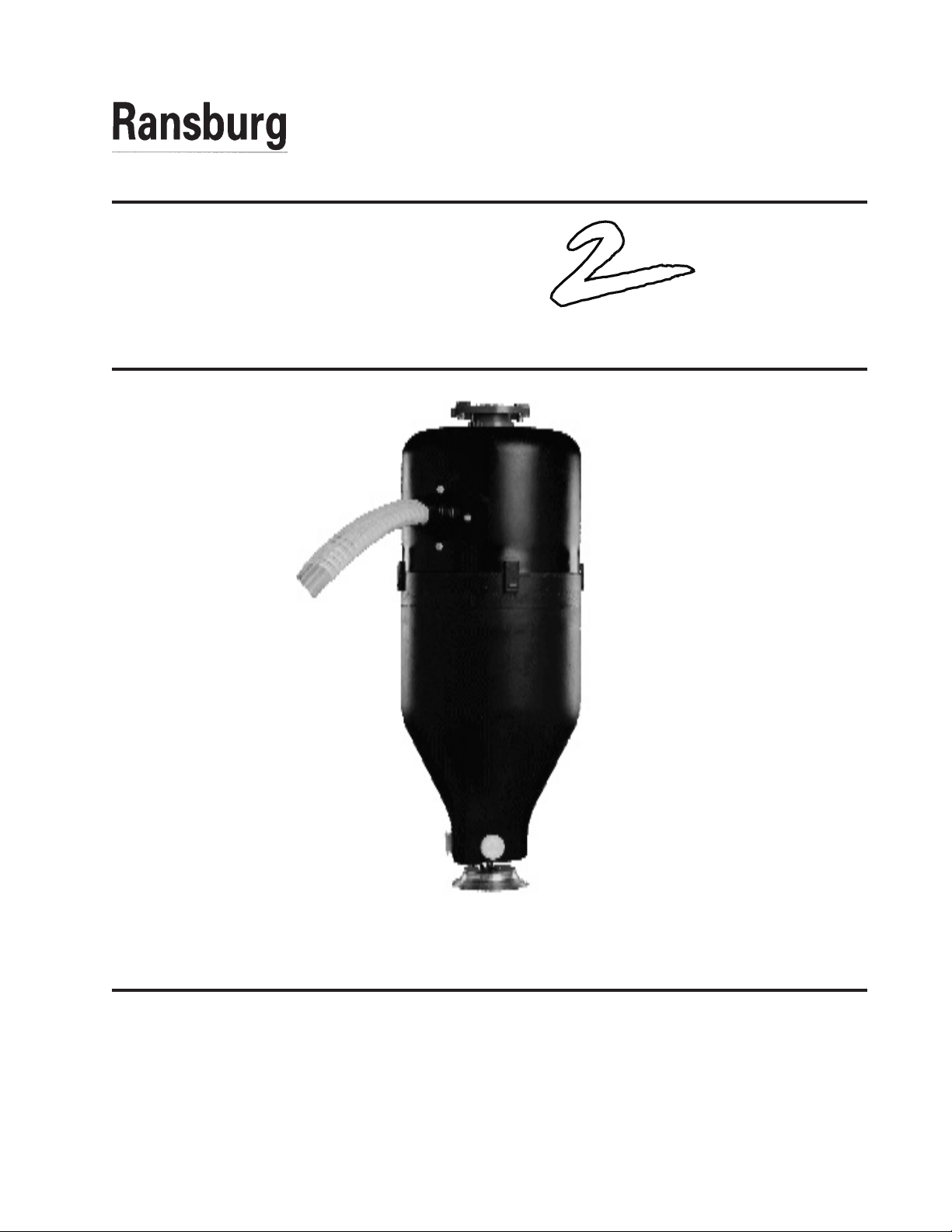

TURBODISK

ASSEMBLY

SERVICE MANUAL

LN-9240-02.1

(Replaces LLN-9240-02.1)

January - 2013

MODELS: 78715

IMPORTANT: Before using this equipment, carefully

read SAFETY PRECAUTIONS, starting on page 1, and all

instructions in this manual. Keep this Service Manual for

future reference.

Service Manual Price: $50.00 (U.S.)

CONTENTS

SAFETY:

Turbodisk 2 - Contents

PAGE

1-7

SAFETY PRECAUTIONS.........................................................

HAZARDS / SAFEGUARDS.....................................................

GENERAL SAFETY GUIDELINES...........................................

INTRODUCTION:

FEATURES................................................................................

GENERAL DESCRIPTION.......................................................

SPECIFICATIONS.....................................................................

TYPICAL SPEED CHART (RPM'S)..........................................

INSTALLATION:

EQUIPMENT..............................................................................

AIR CONTROL..........................................................................

MOUNTING................................................................................

INTERLOCKS............................................................................

TYPICAL TURBODISK 2 DRIVE AIR SYSTEM & AIR LOGIC CONTROL

PANEL........................................................

UPPER TURBODISK 2 BULKHEAD PLATE...........................

TURBODISK 2 SIGNAL / PORT IDENTIFICATION TABLE...

OPERATION:

COATING MATERIALS.............................................................

FLUID FLOW CONTROL..........................................................

FLUID VALVE CONTROL.........................................................

FLUID & AIR PRESSURE REQUIREMENTS..........................

TURBINE SPEED......................................................................

ELECTROSTATIC VOLTAGE..................................................

TARGET DISTANCE.................................................................

1

2

5

8-11

8

8

9

10

12-15

12

12

12

12

13

14

15

16-19

16

16

17

17

18

19

19

MAINTENANCE:

GENERAL..................................................................................

CLEANING PROCEDURES.....................................................

VIBRATION NOISE...................................................................

TURBINE REPAIR & REBUILD...............................................

VALVES & REGULATORS.......................................................

PREVENTIVE MAINTENANCE................................................

DISASSEMBLY PROCEDURES..............................................

TROUBLESHOOTING GUIDE.................................................

NO VALVE APPLICATION SCHEMATIC................................

3-WAY VALVE APPLICATION SCHEMATIC..........................

TRIGGER / DUMP w/REGULATOR SCHEMATIC.................

TRIGGER / DUMP w/REGULATOR (DR-1) SCHEMATIC.....

LN-9240-02.1

20-33

20

20

22

22

22

22

23

28

30

31

32

33

(CONTINUED ON NEXT PAGE)

Turbodisk 2 - Contents

PARTS IDENTIFICATION:

PAGE

34-69

TURBODISK 2 ASSY MODEL IDENTIFICATION...................

TURBODISK 2 ASSY, NO VALVES / PARTS LIST................

TURBODISK 2 ASSY, 3-WAY VALVE / PARTS LIST.............

TURBODISK 2 ASSY, TRIGGER & DUMP VALVE W/FLUID REGULATOR

/ PARTS LIST....................................................

TURBODISK 2 ASSY, TRIGGER & DUMP VALVE W/DR-1 FLUID REGU-

LATOR / PARTS LIST........................................

LOWER TURBODISK 2 FLUID CONTROL ASSEMBLY / PARTS LIST........

......................................................................

UPPER TURBODISK 2 BULKHEAD PLATE & FAIRING MOUNTING /

PARTS LIST.......................................................

FLUID SUPPLY LINE PACKAGE / PARTS LIST....................

3-WAY VALVE ASSY / PARTS LIST........................................

HIGH FLOW FLUID REGULATOR ASSY / PARTS LIST.......

DR-1 FLUID REGULATOR ASSY / PARTS LIST...................

DR-1 FLUID REGULATOR ASSY / PARTS LIST...................

TURBODISK 2 AIR HEATER / PARTS LIST...........................

TURBODISK 2 QUICK RELEASE FAIRING ASSY /

PARTS LIST..............................................................................

TRIGGER & DUMP VALVE ASSY / PARTS LIST...................

BULKHEAD PLATE FITTING LAYOUT / PARTS LIST...........

TURBODISK 2 AIR TURBINE ASSY / PARTS LIST...............

34

38

40

42

44

46

48

50

52

54

56

58

60

62

64

66

68

WARRANTY POLICIES:

LIMITED WARRANTY...............................................................

APPENDIX:

PAINT AND SOLVENT SPECIFICATIONS.............................

VISCOSITY CONVERSION CHART........................................

VOLUMETRIC CONTENT OF HOSE OR TUBE.....................

70

70

71-74

71

72

74

LN-9240-02.1

SAFETY

SAFETY PRECAUTIONS

Turbodisk 2 - Safety

Before operating, maintaining or servicing any

Ransburg electrostatic coating system, read and

understand all of the technical and safety literature

for your Ransburg products. This manual contains

information that is important for you to know and

understand. This information relates to USER SAFETY

and PREVENTING EQUIPMENT PROBLEMS. To help

you recognize this information, we use the following

symbols. Please pay particular attention to these

sections.

A WARNING! states information to alert you to a

situation that might cause serious injury if instructions

are not followed.

A CAUTION! states information that tells how to

prevent damage to equipment or how to avoid a

situation that might cause minor injury.

A NOTE is information relevant to the procedure in

progress.

While this manual lists standard specications and

service procedures, some minor deviations may be

found between this literature and your equipment.

Dierences in local codes and plant requirements,

material delivery requirements, etc., make such

variations inevitable. Compare this manual with

your system installation drawings and appropriate

Ransburg equipment manuals to reconcile such

dierences.

W A R N I N G

!

> The user MUST read and be familiar with the

Safety Section in this manual and the Ransburg

safety literature therein identied.

> This manual MUST be read and thoroughly

understood by ALL personnel who operate, clean

or maintain this equipment! Special care should

be taken to ensure that the WARNINGS and safety

requirements for operating and servicing the

equipment are followed. The user should be

aware of and adhere to ALL local building and re

codes and ordinances as well as NFPA 33 SAFETY

STANDARD, 2000 EDITION, prior to installing,

operating, and/or servicing this equipment.

W A R N I N G

!

> The hazards shown on the following page may

occur during the normal use of this equipment.

Please read the hazard chart beginning on page

2.

Careful study and continued use of this manual will

provide a better understanding of the equipment and

process, resulting in more ecient operation, longer

trouble-free service and faster, easier troubleshooting.

If you do not have the manuals and safety literature

for your Ransburg system, contact your local Ransburg

representative or Ransburg.

1LN-9240-02.1

Turbodisk 2 - Safety

AREA

Tells where hazards

may occur.

Spray Area

HAZARD

Tells what the hazard is.

Fire Hazard

Improper or inadequate opera-tion

and maintenance procedures will

cause a re hazard.

Protection against inadver tent

arcing that is capable of causing

re or explosion is lost if any safety

interlocks are disabled during

operation. Frequent power supply

shutdown indicates a problem in the

system requiring correction.

SAFEGUARDS

Tells how to avoid the hazard.

Fire extinguishing equipment must be present in the

spray area and tested periodically.

Spray areas must be kept clean to prevent the

accumulation of combustible residues.

Smoking must never be allowed in the spray area.

The high voltage supplied to the atomizer must be

turned o prior to cleaning, ushing or maintenance.

When using solvents for cleaning:

Those used for equipment ushing should have ash

points equal to or higher than those of the coating

material.

Those used for general cleaning must have ash points

above 100oF (37.8oC).

Spray booth ventilation must be kept at the rates

required by NFPA 33, 2000 Edition, OSHA and local codes.

In addition, ventilation must be maintained during

cleaning operations using ammable or combustible

solvents.

General Use and

Maintenance

Improper operation or maintenance

may create a hazard.

Personnel must be properly trained

in the use of this equipment.

Electrostatic arcing must be prevented.

Test only in areas free of combustible material.

Testing may require high voltage to be on, but only as

instructed.

Non-factory replacement parts or unauthorized

equipment modications may cause re or injury.

If used, the key switch bypass is intended for use only

during setup operations. Production should never be

done with safety interlocks disabled.

Never use equipment intended for use in waterborne

installations to spray solvent based materials.

Personnel must be given training in accordance with the

requirements of NFPA 33, Chapter 16, 2000 edition.

Instructions and safety precautions must be read and

understood prior to using this equipment.

Comply with appropriate local, state, and national

codes governing ventilation, re protection, operation

maintenance, and housekeeping. OSHA references

are Sections 1910.94 and 1910.107. Also refer to

NFPA 33, 2000 edition and your insurance company

requirements.

2

LN-9240-02.1

Turbodisk 2 - Safety

AREA

Tells where hazards

may occur.

Electrical Equipment

HAZARD

Tells what the hazard is.

High voltage equipment is utilized.

Arcing in areas of ammable or

combustible materials may occur.

Personnel are exposed to high

voltage during operation and

maintenance.

Protection against inadver tent

arcing that may cause a fire or

explosion is lost if safety circuits are

disabled during operation.

Frequent power supply shutdown

indicates a problem in the system

which requires correction.

An electrical arc can ignite coating

mater ials and cause a fire or

explosion.

SAFEGUARDS

Tells how to avoid the hazard.

The power supply, optional remote control cabinet, and

all other electrical equipment must be located outside

Class I or II, Division 1 and 2 hazardous areas. Refer to

NFPA No. 33, 2000 Edition.

Turn the power supply OFF before working on the

equipment.

Test only in areas free of ammable or combustible

material.

Testing may require high voltage to be on, but only as

instructed.

Production should never be done with the safety circuits

disabled.

Before turning the high voltage on, make sure no objects

are within the sparking distance.

Explosion Hazard /

Incompatible

Materials

Toxic Substances

Halogenated hydrocarbon solvents

for example: methylene chloride

and 1,1,1,-Trichloro-ethane are not

chemically compatible with the

aluminum that might be used in

many system components. The

chemical reaction caused by these

solvents reacting with aluminum

can become violent and lead to an

equipment explosion.

Certain material may be harmful if

inhaled, or if there is contact with

the skin.

Aluminum is widely used in other spray application

equipment - such as material pumps, regulators,

triggering valves, etc. Halogenated hydrocarbon

solvents must never be used with aluminum equipment

during spraying, ushing, or cleaning. Read the label

or data sheet for the material you intend to spray. If

in doubt as to whether or not a coating or cleaning

material is compatible, contact your material supplier.

Any other type of solvent may be used with aluminum

equipment.

Follow the requirements of the Material Safety Data

Sheet supplied by coating material manufacturer.

Adequate exhaust must be provided to keep the air free

of accumulations of toxic materials.

Use a mask or respirator whenever there is a chance

of inhaling sprayed materials. The mask must be

compatible with the material being sprayed and its

concentration. Equipment must be as prescribed by

an industrial hygienist or safety expert, and be NIOSH

approved.

LN-9240-02.1

3

Turbodisk 2 - Safety

AREA

Tells where hazards

may occur.

Spray Area / High

Voltage Equipment

Personnel Safety /

Mechanical Hazards

HAZARD

Tells what the hazard is.

There is a high voltage device that

can induce an electrical charge

on ungrounded objects which

is capable of igniting coating

materials.

Inadequate grounding will cause

a spark hazard. A spark can ignite

many coating materials and cause

a re or explosion.

The disk atomizer can rotate at

speeds up to 40,000 RPM. At these

speeds, the edge of the applicator

can easily cut into skin. Loose

articles can also be caught by the

rotating disk.

SAFEGUARDS

Tells how to avoid the hazard.

Parts being sprayed must be supported on conveyors

or hangers and be grounded. The resistance between

the part and ground must not exceed 1 megohm.

All electrically conductive objects in the spray area, with

the exception of those objects required by the process

to be at high voltage, must be grounded.

Any person working in the spray area must be

grounded.

Unless specically approved for use in hazardous

locations, the power supply and other electrical control

equipment must not be used in Class 1, Division 1 or

2 locations.

Personnel must stay clear of the disk whenever it is

rotating.

Before touching the disk, the turbine air must be shut

o.

If the disk has been rotating, allow at least three minutes

for it to come to a complete stop before touching it.

4

LN-9240-02.1

Turbodisk 2 - Safety

GENERAL SAFETY GUIDELINES

• The articles being coated MUST be grounded at all

times.

W A R N I N G

!

> The simple safety measures outlined here

are vital. Failure to observe them could cause a

spark capable of starting a re.

• All components of the applicator system (except the

atomizing head) MUST be grounded at all times.

• All contact points MUST be free of any accumulation

of nonconductive residue.

• All electrically conductive objects, especially solvent

containers within the spray area, MUST be either

removed or grounded.

Any tool, if used improperly, can be dangerous. Safety

is ultimately the responsibility of those using a tool.

In like manner, safe operation of electrostatic coating processes is the responsibility of those who use

such processes and those who operate electrostatic

coating equipment. Procedures to be followed on

conducting electrostatic coating operations safely are

outlined in the Ransburg brochure IL-247: "Operating

Your Electrostatic Coating System Safely". Additional

copies are available from Ransburg upon request.

All personnel connected with coating operations

should read and understand this brochure. It is

most important that the equipment operators and

supervisory personnel understand the requirements

for safe operation.

W A R N I N G

!

Additional cards summarizing these safety requirements are available from Ransburg on request. These

cards should be posted in the spraying area so that

they can be readily referred to and serve as a reminder

to personnel in that area of responsibility. Additional

copies of the sign SL-00-07: "Cleaning Safety Requirements" are available upon request.

Each user should examine his own coating operation,

develop his own safety program, and ensure that his

workers follow correct procedures. Ransburg hopes

that the information it provides is helpful to the user

in establishing such a program.

In addition to the available cards, labels, brochures,

and service manuals, the user should consult other

standards and recognized safety authorities. Section

1910.107 of the regulations established under the

Occupational Safety and Health Act [OSHA] apply to

spray nishing operations. Paragraph (i) specically

applies to electrostatic hand spraying equipment.

NFPA No. 33 "Spray Application", is another standard

for spray painting operations. Chapters 9, 10, and

13 are specically applicable to electrostatic coating. Copies of NFPA No. 33 are available from the

National Fire Protection Association, Batterymarch

Park, Quincy, Mass. 02269 (at nominal cost).

The National Fire Protection Association also publishes standards other than NFPA No. 33 relating to

the control of re hazards. NFPA No. 33 specically

refers to the following bulletins of the National Fire

Protection Association as applicable to coating operations:

NFPA No.63: Dust Explosion, Industrial Plants

NFPA No.70: National Electrical Code

NFPA No.86A: Ovens and Furnaces

NFPA No.91: Blower and Exhaust Systems

NFPA No.654: Dust Explosions, Plastics Industry

NFPA No.77: Static Electricity, also contains much

useful information. Copies of these brochures will be

helpful in arriving at a program for safe operation.

> If ANY symptom of improper operation

occurs, suspend use of the unit until the problem

has been diagnosed and corrected. See the

appropriate "Troubleshooting Guide" or contact

your Ransburg representative.

LN-9240-02.1

Local codes and authorities also have standards to be

followed in the operation of your spray equipment.

Your insurance carrier will be helpful in answering

questions that arise in your development of spray

coating procedures.

5

Turbodisk 2 - Safety

All personnel MUST read and understand the

following Ransburg Safety Publications:

IL-247: Operating Your Electrostatic Coating System

Safely SL-77-01: Personnel Grounding

Ransburg also suggests that all personnel read the

HEW publication "Spray Painting: Good Practices for

Employees", number (NIOSH) 78-178 available from

the regional NIOSH oce or the U.S. Government

Printing Oce.

NIOSH and OSHA regional offices can provide

information on OCCUPATIONAL SAFETY AND

HEALTH ACT, including questions on standards

interpretations, voluntary compliance information,

copies of the OSHA Standards, OSHA Act, Employee

Rights Posting Notice and Publications.

Personnel

• All personnel should read and understand local

codes, appropriate NFPA bulletins, OSHA Act of

1970, and this service manual.

Parts

• Articles being painted MUST be grounded at

ALL times. Paint MUST NEVER be permitted to

accumulate on workholders, particularly on points

where workholders touch conveyor. Hooks MUST

be clean to ensure proper contact. It is advisable to

have extra sets of workholders to enable cleaning of

the sets not being used at regular intervals. Areas

of hanger contact should be sharp points or edges

where possible.

• All electrically conductive objects within the

spray area (including spray booth, paint tank, and

conveyor) MUST BE GROUNDED. This requirement

applies to the solvent safety container, paint

containers, wash cans, and all other objects in the

area.

Ventilation

We recommend interlocking the ventilation with the

spraying equipment to ensure proper ventilation

when equipment is in operation. See NFPA Bulletin

No. 33.

• Personnel working in the spray area MUST be

adequately grounded. Insulated shoes such as

rubber, composition, or cork soles should NOT

be worn unless an alternate grounding method

is provided. (See Ransburg Bulletin SL-77-01,

"Personnel Grounding".)

W A R N I N G

!

> ALWAYS turn power supply OFF prior to

cleaning or working on equipment.

> ENSURE that the grounding hook has been

properly secured to the motor housing.

• Personnel working on applicators MUST always

be sure that the high voltage is o, the rotator has

stopped and that the grounding hook has been

properly secured to the motor housing.

Housekeeping

• Good housekeeping is essential to safe operation.

Clean-up and maintenance schedules should be

established by the user, based on observations of

the initial production operations. Maintenance and

safety cards should be posted in clear view of the

operator.

• Normal re protection measures are required.

These include proper storage of paints, solvents,

and waste, plus ready access to re extinguishing

equipment. For details, consult NFPA Bulletins No.

30, 33, 70 and 77, your local re codes, local paint

equipment standards, OSHA Act of 1970, and your

insurance carrier’s recommendations.

Floor Covering and Masking

If it is necessary to cover booth ooring, Ransburg

suggests that the user employ a material which will

NOT support combustion, such as Spark Gard Grade

BWA-100.

6

LN-9240-02.1

Turbodisk 2 - Safety

Halogenated Hydrocarbons

W A R N I N G

!

> A chemical reaction, resulting in the

possibility of a pressure EXPLOSION, may occur

if 1,1,1-Trichloroehtane, Methylene Chloride, or

other Halogenated Hydrocarbon solvents are

used in PRESSURIZABLE FLUID SYSTEMS having

ALUMINUM or GALVANIZED WETTED PARTS.

Such an explosion could cause DEATH, serious

BODILY INJURY, and/or substantial property

damage. See Ransburg Bulletins:

SL-81-05: HHC Explosion Hazard Danger Sign

SL-81-08: HHC Explosion Hazard Safety Bulletin

Consult your uid supplier to determine the

chemical content of your solvents.

NOTES:

LN-9240-02.1

7

Turbodisk 2 - Introduction

INTRODUCTION

FEATURES

Features which make the Turbodisk

advantageous for use in electrostatic applications

include:

• Proven turbine motor reliability.

• Patented serrated edge conical disk provides

excellent atomization quality at minimal rotational

speeds.

• Aerodynamic fairing design for ease of cleaning of

external surfaces.

• Speed readout (or control) uses reliable magnetic

pickup for ber-optic transmission of rotational

speed data. (optional)

• A majority of all assembly components which

come in contact with the uid material are made

of either stainless steel or, which is impervious to

most uids.

• Negligible maintenance down time. With the quick

disconnect feature, the lower Turbodisk 2 uid

section can be exchanged in minimal time for o

line maintenance.

• Quick disconnect feature allows for other uid

control assemblies to be incorporated when

desired.

TM

2 Applicator

GENERAL DESCRIPTION

The Turbodisk 2 Applicator, because of it's high

rotational speed, produces finer atomization,

improved quality, and higher transfer eciency with

any of the wide variety of coating materials (such

as waterborne and high solids) used in production

nishing operations. It's speed is controlled by varying

the drive air. The applicator assembly is designed for

use on vertical overhead mounted reciprocators.

Quick Disconnect

-REFER TO FIGURES 16, 17, & 26

The Turbodisk 2 Applicator is a quick disconnect

design that allows the lower uid section that carries

all the uid/ air controls to be separated from the

upper section carrying the tubing supply lines. The

incoming air lines, uid lines, high voltage cable,

and ber optic cable are connected to the ttings

provided on the upper xed bulkhead plate. Each

bulkhead plate (upper and lower) utilizes special

male and female ttings with o-rings that seal the

uid and air line passages when both sections are

assembled together. Two latching mechanisms have

been incorporated into the design allowing the lower

section to be supported while the operator tightens or

loosens the retaining screws that hold the upper and

lower sections together. Alignment arrows engraved

into the side of the bulkhead plates provide for quick

visual assembly orientation.

• The easily removable lower fairing, turbine air motor

assembly, and the externally mounted regulators

and uid valves, make o line maintenance more

ecient and economical.

• Control air lines are color coded for ease of

identication.

• Higher uid delivery rates can be achieved using a

dual feed uid system.

• High ow regulators and uid valves provide for

simultaneous paint push out while solvent washes

the feed tube and disk.

8

Conical Disk Assembly

The Turbodisk 2 Applicator uses conical disk

assemblies that are made from high grade aluminum

construction and are force balanced to .10 grams•in or

better. With the patented serrated edge, these disks

come in sizes of 6, 9, and 12 inch diameters.

LN-9240-02.1

Turbodisk 2 - Introduction

Turbodisk 2 Fairing

-REFER TO FIGURE 24

The Turbodisk 2 Applicator fairing is required for

safe operation. The two piece fairing provides high

voltage isolation from the metal rotator assembly

and valve components, as well as ease of cleaning

and maintenance. Provided on the fairing are (4)

draw latches which allow for easy on/o removal of

the lower fairing.

W A R N I N G

!

> Both sections of the fairing to be in place

when the Turbodisk 2 is in operation or when

high voltage is supplied to the applicator.

Paint Valve Options

Four paint valve options in single or dual feed

applications are available:

SPECIFICATIONS

Mechanical

Turbine Speed: Variable to 40,000 rpm

max. (6" conical disk)

Turbine Type: Ball Bearing

Weight: 57 lbs. (approximately)

Length: 36 in.

Diameter: 13.25 in.

Turbine Air: At max. speed (40krpm),

requires 103.1 psi and

61.1 scfm, unloaded

(see Figure 1)

Fluid Pressure

Inlet: See Figure 4

• No Valves (refer to Figures 7,12,18)

• 3-Way On/O Valve (refer to Figures 8,13,19)

• Trigger and Dump Valve with High Flow Regulator

(refer to Figures 9,14,20,25)

• Trigger and Dump Valve with Low Flow

Regulator (refer to Figures 10,15,21,22,25)

Power Supply and Controls

In the system, the high voltage is supplied to the

Turbodisk 2 by either the MicroPak™ Industrial power

supply system or a Voltage Master™ series power

supply.

The MicroPak Indus trial power supply uses

proven high voltage generator technology that

is microprocessor controlled for diagnostics and

communication. The controller is packaged in

standard rack mounted Eurocard format for easy

access and system integration.

The Voltage Master™ power supplies are general

purpose heavy duty power supplies with years of

proven reliability. They have variable voltage control,

many safety features, and remote analog voltage

control capabilities.

Single Fluid Flow Range:

Waterborne: To 1,200 cc/min.

Solvent Base: To 1,500 cc/min.

High Solids: To 1,000 cc/min. (80%+)

Air Inlet Trigger/

Dump: 70-100 psi

Air Pilot for Fluid

Pressure: See Figure 4

Electrical

Power Supply MicroPakTM Industrial

or Type: Voltage Master

Charging Method: Direct

Input Voltage: 0-100 kV

Turbine Speed

Control or Monitor: PulseTrackTM

(Optional)

TM

LN-9240-02.1

9

Turbodisk 2 - Introduction

NOTES:

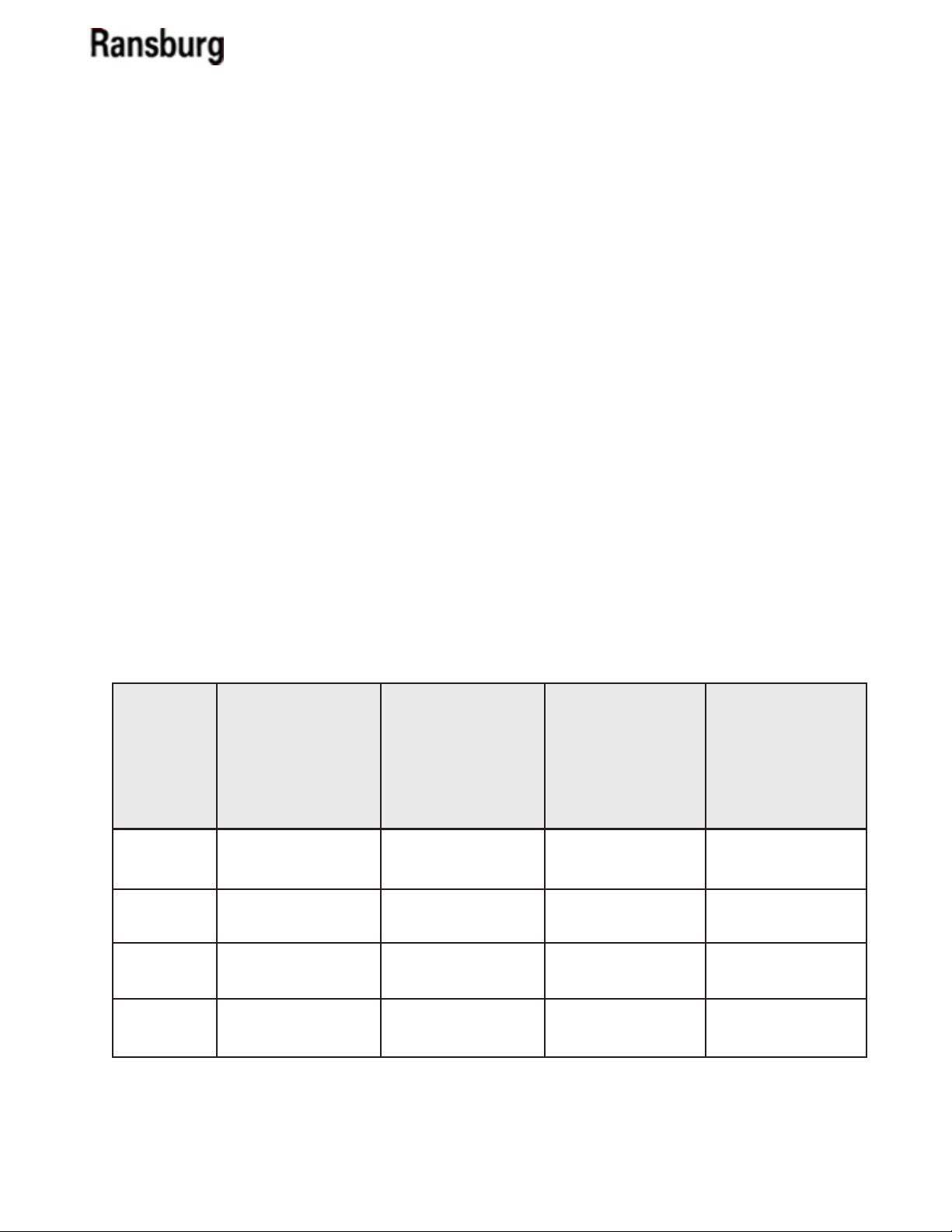

TYPICAL SPEED CHART (RPM's)

-REFER TO FIGURES 1 & 23

The following represents data collected under lab

conditions. Flow meters were installed on each of

the two 3/8 I.D. heated air lines used to supply the

Turbodisk 2 turbine motor. The airow through

each ow meter was recorded and added together

to obtain the total air ow through the system. The

speed of the disk was monitored through the means

of a PulseTrack™ system. The air heater was set at 120

degrees during all data collection.

Rotational speeds are unloaded and can be expected

to drop 20 to 30% when under a uid load condition.

Heated turbine air increases eciency of motor up

to 10%. This chart should be used as a guide ONLY.

Speeds will vary due to rotator wear, tubing size or

lengths, etc.

NOTE

> Never run disk over it's maximum safe

operating speed.

10

LN-9240-02.1

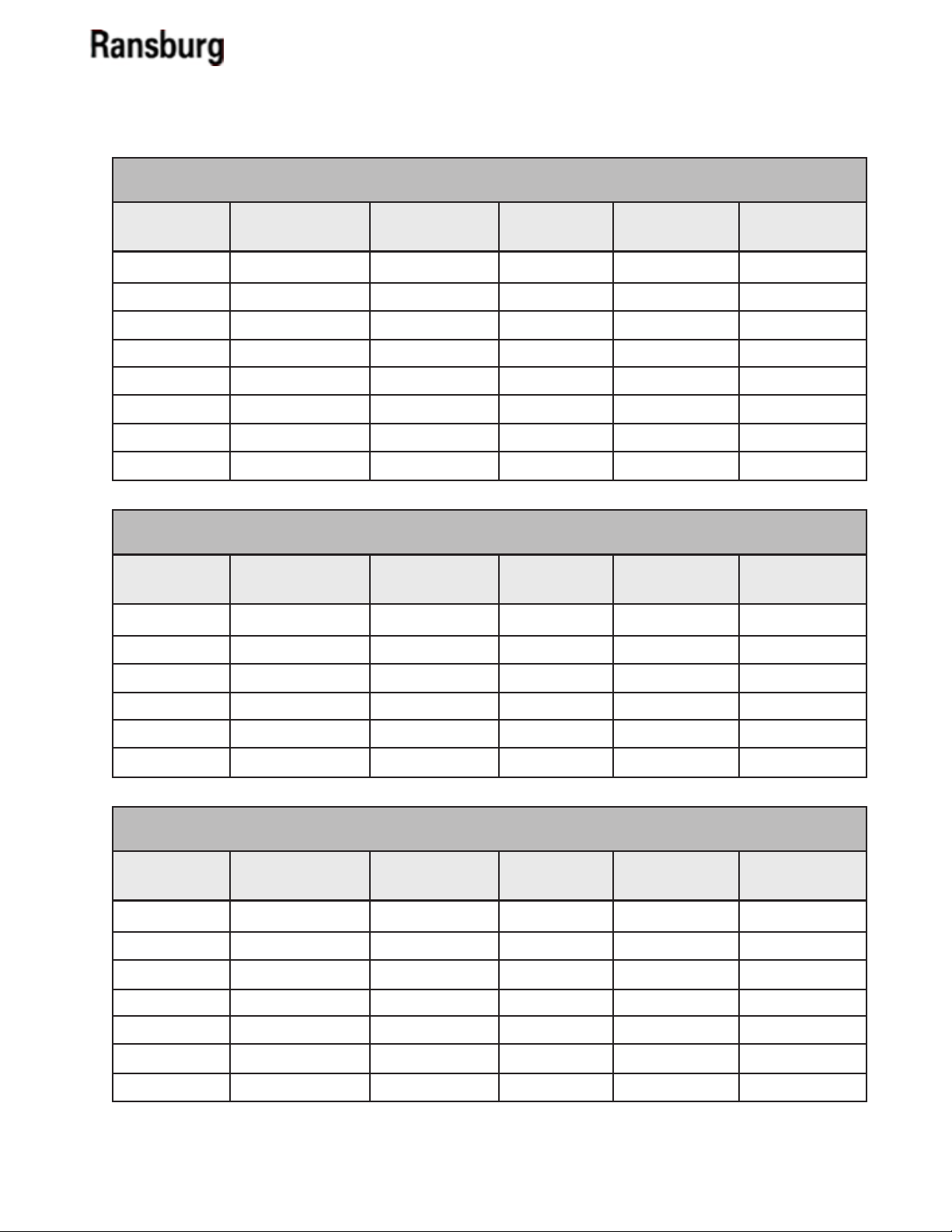

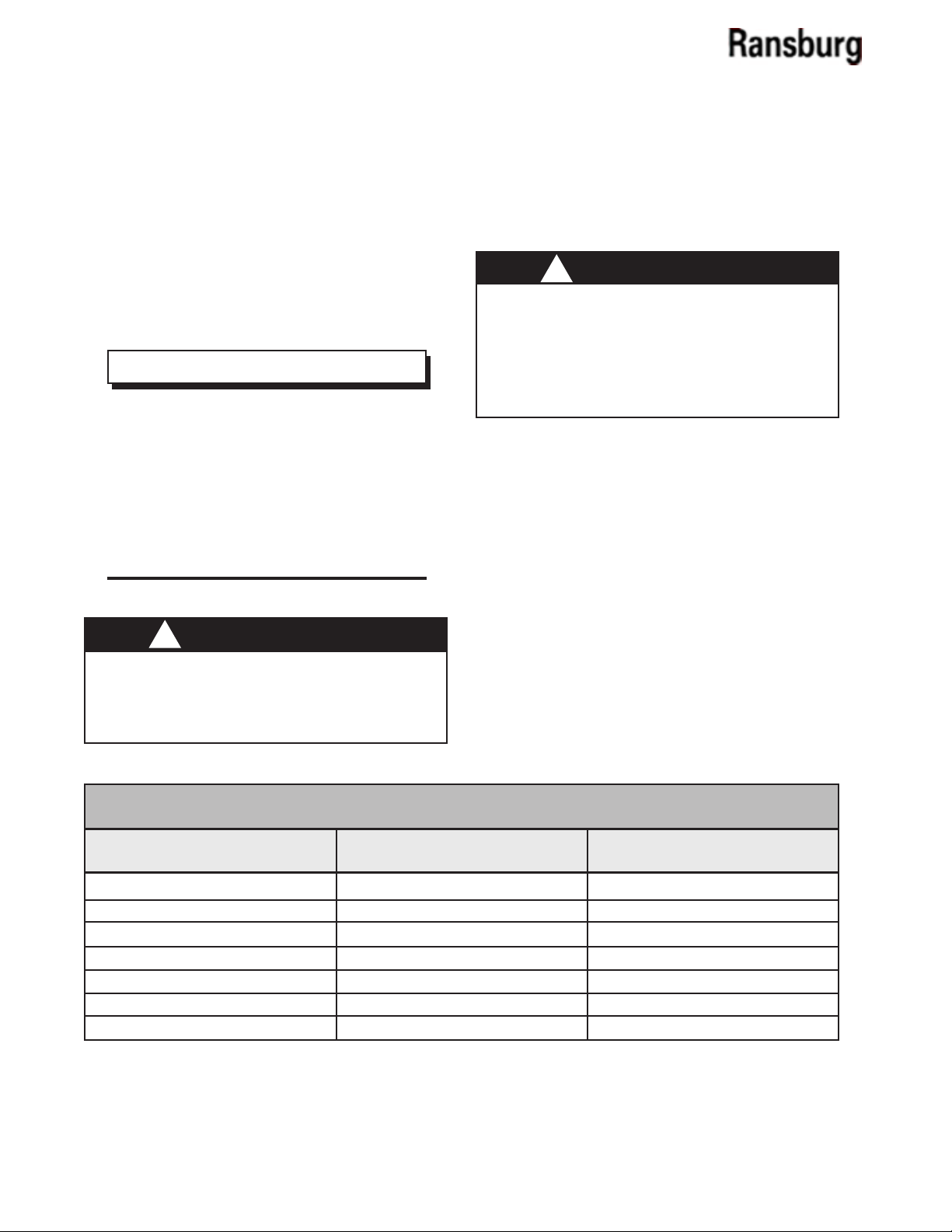

TYPICAL SPEED CHART - 10 HOLE ORIFICE PLATE

6" Conical Disk

Turbodisk 2 - Introduction

Disk Speed

(RPM)

5,000

10,000

15,000

20,000

25,000

30,000

35,000

40,000

9" Conical Disk

Disk Speed

(RPM)

5,000

10,000

Supply Air

Pressure (PSI)

6.6

10.5

18.2

27.8

40.4

56.3

76.4

103.1

Supply Air

Pressure (PSI)

11.3

26

Air Flow #1

(SLPM)

140

190

260

340

440

560

730

930

Air Flow #1

(SLPM)

200

330

Air Flow #2

(SLPM)

100

140

200

260

350

460

610

800

Air Flow #2

(SLPM)

140

250

Total Air Flow

(SLPM)

240

330

460

600

790

1,020

1,340

1,730

Total Air Flow

(SLPM)

340

580

Total Air Flow

(SCFM)

8.5

11.7

16.2

21.2

27.9

36.0

47.3

61.1

Total Air Flow

(SCFM)

12.0

20.5

13,000

16,000

19,000

22,000

12" Conical Disk

Disk Speed

(RPM)

2,000

4,000

6,000

8,000

10,000

12,000

12,500

39.5

55.4

79.8

102

Supply Air

Pressure (PSI)

8.7

18.6

31.0

48.3

68.5

95.8

102.0

430

560

760

930

Air Flow #1

(SLPM)

170

270

370

500

670

880

930

340

460

640

800

Air Flow #2

(SLPM)

120

200

290

400

560

750

780

770

1,020

1,400

1,730

Total Air Flow

(SLPM)

290

470

660

900

1,230

1,630

1,710

27.2

36.0

49.4

61.1

Total Air Flow

(SCFM)

10.2

16.6

23.3

31.8

43.4

57.6

60.4

LN-9240-02.1

Figure 1: Typical Speed Chart - 10 Hole Orice Plate

11

Turbodisk 2 - Installation

INSTALLATION

EQUIPMENT

This system should be installed by, or under the

supervision of an Ransburg representative. Should the

need arise to replace any component assembly within

the system, contact your Ransburg representative.

This manual concerns normal operation, maintenance,

and service of the specied applicator assemblies. The

air and uid connections vary with dierent models

and installations. This manual deals primarily with

those at, or within the assembly.

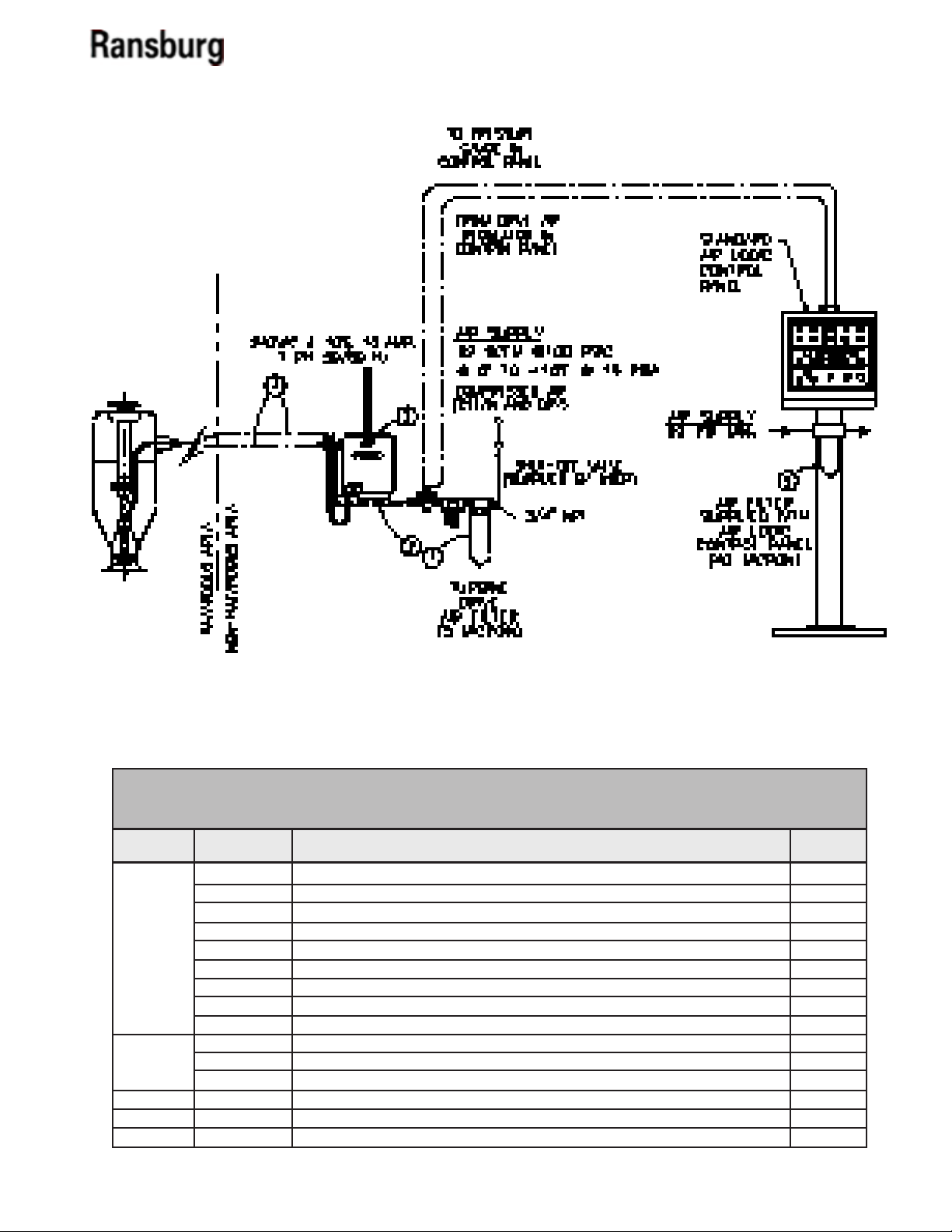

AIR CONTROL

-REFER TO FIGURE 2

Air control of the applicator is from a standard

Ransburg air logic panel, which includes two lters

(one 40 micron lter located at the air logic station

and one 5 micron lter located at the inlet of the inline air heater panel). Clean, dry factory air must be

provided to the inlet lter of the air logic station via

a minimum 1/4-inch I.D. pipe and to the inlet lter of

the heater panel via a minimum 3/4-inch I.D. pipe.

MOUNTING

-REFER TO FIGURE 17 & 24

The Turbodisk 2 assembly is mounted on the

reciprocator using (4) 5/16-18 screws provided on

the ram ange. Loosening (2) 1/4-20 screws on the

same ram ange will allow the assembly to rotate.

Position the Turbodisk 2 assembly so that the strain

relief boot is positioned toward the incoming uid

and air lines and retighten.

Remove lower fairing by releasing the (4) quick release

draw latches. Thread all the required air, high voltage,

ber optic, and uid service lines through the strain

relief boot. The strain relief boot may have to be cut

larger in order to feed all the lines through. Refer to the

78718 assembly/schematic diagram for connection

reference to upper bulkhead plate.

Reinstall lower fairing. Install conical disk and torque

to 50-60 lb•in.

INTERLOCKS

Flow of coating material should be locked out unless

all of the following conditions are met:

12

1. Booth exhaust is turned on.

2. The turbine is spinning.

3. High voltage is on or in the bypass mode.

LN-9240-02.1

Turbodisk 2 - Installation

Figure 2: Typical Turbodisk 2 Drive Air System and Air Logic Control Panel

TYPICAL TURBODISK 2 DRIVE AIR SYSTEM & AIR LOGIC CONTROL PANEL - PARTS

LIST (Figure 2)

Item # Part # Description Qty

1 78170-00 Regulator Assembly, Turbodisk 2 Drive Air (Includes the Following:) 1

SSP-6439 Elbow, 1/4 O.D. Tube x 1/4 NPT Male Swivel 2

SSV-8221 Regulator, 1/2 NPT Ported, Air Piloted 1

7819-16 Nipple, 1/2 NPT x 1.5 Long, Brass Pipe 1

LS0147 Regulator, 1" Ported, Manual Adj. Air, 0-125 psi, 250 CFM 1

7596-12 Bushing, 1" NPT x 1/2 NPT, Brass 1

GA-316 Gauge, 0-160 psig, 1/4 NPT, Air 1

41-FP-1021 Nipple, 1" NPT x 3/4 NPT, Hex Reducing 1

HAF-503 Air Filter, 3/4 NPT 1

2 78166-00 Hose Assembly, Compressed Air (Includes the Following:) 1

78164-00 Hose, 3/4" I.D., Push-Loc Air 5 ft.

78165-00 Fitting, Female SAE 45o Swivel x 3/4" I.D. Hose 2

3 20222-00 Air Heater Assembly 1

4 78176-01 Tubing, 1/2" O.D. x .375" I.D., Green Nylon To Suit

5 SSM-5805 Air Filter, 1/4 NPT 1

LN-9240-02.1

13

Turbodisk 2 - Installation

14

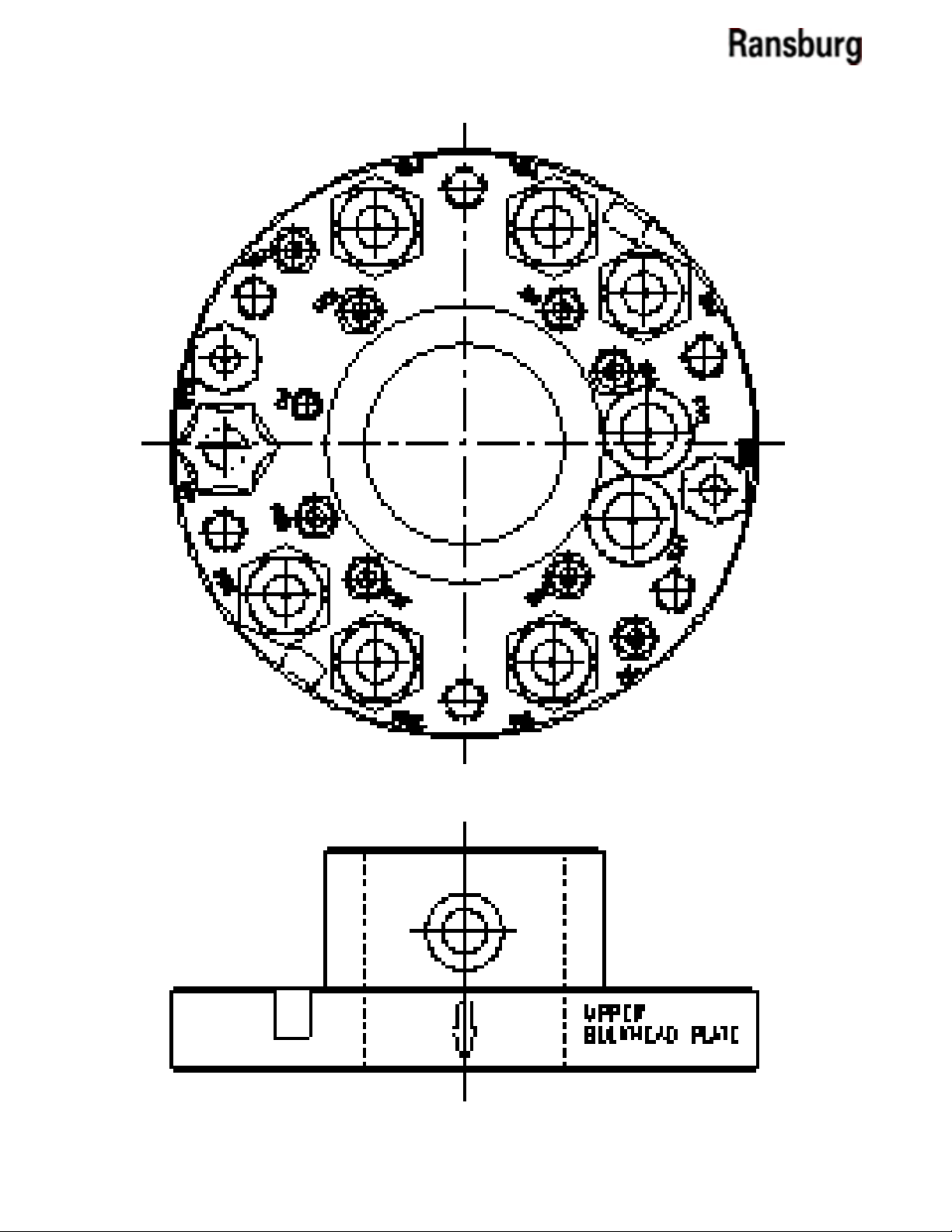

Figure 3a: Upper Turbodisk 2 Bulkhead Plate (Reference Figure 26)

LN-9240-02.1

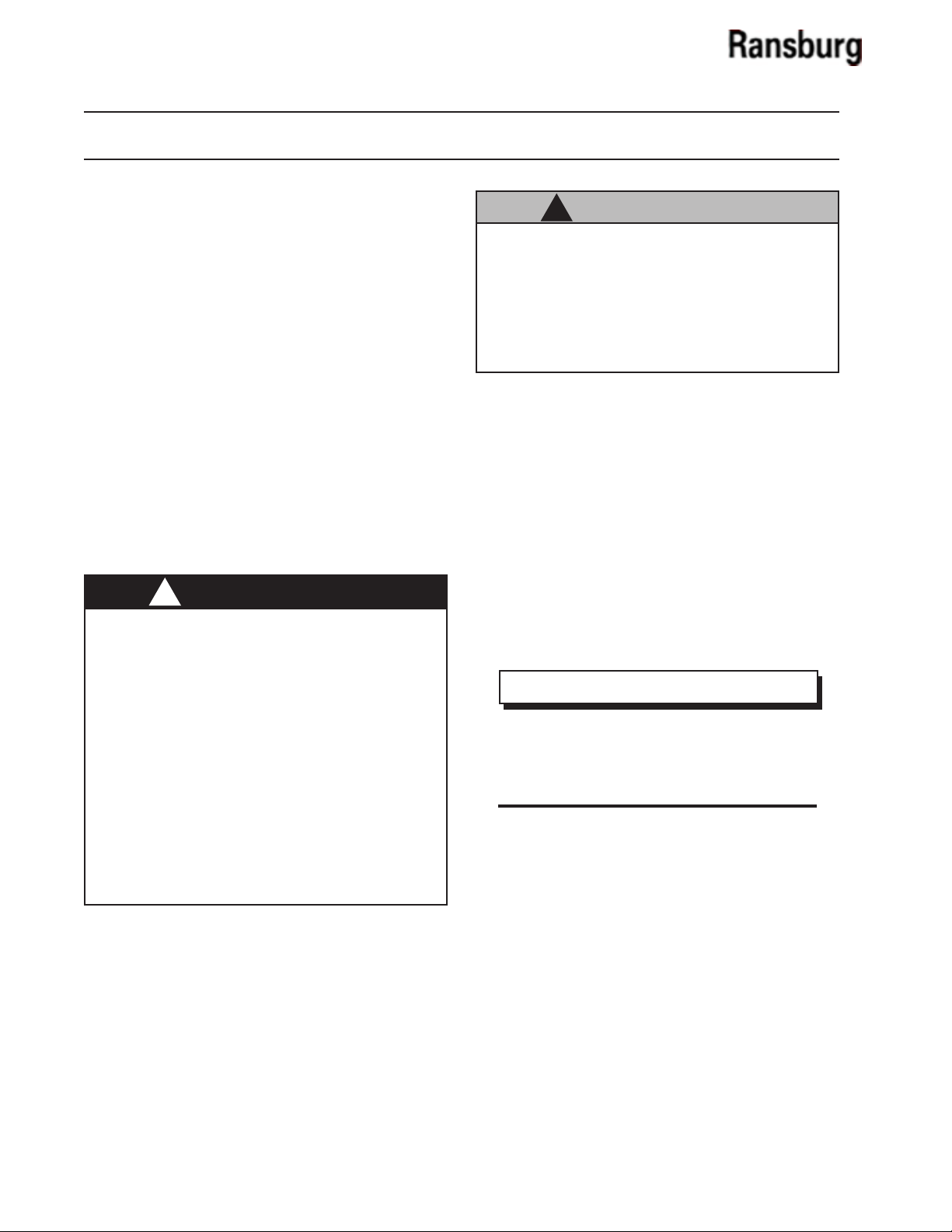

TURBODISK 2 SIGNAL/PORT IDENTIFICATION TABLE

(Figure 3b)

Turbodisk 2 - Installation

Designation as Marked

on Bulkhead

F.O

HV

P1D

P1DL

R1H

R1L

P1S

P1R

P1T

P2D

P2DL

R2H

R2L

P2S

P2R

Fiber Optic Cable

High Voltage Cable

Paint #1 Dump

Paint #1 Dump Line

Regulator #1 High

Regulator #1 Low

Paint #1 Supply Line

Paint #1 Return Line

Paint #1 Trigger

Paint #2 Dump

Paint #2 Dump Line

Regulator #2 High

Regulator #2 Low

Paint #2 Supply Line

Paint #2 Return Line

Description

Tubing Color

Natural

Natural

Red

Natural

Orange

Yellow

Natural

Natural

Green

Black

Natural

Silver

Blue

Natural

Natural

P2T

S1.IN

S2.IN

T.A1

T.A2

Paint #2 Trigger

Solvent #1 Supply

Solvent #2 Supply

Turbine Air #1

Turbine Air #2

Figure 3b: Turbodisk 2 Signal/Port Identication Table

Natural

Natural

Natural

Green

Green

LN-9240-02.1

15

Turbodisk 2 - Operation

OPERATION

!

C A U T I O N

> Fluids and lubricants used in this system

must contain NO silicones!

> Do NOT operate the unit without an atomizer

disk! Without a disk, overspeed, resulting in

premature bearing failure, is possible.

> The air supplied to the motor must be dry,

clean and free of oil or moisture. The atmospheric

dew point should be 10oF or less. The air heater

used should be adjusted only high enough to

prevent condensation from forming on the motor

housing or at the exhaust port.

W A R N I N G

!

> Operators must be fully trained in safe

operation of electrostatic equipment. Operators

must read all instructions and safety precautions

prior to using this equipment (See NFPA 33,

Chapter 16).

As with any spray nishing system, operation of the

Turbodisk 2 involves properly setting the operating

parameters to obtain the best nish quality for the

coating material being sprayed, while maintaining

correct operation and reliability of the equipment

used. Adjustments to operating parameters,

which cover spraying, cleaning and on/o control,

include:

• Fluid Type

• Fluid Flow Rate

• Turbine Speed

• Electrostatic Voltage

• Target Distance

COATING MATERIALS

The Turbodisk 2 can be used with a broad range

of coating material conductivities. However, with

waterborne paints, it may be necessary to isolate the

paint supply from ground.

W A R N I N G

!

> Isolated uid supplies using either waterborne

or highly conductive solvent base coatings can

produce hazardous high voltage discharges

which can cause res or injury to personnel.

FLUID FLOW CONTROL

-REFER TO FIGURES 19-22

Fluid flow control is dependent on the valve

conguration of the Turbodisk 2. If the Turbodisk 2

is congured with no valves or a 3-way valve, uid

ow is controlled externally at the paint source. If the

Turbodisk 2 is equipped with a regulator, uid ow

can be controlled via the air pilot signal. The high

ow and low ow regulators each have procedures

on how to control and deliver consistent uid ows.

For more information on controlling the uid delivery

using regulators, refer to that specic manual which

is included with the system.

To check uid ow rates, the disk must be removed.

See the maintenance section for removal procedure.

The uid can then be manually triggered to measure

actual ow in a graduated beaker over a specied

time period.

W A R N I N G

!

> Danger of shock and/or personal injury can

occur. Proper grounding procedures, which are

outlined in the Ransburg safety bulletins, must

be followed. Personnel must never work near or

perform work on the turbine when the turbine

is spinning or when high voltage is on.

16

LN-9240-02.1

FLUID VALVE CONTROL

Trigger and Dump

-REFER TO FIGURES 4 & 25

Turbodisk 2 - Operation

The uid valves in the Turbodisk 2 are actuated by an

air signal. The air pressure must exceed 70 psi to assure

proper actuation of the valve. Applying air to the valve

actuator turns on the uid ow for that valve.

The trigger valve controls the paint ow to the disk.

When actuated, paint ows through the valve to

the uid tube. The disk should be spinning at a RPM

speed that is fast enough, (that when uid is turned

on) to enable the uid to ow through the disk paint

passage holes and be atomized.

The dump valve controls the paint ow through the

dump line. When actuated, paint ow is directed to the

dump return line. This provides a method of rapidly

removing paint from the incoming line for cleaning

and/or color change. Normally, the dump valve is not

actuated at the same time as the paint trigger valve

since the trigger valve is intended to cause the uid

ow to the disk at the prescribed input pressure.

FLUID & AIR PRESSURE

REQUIREMENTS

-REFER TO FIGURE 4

Fluid and air pressure requirements are dependent

on the uid trigger valve conguration.

No Valves

78718-01 thru -10

Air Pilot Fluid

Regulator

Air Inlet Trig/

Dump Valve

Fluid Inlet

Pressure

Solvent Inlet

Note: Trigger/dump valves (CCV-403-SS) are rated to 300 psi maximum inlet uid pressure but are

limited to the lower pressure limit of the uid regulators.

------------------

------------------

------------------

------------------

Figure 4: Turbodisk 2 Fluid & Air Pressure Requirements

3-Way ON/OFF

(18283)

78718-11 thru -20

------------------

120 psi max.

300 psi max.

30-60 psi max.

Trigger/Dump

w/High Flow

(70171-04)

Regulator

78718-21 thru -30

100 psi max.

70-100 psi

80-100 psi max.

30-60 psi max.

Trigger/Dump

w/Low Flow

DR-1 (74151)

Regulator

78718-31 thru -xx

100 psi

70-100 psi

80-100 psi max.

30-60 psi max.

LN-9240-02.1

17

Turbodisk 2 - Operation

TURBINE SPEED

Turbine speed is determined by the drive air pressure

at the rotary atomizer and uid ow rate.

Turbine speed can be closed loop controlled using

the ber optic speed transmitter mounted at the back

of the turbine rotator assembly as a speed input to

remote speed controls such as the PulseTrack.

NOTE

> The disk rotational speed determines

the quality of atomization and can be varied

for dierent ow rates and viscosities. For

optimum transfer eciency and spray pattern

control, the disk rotational speed should be

set at the minimum required speed to achieve

proper atomization. Excessive speed reduces

transfer eciency!

W A R N I N G

!

> Do not exceed the maximum rated speed of

40,000 RPM for the 6 inch conical disk and 27,000

RPM for the 6 inch uni-disk.

Atomizers

-REFER TO FIGURE 5

W A R N I N G

!

> Never operate any disk atomizer in excess of

it's maximum rated speed ("K" number) as listed

in the service manual. Excessive speed may cause

the disk to disintegrate, causing serious damage

and/or injury.

All atomizers manufactured after April 6, 1982, bear

a “K” number. That number indicates the maximum

safe rotation speed for that series in tens of thousands.

For example:

9K = 9,000 RPM maximum safe speed,

40K = 40,000 RPM, etc.

If you have an atomizer that does not have a “K”

number, contact your Ransburg representative for

its maximum safe operating speed.

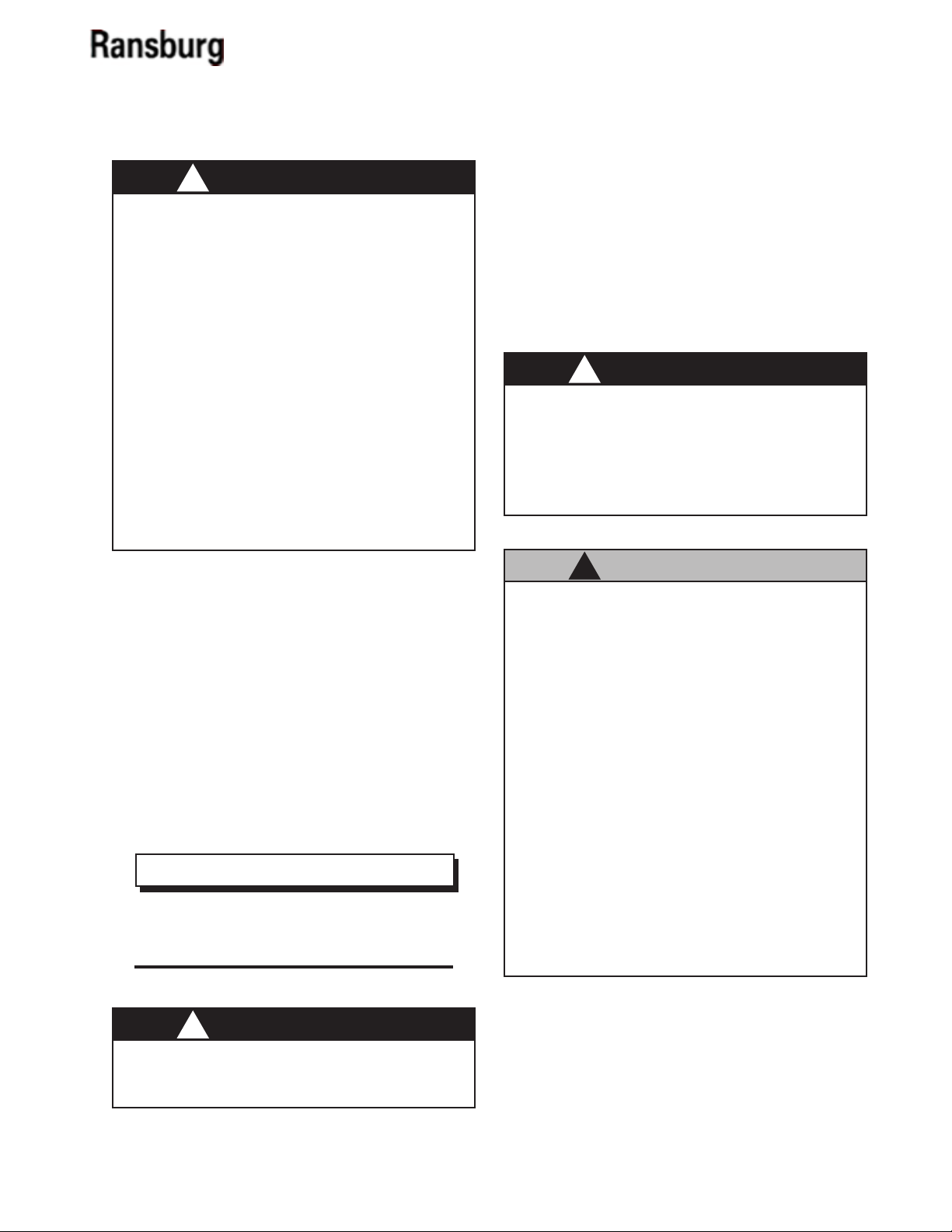

TYPICAL MAXIMUM SAFE OPERATING SPEEDS

Atomizer Disk

6" Uni-Disk

8" Uni-Disk

10" Uni-Disk

12" Uni-Disk

6" Conical

9" Conical

12" Conical

Figure 5: Typical Maximum Safe Operating Speeds

18

Part Number

19830-06

19830-08

19830-10

19830-12

20485-62

20485-92

20485-12x

Max. RPM

27,000

23,000

15,000

15,000

40,000

25,000

20,000

LN-9240-02.1

Turbodisk 2 - Operation

ELECTROSTATIC VOLTAGE

In the system, the high voltage is supplied to the

Turbodisk 2 by either the MicroPak Industrial power

supply system or Voltage Master series power

supplies.

The MicroPak Indus trial power supply uses

proven high voltage generator technology that

is microprocessor controlled for diagnostics and

communication. The controller is packaged in

standard rack mounted Eurocard format for easy

access and system integration.

The Voltage Master power supplies are general

purpose heavy duty power supplies with years of

proven reliability. They have variable voltage control,

many safety features, and remote analog voltage

control capabilities.

NOTES:

TARGET DISTANCE

The distance between the Turbodisk 2 and the target

will aect the nish quality, penetration and eciency.

Closer distances give wetter nishes and greater

eciency, while greater distances give drier nishes.

The recommended normal disk edge to target range

is 12 inches minimum for optimum performance.

LN-9240-02.1

19

Turbodisk 2 - Maintenance

MAINTENANCE

GENERAL

Verify daily that the operating parameters have

not varied dramatically. A sudden change or even

a gradual decay in performance could be early

indications of component failure.

No rmal ma intenance procedures should be

established and recorded at the initial start-up. All

maintenance schedules are subject to variation

based on use. Periodically review these maintenance

schedules as equipment ages and needs change.

CLEANING PROCEDURES

W A R N I N G

!

> Electrical shock and re hazards can exist

during maintenance. The power supply must be

turned o before entering the spray area. Spray

booth fans should remain on while cleaning

with solvents.

> Never touch the disk atomizer while it is

spinning. The edge of the disk can easily cut into

human skin, gloves or other materials. Be sure the

disk atomizer has completely stopped spinning

before attempting to touch it. Approximate time

for the disk to stop spinning after turning o the

drive air is about three minutes.

!

> Do not immerse the Turbodisk 2 assembly

in solvent or other liquids. Turbine components

will be damaged.

> Do not soak the disk in solvent longer than

24 hours.

C A U T I O N

Internal Fluid Path Cleaning

With the high voltage turned o and the disk spinning,

ush cleaning solvent through the incoming paint

line or through the solvent inlet line. If it is desired to

clean just the face of the disk o, ush solvent through

the solvent inlet. If a color change is required, ush

the entire system. The spinning disk will atomize the

solvent and clean out the disk passages. If equipped,

trigger the dump valve to catch the wasted paint from

the incoming line, then ush the disk with solvent

after closing the dump valve.

NOTE

> Solvent ushing of the system (except

during color change) should be done with

the disk dismounted and with waste solvent

collected in a grounded container.

In addition to the above Warning, which relates to

potential safety hazards, the following information

must be observed to prevent damage to the

equipment.

20

LN-9240-02.1

Turbodisk 2 - Maintenance

External Atomizer Surface Cleaning

W A R N I N G

!

> To reduce the risk of re or explosion,

OSHA and NFPA 33 require that solvents used

for exterior cleaning, including disk cleaning

and soaking, be nonammable (ash points

higher than 100oF/37.8oC). Since electrostatic

equipment is involved, these solvents should

also be nonpolar. Examples of nonammable,

nonpolar solvents for cleaning are: Amyl acetate,

methyl amyl acetate, high ash naphtha and

mineral spirits.

> Do not use conductive solvents such as MEK to

clean the external surfaces of the Turbodisk 2.

> Never lower the Turbodisk 2 assembly into a

drum for ushing or color changing.

Clean the disk by soaking in an appropriate solvent

to loosen paint residue. Do not soak for more than a

24 hour period. Use a soft cloth to remove the paint

from the surface and a soft bristle brush to remove

paint from the well area. The splash plate may need

to be removed to clean the paint well. The screws

must be retorqued to 24 lb•in after cleaning.

Reinstall the disk and torque the mounting nut to

50-60 lb•in.

W A R N I N G

!

> Do not attempt to clean the disk edge while

it is rotating. Do not attempt to slow down or

stop the disk by holding a rag or a gloved hand

against the edge. This could cause physical harm

and/or damage to the disk.

!

C A U T I O N

Disk Cleaning

Normally, the internal cleaning instructions will

suce to clean the disk. If ushing the disk does not

remove all the residue, the disk may be removed for

hand cleaning. Unscrew mounting nut and remove

the disk by using the supplied disk puller.

Inspection of the disk is required to determine if

wear to the serrated edge or damage has occurred.

Wear can cause a reduction in transfer eciency and

excessive paint wrap on the atomizer fairing.

NOTE

> The turbine shaft must be held with a

7/16” open end wrench while using the disk

puller.

W A R N I N G

!

> Do not use abrasive materials which will

scratch or damage the disk. Cleaning pads such

as Scotch-Brite® should not be used.

> Using an atomizer disk with paint buildup may

cause an imbalance. This may result in bearing

damage and turbine failure. This condition

may also stress the disk when operating at high

speeds.

> Before reinstalling the disk onto the shaft,

check and clean the tapered mating surface for

paint residue.

> Care must be taken when mounting the disk

assembly to the motor shaft. The mounting nut

should turn freely for several turns until it fully

bottoms on the disk assembly.

> Do not hold disk edge during removal. This

could result in injury.

LN-9240-02.1

21

Turbodisk 2 - Maintenance

VIBRATION NOISE

If the Turbodisk 2 is vibrating or making an unusual

loud noise, it may mean that there is an unbalanced

situation or a bearing failure. The disk could have

dried paint or could be damaged. This situation

should be corrected immediately. Do not continue

to operate a noisy turbine.

W A R N I N G

!

> If a disk has been mishandled or there appears

to be damage on the face, DO NOT USE. Serious

injury can result from rotating a defective disk. If

there is a concern about the condition of a disk,

please return it to Ransburg for evaluation.

TURBINE REPAIR & REBUILD

PREVENTIVE MAINTENANCE

Before any shutdown or maintenance, the uid system

should be thoroughly ushed. All cleaning should

be done with a minimum of the appropriate clean

solvent and clean, soft, lint free rags or soft brushes

where indicated.

W A R N I N G

!

> Do not stop disk rotation by using a rag or

gloved hand.

> Make sure high voltage is off before

approaching applicator.

> Follow proper grounding procedures.

!

C A U T I O N

-REFER TO FIGURE 27

Turbine eld repair or rebuild only after factory

warranty expires. Any attempt to disassemble turbine

during warranty period will void the warranty.

VALVES & REGULATORS

-REFER TO FIGURES 19, 20, 21, & 22

No maintenance is normally required on the valves

or regulator other than ushing with solvent daily.

Visual inspections should be made on the valves

and regulator on a weekly basis. Should the valve

or regulator not function properly, refer to the

individual manuals for troubleshooting and repair

procedures.

> Because of the hazard of bearing penetration,

solvents should be used sparingly. They should

never be hosed directly onto the atomizer, motor

housing or ber optic juncture.

Daily Maintenance

W A R N I N G

!

> Personnel working on applicators MUST

always be sure that the high voltage is o, the

uid system is ushed and o, the rotator has

stopped, and that the grounding hook has been

properly secured to the motor housing.

• Clean the atomizer disk, motor housing, fairing,

and as needed, the peripheral equipment with

nonpolar high ash point solvents.

22

LN-9240-02.1

Turbodisk 2 - Maintenance

• To prevent solvent penetration beyond the slinger, a

minimal air pressure of 5 to 10 psi should be applied

to the motor in order to maintain a positive pressure.

The motor should be run at operating speed for

several minutes after cleaning to keep any solvent

that has accumulated at the seals from penetrating

into the motor housing.

• Inspect the disk edge and face. If damage exists, DO

NOT USE. Return it to Ransburg for evaluation.

• Check the uid feed tube to make sure it is not

rubbing the disk.

Weekly Maintenance

• Follow the normal daily maintenance schedule,

then:

• Monitor rotational speed at the control and verify

it is within 5% of target speed.

• Monitor high voltage output indicated on the power

supply display. Verify with high voltage probe and

meter.

• Remove fairing and clean all internal components:

valves, regulators, and tubing. Check tubing for

evidence of pin-holes, kinks, and abrasions.

DISASSEMBLY PROCEDURES

Prior to disassembly, verify the following:

• The atomizer disk, valves and regulator have been

ushed with solvent and purged dry with air.

• The disk has stopped rotating.

• The air supply to the trigger valves and regulator

have been turned o.

• The uid and solvent supply have been turned o

and the pressure has been relieved.

• The high voltage has been turned o and the motor

housing grounded.

Turbine Cartridge Exchange

-REFER TO FIGURE 27

Removal

1. Remove disk mounting nut by holding the

rotator shaft above the disk with a 7/16" open

end wrench and unscrewing the mounting

nut with a 3/8-inch wrench.

• If the muer needs to cleaned (item is to be solvent

cleaned) remove it from the motor. Clean and dry

the muer before reinstalling it.

• Check uid ows by removing the disk and manually

triggering the paint valve. Measure the amount of

uid in a graduated beaker over a specic time to

determine ow rate.

• Clean and inspect the disk face. Look for wear, which

can cause poor transfer eciency and excessive

paint wrap on the atomizer fairing. Disk removal,

cleaning and inspection may be done more or less

frequently, depending upon use.

2. Install the Ransburg 19850-00 disk puller into

disk to remove it.

3. Unlatch the four fairing draw latches and

carefully remove lower fairing.

4. The lower uid section of the Turbodisk 2

Applicator, containing the turbine cartridge,

may now be disconnected for continued o

line removal procedures through means of

the "quick disconnect" feature incorporated

into the unit.

W A R N I N G

!

> Handle the disk with caution. The sharp edge

can cut even though it is not rotating.

LN-9240-02.1

23

Turbodisk 2 - Maintenance

With a 5/16-inch wrench, loosen the six

captive retaining screws used to hold the

upper and lower sections together. Note:

As the last screw releases, the lower unit will

drop only enough to allow for the bulkhead

plates to be separated. The two latching

mechanisms on the bulkhead plates will hold

the unit in place until the operator is ready

to move the lower section to a proper work

place.

5. Once the lower uid section is placed in

a stationary condition, the removal of the

cartridge can be continued.

6. Next remove screws holding the uid tube

assembly.

7. With a 7/64-inch wrench, remove six socket

head cap screws, which secures the turbine

cartridge to the motor housing.

8. Using a 1/16-inch wrench, turn each of the

three jack screws, located next to socket head

cap screw, clockwise not more than one half

turn at a time in sequence to separate the

motor from the housing.

Installation

Always check the inside of the motor housing and

clean, if required, with a minimum amount of an

appropriate cleaning solvent and a soft cloth.

1. Using a 1/16-inch wrench, retract the three

jack screws.

!

C A U T I O N

> Lightly lubricate o-rings with petroleum

jelly before assembly. Fit parts with o-rings very

carefully. They must not be allowed to distort,

unseat or break.

2. With o-rings in place on the nozzle plate and

housing, insert the turbine cartridge into

motor housing.

3. Secure the rotator assembly to the housing

with six socket head cap screws. Tighten

the screws in sequence until the cartridge

is fully engaged into the housing to prevent

misalignment and possible damage. Torque

to 10 lb•in.

!

C A U T I O N

> Failure to perform this step correctly may

result in misalignment and possible damage.

> Use caution in removing cartridge to prevent

it from falling out of the housing.

4. To avoid losing the jack screws during normal

operation, torque to 2-3 lb•in.

Turbine Cartridge Service

This cartridge is a precision instrument and should

be handled with care. The bearings are preloaded

to 30 pounds and dynamically balanced to 0.01

grams•in or better.

NOTE

> Bearings used in this cartridge contain

special grease that is available exclusively to

Ransburg. The purchase of replacement bearings from sources other than Ransburg is not

recommended.

Turbine eld repair or rebuild ONLY after factory

warranty expires. Any attempt to disassemble turbine

during the warranty period will void the warranty.

24

LN-9240-02.1

Turbodisk 2 - Maintenance

Disassembly

-REFER TO FIGURE 28

1. After turbine cartridge has been removed

from housing, secure the rotating assembly

by inserting a 1/4-inch wrench, which may

be secured in a vise for this procedure, in

the hex socket at the rear end of shaft and

remove slinger with a spanner wrench.

2. With the 1/4-inch wrench still inserted in the

hex socket at the rear end of shaft, remove hex

nut using a 15/16-inch box end wrench.

3. Secure a wheel puller tool to turbine rotator.

Rotate the center screw of the tool until the

rotor is free of the shaft. Remove key.

4. Using a 5/64-inch wrench, remove the six at

head socket screws which secure bearing

retainer to bearing housing. Remove the

retainer.

5. Support bearing housing, front face down,

on two parallel supports on the arbor press

table. Press shaft from the housing. Remove

spacer from the shaft.

!

C A U T I O N

> Never use a tool that is harder than the part

it is used on.

8. With a 5/64-inch wrench, remove the six

at head socket screws from nozzle plate.

Remove the nozzle plate.

9. Remove all o-rings.

Inspection and Preparation

!

C A U T I O N

> Failure to observe the following cautions will

result in diminished performance and premature

motor failure.

• Never use any silicone compound in this system!

• Never use any lubrication on the bearings!

• Never use any solvent on the bearings!

!

C A U T I O N

> The space between the supports must

be greater than the outside diameter of front

bearing.

6. On the arbor press table, support the

assembled shaft/bearing, front end down, on

the two parallel supports. With the bearing

faces resting on the supports, press the shaft

free of the bearing.

7. Remove rear bearing, spring, spring retainer

(wave spring washer, and shims in some older

models instead of spring and spring retainer),

and bearing spacer from bearing housing. It

may be necessary to press the bearing from

the housing using a wood or plastic rod or

tool handle inserted through the bore from

the front.

• Never exert force on one race of a bearing assembly

that may be transmitted to the other race through

the bearings! Force and resistance must always be

on the same race in order to prevent damage.

• Do not enlarge the nozzle passages during cleaning,

as it will eect performance.

• Always observe the specied torque in tightening

fasteners.

• Clean all parts thoroughly with an appropriate,

clean solvent. Inspect them for wear or damage

and replace as required.

• Check all ow passages for obstruction, particularly

the nozzle plate. Clear as required.

• Discard all bearings and o-rings and replace with

new. Lightly lubricate o-rings with petroleum jelly

before assembly. Fit parts with o-rings very carefully.

They must not be allowed to distort, unseat, or

break.

LN-9240-02.1

25

Turbodisk 2 - Maintenance

Assembly

1. With o-ring in its groove on the rear face of

bearing housing, secure nozzle plate in place

with the six screws.

NOTE

> Torque the screws to 10 lb•in. Do NOT

lubricate o-ring.

2. Using a press tool device on the arbor press

table, place front bearing over the rear end

of shaft. Insert the shaft into the press tool

rear end down and press the shaft through

the bearing until the bearing seats against

the shoulder on the shaft.

3. Place bearing housing on the arbor press

table, front face up, resting on two parallel

supports.

4. Insert the bearing/shaft into the bore of the

bearing housing. With o-ring in place against

it, place bearing retainer over the shaft so

that it rests on the bearing. Place the press

tool, large end down, over the shaft so that it

rests against the bearing retainer. Press until

the bearing seats in the housing.

5. Remove the assembly from the press and

secure the retainer with the six screws.

8. With the housing assembly, front face down,

resting on two parallel supports on the arbor

table, place the rear bearing over shaft. Be

sure that o-ring is in place in its groove in

the housing bore. Place the small end of

the press tool over the end of the shaft so

that it rests against the inner face of the

bearing. CAREFULLY press the bearing onto

the shaft.

!

C A U T I O N

> The same number of shims that were removed

from the assembly MUST be placed into it or the

bearing preload will NOT be correct! Each unit

is individually preloaded. The number of shims

used for this purpose may vary from unit to unit.

It is therefore necessary that the same number

of shims be installed in a repaired unit as were

removed. If more than one unit is serviced at one

time, be SURE that the shims removed from each

unit are returned to that same unit!

9. With the assembly still on the press table,

place the turbine rotor, anged side up, over

the shaft. Insert key into the key slot in the

shaft, align it with the key slot in the rotor, and

press the rotor down until the key is engaged.

With the small end of the press tool against

the rotor ange, press it onto the shaft until

it seats.

NOTE

> Torque the screws to 10 lb•in.

6. From the rear of the assembly, place bearing

spacer over the shaft and into the bore so

that it seats against the front bearing.

7. From the rear of the assembly, place spring

and spring retainer over the shaft and into the

bore over the bearing spacer. In some older

models, shims and a wave spring washer are

used in place of the spring and retainer. In

those models, place shims and wave spring

washer over the shaft and into the bore.

26

!

C A U T I O N

> The outer face of the bearing should be a

slip t into the bore of the housing. Be careful

that the bearing does not hang up on the outer

edge of the bore during the pressing.

10. Place hex nut and the 15/16-inch box end

wrench on the rear end of the shaft. Secure

the rotating assembly by inserting a 1/4-inch

wrench, which may be secured in a vise for

this procedure, in the hex socket at the rear

end of the shaft. Secure the nut using the

box end wrench.

LN-9240-02.1

Turbodisk 2 - Maintenance

!

> If the key is not secure or is missing, the unit

will malfunction!

11. With the shaft still secured from rotation,

screw slinger onto the front end of the shaft

and secure it using a spanner wrench.

C A U T I O N

NOTE

> Torque the nut to 350 lb•in.

NOTES:

LN-9240-02.1

27

Turbodisk 2 - Maintenance

TROUBLESHOOTING GUIDE

General Problem

Fluctuating Pattern

Light Coverage on

Some Parts

Poor Transfer Eciency

Low Current Readings

High Current Readings /

Power Supply Overloads

Cause

1. Not enough back

pressure on regulator.

1. Part hangers, hooks, are

not clean.

1. Low voltage.

2. Disk RPM to high.

3. Booth ow to high.

4. Disk edge to part

distance to great.

1. Dirty H.V. contacts.

1. Target distance to close.

2. Conductive paint.

Solution

1. See regulator manual for diagnosis.

1 a. Clean hangers.

b. Check ground continuity. (Must be less

than 1 Megohm.)

1. Check disk voltage with H.V. probe.

2. Slow disk speed.

3. Reduce booth air ow.

4. Decrease conveyor loop diameter.

1. Clean and/or replace.

1. Check target distance. Ideal target distance is

12 inches minimum.

2. Solvent base paint conductivity should be

between .05 and 20 megohms on Ransburg

paint test meter.

Low Voltage

3. Fairing dirty.

4. H.V. cable breakdown.

5. Fluid tube pinholed to

ground on conductive

paint systems.

6. Isolation mounting rod

dirty or carbon tracked.

1. Power Supply

2. Faulty H.V. switch or

junction tank.

3. H.V. cable.

3. Clean with nonpolar solvent.

4. Replace cable.

5. Check tubing routing for areas where uid tube

comes near a ground.

6. Clean with nonpolar solvent or replace.

Use following procedure to isolate problem:

- Verify power supply output. Refer to power

supply manual for procedure.

- Remove the fairing and measure input voltage

to the rotator assembly by removing the H.V.

cable from the connector tting and inserting

it into the H.V. probe. If voltage is low, replace

H.V. cable with a known good one and retest.

- If voltage is still low, check for bad connections

in the H.V. Junction or Switch Tank. Refer to

procedures in the proper manual.

- Reinstall the H.V. cable. Check voltage at the

rotator housing.

28

Figure 6: Troubleshooting Guide

LN-9240-02.1

NOTES:

Turbodisk 2 - Maintenance

LN-9240-02.1

29

Turbodisk 2 - Maintenance

30

Figure 7: Typical No Valve Application Schematic - Dual Fluid Supply Option

(Reference Figure 12)

LN-9240-02.1

Turbodisk 2 - Maintenance

LN-9240-02.1

Figure 8: Typical 3-Way Valve Application Schematic - Dual Fluid Supply Option

(Reference Figure 13)

31

Turbodisk 2 - Maintenance

Figure 9: Typical Trigger and Dump Valve Application with (High Flow) Fluid Regulator Schematic - Dual Fluid Supply

Option (Reference Figure 14)

32

LN-9240-02.1

Turbodisk 2 - Maintenance

Figure 10: Typical Trigger and Dump Valve Application with DR-1 Fluid Regulator Schematic - Dual Fluid Supply with

Recirculating Option (Reference Figure 15)

LN-9240-02.1

33

Turbodisk 2 - Parts Identication

PARTS IDENTIFICATION

78715 TURBODISK 2 ASSEMBLY MODEL IDENTIFICATION

Turbodisk 2 Assemblies are available with the various options as follows:

Model No. 78715 - xx xx

DR-1 Fluid Regulator Ratio Option (See Table B)

(Dash # required only when applicable)

Upper & Lower Turbodisk 2 Sections, Fluid Control Parts, and Air

Motor (See Table A)

4

5

Figure 11: Turbodisk 2 Assembly Standard Model Identication

TABLE "A" (Figure 11)

Dash #

01

02

03

04

05

06

07

08

21

22

23

Basic

Turbodisk 2

Assy

78718-01

78718-02

78718-03

78718-04

78718-01

78718-02

78718-03

78718-04

78718-11

78718-12

78718-13

Turbine

Air Motor

Assy

78175-01

78175-01

78175-01

78175-01

78175-11

78175-11

78175-11

78175-11

78175-01

78175-01

78175-02

Basic Part Number

Air Heater &

Filter/Reg.

Assy

78781-00

78781-00

78781-00

78781-00

78781-00

78781-00

78781-00

78781-00

78781-00

78781-00

78781-00

Disk

Mounting

Nut

3

19836-01

19836-01

19836-01

19836-01

19836-02

19836-02

19836-02

19836-02

19836-01

19836-01

19836-01

Description

No valves, Down Feed CW, Single Fluid System, 3/8 ID Tubing

Option

No valves, Down Feed CW, Single Fluid System, 1/4 ID Tubing

Option

No valves, Down Feed CW, Dual Fluid System, 3/8 ID Tubing

Option

No valves, Down Feed CW, Dual Fluid System, 1/4 ID Tubing

Option

No valves, Down Feed CCW, Single Fluid System, 3/8 ID Tubing

Option

No valves, Down Feed CCW, Single Fluid System, 1/4 ID Tubing

Option

No valves, Down Feed CCW, Dual Fluid System, 3/8 ID Tubing

Option

No valves, Down Feed CCW, Dual Fluid System, 1/4 ID Tubing

Option

3-Way On/O, Down Feed CW, Single Fluid System, 3/8 ID Tubing Option

3-Way On/O, Down Feed CW, Single Fluid System, 1/4 ID Tubing Option

3-Way On/O, Down Feed CW, Dual Fluid System, 3/8 ID Tubing Option

* See "Parts List Bullet Denition Table" on page 37.

34

LN-9240-02.1

TABLE "A" (Figure 11) - (Continued)

Turbodisk 2 - Parts Identication

Disk

Mounting

Nut 3

19836-01

Description

3-Way On/O, Down Feed CW, Dual Fluid System, 1/4 ID Tub-

Dash #

24

Basic

Turbodisk 2

Assy

78718-14

Turbine

Air Motor

Assy

78175-02

Air Heater &

Filter/Reg.

Assy

78781-00

ing Option

25

78718-11

78175-11

78781-00

19836-02

3-Way On/O, Down Feed CCW, Single Fluid System, 3/8 ID

Tubing Option

26

78718-12

78175-11

78781-00

19836-02

3-Way On/O, Down Feed CCW, Single Fluid System, 1/4 ID

Tubing Option

27

78718-13

78175-12

78781-00

19836-02

3-Way On/O, Down Feed CCW, Dual Fluid System, 3/8 ID Tubing Option

28

78718-14

78175-12

78781-00

19836-02

3-Way On/O, Down Feed CCW, Dual Fluid System, 1/4 ID Tubing Option

1

41

78718-21

78175-02

78781-00

19836-01

Trigger & Dump Valve w/Fluid Reg. (High Flow), Down Feed

CW, Single Fluid System, 3/8 ID Tubing Option

1

42

78718-22

78175-02

78781-00

19836-01

Trigger & Dump Valve w/Fluid Reg. (High Flow), Down Feed

CW, Single Fluid System, 1/4 ID Tubing Option

1

43

78718-23

78175-02

78781-00

19836-01

Trigger & Dump Valve w/Fluid Reg. (High Flow), Down Feed

CW, Dual Fluid System, 3/8 ID Tubing Option

1

44

78718-24

78175-02

78781-00

19836-01

Trigger & Dump Valve w/Fluid Reg. (High Flow), Down Feed

CW, Dual Fluid System, 1/4 ID Tubing Option

1

45

78718-21

78175-12

78781-00

19836-02

Trigger & Dump Valve w/Fluid Reg. (High Flow), Down Feed

CCW, Single Fluid System, 3/8 ID Tubing Option

1

46

78718-22

78175-12

78781-00

19836-02

Trigger & Dump Valve w/Fluid Reg. (High Flow), Down Feed

CCW, Single Fluid System, 1/4 ID Tubing Option

1

47

78718-23

78175-12

78781-00

19836-02

Trigger & Dump Valve w/Fluid Reg. (High Flow), Down Feed

CCW, Dual Fluid System, 3/8 ID Tubing Option

1

48

78718-24

78175-12

78781-00

19836-02

Trigger & Dump Valve w/Fluid Reg. (High Flow), Down Feed

CCW, Dual Fluid System, 1/4 ID Tubing Option

2

61

78718-31

78175-02

78781-00

19836-01

Trigger & Dump Valve w/DR-1 Fluid Reg. (Low Flow), Down

Feed CW, Single Fluid System, Non-Circulating Fluid Return,

3/8 ID Tubing Option

2

62

78718-32

78175-02

78781-00

19836-01

Trigger & Dump Valve w/DR-1 Fluid Reg. (Low Flow), Down

Feed CW, Single Fluid System, Non-Circulating Fluid Return,

1/4 ID Tubing Option

2

63

78718-33

78175-02

78781-00

19836-01

Trigger & Dump Valve w/DR-1 Fluid Reg. (Low Flow), Down

Feed CW, Dual Fluid System, Non-Circulating Fluid Return, 3/8

ID Tubing Option

2

64

78718-34

78175-02

78781-00

19836-01

Trigger & Dump Valve w/DR-1 Fluid Reg. (Low Flow), Down

Feed CW, Dual Fluid System, Non-Circulating Fluid Return, 1/4

ID Tubing Option

2

65

78718-35

78175-02

78781-00

19836-01

Trigger & Dump Valve w/DR-1 Fluid Reg. (Low Flow), Down

Feed CW, Single Fluid System, Recirculating Fluid Return, 3/8 ID

Tubing Option

2

66

78718-36

78175-02

78781-00

19836-01

Trigger & Dump Valve w/DR-1 Fluid Reg. (Low Flow), Down

Feed CW, Single Fluid System, Recirculating Fluid Return, 1/4 ID

Tubing Option

2

67

78718-37

78175-02

78781-00

19836-01

Trigger & Dump Valve w/DR-1 Fluid Reg. (Low Flow), Down

Feed CW, Dual Fluid System, Recirculating Fluid Return, 3/8 ID

Tubing Option

* See "Parts List Bullet Denition Table" on page 37.

LN-9240-02.1

35

Turbodisk 2 - Parts Identication

TABLE "A" (Figure 11) - (Continued)

Basic

Dash #

Turbodisk 2

Assy

2

68

78718-38

Turbine

Air Motor

Assy

78175-02

Air Heater &

Filter/Reg.

Assy

78781-00

Disk

Mounting

3

Nut

19836-01

Description

Trigger & Dump Valve w/DR-1 Fluid Reg. (Low Flow), Down

Feed CW, Dual Fluid System, Recirculating Fluid Return, 1/4 ID

Tubing Option

2

69

78718-31

78175-12

78781-00

19836-02

Trigger & Dump Valve w/DR-1 Fluid Reg. (Low Flow), Down

Feed CCW, Single Fluid System, Non-Circulating Fluid Return,

3/8 ID Tubing Option

2

70

78718-32

78175-12