Page 1

Edition 10-2008a

1

Training Manual

SCC Line

SelfCooking Center - Combi Master

All manuals and user guides at all-guides.com

all-guides.com

Page 2

2

Edition 10-2008a

All manuals and user guides at all-guides.com

Page 3

3

Edition 10-2008a

Training Manual

SCC Line

Edition 10 - 2008a

General hints:

Isolate the appliance from mains supply before opening the appliance

When working with chemicals, i.e. aggressive cleaning materials

always wear protective clothing, goggles and gloves!

After maintenance / repair the appliance must be checked for electric

safety in accordance with your national, state and local requirements!

Whenever working on any gas component like:

Gas valve, gas blower and / or changing connected type of gas a detailed

ue gas analysis MUST be done using adequate CO and CO2

measuring equipment! This shall ONLY be done by trained technicians!

Always check appliance for possible gas leakages!

All manuals and user guides at all-guides.com

Page 4

4

Edition 10-2008a

Structure of serial number 6

CM Control Panel 7

CM Technique 8

Water level control Steam Generator 9

RATIONAL SC Automatic 10

Steam Control CM 11

Additional functions CM 12

CM PCB 14

Fan motor 40.00.274 15

CM - Sequence of events 16

Failure Codes CM 21

Service level CM 23

Software update CM units 31

Fault tree: Changing CM pcb / replace EEPROM 33

List of content

Part 1: CM

Part 2: SCC

SCC Control panel 35

Comparing display of software version 36

Display since software version SCC 02-01-01 37

CleanJet 41

Display Cleanjet +Care Index “G” (10-2008) 44

SCC Electric - Basic principle 45

Parts identification 46

General information to software version SCC 04-01-01 48

Difference SCC Index „E“ versus Index „G“ SCC Care Control 51

SCC pcb (42.00.002) 54

New I/O PCB SCC (42.00.064) 55

Fan motor SCC 40.00.274 56

Clima Plus Control SCC 57

SCC - Sequence of events 59

Service level SCC 65

Diagnostic mode SCC 67

Running Times SCC 73

Basic Settings 79

Function test SCC 87

Error code SCC 93

Flash SCC Software 98

SCC pcb change - EEPROM change 99

Download of unit service data 101

Download of HACCP data 105

Calibration SCC 107

Control Drain Valve 54.00.357 111

All manuals and user guides at all-guides.com

Page 5

5

Edition 10-2008a

Gas burner principle 11 2

Gas Valve 113

Identification of gas burners / Gas blowers: 114

Sequence of events of Burner and Ignition control 115

CO

2

Values 116

CM Gas principle 117

Check Gas Type / Gas Conversion 118

Changing installation altitude: CM gas 119

Checking of dynamic input gas flow pressure 120

Flue gas analysis 121

Burner adjustment SCC - CM 07-2008 124

Changing Gas blower speed 125

SCC Gas principle 127

Gas conversion / fitting new gas valve 128

Adjustment of installation altitude above sea level 129

Checking of dynamic input gas flow pressure 130

Flue gas analysis 131

Burner adjustment SCC - CM 07-2008 134

Changing gas blower speed SCC Gas 135

Ultravent 136

Water info 140

Intruction for manual descaling 141

Installation and Commissioning checklist 146

COMMISSIONING CHECKLIST SCC / CM 146

Preventative maintenance 150

List of fault tree for SCC - CM 154

Circuit diagram Training 178

Part 3: GAS

Part 4: Common information

Part 5: Fault trees

Part 6: Circuit diagram Training

Part 7: Service reference

SCC Service Reference 196

CM Service Reference 198

All manuals and user guides at all-guides.com

Page 6

6

Edition 10-2008a

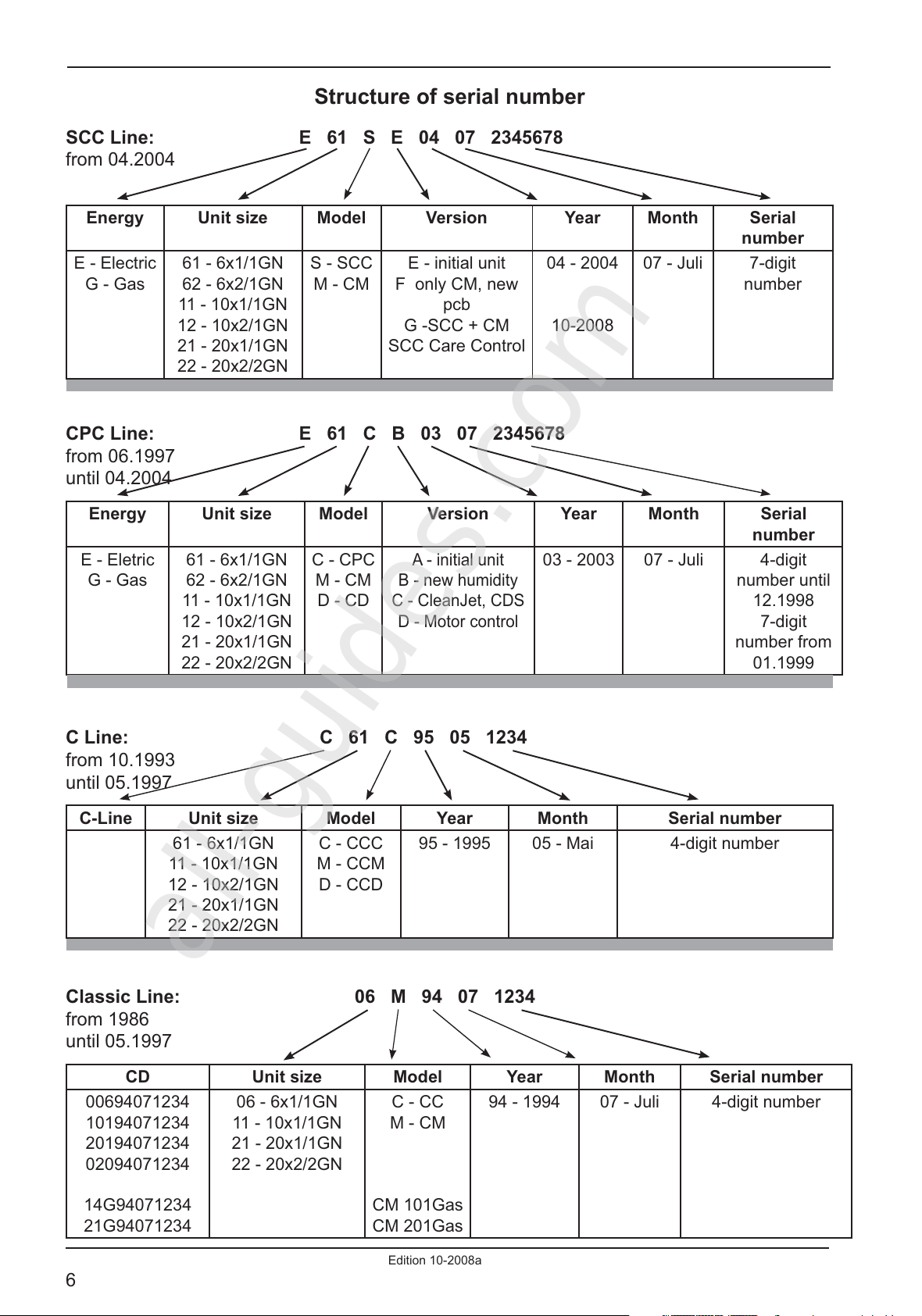

Structure of serial number

Energy Unit size Model Version Year Month Serial

number

E - Electric

G - Gas

61 - 6x1/1GN

62 - 6x2/1GN

11 - 10x1/1GN

12 - 10x2/1GN

21 - 20x1/1GN

22 - 20x2/2GN

S - SCC

M - CM

E - initial unit

F only CM, new

pcb

G -SCC + CM

SCC Care Control

04 - 2004

10-2008

07 - Juli 7-digit

number

Energy Unit size Model Version Year Month Serial

number

E - Eletric

G - Gas

61 - 6x1/1GN

62 - 6x2/1GN

11 - 10x1/1GN

12 - 10x2/1GN

21 - 20x1/1GN

22 - 20x2/2GN

C - CPC

M - CM

D - CD

A - initial unit

B - new humidity

C - CleanJet, CDS

D - Motor control

03 - 2003 07 - Juli 4-digit

number until

12.1998

7-digit

number from

01.1999

C-Line Unit size Model Year Month Serial number

61 - 6x1/1GN

11 - 10x1/1GN

12 - 10x2/1GN

21 - 20x1/1GN

22 - 20x2/2GN

C - CCC

M - CCM

D - CCD

95 - 1995 05 - Mai 4-digit number

CD Unit size Model Year Month Serial number

00694071234

10194071234

20194071234

02094071234

14G94071234

21G94071234

06 - 6x1/1GN

11 - 10x1/1GN

21 - 20x1/1GN

22 - 20x2/2GN

C - CC

M - CM

CM 101Gas

CM 201Gas

94 - 1994 07 - Juli 4-digit number

SCC Line: E 61 S E 04 07 2345678

from 04.2004

CPC Line: E 61 C B 03 07 2345678

from 06.1997

until 04.2004

C Line: C 61 C 95 05 1234

from 10.1993

until 05.1997

Classic Line: 06 M 94 07 1234

from 1986

until 05.1997

All manuals and user guides at all-guides.com

all-guides.com

Page 7

7

CM

Edition 10-2008

Steam (100°C / 212°F)

Hot Air (30°C - 300°C / 86 - 572°F)

Combi Steam (30°C - 300°C / 86 - 572°F)

Low Temp. Steam (30°C - 99°C / 86 - 210°F)

Finishing (30°C - 300°C / 86 - 572°F)

Cool Down

Cabinet temperature display

Cabinet temperature setting

Timer

Set-Temp. -control

Gas: Reset key

Core temperature Set-Temp. -control

Timer - Core temperature display

Timer - Core temperature dial

CM Control Panel

All manuals and user guides at all-guides.com

Page 8

8

CM

Edition 10-2008

CM Technique

B1 Thermocouple cabinet

B2 Thermocouple quenching / Steam control

B3 Thermocouple core temperature

B5 Thermocouple steam generator (preheating, 180°C (356°F) max)

F3 Safety temperature limiter steam generator 160°C / 320°F

F4 Safety temperature limiter cabinet 360°C / 680°F

Y1 Solenoid valve lling

Y2 Solenoid valve quenching

M1 Fan motor (without jumper)

M4 Pump SC-Automatic

S2 Level electrode

S3 Door contact switch

CM 201/202 only:

M2 Fan motor top (with jumper)

B1

B3

F4

M4

Y1

Y2

B2

M1

S2

B5

F3

S3

All manuals and user guides at all-guides.com

Page 9

9

CM

Edition 10-2008

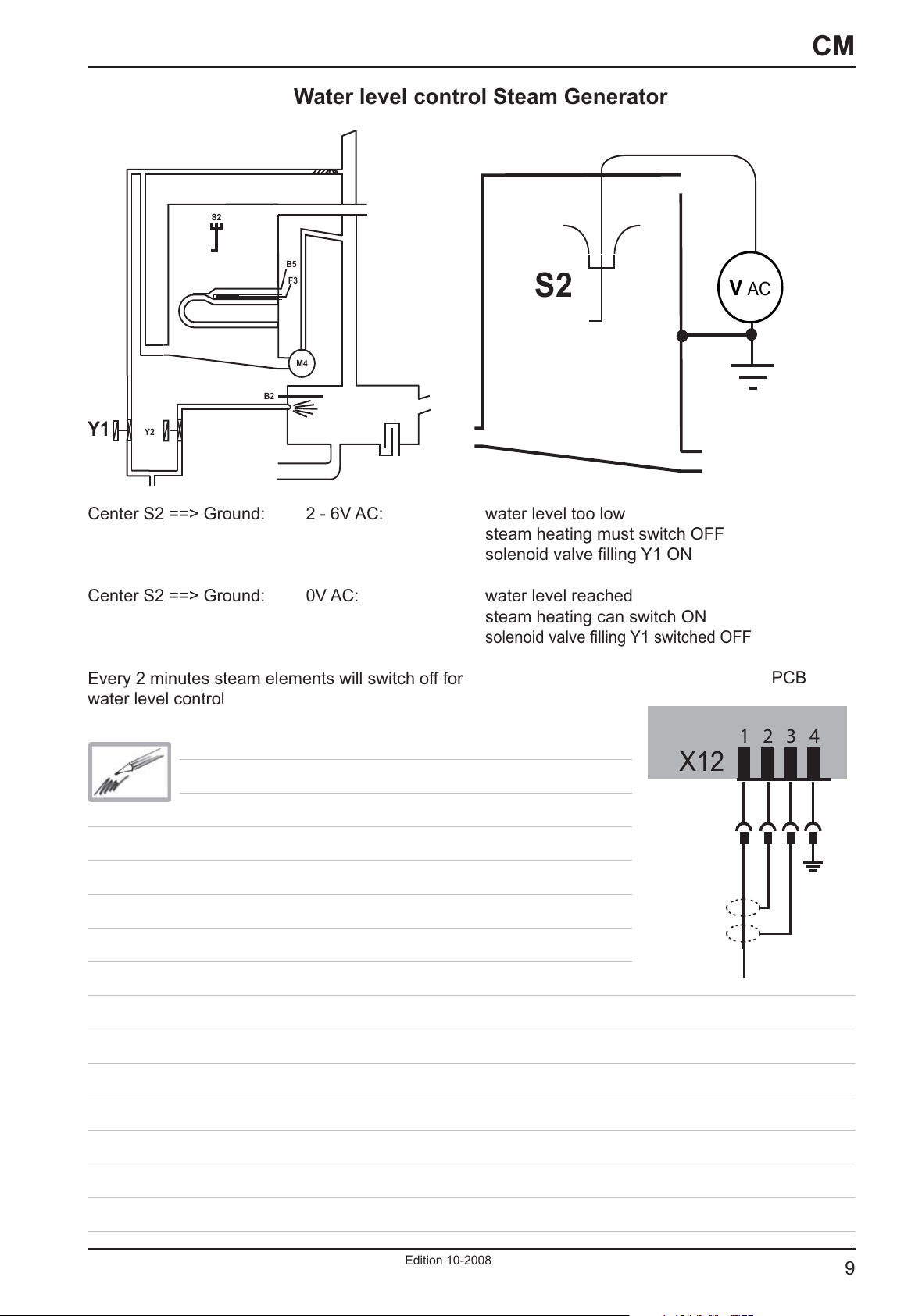

Water level control Steam Generator

V

AC

S2

M4

Y1

Y2

B2

S2

B5

F3

Center S2 ==> Ground: 2 - 6V AC: water level too low

steam heating must switch OFF

solenoid valve lling Y1 ON

Center S2 ==> Ground: 0V AC: water level reached

steam heating can switch ON

solenoid valve lling Y1 switched OFF

Every 2 minutes steam elements will switch off for

water level control

PCB

X12

1 2 3 4

All manuals and user guides at all-guides.com

Page 10

10

CM

Edition 10-2008

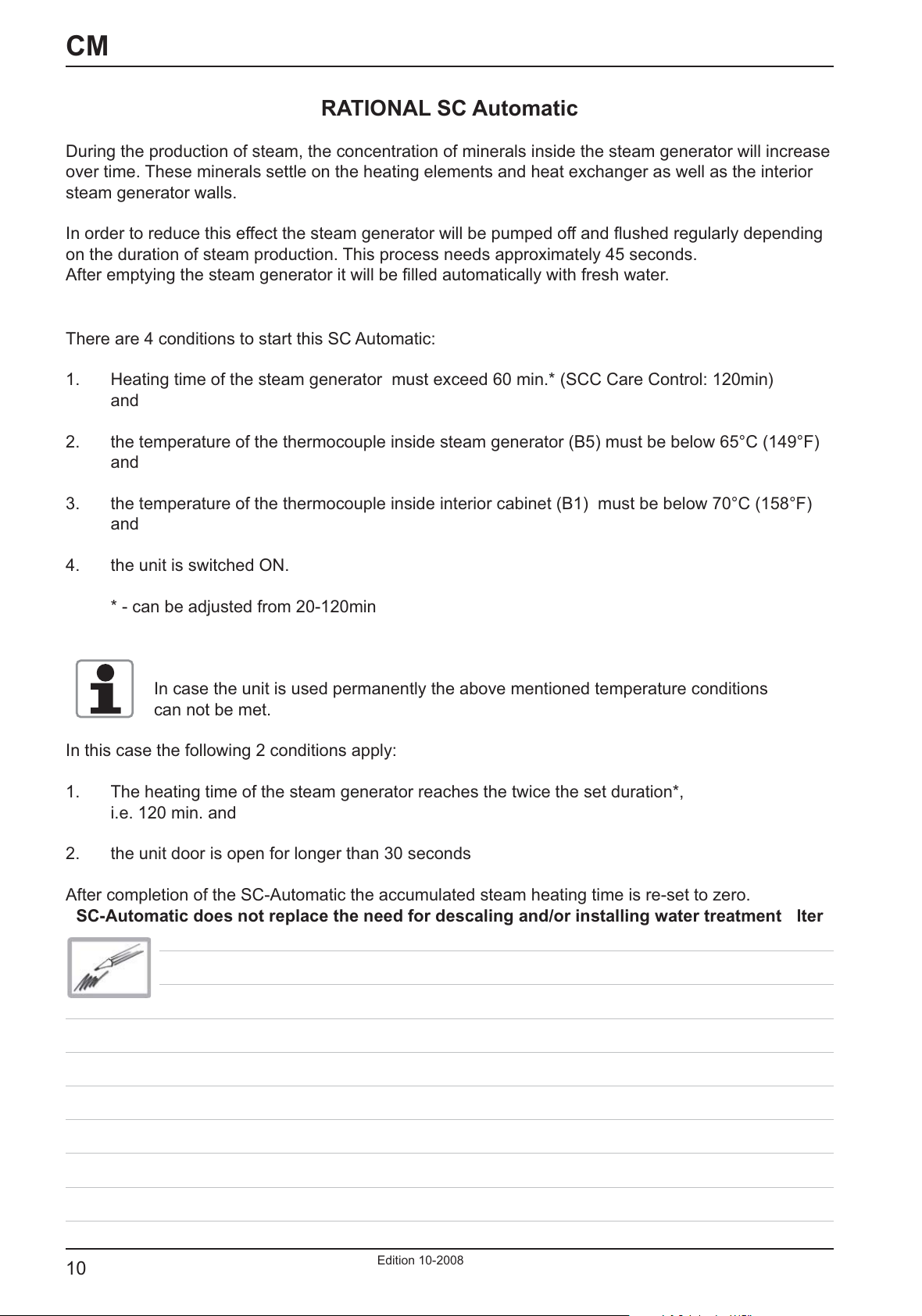

RATIONAL SC Automatic

During the production of steam, the concentration of minerals inside the steam generator will increase

over time. These minerals settle on the heating elements and heat exchanger as well as the interior

steam generator walls.

In order to reduce this effect the steam generator will be pumped off and ushed regularly depending

on the duration of steam production. This process needs approximately 45 seconds.

After emptying the steam generator it will be lled automatically with fresh water.

There are 4 conditions to start this SC Automatic:

1. Heating time of the steam generator must exceed 60 min.* (SCC Care Control: 120min)

and

2. the temperature of the thermocouple inside steam generator (B5) must be below 65°C (149°F)

and

3. the temperature of the thermocouple inside interior cabinet (B1) must be below 70°C (158°F)

and

4. the unit is switched ON.

* - can be adjusted from 20-120min

In case the unit is used permanently the above mentioned temperature conditions

can not be met.

In this case the following 2 conditions apply:

1. The heating time of the steam generator reaches the twice the set duration*,

i.e. 120 min. and

2. the unit door is open for longer than 30 seconds

After completion of the SC-Automatic the accumulated steam heating time is re-set to zero.

SC-Automatic does not replace the need for descaling and/or installing water treatment lter

All manuals and user guides at all-guides.com

Page 11

11

CM

Edition 10-2008

Y1

Y2

B2

B1

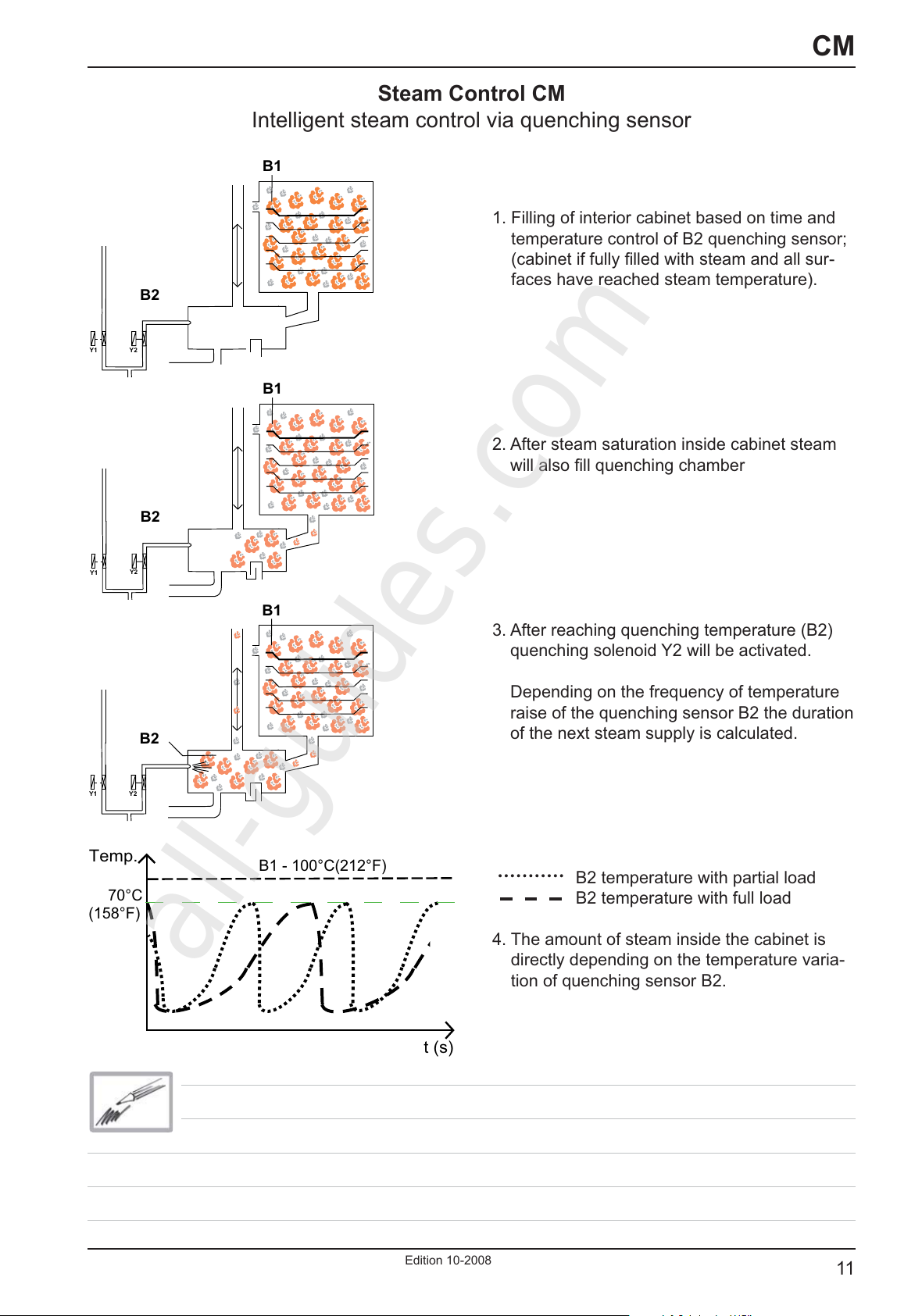

Steam Control CM

Intelligent steam control via quenching sensor

Temp.

t (s)

B1 - 100°C(212°F)

70°C

(158°F)

1. Filling of interior cabinet based on time and

temperature control of B2 quenching sensor;

(cabinet if fully lled with steam and all sur-

faces have reached steam temperature).

2. After steam saturation inside cabinet steam

will also ll quenching chamber

3. After reaching quenching temperature (B2)

quenching solenoid Y2 will be activated.

Depending on the frequency of temperature

raise of the quenching sensor B2 the duration

of the next steam supply is calculated.

B2 temperature with partial load

B2 temperature with full load

4. The amount of steam inside the cabinet is

directly depending on the temperature varia-

tion of quenching sensor B2.

Y1

Y2

B2

B1

Y1

Y2

B2

B1

All manuals and user guides at all-guides.com

all-guides.com

Page 12

12

CM

Edition 10-2008

Additional functions CM

Below are listed the additionaly functions for the user / operator:

1. Cleaning program

1) Cool down cabinet below 60°C / 140°F

2) Spray inside cabinet with Rational cleaner

3) Close cabinet door

4) Select „Cool Down

5) Press core temperature key for 10 sec.

6) „CLEn“ will show in cabinet temperature display

7) Press timer key 1x; Cleaning program starts automatically (open cabinet door

and rinse interior cabinet after 40 min.) Close door again. Since Software ver-

sion C1-06-05 a 10 min step hot air will follow to dry the interior cabinet.

8) After end of program, leave cabinet door open over night.

2. Empty steam generator

1) Open cabinet door

2) Select „Cool Down“

3) Press core temperature key for 10 sec.

4) „CLEn“ will be shown in cabinet temperature display

5) Select „SC“ with temperature dial

6) Close water tap

7) Press timer key 1x and remain on „Cool Down“ position for about 45 sec.

3. Descaling program

1) Open cabinet door

2) Select „Cool Down“

3) Press core temperature key for 10 sec.

4) „CLEn“ will be shown in cabinet temperature display

5) Select „CALC“ with temperature dial

6) Press timer key 1x and follow procedure of the decalci cation instruction. (See

user manual CM).

This should be done after each installation to verify free drain connection and prior to disconnection

the unit for storage.

All manuals and user guides at all-guides.com

Page 13

13

CM

Edition 10-2008

Additional functions CM

4. Changing temperature display from °C to °F

1) Select any mode

2) Press timer and core temperature key simultaneously for 10 sec. until Display

changes from °C to °F or vice versa

3) Release both keys

Aborting of descaling program CM:

- Switch unit off and on again

- press core temperature key 1x

- remaining time of 20 minutes will be displayed. During this time the steam generator will be

ushed and the unit will be operated in steam mode for a couple of minutes to eliminate all re-

maining chemical residues.

All manuals and user guides at all-guides.com

Page 14

14

CM

Edition 10-2008

X7

X19

X20

F1 F2

Transformer

0,1 AT

2 AT

1

1

X7

X19

X20

X18

X23

X31

RS 485

X8

X12

X26

X27

X32X24

X30

RS 232

X63

X3X4X6

X2

X50

2 AT

1

2

3

4

on

off

1

1

1

1

1

1

1

F6.1

F6.1

2 AT

2 AT

X16

X16

F6

F6

42.00.004

42.00.047

X2 B3 Core temperature

X3 B1 Interior cabinet

X4 B2 Quenching / Steam control

X6 B5 Steam generator

X7 ON - OFF switch

X8 Buzzer

X12 Level electrode

X 16 power supply from transformer (42.00.047)

X18 SC - pump

X19 Solenoid valves

X20 Energy management system / Sicotronic

X23 Vent hood (signal door open / closed)

X24 SSR

X26 SSR pulsing (USA version only)

X27 Door contact switch

X30 Serial interface (RS232)

X31 BUS interface

X32 Timer / Core Temp. Potentiometer

X50 external EEPROM

X63 Not used

Since February 2006 PCB 42.00.004 is replaced by 42.00.047.

(Conversion kit: 87.00.139, pls. see Technical info 04-2006)

The transformer on the new PCB 42.00.047 is no more existing and replaced by

external transformer 40.00.227

CM PCB

1

Temperatur

Poti

42.00.004 from 04-2004 ---- 42.00.047 from 02-2006

Counting sequence

All manuals and user guides at all-guides.com

Page 15

15

CM

Edition 10-2008

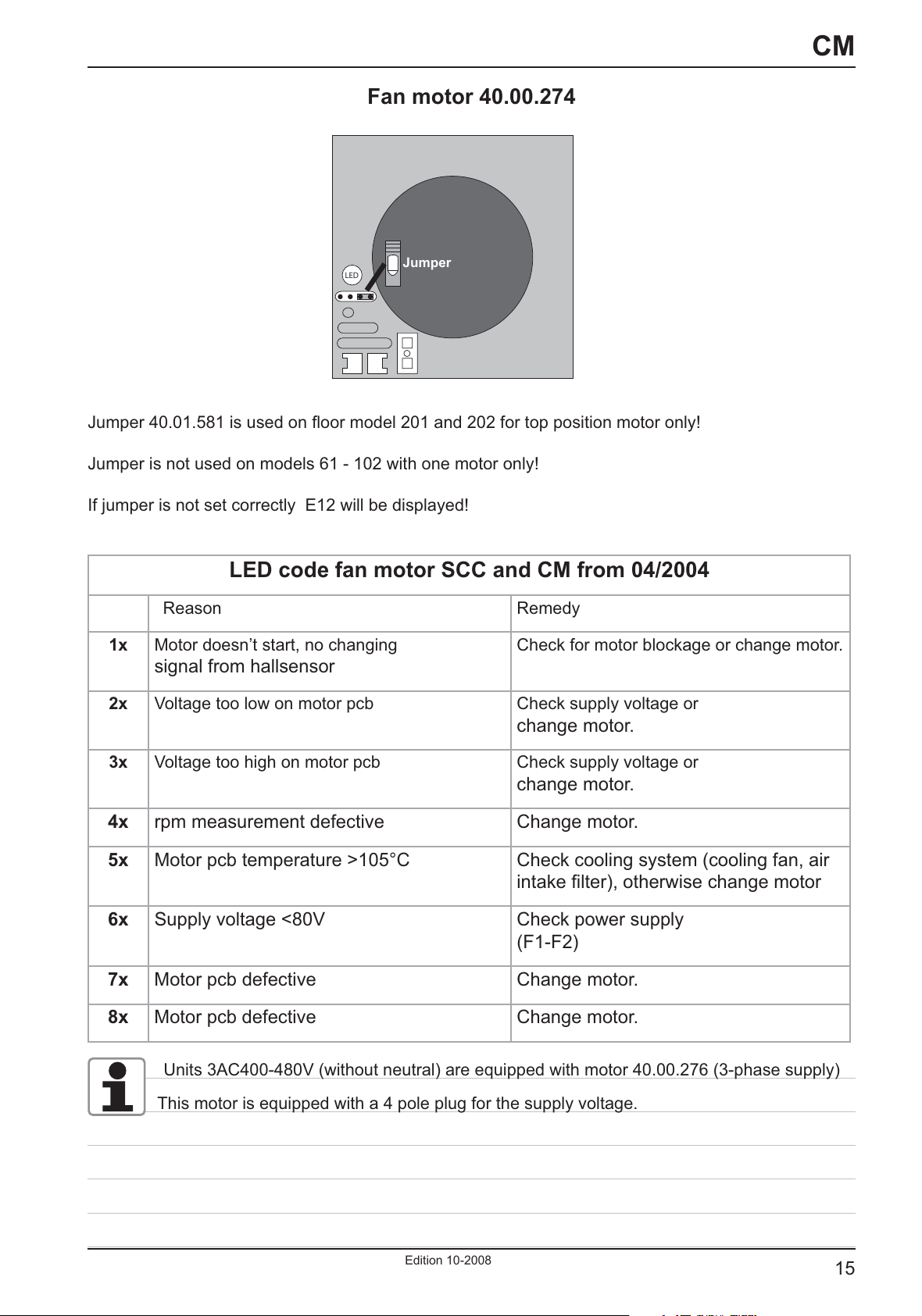

Fan motor 40.00.274

Jumper 40.01.581 is used on oor model 201 and 202 for top position motor only!

Jumper is not used on models 61 - 102 with one motor only!

If jumper is not set correctly E12 will be displayed!

LED code fan motor SCC and CM from 04/2004

Reason Remedy

1x Motor doesn’t start, no changing

signal from hallsensor

Check for motor blockage or change motor.

2x Voltage too low on motor pcb Check supply voltage or

change motor.

3x Voltage too high on motor pcb Check supply voltage or

change motor.

4x rpm measurement defective Change motor.

5x Motor pcb temperature >105°C Check cooling system (cooling fan, air

intake lter), otherwise change motor

6x Supply voltage <80V Check power supply

(F1-F2)

7x Motor pcb defective Change motor.

8x Motor pcb defective Change motor.

Units 3AC400-480V (without neutral) are equipped with motor 40.00.276 (3-phase supply)

This motor is equipped with a 4 pole plug for the supply voltage.

LED

Jumper

All manuals and user guides at all-guides.com

Page 16

16

CM

Edition 10-2008

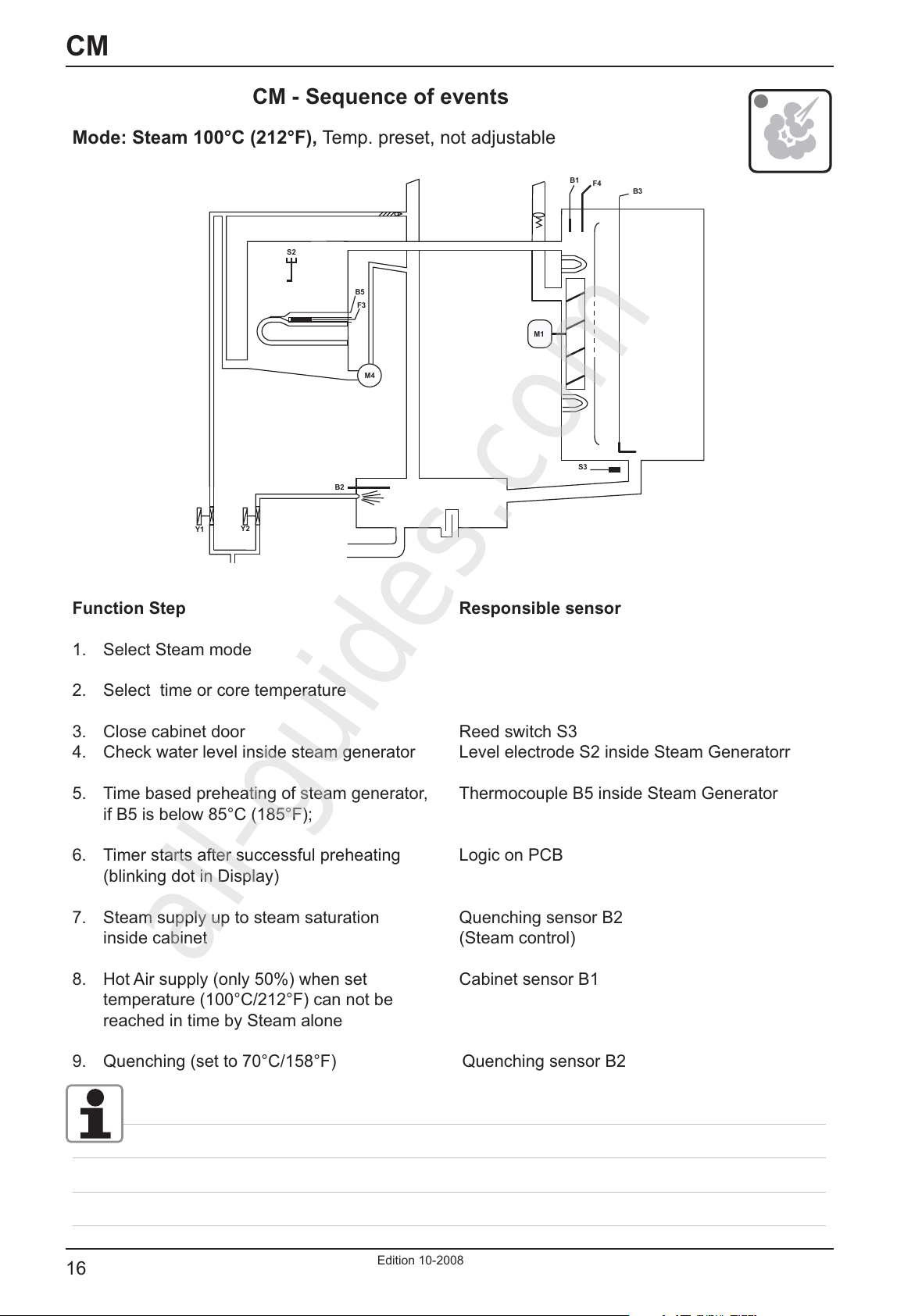

Function Step Responsible sensor

1. Select Steam mode

2. Select time or core temperature

3. Close cabinet door Reed switch S3

4. Check water level inside steam generator Level electrode S2 inside Steam Generatorr

5. Time based preheating of steam generator, Thermocouple B5 inside Steam Generator

if B5 is below 85°C (185°F);

6. Timer starts after successful preheating Logic on PCB

(blinking dot in Display)

7. Steam supply up to steam saturation Quenching sensor B2

inside cabinet (Steam control)

8. Hot Air supply (only 50%) when set Cabinet sensor B1

temperature (100°C/212°F) can not be

reached in time by Steam alone

9. Quenching (set to 70°C/158°F) Quenching sensor B2

CM - Sequence of events

Mode: Steam 100°C (212°F), Temp. preset, not adjustable

B1

B3

F4

M4

Y1

Y2

B2

M1

S2

B5

F3

S3

All manuals and user guides at all-guides.com

all-guides.com

Page 17

17

CM

Edition 10-2008

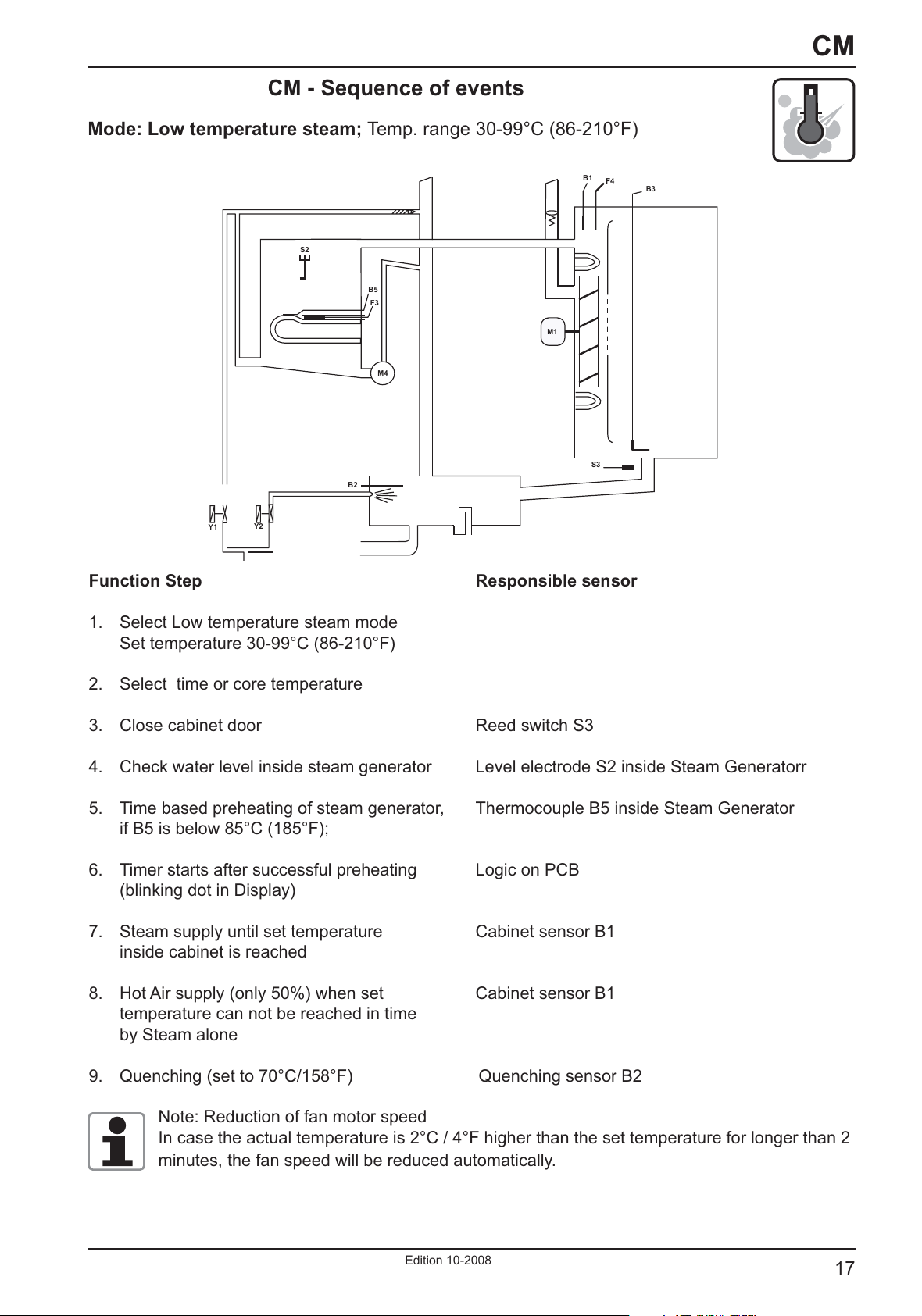

CM - Sequence of events

Mode: Low temperature steam; Temp. range 30-99°C (86-210°F)

Function Step Responsible sensor

1. Select Low temperature steam mode

Set temperature 30-99°C (86-210°F)

2. Select time or core temperature

3. Close cabinet door Reed switch S3

4. Check water level inside steam generator Level electrode S2 inside Steam Generatorr

5. Time based preheating of steam generator, Thermocouple B5 inside Steam Generator

if B5 is below 85°C (185°F);

6. Timer starts after successful preheating Logic on PCB

(blinking dot in Display)

7. Steam supply until set temperature Cabinet sensor B1

inside cabinet is reached

8. Hot Air supply (only 50%) when set Cabinet sensor B1

temperature can not be reached in time

by Steam alone

9. Quenching (set to 70°C/158°F) Quenching sensor B2

Note: Reduction of fan motor speed

In case the actual temperature is 2°C / 4°F higher than the set temperature for longer than 2

minutes, the fan speed will be reduced automatically.

B1

B3

F4

M4

Y1

Y2

B2

M1

S2

B5

F3

S3

All manuals and user guides at all-guides.com

Page 18

18

CM

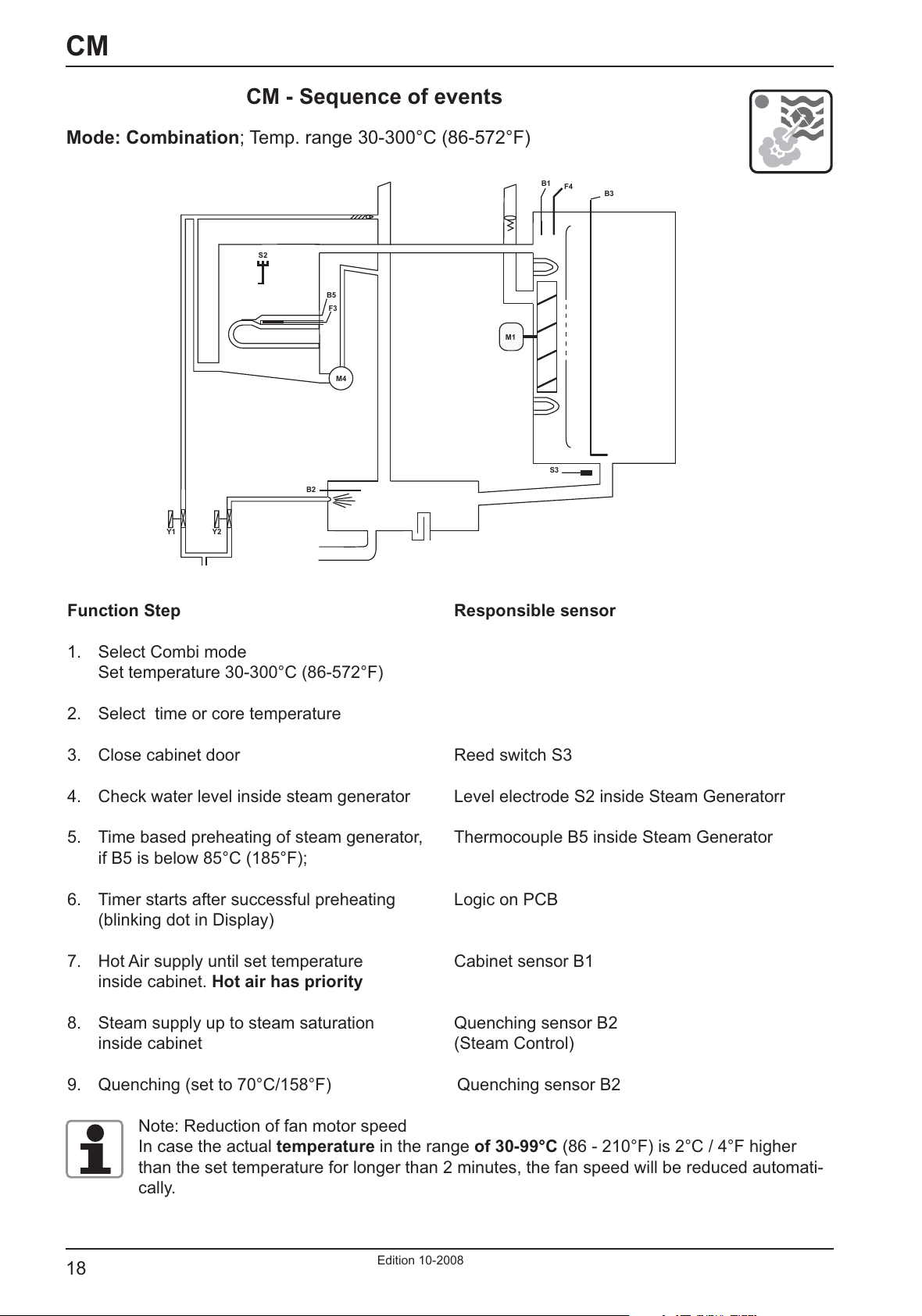

Edition 10-2008

Function Step Responsible sensor

1. Select Combi mode

Set temperature 30-300°C (86-572°F)

2. Select time or core temperature

3. Close cabinet door Reed switch S3

4. Check water level inside steam generator Level electrode S2 inside Steam Generatorr

5. Time based preheating of steam generator, Thermocouple B5 inside Steam Generator

if B5 is below 85°C (185°F);

6. Timer starts after successful preheating Logic on PCB

(blinking dot in Display)

7. Hot Air supply until set temperature Cabinet sensor B1

inside cabinet. Hot air has priority

8. Steam supply up to steam saturation Quenching sensor B2

inside cabinet (Steam Control)

9. Quenching (set to 70°C/158°F) Quenching sensor B2

Note: Reduction of fan motor speed

In case the actual temperature in the range of 30-99°C (86 - 210°F) is 2°C / 4°F higher

than the set temperature for longer than 2 minutes, the fan speed will be reduced automati-

cally.

CM - Sequence of events

Mode: Combination; Temp. range 30-300°C (86-572°F)

B1

B3

F4

M4

Y1

Y2

B2

M1

S2

B5

F3

S3

All manuals and user guides at all-guides.com

Page 19

19

CM

Edition 10-2008

F

CM - Sequence of events

Mode: Finishing; Temp. range 30-300°C (86-572°F)

Function Step Responsible sensor

1. Select Finishing mode

Recommended temperature

30-300°C (86-572°F)

2. Select time or core temperature

3. Close cabinet door Reed switch S3

4. Check water level inside steam generator Level electrode S2 inside Steam Generator

5. Time based preheating of steam generator, Thermocouple B5 inside Steam Generator

if B5 is below 85°C (185°F);

6. Timer starts after successful preheating Logic on PCB

(blinking dot in Display)

7a. Electric units: alternating

12 sec. Hot Air Cabinet sensor B1

6 sec. Steam Quenching sensor B2

7b Gas units: alternating

30 sec. Hot Air Cabinet sensor B1

15 sec. Steam Quenching sensor B2

8. Quenching (set to 70°C/158°F) Quenching sensor B2

Note: Reduction of fan motor speed

In case the actual temperature in the range of 30-99°C (86 - 210°F) is 2°C / 4°F higher

than the set temperature for longer than 2 minutes, the fan speed will be reduced automati-

cally.

B1

B3

F4

M4

Y1

Y2

B2

M1

S2

B5

F3

S3

All manuals and user guides at all-guides.com

Page 20

20

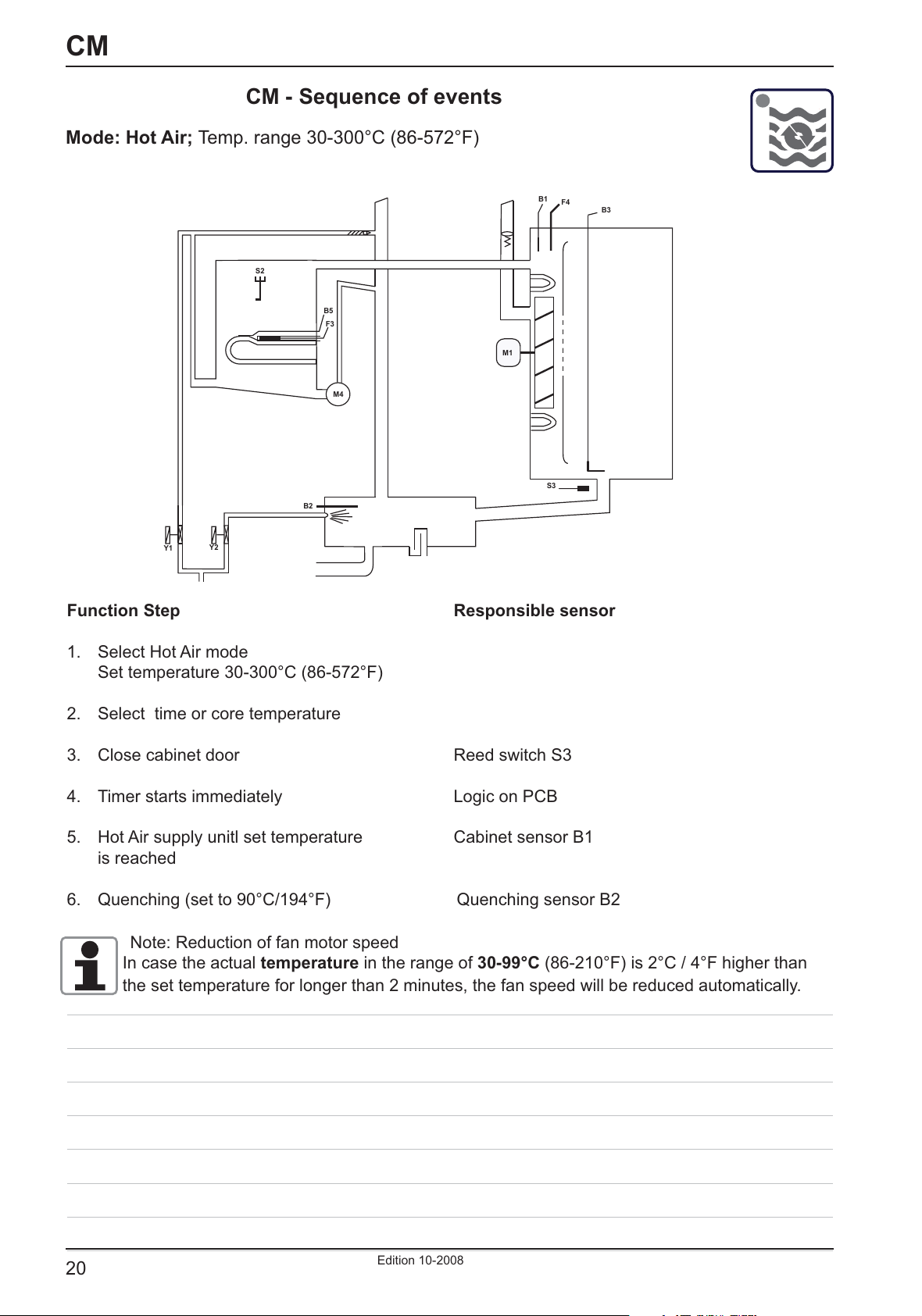

CM

Edition 10-2008

CM - Sequence of events

Mode: Hot Air; Temp. range 30-300°C (86-572°F)

Function Step Responsible sensor

1. Select Hot Air mode

Set temperature 30-300°C (86-572°F)

2. Select time or core temperature

3. Close cabinet door Reed switch S3

4. Timer starts immediately Logic on PCB

5. Hot Air supply unitl set temperature Cabinet sensor B1

is reached

6. Quenching (set to 90°C/194°F) Quenching sensor B2

Note: Reduction of fan motor speed

In case the actual temperature in the range of 30-99°C (86-210°F) is 2°C / 4°F higher than

the set temperature for longer than 2 minutes, the fan speed will be reduced automatically.

B1

B3

F4

M4

Y1

Y2

B2

M1

S2

B5

F3

S3

All manuals and user guides at all-guides.com

Page 21

21

CM

Edition 10-2008

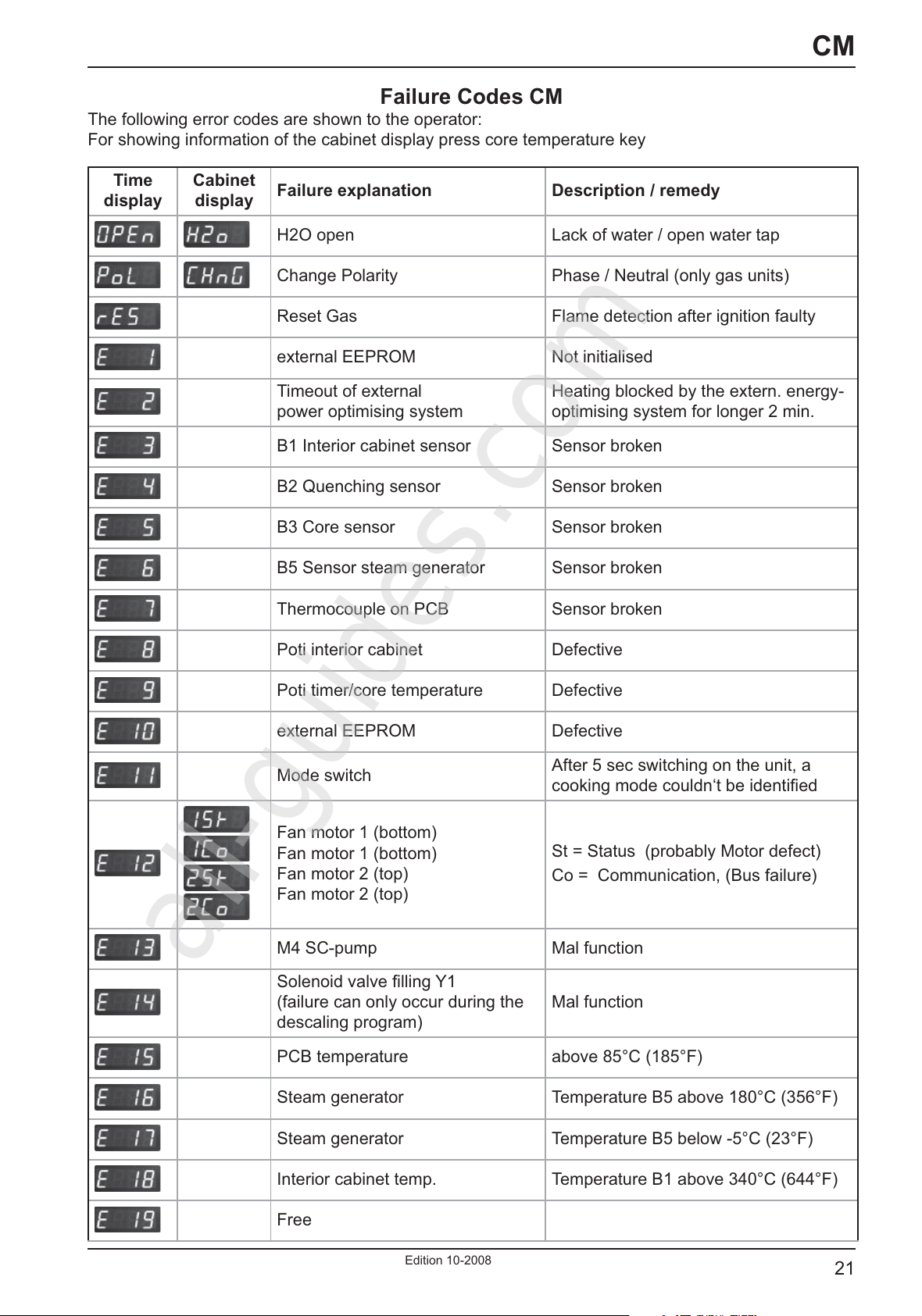

Failure Codes CM

The following error codes are shown to the operator:

For showing information of the cabinet display press core temperature key

Time

display

Cabinet

display

Failure explanation Description / remedy

H2O open Lack of water / open water tap

Change Polarity Phase / Neutral (only gas units)

Reset Gas Flame detection after ignition faulty

external EEPROM Not initialised

Timeout of external

power optimising system

Heating blocked by the extern. energy-

optimising system for longer 2 min.

B1 Interior cabinet sensor Sensor broken

B2 Quenching sensor Sensor broken

B3 Core sensor Sensor broken

B5 Sensor steam generator Sensor broken

Thermocouple on PCB Sensor broken

Poti interior cabinet Defective

Poti timer/core temperature Defective

external EEPROM Defective

Mode switch

After 5 sec switching on the unit, a

cooking mode couldn‘t be identi ed

Fan motor 1 (bottom)

Fan motor 1 (bottom)

Fan motor 2 (top)

Fan motor 2 (top)

St = Status (probably Motor defect)

Co = Communication, (Bus failure)

M4 SC-pump Mal function

Solenoid valve lling Y1

(failure can only occur during the

descaling program)

Mal function

PCB temperature above 85°C (185°F)

Steam generator Temperature B5 above 180°C (356°F)

Steam generator Temperature B5 below -5°C (23°F)

Interior cabinet temp. Temperature B1 above 340°C (644°F)

Free

All manuals and user guides at all-guides.com

all-guides.com

Page 22

22

CM

Edition 10-2008

Failure Codes CM (cont.)

For showing information of the cabinet display press core temperature key

Time

display

Cabinet

display

Failure explanation Description / remedy

Ignition box 1

Ignition box 2 Ignition box does not reply, Bus failure

Ignition box 1 Steam

Ignition box 1 Hot air

Ignition box 2 Hot air

Ignition box defective (change box)

Ignition box 1 Steam

Ignition box 1 Hot air

Ignition box 2 Hot air

Testing of ignition and monitoring

necessary

Free

EEPROM

Actual data structure of the EEPROM

does not match with the software; flash

pcb first

All manuals and user guides at all-guides.com

Page 23

23

CM

Edition 10-2008

Service level CM

1) Switch unit ON

2) On operator PCB set DIP switch 1 to „ON“ position

3) Select service package with timer dial:

Diagnostic Program

Error code history

Running times

Basic settings

4)

Activate with core temperature key the desired service package

5) Select with timer dial the desired step

6) Activate selected step by pressing timer key

7)

To de-activate service package set DIP switch 1 to „OFF“ position

.

Function Test

1) Switch unit ON

2) On operator PCB set DIP switch 3 to „ON“ position

First step of function test is displayed.

3) Select desired step of function test with timer dial

4) Activate preselected step by pressing timer key

5) Activate selected function step with core temperature key

6)

To de-activate function test set DIP switch 3 to „OFF“ position

.

X7

X19

X20

F1 F2

Transformer

0,1 AT

2 AT

1

1

X7

X19

X20

X18

X23

X31

RS 485

X8

X12

X26

X27

X32X24

X30

RS 232

X63

X3X4X6

X2

X50

2 AT

1

2

3

4

on

off

1

1

1

1

1

1

1

F6.1

F6.1

2 AT

2 AT

X16

X16

F6

F6

42.00.004

42.00.047

1

234

on

1

234

on

1

234

on

1

234

on

All manuals and user guides at all-guides.com

Page 24

24

CM

Edition 10-2008

Service level: dP -- Diagnostic Program

Description Connection

Cabinet

Display

Time display

Software Version

Software

Version: C - 1

Software

07.01

B1 Cabinet sensor X 3 actual value max value

Reset by pressing

for 5 sec.

B2 Quenching sensor X 4 actual value max value

Reset by pressing

for 5 sec.

B3 Core sensor X 2 actual value max value

Reset by pressing

for 5 sec.

B5 Steam generator

sensor

X 6 actual value max value

Reset by pressing

for 5 sec.

PCB temperature actual value max value

Reset by pressing

for 5 sec.

S3 Door contact X27:(1-2) 1 - 0

0 = door open

1 = door closed

S2 Water level steam

generator

X12:(1-4) S2

X19:(1-3) Y1

S2: 0 - 1 Y1: 1 - 0

Steam elements

0 - off; 1 - 50%; 2 - 100%

actual Temp.

B5

0 - 1 - 2

Hot Air elements

0 - off; 1 - 50%; 2 - 100%

actual Temp.

B1

0 - 1 - 2

Speed fan motor bottom BUS Set rpm actual rpm

Speed fan motor top BUS Set rpm actual rpm

only oor model

201/202

Energy management

(Sicotronic)

X 20 1 - 0

SSR control (US version)

X24

1 - 0 0 = US version only

Unit size and type

61 - 202 ELE - GAS

Flame current Steam x.x A*

since SW Version:

C1-06-05 ( ame current)

Flame current Hot air

top

Hot air top

x.x A*

since SW Version:

C1-06-05 ( ame current)

Flame current Hot air

bottom

Hot air bottom

x.x A*

since SW Version:

C1-06-05 ( ame current)

*

With SW Version C1-06-05 the ame current will show as 20-24A

(This value must be divided by 4 to get the correct ame current e. g. 22:4 = 5,5A.)

Starting with SW version C1-07-01 the actual ame current is shown .

+

+

+

+

+

All manuals and user guides at all-guides.com

Page 25

25

CM

Edition 10-2008

Service Level: ER -- Error code history

Since software version C1-07-01 the last 10 general error messages are shown

(applies for electric and gas models)

Er When timer key is pressed the error code will be displayed. i.e.:

Error number Error Code Description

Er1 3 B1 Cabinet sensor defective

Er2 14 Y1 Filling solenoid defective

Er3 ---- ER10

Gas error GE: (gas units only!)

Since software version C1-07-01 the last 16 gas error messages (GE11 - GE26) are shown in

addition to the general error messages. These error codes are generated by the ignition box

Error number Error Code Description

GE11 20 No rpm signal

GE12 32 No ame after 5 ignition sequences

GE13 --- GE26

Indication of ignition box error messages (1-32 is shown to the operator as „rES“):

1 Hot air or Steam no gas, gas valve or electrode defective

14 Hot air gas valve control, change ignition box

19 Hot air no ame because ame current is too low

check burner setting, ame current, ignition cable and plug

20 Hot air wrong or no rpm signal from gas blower

check gas blower, power supply gas blower and control harness of gas blower

22 Hot air no ame after 5 ignition sequences

no gas, gas valve or electrode defective

24 Steam gas valve control, change ignition box

29 Steam no ame because ame current is too low

check burner setting, ame current, ignition cable and plug

30 Steam wrong or no rpm signal from gas blower

check gas blower, power supply gas blower and control harness of gas blower

32 Steam no ame after 5 ignition sequences

no gas, gas valve or electrode defective

Possible failure in case of „E21“

33, 36 Change ignition box

35 Check frequency of main

39 Hot air Check burner setting, ignition electrode and distance, and ame current

40 Hot air Check ignition cable

42 Steam Check burner setting, ignition electrode and distance, and ame current

43 Steam Check ignition cable

Is shown on display „CHnG PoL“

34 Change polarity of mains

All other numbers (2-13, 15-18, 21, 23, 25-28, 31): change ignition box

All manuals and user guides at all-guides.com

Page 26

26

CM

Edition 10-2008

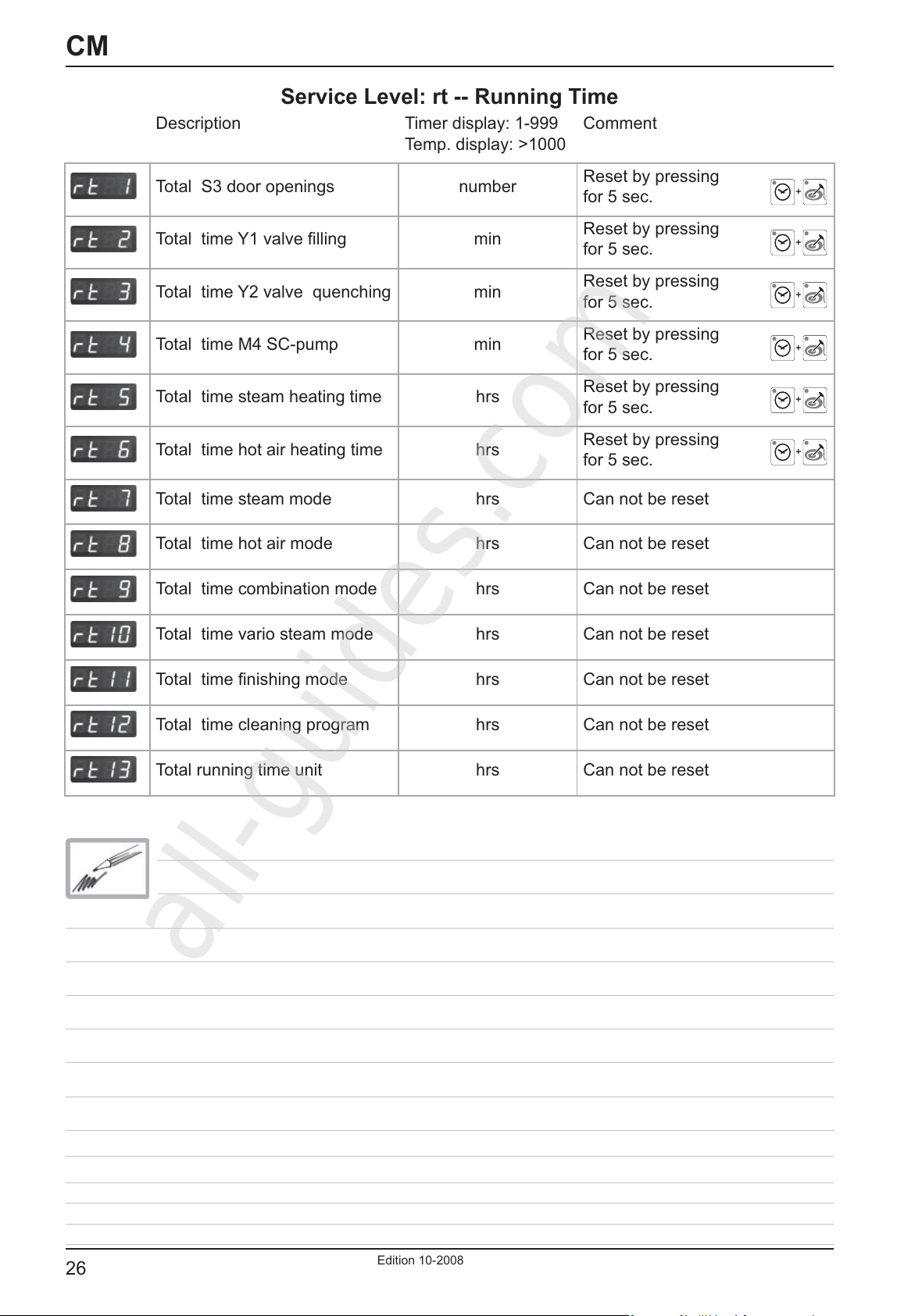

Service Level: rt -- Running Time

Description Timer display: 1-999

Temp. display: >1000

Comment

Total S3 door openings number

Reset by pressing

for 5 sec.

Total time Y1 valve lling min

Reset by pressing

for 5 sec.

Total time Y2 valve quenching min

Reset by pressing

for 5 sec.

Total time M4 SC-pump min

Reset by pressing

for 5 sec.

Total time steam heating time hrs

Reset by pressing

for 5 sec.

Total time hot air heating time hrs

Reset by pressing

for 5 sec.

Total time steam mode hrs Can not be reset

Total time hot air mode hrs Can not be reset

Total time combination mode hrs Can not be reset

Total time vario steam mode hrs Can not be reset

Total time nishing mode hrs Can not be reset

Total time cleaning program hrs Can not be reset

Total running time unit hrs Can not be reset

+

+

+

+

+

+

All manuals and user guides at all-guides.com

all-guides.com

Page 27

27

CM

Edition 10-2008

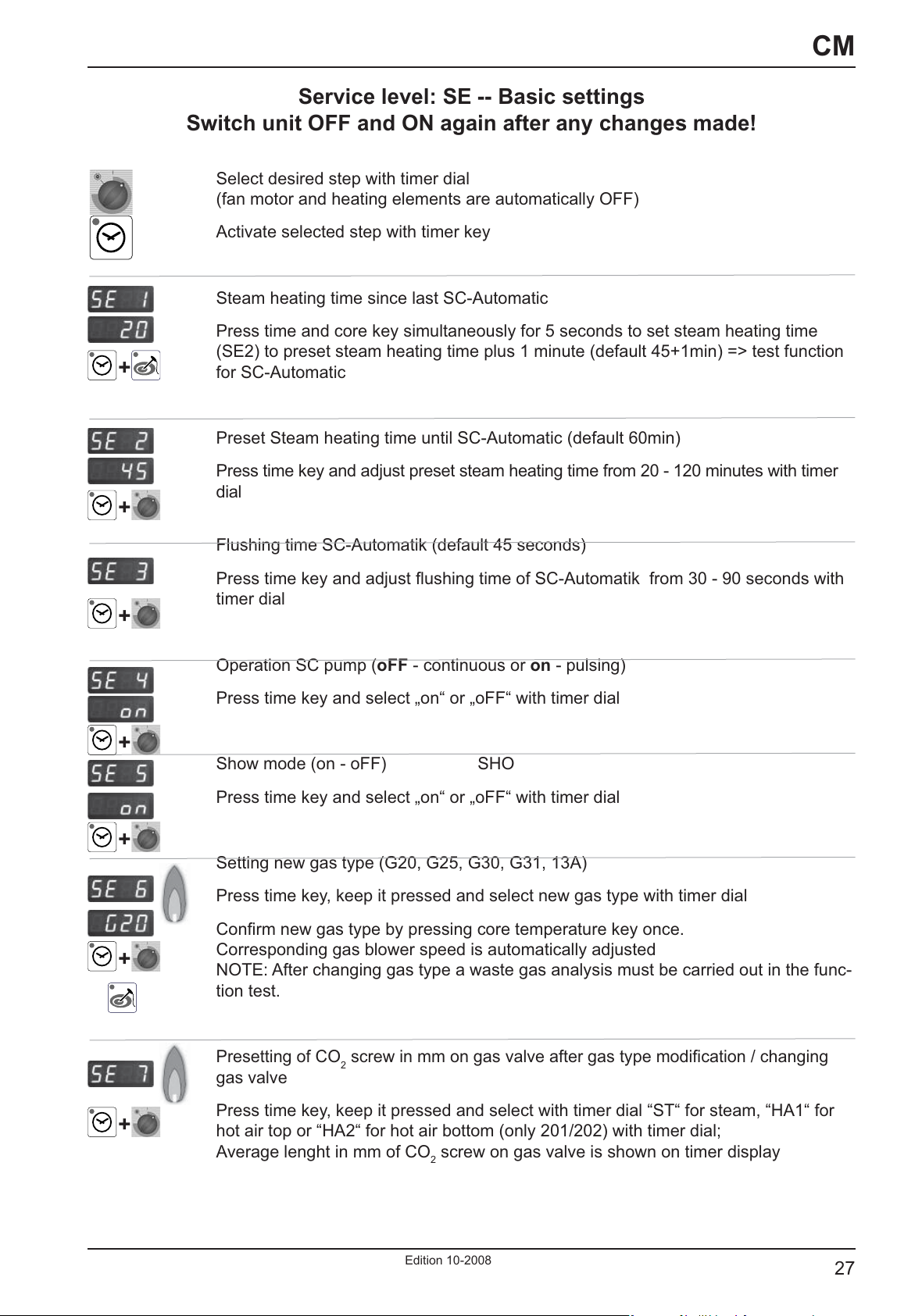

Service level: SE -- Basic settings

Switch unit OFF and ON again after any changes made!

Select desired step with timer dial

(fan motor and heating elements are automatically OFF)

Activate selected step with timer key

Steam heating time since last SC-Automatic

Press time and core key simultaneously for 5 seconds to set steam heating time

(SE2) to preset steam heating time plus 1 minute (default 45+1min) => test function

for SC-Automatic

Preset Steam heating time until SC-Automatic (default 60min)

Press time key and adjust preset steam heating time from 20 - 120 minutes with timer

dial

Flushing time SC-Automatik (default 45 seconds)

Press time key and adjust ushing time of SC-Automatik from 30 - 90 seconds with

timer dial

Operation SC pump (oFF - continuous or on - pulsing)

Press time key and select „on“ or „oFF“ with timer dial

Show mode (on - oFF) SHO

Press time key and select „on“ or „oFF“ with timer dial

Setting new gas type (G20, G25, G30, G31, 13A)

Press time key, keep it pressed and select new gas type with timer dial

Con rm new gas type by pressing core temperature key once.

Corresponding gas blower speed is automatically adjusted

NOTE: After changing gas type a waste gas analysis must be carried out in the func-

tion test.

Presetting of CO2 screw in mm on gas valve after gas type modi cation / changing

gas valve

Press time key, keep it pressed and select with timer dial “ST“ for steam, “HA1“ for

hot air top or “HA2“ for hot air bottom (only 201/202) with timer dial;

Average lenght in mm of CO

2

screw on gas valve is shown on timer display

+

+

+

+

+

+

+

All manuals and user guides at all-guides.com

Page 28

28

CM

Edition 10-2008

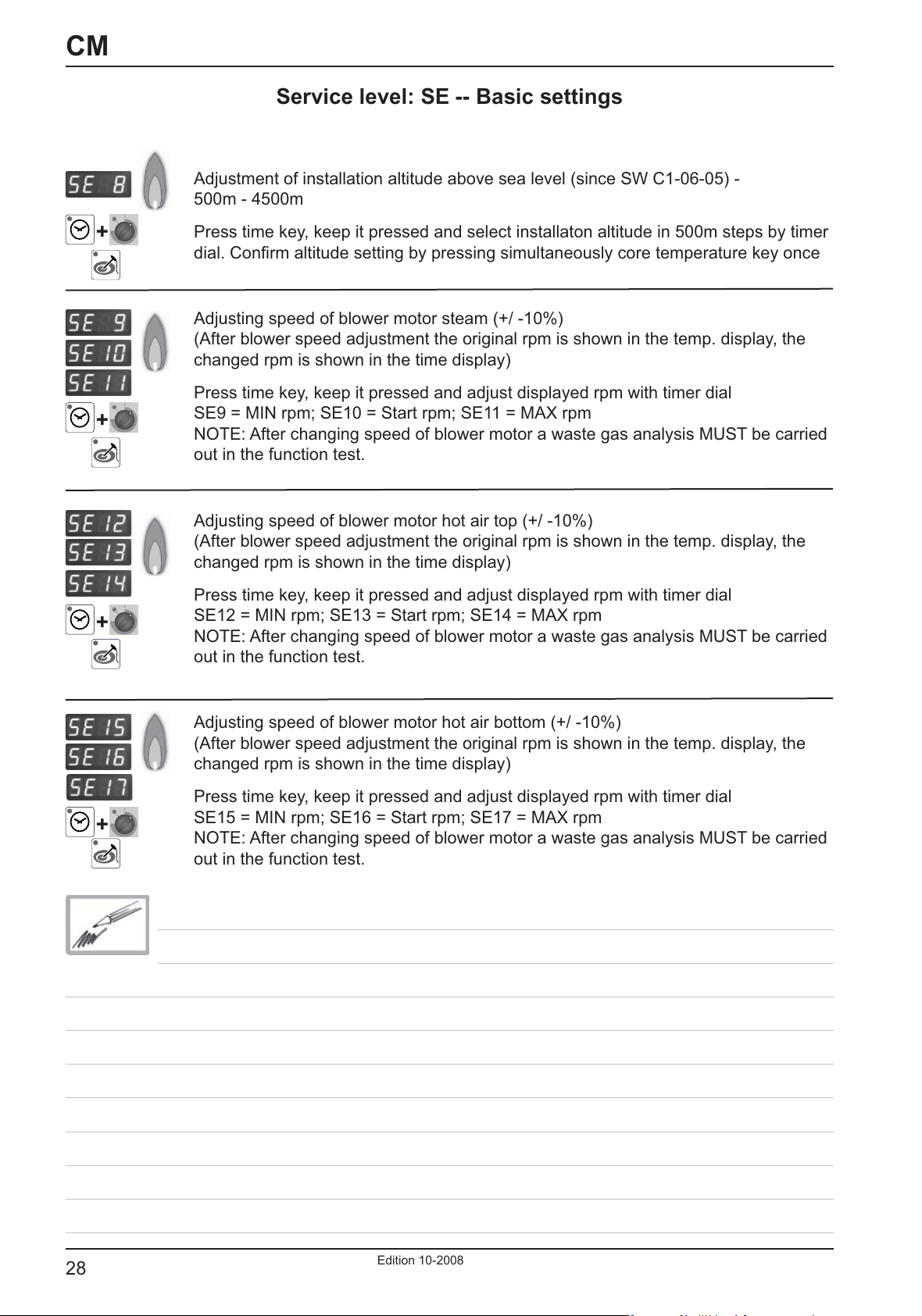

Service level: SE -- Basic settings

Adjustment of installation altitude above sea level (since SW C1-06-05) -

500m - 4500m

Press time key, keep it pressed and select installaton altitude in 500m steps by timer

dial. Con rm altitude setting by pressing simultaneously core temperature key once

Adjusting speed of blower motor steam (+/ -10%)

(After blower speed adjustment the original rpm is shown in the temp. display, the

changed rpm is shown in the time display)

Press time key, keep it pressed and adjust displayed rpm with timer dial

SE9 = MIN rpm; SE10 = Start rpm; SE11 = MAX rpm

NOTE: After changing speed of blower motor a waste gas analysis MUST be carried

out in the function test.

Adjusting speed of blower motor hot air top (+/ -10%)

(After blower speed adjustment the original rpm is shown in the temp. display, the

changed rpm is shown in the time display)

Press time key, keep it pressed and adjust displayed rpm with timer dial

SE12 = MIN rpm; SE13 = Start rpm; SE14 = MAX rpm

NOTE: After changing speed of blower motor a waste gas analysis MUST be carried

out in the function test.

Adjusting speed of blower motor hot air bottom (+/ -10%)

(After blower speed adjustment the original rpm is shown in the temp. display, the

changed rpm is shown in the time display)

Press time key, keep it pressed and adjust displayed rpm with timer dial

SE15 = MIN rpm; SE16 = Start rpm; SE17 = MAX rpm

NOTE: After changing speed of blower motor a waste gas analysis MUST be carried

out in the function test.

+

+

+

+

All manuals and user guides at all-guides.com

Page 29

29

CM

Edition 10-2008

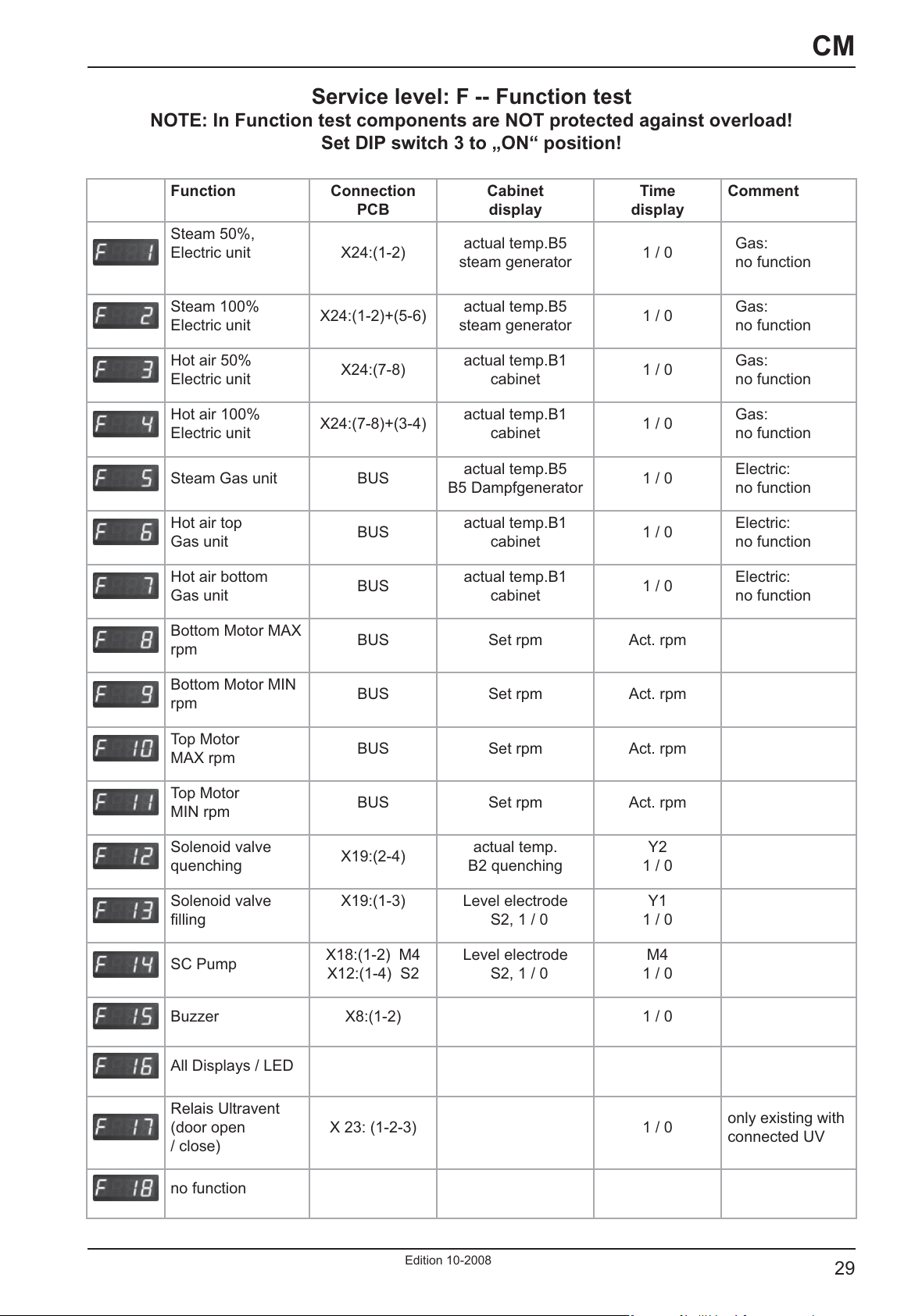

Service level: F -- Function test

NOTE: In Function test components are NOT protected against overload!

Set DIP switch 3 to „ON“ position!

Function Connection

PCB

Cabinet

display

Time

display

Comment

Steam 50%,

Electric unit X24:(1-2)

actual temp.B5

steam generator

1 / 0

Gas:

no function

Steam 100%

Electric unit

X24:(1-2)+(5-6)

actual temp.B5

steam generator

1 / 0

Gas:

no function

Hot air 50%

Electric unit

X24:(7-8)

actual temp.B1

cabinet

1 / 0

Gas:

no function

Hot air 100%

Electric unit

X24:(7-8)+(3-4)

actual temp.B1

cabinet

1 / 0

Gas:

no function

Steam Gas unit BUS

actual temp.B5

B5 Dampfgenerator

1 / 0

Electric:

no function

Hot air top

Gas unit

BUS

actual temp.B1

cabinet

1 / 0

Electric:

no function

Hot air bottom

Gas unit

BUS

actual temp.B1

cabinet

1 / 0

Electric:

no function

Bottom Motor MAX

rpm

BUS Set rpm Act. rpm

Bottom Motor MIN

rpm

BUS Set rpm Act. rpm

Top Motor

MAX rpm

BUS Set rpm Act. rpm

Top Motor

MIN rpm

BUS Set rpm Act. rpm

Solenoid valve

quenching

X19:(2-4)

actual temp.

B2 quenching

Y2

1 / 0

Solenoid valve

lling

X19:(1-3) Level electrode

S2, 1 / 0

Y1

1 / 0

SC Pump

X18:(1-2) M4

X12:(1-4) S2

Level electrode

S2, 1 / 0

M4

1 / 0

Buzzer X8:(1-2) 1 / 0

All Displays / LED

Relais Ultravent

(door open

/ close)

X 23: (1-2-3) 1 / 0

only existing with

connected UV

no function

All manuals and user guides at all-guides.com

Page 30

30

CM

Edition 10-2008

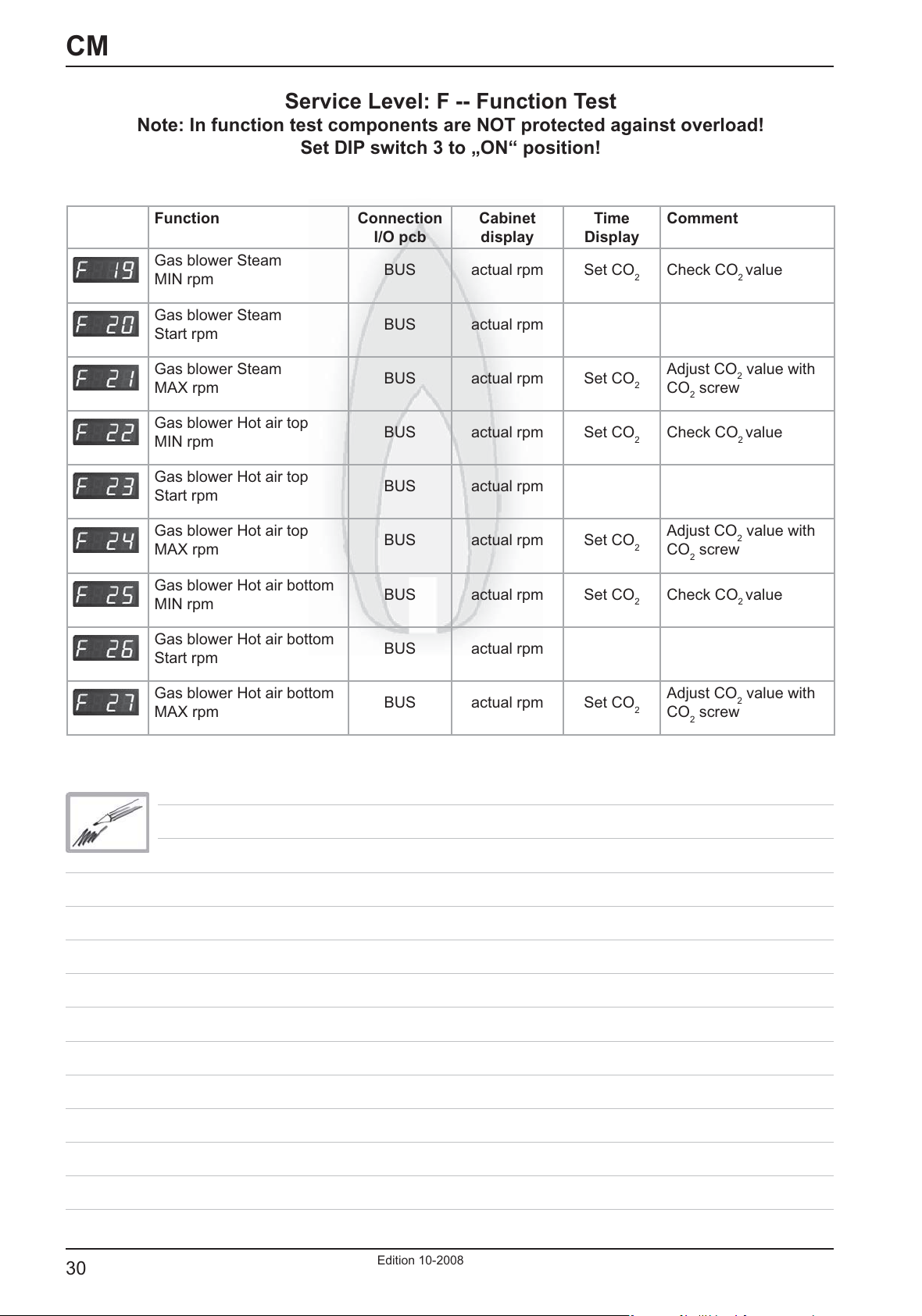

Service Level: F -- Function Test

Note: In function test components are NOT protected against overload!

Set DIP switch 3 to „ON“ position!

Function Connection

I/O pcb

Cabinet

display

Time

Display

Comment

Gas blower Steam

MIN rpm

BUS actual rpm Set CO

2

Check CO2 value

Gas blower Steam

Start rpm

BUS actual rpm

Gas blower Steam

MAX rpm

BUS actual rpm Set CO

2

Adjust CO2 value with

CO

2

screw

Gas blower Hot air top

MIN rpm

BUS actual rpm Set CO

2

Check CO2 value

Gas blower Hot air top

Start rpm

BUS actual rpm

Gas blower Hot air top

MAX rpm

BUS actual rpm Set CO

2

Adjust CO2 value with

CO

2

screw

Gas blower Hot air bottom

MIN rpm

BUS actual rpm Set CO

2

Check CO2 value

Gas blower Hot air bottom

Start rpm

BUS actual rpm

Gas blower Hot air bottom

MAX rpm

BUS actual rpm Set CO

2

Adjust CO2 value with

CO

2

screw

All manuals and user guides at all-guides.com

Page 31

31

CM

Edition 10-2008

- Connect RS 232 adapter cable to Flash-Box and to the selected interface (e. g. COM 1) of the PC.

- Connect USB-cable to Flash-Box and PC.

- After the USB cable was connected the les which are transferred will appear on the Message

window. An end sign indicates that the transfer is completed.

- On the Flash-Box set DIP- switch 2 to „OFF“ and 3 to „ON“ (the other switches remain „OFF“).

Flash-Box is ready for use.

Software update CM units

1 General

To update a CM unit of new generation you need:

- CM-Software e.g. C-1-07.01.hex

- software „Megaload.zip“.

Both are available on the Rational Service internet page under:

„Technical documentation/Software update SCC-Line/CM“.

- download CM-Software e.g.“C-1-07.01.hex“

- download „megaload.zip“ to PC,

- open le„megaload.zip“,

- Start the program Setup.exe and follow the description on the screen,

- Start the program Megaload and carry out basic settings.

Open CM Software; e.g.: C-1-07.01.hex

Select desired interface on the PC, e.g. Com1

Transfer rate must be set to 19200 bps.

On the „Message“ window the progress of the download

software download is indicated.

Now You can load the software:

- direct from PC to CM unit, (see item 4 next page) or

- with Flash-Box 87.00.037 to CM unit, (see following items 2, 3).

Flash-Box kit contains of:

- Flash-Box

- Adapter cable RS 232

and USB-cable

(only required for down

loading the unit soft-

ware to the Flash-Box).

- Open lid of the

Flash-Box

- Set DIP - switch

2 to „ON“. (other

switches remain in

the „OFF“ position)

2

Load software to Flash-Box

All manuals and user guides at all-guides.com

all-guides.com

Page 32

32

CM

Edition 10-2008

1

2

3

4

on

on

X7

X19

X20

X18

X23

X31

RS 485

X8

X12

X16

X17

X26

X27

X

3X32

X24

X24

X63

X63

F6.1

F6.1

F6

X3X4XX6

X2

X2

X50

X50

on

on

off

off

0,1 AT

0,1 AT

2 AT

X7

X7

X19

X19

X20

X20

F1F1F2

F2

0,1 AT

0,1 AT

2 AT

2 AT

Transformer

Transformer

X16

X16

42.00.004

42.00.047

X30

X30

RS 232

RS 232

3 Copy software from ash box to unit:

- Switch off unit with mode switch and open control panel;

- Connect RS 232 interface of CM pcb with ash box;

- Switch CM unit on. Displays of pcb remain off. Green LED of ash box starts

blinking.

- After successful uploading the CM pcb will switch on; the green LED on the

ash box stops blinking and remains on continuously.

- Switch unit off and disconnect ash box.

- Unit is ready for operation;

4 Load software via PC to CM unit:

- Switch off unit with mopde switch and open control panel

- Connect RS 232 interface of CM pcb with standard RS 232 cable to PC.

- Switch CM unit on. Displays of pcb remain off. The transfer status will be

displayed in a message window.

- After successful uploading the CM pcb will switch on;

- Switch unit off;

- Close megaload program and disconnect RS 232 cable.

- Unit is ready for operation;

To connect via USB adapter the driver must be installed on the PC.

Set driver with the following setting:

Bit: 9600

Data bit: none

Parity: 8

Stop bit: none

Flow control: none

Connect USB cable with ash box and PC

Start Megaloader

Connect null modem cable with ash box and USB Adapter

After connecting the USB cable the download is shown in the display window.

RS 232

All manuals and user guides at all-guides.com

Page 33

33

CM

Edition 10-2008

Fault tree: Changing CM pcb / replace EEPROM

Disconnect unit from power supply

(Remove fuses F1 and F2)

Reconnect unit from power supply

( x fuses F1 and F2 back)

Software update of pcb to

C1-07-01 or later

Disconnect unit from power supply

(Remove fuses F1 and F2)

Reconnect EEPROM to pcb

Reconnect unit from power supply

( x fuses F1 and F2 back)

Error „E1“ still existing

Call Rational Service

OK

Replace new PCB

Note:

Do NOT connect external EEPROM as software version of pcb might

not be compatible with pcb without updating!

2 reasons to follow below procedure:

- Changing of pcb (software version on replacement pcb is not known)

- Unit display „E1“ - replace external memory with new EEPROM

All manuals and user guides at all-guides.com

Page 34

34

CM

Edition 10-2008

All manuals and user guides at all-guides.com

Page 35

35

SCC

Edition 10-2008a

SCC Control panel

All manuals and user guides at all-guides.com

Page 36

36

SCC

Edition 10-2008a

Comparing display of software version

1

2

3

4

1

2

3

4

13:45

Display up to software version

SCC 01-07-12

Display since software version

SCC 02-01-01

All manuals and user guides at all-guides.com

all-guides.com

Page 37

37

SCC

Edition 10-2008a

1

2

3

4

1

2

3

4

1

2

3

4

Large roast

Pan fries

Poultry

Fish

Side dishes

Potato product

Egg dishes/Desserts

Bakery products

Finishing

SelfCooking Control

Level 1

SelfCooking Control

Level 2

SelfCooking Control

Level 3

roast braise

roast with

crackling

soft

roasting

soft cooking

low

high

medium

62°C

close

door

Display since software version SCC 02-01-01

overnight

roasting

13:45

overnight

roasting

13:45

Back to previous level

CleanJet, HACCP, Delta T, E1/2

Start time, CDS, Descaling, Settings

Selection of core temperature

Help: guide line for selected setting;

practical hints for product to be used in the

respective SCC cooking process

Store selected setting

Searing

All manuals and user guides at all-guides.com

Page 38

38

SCC

Edition 10-2008a

Setting of humidity

Setting of cabinet temperature

Setting of time

Setting of core temperature

Moistening

Setting of fan speed (lowest level=intermittent)

Cool Down

Function level no link on I/O X20

No 230V on I/O X21

1

2

3

4

1

2

3

4

1

2

3

4

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

200°C

10:24

10:24

english

am/pm

24 h

h:m

m:s

english

h:m

m:s

am/pm

24 h

08/22/03

22.08.03

°C /

°F

CleanJet programs

Delta -T cooking - 1/2 Energy

Telephone Chef-Line, delete all programs,

program lock, buzzer setting, time setting

setting start time

Download and upload of unit data like customer

programs, HACCP and service data

Service level

Settings

Setting of time format

Setting of time laps

Setting of date format

Setting of °C/°F

Setting of language

reset to factory setting

english, °C, buzzer perm., h:min

buzzer, Setting of buzzer sound

Setting of display intensity

Setting CleanJet request

(only active when frame shows in red)

Settings

Settings

Start time

Start time

CleanJet

CleanJet

IP

IP

10/22/06

22.10.06

°C / °F

Display since software version SCC 02-01-01 to 03-01-05

continous

Combi Steamer mode

Function level

Settings

actual time IP Adress

E

E

All manuals and user guides at all-guides.com

Page 39

39

SCC

Edition 10-2008a

No: E11SE0707200.... Serial number

SW: SCC - 03 - 01 - 04 Software version

Mod: SCC_101 - Model and size

humidity emergency control currently active

humidity emergency control was active since last switch

ON (will not be displayed when in „dry heat mode“)

English selected language

1

2

3

4

Service Info: Display of pending service faults

Descaling program: automatic process

empty steam generator (Door must be open!)

Display of scale level inside steam generator

Display of software version

1

2

3

4

1

2

3

4

Descale

Descale

Display since software version SCC 02-01-01 to 03-01-05

Service Info

No: E11SE0707200.........

SW: SCC - 03 - 01 - 04

Mod: SCC_101

English

Chef Line

h:m

m:s

h:m

m:s

Prog

Prog

Prog

Display phone number of Chef-hotline

erase all customer programs

Setting time in hours/minutes (h:m) or

minutes/seconds (m:s)

setting buzzer (sound-duration)

setting existing SCC process or program can be

copied and get an index number, i.e. 1; name can

be edited and changed; „Program lock“

Password: 12345; TTREU

Prog

Chef Line

CDS

CDS

Typ

Typ

All manuals and user guides at all-guides.com

Page 40

40

SCC

Edition 10-2008a

1

2

3

4

erase

Prog

new

level

control

copy

change

Roast

Select customer program with central dial

Give program name

(blank - between _ and @ sign)

existing SCC process or program can be copied

and get an index number, i.e. 1; name can be

edited and changed;

Change parameter and / or cooking mode of

program in a non-active program;

con rm change by:

selected program ashes; con rm delete by

pressing again;

1. Give program name

2. Store

3. select mode, temperature, time (in minutes

and seconds) or core temperature,

4. Additional program with identical mode and

temperature, but different time can be stored

and selected alternating after pre-heating;

new

copy

change

erase

level

control

Programming

1

2

3

4

HACCP

Prog

Prog

Prog

Software

update

Info

update

P, H, I 05, S05

P, H, I 05, S05

Copy customer program to stick

Reload customer programs from stick to unit

Erase customer programs

Download of HACCP-Data

Software updates (Icon only shows when unit detects

valid software on the USB stick

)

Download of service data to stick.

Only shows when USB stick is connected

HACCP

Prog

Prog

Prog

Info

update

Data downloading

All manuals and user guides at all-guides.com

Page 41

41

SCC

Edition 10-2008a

1

2

3

4

CleanJet

Rinse with water only; cabinet will be dried out;

Rinse with 1 tab for cleaning after steaming;

Rinse with 1 cleaner tab for cleaning in between

cooking cycles; no drying of cabinet;

Cleaning of light soiling with drying of cabinet

Cleaning of medium soiling with drying of cabinet

Cleaning of strong soiling with drying of cabinet

rinse without

Tabs

rinse

interim

cleaning

light

medium

strong

CleanJet

rinse without

Tabs

rinse

interim

cleaning

light

medium

strong

CleanJet

Indicated number of tabs can be changed from software 03-01-01!

If unit shows Servcie 25 check if water hits the left rack at levels 3-4. Refer to fault tree at end

of manual.

Interrupting CleanJet programs

- A CleanJet program can only be interrupted by switching the unit off and back on again.

- After restarting the unit “CleanJet interrupt” is shown and the buzzer sounds for 20 seconds.

- If the interrupt key was not touched within 20 seconds, then the CleanJet program continuous

- If the interrupt key was touched, then the interrupt program starts. Next the request for removing the

tabs is coming up.

- After the door was opened and closed again, then the interrupt program starts with a duration of 10

minutes

- The interrupt program can also be aborted by switching the unit of and back on again. In this case

cabinet must be rinsed manually and by pressing the arrow back key the cleanjet function can be

stopped

Interrupting descaling program SCC:

As long as no descaler was lled into the steam generator the „Arrow back“ in window 1 is still

showing.

After the descaler was con rmed to be lled the only way to interrupt the descaling process is to:

- Switch unit OFF and ON again- Press „Abort“

- Remaining time of 1:08 will be displayed

- If now the key „Aborted“ is pressed again and the unit is switched OFF and ON again a

remaining time of 23 min will show.

- After another 2 min this time display will drop to 5 min

- Now the steam generator will be ushed 2x. After this the „Arrow Back“ will be shown.

- By touching this key the descaling program will be exited

Note: Rinse the cabinet thoroughly with fresh water and operate the unit in steam mode for some

minutes.

- Now the unit can be accessed for cooking again.

All manuals and user guides at all-guides.com

all-guides.com

Page 42

42

SCC

Edition 10-2008a

1

2

3

4

1

2

3

4

10:24

10:24

english

am/pm

24 h

h:m

m:s

english

h:m

m:s

am/pm

24 h

08/22/03

22.08.03

CleanJet programs

Telephone Chef-Line, delete all programs,

program lock, buzzer setting, time setting

setting start time

Download and upload of unit data like customer

programs, HACCP and service data

Service level

Settings

Setting of time format

Setting of time laps

Setting of date format

Setting of °C/°F

Setting of language

reset to factory setting

english, °C, buzzer perm., h:min

buzzer, Setting of buzzer sound

Setting of display intensity

Setting CleanJet request

(only active when frame shows in red)

Settings

Settings

Start time

Start time

CleanJet

CleanJet

IP

IP

10/22/06

22.10.06

Display Unit Index “E” since software version SCC 04-01-01

Function level

Settings

actual time IP Adress

Half energy

°C

°F

°C

°F

1

2

3

4

Chef Line

h:m

m:s

h:m

m:s

Prog

Prog

Prog

Display phone number of Chef-hotline

erase all customer programs

Setting time in hours/minutes (h:m) or

minutes/seconds (m:s)

setting buzzer (sound-duration)

setting existing SCC process or program can be

copied and get an index number, i.e. 1; name can

be edited and changed; „Program lock“

Password: 12345; TTREU

only possible with manual mode selected

Prog

Chef Line

All manuals and user guides at all-guides.com

Page 43

43

SCC

Edition 10-2008a

Setting of humidity

Setting of cabinet temperature

Setting of time

Setting of core temperature

Moistening

Setting of fan speed (lowest level=intermittent)

Cool Down

Function level no link on I/O X20

No 230V on I/O X21

1

2

3

4

1

2

3

4

1

2

3

4

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

200°C

10:24

10:24

english

am/pm

24 h

h:m

m:s

english

h:m

m:s

am/pm

24 h

08/22/03

22.08.03

Indication of care status

CleanJet programs

Telephone Chef-Line, delete all programs,

program lock, buzzer setting, time setting

setting start time

Download and upload of unit data like customer

programs, HACCP and service data

Service level

Settings

Setting of time format

Setting of time laps

Setting of date format

Setting of °C/°F

Setting of language

reset to factory setting

english, °C, buzzer perm., h:min

buzzer, Setting of buzzer sound

Setting of display intensity

Setting CleanJet request

(only active when frame shows in red)

Settings

Settings

Start time

Start time

IP

IP

10/22/06

22.10.06

Display Index “G” since software version SCC 04-01-01

continous

Combi Steamer mode

Function level

Settings

actual time IP Adress

Half energy

E

E

CleanJet

+ care

+ care

CleanJet

+ care

+ care

CareControl

CareControl

°C

°F

°C

°F

All manuals and user guides at all-guides.com

Page 44

44

SCC

Edition 10-2008a

Intelligent cleaning process: The unit recognizes automatically the likely soiling of the

cabinet using the data of used cooking programs, cooking temperatures and running times.

Cleanjet demand

The customer usage (based on used cooking programs, cooking tem-

peratures and running times) determines the number of red bars in the

display “Cleanjet demand” ==> Intelligent cleanjet process.

If all bars show in red, “Care Control” is displayed.

CDS display

The number of pulses of the CDS sensor determines the number of red

bars in the CDS display.

If the customer always uses the recommended Care tabs when using

cleanjet, the steam generator will stay free of scale and the display will

not change to red bars.

Display Care Control

The combination of the above mentioned information is a measure of the

overall care status of the unit and as such the customers daily cleaning

pattern

Less cleaning (and less usage of care tabs) causes less blue bars.

Should the customer continue the low level cleaning pattern the bars will

start showing in red.

Display Cleanjet +Care Index “G” (10-2008)

Software SCC 04-01-01

CareControl

DS

+

=

CareControl

DS

CareControl

1

2

3

4

CleanJet

Rinse with water only; cabinet will be dried out;

Rinse with 1 tab for cleaning after steaming;

Rinse with 1 cleaner tab for cleaning in between

cooking cycles; no drying of cabinet;

Cleaning of light soiling with drying of cabinet

Cleaning of medium soiling with drying of cabinet

Cleaning of strong soiling with drying of cabinet

rinse without

Tabs

rinse

interim

cleaning

light

medium

strong

rinse without

Tabs

rinse

interim

cleaning

light

medium

strong

Air Baf e

Care Container

All manuals and user guides at all-guides.com

Page 45

45

SCC

Edition 10-2008a

B1 Thermocouple interior cabinet

B2 Thermocouple quenching

B4 Thermocouple humidity

B5 Thermocouple steam generator (preheat, 180°C (356°F) max)

B6-B11 Thermocouples core temperature

F3 Safety thermostat steam generator 160°C (320°F)

F4 Safety thermostat interior cabinet 360°C (680°F)

Y1 Solenoid valve lling

Y2 Solenoid valve quenching

Y3 Solenoid valve moistening

Y4 Solenoid valve care

M1 Fan motor bottom

M3 Humidity ap motor

M4 SC-pump

M6 CleanJet pump

M7 Motor drain valve / ball valve

M12 Care pump

S2 Level electrode

S3 Door reed switch

S4 Micro switch humidity motor

S11 CDS sensor

S12 Micro switch drain valve

P1 Pressure sensor humidity

SCC 201/202 only:

M2 Fan motor top with jumper ( oor units only)

SCC Electric - Basic principle

B1

B6 - B11

F4

P1

M3

S4

M4

M6

Y

1

Y2

Y3

B2

M1

S2

M7

S12

B4

B5

F3

S3

Y4

S11

M12

Care

All manuals and user guides at all-guides.com

Page 46

46

SCC

Edition 10-2008a

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Parts identification

(no CareControl)

16

6

14

15

8

7

2

4

17

23

5

11

12

13

1

3

22

18

19

21

20

9

10

All manuals and user guides at all-guides.com

all-guides.com

Page 47

47

SCC

Edition 10-2008a

Parts identi cation CareControl

1

2

3

3

4

4

11

1

2

3

4

11

4

2

3

1

2

11

All manuals and user guides at all-guides.com

Page 48

48

SCC

Edition 10-2008a

General information to software version SCC 04-01-01

Software SCC 04-01-01 can also be used for units with index „E“ (from 04-2004).

With this software you have the following options:

Using the button “Cleanjet request” you can select the “Intelligent Cleanjet request”.

In this case the cleanjet request will be based on used cooking programs, tempratures

and cooking duration.

Selecting Cleanjet you will see the below symbol in window 4 of your display:

The second setting to choose is Cleanjet request based on cooking time only (as known from older

software versions).

In order to deselect the Cleanjet request (turn symbol from red to blue again) select time functions

and setb time to “0”..

In Service Mode Basic Settings position 26 you select „Softwater“ ON to indicate only the half

amount of detergent tabs when cleanjet is choosen. The individual tab setting (as available since

software SCC 03-01-01) is no more existing.

Software SCC 04-01-01 in units with index „G“ (from 10-2008)

Basic Settings 26 „Softwater“

In Service Mode Basic Settings position 26 you select „Softwater“ ON to indicate only the half

amount of detergent tabs when cleanjet is choosen.

Basic Settings 28 „Selftest“:

After installation the unit will ask the user to start a Selftest. Water MUST be connected!

After the Clima Control valve and the drain valve have initialised the steam generator will ll,

SC pump will start shortly and Y1 will re ll again.

In case the temperatures of B1, B2 and B4 are below 40°C now “Start” will be displayed.

After pressing “Start” the unit will adapt to the present installation conditions (duration appr. 15 min).

Should the unit be installed later at a different location, this “Selftest” can be re-initialised by setting

“Selftest” to ON in basic settings position 28.

Basic Settings 29 „Warranty“:

After rst switch on the unit will prompt the customer to register and validate his second year war-

ranty online under www.rational-ag.com/warranty.

This prompting will discontinue after 4 days.

After registration a warranty certi cate will be issued:

In case the unit was installed in a show room or exhibition, this prompting can be re-initialised by set-

ting “Warranty” to ON in basic settings position 29.

Basic Settings 30 „Steam corrosion control“

The unit automatically recognises if the customer used it predominantely in steam mode. In case this

usage is more than 90% during the last 20 hours of operation the unit will prompt a Cleanjet request

daily regardless of the total duration of cooking time

Basic Settings 31 „Care Control Reset“

By setting the switch to “ON” all Care Control bars will be set to blue.

All manuals and user guides at all-guides.com

Page 49

49

SCC

Edition 10-2008a

Controling the SC pump and solenoid valves before starting the cleanjet process:

If the Cleanjet Start key is pressed the unit will check rst for the proper function of the SC pump and

the solenoid valves.

The SC pump is operated shortly until the level electrode shows low water.

In case of failure “Servcie 10” is displayed and Cleanjet can not be started.

Y1 lling solenoid valve is started, function checked by CDS sensor

In case of failure “Low Water” will be indicated

Y3 moistening solenoid valve is started, function checked by CDS sensor

In case of failure Service 41

Y4 care solenoid valve is started, function checked by CDS sensor

In case of failure Service 42

All solenoid valves are switched off, CDS shall not send any pulses;

In case of failure Service 43

New Service Error codes

Service 40

Care pump faulty or does not ll enough care solution into steam generator;

- After lling of the care solution into the steam generator the CDS sensor sends too many pulses

until the level electrode recognises water.

- Cleanjet nishes without care phase;

- Reset by successfull completion of Cleanjet process;

Service 41

- Solenoid valve Y3 defective or moistening nozzle blocked; CDS does not send any pulses;

- Reset error by successfull CDS measuring during next Cleanjet start;

Service 42

- Solenoid Y4 Care defective or hose to care container vlocked or kinked; CDS does not send any pulses;

- Reset error by successfull CDS measuring during next Cleanjet start;

Service 43

- CDS sensor sends always pulses; Solenoid Y1, Y3 or Y4 is passing water

- Reset error by successfull CDS measuring during next Cleanjet start (Self test)

Service 44

- No temperature raise during recognised by B5 during steaming time while being in Cleanjet phase

- Reset error by successfull B5 tempoerature measuring during next Cleanjet;

Service 110

- Malfunction of SC pump during the time when Care solution was inside the steam generator,

- Reset error by successfull completing a cleanjet abort cycle;

Service 120

- After operating care pump M12 ( lling care solution into steam generator) and topping up with water (Y1)

the level electrode does not recognise water;

- Y1 or level electrode defective;

- Display only after twice starting lling solenoid Y1 yet no water is detected;

- Reset error by successfull completing a cleanjet abort cycle;

All manuals and user guides at all-guides.com

Page 50

50

SCC

Edition 10-2008a

It is possible to abort the cleanjet program. However the abort program of 30min. can not be short-

ened again as the steam generator must be neutralised from possible remaining care solution.

Cleanjet Abort program

During the abort program the steam generator will first be filled with Y1. After draining the steam eg-

nerator it will be filled a second time to a level above the level electrode. After a second draining the

steam generator will fill again exactly to the level electorde.

In case the level electrode does not recognise the water Error 120 will be shown.

At the end of the abort program a short steam period and rinsing the cabinet with Cleanjet pump will

follow.

The duration of steam heating time unitl next SC automatic is now 120min (units with index “G”) .

However should the steam generator develop scale because the customer does not use the care

tabs, this time will automatically be reset to 60 minutes.

All manuals and user guides at all-guides.com

Page 51

51

SCC

Edition 10-2008a

Difference SCC Index „E“ versus Index „G“ SCC Care Control

Index „E“

Index „G“

B1

B6

F4

P1

M3

S4

M4

M6

S11

Y

1

Y2

Y3

B2

M1

S2

M7

S12

B4

B5

F3

B1

B6 - B11

F4

P1

M3

S4

M4

M6

Y

1

Y2

Y3

B2

M1

S2

M7

S12

B4

B5

F3

S3

Y4

S11

M12

Care

All manuals and user guides at all-guides.com

all-guides.com

Page 52

52

SCC

Edition 10-2008a

Sequence Cleanjet+Care Process: 1. step - Cleaning cabinet; example: SCC 61, Index G

Prepare Cleanjet Cleanjet Phase 1 Cleanjet Phase 2 Prepare for care phase

SC Pump M4 1

0

Solenoid Y1 lling steam generator 1

Function test (CDS) 0

Solenoid Y3 moistening 1

Function test (CDS) 0

Solenoid Y4 Care 1

Function test (CDS) 0

Drain valve M7 1

0

Solenoid Y2 quenching

Filling quenching box (pre-cleaning) 1

Level control by prm signal M1 0

Solenoid Y3 moistening 1

Filling quenching box Phase 2 0

level control by CDS

Cleanjet pump M6 1

1. Phase Cleanjet 0

2. Phase Cleanjet

Steam heating

Pre heating steam generator

Steam Cabinet 90°C

All manuals and user guides at all-guides.com

Page 53

53

SCC

Edition 10-2008a

Sequence Cleanjet+Care Process: 2. step - Care Steam generator and cabinet; example: SCC 61, Index G

Prepare care solution Care process Neutralising steam generator and cabinet

Solenoid Y4 Care

Care Tabs are disolved in several setps 1

Drain care solution from container 0

Care Pump M12

Pump care solution into steam generator 1

Pump remaining care solution from container 0

Drain valve M7 1

0

Solenoid Filling Y1

Topping up of care solution above level electrode 1

Fill steam generator 0

SC-Pump M4 , Partial separation of care solution

from steam generator to quenching box 1

Rinse steam generator 0

Level electrode S2 1

0

Solenoid Moistening Y3

Topping up of care solution for cabinet 1

0

Steam heating element to 80° water temperature 1

Neutralising of cabinet and steam generator 0

Cleanjet Pump M6 1

Pumping of care solution through cabinet 0

Service 110Service 120

All manuals and user guides at all-guides.com

Page 54

54

SCC

Edition 10-2008a

LED Code: SCC PCB

Green LED on - ok

Red LED blinks 1x during re-booting when switching on - ok

Green LED off - : Bus cable defective; CPU defective; I/O pcb or transformer defective

Red LED on: CPU defective

Red LED doesn‘t blink during re-booting when switching on - CPU defective

Yellow LED blinking: No operational software / CPU defective

SCC pcb (42.00.002)

X12

X11

X1

X8

X7

X110

X2

42.00.002 REV 802

Operator PCB

CPU

X54

X52

X102

X10

X50

X5 X2 X6 X4 X3

V10 V9 V8

X51

X7

X8

X103

Battery

CPU

Add on X2 B6-11 thermocouple core probe

Add on X3 B1 thermocouple interior cabinet

Add on X4 B2 thermocouple quenching

Add on X5 B4 thermocouple ClimaPlus

Add on X6 B5 thermocouple Steam generator

Add on X10 Central dial

Add on X50 External EEPROM

Add on X51 BUS interface

and power supply for cpu from I/O pcb

Add on X52 RS232 interface

Add on X53 USB interface (up to 12-2005)

Add on X54 USB intefarce

Add on X102 TouchPad connection

X1 P1 pressure sensor

X2 Free

X7 200 - 240V input to I/0 Switch

X8 Buzzer

X11 ClimaPlus motor / Micro switch

X12 Level electrode

X110 Power suply for display 2,5 - 0 - 2,5

A3 Add on pcb

All manuals and user guides at all-guides.com

Page 55

55

SCC

Edition 10-2008a

New I/O PCB SCC (42.00.064P)

Wires of pcb edge connectors are pointing to component side of pcb!

18: SC-pump M4, Cleanjet pump M6

19: Solenoid vales Y1- lling, Y2 - quenching, Y3 - moistening

20. Energy optimizing plug with link on 5-6 used only on I/O pcb with 12 relais card!

21. 230V input

75. Care pump M12 and Care solenoid Y4 (free when used in Index “E” unit)

23. Connection to Ultravent (used for Ultravent without BUS connection only)

24. Output 12VDC to SSR

25. Output 12VDC to M7 drain valve, S12 micro switch drain valve

26. free

27. Output 12VDC to door contact

14. Input from Control transformer T1, 11.5V interior light, 12V CPU,

13. Output 11.5VAC to interior cabinet light

15. Output 12VDC to CDS sensor

17. Link Care unit (only existing when build into an Index “G” unit)

16. free

X3, X4. BUS connection

LED Code: I/O PCB

Green LED on - ok

Green LED off during operation ok

Yellow LED always blinking: unit switched off, unit in booting process, DIP switches not all

set to OFF, bus connection defective

Green LED off: I/O PCB defectice, Transformer defective

S3

T1

K1:L1

F2: N

230 V

GND

IN

OUT

CDS-HALL

S12

M7

M

+

_

16 V DC

11,5 V AC

Y1

A1

A2

A1

A2

Y3

A1

A2

M4

M

~

M6

M

~

12 V DC

12 V AC

12 V DC

H1

11,5 V

AC

230 V

230 V

+ 12V

SSR1: A-

SSR1: B-

SSR2: A-

SSR2: B-

N

Y2

12 V DC

12 V DC

2A T

2A T

LED Gr

LED Ye

X 24.1

X 25.1

X 26.1

X 27.1

X 14.1

X 13.1

X 15.1

X 17.1

X 16.1

X 23.1

X 75

X 20.1

X 19.1

X 18.1

X 21.1

M12

M

~

230 V

A1

A2

Y4

Y1

230 V

Y3

230 V

Y2

230 V

ON

1234

18

19

20

21

75

23

24 25 26

27

14

13

15

17

16

X 3X 4

All manuals and user guides at all-guides.com

Page 56

56

SCC

Edition 10-2008a

Fan motor SCC 40.00.274

Jumper 40.01.581 is used on oor model 201 and 202 for top position motor only!

Jumper is not used on models 61 - 102 with one motor only!

(Service 34 will be shown when jumper is set wrongly)

LED code fan motor SCC and CM from 04/2004

Reason Remedy

1x Motor doesn’t start, no changing

signal from hallsensor

Check for motor blockage or change motor.

2x Voltage too low on motor pcb Check supply voltage or

change motor.

3x Voltage too high on motor pcb Check supply voltage or

change motor.

4x rpm measurement defective Change motor.

5x Motor pcb temperature >105°C Check cooling system (cooling fan, air

intake lter), otherwise change motor

6x Supply voltage <80V Check power supply

(F1-F2)

7x Motor pcb defective Change motor.

8x Motor pcb defective Change motor.

Fan motor SCC 40.00.276 for units 3AC 400-480V (without neutral)

LED

Jumper

All manuals and user guides at all-guides.com

all-guides.com

Page 57

57

SCC

Edition 10-2008a

Clima Plus Control SCC

The calculated humidity inside the cabinet is based on:

1. Voltage output signal P1 (depending on fan motor speed, ref: function test #5)

2. Temperature B4 (thermocouple behind motor mounting plate)

3. RPM signal of the fan motor (via BUS signal)

The offset voltage of P1 (Motor not turning) is appr.: 0.45 - 0.55V

Basic rule: The less humid, the higher is the voltage of P1,

The higher the rpm, the higher the voltage of P1.

Example: SCC 101 E

RPM P1 (approx. Volt)

Dry 1,1

Speed 500rpm Wet 0,7

Combi 0,6

Dry 2.3

Speed 1250rpm Wet 1.7

Combi 1.5

Dry 2.9

Speed 1800rpm Wet 2.4

Combi 1.9

Dry 3,1

Speed 1900rpm Wet 2.5

Combi 2.2

Thermocouple

humidity control

rpm measurement

RPM

B4

Differential pressure sensor

ClimaPlus

P1

Clima Status (approx. value in Pascal)

Indicated values shall NOT be “0” or “85000”

If “0” or “85000” is indicated

re-calibration is needed

All manuals and user guides at all-guides.com

Page 58

58

SCC

Edition 10-2008a

All manuals and user guides at all-guides.com

Page 59

59

SCC

Edition 10-2008a

SCC - Sequence of events

Steam: Temperature range 98-103°C (208-218°F)

Function step Responsible sensor

1 Select Wet heat (Temp 98-103°C (208-218°F))

2 Select time or core temperature

3 Close cabinet door Reed switch S3

4 Check water level inside steam generator Level electrode S2 inside Steam Gen

5 Time based preheating of steam generator,

if B5 is below 85°C (185°F)

Thermocouple B5 inside Steam Gen.

6 Timer starts after successful preheating Logic on PCB

7 Steam production up to saturation in cabinet Pressure sensor P1, Thermocouple B4

rpm motor via BUS

8 Adding of Hot Air from 70°C (158°F)

only possible, if 70% humidity reached

Cabinet sensor B1

9 Quenching (set to 70°C/158°F) Thermocouple B2

Note: Steam heating only active when humidity ap (S4) is in closed position!

Additional functions possible: 4 Fan speeds (Standard = Level 3), pulsed fan wheel, ½ Energy,

HACCP output, T.

B1

B6 - B11

F4

P1

M3

S4

M4

M6

Y

1

Y2

Y3

B2

M1

S2

M7

S12

B4

B5

F3

S3

Y4

S11

M12

Care

All manuals and user guides at all-guides.com

Page 60

60

SCC

Edition 10-2008a

SCC - Sequence of events

Low temperature steam: Temperature range 30-97°C (85-207°F)

Function step Responsible sensor

1 Select Wet heat (Temp 30-97°C (85-207°F))

2 Select time or core temperature

3 Close cabinet door Reed switch S3