Ransburg 7952 User Manual

SERVICE MANUAL

AH-06-01.13

(REPLACES: AH-06-01.12)

September - 2013

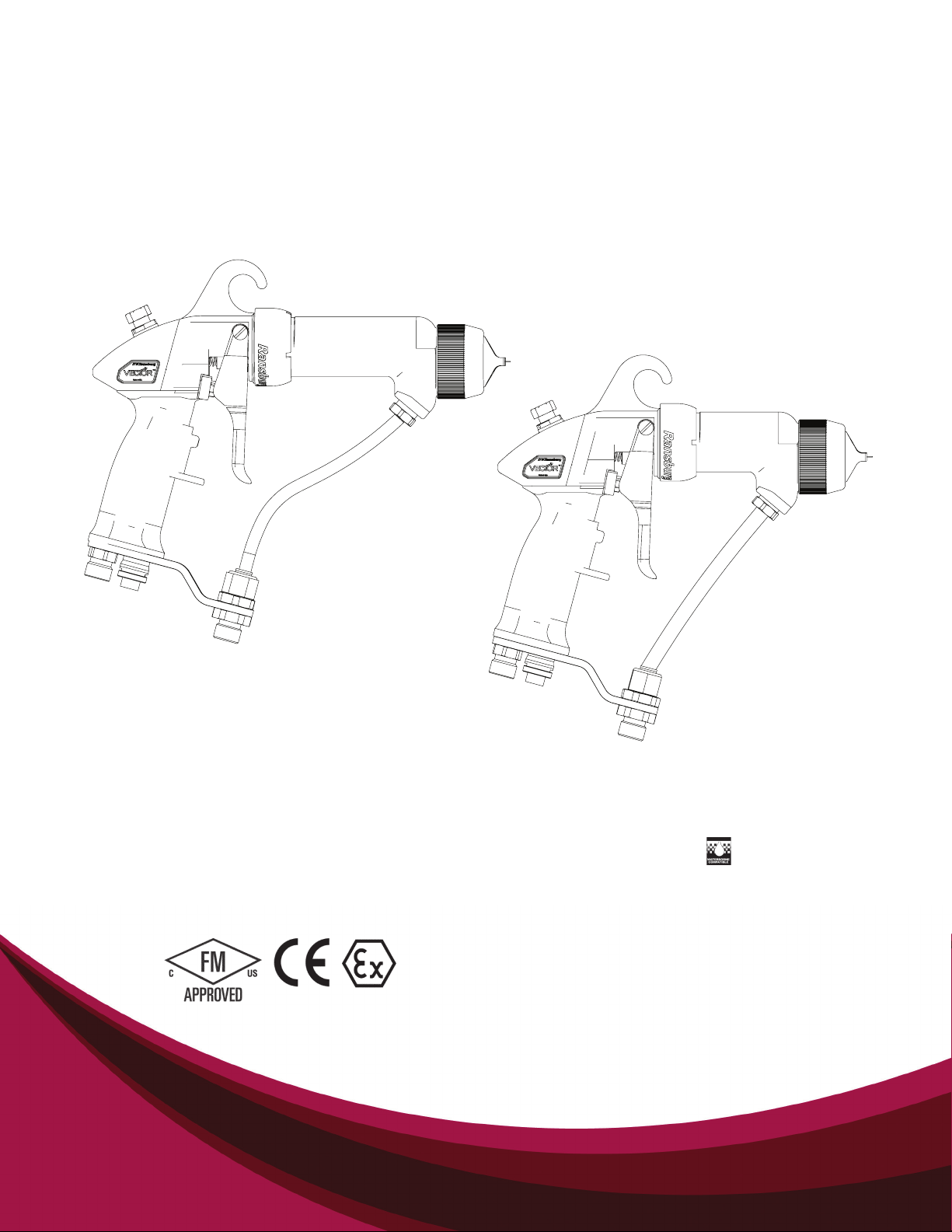

VECTOR R SERIES

CASCADE APPLICATORS

Ransburg

TM

MODELS:

79500 R90 Cascade - Solventborne

79501 R70 Cascade - Solventborne

79523 R90 Cascade - Waterborne

For Use With 80131-xxx Control Unit

IMPORTANT: Before using this equipment,

carefully read SAFETY PRECAUTIONS, starting

on page 1, and all instructions in this manual.

Keep this Service Manual for future reference.

Service Manual Price: $50.00 (U.S.)

Ransburg

NOTE: This manual has been changed from revision AH-06-01.12 to revision AH-06-01.13. Reasons

for this change are noted under “Manual Change Summary” inside the back cover of

this manual.

AH-06-01.13

Ransburg

Vector R Series Cascade Applicators - Contents

CONTENTS

PAGE

SAFETY: 1-4

SAFETY PRECAUTIONS ........................................................................................................ 1

HAZARDS / SAFEGUARDS .................................................................................................... 2-4

ATEX/FM: 5-12

EUROPEAN ATEX DIRECTIVE .............................................................................................. 5

EUROPEAN ATEX LABELS .................................................................................................... 6

FM CONFIGURATION DRAWINGS ........................................................................................ 7-12

INTRODUCTION: 13-17

GENERAL DESCRIPTION ...................................................................................................... 13

79500 R90 CASCADE SOLVENTBORNE SPECIFICATIONS .............................................. 14

79501 R70 CASCADE SOLVENTBORNE SPECIFICATIONS ............................................... 14

R90/70 CASCADE SOLVENTBORNE ELECTROSTATIC

SPRAY APPLICATOR FEATURES ......................................................................................... 15

80131-XXX 9060 POWER SUPPLY ELECTRICAL SPECIFICATIONS .................................. 16

80131-XXX CASCADE CONTROL UNIT FEATURES ............................................................ 17

INSTALLATION: 18-25

79500 R90 / 79501 R70 SOLVENTBORNE INSTALLATION .................................................. 18

TYPICAL SOLVENTBORNE INSTALLATION ......................................................................... 18-20

LOW VOLTAGE CABLE .......................................................................................................... 21

FILTERS .................................................................................................................................. 21

AIR HOSE RECOMMENDATION ............................................................................................. 22

FLUID HOSE RECOMMENDATION ........................................................................................ 22

AIR AND FLUID HOSE INSTALLATION .................................................................................. 22

ROUTING OF AIR FLUID HOSES ........................................................................................... 22

PAINT PREPARATION ............................................................................................................ 23

SPRAY PATTERN ADJUSTMENT .......................................................................................... 23

APPLICATOR TO TARGET DISTANCE .................................................................................. 23

FLUID NOZZLE / AIR CAP SELECTION CHARTS ................................................................. 24-25

ROUND SPRAY PERFORMANCE CHART ............................................................................ 25

OPERATION: 26-31

POWERING UP CONTROL UNIT ........................................................................................... 26

SETPOINT VOLTAGE ............................................................................................................. 26-27

LOCKOUTS ............................................................................................................................. 27-28

KV TEST JUMPER .................................................................................................................. 29

BASIC OPERATION ................................................................................................................ 29-30

FAULT DESCRIPTIONS .......................................................................................................... 30

(Continued On Next Page)

AH-06-01.13

Vector R Series Cascade Applicators - Contents

Ransburg

CONTENTS (Cont.)

MAINTENANCE: 31-50

SUITABLE SOLVENTS FOR CLEANING VECTOR R90/70 APPLICATORS ......................... 31

ROUTINE SCHEDULE ............................................................................................................ 32

APPLICATOR ASSEMBLY CLEANING PROCEDURE .......................................................... 33-34

FLUSHING PROCEDURES .................................................................................................... 35

APPLICATOR REPAIR ............................................................................................................ 35

TO REMOVE THE APPLICATOR FROM THE WORK SITE ...................................................36

AIR CAP ..................................................................................................................................36-37

FLUID NOZZLE ....................................................................................................................... 37-38

NEEDLE / ELECTRODE ......................................................................................................... 38

NEEDLE / ELECTRODE RESISTANCE TESTING ................................................................. 39

BARREL ASSEMBLY .............................................................................................................. 39-40

DISASSEMBLY / REASSEMBLY OF BARREL WITH

THE 2K FLUID NEEDLE PACKINGS ...................................................................................... 40-44

HANDLE / PLUG ASSEMBLY ................................................................................................. 45-47

TROUBLESHOOTING GUIDE ................................................................................................ 48-50

PAGE

PARTS IDENTIFICATION: 51-71

R90/70 CASCADE SOLVENTBORNE APPLICATOR

BREAKDOWN / PARTS LIST ..................................................................................................51-54

VECTOR R90/70 CASCADE SOLVENTBORNE MODEL IDENTIFICATION .........................54

R90 (78628-11) AND R70 (78628-12) CASCADE NEEDLE SHAFT

(STANDARD PACKINGS) / PARTS LIST ................................................................................ 55

R90 (79599-01) AND R70 (79599-02) CASCADE NEEDLE SHAFT PARTS LIST ................. 56

WATERBORNE APPLICATOR MODEL 79523 SECTION

- R90 CASCADE WATERBORNE ELECTROSTATIC

SPRAY APPLICATOR FEATURES .................................................................................... 58

- 79523 R90 CASCADE WATERBORNE SPECIFICATIONS .............................................. 59

- 79513-1XX 9050 POWER SUPPLY ELECTRICAL SPECIFICATIONS ............................59

- R90 CASCADE WATERBORNE TYPICAL INSTALLATION ............................................. 60

- WATERBORNE ISOLATION SYSTEM INSTALLATION GUIDELINES ............................. 61

- WATERBORNE HOSE FITTING INSTALLATION ............................................................. 61-63

- WATERBORNE FLUID DELIVERY COMPONENTS / PARTS LIST ................................. 64

- VECTOR R90 CASCADE WATERBORNE MODEL IDENTIFICATION ............................ 65

VECTOR AIR HOSE OPTIONS / PARTS LIST ....................................................................... 66

VECTOR FLUID HOSE OPTIONS / PARTS LIST ...................................................................66

VECTOR APPLICATOR COVER OPTIONS / PARTS LIST .................................................... 67

VECTOR SWIRL NOZZLE OPTIONS / PARTS LIST .............................................................. 67

VECTOR FLUID TUBE OPTIONS / PARTS LIST ................................................................... 67

LOW VOLTAGE CABLE OPTION / PARTS LIST .................................................................... 67

PARTS COMPARISON / TRANS-TECH. ATOMIZATION / PARTS LIST ................................ 68

79555 TRANS-TECH. CONVERSION KITS AVAILABLE ........................................................ 69

ACCESSORIES FOR ECON FLUSH BOX COMPATIBILITY (OPTIONAL) ............................ 69

VECTOR CASCADE APPLICATORS RECOMMENDED SPARE PARTS .............................. 70-71

WARRANTY POLICIES: 72

LIMITED WARRANTY ............................................................................................................. 72

AH-06-01.13

Vector R Series Cascade Applicators - Safety

SAFETY

Ransburg

SAFETY PRECAUTIONS

Before operating, maintaining or servicing any

Ransburg electrostatic coating system, read and

understand all of the technical and safety literature for your Ransburg products. This manual

contains information that is important for you to

know and understand. This information relates to

USER SAFETY and PREVENTING EQUIPMENT

PROBLEMS. To help you recognize this information, we use the following symbols. Please pay

particular attention to these sections.

A WARNING! States information to alert you

to a situation that might cause serious injury

if instructions are not followed.

A CAUTION! States information that tells how

to prevent damage to equipment or how to

avoid a situation that might cause minor injury.

A NOTE is information relevant to the procedure in progress.

W A R N I N G

!

The user MUST read and be familiar

with the Safety Section in this manual and

the Ransburg safety literature therein iden-

tied.

This hand held device is intended to be

used by trained personnel ONLY.

This manual MUST be read and thor-

oughly understood by ALL personnel who

operate, clean or maintain this equipment!

Special care should be taken to ensure that

the WARNINGS and safety requirements

for operating and servicing the equipment

are followed. The user should be aware of

and adhere to ALL local building and re

codes and ordinances as well as NFPA-

33 EN 50176 SAFETY STANDARD, or

applicable country safety standards pri-

or to installing, operating, and/or servicing

this equipment.

While this manual lists standard specications

and service procedures, some minor deviations

may be found between this literature and your

equipment. Differences in local codes and plant

requirements, material delivery requirements,

etc., make such variations inevitable. Compare

this manual with your system installation drawings

and appropriate Ransburg equipment manuals to

reconcile such differences.

Careful study and continued use of this manual will

provide a better understanding of the equipment

and process, resulting in more efcient operation,

longer trouble-free service and faster, easier troubleshooting. If you do not have the manuals and

safety literature for your Ransburg system, contact

your local Ransburg representative or Ransburg.

W A R N I N G

!

The hazards shown on the following

page may occur during the normal use of

this equipment. Please read the hazard

chart beginning on page 2.

1

AH-06-01.13

Ransburg

Vector R Series Cascade Applicators - Safety

AREA

Tells where hazards

may occur.

Spray Area

HAZARD

Tells what the hazard is.

Fire Hazard

Improper or inadequate operation and maintenance proce-

dures will cause a re hazard.

Protection against inadvertent

arcing that is capable of causing

re or explosion is lost if any

safety interlocks are disabled

during operation. Frequent power supply shutdown indicates a

problem in the system requiring

correction.

SAFEGUARDS

Tells how to avoid the hazard.

Fire extinguishing equipment must be present in

the spray area and tested periodically.

Spray areas must be kept clean to prevent the

accumulation of combustible residues.

Smoking must never be allowed in the spray area.

The high voltage supplied to the atomizer must be

turned off prior to cleaning, ushing or maintenance.

When using solvents for cleaning:

Those used for equipment ushing should have

ash points equal to or higher than those of the

coating material.

Those solvents used for cleaning must have a

ash point at minimum of 5°C (9°F) greater than

the ambient temperature. It is the end users responsibility to insure this condition is met.

Spray booth ventilation must be kept at the rates

required by local and/or country codes. In addition,

ventilation must be maintained during cleaning op-

erations using ammable or combustible solvents.

Electrostatic arcing must be prevented.

Test only in areas free of combustible material.

Testing may require high voltage to be on, but only

as instructed.

Non-factory replacement parts or unauthorized

equipment modications may cause re or injury.

If used, the key switch bypass is intended for use

only during setup operations. Production should

never be done with safety interlocks disabled.

The paint process and equipment should be set

up and operated in accordance with local and/or

country safety codes.

AH-06-01.13

2

Vector R Series Cascade Applicators - Safety

Ransburg

AREA

Tells where hazards

may occur.

Toxic Substances

Explosion

Hazard /

Incompatible

Materials

HAZARD

Tells what the hazard is.

Certain material may be harmful

if inhaled, or if there is contact

with the skin.

Halogenated hydrocarbon sol-

vents, for example: methylene

chloride and 1,1,1, - Trichloroethane, are not chemically

compatible with the aluminum

that might be used in many

system components. The chemical reaction caused by these

solvents reacting with aluminum

can become violent and lead to

an equipment explosion.

SAFEGUARDS

Tells how to avoid the hazard.

Follow the requirements of the Material Safety Data

Sheet supplied by coating material manufacturer.

Adequate exhaust must be provided to keep the

air free of accumulations of toxic materials.

Use a mask or respirator whenever there is a

chance of inhaling sprayed materials. The mask

must be compatible with the material being sprayed

and its concentration. Equipment must be as pre-

scribed by an industrial hygienist or safety expert,

and be approved.

Spray applicators require that aluminum inlet ttings

be replaced with stainless steel. (See "Accessories"

in the "Parts Identication" section.) Aluminum is

widely used in other spray application equipment

- such as material pumps, regulators, valves, etc.

Check all other equipment items before use and

make sure they can also be used safely with these

solvents. Read the label or data sheet for the material you intend to spray. If in doubt as to whether

or not a coating or cleaning material is compatible,

contact your material supplier. Any other type of

solvent may be used with aluminum equipment.

Electrical

Equipment

High voltage equipment is utilized. Arcing in areas of ammable or combustible materials may

occur. Personnel are exposed

to high voltage during operation

and maintenance.

Protection against inadvertent

arcing that may cause a re or

explosion is lost if safety circuits

are disabled during operation.

An electrical arc can ignite coat-

ing materials and cause a re or

explosion.

Turn the power module OFF before working on

the equipment.

Test only in areas free of ammable or combustible material.

Testing may require high voltage to be on, but

only as instructed.

Production should never be done with the safety

circuits disabled.

Before turning the high voltage on, make sure

no objects are within the sparking distance.

3

AH-06-01.13

Ransburg

Vector R Series Cascade Applicators - Safety

AREA

Tells where hazards

may occur.

Spray Area

HAZARD

Tells what the hazard is.

Electrostatic Arcing

SAFEGUARDS

Tells how to avoid the hazard.

Never operate the applicator without properly

grounding the following.

A. Operators

Operators must be grounded. Rubber

soled insulating shoes should not be worn.

Grounding leg or wrist straps may be used.

Operators must maintain contact with the

handle of the applicator. If work gloves are

used, the palm section must be cut out.

Operators must remove from themselves all

metal objects that are not grounded.

NOTE: REFER TO NFPA-33, EN 50176 REGARDING OPERATOR GROUNDING OR SPECIFIC COUNTRY SAFETY CODE.

B. Parts being sprayed. Resistance between

the part and a grounded conveyor must not

exceed 1 megohm.

General Use and

Maintenance

Improper operation or main-tenance may create a hazard.

Personnel must be properly

trained in the use of this equipment.

C. Every metal and conductive object in the

spray area. This includes the booth, parts

hangers, re extinguishers, conductive

ooring, etc.

Grounded conductive ooring must be provided

in the spray area.

Turn off voltage at the power module before

ushing out, cleaning, or removing any parts

from the applicator.

Never install an applicator into a uid system

using an isolated solvent supply.

Do not touch applicator electrode while applicator is energized.

Personnel must be given training in accordance

with the requirements of NFPA-33, EN 50176.

Instructions and safety precautions must be

read and understood prior to using this equipment.

AH-06-01.13

Comply with appropriate local, state, and nation-

al codes governing ventilation, re protection,

operation maintenance, and housekeeping.

4

Vector R Series Cascade Applicators - Atex/FM

EUROPEAN ATEX DIRECTIVE 94/9/EC, ANNEX II, 1.0.6

Ransburg

The following instructions apply to equipment

covered by certicate number Sira 08ATEX5060X:

1. The equipment may be used with ammable

gases and vapors with apparatus groups II and

with temperature class T6.

2. The equipment is only certied for use in ambient temperatures in the range +0°C to +40°C

and should not be used outside this range.

3. Installation shall be carried out by suitably trained

personnel in accordance with the applicable code

of practice e.g. EN 60079-14:1997.

4. Inspection and maintenance of this equipment

shall be carried out by suitably trained personnel

in accordance with the applicable code of practice

e.g. EN 60079-17.

5. Repair of this equipment shall be carried out by

suitable trained personnel in accordance with the

applicable code of practice e.g. EN 60079-19.

6. Putting into service, use, assembling, and

adjustment of the equipment shall be tted by

suitably trained personnel in accordance with the

manufacturer's documentation.

Refer to the "Table of Contents" of this service

manual:

a. Installation

b. Operation

c. Maintenance

d. Parts Identication

7. Components to be incorporated into or used as

replacement parts of the equipment shall be tted

by suitably trained personnel in accordance with

the manufacturer's documentation.

8. The certication of this equipment relies upon

the following materials used in its construction:

If the equipment is likely to come into contact with

aggressive substances, then it is the responsibility

of the user to take suitable precautions that prevent

it from being adversely affected, thus ensuring that

the type of protection provided by the equipment

is not compromised.

Aggressive substances: e.g. acidic liquids or

gases that may attack metals, or solvents that

may affect polymeric materials.

Suitable precautions: e.g. regular checks as

part of routine inspections or establishing from

the material's data sheets that it is resistant to

specic chemicals.

Refer to "Specications" in the "Introduction"

section:

a. All uid passages contain stainless steel or

nylon ttings.

b. High voltage cascade is encapsulated with

a solvent resistant epoxy.

9. A recapitulation of the certication marking is

detailed in the "ATEX" section, on the next page,

drawing numbers: 79846-01 and 79852-01.

10. The characteristics of the equipment shall

be detailed e.g. electrical, pressure, and voltage

parameters.

The manufacturer should note that, on being

put into service, the equipment must be accompanied by a translation of the instructions

in the language or languages of the country in

which the equipment is to be used and by the

instructions in the original language.

5

AH-06-01.13

Ransburg

Vector R Series Cascade Applicators - Atex/FM

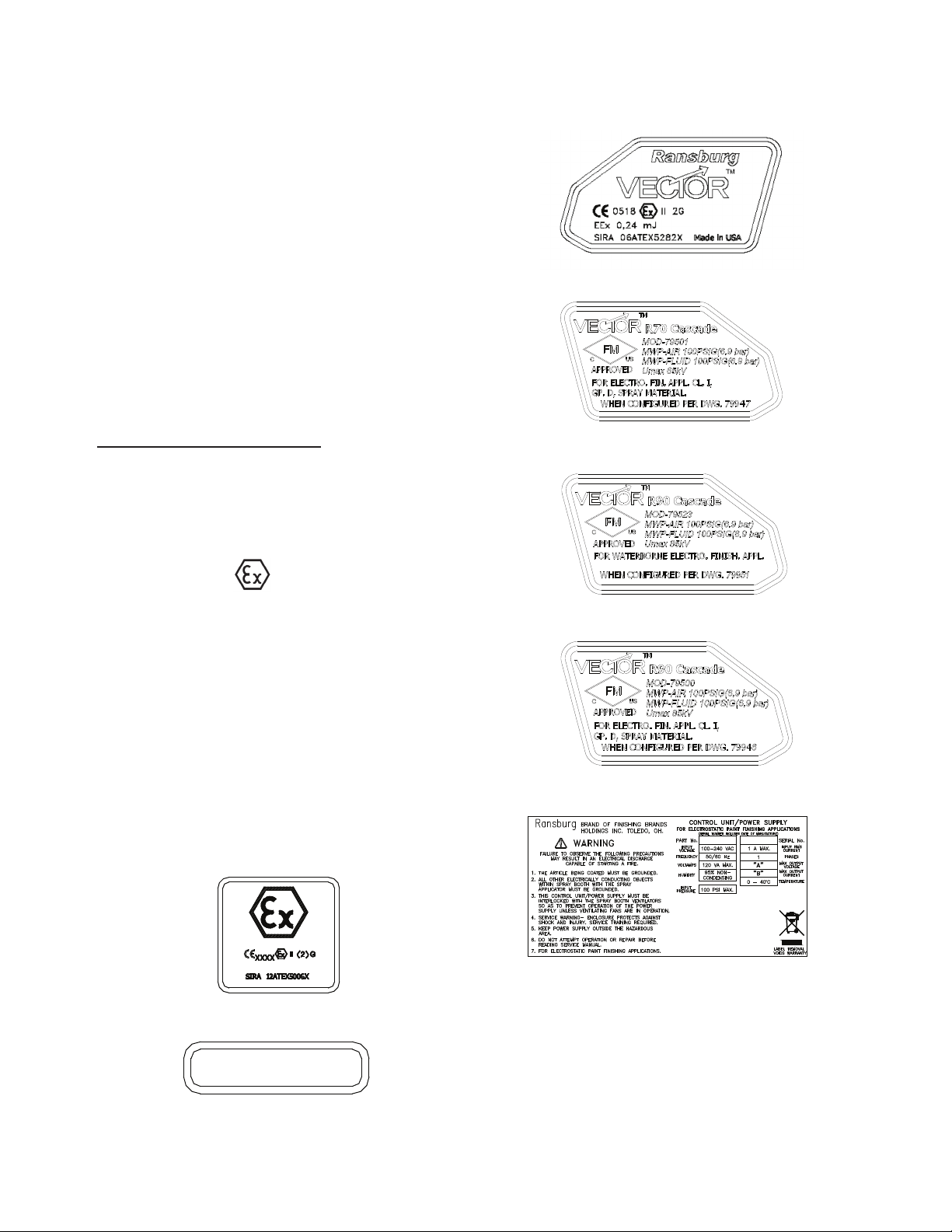

VECTOR R SERIES 79500, 79501,

AND 79523 ATEX PRODUCT

MARKING DEFINITIONS

Ex Certicate Number: Sira 06ATEX5282X

Sira = Notied Body performing EC-type

examination

06 = Year of certication

ATEX = Reference to ATEX Directive

5 = Protection Concept Code (code 5 is titled

Encapsulation)

282 = Document serial number

X = Special conditions for safe use apply

Special conditions for safe use: The Vector 79500,

79501, and 79523 R Series Cascade Applicators

shall only be used with associated 80131-21X

Control Unit.

Product Marking

Label 79515

Label 79516-70

Label 79516-91

II 2 G

Ex = Specic marking of explosive protection

II = Equipment Group hazardous area characteristics

2 = Equipment Category

G = Type of explosive atmosphere (gases, vapors,

or mists)

EEx 0.24mJ = The Vector R Series 79500, 79501,

and 79523 Cascade Applicators are suitable for

use in manual spraying installations complying

with EN 50 050 as they are a Type A class with a

discharge energy limit of 0.24mJ.

Label 80082

Label 79516-90

Label 80108

AH-06-01.13

E N 50 050 COMP LI A NT

Label 80081

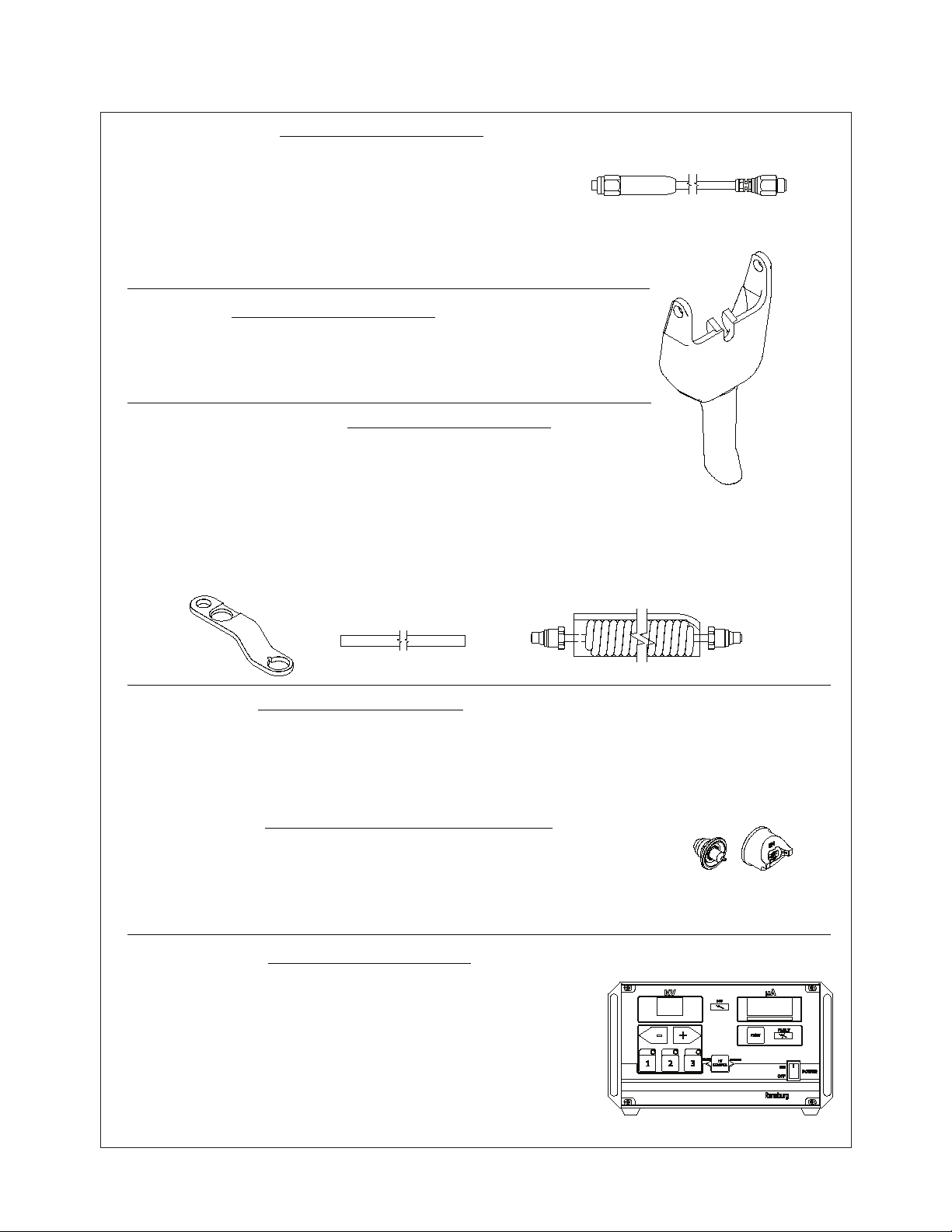

FM Conguration

These applicators are FM approved when congured to drawings 79946, 79947, 79951, shown on

pages 7 thru 12.

6

Vector R Series Cascade Applicators - Atex/FM

CONFIGURATION DWG. 79946 REV B

VECTOR R90 CASCADE, SOLVENT BASED

79500 - ABCDE

BASE

MODEL NO.

(ORDERING INFORMATION ONLY)

DESIGNATIONS

Ransburg

OPTION

"A" DESIGNATIONS

"D" DESIGNATIONS

"B" DESIGNATIONS

"C" DESIGNATIONS

"E" DESIGNATIONS

7

AH-06-01.13

Ransburg

CONFIGURATION DWG. 79946 REV B

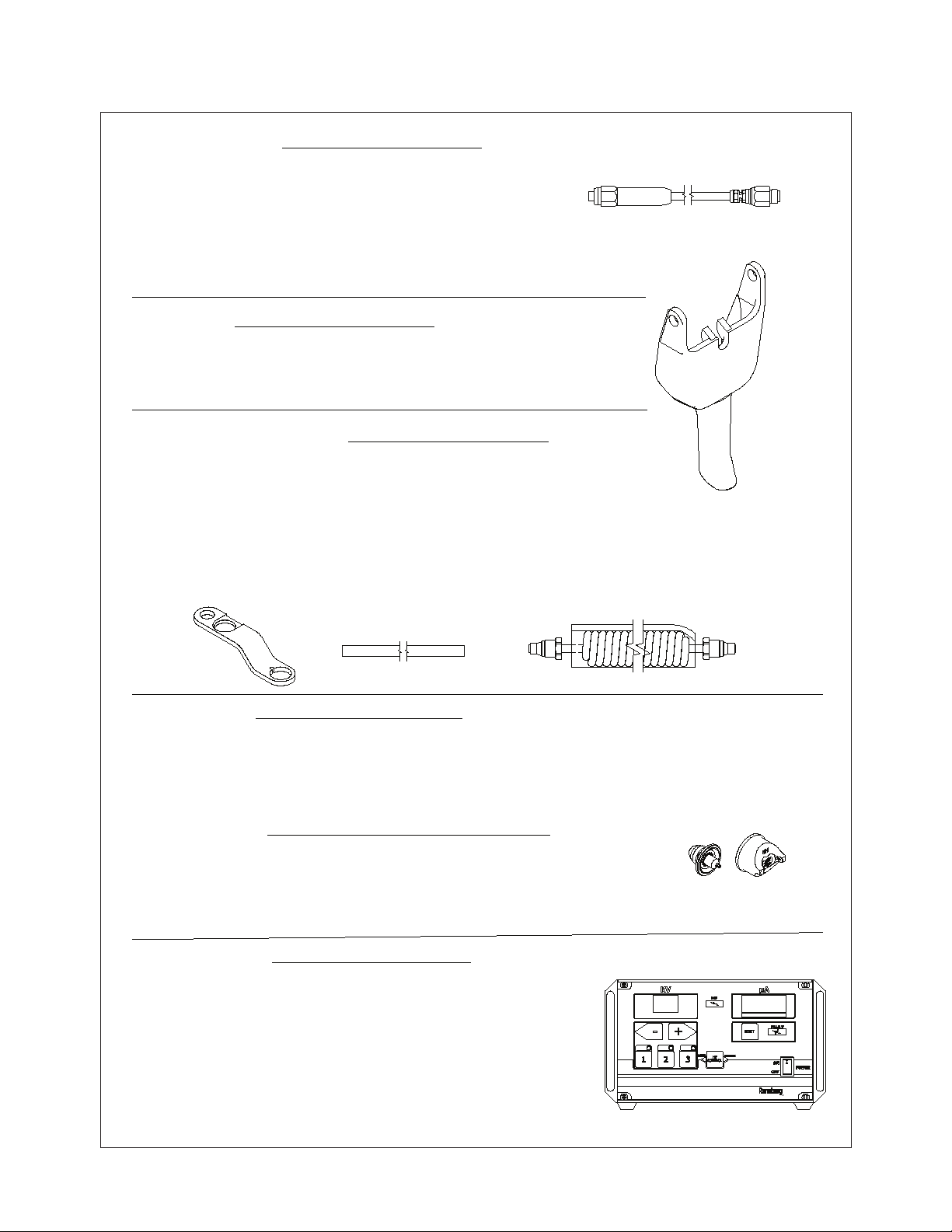

OPTION "A" DESIGNATIONS

CABLE LENGTH

0 FOR NO CABLE

1 FOR 10 METER CABLE-PART NUMBER: 79338-10

2 FOR 15 METER CABLE-PART NUMBER: 79338-15

3 FOR 20 METER CABLE-PART NUMBER: 79338-10 (2)

4 FOR 25 METER CABLE-PART NUMBER: 79338-10 (1) & 79338-15 (1)

5 FOR 30 METER CABLE-PART NUMBER: 79338-15 (2)

OPTION "B" DESIGNATIONS

TRIGGER TYPE

2 FOR TWO FINGER TRIGGER-PART NUMBER: 79325-02

4 FOR FOUR FINGER TRIGGER-PART NUMBER:79325-04

OPTION "C" DESIGNATIONS

FLUID DELIVERY COMBINATION

1 OFFSET WITH .093" ID FLUID TUBE-PART NUMBER: 79438-00 & 9704-16

2 45° WITH .093" ID FLUID TUBE-PART NUMBER: 79439-00 & 9704-16

3 OFFSET STAINLESS WITH .093" ID FLUID TUBE-PART NUMBER: 79438-01 & 9704-16

4 OFFSET WITH .250" ID FLUID TUBE-PART NUMBER: 79438-00 & 9704-11

5 45° WITH .250" ID FLUID TUBE-PART NUMBER: 79439-00 & 9704-11

6 OFFSET STAINLESS WITH .250" ID FLUID TUBE-PART NUMBER: 79438-01 & 9704-11

7 OFFSET WITH .125" ID COILED FLUID TUBE-PART NUMBER: 79438-00 & 79871-00

Vector R Series Cascade Applicators - Atex/FM

OPTION "D" DESIGNATIONS

SPRAY TECHNOLOGY

0 FOR STANDARD SPRAY, 65V CAP, #44 NOZZLE

1 FOR STANDARD SPRAY, 65V CAP, #45 NOZZLE

2 FOR TRANSTECH SPRAY, 122V CAP, #245 NOZZLE

3 FOR ROUND SPRAY

79377-46 (1.06mm ID, STD. WEAR), 79377-47 (.71mm ID, STD. WEAR),

79377-48 (1.19mm ID, STD. WEAR), 79377-144 (1.40mm ID, HIGH WEAR),

79377-145 (1.78mm ID, HIGH WEAR), 79377-146 (1.06mm ID, HIGH WEAR),

79377-147 (.71mm ID, HIGH WEAR), 79552-244 (1.40mm ID, STD. WEAR),

79552-344 (1.40mm ID, HIGH WEAR), 79552-345 (1.78mm ID, HIGH WEAR)

0 FOR NO CONTROL UNIT

1 FOR DOMESTIC SALES, 110/120 V

2 FOR EUROPE, 240V-50/60 Hz

3 FOR CHINA, 240V-50/60 Hz - PART NUMBER: 80131-313

-PART NUMBER: 79962-00 & 79959-00

APPROVED SPARE FLUID NOZZLES LIST

OPTION "E" DESIGNATIONS

CONTROL UNIT

-PART NUMBER: 80131-311

-PART NUMBER: 80131-312

-PART NUMBER: 79374-65 & 79377-44

-PART NUMBER: 79374-65 & 79377-45

-PART NUMBER: 79374-122 & 79552-245

AH-06-01.13

8

Vector R Series Cascade Applicators - Atex/FM

CONFIGURATION DWG. 79947 REV B

VECTOR R70 CASCADE, SOLVENT BASED

79501 - ABCDE

BASE

MODEL NO.

(ORDERING INFORMATION ONLY)

OPTION

DESIGNATIONS

Ransburg

"A" DESIGNATIONS

"D" DESIGNATIONS

"B" DESIGNATIONS

"C" DESIGNATIONS

"E" DESIGNATIONS

9

AH-06-01.13

Ransburg

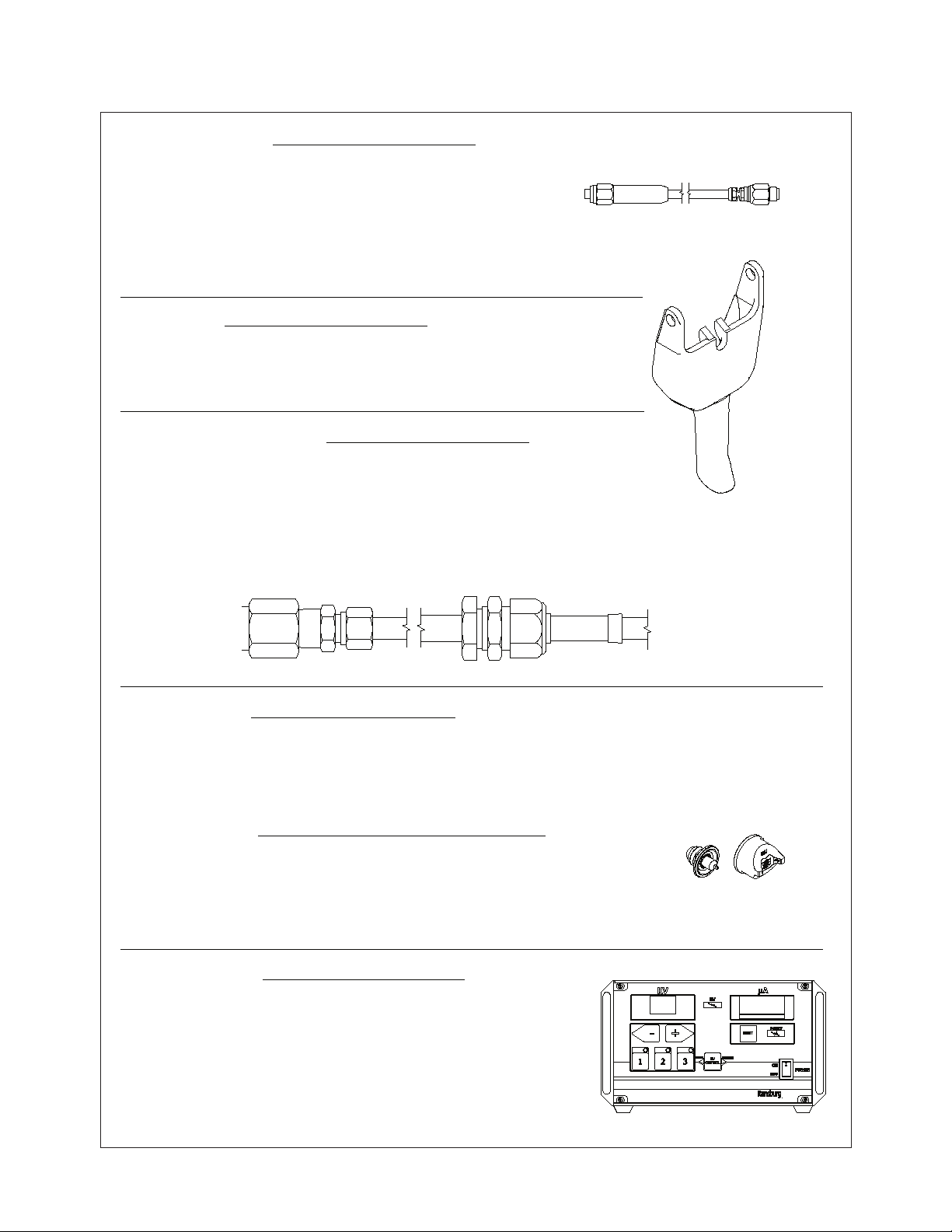

CONFIGURATION DWG. 79947 REV B

0 FOR NO CABLE

1 FOR 10 METER CABLE-PART NUMBER: 79338-10

2 FOR 15 METER CABLE-PART NUMBER: 79338-15

3 FOR 20 METER CABLE-PART NUMBER: 79338-10 (2)

4 FOR 25 METER CABLE-PART NUMBER: 79338-10 (1) & 79338-15 (1)

5 FOR 30 METER CABLE-PART NUMBER: 79338-15 (2)

2 FOR TWO FINGER TRIGGER-PART NUMBER: 79325-02

4 FOR FOUR FINGER TRIGGER-PART NUMBER:79325-04

1 OFFSET WITH .093" ID FLUID TUBE-PART NUMBER: 79438-00 & 9704-16

2 45° WITH .093" ID FLUID TUBE-PART NUMBER: 79439-00 & 9704-16

3 OFFSET STAINLESS WITH .093" ID FLUID TUBE-PART NUMBER: 79438-01 & 9704-16

4 OFFSET WITH .250" ID FLUID TUBE-PART NUMBER: 79438-00 & 9704-11

5 45° WITH .250" ID FLUID TUBE-PART NUMBER: 79439-00 & 9704-11

6 OFFSET STAINLESS WITH .250" ID FLUID TUBE-PART NUMBER: 79438-01 & 9704-11

7 OFFSET WITH .125" ID COILED FLUID TUBE-PART NUMBER: 79438-00 & 79871-00

Vector R Series Cascade Applicators - Atex/FM

OPTION "A" DESIGNATIONS

CABLE LENGTH

OPTION "B" DESIGNATIONS

TRIGGER TYPE

OPTION "C" DESIGNATIONS

FLUID DELIVERY COMBINATION

OPTION "D" DESIGNATIONS

SPRAY TECHNOLOGY

0 FOR STANDARD SPRAY, 65V CAP, #44 NOZZLE

1 FOR STANDARD SPRAY, 65V CAP, #45 NOZZLE

2 FOR TRANSTECH SPRAY, 122V CAP, #245 NOZZLE

3 FOR ROUND SPRAY

79377-46 (1.06mm ID, STD. WEAR), 79377-47 (.71mm ID, STD. WEAR),

79377-48 (1.19mm ID, STD. WEAR), 79377-144 (1.40mm ID, HIGH WEAR),

79377-145 (1.78mm ID, HIGH WEAR), 79377-146 (1.06mm ID, HIGH WEAR),

79377-147 (.71mm ID, HIGH WEAR), 79552-244 (1.40mm ID, STD. WEAR),

79552-344 (1.40mm ID, HIGH WEAR), 79552-345 (1.78mm ID, HIGH WEAR)

0 FOR NO CONTROL UNIT

1 FOR DOMESTIC SALES, 110/120 V

2 FOR EUROPE, 240V-50/60 Hz

3 FOR CHINA, 240V-50/60 Hz - PART NUMBER: 80131-213

-PART NUMBER: 79962-00 & 79959-00

APPROVED SPARE FLUID NOZZLES LIST

OPTION "E" DESIGNATIONS

CONTROL UNIT

-PART NUMBER: 80131-211

-PART NUMBER: 80131-212

-PART NUMBER: 79374-65 & 79377-44

-PART NUMBER: 79374-65 & 79377-45

-PART NUMBER: 79374-122 & 79552-245

AH-06-01.13

10

Vector R Series Cascade Applicators - Atex/FM

CONFIGURATION DWG. 79951 REV B

VECTOR R90 CASCADE, WATER BASED

79523 - ABCDE

BASE

MODEL NO.

(ORDERING INFORMATION ONLY)

OPTION

DESIGNATIONS

Ransburg

"A" DESIGNATIONS

"D" DESIGNATIONS

"B" DESIGNATIONS

"C" DESIGNATIONS

"E" DESIGNATIONS

11

AH-06-01.13

Ransburg

OPTION "A" DESIGNATIONS

CABLE LENGTH

0 FOR NO CABLE

1 FOR 10 METER CABLE-PART NUMBER: 79338-10

2 FOR 15 METER CABLE-PART NUMBER: 79338-15

3 FOR 20 METER CABLE-PART NUMBER: 79338-10 (2)

4 FOR 25 METER CABLE-PART NUMBER: 79338-10 (1) & 79338-15 (1)

5 FOR 30 METER CABLE-PART NUMBER: 79338-15 (2)

OPTION "B" DESIGNATIONS

TRIGGER TYPE

2 FOR TWO FINGER TRIGGER-PART NUMBER: 79325-02

4 FOR FOUR FINGER TRIGGER-PART NUMBER:79325-04

OPTION "C" DESIGNATIONS

FLUID HOSE LENGTH & TYPE

0 FOR NO FLUID HOSE

1 FOR WATERBORNE FLUID HOSE-1/4" ID X 10m (30ft)-PART NUMBER: 79525-10

2 FOR WATERBORNE FLUID HOSE-3/16" ID X 10m (30ft)-PART NUMBER: 79524-10

3 FOR WATERBORNE FLUID HOSE-1/4" ID X 15m (50ft)-PART NUMBER: 79525-15

4 FOR WATERBORNE FLUID HOSE-3/16" ID X 15m (50ft)-PART NUMBER: 79524-15

Vector R Series Cascade Applicators - Atex/FM

OPTION "D" DESIGNATIONS

SPRAY TECHNOLOGY

0 FOR STANDARD SPRAY, 65V CAP, #44 NOZZLE

1 FOR STANDARD SPRAY, 65V CAP, #45 NOZZLE

2 FOR TRANSTECH SPRAY, 122V CAP, #245 NOZZLE

3 FOR ROUND SPRAY

79377-46 (1.06mm ID, STD. WEAR), 79377-47 (.71mm ID, STD. WEAR),

79377-48 (1.19mm ID, STD. WEAR), 79377-144 (1.40mm ID, HIGH WEAR),

79377-145 (1.78mm ID, HIGH WEAR), 79377-146 (1.06mm ID, HIGH WEAR),

79377-147 (.71mm ID, HIGH WEAR), 79552-244 (1.40mm ID, STD. WEAR),

79552-344 (1.40mm ID, HIGH WEAR), 79552-345 (1.78mm ID, HIGH WEAR)

0 FOR NO CONTROL UNIT

1 FOR DOMESTIC SALES, 110/120 V

2 FOR EUROPE, 240V-50/60 Hz

3 FOR CHINA, 240V-50/60 Hz - PART NUMBER: 80131-513

-PART NUMBER: 79962-00 & 79959-00

APPROVED SPARE FLUID NOZZLES LIST

OPTION "E" DESIGNATIONS

CONTROL UNIT

-PART NUMBER: 80131-511

-PART NUMBER: 80131-512

-PART NUMBER: 79374-65 & 79377-44

-PART NUMBER: 79374-65 & 79377-45

-PART NUMBER: 79374-122 & 79552-245

CONFIGURATION DWG. 79951 REV B

AH-06-01.13

12

Vector R Series Cascade Applicators - Introduction

INTRODUCTION

GENERAL DESCRIPTION

Ransburg

The Vector

is an air-atomized method for electrostatically

applying product coatings. The Vector R90/R70

Spray Applicator system applies a high voltage

DC charge to the applicator electrode, creating

an electrostatic eld between the atomizer and

the target object.

Vector™ R90 Cascade Spray Applicator (see

Figure 1) applies a -85 kV DC charge to the coating

materials at the point of atomization. The Vector™

R70 Cascade Spray Applicator applies a -65 kV

charge. This electrostatic charge allows a more

efcient, uniform application of coating material to

the front, edges, sides, and back of products. It is

highly suitable for applying coatings to a variety of

surface congurations: large targets, small parts,

tubular wares, concave and recessed parts, etc.

Because it is a grounded uid system (for solvent

based systems), it is highly suitable for applying

a wide range of solvent reduced coatings such

as enamels, lacquers, epoxies, etc. The 79523

model is available to accommodate waterborne

materials.

A regulated pressure uid system delivers coating

material to the atomizer. At the time of triggering

the applicator, fan and atomization air is introduced,

which atomizes the coating material into a spray

mist. The atomized spray particles under the inuence of the electrostatic eld become electrically

charged. The charged particles are attracted to,

and deposited on, the target object. The forces

between the charged particles and the grounded

target are sufcient to turn most normal overspray

around and deposit it on the back surface of the

target. Therefore, a high percentage of the coating

is deposited on the target.

TM

R90/70 Spray Applicator process

One of the many features of the Vector

applicator system is that the electrical energy,

which is available from the resistive charging

electrode, is limited to the optimum level of safety

and efciency. The system is incapable of releasing sufcient electrical or thermal energy during

normal operating conditions to cause ignition of

specic hazardous materials in their most easily

ignited concentrations in air.

The control unit or power supply provides voltage

output to the applicator and contains controls for

AC on/off, high voltage adjust, and displays kV

and µA in real time.

As the applicator electrode approaches ground,

the control unit and applicator circuitry cause the

high voltage to approach zero while the current

approaches its maximum value.

W A R N I N G

!

When more than one waterborne appli-

cator is fed from a common isolated uid

supply, there is a potential for electrical energy discharge through any other applicators

when one applicator is triggered. Depending upon the system capacity, this discharge

could be hazardous. It is best to only install

one applicator per isolated supply.

R90/70

13

AH-06-01.13

Ransburg

Vector R Series Cascade Applicators - Introduction

79500 R90 CASCADE

SOLVENTBORNE

SPECIFICATIONS

Environmental/Physical

Gun Length: 27cm (10.7 inches)

Weight: 735 grams (25.9 oz.)

Hose & Cable

Lengths (Std): 10m, 15m, 20m, 25m,

and 30m

Atomizer Nozzle

Assembly (Std): 79374-65, 79377-45

Electrical

Operating Voltage: 85 kV DC (-) maximum

Current Output:

Paint Resistance:* .1 MW to ∞

*(Use Model No. 76652, Test Equipment)

100 microamperes maximum

79501 R70 CASCADE

SOLVENTBORNE

SPECIFICATIONS

Environmental/Physical

Gun Length: 24cm (9.6 inches)

Weight: 650 grams (22.9 oz.)

Hose & Cable

Lengths (Std): 10m, 15m, 20m, 25m,

and 30m

Atomizer Nozzle

Assembly (Std): 79374-65, 79377-45

Electrical

Operating Voltage: 65 kV DC (-) maximum

Current Output: 90 microamperes maximum

Paint Resistance:* .1 MW to ∞

*(Use Model No. 76652, Test Equipment)

Part Sprayability: Determine sprayability of

part to be coated using

76652, Test Equipment

(See current "Paint, HV & SCI Test Equipment"

service manual.)

Mechanical

Fluid Flow

Capacity: 1000 cc/minute**

Operating Pressure (Air Spray)

Fluid: (0-6.9 bar) 0-100 psi

Air: (0-6.9 bar) 0-100 psi

Ambient Temp.: 40°C to 12.8°C

Consumption: 510 slpm (18 SCFM) @

3.4 bar (50 psig) inlet

Sound Level: 92dB (A) @ 50 psig inlet,

1m from applicator

Part Sprayability: Determine sprayability of

part to be coated using

76652, Test Equipment

(See current "Paint, HV & SCI Test Equipment"

service manual.)

Mechanical

Fluid Flow

Capacity: 1000 cc/minute**

Operating Pressure (Air Spray)

Fluid: (0-6.9 bar) 0-100 psi

Air: (0-6.9 bar) 0-100 psi

Ambient Temp.: 40°C to 12.8°C

Consumption: 510 slpm (18 SCFM) @

3.4 bar (50 psig) inlet

Sound Level: 92dB (A) @ 50 psig inlet,

1m from applicator

** This reects the maximum uid volume the applicator can deliver. The maximum spray volume that

can be effectively atomized depends on uid rheology, spray technology, and nish quality required.

AH-06-01.13

** This reects the maximum uid volume the applicator can deliver. The maximum spray volume that

can be effectively atomized depends on uid rheology, spray technology, and nish quality required.

14

Vector R Series Cascade Applicators - Introduction

Ransburg

15

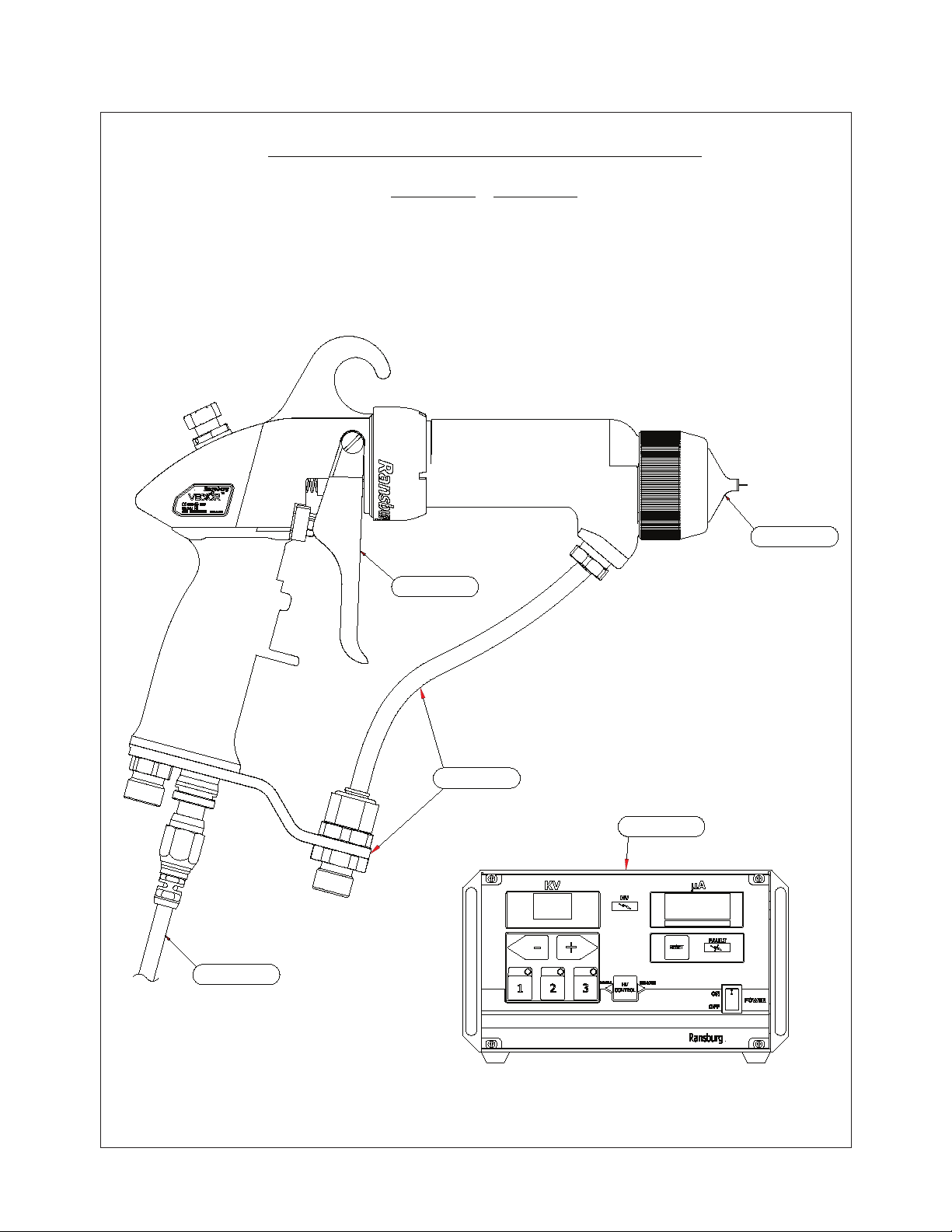

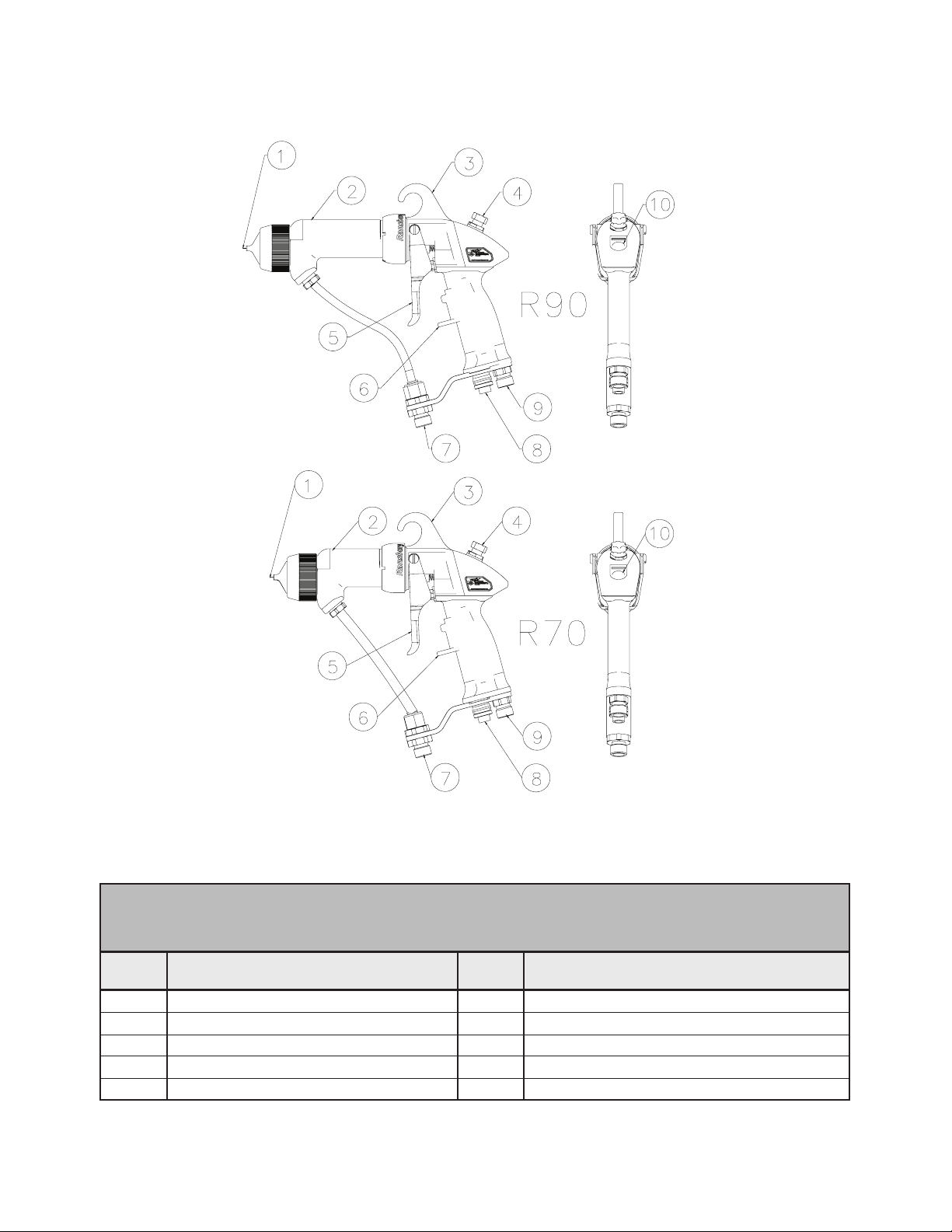

Figure 1: R90/70 Cascade Solventborne Electrostatic Spray Applicator Features

R90/70 CASCADE SOLVENTBORNE ELECTROSTATIC

SPRAY APPLICATOR FEATURES

No.

1

2

3

4

5

Description

Needle/Electrode

Barrel

Replaceable Hook

Fan Air Adjust

2-Finger/4-Finger Trigger

No.

6

7

8

9

10

Adjustable Trigger Shelf

Fluid Hose Connection

Low Voltage Cable Connection

Air Inlet Connection

kV Setpoint Switch/Microamp Display

Description

AH-06-01.13

Ransburg

Vector R Series Cascade Applicators - Introduction

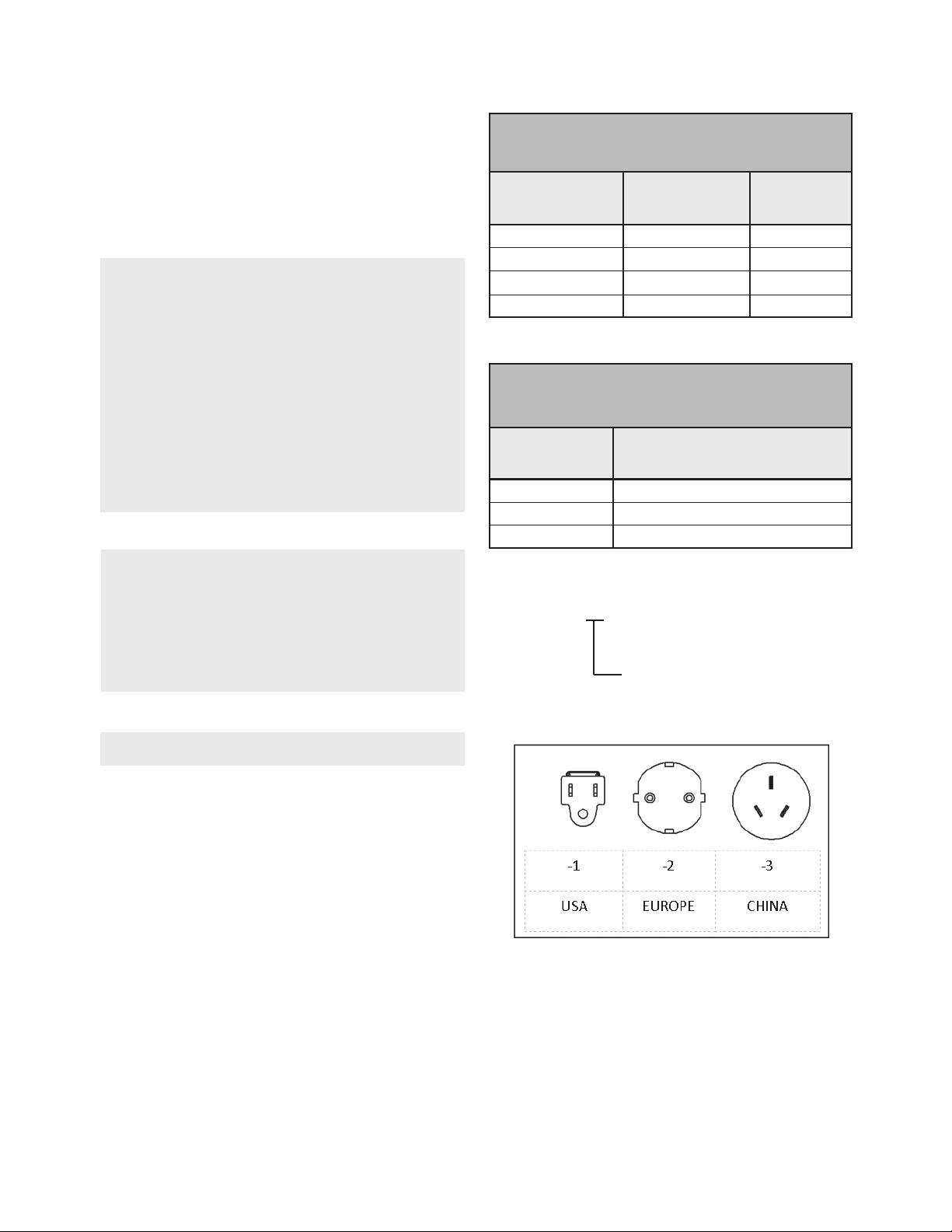

80131-XXX 9060 POWER

SUPPLY ELECTRICAL

SPECIFICATIONS

Electrical

Input Voltage: 100-240 VAC

Current: 1 A max. RMS

Frequency: 50/60 Hz

Wattage: 40 watts (max.)

Output Voltage: 20-65 kV DC (79513-11X)

20-85 kV DC (79513-12X)

Current: 100 microamps (max.) (79513-12X)

90 microamps (max.) (79513-11X)

Physical

Height: 14.0cm (5.5-inches)

Width: 21.6cm (8.5-inches)

CONTROL UNIT INPUTS /

OUTPUTS

9060

Part #

80131-211

80131-212/213

80131-311

80131-312/313

Voltage

Designation

110/120 VAC

220/240 VAC

110/120 VAC

220/240 VAC

Maximum

Output

-65 kV DC

-65 kV DC

-85 kV DC

-85 kV DC

CONTROL UNIT / APPLICATOR

COMBINATIONS

9060

Part #

80131-21X

80131-31X

80131-51X

Plug Styles

80131-XXX

For Use With

79501-XXXXX

79500-XXXXX

79523-XXXXX

Depth: 19.1cm (7.5-inches)

Weight: 3.4 kg (7.5 lbs.)

Pneumatic

Supply Air: 6.9 bar (100 psig) maximum

-1 USA/Canada

-2 Europe

-3 China

AH-06-01.13

16

Vector R Series Cascade Applicators - Introduction

Ransburg

μ

17

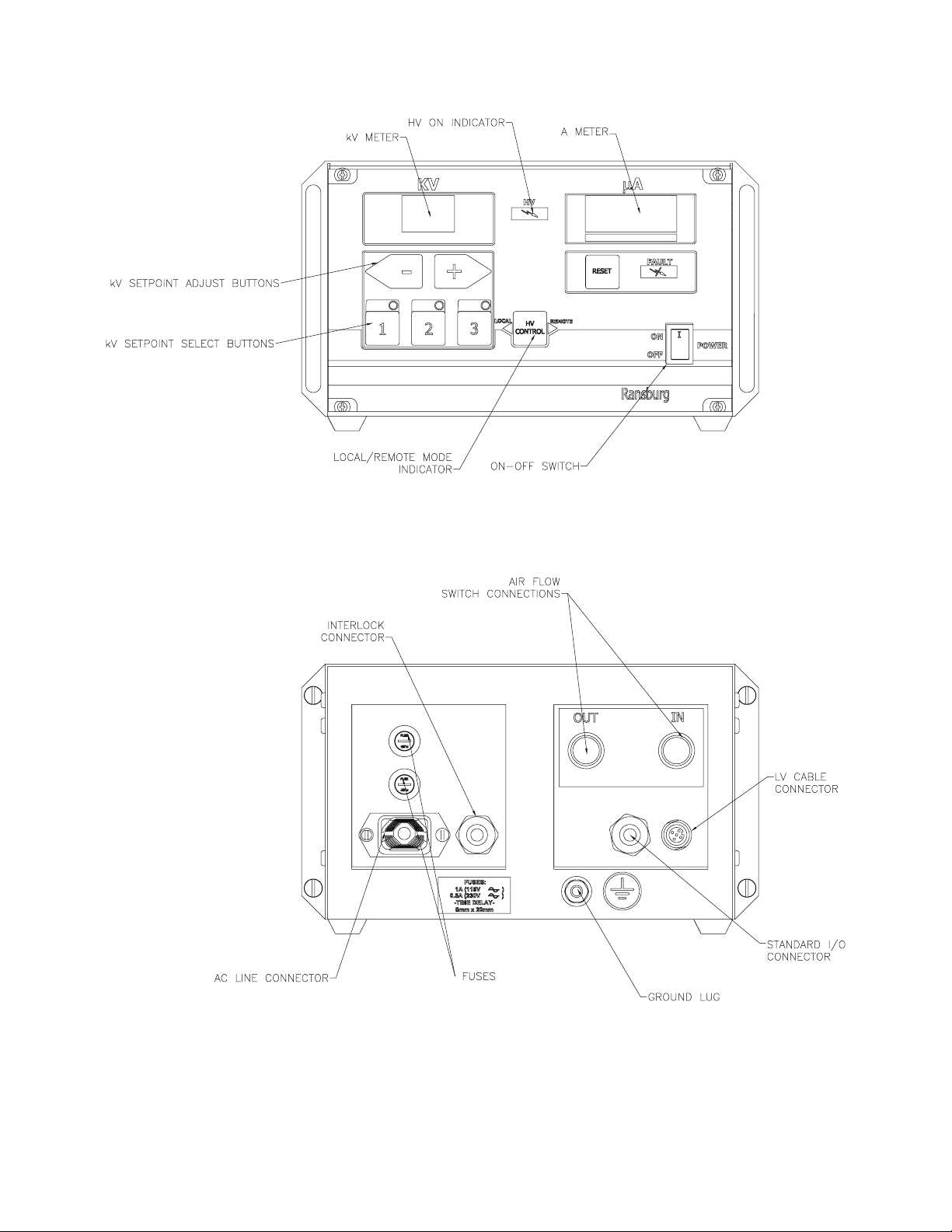

Figure 2: 80131-XXX Cascade Control Unit Features

AH-06-01.13

Ransburg

INSTALLATION

Vector R Series Cascade Applicators - Installation

79500 R90 SOLVENTBORNE

79501 R70 SOLVENTBORNE

INSTALLATION

W A R N I N G

!

The control unit MUST be located out-

side of the spray area.

The User MUST read and be familiar

with the "Safety" section of thismanual.

This manual MUST be read and thor-

oughly understood by ALL personnel who

operate, clean, or maintain this equipment!

Special care should be taken to ensure that

the warnings and requirements for operating

and servicing safety are followed. The user

should be awre of and adhere to ALL local

building and re codes and ordinances as

well as NFPA, OSHA, and all related country safety codes prior to installing, operating,

and/or servicing this eqiupment.

The uid lines and uid sources MUST

be isolated from ground for waterbase applications.

Personnel MUST be GROUNDED to

prevent a shock or spark during electrostatic

operation.

W A R N I N G

!

NEVER wrap the applicator, associated

valves and tubing, and supporting hardware

in plastic to keep it clean. A surface charge

may build up on the plastic surface and discharge to the nearest grounded object. Efciency of the applicator will also be reduced

and damage or failure of the applicator

components may occur. WRAPPING THE

APPLICATOR IN PLASTIC WILL VOID

WARRANTY. Only approved applicator

covers should be used.

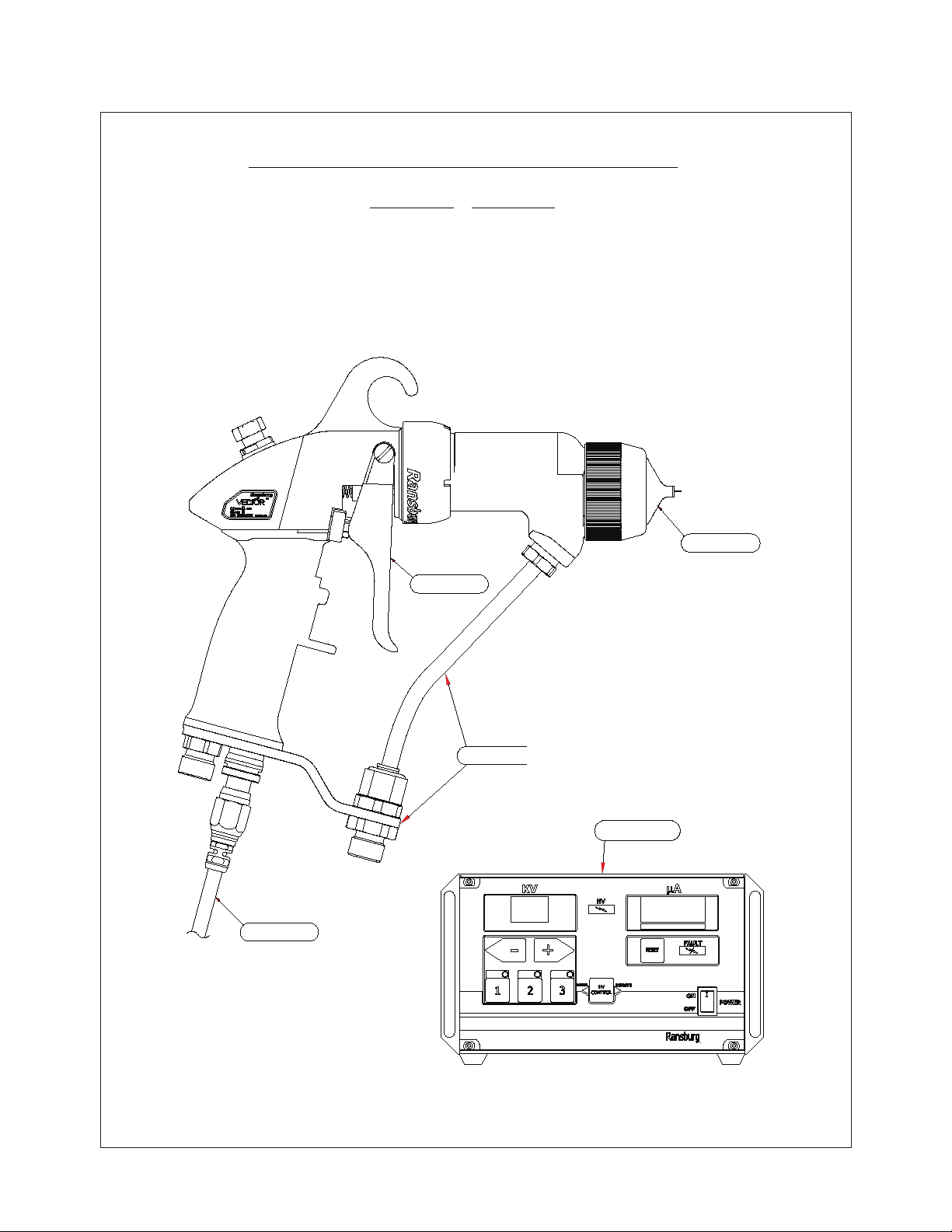

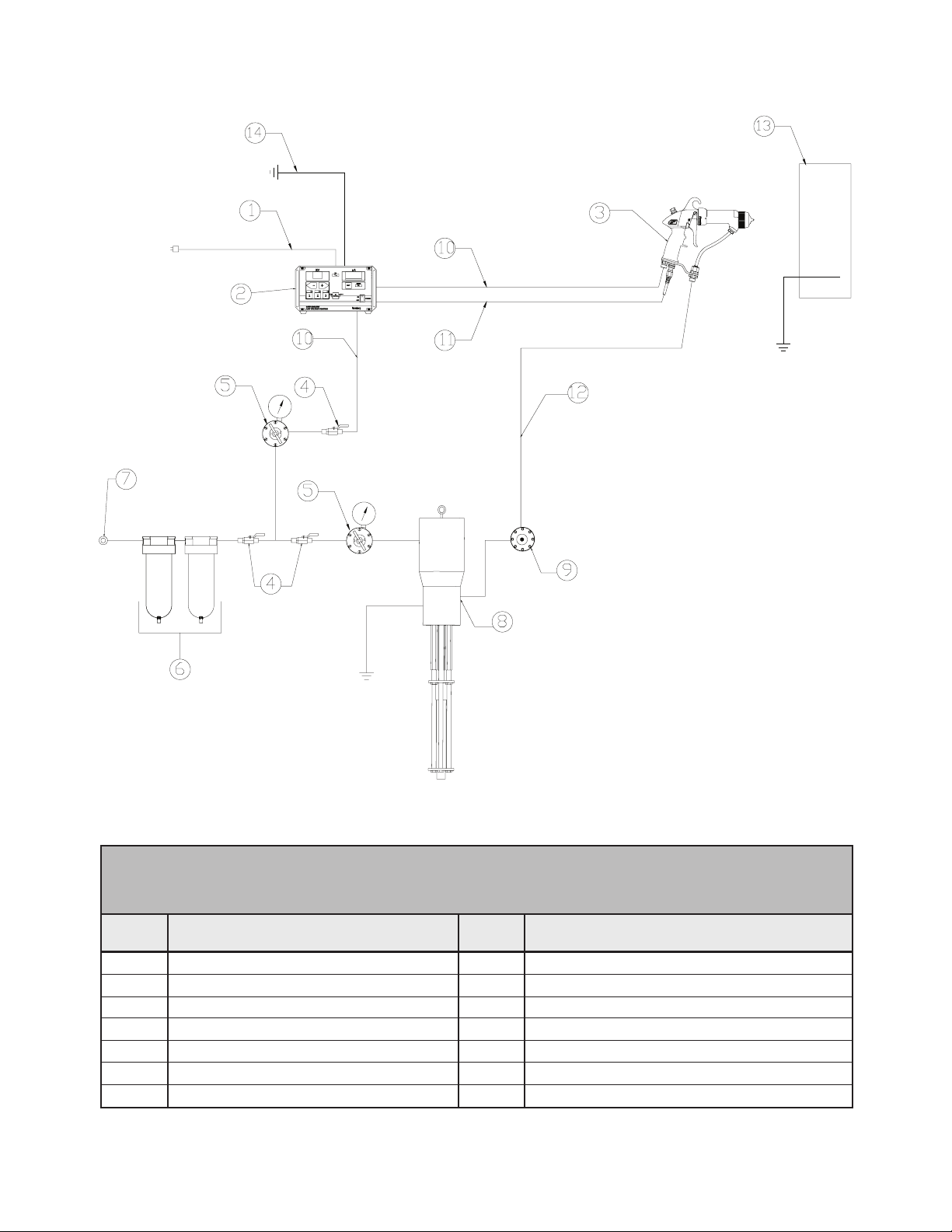

TYPICAL

SOLVENTBORNE

INSTALLATION

(See "Figure 3 - Typical Solventborne

Installation Features")

Location of Control Unit

Install the low voltage control unit in an area outside the hazardous location in accordance with

federal, state, and local codes. The area should

protect the control unit from the possibility of environmental intrusion (such as dust or moisture),

have ambient temperatures that do not exceed

120°F, and be as close to the applicator as possible to minimize the length of low voltage cable.

AH-06-01.13

Install and route the hoses and cable so

they are NOT exposed to temperatures in

excess of 120°

cable bends are NO LESS than a 6 inch

(15cm) radius. Failure to comply with these

parameters cold cause equipment malfunction that might create HAZARDOUS CON-

DITIONS!

Install only one spray applicator per iso-

lated waterborne uid supply system.

F and so that all hose and

18

Vector R Series Cascade Applicators - Installation

Ransburg

R<1 MEG OHM

19

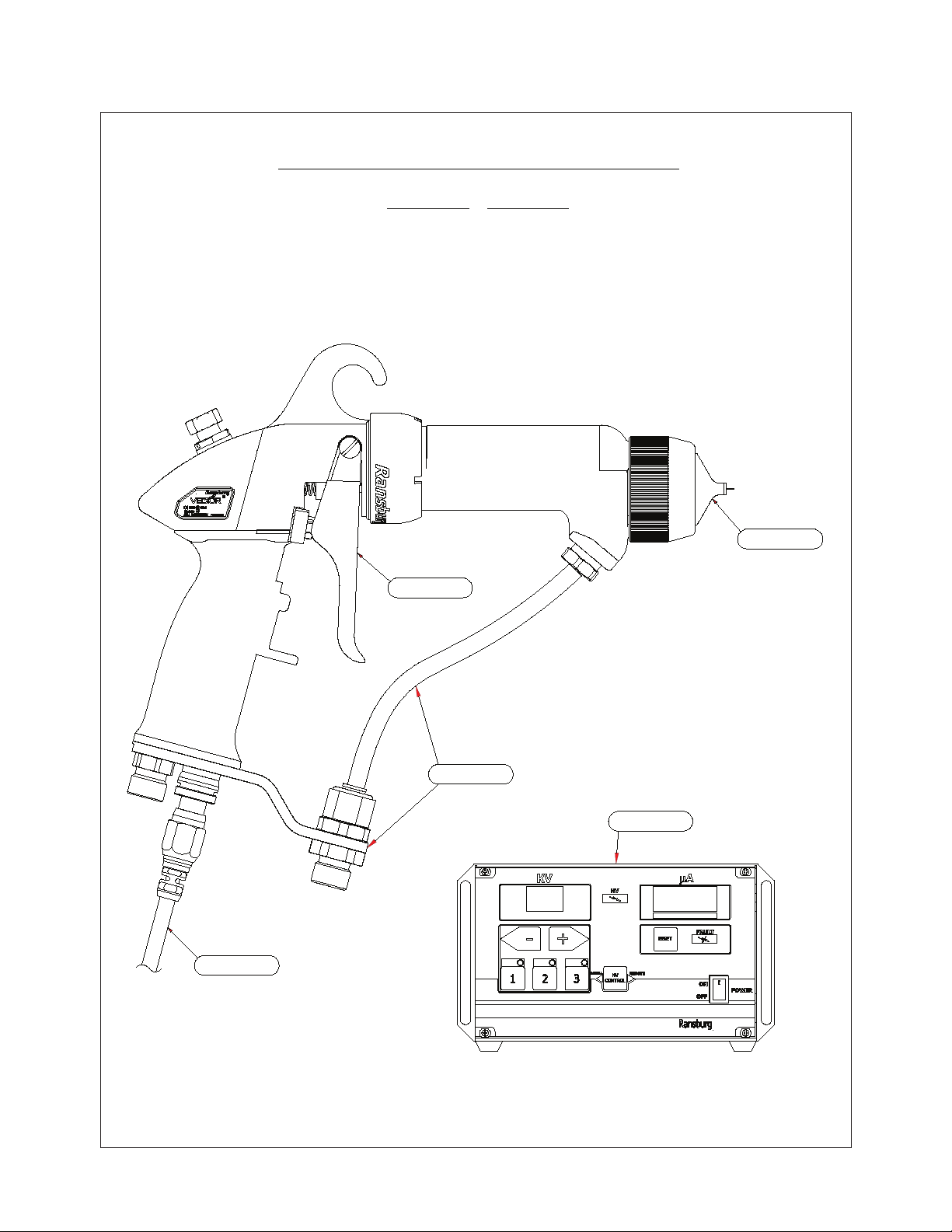

Figure 3: Typical Solventborne Installation Features

TYPICAL SOLVENTBORNE INSTALLATION FEATURES

No.

1

2

3

4

5

6

7

Description

AC Line Cord (110/220)

9060 Control Unit

Vector Applicator

Ball Valve

Air Regulator W/Pressure Gauge

Air/Water Separator

Main Air Supply Line

No.

8

9

10

11

12

13

14

Fluid Supply (Grounded)

Fluid Regulator

Air Line

Low Voltage Cable

Fluid Line

Target (Earth or Building Ground)

9060 Ground (Separate Earth or Building Ground)

Description

AH-06-01.13

Ransburg

Vector R Series Cascade Applicators - Installation

The 9060 Control

Unit must be located a minimum of 5’ (1.5 m)

outside of what is considered to be the hazardous

area. Any mounting method used must properly

support the unit to a minimum of 4X the unit weight.

W A R N I N G

!

For safe use these applicators 79500,

79501 and 79523 must be used with the

appropriate 9060 Control Unit part number

80131-XXX. For exact congurations see

the approved conguration drawings in the

front of this manual.

NOTE

See manual CP-13-07 for the installa-

tion instructions for the 9060 control unit.

AH-06-01.13

20

Loading...

Loading...