Ransburg Vector Solo User Manual

Ransburg

TECHNICAL MANUAL

IL-246-C

(Replaces IL-246-B)

April - 2013

RANSBURG

VECTOR AND SOLO

™ ™

APPLICATORS

ELECTROSTATIC

SPRAY

TECHNIQUES

IMPORTANT: Before using this equipment, carefully read SAFETY PRECAUTIONS, starting on

page 1, and all instructions in this manual. Keep

this Technical Manual for future reference.

Technical Manual Price: €15.00 Euro)

$20.00 (U.S.)

Vector/Solo Applicators Spray Techniques

NOTE: This manual has been changed from IL-246-B to revision IL-246-C. Reasons for this

change are noted under “Manual Change Summary” inside the back cover of this manual.

Ransburg

IL-246-C

Ransburg

Vector/Solo Applicators Spray Techniques

CONTENTS

VECTOR AND VECTOR SOLO APPLICATOR SPRAY TECHNIQUES:

PAGE

1-11

USE THE RIGHT TECHNIQUE.................................................................................................

FAN CONTROL.........................................................................................................................

PATTERN..................................................................................................................................

FLAT SURFACES.......................................................................................................................

HORIZONTAL PASSES.............................................................................................................

VERTICAL PASSES...................................................................................................................

APPLICATOR TO TARGET DISTANCE...................................................................................

OVERLAP.................................................................................................................................

TRIGGERING.............................................................................................................................

LARGE OBJECTS......................................................................................................................

TUBULAR WORK.....................................................................................................................

RECESSED AREAS...................................................................................................................

SUMMARY................................................................................................................................

SAFETY REQUIREMENTS......................................................................................................

1

2

2

3

3

3

4

5

5

6

7

8

9-10

11

IL-246-C

Vector/Solo Applicators Spray Techniques

Before operating, maintaining, or servicing any Ransburg electrostatic coating system, read and understand all of the technical and safety literature provided with Ransburg products. If you do not have

the manuals and safety literature for your Ransburg system, contact your Ransburg representative.

USE THE RIGHT TECHNIQUES

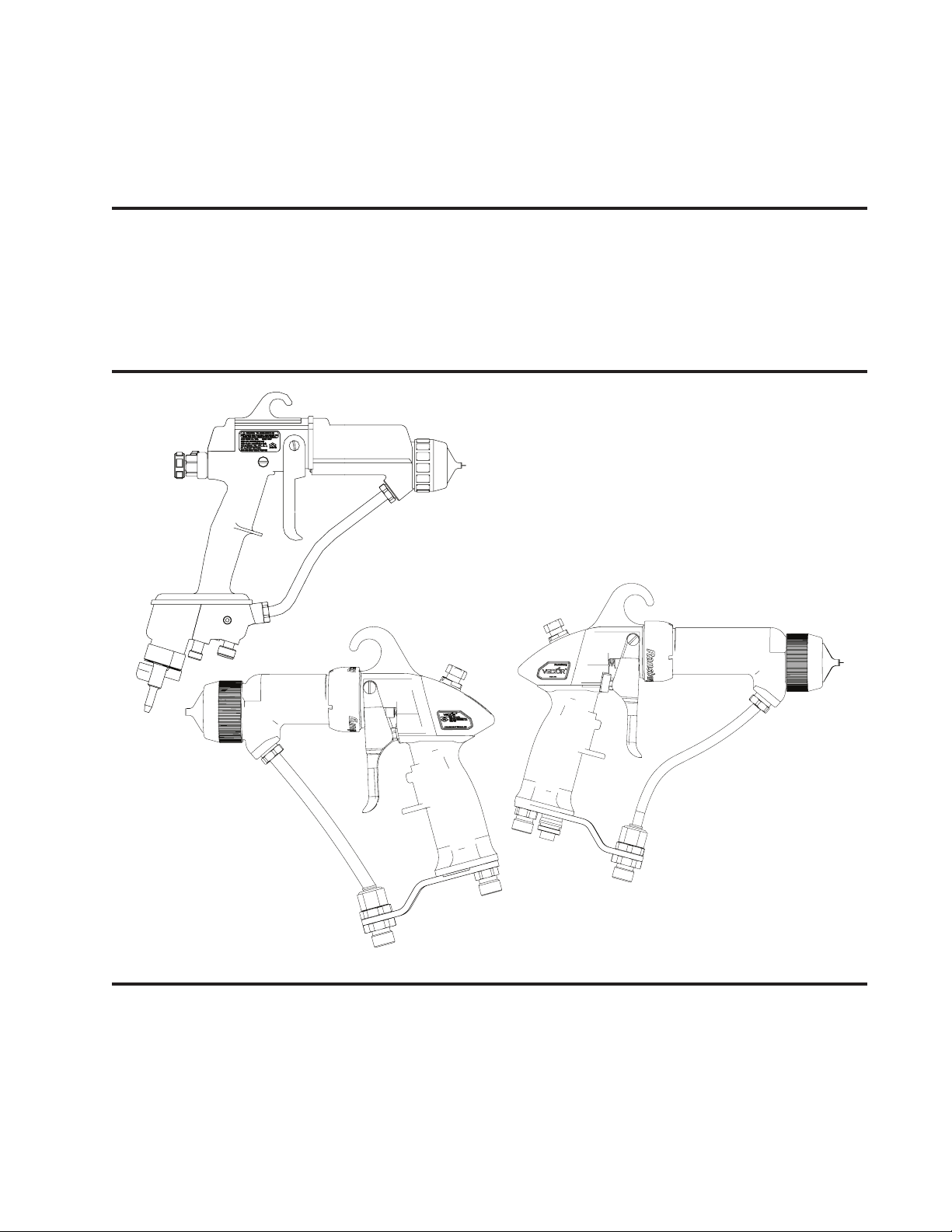

Vector/Solo (Electrostatic) Applicators

Savings of 25% to 50% in paint is possible when you replace conventional air spray with Ransburg

Electrostatic Applicators. You nish curved and recessed surfaces uniformly in fewer passes, because

combined air and electrostatic forces literally follow the shape of the work surface. Bounce losses

from work are reduced by the electrostatic attraction, when proper techniques are used.

The following describes basic electrostatic spray techniques. Depending on the type of work being

sprayed, it may be necessary to change the technique slightly.

Ransburg

1

IL-246-C

Ransburg

Vector/Solo Applicators Spray Techniques

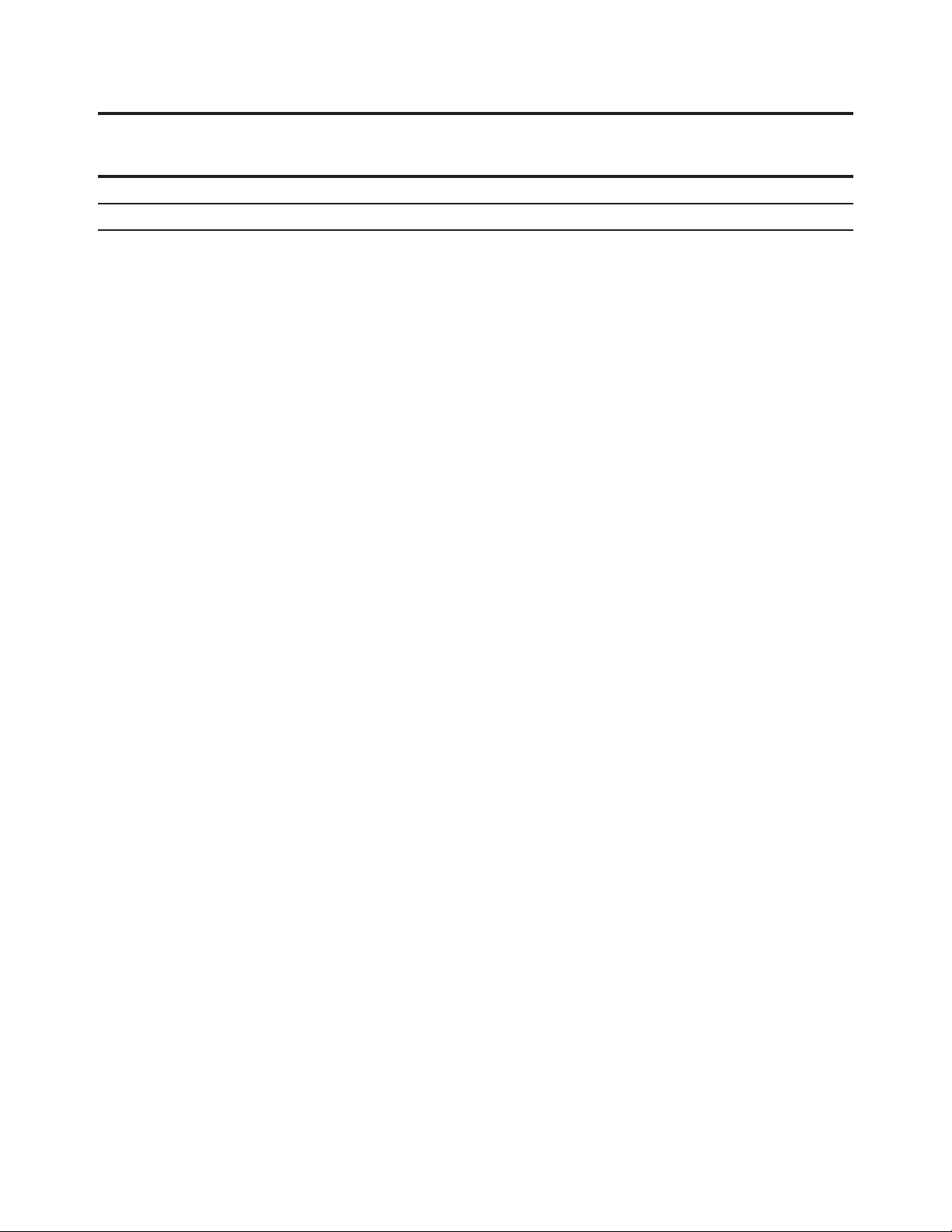

FAN CONTROL

Minimum

Maximum

The size of the object being coated is the determining factor in adjusting the fan pattern; the larger

the object, the larger the required fan pattern. Fan control of the Ransburg Vector/Solo applicators is

accomplished by rotating the adjusting knob located at the rear of the applicator. Fan width can be

set for approximately a 3-inch width (minimum) to approximately a 14-inch (maximum). Fan widths

and overall pattern appearances are illustrated.

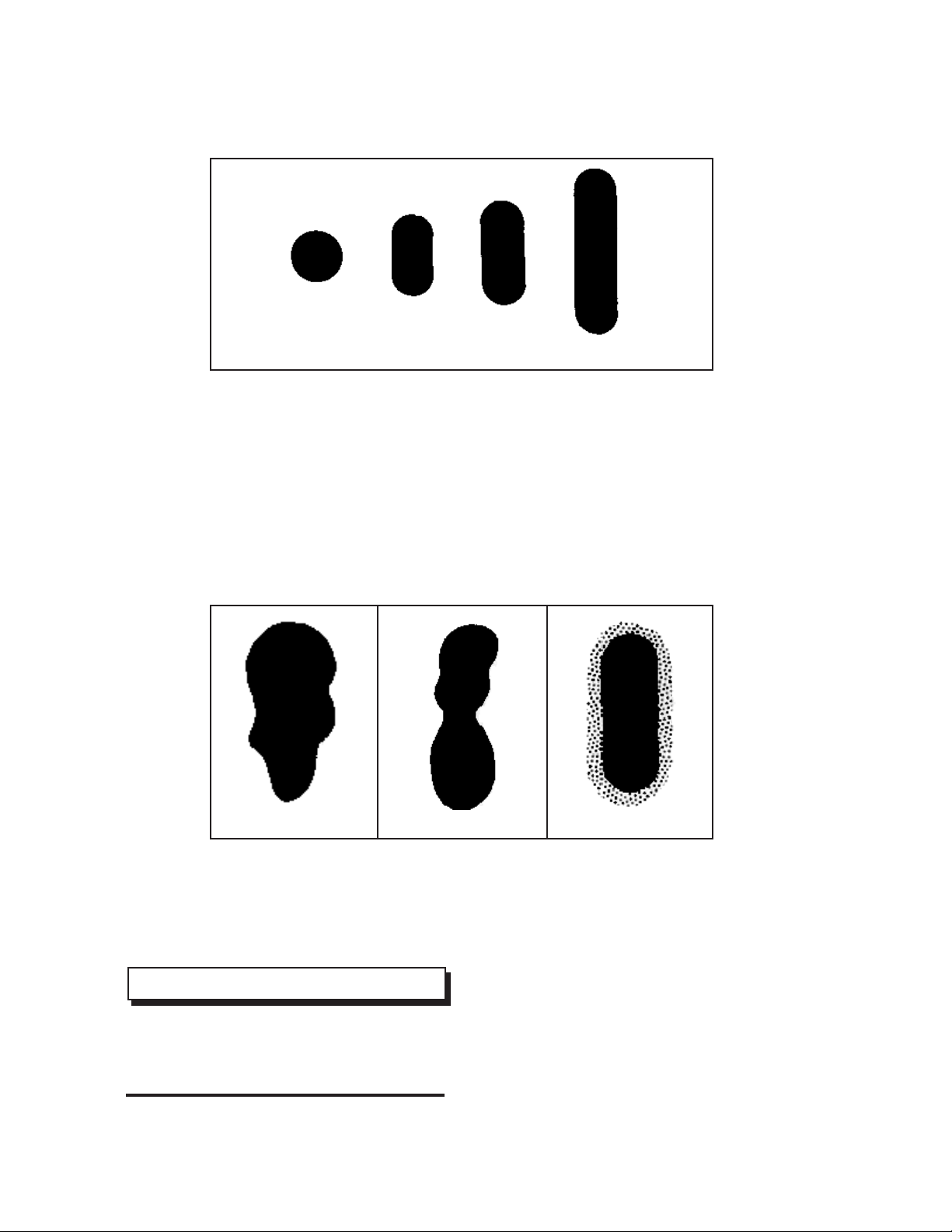

PATTERN

A

POOR PATTERN

Dirty, worn, or

damaged nozzle.

Clean or replace.

NOTE

> The degree of atomization is depen-

dent on the viscosity of the paint formulation, the applied air pressure, and nozzle

selection.

B

SPLIT PATTERN

Fan too wide - narrow

adjustment slightly.

C

GOOD PATTERN

IL-246-C

2