,

if B5 is below 85°C (185°F);

Timer starts after successful preheating

Steam supply up to steam saturation

inside cabinet

Hot Air supply (only 50%) when set

temperature (100°C/212°F) can not be

reached in time by Steam alone

Quenching (set to 70°C/158°F)

Responsible sensor

Reed switch S3

Level electrode S2 inside Steam Generator

Thermocouple B5 inside

Steam Generator

Logic on PCB

Quenching sensor B2

(Steam control)

Cabinet sensor B1

Quenching sensor B2

Signal

Door open: 12VDC X27:(1-2)

Door closed: 0VDC X27:(1-2)

X12:(1-4) > 2VAC => no water

X12:(1-4) ~ 0VAC => water

SSR active: 12VDC X24:(1-2)+(5-6)

SSR not act: 0VDC X24:(1-2)+(5-6)

Gas units: Bus signal

SSR active: 12VDC X24:(1-2)+(5-6)

SSR not act.: 0VDC X24:(1-2)+(5-6)

Gas units: Bus signal

SSR active: 12VDC X24:(7-8)

SSR not act.: 0VDC X24:(7-8)

Gas units: Bus signal

B2 above set Temp.: Y2 active

B2 below set Temp.: Y2 not active

Remark

Solenoid Y1 energizes when

no water, 230VAC, X19:(1-3)

Heating off,

if B5 > 180°C (356°F)

Blinking dot in timer

Steam saturation is calculated

by quenching duration and rate

Decision of Hot Air supply by

PCB logic

Y2 active: 230VAC X19:(2-4)

Y2 not act.: 0VAC X19:(2-4)

1

2

3

4

5

6

7

8

9

-13-

S

C

M

Mode: Low temperature steam

Temp. range

30-99°C (86-210°F)

Function Step

Select vario steam mode

(Temp. setting 30-99°C (86-210°F))

Select time or core temperature

Close cabinet door

Check water level inside

steam generator

Preheat steam generator,

if B5 is below 85°C (185°F);

Timer starts after successful preheating

Steam supply until set temperature

inside cabinet is reached

Hot Air supply (only 50%) when set

temperature can not be reached

in time by Steam alone

Quenching (set to 70°C/158°F)

Responsible sensor

Reed switch S3

Level electrode S2 inside Steam Generator

Thermocouple B5 inside

Steam Generator

Logic on PCB

Cabinet sensor B1

Cabinet sensor B1

Thermocouple B2

Signal

Door open: 12VDC X27:(1-2)

Door closed: 0VDC X27:(1-2)

X12:(1-4) > 2VAC => no water

X12:(1-4) ~ 0VAC => water

SSR active: 12VDC X24:(1-2)+(5-6)

SSR not act: 0VDC X24:(1-2)+(5-6)

Gas units: Bus signal

SSR active: 12VDC X24:(1-2)+(5-6)

SSR not act.: 0VDC X24:(1-2)+(5-6)

Gas units: Bus signal

SSR active: 12VDC X24:(7-8)

SSR not act.: 0VDC X24:(7-8)

Gas units: Bus signal

B2 above set Temp.: Y2 active

B2 below set Temp.: Y2 not active

Remark

Solenoid Y1 energizes when no

water, 230VAC, X19:(1-3)

Heating off,

if B5 > 180°C (356°F)

Blinking dot in timer

Blinking dot in timer display

Decision of Hot Air supply by

PCB logic

Y2 active: 230VAC X19:(2-4)

Y2 not act.: 0VAC X19:(2-4)

1

2

3

4

5

6

7

8

9

Note:

Below 100°C (212°F) fan at lowest speed when no energy required for longer than 2 minutes.

-14-

S

C

M

Mode: Combination

Temp. range

30-300°C (86-572°F)

Function Step

Select Combination mode

(Temp. 30-300°C (86-572°F))

Select time or core temperature

Close cabinet door

Check water level inside

steam generator

Preheat steam generator,

if B5 is below 85°C (185°F);

Timer starts after successful preheating

Hot Air supply until set temperature

inside cabinet.

Hot air has priority

Steam supply up to steam saturation

inside cabinet

Quenching (set to 70°C/158°F)

Responsible sensor

Reed switch S3

Level electrode S2 inside Steam Generator

Thermocouple B5 inside

Steam Generator

Logic on PCB

Cabinet sensor B1

Quenching sensor B2

(Steam control)

Quenching sensor B2

Signal

Door open: 12VDC X27:(1-2)

Door closed: 0VDC X27:(1-2)

X12:(1-4) > 2VAC => no water

X12:(1-4) ~ 0VAC => water

SSR active: 12VDC X24:(1-2)+(5-6)

SSR not act: 0VDC X24:(1-2)+(5-6)

Gas units: Bus signal

SSR active: 12VDC X24:(7-8)

SSR not act.: 0VDC X24:(7-8)

Gas units: Bus signal

SSR active: 12VDC X24:(1-2)+(5-6)

SSR not act.: 0VDC X24:(1-2)+(5-6)

Gas units: Bus signal

B2 above set Temp.: Y2 active

B2 below set Temp.: Y2 not active

Remark

Solenoid Y1 energizes when

no water, 230VAC, X19:(1-3)

Heating off,

if B5 > 180°C (356°F)

Blinking dot in timer

Hot air supply active, until

set temperature is reached

Steam saturation is calculated

by quenching duration and rate

Y2 active: 230VAC X19:(2-4)

Y2 not act.: 0VAC X19:(2-4)

1

2

3

4

5

6

7

8

9

Note:

Below 100°C (212°F) fan at lowest speed when no energy required for longer than 2 minutes.

-15-

S

C

M

Mode: Finishing

Temp. range

30-300°C (86-572°F)

Function Step

Select Finishing

(Recom. Temp. 100-140°C (212-284°F))

Select time or core temperature

Close cabinet door

Check water level inside

steam generator

Preheat steam generator,

if B5 is below 85°C (185°F);

Timer starts after successful preheating

Hot Air supply

Electric units: 12 sec on - 6 sec off

Gas units: 30 sec on - 15 sec off

Steam supply

Electric units: 6 sec on - 12 sec off

Gas units: 15 sec on - 30 sec off

Quenching (set to 70°C/158°F)

Responsible sensor

Reed switch S3

Level electrode S2 inside Steam Generator

Thermocouple B5 inside

Steam Generator

Logic on PCB

Cabinet sensor B1

Quenching sensor B2

(Steam Control)

Quenching sensor B2

Signal

Door open: 12VDC X27:(1-2)

Door closed: 0VDC X27:(1-2)

X12:(1-4) > 2VAC => no water

X12:(1-4) ~ 0VAC => water

SSR active: 12VDC X24:(1-2)+(5-6)

SSR not act: 0VDC X24:(1-2)+(5-6)

Gas units: Bus signal

SSR active: 12VDC X24:(7-8)

SSR not act.: 0VDC X24:(7-8)

Gas units: Bus signal

SSR active: 12VDC X24:(1-2)+(5-6)

SSR not act.: 0VDC X24:(1-2)+(5-6)

Gas units: Bus signal

B2 above set Temp.: Y2 active

B2 below set Temp.: Y2 not active

Remark

Solenoid Y1 energizes when no

water, 230VAC, X19:(1-3)

Heating off,

if B5 > 180°C (356°F)

Blinking dot in timer

Hot air supply active, until

set temperature is reached

Steam saturation is calculated

by quenching duration and rate

Y2 active: 230VAC X19:(2-4)

Y2 not act.: 0VAC X19:(2-4)

1

2

3

4

5

6

7

8

9

NOTE: For initial heating of cabinet => alternately energy supply of Hot Air and Steam (Electric 12/6 sec, Gas 30/15 sec)

F

Note:

Below 100°C (212°F) fan at lowest speed when no energy required for longer than 2 minutes.

-16-

S

C

M

Mode: Hot Air

Temp. range

30-300°C (86-572°F)

Function Step

Select Hot Air

(Temp. 30-300°C (86-572°F))

Select time or core temperature

Close cabinet door

Timer starts at once

Hot Air supply until set temperature

inside cabinet is reached

Quenching (set to 90°C/194°F)

Responsible sensor

Reed switch S3

Logic on PCB

Cabinet sensor B1

Quenching sensor B2

Signal

Door open: 12VDC X27:(1-2)

Door closed: 0VDC X27:(1-2)

SSR active: 12VDC X24:(7-8)+(3-4)

SSR not act.: 0VDC X24:(7-8)+(3-4)

B2 above set Temp.: Y2 active

B2 below set Temp.: Y2 not active

Remark

Blinking dot in timer display

Y2 active: 230VAC, X19:(2-4)

Y2 not act.: 0VAC, X19:(2-4)

1

2

3

4

5

6

Note:

Below 100°C (212°F) fan at lowest speed when no energy required for longer than 2 minutes.

-17-

S

C

M

X7

X19

X20

F1 F2

Transformer

0,1 AT

2 AT

1

1

X7

X19

X20

X18

X23

X31

RS 485

X8

X12

X26

X27

X32X24

X30

RS 232

X63

X3X4X6

X2

X50

2 AT

1

2

3

4

on

off

1

1

1

1

1

1

1

F6.1

F6.1

2 AT

2 AT

X16

X16

F6

F6

42.00.004

42.00.047

1

2

3

4

on

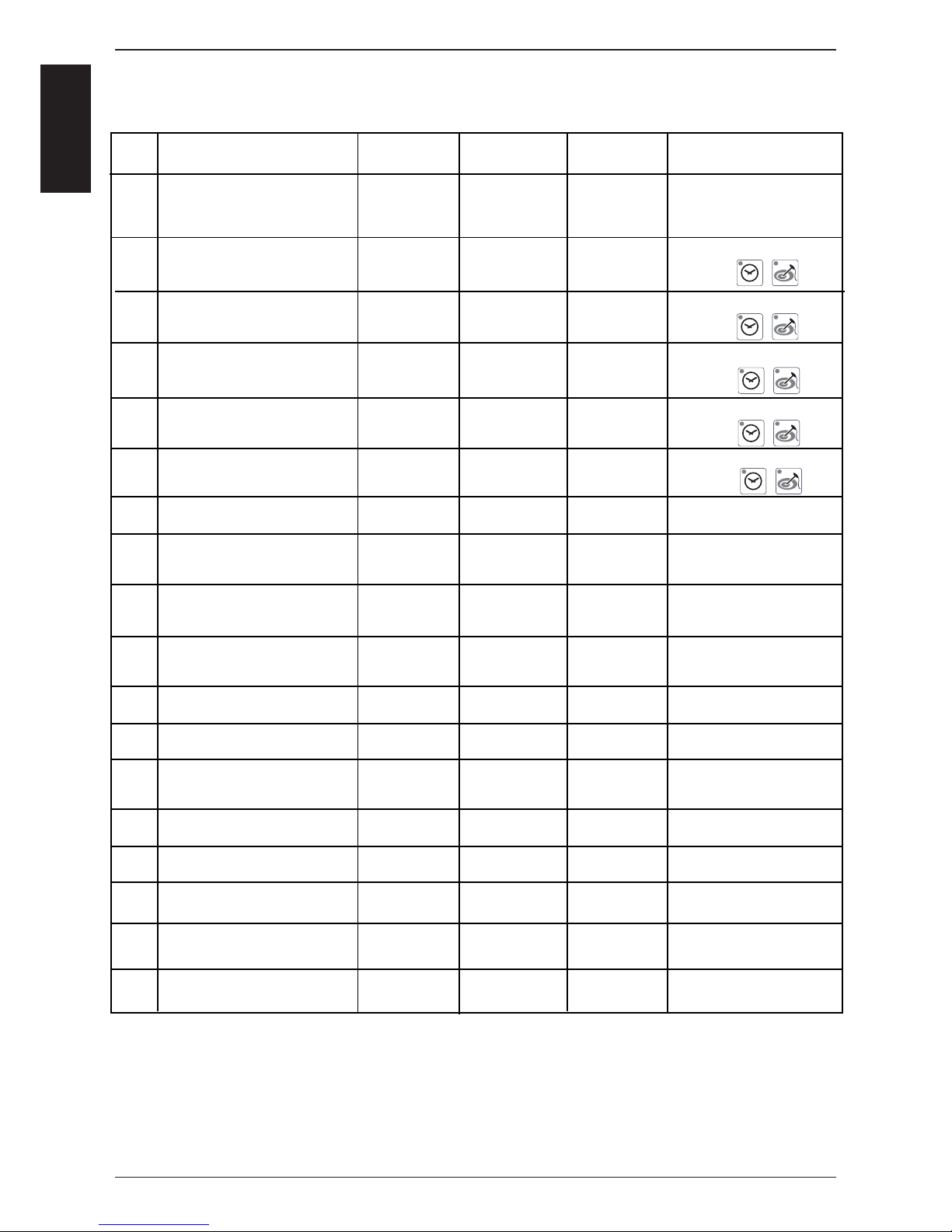

Switch unit ON

On operator PCB set DIP switch 1 to „ON“ position

Select service package with timer dial:

Diagnostic Program

Error code history

Running times

Basic settings

Activate with core temperature key the desired service package

Select with timer dial the desired step

Activate selected step by pressing timer key

To de-activate service package set DIP switch 1 to „OFF“ position

.

Switch unit ON

On operator PCB set DIP switch 3 to „ON“ position

First step of function test is displayed

Select desired step of function test with timer dial

Activate selected step by pressing timer key

Activate selected step with core temperature key

To de-activate function test set DIP switch 3 to „OFF“ position.

A)

B)

C)

D)

E)

F)

G)

A)

B)

C)

D)

E)

F)

G)

dP

SE

rt

1

2

3

4

on

Function Test

Service level CM from 04 - 2004

F1

1

2

3

4

on

1

2

3

4

on

Notes:

Er

-18-

S

C

M

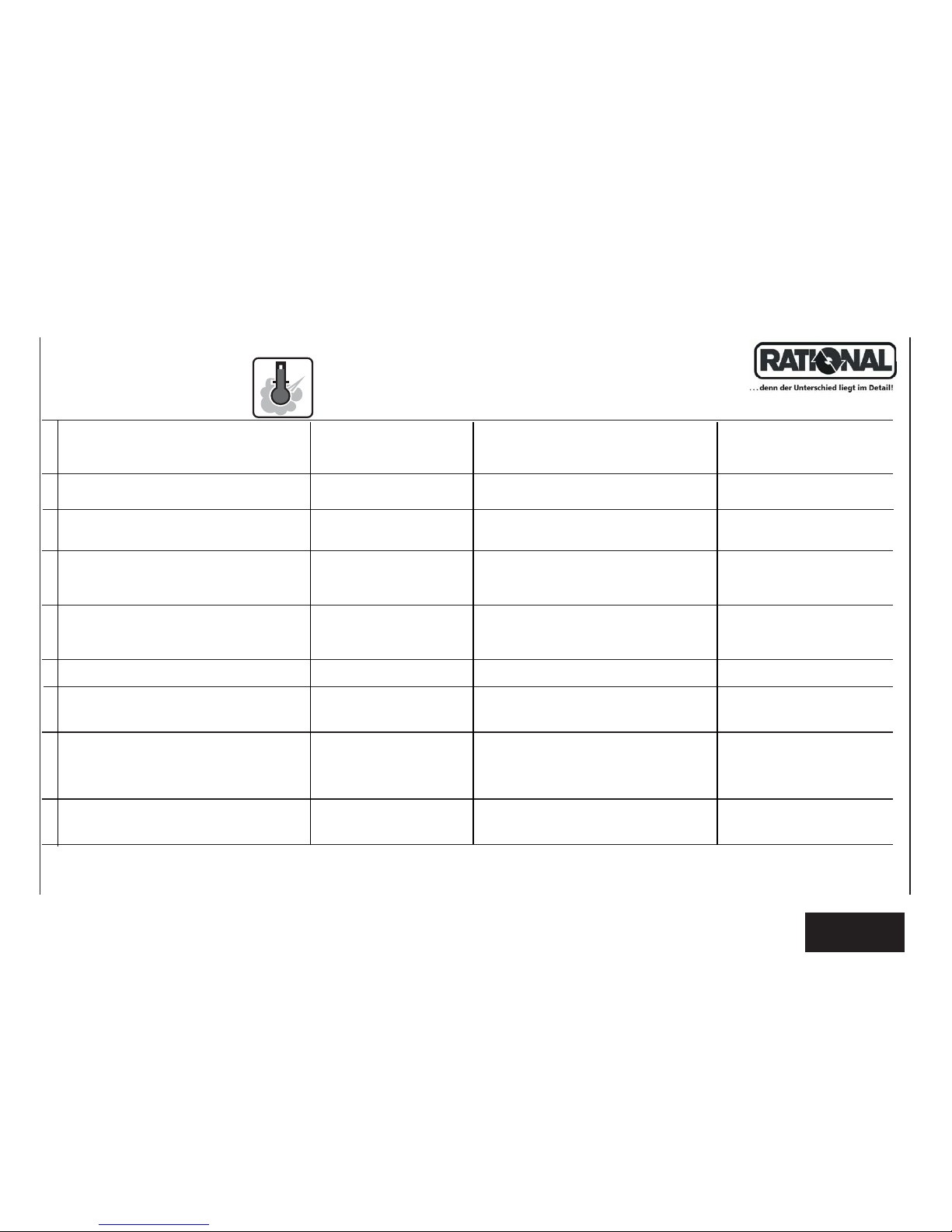

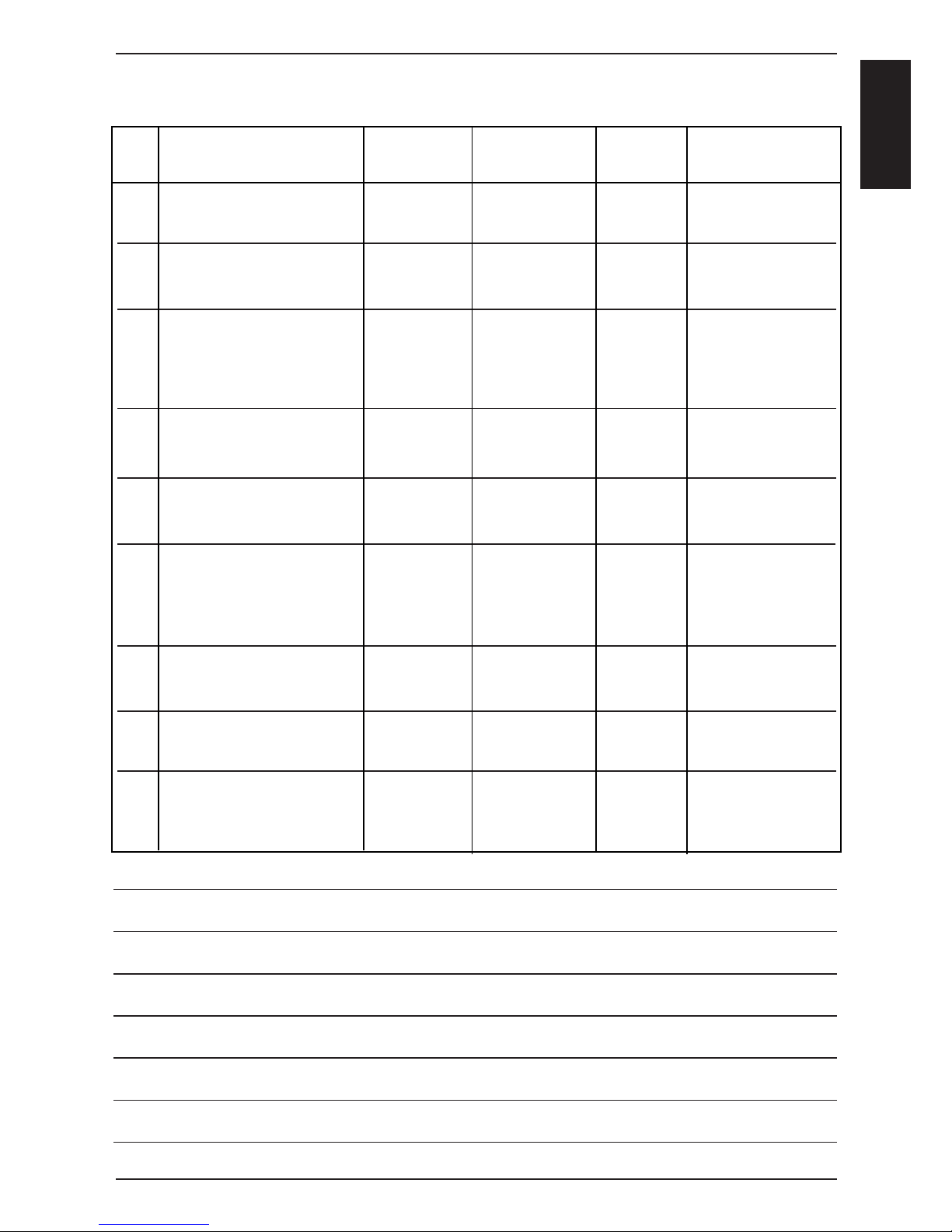

Description

Software Version

B1 Cabinet sensor

B2 Quenching sensor

B3 Core sensor

B5 Steam generator sensor

PCB temperature

S3 Door contact

S2 Water level steam

generator

Steam elements

0 - off; 1 - 50%; 2 - 100%

Hot Air elements

0 - off; 1 - 50%; 2 - 100%

Speed fan motor top

Speed fan motor bottom

Energy optimising

(Sicotronic)

SSR pulsing (US version)

Unit size and type

Flame Current Steam

Flame Current Hot Air top

Flame Current Hot Air bottom

dP #

dP 1

dP 2

dP 3

dP 4

dP 5

dP 6

dP 7

dP 8

dP 9

dP 10

dP 11

dP 12

dP 13

dP 14

dP 15

dP 16

dP 17

dP 18

Connector

X 3

X 4

X 2

X 6

X27:(1-2)

X12:(1-4) S2

X19:(1-3) Y1

BUS

BUS

X 20

X 26

Cabinet display

Software

version: C - 1 -

actual value

actual value

actual valuet

actual value

actual value

S3: 1 - 0

Temp. B5

Temp. B1

Set rpm

Set rpm

61 - 202

Timer display

Software

Version:06.05

max value

max value

max value

max value

max value

1 - 0

Y1: 1 - 0

0 - 1 - 2

0 - 1 - 2

actual rpm

actual rpm

1 - 0

1 - 0

ELE - GAS

x.x µA

*

x.x µA*

x.x µA

*

Comment

Reset by pressing

for 5 sec.

Reset by pressing

for 5 sec.

Reset by pressing

for 5 sec.

Reset by pressing

for 5 sec.

Reset by pressing

for 5 sec.

USA version only

since SW Version:

C1-06-05 (fl ame current)

since SW Version:

C1-06-05 (fl ame current)

since SW Version:

C1-06-05 (fl ame current)

Service level: dP -- Diagnostic Program

+

*

With SW Version C1-06-05 the fl ame current will show as 20-24µA

(This value must be divided by 4 to get the correct fl ame current e. g. 22:4 = 5,5µA.)

Starting with SW version C1-07-01 the actual fl ame current is shown .

+

+

+

+

-19-

S

C

M

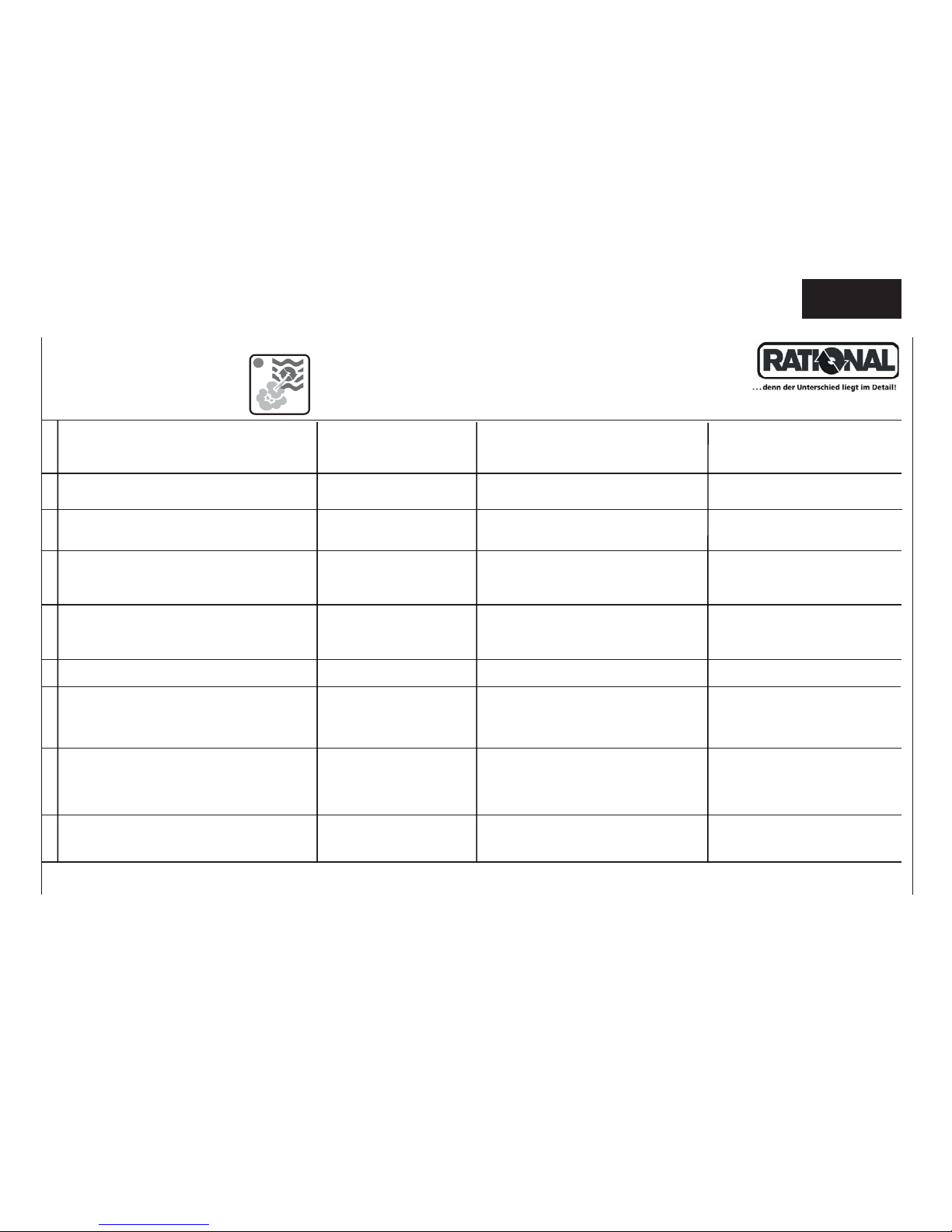

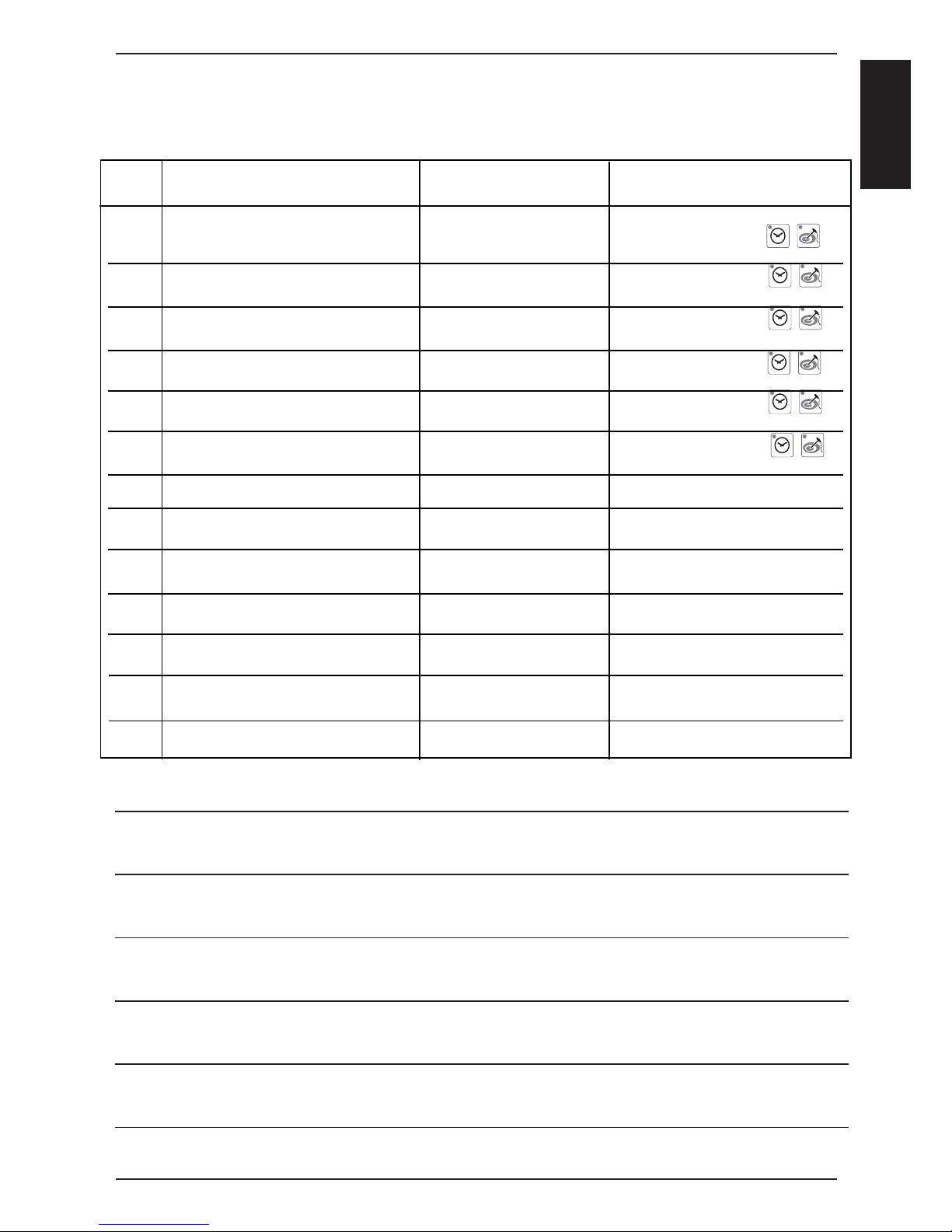

Service Level: rt -- Running Time

rt #

rt 1

rt 2

rt 3

rt 4

rt 5

rt 6

rt 7

rt 8

rt 9

rt 10

rt 11

rt 12

rt 13

Description

Total S3 door openings

Total time Y1 valve fi lling

Total time Y2 valve quenching

Total time M4 SC-pump

Total time steam heating time

Total time hot air heating time

Total time steam mode

Total time hot air mode

Total time combination mode

Total time vario steam mode

Total time fi nishing mode

Total time cleaning program

Total running time unit

Timer display: 1-999

Temp. display: >1000

number

min

min

min

hrs

hrs

hrs

hrs

hrs

hrs

hrs

hrs

hrs

Comment

Reset by pressing

for 5 sec.

Reset by pressing

for 5 sec.

Reset by pressing

for 5 sec.

Reset by pressing

for 5 sec.

Reset by pressing

for 5 sec.

Reset by pressing

for 5 sec.

Can not be reset

Can not be reset

Can not be reset

Can not be reset

Can not be reset

Can not be reset

Can not be reset

+

+

+

+

+

+

Notes:

-20-

S

C

M

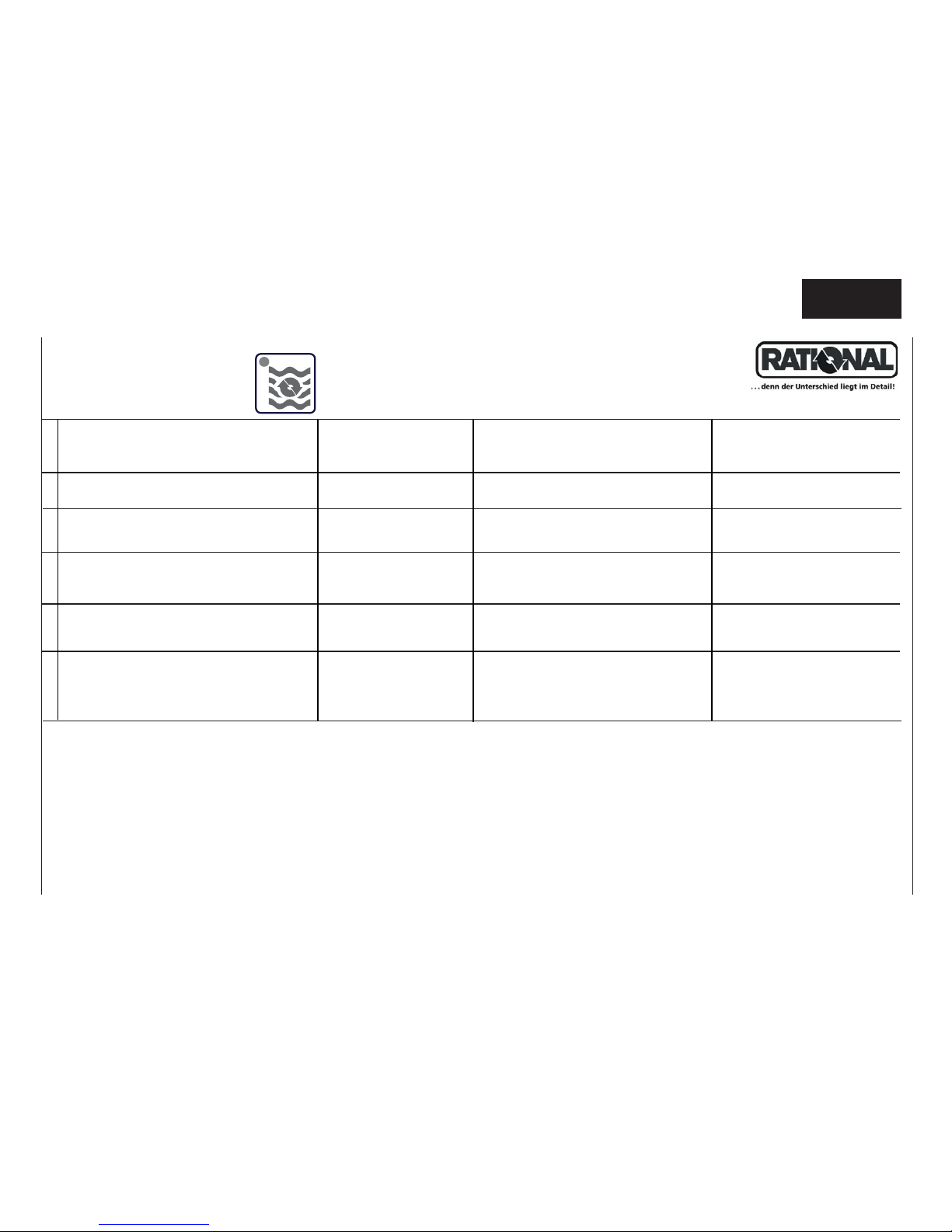

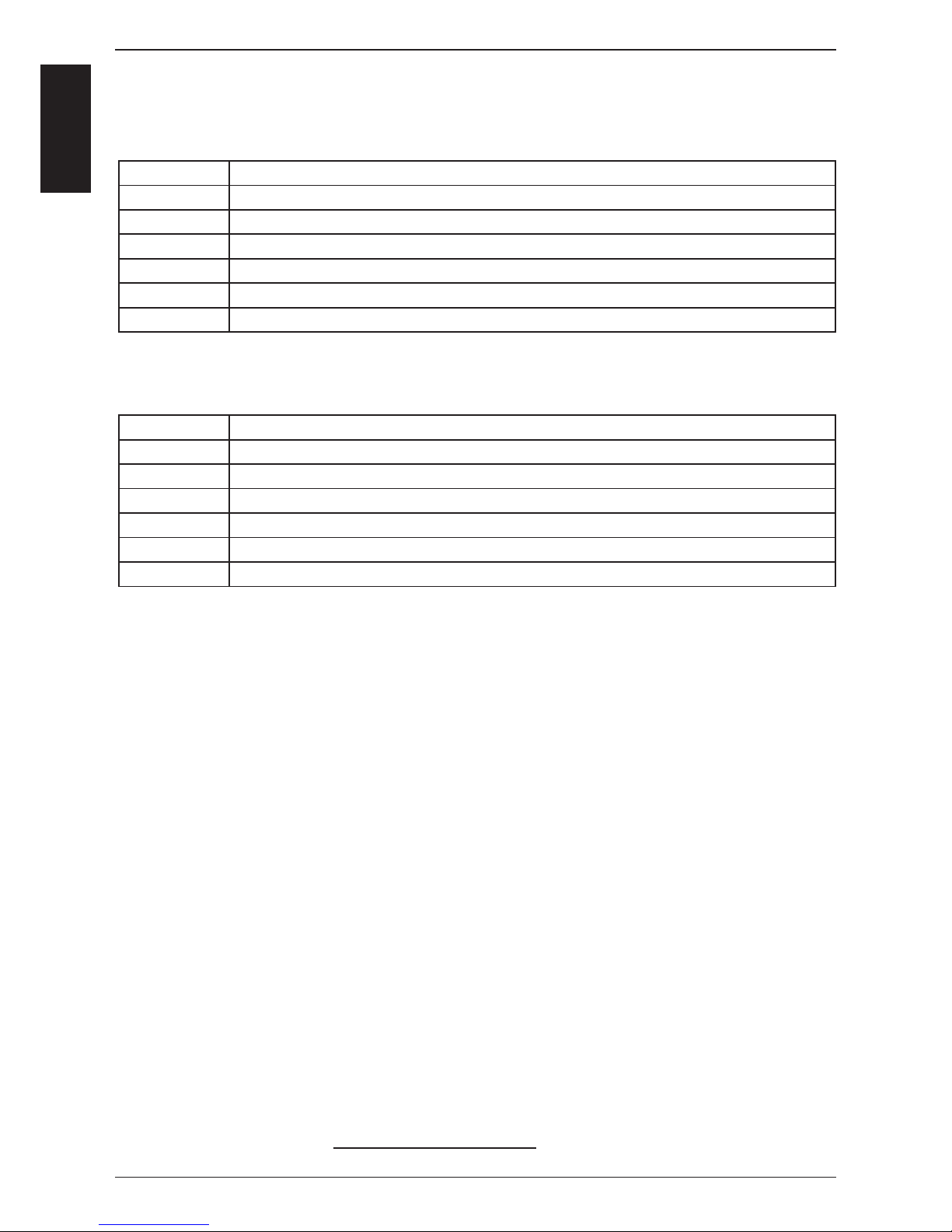

Service level: SE -- Basic settings

Select desired step with timer dial

(fan motor and heating elements are automatically OFF)

Activate selected step with timer key

Steam heating time since last SC-Automatic

Press time and core key simultaneously for 5 seconds to set steam heating time to

preset steam heating time plus 1 minute ==> test function for SC-Automatic

Preset Steam heating time until SC-Automatic

(default 45min)

Press time key and adjust preset steam heating time from 20 - 120 minutes with

timer dial

Flushing time SC-Automatik

(default 45 seconds)

Press time key and adjust fl ushing time of SC-automatik from 30 - 90 seconds with

timer dial

Operation steam generator pump

(oFF - continous or on - pulsing)

Press time key and select „on“ or „oFF“ with timer dial

Show mode (on - oFF) SHO

Press time key and select „on“ or „oFF“ in with timer dial

Setting new gas type (G20, G25, G30, G31, 13A)

Press time key, keep it pressed and select new gas type with timer dial

Confi rm new gas type by pressing core temperature key once

NOTE: After changing gas type a waste gas analysis must be carried out in the function test. Corresponding gas blower speed is automatically adjusted

Presetting of CO2 screw on gas valve after gas type modifi cation / changing gas valve

Press time key, keep it pressed and select with timer dial “ST“ for steam, “HA1“ for

hot air top or “HA2“ for hot air bottom (only 201/202) with timer dial;

Average lenght in mm of CO2 screw on gas valve is shown on timer display

Adjustment of installation altitude above sea level (since SW C1-06-05)

-500- -1m, 0-999m, 1000-1499m, 1500-1999m, 2000-2499m, 2500-2499m, 30003499m, 3500-3499m, 4000-4499m, 4500-4499m

Press time key, keep it pressed and select installaton altitude in 500m steps by timer

dial. Confi rm altitude setting by pressing simultaneously core temperature key once.

SE 1

SE 2

+

SE 3

SE 4

SE 5

SE 6

SE 7

SE 8

+

+

+

+

+

+

-21-

S

C

M

Adjusting speed of blower motor steam (+/ -10%)

(After blower speed adjustment the original rpm is shown in the temp. display, the

changed rpm is shown in the time display)

Press time key, keep it pressed and adjust displayed rpm with timer dial

SE9 = MIN rpm; SE10 = Start rpm; SE11 = MAX rpm

Always check CO

2

values of MAX rpm and MIN rpm in function test

Adjusting speed of blower motor hot air top (+/ -10%)

(After blower speed adjustment the original rpm is shown in the temp. display, the

changed rpm is shown in the time display)

Press time key, keep it pressed and adjust displayed rpm with timer dial

SE12 = MIN rpm; SE13 = Start rpm; SE14 = MAX rpm

Always check CO2 values of MAX rpm and MIN rpm in function test

Adjusting speed of blower motor hot air bottom (+/ -10%)

(After blower speed adjustment the original rpm is shown in the temp. display, the

changed rpm is shown in the time display)

Press time key, keep it pressed and adjust displayed rpm with timer dial

SE15 = MIN rpm; SE16 = Start rpm; SE17 = MAX rpm

Always check CO2 values of MAX rpm and MIN rpm in function test

SE 9,10,11

+

SE 12,13,14

+

SE 15,16,17

+

Notes:

Service Level: SE -- Basic settings

-22-

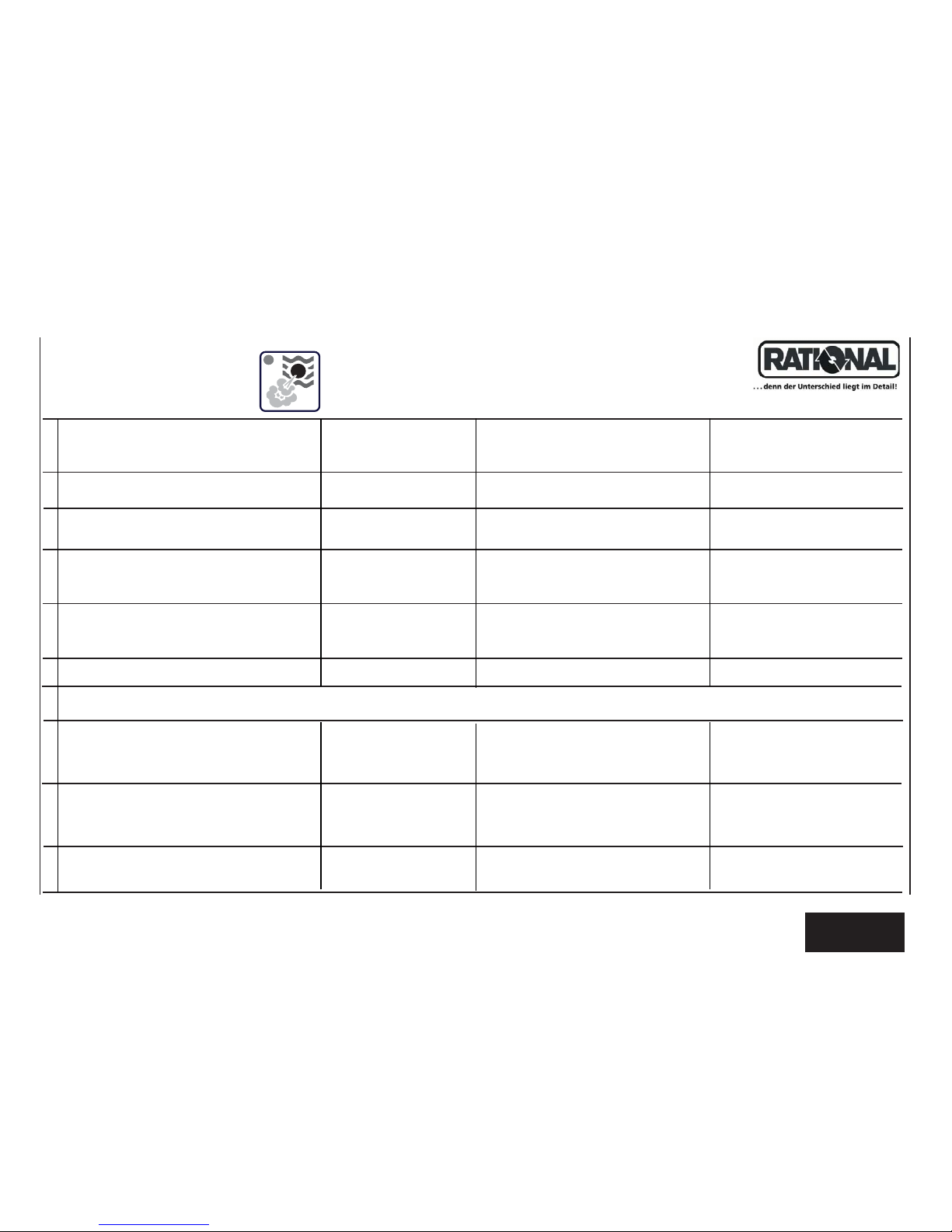

S

C

M

Function Connection

I/O PCB

Cabinet

Display

Time

Display

Comment

F1 Steam 50%, Electric unit X24:(1-2) actual temp.

B5 steam generator

1 / 0 Gas:

no function

F2 Steam 100%, Electric unit X24:(1-2)+(5-6) actual temp.

B5 steam generator

1 / 0 Gas:

no function

F3 Hot Air 50%, Electric unit X24:(7-8) actual temp.

B1 cabinet

1 / 0 Gas:

no function

F4 Hot Air 100%, Electric unit X24:(7-8)+(3-4) actual temp.

B1 cabinet

1 / 0 Gas:

no function

F5 Steam, Gas unit BUS actual temp.

B5 steam

generator

1 / 0 Electric:

no function

F6 Hot Air Top, Gas unit BUS actual temp.

B1 cabinet

1 / 0 Electric:

no function

F7 Hot Air Bottom, Gas unit BUS actual temp.

B1 cabinet

1 / 0 Electric:

no function

F8 Bottom Motor MAX speed BUS Set rpm Act. rpm

F9 Bottom Motor MIN speed BUS Set rpm Act. rpm

F10 Top Motor MAX speed BUS Set rpm Act. rpm

F11 Top Motor MIN speed BUS Set rpm Act. rpm

F12 Solenoid valve quenching X19:(2-4) actual temp.

B2 quenchingY21 / 0

F13 Solenoid valve fi lling X19:(1-3) Level electrode

S2, 1 / 0

Y1

1 / 0

F14 Steam generator pump X18:(1-2) M4

X12:(1-4) S2

Level electrode

S2, 1 / 0

M4

1 / 0

F15 Buzzer 1 / 0

F16 All Displays / LED

F17 Relais Vent hood

UltraVent

(door open/close)

X 23: (1-2-3) 1 / 0

F18 no function

Service level: F -- Function test

NOTE: In Function test components are NOT protected against overload!

-23-

S

C

M

Service level: F -- Function test

NOTE: In Function test components are NOT protected against overload!

Connection

I/O PCB

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

Cabinet

Dispaly

Actual blower

rpm

Actual blower

rpm

Actual blower

rpm

Actual blower

rpm

Actual blower

rpm

Actual blower

rpm

Actual blower

rpm

Actual blower

rpm

Actual blower

rpm

Time

Display

Set CO

2

value

Set CO2

value

Set CO2

value

Set CO2

value

Set CO2

value

Set CO2

value

Comment

Check CO

2

value only

Adjust CO2 value

with CO2 screw

on gas valve

Check CO2

value only

Adjust CO2 value

with CO2 screw

on gas valve

Check CO2

value only

Adjust CO2 value

with CO2 screw

on gas valve

F #

F19

F20

F21

F22

F23

F24

F25

F26

F27

Function

Steam blower motor

MIN rpm

Steam blower motor

Start rpm

Steam blower motor

MAX rpm

Hot air blower motor, top

MIN rpm

Hot air blower motor, top

Start rpm

Hot air blower motor, top

MAX rpm

Hot air blower motor,

bottom, MIN rpm

Hot air blower motor,

bottom, Start rpm

Hot air blower motor,

bottom, MAX rpm

Notes:

-24-

S

C

M

Since software version C1-07-01 the last 10 error messages are shown.

Er When Timer key is pressed the error code will be displayed, i.e.

Er1 3 B1 Cabinet sensor defective

Er2 14 Y1 Filling solenoid defective

Er3

--

--

Er10

Since software version C1-07-01 the last 16 gas error messages are shown

in addition to the general error messages (gas units only!)

GE11 20 No rpm signal

GE12 32 No fl ame after 5 ignition sequences

GE13

--

-GE25

GE26

Indication of ignition box error messages (1-32 is shown to the operator as „rES“):

1 Hot air or Steam no gas, gas valve or electrode defective

14 Hot air gas valve controll, change ignition box

19 Hot air no fl ame because fl ame current is too low

check burner setting, fl ame current, ignition cable and plug

20 Hot air wrong or no rpm signal from gas blower

check gas blower, power supply gas blower and control harness of gas blower

22 Hot air no fl ame after 5 ignition sequences

no gas, gas valve or electrode defective

24 Steam gas valve controll, change ignition box

29 Steam no fl ame because fl ame current is too low

check burner setting, fl ame current, ignition cable and plug

30 Steam wrong or no rpm signal from gas blower

check gas blower, power supply gas blower and control harness of gas blower

32 Steam no fl ame after 5 ignition sequences

no gas, gas valve or electrode defective

Possible failure in case of „E21“

33, 36 Change ignition box

35 Check frequency of main

39 Hot air Check burner setting, ignition electrode and distance,and fl ame current

40 Hot air Check ignition cable

42 Steam Check burner setting, ignition electrode and distance,and fl ame current

43 Steam Check ignition cable

Is shown on display „CHnG PoL“

34 Change polarity of mains

All other numbers (2-13, 15-18, 21, 23, 25-28, 31): change ignition box

Service Level: ER -- Error code history

-25-

S

C

M

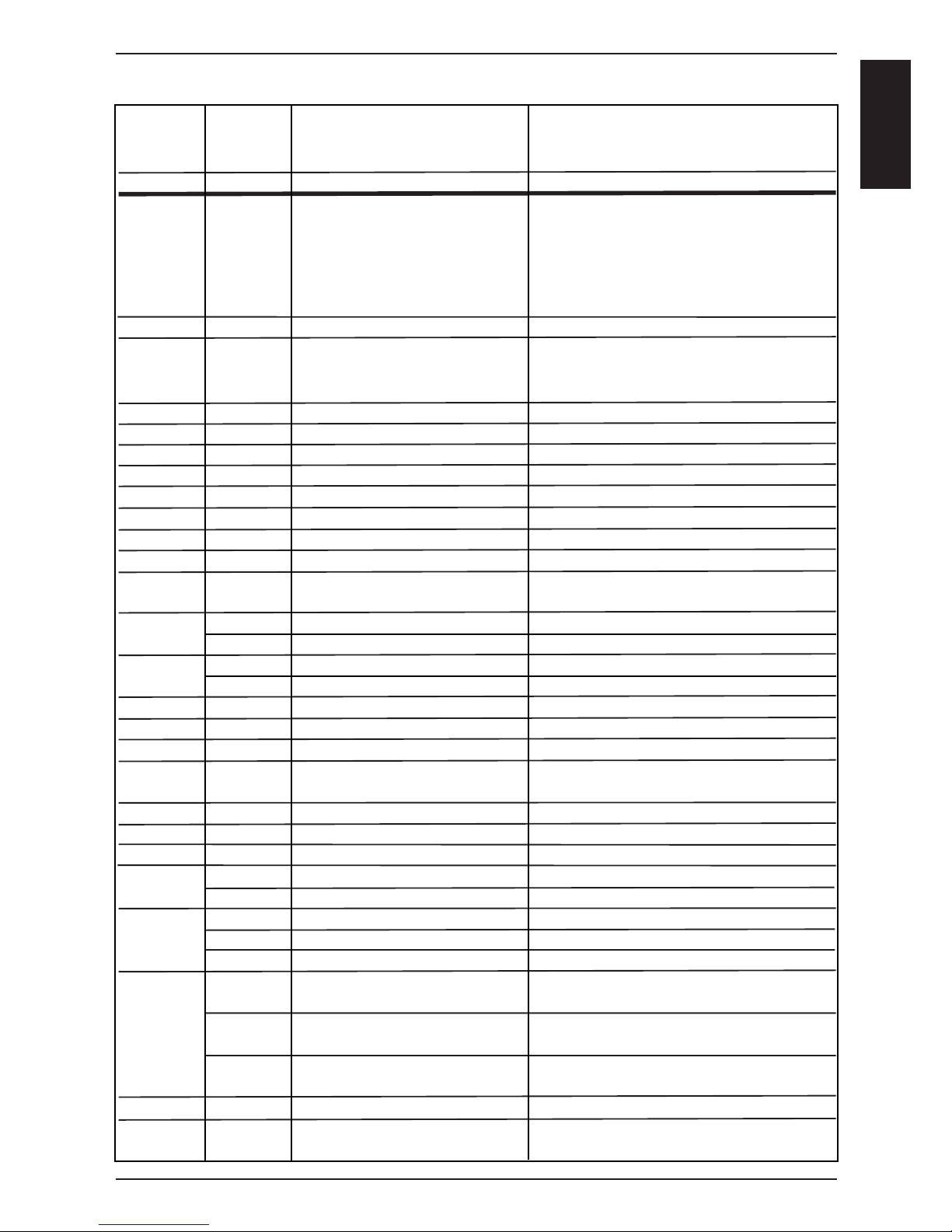

Int. cab.

display

H2o

CHnG

Timer

display

E1

E2

E3

E4

E5

E6

E7

E8

E9

E10

E11

E12

E 12

E13

E14

E15

E16

E17

E18

E19

E20

E21

E22

E23

E24

Timer

display

OPEn

PoL

Int. cab.

display

(E -press

core temp.

key)

1 St

1 Co

2 St

2 Co

1_

2_

1xx

2xx

3xx

1xx

2xx

3xx

Failure explanation

H2O open

Change Polarity

Part concerned

external EEPROM

Timeout of external

power optimising system

(Sicotronic)

B1 Interior cabinet sensor

B2 Quenching sensor

B3 Core sensor

B5 Sensor steam generator

Thermocouple on PCB

Poti interior cabinet

Poti timer/core temperature

External EEPROM

Mode switch

Fan motor 1 (bottom)

Fan motor 1 (bottom)

Fan motor 2 (top)

Fan motor 2 (top)

M4 SC-pump

Solenoid valve fi lling Y1

PCB temperature

Steam generator

Steam generator

Interior cabinet temp.

free

Ignition box 1

Ignition box 2

Ignition box 1 Steam

Ignition box 1 Hot air

Ignition box 2 Hot air

Ignition box 1 Steam

Ignition box 1 Hot air

Ignition box 2 Hot air

free

EEPROM

Description

Lack of water / open water tap

Phase / Neutral (only gas units)

Description

Not initialised

Heating blocked by the extern. energyoptimising system for longer 2 min.

Sensor broken

Sensor broken

Sensor broken

Sensor broken

Sensor broken

Defective

Defective

Defective

After 5 sec switching on the unit, a

cooking mode couldn‘t be identifi ed

St = Status (probably Motor defect)

Co = Communication,(Bus failure)

St = Status (probably Motor defect)

Co = Communication,(Bus failure)

Mal function

Mal function

above 85°C (185°F)

Temperature B5 above

180°C (356°F)

Temperature B5 below -5°C (23°F)

Temperature B1 above 340°C (644°F)

Ignition box does not reply, Bus failure

Ignition box does not reply, Bus failure

Ignition box defective (change box)

Ignition box defective (change box)

Ignition box defective (change box)

Testing of ignition and monitoring

necessary

Testing of ignition and monitoring

necessary

Testing of ignition and monitoring

necessary

Actual data structure of the EEPROM

does not match with the software; flash

pcb first

Failure Codes CM from 04-2004

-26-

S

C

M

S2

B1

B3

F4

M4

Y1

Y2

B2

M1

B5

F3

M8

M9

Y11

Y12

A5

B11

B12

CM Gas from 04 - 2004

A5 Ignition module (Steam and Hot Air) (without jumper)

B1 Thermocouple interior cabinet

B2 Thermocouple quenching / Steam control

B3 Thermocouple core temperature

B5 Thermocouple steam generator

B11 Ignition/monitoring electrode steam

B12 Ignition/monitoring electrode hot air

F3 Safety thermostat steam generator 135°C

F4 Safety thermostat interior cabinet 360°C

M1 Fan motor

M4 SC-pump

M8 Gas blower motor hot air

M9 Gas blower motor steam

Y1 Solenoid valve fi lling

Y2 Solenoid valve quenching

Y11 Gas valve steam

Y12 Gas valve hot air

S2 Level electrode

Only fl oor units 201 - 202

A6 Ignition module hot air bottom (with jumper)

M2 Fan motor top (with jumper)

M10 Gas blower motor hot air bottom

Y13 Gas valve hot air bottom

B13 Ignition/monitoring electrode hot air bottom

-27-

S

C

M

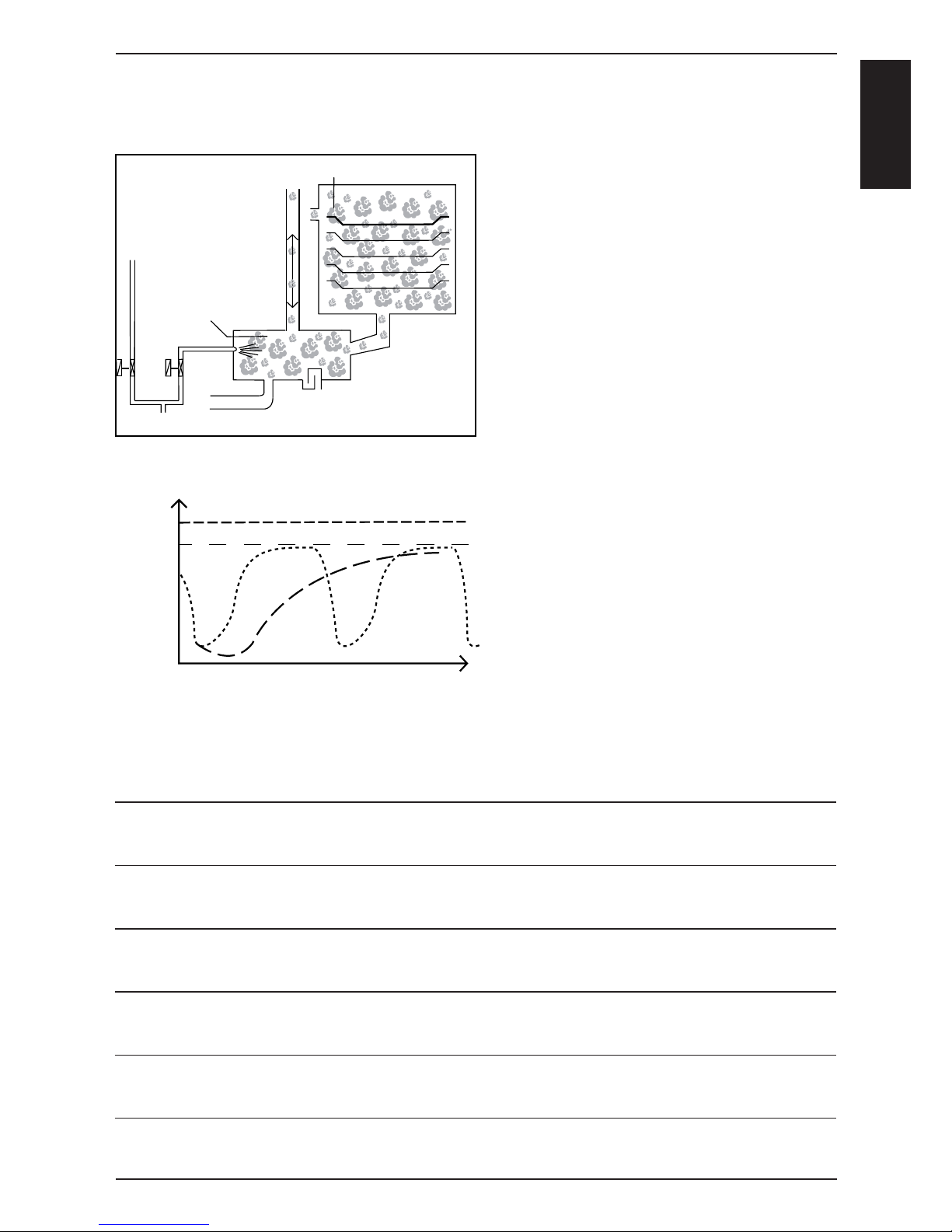

Identifi cation of the different gas burners / Gas blowers:

CM 201 - 202

CM 61 - 62 - 101 - 102

Steam Blower

(ignition box fi tted)

Hot Air blower top

(ignition box not fi tted)

Hot Air blower bottom

(ignition box fi tted)

Ignition box of Hot Air Blower, Bottom (201-202):

Jumper must ONLY be set

on Ignition Box for

Hot Air Blower Bottom

(201 - 202)

Gas valve components

Measuring test point for

gas fl ow pressure

Gas supply

Compensation hose

CO

2

Srew

Basic info about CM Gas from 04-2004

Ignition box

-28-

S

C

M

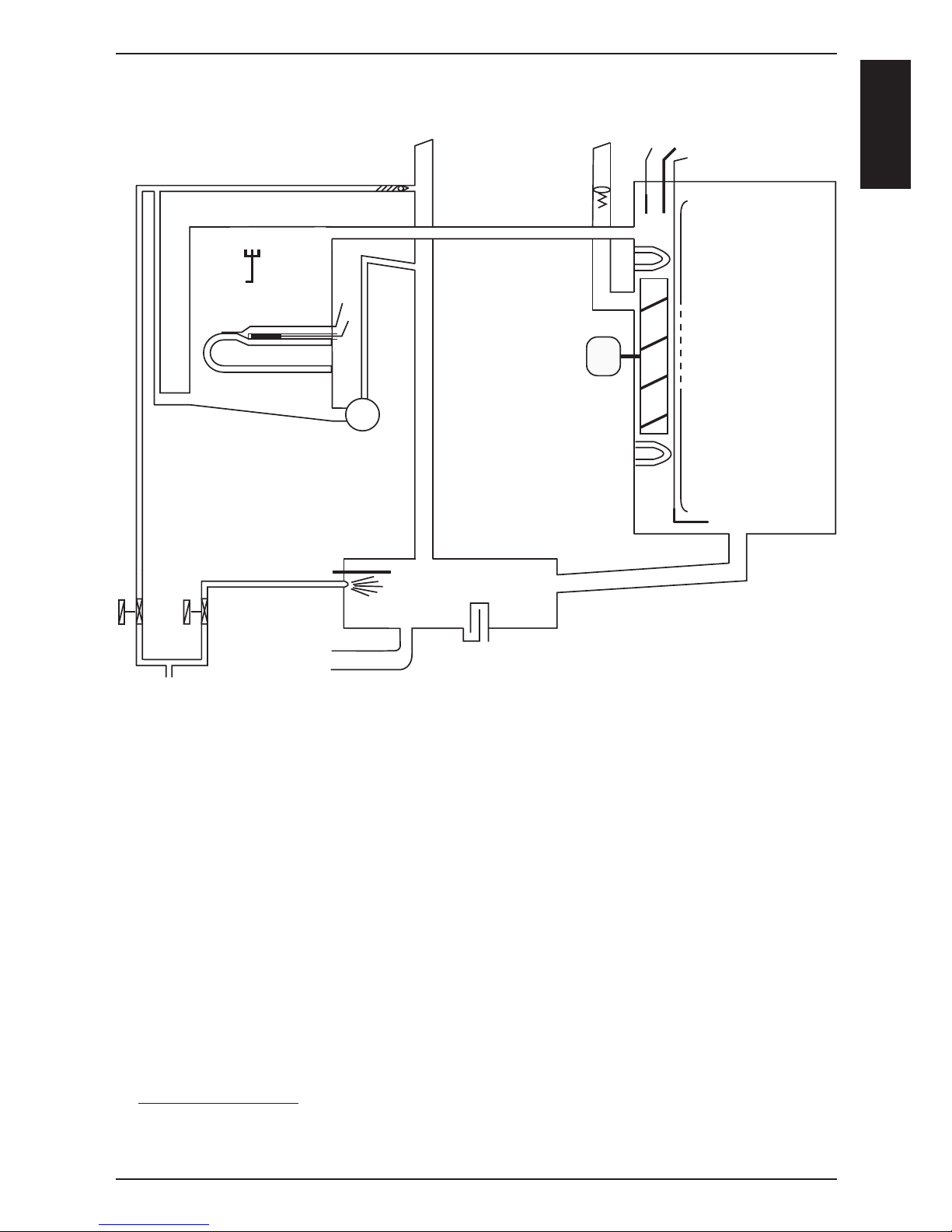

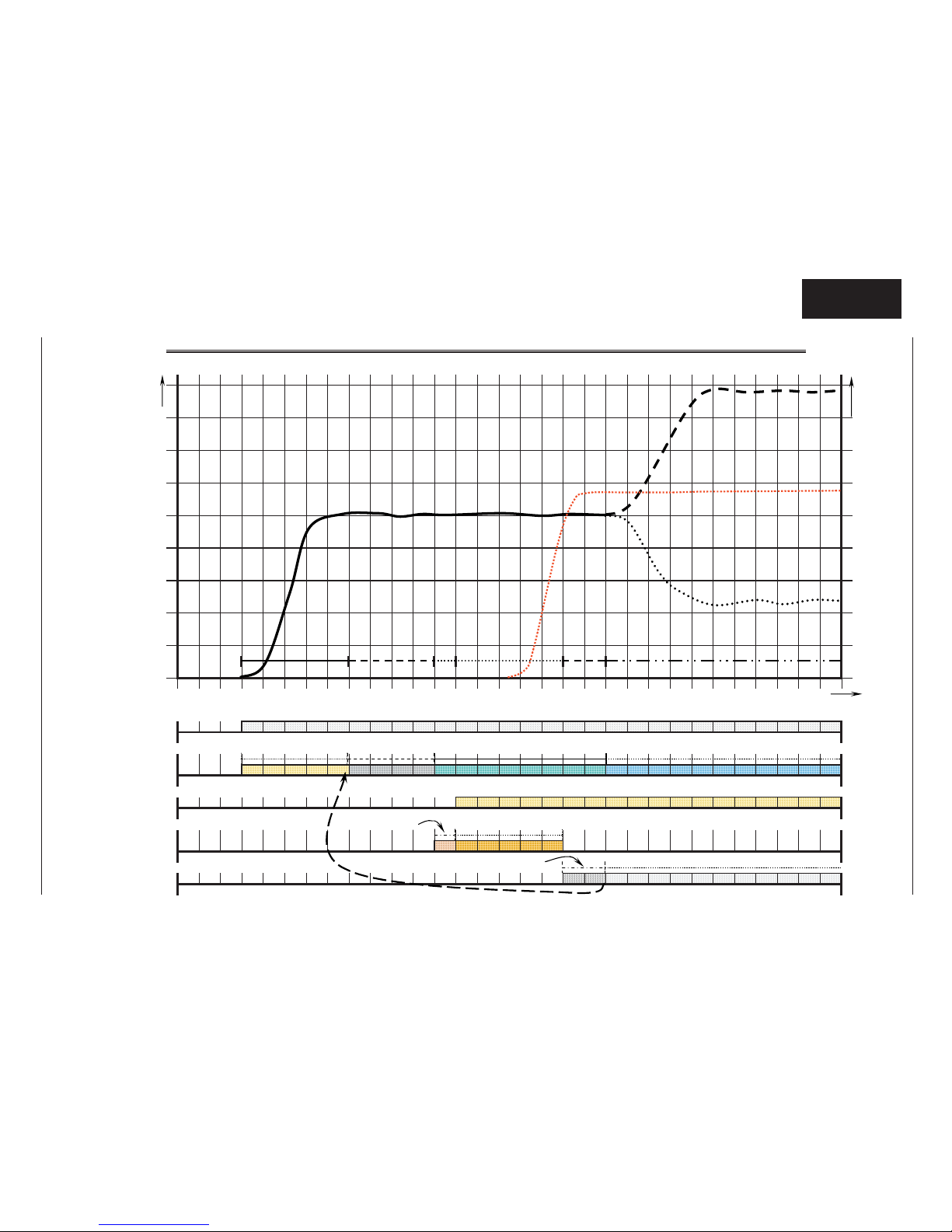

Sequence of events of Steam / Hot Air Burner (SCC as well as CM)

If no flame detected => new ignition sequence. After 5th ignition without success => RESET

16 2419 2017 1810 11 14 15

Speed of burner blower motor in U/min

21 22 23 26 27678901 45

8

4

3

2

1

2512 13

F l a m e c u r r e n t in µA

Time 2 3

7

6

5

Flame monitoring

Energise Solenoids: Black coils ca 205V DC / orange coils ca 108V DC

Ignition box gets heat demand over the BUS cable

Ignition, ca 20KV

Burner blower motor

Gas valve

Heat demand

Start - pre purge

about. 4-5 sec

Pre purge, 4 sec

RPM monitored

Blower runs with Start RPM

RPM monitoring by ignition box

Blower runs with Max or Min RPM

RPM monitoring by ignition box

Flame monitoring within. 2 sec

C

continuous flame control

Start RPM

Max RPM

Min RPM

sec

RPM

Igniti

on,5 secPre ignition, 1sec

Start up Pre purge

Pre ignition

Ignition Burner running

Flame

control

µA

Flame current

-29-

S

C

M

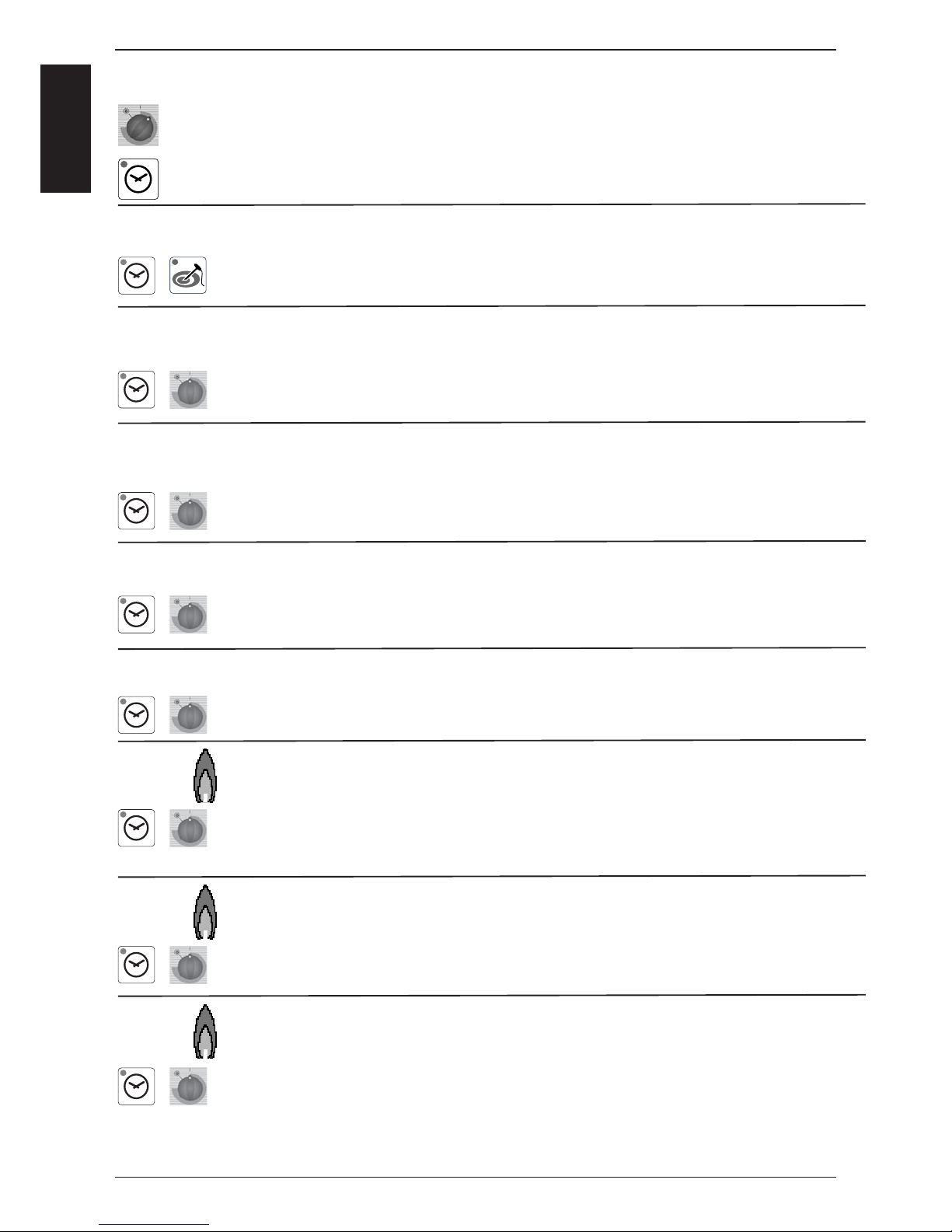

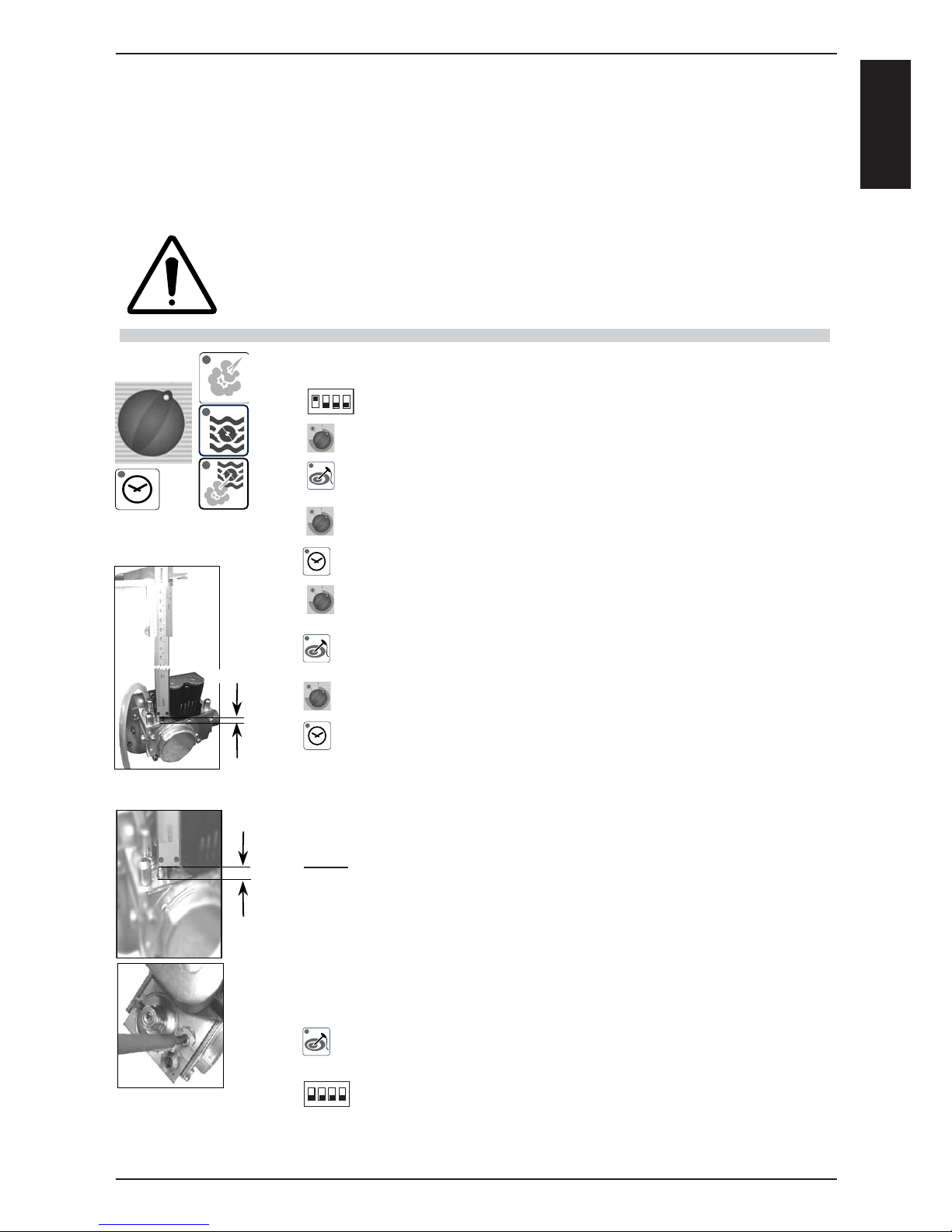

Check Gas Type / Gas Conversion: CM Gas from 04-2004

Select any mode and cooking time

Open control panel

Set DIP switch 1 on PCB to „ON“ position

With timer dial select: „SE“ = Settings:

Activate „Settings“ by pressing core temperature key;

display changes to „SE1“

With timer dial select: SE6

Activate position SE6 with timer key (keep key pressed)

Select new gas type with timer dial:

G20=Nat Gas H, G25=Nat Gas L, G30=3BP, G31=3P, 13A=Nat. Gas Japan

Confi rm new gas type with core temperature key

(now timer key can be released)

With timer dial select: SE7

Activate position SE7 with timer key (keep key pressed)

Keeping the timer key pressed the average length of the CO

2

screw is indicated.

„St“ Steam, „HA1“ Hot air top, HA2“ Hot air bottom

Select the corresponding value with the timer dial (keep timer key pressed).

Note: Setting this screw to the given length shall ONLY bring the unit into wor-

king condition with the newly supplied gas.

This does NOT replace fl ue gas analysis or make the fl ue gas analysis obsolete!

Set the CO2 screw according the values of timer display or according

the table “Values for burner adjustments“ (! ! ! Set all CO2 screws ! ! !)

If the mm setting of CO2 screw is too high, turn CO2 screw fi rst 2 turns clockwise

and then to the requested length (Screw adjustment tolerance)

De-activate selected package “SE“ by pressing core temperature key

To exit service program set DIP switch 1 to „OFF“ position

Check / Set Installation Altitude in Basic settings

Perform fl ue gas analysis in function test at F21, F24, F27

as well as the check of CO2 values at F19, F22, F25

A)

B)

C)

D)

E)

F)

G)

H)

I)

J)

K)

L)

M)

N)

O)

P)

1

234

on

1

234

on

x,x mm

x,x mm

Whenever working on any gas component like:

Gas valve, gas blower and / or changing connected type of gas, a detailed fl ue gas analysis

MUST be done using adequate CO and CO2 measuring equipment!

This shall ONLY be done by trained technicians!

Always check appliance for possible gas leakages!

Danger:

Changing the gas type of your SelfCooking Center or Combi Master

shall only be done if you have a fl ue gas analyser at hand.

Changing the gas setting only by adjusting the CO2 screw

will result in an unsafe fl ue gas condition,

is dangerous to life and will damage the equipment.

-30-

S

C

M

Changing installation altitude: CM gas from 04-2004

SE

A)

B)

C)

D)

E)

F)

G)

H)

I)

J)

K)

L)

M)

N)

6250

Select any mode and cooking time

Open control panel

Set DIP switch 1 on PCB to „ON“ position

With timer dial select: „SE“ = Settings.

Activate „Settings“ by pressing core temperature key; display

changes to „SE1“.

With timer dial select: SE8

Activate position SE8 with timer key and keep it pressed.

While pressing timer key corresponding installation altitude above

sea level can be selected with the timer dial.

Possible altitude selection:

-500 - -1m

0 - 499m

500 - 999m

1000 - 1499m

1500 - 1999m

2000 - 2499m

2500 - 2999m

3000 - 3499m

3500 - 3999m

4000 - 4499m

4500 - 4999m

Confi rm new altitude setting with core temperature key

(Keep timer key pressed)

Release timer and core temperature key

De-activate selected package by pressing core temperature key;

To exit service program set DIP switch 1 to „OFF“ position

To store the new altitude setting the unit must be switched

OFF and ON again.

Perform fl ue gas analysis in function test at F21, F24, F27

as well as the check of CO2 values at F19, F22, F25

1

234

on

1

234

on

Note: The altitude settings of 0-499 and 500-999m are identical.

Therefore resetting of installation altitude needs to be done only when installing

above 1000m (3280ft) or below sea level (i.e. Red Sea)

Loading...

Loading...