Ransburg 79190-XXXXXXXX User Manual

Ransburg

EVOLVERTM SOLVENTBORNE

SERVICE MANUAL

AA-03-02.12

(Replaces AA-03-02.11)

March - 2013

ROBOTIC ATOMIZERS

MODEL: 79190-XXXXXXXX

IMPORTANT: Before using this equipment, carefully read SAFETY PRECAUTIONS, starting on

page 1, and all instructions in this manual. Keep

this Service Manual for future reference.

Service Manual Price: $50.00 (U.S.)

Evolver Solventborne Robotic Atomizers

NOTE: This manual has been changed from revision AA-03-02.11 to revision AA-03-02.12. Reasons for this

change are noted under “Manual Change Summary” inside the back cover of this manual.

DRAFT

Ransburg

AA-03-02.12

Ransburg

CONTENTS

SAFETY:

Evolver Solventborne Robotic Atomizers - Contents

PAGE

1-5

SAFETY PRECAUTIONS.............................................................................................................

HAZARDS / SAFEGUARDS.........................................................................................................

ATEX

EUROPEAN ATEX DIRECTIVE...................................................................................................

EUROPEAN ATEX LABELS........................................................................................................

INTRODUCTION:

RANSBURG ELECTROSTATIC PROCESS........................................................................

EVOLVER SOLVENTBORNE GUNS.........................................................................................

SPECIFICATIONS.......................................................................................................................

EVOLVER GUN SELECTION GUIDE........................................................................................

EVOLVER SOLVENTBORNE ROBOTIC ATOMIZER GUNS ....................................................

FEATURES.................................................................................................................................

79190-XXXXXXXX EVOLVER GUN ASSEMBLY......................................................................

INSTALLATION:

EVOLVER ROBOTIC ATOMIZER INSTALLATION.....................................................................

POWER SUPPLY ASSEMBLY...................................................................................................

LOW VOLTAGE CABLE CONNECTIONS.................................................................................

GUN AND MANIFOLD ASSEMBLY / PARTS LIST...................................................................

1

2-5

6-7

6

7

8-14

8

8-9

9

10-11

12

13

14

15-20

15

15

16

17-20

OPERATION:

SPRAY GUN CONTROLS............................................................................................................

HVLP SPRAY...............................................................................................................................

BACK PRESSURE - 48-1 & 481-1...............................................................................................

FLUID VALVE CONTROLS..........................................................................................................

DUAL PURGE SPRAYING...........................................................................................................

SIMPLIFIED AIR AND FLUID FLOW PASSAGE LAYOUT.........................................................

MAINTENANCE:

ROUTINE MAINTENANCE SCHEDULE.....................................................................................

PROCEDURES.............................................................................................................................

SPRAY HEAD REMOVAL ASSEMBLY / PARTS LIST..............................................................

SERVICE......................................................................................................................................

SPRAY HEAD ASSEMBLY..........................................................................................................

79138 EVOLVER GUN HEAD ASSEMBLY / PARTS LIST.........................................................

REMOVING GUN FROM THE REAR MANIFOLD ASSEMBLY...............................................

(Continued On Next Page)

AA-03-02.12

21-24

21

21

21

22

22-23

24

25-50

25-26

26-27

28-29

30

30-32

33-34

35

Evolver Solventborne Robotic Atomizers - Contents

Ransburg

PAGE

MAINTENANCE (Cont.):

79190 EVOLVER GUN ASSEMBLY / PARTS LIST....................................................................

MOUNTING BLOCK, SHROUD HALVES & RETAINING

RING REMOVAL / PARTS LIST.................................................................................................

DISASSEMBLY OF INTERMEDIATE GUN

HOUSING / PARTS LIST.............................................................................................................

VALVE MANIFOLD DISASSEMBLY / PARTS LIST...................................................................

LOW VOLTAGE CABLE REMOVAL / PARTS LIST...................................................................

FLUID REGULATOR (When Equipped)......................................................................................

FLUID REGULATOR ASSEMBLY / PARTS LIST.......................................................................

A10406 OR LECU5004 MICROPAK CONTROL UNIT...............................................................

ACCESSORIES............................................................................................................................

TROUBLESHOOTING GUIDE....................................................................................................

PARTS IDENTIFICATION:

79190-XXXXXXXX GUN ASSEMBLY / PARTS LIST...................................................................

SPRAY HEAD ASSEMBLY...........................................................................................................

79138-01 CONVENTIONAL SPRAY HEAD

ASSEMBLY / PARTS LIST...........................................................................................................

79138-02 HVLP SPRAY HEAD ASSEMBLY

PARTS LIST..................................................................................................................................

79179-00 SINGLE HEAD 60° / PARTS LIST...............................................................................

79243-00 DUAL HEAD 60° / PARTS LIST...................................................................................

79180-00 SINGLE HEAD 90° / PARTS LIST...............................................................................

79224-00 DUAL HEAD 90° / PARTS LIST...................................................................................

79175-XX MANIFOLD ASSEMBLY..............................................................................................

79175-XX OPTIONAL REGULATED VERSION.........................................................................

79175-XX MANIFOLD ASSEMBLY PARTS LIST.......................................................................

79175-07 MANIFOLD ASSEMBLY (ONLY) / PARTS LIST.........................................................

79156 REAR TUBING MANIFOLD ASSEMBLY -

ENGLISH / PARTS LIST..............................................................................................................

A10853 REAR TUBING MANIFOLD ASSEMBLY -

METRIC / PARTS LIST ................................................................................................................

SIGNAL IDENTIFICATION TABLE - ENGLISH

AND METRIC................................................................................................................................

SERVICE PARTS.........................................................................................................................

REPAIR KITS................................................................................................................................

25-50

36

37-38

39-40

41-42

43-44

44-45

46

47

47-48

49-50

51-75

51-54

55

56

57

58

58

59

59

60

61

62-63

64-65

66-68

69-71

72

73

74-75

WARRANTY POLICIES:

LIMITED WARRANTY..................................................................................................................

76

76

AA-03-02.12

Ransburg

SAFETY

Evolver Solventborne Robotic Atomizers - Safety

SAFETY PRECAUTIONS

Before operating, maintaining or servicing any

Ransburg electrostatic coating system, read and

understand all of the technical and safety literature for your Ransburg products. This manual

contains information that is important for you to

know and understand. This information relates to

USER SAFETY and PREVENTING EQUIPMENT

PROBLEMS. To help you recognize this information, we use the following symbols. Please pay

particular attention to these sections.

A WARNING! states information to alert you

to a situation that might cause serious injury

if instructions are not followed.

A CAUTION! states information that tells how

to prevent damage to equipment or how to

avoid a situation that might cause minor injury.

A NOTE is information relevant to the procedure in progress.

While this manual lists standard specications

and service procedures, some minor deviations

may be found between this literature and your

equipment. Differences in local codes and plant

requirements, material delivery requirements,

etc., make such variations inevitable. Compare

this manual with your system installation drawings and appropriate Ransburg equipment manuals to reconcile such differences.

W A R N I N G

!

The user MUST read and be familiar with

the Safety Section in this manual and the

Ransburg safety literature therein identied.

This manual MUST be read and thor-

oughly understood by ALL personnel who

operate, clean or maintain this equipment!

Special care should be taken to ensure that

the WARNINGS and safety requirements for

operating and servicing the equipment are

followed. The user should be aware of and

adhere to ALL local building and re codes

and ordinances as well as NFPA-33 SAFE-

TY STANDARD, LATEST EDITION, prior

to installing, operating, and/or servicing this

equipment.

W A R N I N G

!

The hazards shown on the following pag-

es may occur during the normal use of this

equipment. Please read the hazard chart beginning on page 2.

Careful study and continued use of this manual will

provide a better understanding of the equipment

and process, resulting in more efcient operation,

longer trouble-free service and faster, easier

troubleshooting. If you do not have the manuals

and safety literature for your Ransburg system,

contact your local Ransburg representative or

Ransburg.

AA-03-02.12

1

Evolver Solventborne Robotic Atomizers - Safety

Ransburg

AREA

Tells where hazards

may occur.

Spray Area

HAZARD

Tells what the hazard is.

Fire Hazard

Improper or inadequate

operation and maintenance

procedures will cause a re

hazard.

Protection against inadvertent arcing that is capable of

causing re or explosion is

lost if any safety interlocks

are disabled during operation. Frequent Power Supply

or Controller shutdown indicates a problem in the system

requiring correction.

SAFEGUARDS

Tells how to avoid the hazard.

Fire extinguishing equipment must be present in

the spray area and tested periodically.

Spray areas must be kept clean to prevent the

accumulation of combustible residues.

Smoking must never be allowed in the spray

area.

The high voltage supplied to the atomizer must

be turned off prior to cleaning, ushing or maintenance.

When using solvents for cleaning:

• Those used for equipment ushing should

have ash points equal to or higher than

those of the coating material.

• Those used for general cleaning must have

ash points above 100°F (37.8°C).

Spray booth ventilation must be kept at the rates

required by NFPA-33, OSHA, country, and local

codes. In addition, ventilation must be maintained during cleaning operations using ammable or combustible solvents.

Electrostatic arcing must be prevented. Safe

sparking distance must be maintained between

the parts being coated and the applicator. A distance of 1 inch for every 10KV of output voltage

is required at all times.

Test only in areas free of combustible material.

Testing may require high voltage to be on, but

only as instructed.

Non-factory replacement parts or unautho-

rized equipment modications may cause re or

injury.

If used, the key switch bypass is intended for

use only during setup operations. Production

should never be done with safety interlocks disabled.

Never use equipment intended for use in waterborne installations to spray solvent based materials.

The paint process and equipment should be

set up and operated in accordance with NFPA33, NEC, OSHA, local, country, and European

Health and Safety Norms.

2

AA-03-02.12

Ransburg

Evolver Solventborne Robotic Atomizers - Safety

AREA

Tells where hazards

may occur.

Spray Area

HAZARD

Tells what the hazard is.

Explosion Hazard

Improper or inadequate operation and maintenance proce-

dures will cause a re hazard.

Protection against inadvertent

arcing that is capable of caus-

ing re or explosion is lost if

any safety interlocks are disabled during operation.

Frequent Power Supply or

Controller shutdown indicates

a problem in the system requiring correction.

SAFEGUARDS

Tells how to avoid the hazard.

Electrostatic arcing must be prevented. Safe

sparking distance must be maintained between

the parts being coated and the applicator. A distance of 1 inch for every 10KV of output voltage

is required at all times.

Unless specically approved for use in hazardous locations, all electrical equipment must be

located outside Class I or II, Division 1 or 2

hazardous areas, in accordance with NFPA-33.

Test only in areas free of ammable or combustible materials.

The current overload sensitivity (if equipped)

MUST be set as described in the corresponding section of the equipment manual. Protection against inadvertent arcing that is capable

of causing re or explosion is lost if the current

overload sensitivity is not properly set. Frequent power supply shutdown indicates a problem in the system which requires correction.

General Use and

Maintenance

Improper operation or maintenance may create a hazard.

Personnel must be properly

trained in the use of this equipment.

Always turn the control panel power off prior to

ushing, cleaning, or working on spray system

equipment.

Before turning high voltage on, make sure no

objects are within the safe sparking distance.

Ensure that the control panel is interlocked with

the ventilation system and conveyor in accordance with NFPA-33, EN 50176.

Have re extinguishing equipment readily available and tested periodically.

Personnel must be given training in accordance

with the requirements of NFPA-33, EN 60079-0.

Instructions and safety precautions must be

read and understood prior to using this equipment.

Comply with appropriate local, state, and national codes governing ventilation, re protection, operation maintenance, and housekeeping. Reference OSHA, NFPA-33, EN Norms

and your insurance company requirements.

AA-03-02.12

3

Evolver Solventborne Robotic Atomizers - Safety

Ransburg

AREA

Tells where hazards

may occur.

Spray Area /

High Voltage

Equipment

HAZARD

Tells what the hazard is.

Electrical Discharge

There is a high voltage device

that can induce an electrical

charge on ungrounded objects

which is capable of igniting

coating materials.

Inadequate grounding will

cause a spark hazard. A

spark can ignite many coating

materials and cause a re or

explosion.

SAFEGUARDS

Tells how to avoid the hazard.

Parts being sprayed and operators in the spray

area must be properly grounded.

Parts being sprayed must be supported on conveyors or hangers that are properly grounded. The resistance between the part and earth

ground must not exceed 1 meg ohm. (Refer to

NFPA-33.)

Operators must be grounded. Rubber soled insulating shoes should not be worn. Grounding

straps on wrists or legs may be used to assure

adequate ground contact.

Operators must not be wearing or carrying any

ungrounded metal objects.

When using an electrostatic handgun, operators

must assure contact with the handle of the applicator via conductive gloves or gloves with the

palm section cut out.

NOTE: REFER TO NFPA-33 OR SPECIFIC

COUNTRY SAFETY CODES REGARDING

PROPER OPERATOR GROUNDING.

All electrically conductive objects in the spray

area, with the exception of those objects required by the process to be at high voltage, must

be grounded. Grounded conductive ooring

must be provided in the spray area.

Always turn off the power supply prior to ushing, cleaning, or working on spray system equipment.

Unless specically approved for use in hazardous locations, all electrical equipment must be

located outside Class I or II, Division 1 or 2 hazardous areas, in accordance with NFPA-33.

4

AA-03-02.12

Ransburg

Evolver Solventborne Robotic Atomizers - Safety

AREA

Tells where hazards

may occur.

Electrical

Equipment

HAZARD

Tells what the hazard is.

Electrical Discharge

High voltage equipment is utilized in the process. Arcing

in the vicinity of ammable or

combustible materials may oc-

cur. Personnel are exposed to

high voltage during operation

and maintenance.

Protection against inadvertent

arcing that may cause a re or

explosion is lost if safety circuits

are disabled during operation.

Frequent power supply shutdown indicates a problem in the

system which requires correction.

An electrical arc can ignite coat-

ing materials and cause a re or

explosion.

SAFEGUARDS

Tells how to avoid the hazard.

Unless specically approved for use in hazardous locations, the power supply, control cabinet,

and all other electrical equipment must be located outside Class I or II, Division 1 and 2 hazardous areas in accordance with NFPA-33 and EN

50176.

Turn the power supply OFF before working on

the equipment.

Test only in areas free of ammable or combustible material.

Testing may require high voltage to be on, but

only as instructed.

Production should never be done with the safety

circuits disabled.

Before turning the high voltage on, make sure no

objects are within the sparking distance.

Toxic Substances

Spray Area

Certain material may be harmful

if inhaled, or if there is contact

with the skin.

Explosion Hazard –

Incompatible Materials

Halogenated hydrocarbon sol-

vents for example: methylene

chloride and 1,1,1,-Trichloroethane are not chemically

compatible with the aluminum

that might be used in many system components. The chemical

reaction caused by these solvents reacting with aluminum

can become violent and lead to

an equipment explosion.

Follow the requirements of the Material Safety

Data Sheet supplied by coating material manufacturer.

Adequate exhaust must be provided to keep the

air free of accumulations of toxic materials.

Use a mask or respirator whenever there is a

chance of inhaling sprayed materials. The mask

must be compatible with the material being

sprayed and its concentration. Equipment must

be as prescribed by an industrial hygienist or

safety expert, and be NIOSH approved.

Aluminum is widely used in other spray application equipment - such as material pumps,

regulators, triggering valves, etc. Halogenated

hydrocarbon solvents must never be used with

aluminum equipment during spraying, ushing,

or cleaning. Read the label or data sheet for the

material you intend to spray. If in doubt as to

whether or not a coating or cleaning material is

compatible, contact your coating supplier. Any

other type of solvent may be used with aluminum

equipment.

AA-03-02.12

5

Evolver Solventborne Robotic Atomizers - Atex

EUROPEAN ATEX DIRECTIVE 94/9/EC, ANNEX II, 1.0.6

Ransburg

The following instructions apply to equipment

covered by certicate number Sira 05ATEX5127X:

1. The equipment may be used with ammable

gases and vapors with apparatus groups II and

with temperature class T6.

2. The equipment is only certied for use in ambient temperatures in the range +12.8°C to +55°C

and should not be used outside this range.

3. Installation shall be carried out by suitably trained

personnel in accordance with the applicable code

of practice e.g. EN 60079-14:1997.

4. Inspection and maintenance of this equipment

shall be carried out by suitably trained personnel

in accordance with the applicable code of practice

e.g. EN 60079-17.

5. Repair of this equipment shall be carried out by

suitable trained personnel in accordance with the

applicable code of practice e.g. EN 60079-19.

6. Putting into service, use, assembling, and

adjustment of the equipment shall be tted by

suitably trained personnel in accordance with the

manufacturer's documentation.

Refer to the "Table of Contents" of this service

manual.

a. Installation

b. Operation

c. Maintenance

d. Parts Identication

7. Components to be incorporated into or used as

replacement parts of the equipment shall be tted

by suitably trained personnel in accordance with

the manufacturer's documentation.

of the user to take suitable precautions that prevent

it from being adversely affected, thus ensuring that

the type of protection provided by the equipment

is not compromised.

Aggressive substances: e.g. acidic liquids or

gases that may attack metals, or solvents that

may affect polymeric materials.

Suitable precautions: e.g. regular checks as part

of routine inspections or establishing from the

material's data sheets that it is resistant to specic

chemicals.

Refer to "Specications" in the "Introduction"

section:

a. All uid passages contain stainless steel

or nylon ttings.

b. High voltage cascade is encapsulated with

a solvent resistant epoxy.

9. A recapitulation of the certication marking is

detailed in the "ATEX" section, on the next page,

drawing numbers: A10752, A10754, A10755, and

A10915.

10. The characteristics of the equipment shall

be detailed e.g. electrical, pressure, and voltage

parameters.

The manufacturer should note that, on being

put into service, the equipment must be accompanied by a translation of the instructions

in the language or languages of the country in

which the equipment is to be used and by the

instructions in the original language.

8. The certication of this equipment relies upon

the following materials used in its construction:

If the equipment is likely to come into contact with

aggressive substances, then it is the responsibility

6

AA-03-02.12

Ransburg

Evolver Solventborne Robotic Atomizers - Atex

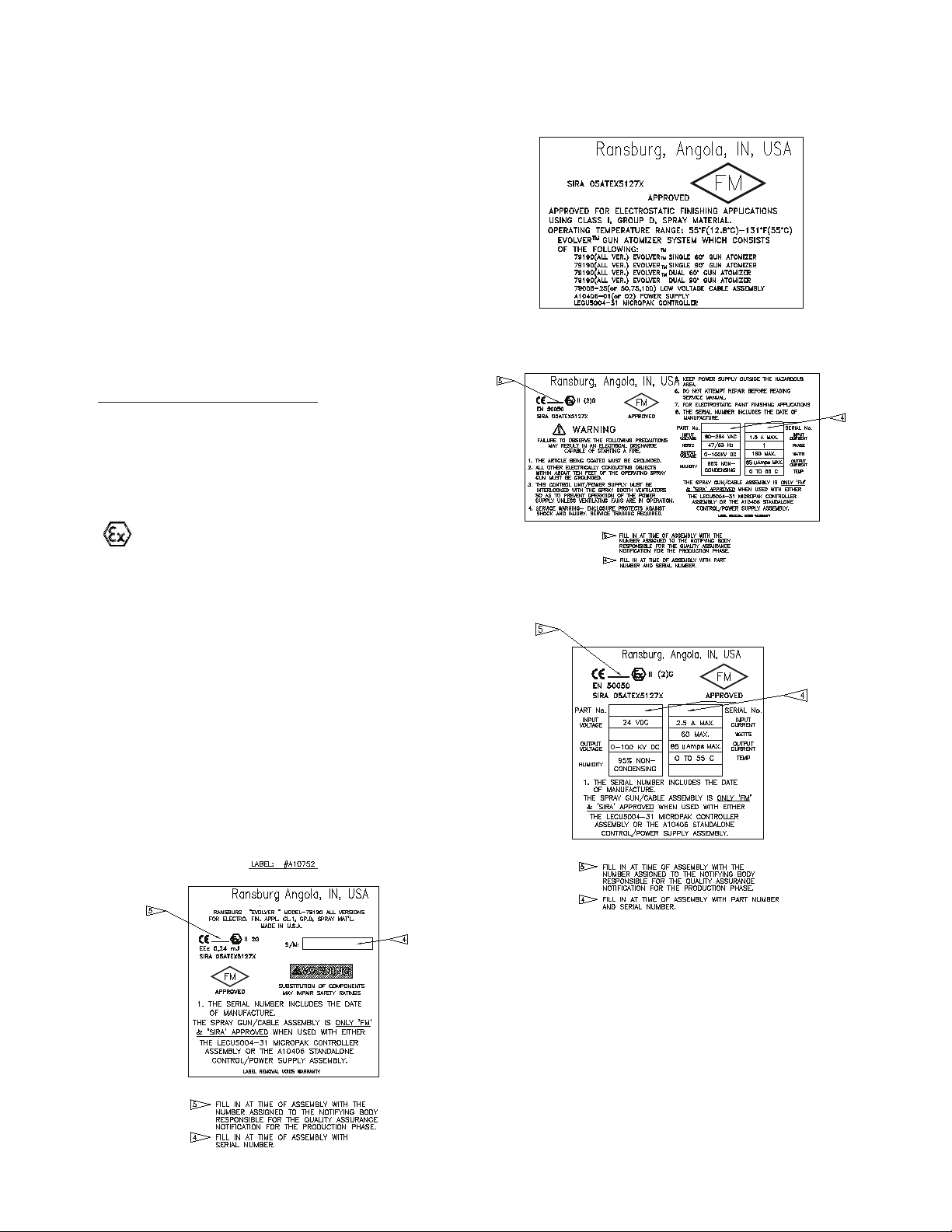

Evolver 79190 ATEX Product Mark-

ing Denitions

Ex Certicate Number: Sira 05 ATEX 5 127 X

Sira = Notied Body performing EC-type exam-

ination

05 = Year of certication

ATEX = Reference to ATEX Directive

5 = Protection Concept Code (code 5 is titled

Encapsulation)

127 = Document serial number

X = Special conditions for safe use apply

Special conditions for safe use: The Evolver 79190

Series Automatic Atomizers shall only be used with

associated Micropak A10406 or LECU5004-31

Power Supplies.

Product Marking

II 2 G

Ex = Specic marking of explosive protection

II = Equipment Group hazardous area charac-teristics

2 = Equipment Category

G = Type of explosive atmosphere (gases, vapors,

or mists)

Label A10754

Label A10755

Label A10915

EEx 0.24mJ = The Evolver 79190 Series of automatic atomizers are suitable for use in automatic

spraying installations complying with EN 50176 as

they are a Type A class with a discharge energy

limit of 0.24mJ.

Label A10752

AA-03-02.12

7

Evolver Solventborne Robotic Atomizers - Introduction

INTRODUCTION

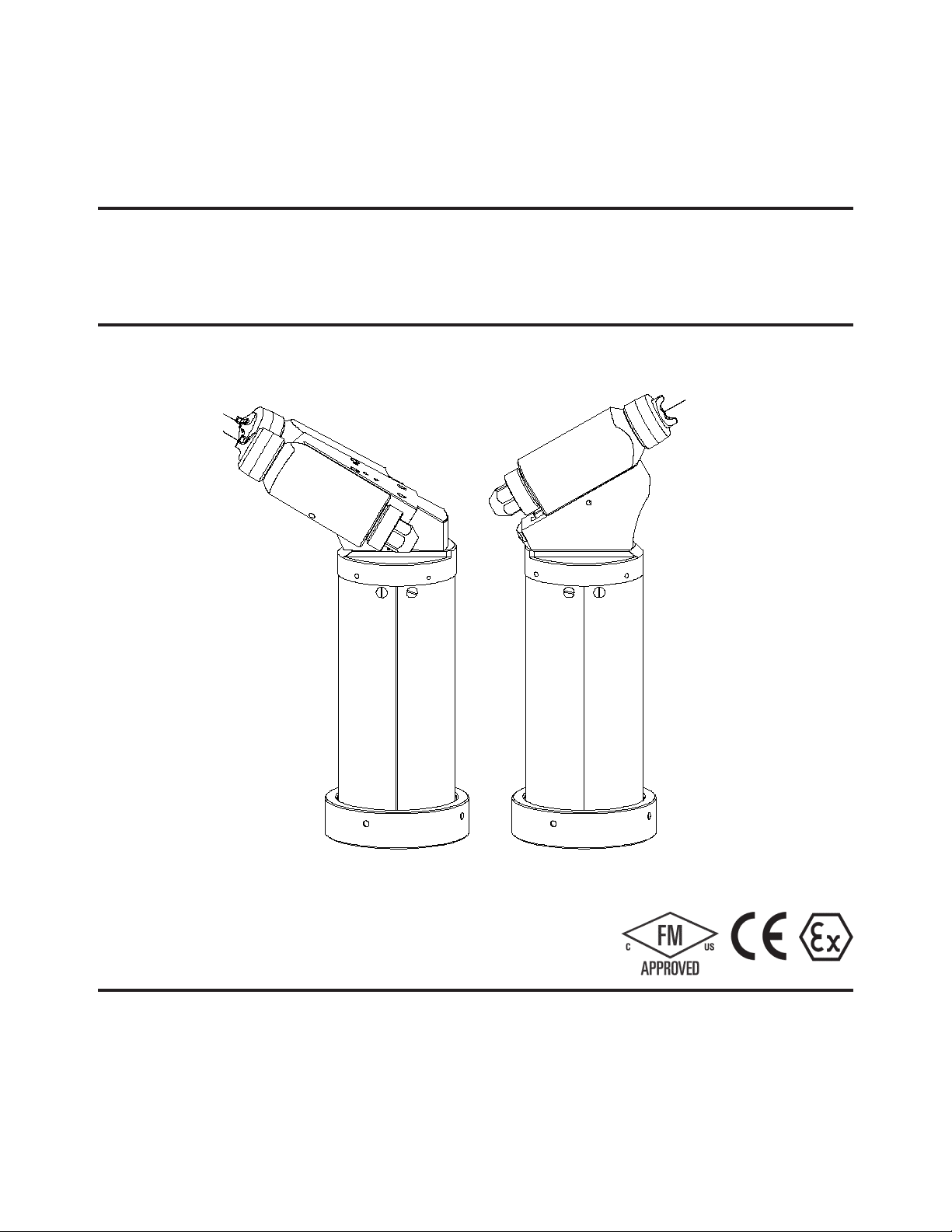

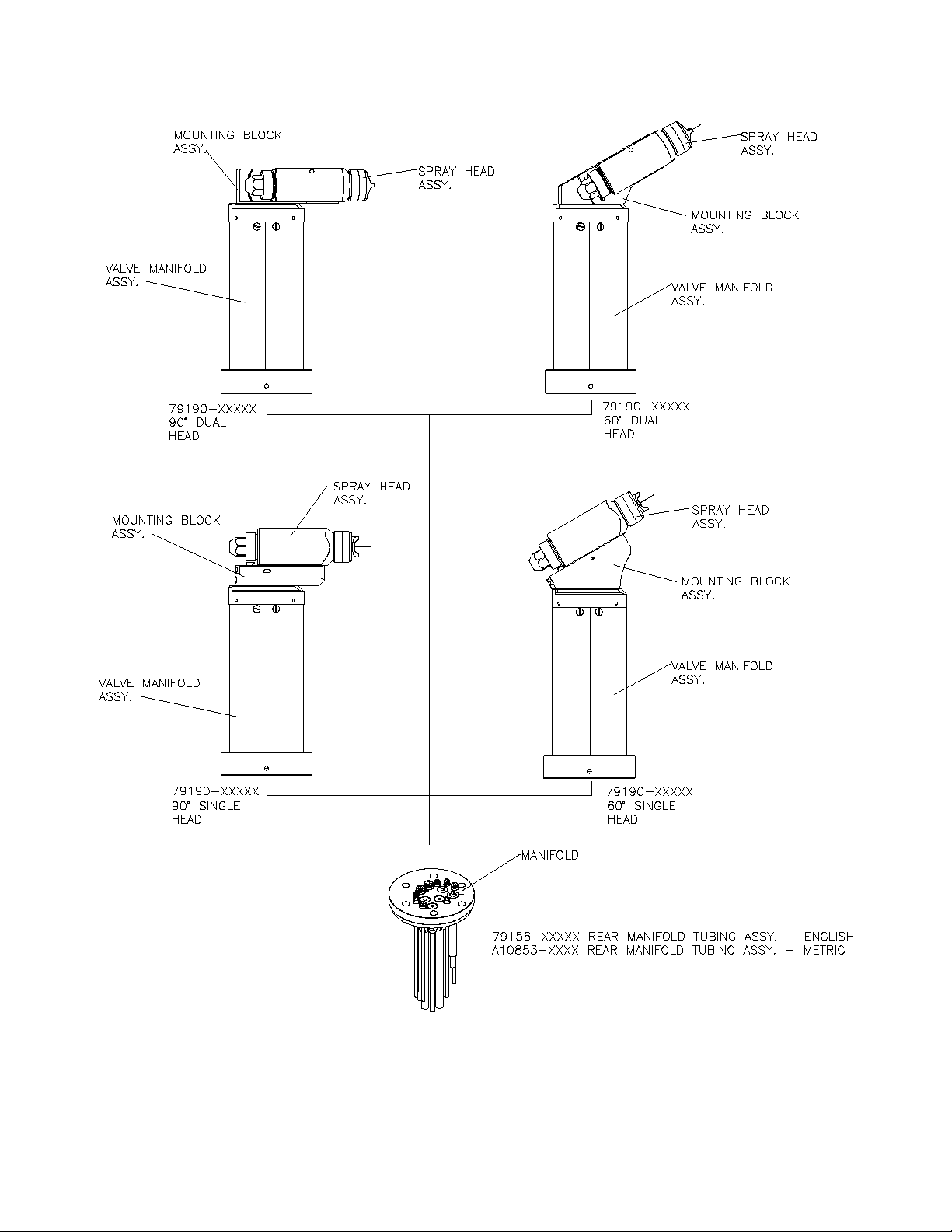

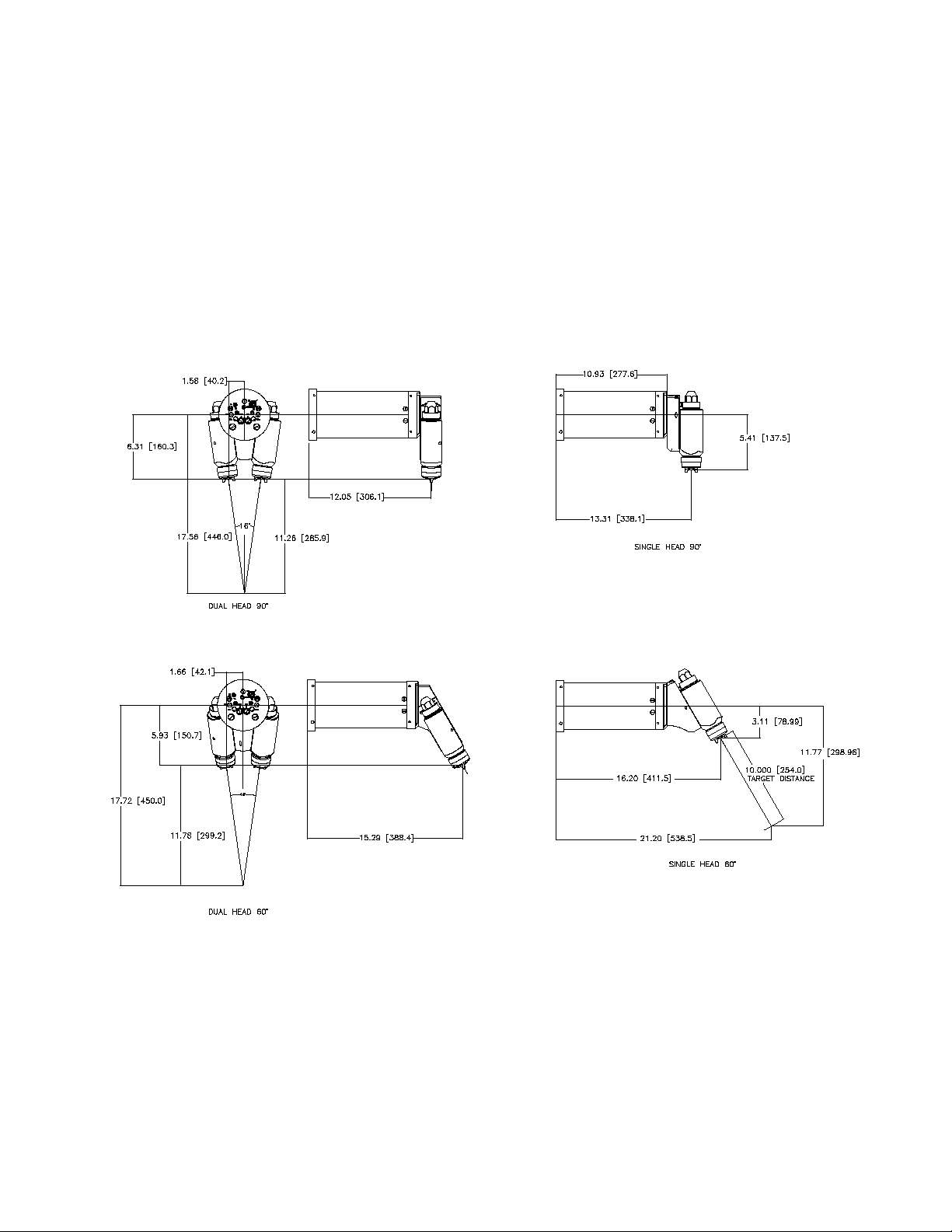

79190-X0XXXXXX 60° Single Head

THE RANSBURG

ELECTROSTATIC

PROCESS

This process is a method for electrostatically applying coatings to objects. A power supply produces

a high voltage charge which is supplied to the

applicator, creating an electrostatic eld between

the applicator and the target object. The target

is electrostatically grounded through its support

which may be either stationary or moving.

79190-X1XXXXXX 90° Single Head

Two dual-head versions of the Evolver Gun are

also available (see Figure 1). The dual headed

guns are primarily used where high volume uid

delivery is required. The dual headed gun is

available in two different congurations as follows:

79190-X2XXXXXX 60° Dual Head

79190-X3XXXXXX 90° Dual Head

The Evolver Spray Gun System consists of four

major components:

Ransburg

A regulated uid system delivers coating material

to the applicator, where it is atomized forming

a spray mist. There, under the inuence of the

electrostatic eld, the atomized coating becomes

electrostatically charged. The charged particles

are attracted to and deposited on the grounded

target object. The forces between the charged

particles and the target are sufcient to turn overspray around and deposit it on the back surface

of the target. Therefore, a higher percentage of

the spray is deposited.

EVOLVER

SOLVENTBORNE GUNS

The EvolverTM Solventborne Gun Line consists

of both 600° and 90° single and dual-headed 100

kV automatic electrostatic spray guns. Developed

for use on robots, the Evolver gun incorporates a

unique 1/3 turn quick-disconnect spray head and

a two piece snap together manifold cover, provid-

ing the user an efcient tool for the electrostatic

application of coatings.

The Evolver gun also has the ability to color change

while spraying with no voltage draw down, a true

dual purge function.

There are two single head models of the Evolver

Gun (see Figure 1). Each model differs in the

gun to axis orientation of the spray head. These

models are:

1. Quick-Disconnect Spray Head

2. Gun Head Mounting Block Assembly

3. Valve Manifold Assembly (Includes the

High Voltage Cascade with a Quick-Discon nect Ring)

4. Rear Tubing Manifold Assembly (Both

English and Metric)

The spray head(s) and valve manifold contain

the uid, air, and high voltage passages. All uid

passages contain stainless steel and/or nylon

ttings, compatible with halogenated hydrocarbon solvents. The robot manifold incorporates

stainless steel uid connections.

The high voltage cascade is entirely encapsulat-

ed with a solvent resistant epoxy. This cascade

generates voltages up to 100 kV fed by a low

voltage cable.

There are two sources for the high voltage supply

to the Evolver guns:

• Stand-alone control/power supply unit

(A10406)

• MicroPakTM control unit (LECU5004-31)

NOTE

> The Evolver Gun assemblies are NOT

FM approved when used with any other

power source.

8

AA-03-02.12

Ransburg

Evolver Solventborne Robotic Atomizers - Introduction

The MicroPak power supply control unit provides

a low voltage signal through the robot manifold

to the spray gun. The high voltage cascade located within the gun converts the low voltage DC

signal to a high voltage electrostatic output. (See

the most current "MicroPak" and "Stand-Alone

Evolver MicroPak Controller" Service Manuals for

details of the control unit.)

SPECIFICATIONS

Environmental/Physical

Robot/Mounting Compatibility:

All hollow wrist robots

Gun Control Unit:

MicroPak Control Unit - LECU5004-31

Stand-Alone Control Unit - A10406

Operating Temperature Range:

55°F (12.8°C) - 131°F (55°C)

Weight

Single-Headed:

60° 9.9 lbs. (4.5 Kg)

90° 9.6 lbs. (4.4 Kg)

Dual-Headed:

60° 10.4 lbs. (4.7 Kg)

90° 10.4 lbs. (4.7 Kg)

Manifold:

79175-XX 1.7 lbs. (.77 Kg)

(No tubing or cable)

Length

Single-Headed:

60° 17" (43.18cm)

90° 14 1/2" (36.83 cm)

Dual-Headed:

60° 16-1/4" (41.28cm)

90° 13" (33.02cm)

Tubing Manifolds (English):

79156-01 25 ft.

79156-02 50 ft.

79156-03 75 ft.

79156-04 100 ft.

Tubing Manifolds (Metric):

A10853-01 7.62m

A10853-02 15.24m

A10853-03 22.86m

A10853-04 30.48m

Electrical Requirements

Output Voltage: 30-100 kV

Output Range: 0-85 µA

Paint Flow Rate:

Variable to 1500 cc/min. (Depending on

viscosity & conguration)

Trigger Response Time: 150m sec. Open

220m sec. Closed

Operating Air Pressures

Atomizing Air: 100 psig (6.9 bar) max.

Fan Air: 100 psig (6.9 bar) max.

Trigger Air: 70 psig min./100 psig

(4.8 - 6.9 bar) max.

Regulator Pilot: 0 psig min./100 psig

(0 - 6.9 bar) max.

Dump Pilot: 70 psig min./

100 psig max.

(4.8 - 6.9 bar)

Operating Fluid

Pressure: 200 psig (13.8 bar) max.

100 psig (6.9 bar) max.

Regulated (with on-board

regulator)

Robot Manifold Tubing Requirements

English Metric

Atomizing Air

Fan Air

Trigger Air

Regulator Pilot

Dump Pilot

Fluid:

Polyethylene

Dump:

3/8"

3/8"

3/16"

3/16"

3/16"

1/4" or 3/16" ID

(Shielded &

Non-Shielded

1/4" or 3/16" ID

(Shielded & NonShielded)

3/16" ID

10mm OD Nylon

10mm OD Nylon

4mm OD Nylon

4mm OD Nylon

4mm OD Nylon

6mm

(Non-Shielded)

6mm

AA-03-02.12

9

Evolver Solventborne Robotic Atomizers - Introduction

EVOLVER GUN SELECTION GUIDE

79190 - A B C D E FF G

Table A = Atomization Technology

0 = Air Spray

1 = HVLP

Table B = Spray Head Conguration

0 = 60° Single Head

1 = 90° Single Head

2 = 60° Dual Head

3 = 90° Dual Head

Table C = Purge/Regulator Conguration

0 = Single Purge / No Regulator

1 = Dual Purge / No Regulator

2 = Single Purge / With Fluid Regulator

3 = Dual Purge / With Fluid Regulator

4 = Single Purge / No Regulator / Non-Electrostatic

5 = Dual Purge / No Regulator / Non-Electrostatic

6 = Single Supply / No Valves / Short Fluid Tube

Ransburg

Table D = Robot Adapter Plate

0 = No Adapter

1 = ABB

2 = Fanuc P-155

3 = Fanuc P-200

4 = Adapter (KAWASAKI-KE610L)

5 = Adapter (MOTOMAN-PX2850)

6 = Adapter (MOTOMAN-PX2900)

Table E = Fluid Hose Type

0 = No Fluid Hose

1 = 3/16" ID Non-Shielded

2 = 3/16" ID Shielded

3 = 1/4" ID Non-Shielded

4 = 1/4" ID Shielded

5 = 6 mm ID Non-Shielded

(Continued on next page)

10

AA-03-02.12

Ransburg

EVOLVER GUN SELECTION GUIDE (Cont.)

79190 - A B C D E FF G

Table FF = Cable & Tubing Manifold Conguration

00 = Gun Only (No cable or manifold)

23 = No Cable (English tubing manifold)

24 = No Cable (Metric tubing manifold)

For Use W/Power Supply Conguration 3 or 4:

English Metric

01 = 25' Cable (one-piece cable) 12 = 7.6m Cable (one-piece cable)

02 = 50' Cable (one-piece cable) 13 = 15.2m Cable (one-piece cable)

03 = 75' Cable (one-piece cable) 14 = 22.9m Cable (one-piece cable)

04 = 100' Cable (one-piece cable) 15 = 30.5m Cable (one-piece cable)

05 = 15' Cable to Junction Box; 15' Cable to Robot 16 = 4.6m Robot to Junction Box; 4.6m Cable to Robot

06 = 40' Cable to Junction Box; 15' Cable to Robot 17 = 12.2m Cable to Junction Box; 4.6m Cable to Robot

07 = 60' Cable to Junction Box; 15' Cable to Robot 18 = 18.3m Cable to Junction Box; 4.6m Cable to Robot

08 = 75' Cable to Junction Box; 15' Cable to Robot 19 = 22.9m Cable to Junction Box; 4.6m Cable to Robot

09 = 25' Cable to Junction Box; 25' Cable to Robot 20 = 7.6m Cable to Junction Box; 7.6m Cable to Robot

10 = 50' Cable to Junction Box; 25' Cable to Robot 21 = 15.2m Cable to Junction Box; 7.6m Cable to Robot

11 = 75' Cable to Junction Box; 25' Cable to Robot 22 = 22.9m Cable to Junction Box; 7.6m Cable to Robot

Evolver Solventborne Robotic Atomizers - Introduction

For Use W/Power Supply Conguration 1 or 2:

English Metric

31 = 25' Cable (one-piece cable) 51 = 7.6m Cable (one-piece cable)

32 = 50' Cable (one-piece cable) 52 = 15.2m Cable (one-piece cable)

33 = 75' Cable (one-piece cable) 53 = 22.9m Cable (one-piece cable)

34 = 100' Cable (one-piece cable) 54 = 30.5m Cable (one-piece cable)

35 = 15' Cable to Junction Box; 15' Cable to Robot 55 = 4.6m Cable to Junction Box; 4.6m Cable to Robot

36 = 40' Cable to Junction Box; 15' Cable to Robot 56= 12.2m Cable to Junction Box; 4.6m Cable to Robot

37 = 60' Cable to Junction Box; 15' Cable to Robot 57 = 18.3m Cable to Junction Box; 4.6m Cable to Robot

38 = 75' Cable to Junction Box; 15' Cable to Robot 58 = 22.9m Cable to Junction Box; 4.6m Cable to Robot

39 = 25' Cable to Junction Box; 25' Cable to Robot 59 = 7.6m Cable to Junction Box; 7.6m Cable to Robot

40 = 50' Cable to Junction Box; 25' Cable to Robot 60 = 15.2m Cable to Junction Box; 7.6m Cable to Robot

41 = 75' Cable to Junction Box; 25' Cable to Robot 61 = 22.9m Cable to Junction Box; 7.6m Cable to Robot

Table G = Power Supply Conguration

0 = No Power Supply

1 = A10406-01 Power Supply Enclosure with one MicroPak and one Discreet I/O Card

2 = A10406-01 Power Supply Enclosure with two MicroPaks and two Discreet I/O Cards

3 = One LECU5004-31 MicroPak (FM Approved)

4 = One LECU5004-11 MicroPak (Not FM Approved)

AA-03-02.12

11

Evolver Solventborne Robotic Atomizers - Introduction

Ransburg

12

Figure 1: Evolver Solventborne Robotic Atomizer Guns

AA-03-02.12

Ransburg

FEATURES

Evolver Solventborne Robotic Atomizers - Introduction

The features of the Evolver series guns include:

• Quick-disconnect spray head

• High quality Ransburg air cap and uid nozzle

• True "dual purge function"

• Dual uid supply passages

• Dual uid dump valves are located adjacent

to the uid passages

• Internal uid regulator

• Field proven high voltage system

• Dual start, dual pitch air cap retaining ring

• Quick-disconnect robot mount plate

• Quick color change capability with integrated

solvent valve

• Clean interior design with split shroud

• Internal fan and atomization air control valve,

with a mechanically timed trigger sequence

• Color coded air and trigger actuation lines

AA-03-02.12

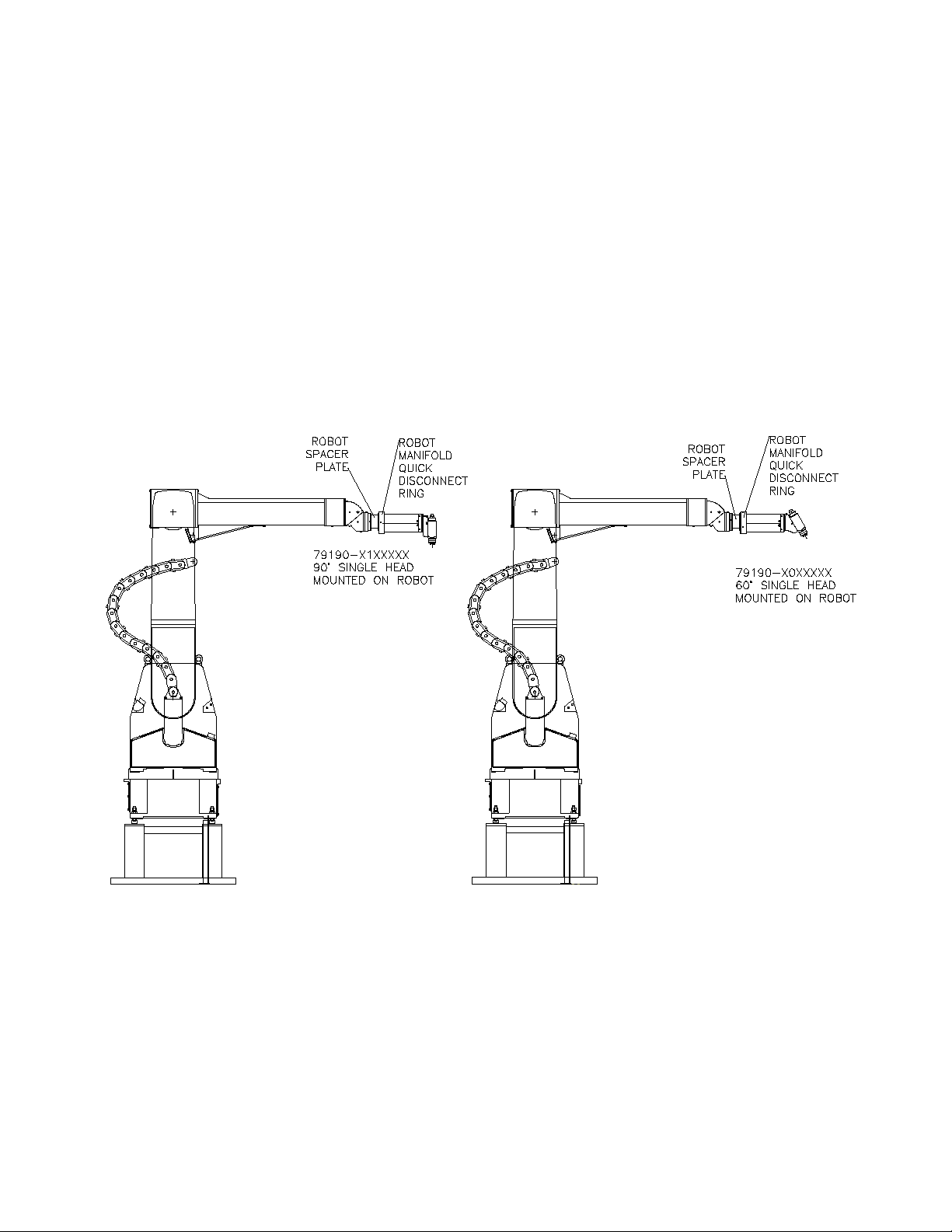

Figure 2: Typical Robotic Applicator Mounting

13

Evolver Solventborne Robotic Atomizers - Introduction

79190-XXXXXXXX

EVOLVER GUN ASSEMBLY

Ransburg

The gun assembly is designed to connect to hollow wrist robots. A low voltage control cable is

supplied with the gun to connect the cascade to

the MicroPak power supply.

The "Paint In" lines come in both 3/16" ID and

1/4" ID shielded or non-shielded.

Tool Center-Point

Figure 3 shows the tool center-point information

for the four guns. They are all based upon a 10"

(245mm) target distance.

14

Figure 3: Tool Center-Point

AA-03-02.12

Ransburg

INSTALLATION

Evolver Solventborne Robotic Atomizers - Installation

EVOLVER ROBOTIC

ATOMIZER INSTALLATION

This information is intended ONLY to indicate the

general installation parameters of this product

and, where applicable, its working relationship

to other Ransburg system components in typical

use. Each installation is unique and should be

directed by an authorized Ransburg representative or conducted from the Ransburg installation

drawings provided for your particular installation.

POWER SUPPLY

ASSEMBLY

Refer to the most current Power Supply Unit

manuals for complete information regarding power

supply installation.

W A R N I N G

!

> The power supply MUST be located outside

the HAZARDOUS area (Reference OSHA,

NFPA-33, and your insurance company requirements.)

> User should be aware of, and adhere to,

all local re codes and ordinances.

> The user MUST provide a properly fused

disconnect between the power source and the

power supply which complies with appropriate

codes.

> Fluid supply must be grounded per NFPA-33.

AA-03-02.12

15

Evolver Solventborne Robotic Atomizers - Installation

Ransburg

16

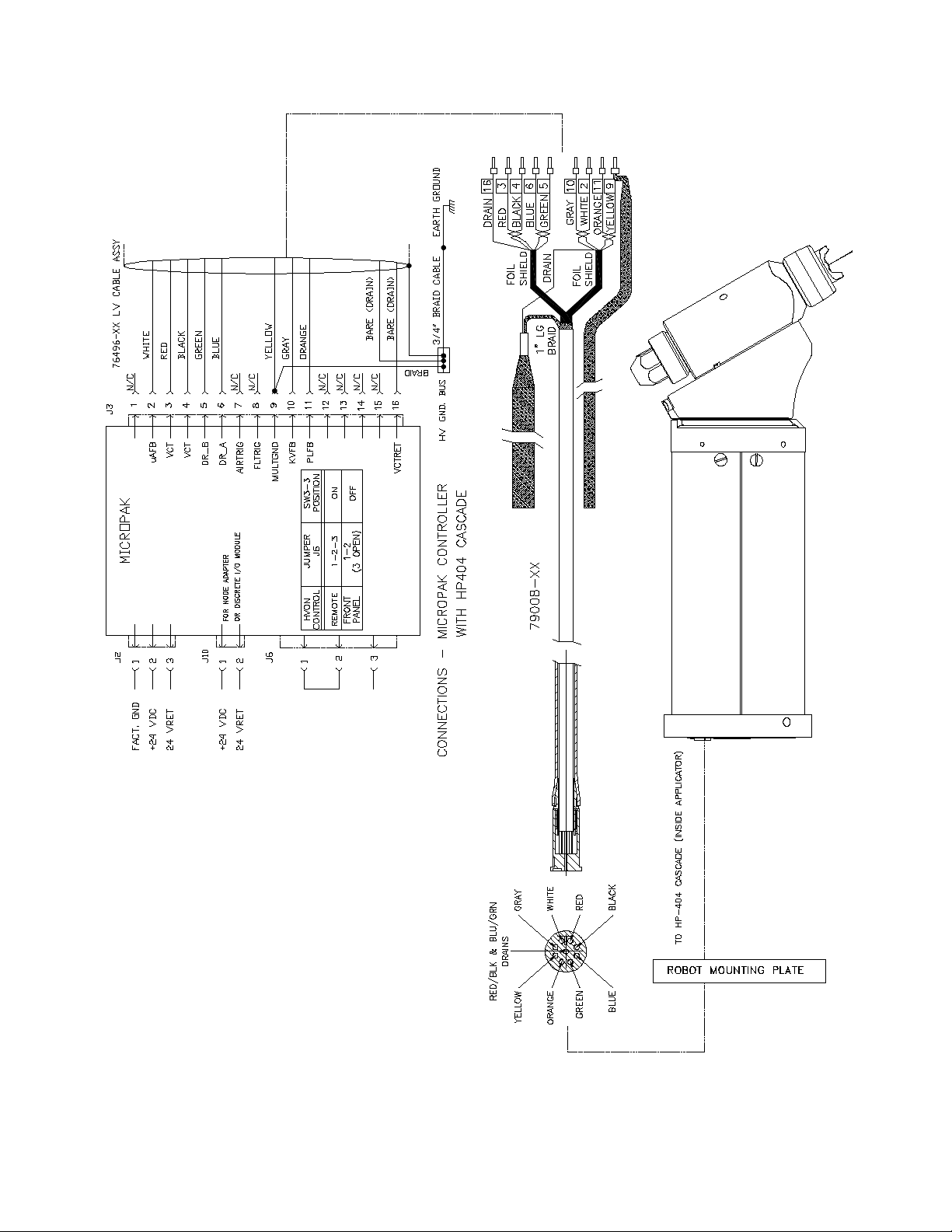

Figure 4: Low Voltage Cable Connections

AA-03-02.12

Ransburg

Evolver Solventborne Robotic Atomizers - Installation

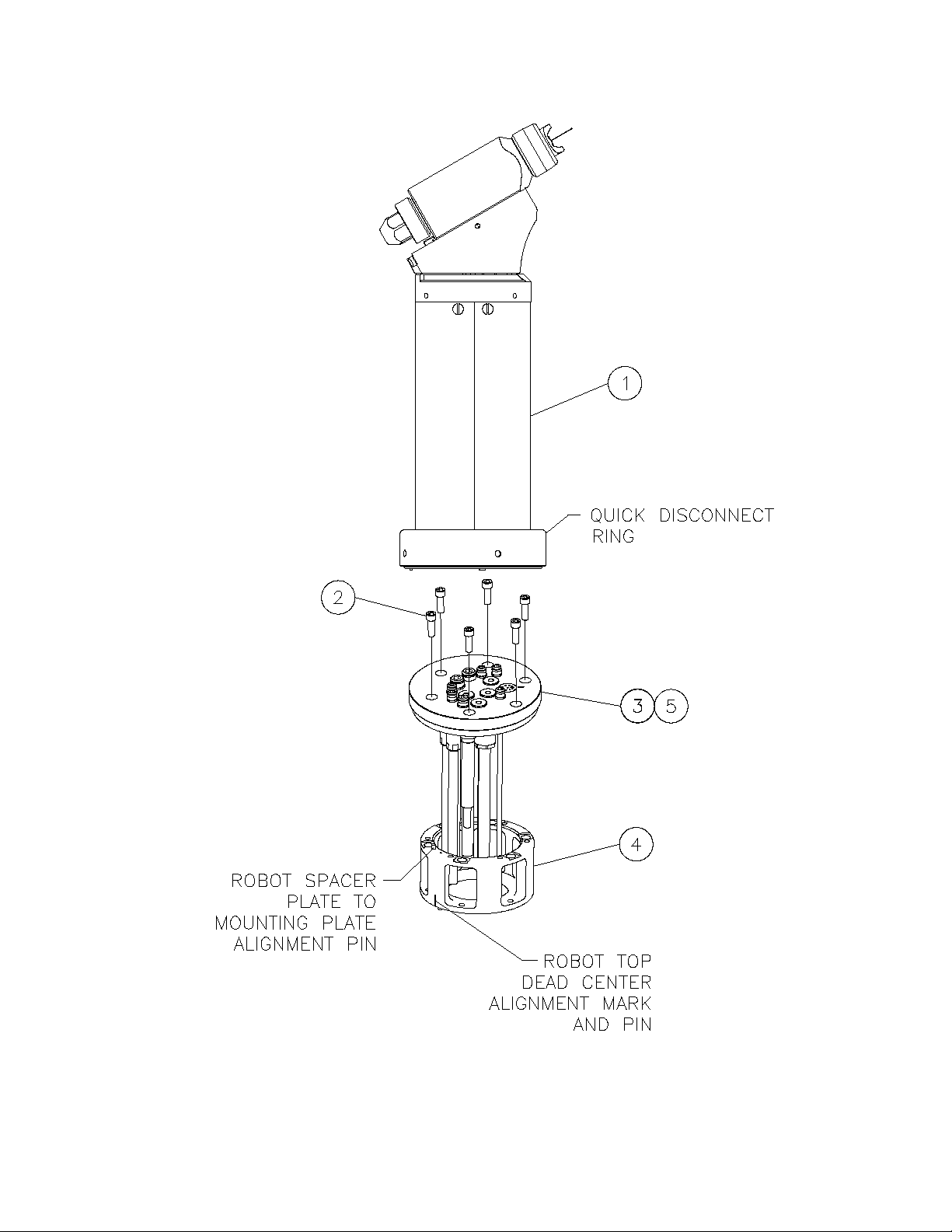

GUN AND MANIFOLD

ASSEMBLY

(See Figures 4 and 5)

The tubing, hose, and low voltage cable come

bundled from the factory. Pull the bundle through

the robot spacer plate and robot wrist carefully

to prevent any cuts on the cable or hoses. Use

the six (6) socket head cap screws (7959-32C)

included with the rear manifold tubing assembly

to attach the rear manifold assembly ( 79156) to

the robot spacer plate (see Table 1).

Connect each signal line as required per signal

legend for both English and Metric tubing bundles,

table following.

Robot Spacer Plate

The robot spacer plate is included with the robot

manifold assembly to increase life of the tubing

bundle. The extra spacing it provides, increases

the bend radius of the tubes and decreases the

hose or cable stress at the connector.

There is only one way the spacer plate may be

assembled to the mounting plate. The spacer

plate has an alignment pin that may only engage

in one hole position in the robot mount plate. This

provides the nal position to top dead center of

the robot.

For installations utilizing the LECU5004-XX MicroPak Power Supply, connect the low voltage cable

(79008-XX) from the robot manifold assembly to

the LECU5004-XX MicroPak Controller or junction

box. If connecting to a junction box, use a junction

cable (77062-XX) to make the connection from

the junction box to the LECU5004-XX MicroPak.

Make connections as shown in Figure 4.

For installations utilizing the A10406-XX Evolver

MicroPak Power Supply, connect the low voltage

cable (A11353-XX or A11356-XX) from the robot

manifold assembly or junction box to the receptacle

on the rear of the A10406-XX power supply. To

maintain FM Approval, this cable must be secured

to the stress relief bar on the rear of the power

supply. (See "A10406-XX Evolver

MicroPak Power Supply" manual for further information on connecting the low voltage cable.)

C A U T I O N

!

> Leave 12-24 inches of extra length on all

lines to prevent extreme tension being applied

to these lines during robot movement.

!

C A U T I O N

> Do not exceed 100' combined length of the

low voltage cables.

The six (6) robot spacer plates, Table 1, are available for this product.

TABLE 1 - SPACER PLATES

Part # Description

79107-00 ABB Robots

78983-00 Fanuc P155, 145 Robots

79131-00 Fanuc P200 Robot

A10847-00 Adapter (Kawasaki-KE610L)

A10848-00 Adapter (Motoman-PX2850)

A10849-00 Adapter (Motoman-PX2900)

AA-03-02.12

W A R N I N G

!

> Install and route the hoses and cable so

that they are NOT exposed to temperatures

in excess of 120° F. Ensure that all hose and

cable bends are NOT LESS THAN a 6 inch

(15cm) radius and are not subjected to more

than 360° of torsional twist. Failure to comply

with these parameters could cause equipment

malfunctions that might create HAZARDOUS

CONDITIONS!

W A R N I N G

!

> If a non-explosion proof junction box/ter-

minal strip is used, it must be located outside

the hazardous area.

17

Evolver Solventborne Robotic Atomizers - Installation

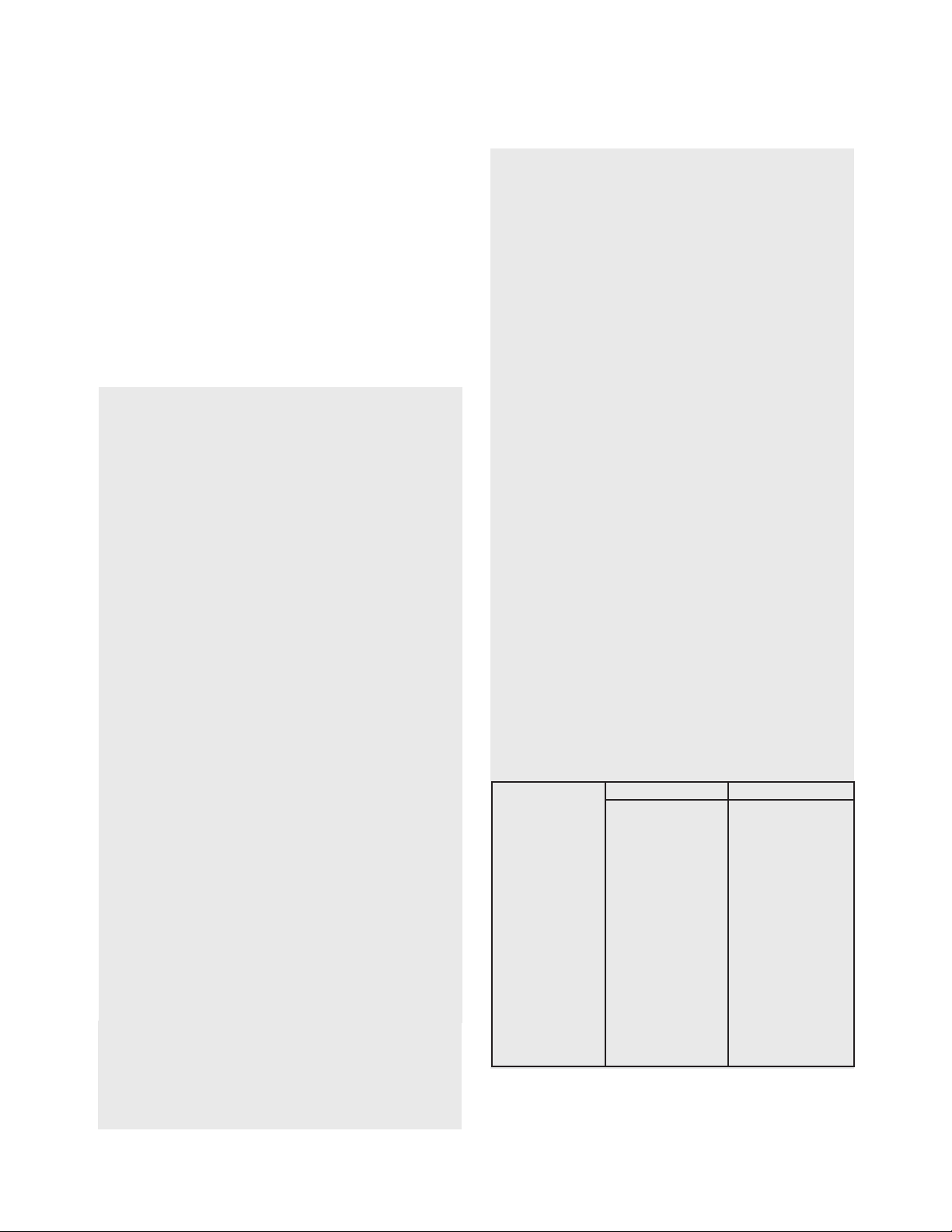

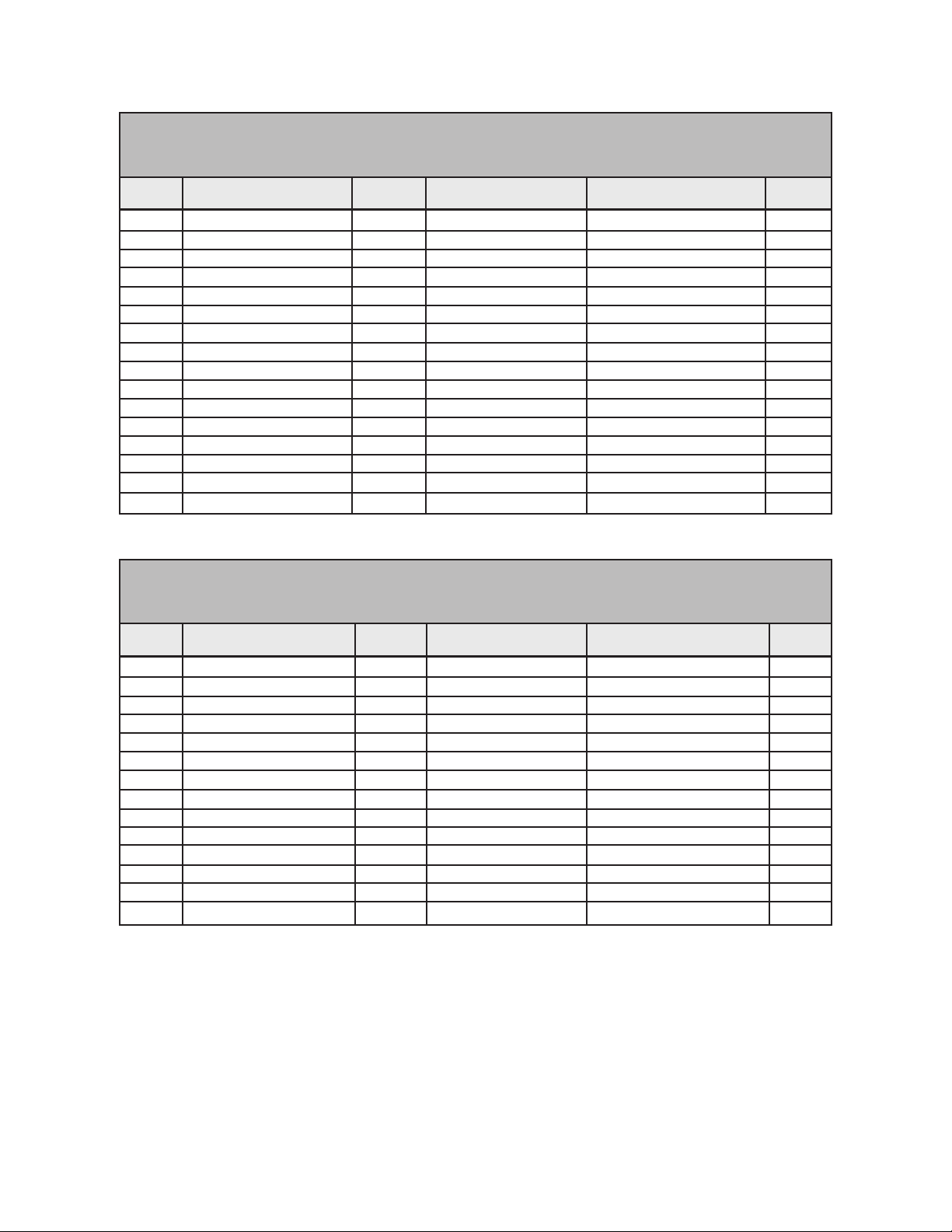

SIGNAL IDENTIFICATION TABLE - ENGLISH

Ransburg

Abbr.

P1 Paint #1 Clear 5/16" OD X 3/16" ID 29

P2 Paint #2 Black Urethane/Poly 5/16" OD X 3/16" ID 29

P1 Paint #1 Clear 3/8" OD X 1/4" ID 29

P2 Paint #2 Black Urethane/Poly 3/8" OD X 1/4" ID 29

SOL Solvent Black Urethane/Poly 3/8" OD X .187" ID 28

P1T Paint #1 Trigger Green Nylon 3/16" OD X .050" Wall 24

P1D Paint #1 Dimp Gray Nylon 3/16" OD X .050 Wall 25

P2T Paint #2 Trigger Natural Nylon 3/16" OD X .050" Wall 17

P2D Paint #2 Dump Black Nylon 3/16" OD X .050" Wall 31

TP Trigger Pilot Black Nylon 3/16" OD X .050" Wall 27

DL Dump Line Natural .313" OD X .188" ID 19

RP Regulator Pilot Natural Nylon 3/16" OD X .050" Wall 17

ST Solvent Trigger Blue Nylon 3/16" OD. X .050" Wall 26

F Fan Air Black Nylon 3/8" OD X .250" ID 23

A Atomization Air Natural Nylon 3/8" OD X .250" ID 16

LV Low Voltage Cable Black N/A N/A 2

Description

Color

Tubing Material

Tubing Size

SIGNAL IDENTIFICATION TABLE - METRIC

Abbr. Description

Color

Tubing Material

Tubing Size

Item #

Item #

P1 Paint #1 Clear 8mm OD X 6mm ID 29

P2 Paint #2 Clear 8mm OD X 6mm ID 29

SOL Solvent Clear 8mm OD X 6mm ID 29

P1T Paint #1 Trigger Green Nylon 4mm OD X .106" ID 24

P1D Paint #1 Dimp Silver Nylon 4mm OD X .106" ID 25

P2T Paint #2 Trigger Natural Nylon 4mm OD X .106" ID 17

P2D Paint #2 Dump Black Nylon 4mm OD X .106" ID 31

TP Trigger Pilot Yellow Nylon 4mm OD X .106" ID 27

DL Dump Line Clear 8mm OD X 6mm ID 29

RP Regulator Pilot Natural Nylon 4mm OD X .106" ID 17

ST Solvent Trigger Blue Nylon 4mm OD X .106" ID 26

F Fan Air Black Nylon 10mm OD X 8mm ID 23

A Atomization Air Natural Nylon 10mm OD X 8mm ID 16

LV Low Voltage Cable Black N/A N/A 2

18

AA-03-02.12

Ransburg

Evolver Solventborne Robotic Atomizers - Installation

AA-03-02.12

Figure 5: Gun and Manifold Assembly

19

Evolver Solventborne Robotic Atomizers - Installation

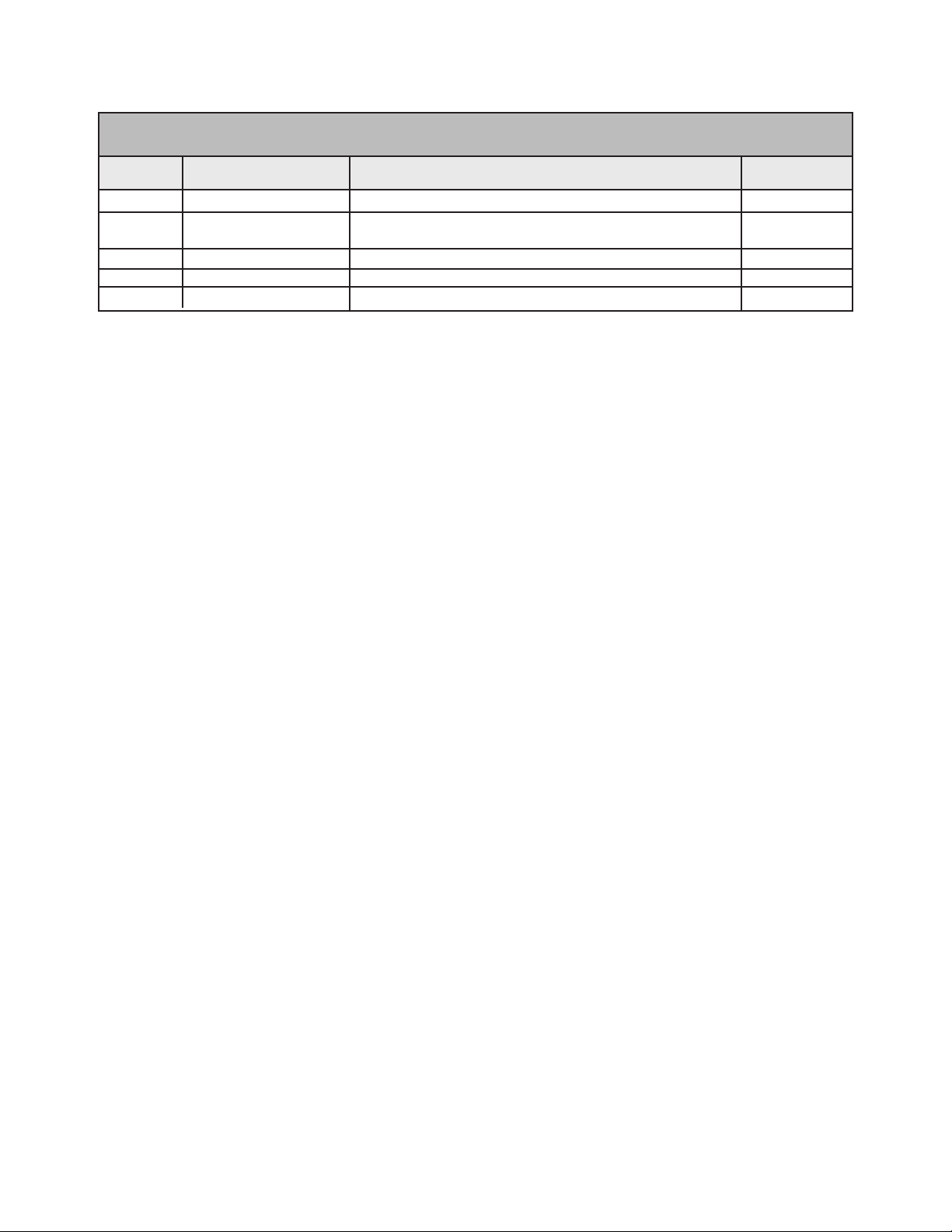

GUN AND MANIFOLD ASSEMBLY - PARTS LIST (Figure 5)

Ransburg

Item #

1 79190-XXXXXXXX Evolver Spray Gun 1

2 76566-32C Socket Head Cap Screws, 1/4-20 X 1" Long, 6

Stainless Steel

3 79156-XXXX Rear Manifold Tubing Assembly (English) 1

4 See Table 1 Spacer Plates 1

5 A10853-XXXX Rear Manifold Tubing Assembly (Metric) 1

Part # Description Qty

20

AA-03-02.12

Ransburg

OPERATION

Evolver Solventborne Robotic Atomizers - Operation

SPRAY GUN CONTROLS

Atom (A) / Fan Air (F)

The atomization and fan air are turned on by the

trigger line and are controlled by an internal air

valve located in the gun head. During normal

operation with gun triggered off, there is a slight

bleed of air through the atomization part.

Atomizing Air

Adjustments are made through the robot PLC or

a manually adjustable air regulator. The lowest

air pressure required to break up the paint should

be used. Lower atomizing air pressures result in

less overspray and increased transfer efciency.

Fan Air

Adjusting the fan air increases or decreases the

size of the spray pattern. Increasing pressure

increases pattern size. Pattern adjustment should

be made to suit the size and shape of the object

being painted. This adjustment is made through the

robot PLC or a manually adjustable air regulator.

Air cap pressures should be set using air cap test

kit. This provides a consistent measurement, so

initial settings may be duplicated at any time. (See

"Parts Identication" section for "Air Cap Test Kit

part numbers".)

HVLP SPRAY

The Evolver HVLP models, when properly set-up,

are designed to provide maximum transfer efciency by limiting air cap pressures to 10 psi (0.7

bar) (in the U.S., this complies with rules issued

by SCAQMD and other air quality authorities).

Air cap pressures should be measured with an

optional air cap test kit. (See "Accessories" in

the "Maintenance" section.)

NOTE

> For HVLP operation (max. 10 psi, -0.7

bar cap pressure), DO NOT exceed the

air inlet pressure, which was read at the

gun base before the tubing manifolds,

given as follows:

PSI (Bar) CAP #

42 (2.9) 48-1

42 (2.9) 481-1

BACK PRESSURE 48-1 and 481-1

AA-03-02.12

NOTE

> Insure that the fan and atomization air

are on and owing prior to triggering the

uid. Failure to follow this sequence will

cause spits and defects on the part being

painted.

Due to the unique cone shape of the MP uid tips

(nozzle), a slight back pressure is created against

the uid column. This will reduce the amount of

uid output. To compensate, increase the uid

regualtor pressure slightly if necessary. With 10

psi (0.7 bar) cap pressure, back pressures are

approximately 3.5 psi (0.24 bar).

21

Loading...

Loading...