Rational SelfCookingCenter XS UV, SelfCookingCenter XS UV Plus, CombiMaster Plus XS UV, CombiMaster Plus XS UV Plus Installation Manual

Page 1

SelfCookingCenter® XS UV and UV Plus

CombiMaster® Plus XS UV and UV Plus

Original Installation Manual

Page 2

Contents

Device transfer..........................................................................................................................4

1 Introduction .................................................................................................................. 5

1.1 About this manual .................................................................................................... 5

1.2 Warnings used ..........................................................................................................6

1.3 Warranty .....................................................................................................................7

2 Safety instructions ......................................................................................................7

3 Installation instructions ............................................................................................. 8

4 Device transportation ............................................................................................. 10

5 Setting up the device .............................................................................................. 12

5.1 Device dimensions ............................................................................................... 12

5.2 Minimum distances .............................................................................................. 13

5.3 Securing the device .............................................................................................. 16

6 Electrical connection ............................................................................................... 17

6.1 General information ............................................................................................. 17

6.2 Power supply cable ............................................................................................... 19

6.3 Equipotential bonding ......................................................................................... 20

6.4 Connection values ................................................................................................ 20

7 Water connection ..................................................................................................... 21

7.1 Prerequisites .......................................................................................................... 21

7.2 Device water connection ................................................................................... 22

7.3 Water treatment .................................................................................................... 23

7.4 Selecting water filters .......................................................................................... 23

8 Wastewater connection ......................................................................................... 25

9 Ventilation, technical data, heat dissipation ..................................................... 27

2

Page 3

10 Initial start-up ........................................................................................................... 28

11 Maintenance: ............................................................................................................. 31

12 Service parts .............................................................................................................. 34

12.1 UltraVent ................................................................................................................. 34

12.2 UltraVent Plus ........................................................................................................ 35

13 Options ....................................................................................................................... 36

14 Conversion tables .................................................................................................... 37

15 Declaration of conformity ..................................................................................... 39

3

Page 4

Device transfer

Device transfer

Dealer

Specify for all queries:

Appliance model

_____________________________________

Device no.:

______________________________________

Installer

Set to gas type:

______________________________________

Your device was checked by:

_____________________________________

4

Page 5

1 Introduction

1 Introduction

1.1 About this manual

> This installation manual is part of the device,

and contains information on its safe installation.

> Read this installation manual completely

before installing the device.

> This installation manual must be kept available

to installers at all times at the installation location.

> Keep this installation manual on hand throug-

hout the entire life of the device.

> This installation manual is to be passed on to

any subsequent operators of the device.

Target group The target group for this installation manual are

competent technicians who are familiar with the

process of installing and operating the device.

Illustrations All illustrations in this manual are examples only.

Deviations between these illustrations and the

device on site are possible.

This manual applies to the following devices:

> SelfCookingCenter® XS UV

> SelfCookingCenter® XS UV Plus

> CombiMaster® Plus XS UV

> CombiMaster® Plus XS UV Plus

Abbreviations used in this manual:

Product name Abbreviation used

SelfCookingCenter® XS UV SCC

CombiMaster® Plus CMP

UltraVent UV

We reserve the right to make technical changes in the interest of progress!

© 2017 RATIONAL Technical Services. All rights reserved. Forwarding product-speci-

c information to third parties is prohibited.

5

Page 6

1 Introduction

1.2 Warnings used

DANGER!

Directly hazardous situation that may result in

severe injury or death.

WARNING!

Possibly hazardous situation that could potentially result in serious injury or death.

CAUTION!

Possibly hazardous situation that could result

in minor injury.

CAUTION!

Fire hazard!

CAUTION!

Danger of burns!

CAUTION!

Corrosive substances!

DANGER!

High voltage.

Caution, danger to life

Non-compliance can result in severe injury or

death.

ATTENTION!

Non-compliance may result in material dama-

6

ge.

Page 7

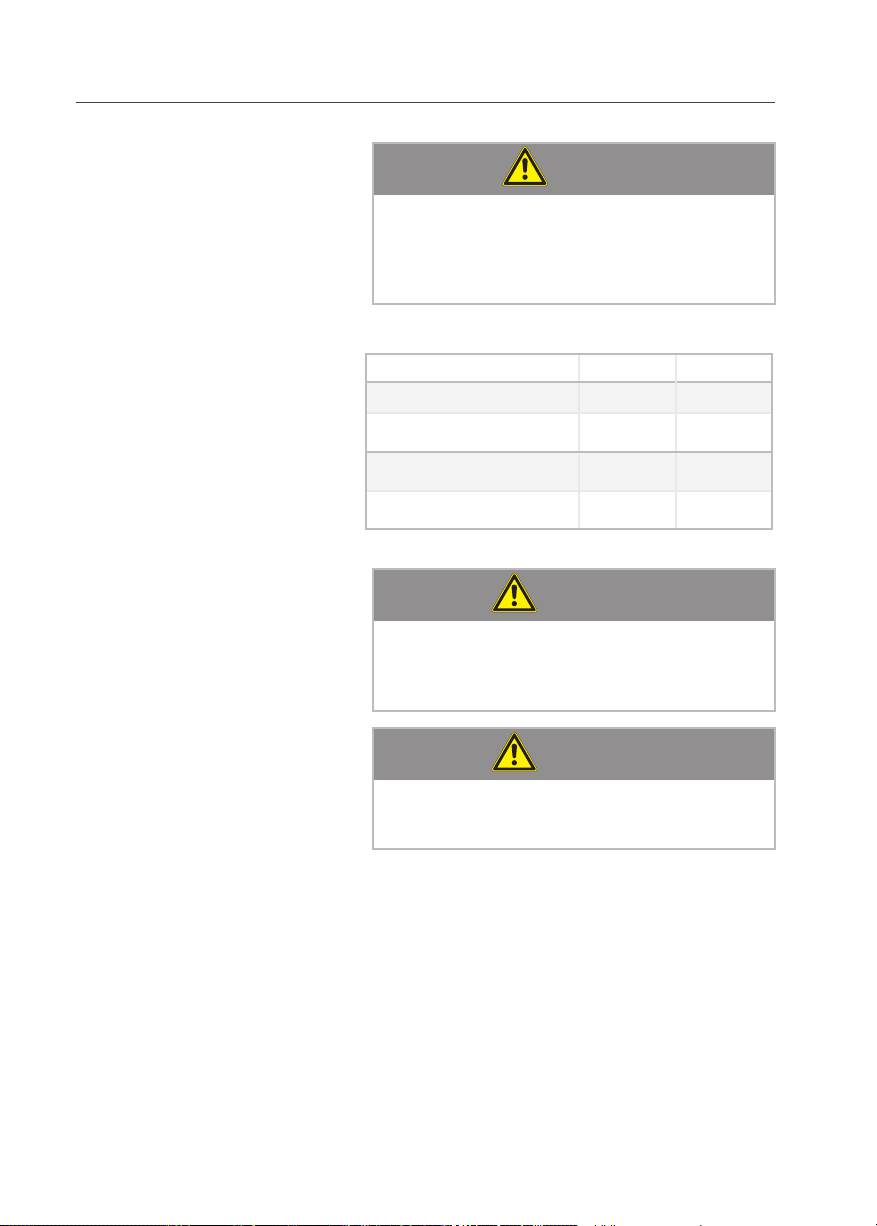

1 Introduction

1.3 Warranty

Exceptions to the warranty include

> Damage to glass, light bulbs and seal materi-

als,

> Damage resulting from improper use, installa-

tion, maintenance, repair or descaling,

> Use of the device for purposes other than

those for which it is intended,

> Modifications or technical alterations to the

device not authorized by the manufacturer,

> Usage of non manufacturer-original service

components,

> Damage resulting from failure to observe the

instructions in this manual.

2 Safety instructions

Incorrect installation > Incorrect installation, service, maintenance or

cleaning of this device can result in damage,

injury or death, as can modifications to the

device. Read the installation manual carefully

prior to installation.

Device usage > The device may only be used for purposes of

cooking food in commercial kitchens. All other

uses are counter to its intended purpose, and

may be dangerous.

Operating personnel > This device must not be used by children or

by persons with reduced physical, sensory or

mental capabilities, or by persons with insufficient experience and/or knowledge, unless

such persons are under the supervision of

another person who takes responsibility for

their safety.

> To avoid accidents or damage to the device, it

is imperative that operating personnel receive

regular training and safety instructions.

7

Page 8

3 Installation instructions

3 Installation instructions

Standards > The mentioned standards are according to

German regulations.

> Local and country-specic standards and

regulations regarding the installation and operation of commercial cooking appliances must

be observed at all times.

> In all other countries, the corresponding

country-specic standards and regulations are

to be observed.

Liability / Warranty > Damage occurring as a result of non-compli-

ance with installation instructions is excluded

from the warranty.

> Installations and repairs not carried out by

authorized professionals or not using original

spare parts, and technical modications to

the machine which are not approved by the

manufacturer, void the manufacturer’s warranty and product liability.

Conformity > Device conformity is in reference to the ove-

rall unit at the time of delivery. The operator is

responsible for ensuring extended conformity

following any expansions/connection of additional functions.

Connection work > The necessary connections (water, electricity,

and gas) must only be set up by trained professionals in accordance with local regulations.

Prior to installation > Check the device for transport damage.

If you suspect the device has been damaged in

transit, contact your specialist dealer/freight

forwarder immediately!

Disposing of old appliances > When the device reaches the end of its ser-

vice life, it must not be taken to a municipal

collection point for trash or used electrical

appliances. We would be pleased to assist you

in disposing of the device.

8

Page 9

1 Introduction

Air lter maintenance: > The device automatically detects dirty air

filters. It will display a service prompt instructing you to replace the air filter.

> Never operate the device without the air filter.

When replacing the air filter, please note:

The user may replace the air filter. To replace the

air filter, carefully latch the new filter into the

correct position. Follow the instructions in the

Building Equipment and Appliances chapter of

the user’s manual.

Air filter part number: 40.04.771

9

Page 10

4 Device transportation

4 Device transportation

Weight (without packaging)

CAUTION!

Risk of injury!

Note device weights.

Use lifting aids.

Wear safety shoes.

kg lbs

SCC XS UV 97 214

SCC XS UV Plus 104 230

CMP XS UV 87 192

CMP XS UV Plus 94 207

ATTENTION!

Risk of damage to the device!

10

When transporting device, ensure that air filter

box and USB port remain undamaged.

ATTENTION!

Risk of damage to the unit!

Do not lift at the front panel of the UV!

Page 11

4 Device transportation

x

x

Transporting unit with pallet:

Note required door width:

880 mm [34 3/4)

Transporting unit without pallet:

Note required entrance width:

630 mm [24 3/4]

11

Page 12

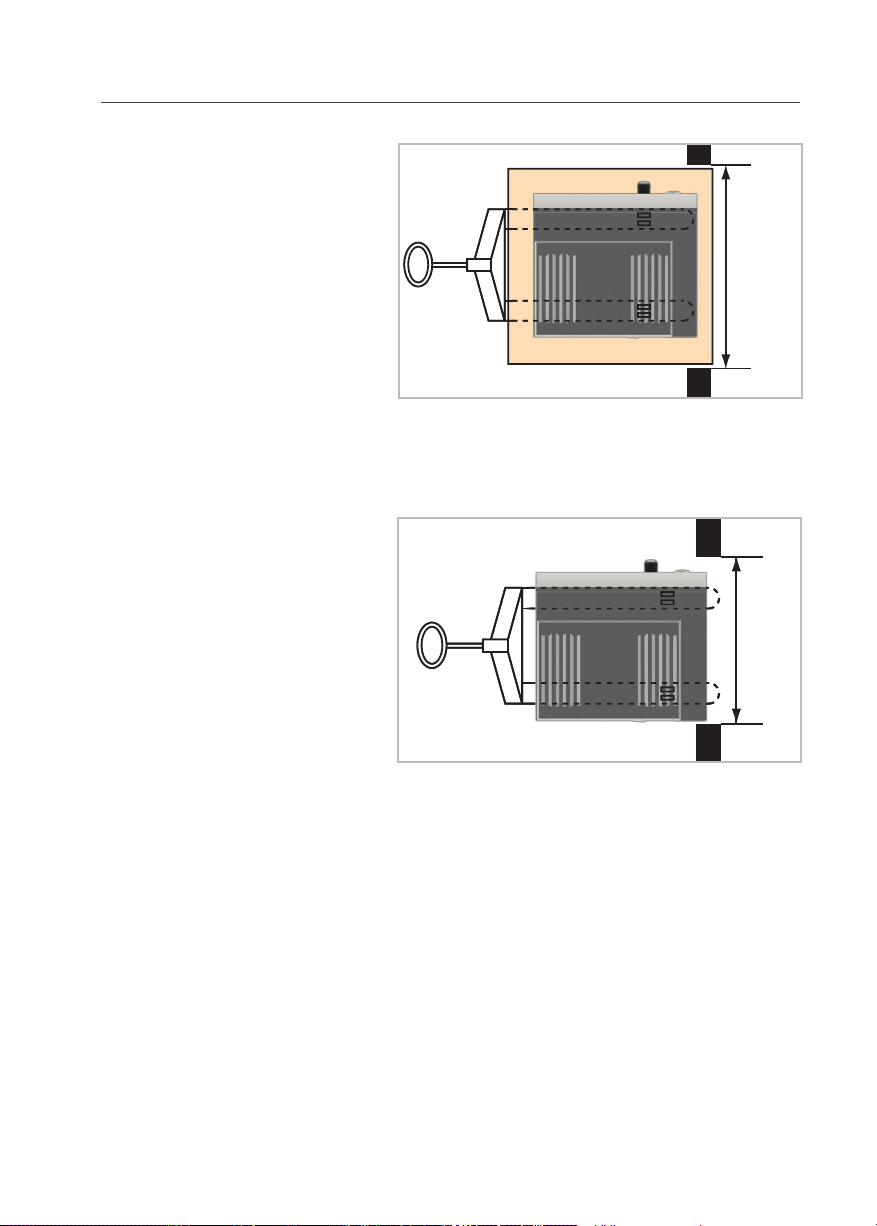

5 Setting up the device

5 Setting up the device

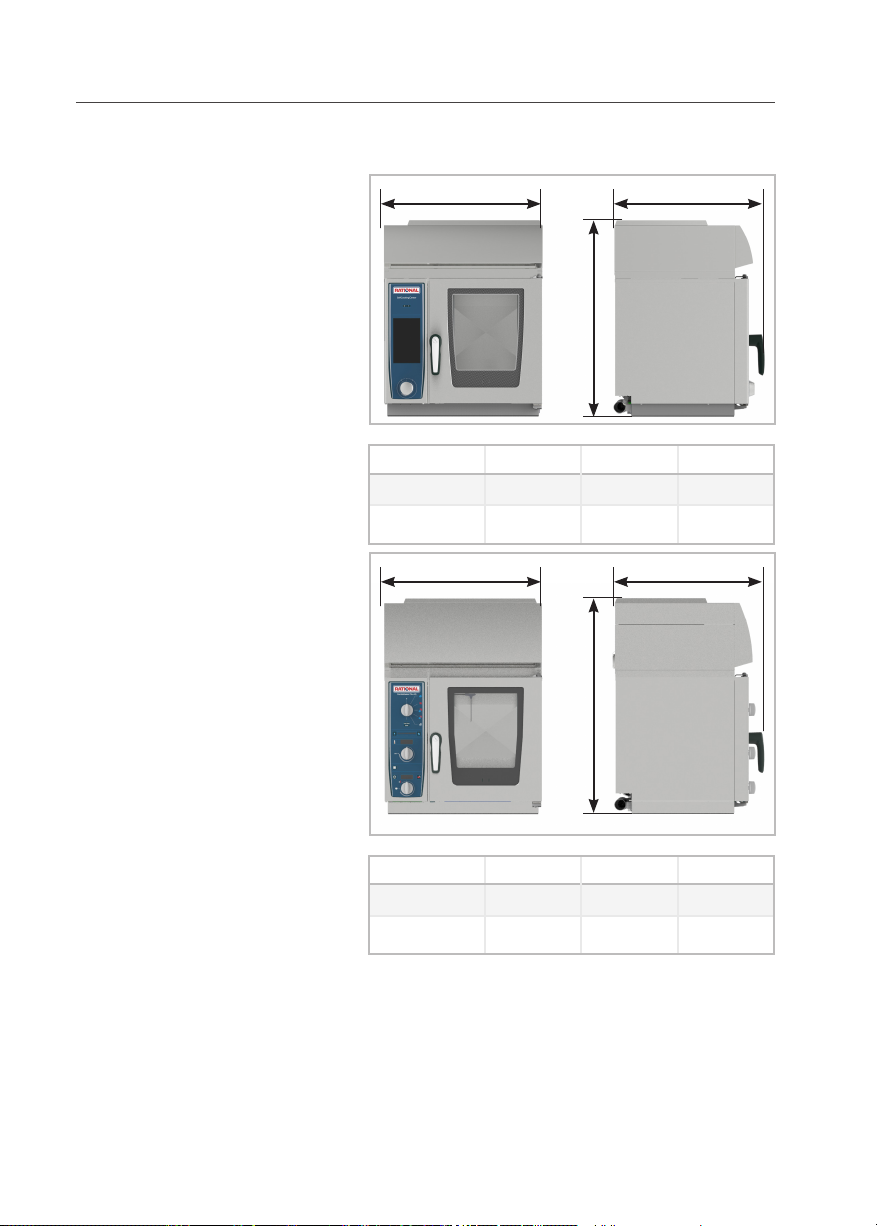

5.1 Device dimensions

with UltraVent XS

x y

z

Width x Depth y Height z

[mm] 657 623 808

[Inch] 25 7/8 24 1/2 31 3/4

x y

with UltraVent XS Plus

12

z

Width x Depth y Height z

[mm] 657 623 897

[Inch] 25 7/8 24 1/2 35 3/8

Page 13

5 Setting up the device

5.2 Minimum distances

ATTENTION!

Device overheating may cause material damage!

If the ambient temperature to the left of the

device becomes too high, it may trigger an

emergency shutdown of the device.

ATTENTION!

Device overheating may cause material damage!

Do not install fryers onto the back of the

device.

ATTENTION!

Frost may cause material damage!

Minimum distance to walls

Only install devices in frost-proof rooms.

x

y

x: 10 mm [1/2]

y: 10 mm [1/2]

13

x

Page 14

5 Setting up the device

500mm

/20"

min. 350 mm

Recommendation At least 500 mm away from left side of the

device so that service work can be performed.

Minimum distance to ceiling

450mm/

18“

Minimum distance to other devices Minimum 350 mm distance between left side of

the device and heat sources.

14

350mm/

14“

Page 15

5 Setting up the device

Other

ATTENTION!

Device malfunction!

Avoid vapor sources near the cooling air filter.

Moisture intake may result in device malfunctions.

15

Page 16

5 Setting up the device

5.3 Securing the device

For safety reasons, tabletop units should only be

placed atop a manufacturer-original oven stand

or base unit. Maximum working height for the

topmost rack is 1600 mm.

Unit size 60 These units do not have height-adjustable feet;

instead, they are set up directly on the installation surface.

The installation surface must be level, clean and

free of grease. Unevenness across the width of

the device must be no greater than 1 mm.

A sealant band is affixed to the underside of the

device to seal the installation site. This prevents

dirt from getting underneath the device. When

moving the device, take care not to damage this

seal.

Mounting onto an oven stand:

> Insert the two included neoprene blind rivet

nuts into the holes in the rear part of the

underbody.

> Place the unit onto the oven stand.

> Secure in place using the screws provided.

16

Page 17

6 Electrical connection

6 Electrical connection

DANGER!

Danger to life!

High voltage.

Observe local energy supply company regulations during installation!

WARNING!

Danger to life!

Connecting incorrectly may result in electric

shock!

Note color coding of wires!

Color coding of wires:

yellow/green = protective conductor,

blue = neutral conductor

brown, gray or black = phase L1, L2, L3

ATTENTION!

Improper connection can cause damage to the

6.1 General information

Only connect the device in accordance with the

Connect the device to a standard power supply

Observe VDE regulations and/or local energy

Connect the device to a Type B (RCD Type B)

17

unit (e.g., fan motor).

installation instructions and the information on

the rating label.

in accordance with the applicable regulations.

supply company regulations!

ground fault circuit interrupter.

Page 18

6 Electrical connection

CAUTION!

Improper installation can lead to personal injury or property damage!

Customer: provide accessible all-pole disconnect device with at least 3mm contact separa-

Remove the left side panel to access the connec-

Removing the left side wall > Remove the screws on the bottom of the side

> Pull the side panel down from the device.

> Remove the side panel.

tion.

tion port.

panel.

Each device should have its own protected

power supply line.

Use a fixed connection to connect each device to

the power supply.

3NAC 400V only Either a fixed connection or a plug connection

may be used to connect the device to the power

supply.

The units are equipped with power cables (without plugs).

The cables are around 2.5 m in length.

.Cable connection point The main fuse is behind the removable left side

panel inside the electrical compartment.

18

Page 19

6 Electrical connection

6.2 Power supply cable

ATTENTION!

In order to avoid hazards, the mains power

cable may only be replaced by the manufacturer, its customer service representative or similarly qualified personnel.

ATTENTION!

Non-functioning device !

Connect a supply cable of at least Type H07RN-F

Connect the cable according to the following

Tighten mains lead cleat.

and tighten the mains lead cleat.

diagram:

Gray connector terminals:

L1, L2, L3 (independent of rotary field).

Blue connector terminal:

Neutral conductor (neutral wire) (3NAC only).

Yellow-green connector terminals: Protective

conductors.

19

Page 20

6 Electrical connection

6.3 Equipotential bonding

A connection site for optional equipotential bon-

ding is located on the bottom or the back of the

device.

6.4 Connection values

SCC, CM_P

Power [kW] /

Current consumption [A]

3 AC 200V 5,3 / 15,4 16

3 AC 230V 5,70 / 14,5 16

3 NAC 400V 5,7 / 8,5 10

3 NAC 415V 6,2 / 8,7 10

1 NAC 230V 5,3/22,9 25

1 NAC 240V 5,7/24 25

2 AC 230V 5,3/22,9 25

2 AC 240V 5,7 / 24 25

Fuse [A]

Maximum permissible tolerance for input voltage (see type label for input voltage) is

within the range of -15% to + 10%.

20

Page 21

7 Water connection

7 Water connection

The device complies with all relevant regulations

(SVGW, KIWA, WRAS).

7.1 Prerequisites

> The user must supply each device with its

own water tap.

> Rinse the water supply line before connecting

the device to water!

> Water pressure 1.5 - 6bar, 3bar recommen-

ded.

> Flow rates required for each unit:

1,8 g/min

Connect the device to drinking water-quality

water.

Connect a flexible drinking-water connection

hose in accordance with EN 61770 or EN 13618

or of similar quality. Take any necessary safety

precautions with the water tap, such as backflow

preventers or CA system separators.

The water connection hose must comply with

country-specific hygiene standards for drinking

water hoses.

Water connection hoses complying with EN

61770 are available through Rational using part

number 2067.0709.

The materials used in this connection hose meet

KTW, DVGW W270, WRAS and FDA requirements.

Use only new hoses as water connections. Do

not re-use old hoses.

ATTENTION!

Non-functioning device!

Ensure that the minimum water conductivity

value of 50µS/cm (Micro Siemens) is maintai-

21

ned.

Page 22

7 Water connection

Unit CMP XS due to descaling of the steam generator:

> Drinking water protection for substance class

3 pursuant to EN 1717, such as a CA system

separator pursuant to EN 14367, must be

installed in the feed line on the tap at the drinking water network connection point.

> The CA system separator is supplied for NL

and CH, and are available through RATIONAL

using part number 50.01.820 for other European countries.

Unit SCC XS meet the requirements for drinking water pro-

tection pursuant to EN1717 in as-delivered condition.

UK only: WRAS approval IRN R160

To be carried out by the installer:

An approved double check valve or some other

no less effective backflow prevention device shall

be fitted at the point of connection directly to

the water tap.

7.2 Device water connection

1

Water connection legend 1 = 3/4” common water supply line.

(cold water up to 30°C [86°F])

Note: The manufacturer recommends preventative

inspection be conducted around six months after

device commissioning to ascertain the degree of

limescale buildup in the steam generator, especially for CMP units.

This inspection should be performed by a trained

technician.

22

Page 23

7 Water connection

7.3 Water treatment

> The water connection must not use treated

water with hardness below 6°e, as such water

is aggressive and corrosive, and can shorten

the lifespan of the device.

> Connecting the SCC to water with hardness

below 8,75°e:

When the self-test begins, the system will

prompt the user to indicate the hardness of

the water the device is connected to. Select

“Water hardness below 8,75°e.

> Observe all country-specific regulations

regarding water and sewer connections, especially those regarding installation of water

intake points.

In most cases, water connections do not require

additional filters or water treatment.

Filtration and/or water treatment (A, B, C, D)

may be necessary if water conditions are critical.

Contact the local water supply company to

inquire about water chloride levels (Cl–), chlorine

levels (Cl2) and hardness.

7.4 Selectingwaterlters

A) Fine filters We recommend fine filters with fineness of 5 -

15µm for filtering water contaminated with sand,

iron particles or suspended matter.

B) Active carbon filters If water contains high levels of Cl2 (over 0.2mg/l,

corresponds to 0.2ppm) (information provided

by water supply company), an upstream active

carbon filter must be installed.

C) Reverse osmosis system Due to corrosion risks, a reverse osmosis system

must be used if and only if chloride (Cl–) concentrations are above 80mg/l (corresponds to

80ppm, information provided by water supply

company).

Note: Ensure that the minimum conductivity

value of 50µS/cm (Micro Siemens) is being

maintained.

23

Page 24

7 Water connection

D) Water softening:

SCC: When used properly, these devices remove lime

from water completely independently, so upscale

water softening is not necessary.

CMP/CM: Recommended for treating water if severe calci-

fication occurs (without chloride contamination).

Systems: Weak acid decarbonization (H+ ion

exchange). Sodium ion exchangers (as are commonly found in dishwashers) are not recommended.

Phosphate metering is also not recommended

due to its negative effects on the water system.

Important for soft water connections:

Filter size sufficient for:

7 l/min

Important for filter connections: Water hose with minimum ø 1/2”.

Filter connection ø 3/4”.

When using a combination of filters, ensure filter

sequence of A-B-C or A-B-D in direction of flow.

24

Page 25

8 Wastewater connection

8 Wastewater connection

ATTENTION!

Use only steam temperature-resistant pipes

> Device complies with all relevant regulations

> Connection set for device drain

for wastewater drainage. Do not use hoses.

(SVGW, KIWA, WRAS).

DN 40/50 Part number: 8720.1031

> Welding a drain pipe onto the device drain is

not permitted (could result in damage to the

device).

> Use DN 50 pipe (DN 40 for size 60 units) with

a constant gradient (at least 5% or 3°); do not

reduce pipe diameter.

> Observe drain dimensioning requirements:

steam generator short-term pump-off rate =

0.7l/s

> Average wastewater temperature: 65°C

[149°F]

> Applicable standard: DIN 1986, T1

> If floor drain has no odor seal, make sure a

2cm [1” ] free outflow zone is in place.

> We recommend integrating a siphon into the

wastewater connection in order to optimize

energy consumption.

> Unit sizes 60 through 12 may have both a

wall drain and a floor drain

> Each device must have its own wastewater

connection (including Combi-Duos).

25

Page 26

8 Wastewater connection

250-300 mm

(10 - 12 “)

max. 1 m (3 ft.)

Ø 40 mm (1¾”)

min. 3°/5%

min. 3°/5%

Ø 40 mm (1½”)

26

Page 27

9 Ventilation, technical data, heat dissipation

9 Ventilation, technical data, heat dissipation

On-site ventilation: When installing an exhaust hood, observe the

following:

> VDI Directive 2052 and local construction

authority regulations on exhaust hoods.

The exhaust hood should protrude 300-500

mm over the front of the device.

> Install the device underneath an exhaust hood

if using a VarioSmoker.

> Install a grease filter into the protruding part

of the exhaust hood.

Technical data Noise emissions value: <70dBA

Water jet protection: IPX5

Thermal load [kJ/h]:

SCC CMP

latent: 1.020 1110

sensible: 1.350 1420

We reserve the right to make technical developments / modifications.

27

Page 28

10 Initial start-up

1600 mm (63”)

10 Initial start-up

WARNING!

Scalding hazard!

To avoid scalding, when working with liquids

or foods that become liquid when heated to

higher temperatures, only use containers that

The “Max. rack height for containers with liquid”

are easy to monitor. (DIN: IEC 60335-2-42).

safety decal is included in the starter kit. After

installing the device, attach the decal at a height

of 1600 mm (see example)

28

ATTENTION!

Risk of fire!

Remove packaging and transportation materials, starter kit, grids and containers from the

cooking chamber.

Page 29

10 Initial start-up

Self test When first commissioning a new device, start a

one-time self-test. This test serves to adjust the

device to its specific ambient conditions.

It runs automatically, and takes 45 minutes; if an

UltraVent is in use, the test will take around 20

minutes longer.

> To perform the self-test, check the hook lad-

ders and the air baffle to ensure they are seated correctly.

> The device must be connected to water,

wastewater, and electricity as per installation

instructions; gas devices must also be connected to gas supply and exhaust lines.

> The left side panel must be closed.

> Insert a flat GN container into the middle of

the hook ladders, with the opening facing the

bottom.

> Do not open the cooking chamber door duri-

ng the self-test.

29

Page 30

10 Initial start-up

SCC

CMP

30

Page 31

11 Maintenance:

11 Maintenance:

NOTIZ

Risk of fire!

Not cleaning the UV can result in the risk of

Before maintenance: > Isolate unit from mains.

> Remove 2 screws at UV top and remove top

fire.

WARNING

Danger of cutting!

The UV Plus ceiling can be sharp-edged.

Wearing safety gloves.

cover.

> Depending on the degree of soiling, unscrew

the UV Plus covers and clean them in the

dishwasher.

> Wash inner chamber of UV with hand shower.

> After cleaning fix the UV top cover back.

31

Page 32

11 Maintenance:

ONLY UV Plus: > Pull out the pre-filter

> Clean the pre-filter in the dishwasher

Exchange of HEPA filter The yellow LED indicates when the HEPA filter

should be replaced.

> Isolate unit from mains.

> Remove the front panel.

> Loose marked screws, pull out the filter unit.

32

Page 33

11 Maintenance:

> Change HEPA filter.

33

Page 34

12 Service parts

12 Service parts

12.1 UltraVent

Art.N.° Description

42.00.284 PCB UV

40.05.843 Bus cable WA44

40.05.963 Main contactor K1/K2

40.04.151 Capacitor 3,5 µF

40.05.413 Capacitor 8 µF

60.72.439 Motor UV WA44 (M1) 200-240 V

60.74.459 Mounting frame

60.73.956 Gasket

60.73.957 Cover plate for right hinged units

60.73.958 Cover plate for le hinged units

60.73.960 Front panel

34

Page 35

12 Service parts

12.2 UltraVent Plus

Art.N.° Description

42.00.284 PCB UV

40.05.843 Bus cable WA44

40.05.963 Main contactor K1/K2

40.04.151 Capacitor 3,5 µF

40.04.152 Capacitor 10 µF

60.72.439 Motor UV WA44 (M1) 200-240 V

60.74.459 Mounting frame

60.73.956 Gasket

60.73.957 Cover plate for right hinged units

60.73.958 Cover plate for le hinged units

60.74.464 Front panel

60.74.403 HEPA filter

60.74.409 Pre-filter

3017.1014 Differential pressure switch

40.05.972 LED yellow

3019.0117 Fuse 5x20 2,5AT

35

Page 36

13 Options

13 Options

Wall mount The device can be attached to the wall using a wall

mount.

ATTENTION!

Be sure to follow the corresponding modification instructions when performing wall instal-

Article number: 60.30.968

Interfaces

lations.

SCC come with an Ethernet interface as part of their

standard equipment. An CAT-5 Ethernet cable

must be used to connect to a network.

Connection location: on the rear of the unit

A detailed description on connecting to a network

is provided in the user manual.

CMP can optionally be ordered or retrofitted with

Ethernet interfaces.

Part number for add-on kit:

87.01.419

.

36

Page 37

14 Conversion tables

14 Conversion tables

°dH °f °e ppm mmol/l gr/

gal(US)

1 °dH 1 1.79 1.25 17.9 0.1783 1.044 0.357

1 °f 0.56 1 0.70 10.0 0.1 0.584 0.2

1 °e 0.8 1.43 1 14.32 0.14 0.84 0.286

1 ppm 0.056 0.1 0.07 1 0.01 0.0584 0.02

1 mmol/l 5.6 0.001 0.0007 100 1 0.00058 2

1 gr/gal (US) 0.96 1.71 1.20 17.1 0.171 1 0.342

1 mval/kg 2.8 5.0 3.5 50 0.5 2.922 1

CaO[mg/l] CaCO3 [mg/l] Ca

1 °dH (Germany) 10.00 17.86 7.14

1 °f (France) 5.60 10.0 4.00

1 °e (GB) 8.01 14.3 5.72

1 ppm (USA) 0.56 1.0 0.40

1 mmol/l (chem. cons.) 56.00 100.0 39.98

1 gr/gal (USA) 9.60 / 64.8 17.11 6.85

1 mval/kg (milliequivalent) 28.00 50.0 19.99

kPa mbar psi inch/wc

0.1 1 0.0147 0.4014

0.2 2 0.0294 0.8028

0.3 3 0.0441 1.2042

0.4 4 0.0588 1.6056

0.5 5 0.0735 2.0070

0.6 6 0.0882 2.4084

0.7 7 0.1029 2.8098

0.8 8 0.1176 3.2112

0.9 9 0.1323 3.6126

1 10 0.147 4.0140

1.2 12 0.1764 4.8168

1.4 14 0.2058 5.6196

1.6 16 0.2352 6.4224

1.8 18 0.2646 7.2252

2 20 0.294 8.0280

2+

[mg/l]

mval/kg

37

Page 38

14 Conversion tables

2.5 25 0.3675 10.0350

3 30 0.441 12.0420

3.5 35 0.5145 14.0490

4 40 0.588 16.0560

4.5 45 0.6615 18.0630

5 50 0.735 20.0700

5.5 55 0.8085 22.0770

6 60 0.882 24.0840

6.5 65 0.9555 26.0910

7 70 1.029 28.0980

7.5 75 1.1025 30.1050

8 80 1.176 32.1120

8.5 85 1.2495 34.1190

9 90 1.323 36.1260

9.5 95 1.3965 38.1330

10 100 1.47 40.1400

20 200 2.94 80.2800

30 300 4.41 120.4200

40 400 5.88 160.5600

50 500 7.35 200.7000

100 1000 14.7 401.4000

38

Page 39

15 Declaration of conformity

15 Declaration of conformity

39

Page 40

80.02.467 · V-13.2 · 04/2018 · RTS · Dja en

Loading...

Loading...