Ransburg

TECHNICAL MANUAL

IL-246-C

(Replaces IL-246-B)

April - 2013

RANSBURG

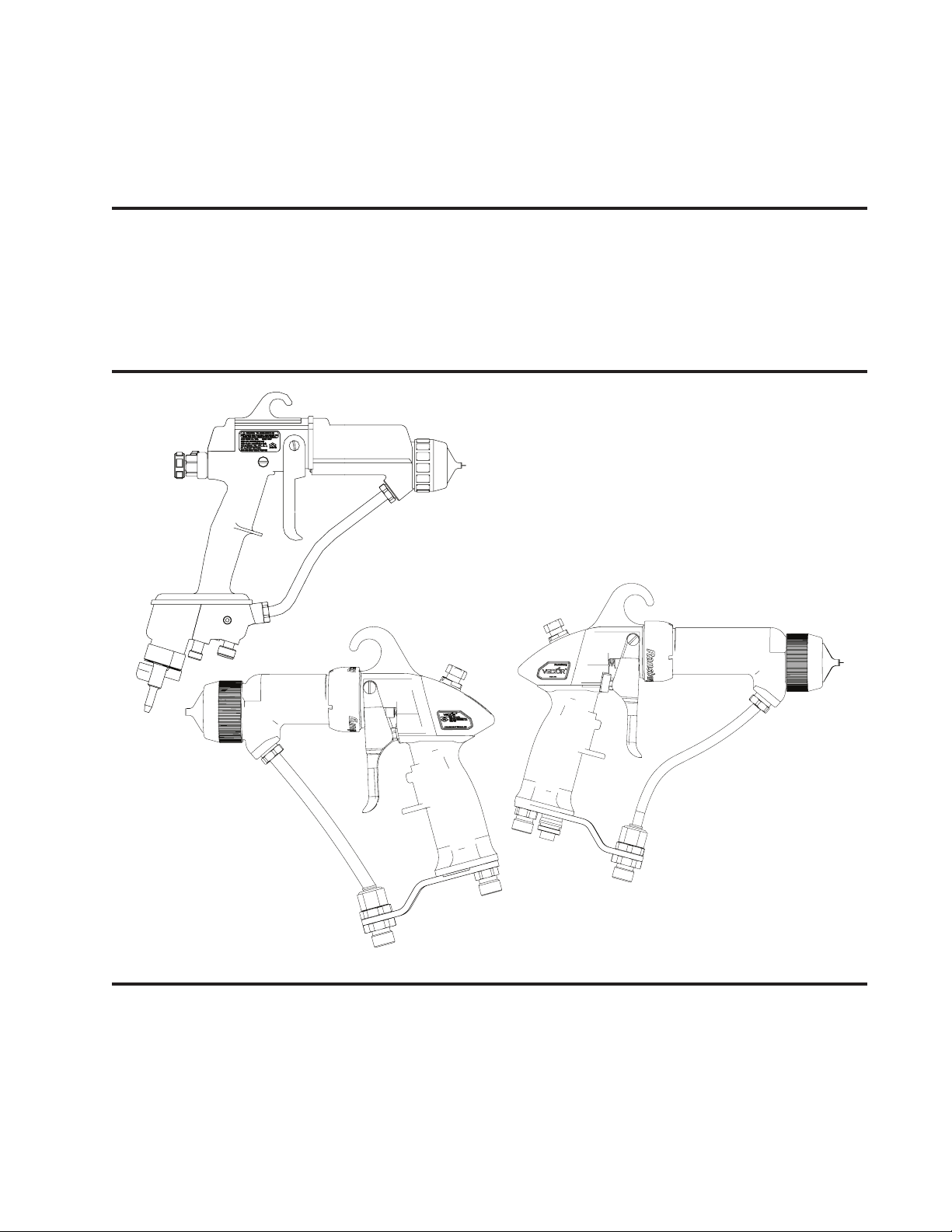

VECTOR AND SOLO

™ ™

APPLICATORS

ELECTROSTATIC

SPRAY

TECHNIQUES

IMPORTANT: Before using this equipment, carefully read SAFETY PRECAUTIONS, starting on

page 1, and all instructions in this manual. Keep

this Technical Manual for future reference.

Technical Manual Price: €15.00 Euro)

$20.00 (U.S.)

Vector/Solo Applicators Spray Techniques

NOTE: This manual has been changed from IL-246-B to revision IL-246-C. Reasons for this

change are noted under “Manual Change Summary” inside the back cover of this manual.

Ransburg

IL-246-C

Ransburg

Vector/Solo Applicators Spray Techniques

CONTENTS

VECTOR AND VECTOR SOLO APPLICATOR SPRAY TECHNIQUES:

PAGE

1-11

USE THE RIGHT TECHNIQUE.................................................................................................

FAN CONTROL.........................................................................................................................

PATTERN..................................................................................................................................

FLAT SURFACES.......................................................................................................................

HORIZONTAL PASSES.............................................................................................................

VERTICAL PASSES...................................................................................................................

APPLICATOR TO TARGET DISTANCE...................................................................................

OVERLAP.................................................................................................................................

TRIGGERING.............................................................................................................................

LARGE OBJECTS......................................................................................................................

TUBULAR WORK.....................................................................................................................

RECESSED AREAS...................................................................................................................

SUMMARY................................................................................................................................

SAFETY REQUIREMENTS......................................................................................................

1

2

2

3

3

3

4

5

5

6

7

8

9-10

11

IL-246-C

Vector/Solo Applicators Spray Techniques

Before operating, maintaining, or servicing any Ransburg electrostatic coating system, read and understand all of the technical and safety literature provided with Ransburg products. If you do not have

the manuals and safety literature for your Ransburg system, contact your Ransburg representative.

USE THE RIGHT TECHNIQUES

Vector/Solo (Electrostatic) Applicators

Savings of 25% to 50% in paint is possible when you replace conventional air spray with Ransburg

Electrostatic Applicators. You nish curved and recessed surfaces uniformly in fewer passes, because

combined air and electrostatic forces literally follow the shape of the work surface. Bounce losses

from work are reduced by the electrostatic attraction, when proper techniques are used.

The following describes basic electrostatic spray techniques. Depending on the type of work being

sprayed, it may be necessary to change the technique slightly.

Ransburg

1

IL-246-C

Ransburg

Vector/Solo Applicators Spray Techniques

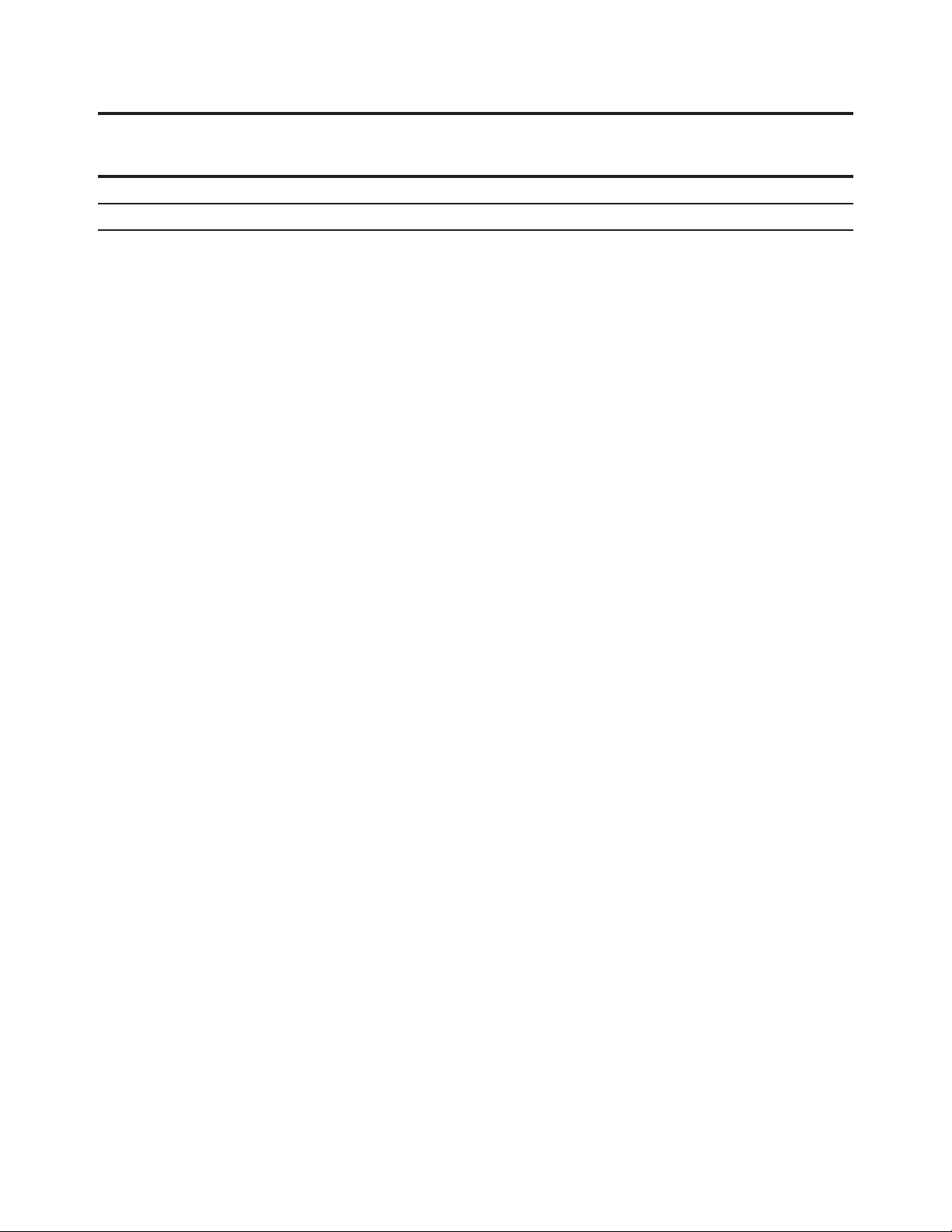

FAN CONTROL

Minimum

Maximum

The size of the object being coated is the determining factor in adjusting the fan pattern; the larger

the object, the larger the required fan pattern. Fan control of the Ransburg Vector/Solo applicators is

accomplished by rotating the adjusting knob located at the rear of the applicator. Fan width can be

set for approximately a 3-inch width (minimum) to approximately a 14-inch (maximum). Fan widths

and overall pattern appearances are illustrated.

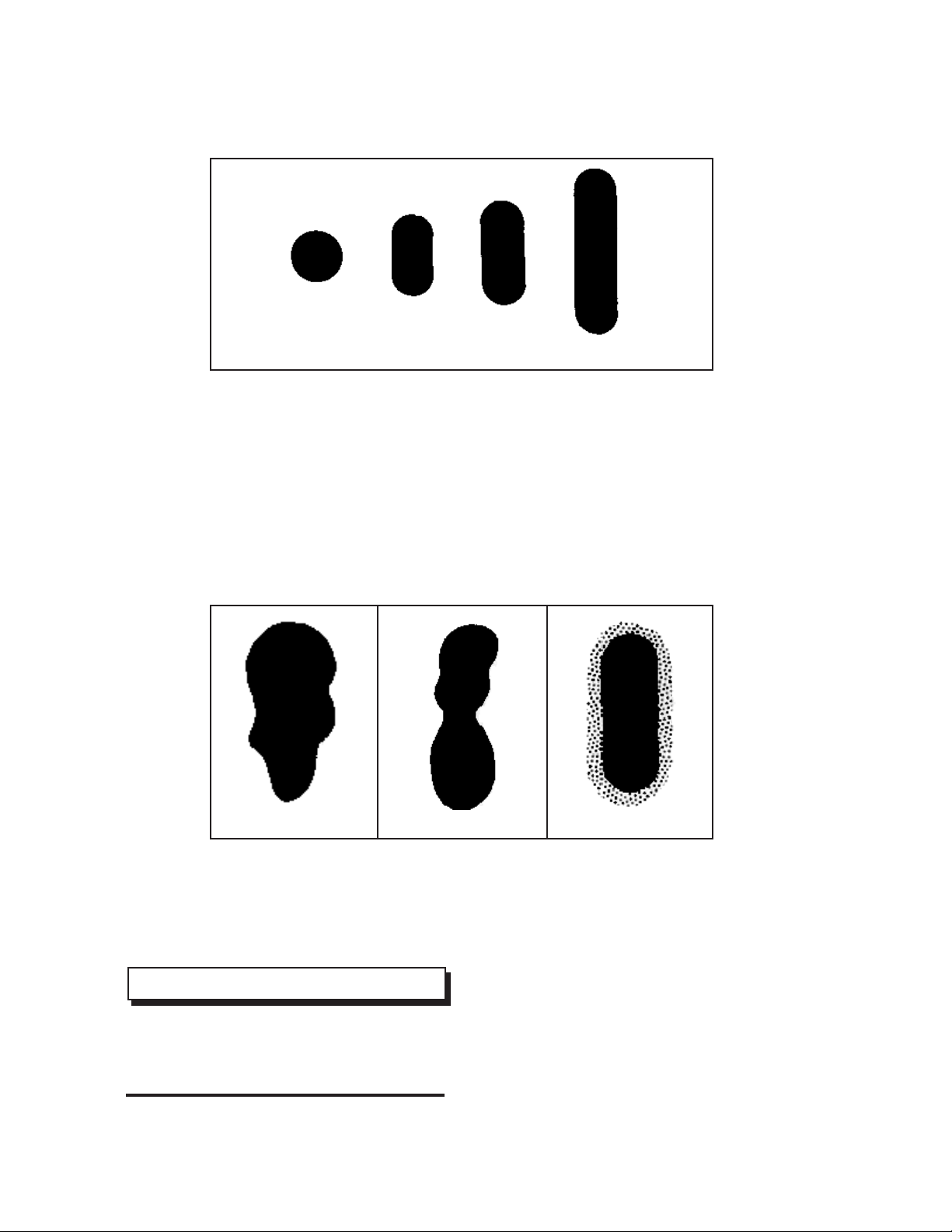

PATTERN

A

POOR PATTERN

Dirty, worn, or

damaged nozzle.

Clean or replace.

NOTE

> The degree of atomization is depen-

dent on the viscosity of the paint formulation, the applied air pressure, and nozzle

selection.

B

SPLIT PATTERN

Fan too wide - narrow

adjustment slightly.

C

GOOD PATTERN

IL-246-C

2

Vector/Solo Applicators Spray Techniques

FLAT SURFACES

One of the most prevalent of "bad" spray painting

habits is the one where the operator holds his arm

steady and swings his wrist back and forth. This is

a hard habit to break, it gives the illusion of adding

speed to the coating operation, when in reality, it is

slower and much more inefcient. Spray painting

in this fashion results in light lms on both sides,

excessive lm at center, and increased overspray

with excessive "bounce-back."

Ransburg

HORIZONTAL PASSES

The spray applicator should be maintained in a

position at right angles to the object and should

be moved in a path parallel to the object.

VERTICAL PASSES

There may be instances where it is more practical

to coat an object using vertical passes rather than

horizontal. First, rotate the nozzle to shift the fan

pattern, then holding the applicator at right angles

to the object, move the applicator in a straight

vertical path as illustrated.

3

IL-246-C

Ransburg

APPLICATOR TO TARGET

DISTANCE

Under 2"

4" to 6"

Vector/Solo Applicators Spray Techniques

The distance between the applicator and the target

inuences the appearance of the nal nish coating

of the object. If the applicator is held too close

(under 4-inches), runs and sags with the excessive

bounce-back can occur. If the applicator is held

too far from the object, the electrostatic attraction is

decreased. Normally, the best spacing between

applicator and target is in the 4 to 12-inch area.

However, this distance can vary with extremely

high delivery systems. Maximum target distance

should not exceed 12-inches.

C A U T I O N

!

> The object being coated is maintained at

ground potential, the spray applicator operator is also grounded, therefore, the operator

has as much attraction for the electrostatic

paint as the object. To prevent "wrapback"

always keep the applicator closer to the target

than it is to you.

Too Far

IL-246-C

4

Vector/Solo Applicators Spray Techniques

OVERLAP

For best hiding and uniformity of lm thickness, stroke overlap should be approximately 50%. There

should be some overlap at the top and bottom of the part to increase edge coverage. Overlap requirements can vary widely with different paint formulations and different compositions of objects being

coated. Individual spray coating operational experience should provide the guidelines for efciency

in this instance.

Ransburg

TRIGGERING

Applicator triggering (ON/OFF) depends largely on the desired results; the amount of wraparound required, edge coating, etc. If front and back of the object are being coated, proper applicator technique

can effect edge coating (in some instances) without making a specic pass for this purpose. Examples

of different trigger times and the results that can be expected are illustrated.

TOP VIEW

D C B A

(Trigger Off)

NOTE

> If front and back are both sprayed, there

may be enough wrap using Technique B or

C to coat a small edge or ange. If wide

anges are to be coated, this may require

individual coating of edges before the at

surfaces are sprayed.

A. Little or no wrap - incomplete coverage

B. Fair - some wrap

C. Good wrap (Triggered 2" to 3" past edge)

D. Too much overstroke may produce heavy

edges and produce more overspray.

5

IL-246-C

Ransburg

LARGE OBJECTS

Blending

If the size of the object is greater than the spray

applicator operator can reach, it should be coated

in segments, the size of each segment being the

length the spray applicator operator can comfortably span. Each segment should be blended

with the adjacent segment using "feathering" or

"over-lapping" strokes. A slight angle of the applicator improves the results of the "blending" pass.

Vector/Solo Applicators Spray Techniques

TOP VIEW

C A U T I O N

!

> Too much overlap can result in runs and

sags or excessive lm, where segments

blend together.

TOP VIEW

IL-246-C

6

Vector/Solo Applicators Spray Techniques

TUBULAR WORK

Tubular parts or objects up to approximately 2-1/2" diameter can be coated successfully from one

side, utilizing wraparound characteristics and proper techniques.

NOTE

> Avoid applicator to targe distances of

over 12-inches, excessive applicator to target distances will result in wrapback.

Ransburg

Adjust the fan for a pattern

width slightly wider than the

object. This allows some

coating material to start

around the sides of the object.

A

MOTION

B

C

FAN POSITION

(Example 1"

Diameter Part)

D

Increase the applicator to target distance to approximately

10-12-inches. This will decrease

the speed of the paint particles in

the vicinity of the target.

A. Wrong fan position - little wrap. Heavy lm on front surface,

possible sags.

B. Correct fan position - better wrap. More accurately con-

trolled lm. Normally fan pattern should be slightly wider

than parts being sprayed.

C. Correct fan position but excessively wide fan may produce

more overspray if used in this position.

D. A wide fan tilted at an angle may also work well. (Wide fans

have slower forward velocity.)

Hold the applicator at an angle of

30o to 45o to the object. This will

direct paint more to target area.

SUGGESTION: Small tubes may be racked in groups to simulate larger targets. This allows the use

of wider fans and may help improve efciency.

7

IL-246-C

Ransburg

Vector/Solo Applicators Spray Techniques

RECESSED AREAS

Do not depend on electrostatic attraction alone for coating recessed areas, remember, the more exposed areas of the object have a stronger attraction for charged paint formulations than the recessed

areas, therefore, the electrostatically charged paint particles will take the path of least resistance, and

tend to build excessively on the more exposed areas.

The best and most efcient technique is to coat the recessed areas rst, utilizing air pressure to drive

DIFFICULT

the paint into difcult areas or by narrowing fan width to effectively increase delivery rate per inch of

pattern width. Then paint the more readily accessible areas, the electrostatic process with its "wraparound" and "opposite attraction" characteristics will probably have already partly coated these areas.

A. Voltage by itself will not pull paint into deep

recesses, but instead, paint will be attracted

to more exposed edges.

C. Doing the outside of the part rst puts little

paint on the inside. If we now coat the inside,

we will be double coating the edges

and possibly overload them.

EASY

B. Solution: Move in closer and use the ad vantages of air atomization to drive paint

into recesses.

NOTE: Narrower fan may also be helpful.

IL-246-C

D. In this example, we coat the difcult area

rst. We may then nd that there was enough

wrap around from overspray to coat much

of the remaining areas.

8

Vector/Solo Applicators Spray Techniques

Ransburg

SUMMARY

1

2

3

4

Adjust fan pattern in accordance with size of

object to be coated.

Never swing spray applicator in an arc, hold

applicator steady in a position at right angles to

the object and move applicator in a straight path

parallel to object.

Be sure applicator is held closer to object being

coated than to the operator.

Stroke overlap of approximately 50% normally

produces adequate lm thickness uniformity.

9

IL-246-C

Ransburg

5

6

7

ON OFF

Vector/Solo Applicators Spray Techniques

For most economical and efcient coating, trigger applicator "ON" just before leading edge of

object, trigger applicator "OFF" just after trailing

edge of target. For best wraparound technique,

trigger applicator "ON" 3-inches before, and "OFF"

3-inches after edges of target.

When painting large objects a section at a time,

use "feather" stroke for blending sections together.

Avoid excessive overlap to prevent runs and sags

with excessive lm thickness.

Tubular component coating; adjust fan width for

a pattern slightly wider than the object, hold applicator 10 to 12-inches from object at an angle

of 30 to 45- inches. Move applicator straight in a

parallel path with the object.

8

Paint "hard to reach" areas rst, let wraparound

and electrostatic attraction get the "easy" areas

for you.

IL-246-C

10

Vector/Solo Applicators Spray Techniques

Ransburg

SAFETY REQUIREMENTS

Personnel

• Operators must NOT wear gloves that insulate

them from the applicator handle.

• ALL personnel in the spraying area MUST wear

non-insulating shoes or alternative grounding

devices so they will be grounded through the

conductive oor. (See Ransburg "Personnel

Grounding" Safety Bulletin.)

• Personnel entering a waterborne paint isolation

enclosure MUST be sure that the system and

the Warning Light are OFF! The grounding hook

must be attached to the paint supply BEFORE

contact, especially during the addition of uid!

The gate MUST be closed and the interlocks

functioning during use. (See the appropriate

Ransburg equipment manual.)

• The operator MUST turn the power supply OFF

before cleaning or servicing the equipment.

• NEVER immerse an applicator in any liquid.

• Exhaust fans MUST be ON during spraying.

• All conductive objects in the spraying area

MUST be removed or grounded.

• A pressure EXPLOSION may occur if HALOGENATED HYDROCARBON solvents are used in

PRESSURIZABLE uid systems having ALUMINUM or GALVANIZED parts. (See Ransburg

"Danger - Explosion Hazard" and "Halogenated

Hydrocarbon" Safety bulletins.)

• The high voltage power supply MUST be

grounded and located outside of the Hazard

Area. (See the appropriate Ransburg equipment manual.)

• Appropriate, functioning fire extinguishing

equipment MUST be provided.

• Good housekeeping is essential to safe operation. Cleanup and maintenance schedules

should be established by the user. Maintenance

and safety cards should be posted in clear view

of the operator.

• All ammable liquids MUST be in approved,

grounded safety containers. Not more than one

gallon should be in any container and the total

amount in the spray area should be no more

than the minimum required for the operation.

Environment and Equipment

• The spray booth (including its oor), paint reser-

voir (except waterborne), and conveyor MUST

be grounded.

• An adequate, grounded, protective enclosure

that will assure safe isolation from personnel

must surround the supply of waterborne paints.

(See OSHA Standard 1910.107 (h) (10).)

• The spray target and all supporting holders,

hooks, and conveyors MUST be grounded to

the supporting structure. All support devices

MUST be free of accumulated coating material.

11

• All applicators MUST be maintained within

proper operating limits. (See the appropriate

Ransburg equipment manual for short circuit

current tests.)

IL-246-C

Ransburg

MANUAL CHANGE SUMMARY

This manual was published to supercede Technical

Manual IL-246-B, Ransburg Vector Applicators

Electro-Air Spray Techniques, to make the

following change:

1. Service literature was reformatted. Made

available electronically.

2. Added "Technical Manual Price: €15.00 (Euro)"

to the "Front and Back Covers".

3. Added "Vector Applicators" to the "Spray

Techniques".

Vector/Solo Applicators Spray Techniques

4. New "Applicator Figures" throughout the

service literature.

5. Added "www.ransburg.com" to "Contact

Information" on the back cover.

IL-246-C

12

Technical Manual Price: €15.00 Euro)

$20.00 (U.S.)

Manufacturing

1910 North Wayne Street

Angola, Indiana 46703-9100

Telephone: 260/665-8800

Fax: 260/665-8516

Technical/Service Assistance

Telephone: 800/ 233-3366

Fax: 419/ 470-2071

www.ransburg.com

Technical Support Representative will direct you to the appropriate

telephone number for ordering Spare Parts.

© 2013 Ransburg. All rights reserved.

Models and specications subject to change without notice.

Form No. IL-246-C

Litho in U.S.A.

04/13

Loading...

Loading...