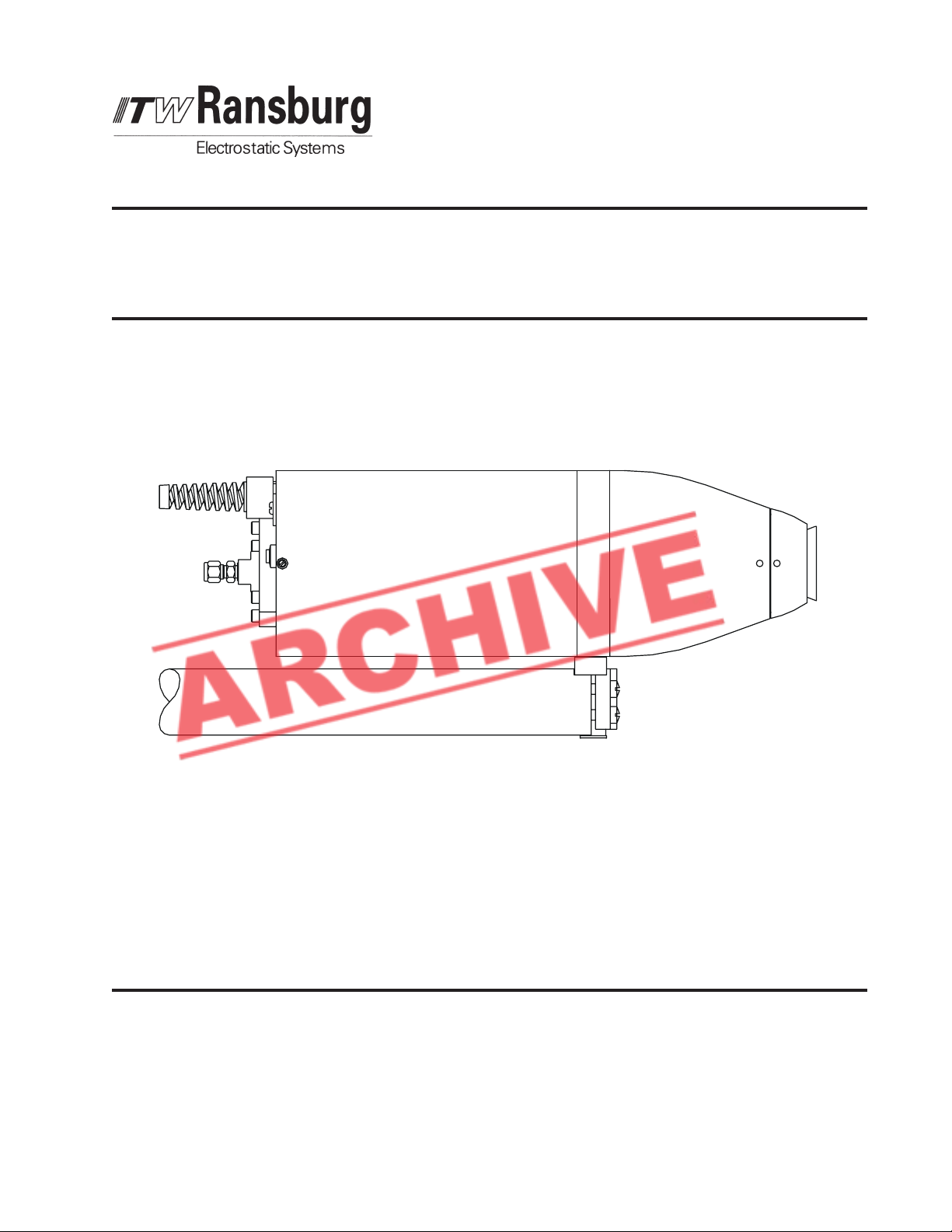

Ransburg 78101 User Manual

AEROBELLAEROBELL

AEROBELL

AEROBELLAEROBELL

®®

®

®®

M M

M

M M

SERVICE MANUAL

LN-9237-00.1LN-9237-00.1

LN-9237-00.1

LN-9237-00.1LN-9237-00.1

(Replaces LN-9237-00)

ROTROT

ROT

ROTROT

ARAR

AR

ARAR

YY

Y

YY

A A

A

A A

TT

OMIZEROMIZER

T

OMIZER

TT

OMIZEROMIZER

MODEL: 78101MODEL: 78101

MODEL: 78101

MODEL: 78101MODEL: 78101

IMPORIMPOR

IMPOR

IMPORIMPOR

fully read SAFETY PRECAUTIONS, starting onfully read SAFETY PRECAUTIONS, starting on

fully read SAFETY PRECAUTIONS, starting on

fully read SAFETY PRECAUTIONS, starting onfully read SAFETY PRECAUTIONS, starting on

page 1, and all instructions in this manual. Keeppage 1, and all instructions in this manual. Keep

page 1, and all instructions in this manual. Keep

page 1, and all instructions in this manual. Keeppage 1, and all instructions in this manual. Keep

this Service Manual for future reference.this Service Manual for future reference.

this Service Manual for future reference.

this Service Manual for future reference.this Service Manual for future reference.

TT

ANTANT

T

ANT

TT

ANTANT

: Before using this equipment, care-: Before using this equipment, care-

: Before using this equipment, care-

: Before using this equipment, care-: Before using this equipment, care-

Service Manual Price: $50.00 (U.S.)Service Manual Price: $50.00 (U.S.)

Service Manual Price: $50.00 (U.S.)

Service Manual Price: $50.00 (U.S.)Service Manual Price: $50.00 (U.S.)

NOTE:NOTE:

NOTE: This manual has been changed from revision

NOTE:NOTE:

Reasons for this change are noted under “Manual Change Summary” inside the back

cover of this manual.

LN-9237-00LN-9237-00

LN-9237-00 to revision

LN-9237-00LN-9237-00

LN-9237-00.1 LN-9237-00.1

LN-9237-00.1.

LN-9237-00.1 LN-9237-00.1

CONTENTSCONTENTS

CONTENTS

CONTENTSCONTENTS

SAFETY:SAFETY:

SAFETY:

SAFETY:SAFETY:

Aerobell M Rotary Atomizer - Contents

PAGEPAGE

PAGE

PAGEPAGE

1-51-5

1-5

1-51-5

SAFETY PRECAUTIONS.........................................................

HAZARDS / SAFEGUARDS.....................................................

INTRODUCTION:INTRODUCTION:

INTRODUCTION:

INTRODUCTION:INTRODUCTION:

FEATURES................................................................................

GENERAL DESCRIPTION.......................................................

SPECIFICATIONS.....................................................................

INSTALLATION:INSTALLATION:

INSTALLATION:

INSTALLATION:INSTALLATION:

AIR FILTER INSTALLATION.....................................................

AIR PRESSURE REQUIREMENTS.........................................

AIR FILTRATION REQUIREMENTS........................................

MOUNTING................................................................................

FLUID CONNECTIONS............................................................

ELECTRICAL CONNECTIONS................................................

SPEED MONITOR CONNECTIONS........................................

INTERLOCKS............................................................................

OPERATION:OPERATION:

OPERATION:

OPERATION:OPERATION:

COATING MATERIALS.............................................................

FLUID FLOW RATE CONTROL...............................................

FLUID VALVE CONTROL.........................................................

TURBINE SPEED......................................................................

BEARING AIR ADJUSTMENT..................................................

SHAPING AIR............................................................................

BRAKE AIR................................................................................

ELECTROSTATIC VOLTAGE..................................................

TARGET DISTANCE.................................................................

1

2

6-96-9

6-9

6-96-9

6

6

8

10-1310-13

10-13

10-1310-13

10

10

11

12

12

12

12

13

14-1914-19

14-19

14-1914-19

14

14

17

17

18

18

18

19

19

MAINTENANCE:MAINTENANCE:

MAINTENANCE:

MAINTENANCE:MAINTENANCE:

CLEANING PROCEDURES.....................................................

VIBRATION NOISE...................................................................

TURBINE REPAIR & REBUILD...............................................

HIGH VOLTAGE CONNECTIONS..........................................

AIR FILTERS / ELEMENT REPLACEMENT............................

VALVES.............................................................................................

GENERAL..................................................................................

PREVENTIVE MAINTENANCE................................................

LOW VOLTAGE TEST..............................................................

DISASSEMBLY PROCEDURES..............................................

TROUBLESHOOTING GUIDE.................................................

LN-9237-00.1

20-3120-31

20-31

20-3120-31

20

22

22

22

22

22

23

23

25

25

29

Aerobell M Rotary Atomizer - Contents

PARTS IDENTIFICATION:PARTS IDENTIFICATION:

PARTS IDENTIFICATION:

PARTS IDENTIFICATION:PARTS IDENTIFICATION:

PAGEPAGE

PAGE

PAGEPAGE

32-4732-47

32-47

32-4732-47

30mm AEROBELL M CROSS SECTION VIEW.......................

57mm AEROBELL M CROSS SECTION VIEW.......................

70mm AEROBELL M CROSS SECTION VIEW.......................

AEROBELL M CROSS SECTION VIEW..................................

AEROBELL M MODEL IDENTIFICATION...............................

AEROBELL M PARTS LIST......................................................

AER4004-02 AIR MANIFOLD ASSEMBLY / PARTS LIST......

FLUID MANIFOLD ASSEMBLY / PARTS LIST........................

WATERBORNE FLUID MANIFOLD ASSEMBLY /

PARTS LIST...............................................................................

RECOMMENDED SPARE PARTS...........................................

SERVICE KITS..........................................................................

AVAILABLE TOOLS..................................................................

WARRANTY POLICIES:WARRANTY POLICIES:

WARRANTY POLICIES:

WARRANTY POLICIES:WARRANTY POLICIES:

LIMITED WARRANTY...............................................................

APPENDIX:APPENDIX:

APPENDIX:

APPENDIX:APPENDIX:

PAINT AND SOLVENT SPECIFICATIONS.............................

VISCOSITY CONVERSION CHART........................................

VOLUMETRIC CONTENT OF HOSE OR TUBE.....................

32

33

34

35

36

38

40

42

44

46

46

46

4848

48

4848

48

49-5249-52

49-52

49-5249-52

49

50

52

LN-9237-00.1

SAFETYSAFETY

SAFETY

SAFETYSAFETY

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

SAFETY PRECAUTIONS

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

Aerobell M Rotary Atomizer - Safety

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

Before operating, maintaining or servicing any

ITW Ransburg electrostatic coating system,

read and understand all of the technical and

safety literature for your ITW Ransburg products. This manual contains information that is

important for you to know and understand. This

information relates to USER SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help

you recognize this information, we use the following symbols. Please pay particular attention

to these sections.

A WARNING! states information to alert you toA WARNING! states information to alert you to

A WARNING! states information to alert you to

A WARNING! states information to alert you toA WARNING! states information to alert you to

a situation that might cause serious injury if in-a situation that might cause serious injury if in-

a situation that might cause serious injury if in-

a situation that might cause serious injury if in-a situation that might cause serious injury if instructions are not followed.structions are not followed.

structions are not followed.

structions are not followed.structions are not followed.

A CAUTION! states information that tells howA CAUTION! states information that tells how

A CAUTION! states information that tells how

A CAUTION! states information that tells howA CAUTION! states information that tells how

to prevent damage to equipment or how toto prevent damage to equipment or how to

to prevent damage to equipment or how to

to prevent damage to equipment or how toto prevent damage to equipment or how to

avoid a situation that might cause minor injury.avoid a situation that might cause minor injury.

avoid a situation that might cause minor injury.

avoid a situation that might cause minor injury.avoid a situation that might cause minor injury.

A NOTE is information relevant to the proce-A NOTE is information relevant to the proce-

A NOTE is information relevant to the proce-

A NOTE is information relevant to the proce-A NOTE is information relevant to the procedure in progress.dure in progress.

dure in progress.

dure in progress.dure in progress.

While this manual lists standard specifications

and service procedures, some minor deviations

may be found between this literature and your

equipment. Differences in local codes and plant

requirements, material delivery requirements,

etc., make such variations inevitable. Compare

this manual with your system installation drawings and appropriate ITW Ransburg equipment

manuals to reconcile such differences.

> The user

with the Safety Section in this manual and

the ITW Ransburg safety literature therein

identified.

> This manual

oughly understood by

operate, clean or maintain this equipment!

Special care should be taken to ensure that

WARNINGSWARNINGS

the

WARNINGS and safety requirements

WARNINGSWARNINGS

for operating and servicing the equipment

are followed. The user should be aware of

and adhere to

codes and ordinances as well as

SAFETY STANDARD, 2000 EDITION,SAFETY STANDARD, 2000 EDITION,

SAFETY STANDARD, 2000 EDITION,

SAFETY STANDARD, 2000 EDITION,SAFETY STANDARD, 2000 EDITION,

prior to installing, operating, and/or servicing this equipment.

MUSTMUST

MUST read and be familiar

MUSTMUST

MUSTMUST

MUST be read and thor-

MUSTMUST

ALLALL

ALL personnel who

ALLALL

ALLALL

ALL local building and fire

ALLALL

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

NFPA 33NFPA 33

NFPA 33

NFPA 33NFPA 33

> The hazards shown on the following

page may occur during the normal use of

this equipment. Please read the hazard

chart beginning on page 2.

Careful study and continued use of this manual

will provide a better understanding of the equipment and process, resulting in more efficient operation, longer trouble-free service and faster,

easier troubleshooting. If you do not have the

manuals and safety literature for your Ransburg

system, contact your local ITW Ransburg representative or ITW Ransburg.

LN-9237-00.1

11

1

11

Aerobell M Rotary Atomizer - Safety

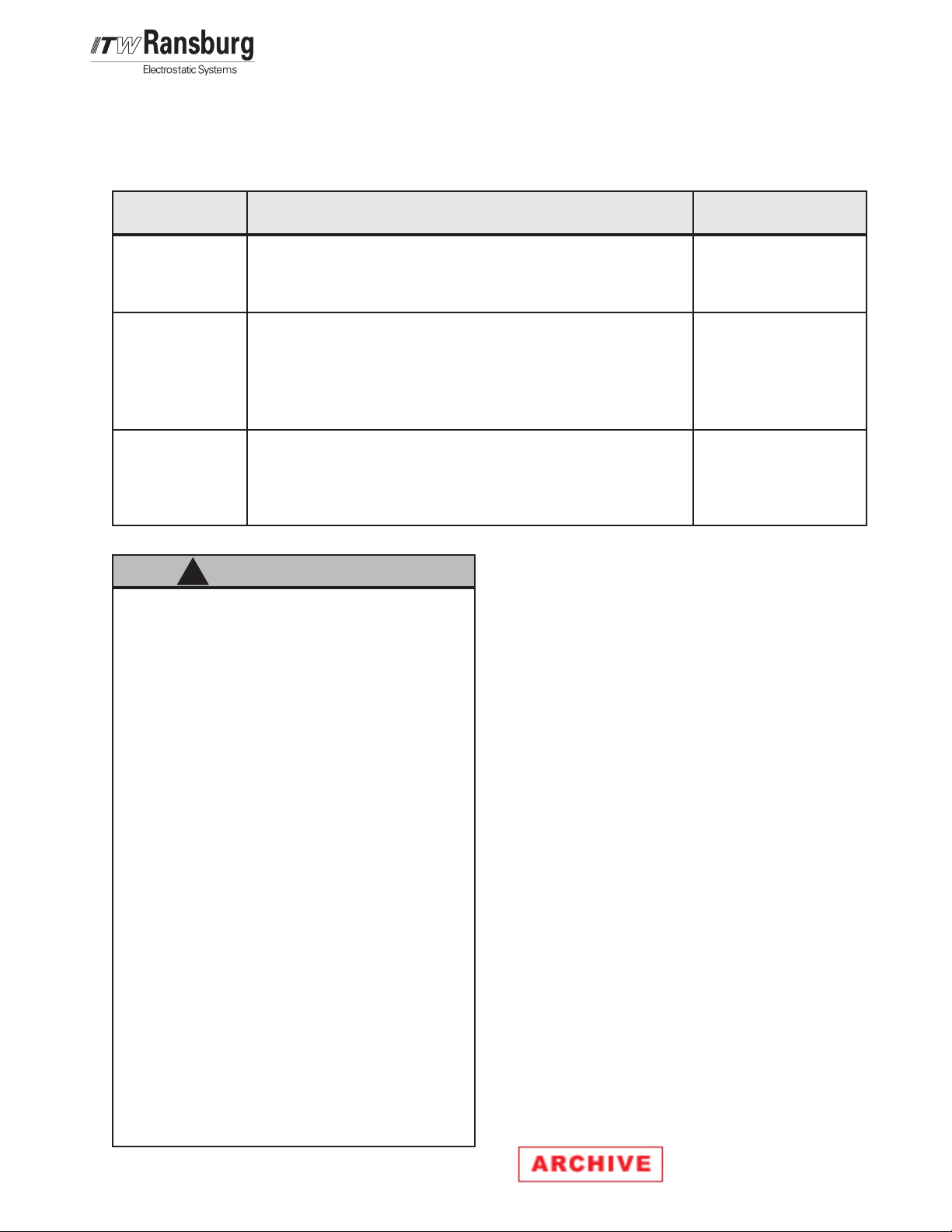

AREAAREA

AREA

AREAAREA

Tells where

hazards may

occur.

Spray AreaSpray Area

Spray Area

Spray AreaSpray Area

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

Fire Hazard

Improper or inadequate operation and maintenance procedures will cause a fire hazard.

Protection against inadvertent

arcing that is capable of causing

fire or explosion is lost if any

safety interlocks are disabled

during operation. Frequent

power supply shutdown indicates a problem in the system

requiring correction.

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

Fire extinguishing equipment must be present in

the spray area and tested periodically.

Spray areas must be kept clean to prevent the

accumulation of combustible residues.

Smoking must never be allowed in the spray area.

The high voltage supplied to the atomizer must be

turned off prior to cleaning, flushing or maintenance.

When using solvents for cleaning:

Those used for equipment flushing should have

flash points equal to or higher than those of the

coating material.

Those used for general cleaning must have flash

points above 100oF (37.8oC).

Spray booth ventilation must be kept at the rates

required by NFPA 33, 2000 Edition, OSHA and

local codes. In addition, ventilation must be maintained during cleaning operations using flammable or combustible solvents.

General Use andGeneral Use and

General Use and

General Use andGeneral Use and

MaintenanceMaintenance

Maintenance

MaintenanceMaintenance

Improper operation or maintenance may create a hazard.

Personnel must be properly

trained in the use of this equipment.

Electrostatic arcing must be prevented.

Test only in areas free of combustible material.

Testing may require high voltage to be on, but

only as instructed.

Non-factory replacement parts or unauthorized

equipment modifications may cause fire or injury.

If used, the key switch bypass is intended for use

only during setup operations. Production should

never be done with safety interlocks disabled.

Never use equipment intended for use in waterborne

installations to spray solvent based materials.

Personnel must be given training in accordance

with the requirements of NFPA 33, Chapter 16,

2000 edition.

Instructions and safety precautions must be read

and understood prior to using this equipment.

Comply with appropriate local, state, and national

codes governing ventilation, fire protection, operation maintenance, and housekeeping. OSHA references are Sections 1910.94 and 1910.107. Also

refer to NFPA 33, 2000 edition and your insurance

company requirements.

22

2

22

LN-9237-00.1

Aerobell M Rotary Atomizer - Safety

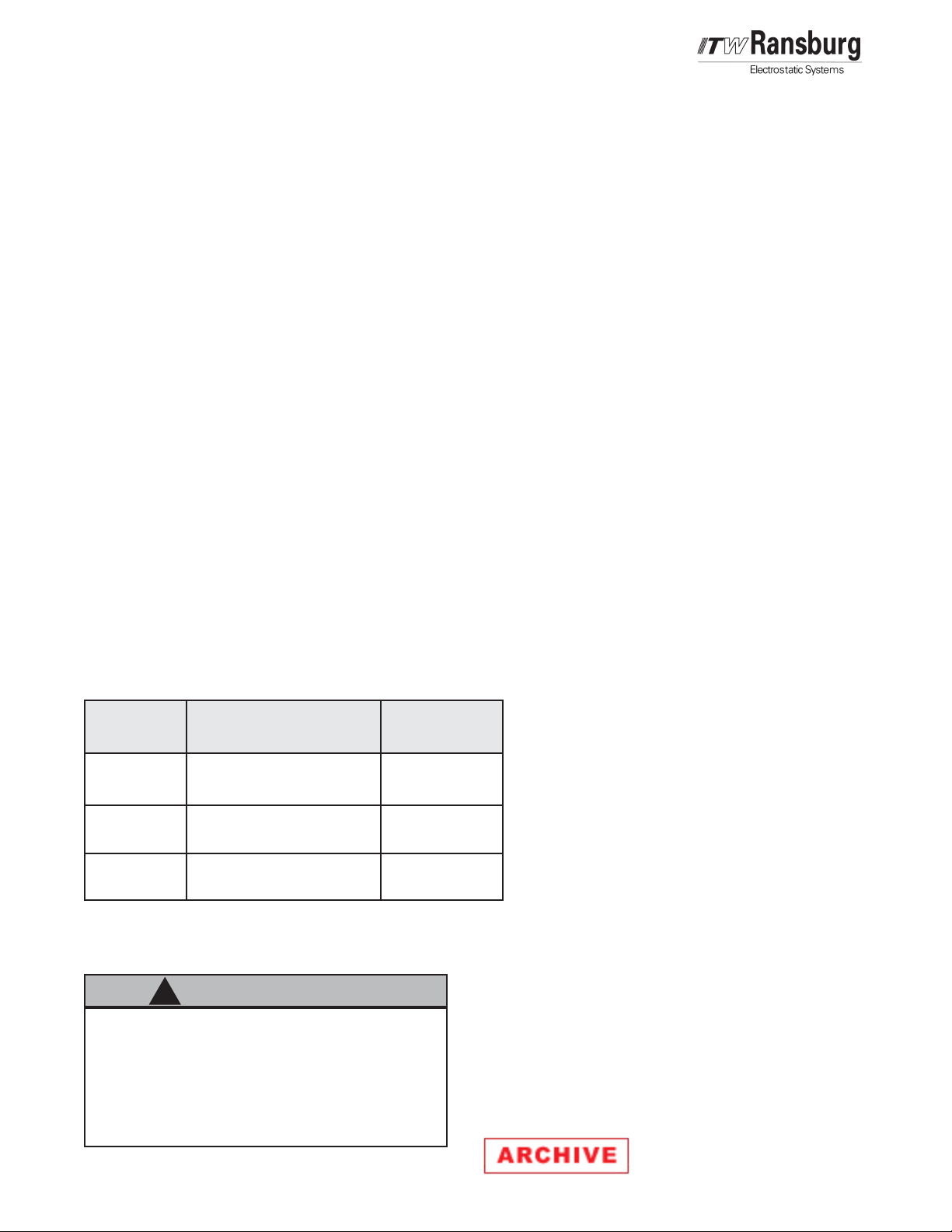

AREAAREA

AREA

AREAAREA

Tells where

hazards may

occur.

ElectricalElectrical

Electrical

ElectricalElectrical

EquipmentEquipment

Equipment

EquipmentEquipment

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

High voltage equipment is utilized. Arcing in areas of flammable or combustible materials

may occur. Personnel are exposed to high voltage during operation and maintenance.

Protection against inadvertent

arcing that may cause a fire or

explosion is lost if safety circuits

are disabled during operation.

Frequent power supply shutdown indicates a problem in the

system which requires correction.

An electrical arc can ignite coating materials and cause a fire or

explosion.

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

The power supply, optional remote control cabinet,

and all other electrical equipment must be located

outside Class I or II, Division 1 and 2 hazardous

areas. Refer to NFPA 33, 2000 Edition.

Turn the power supply OFF before working on the

equipment.

Test only in areas free of flammable or combustible material.

Testing may require high voltage to be on, but

only as instructed.

Production should never be done with the safety

circuits disabled.

Before turning the high voltage on, make sure no

objects are within the sparking distance.

Explosion Hazard /Explosion Hazard /

Explosion Hazard /

Explosion Hazard /Explosion Hazard /

Incompatible MaterialsIncompatible Materials

Incompatible Materials

Incompatible MaterialsIncompatible Materials

Toxic SubstancesToxic Substances

Toxic Substances

Toxic SubstancesToxic Substances

Halogenated hydrocarbon solvents

for example: methylene

chloride and 1,1,1,-Trichloroethane are not chemically compatible with the aluminum that

might be used in many system

components. The chemical reaction caused by these solvents

reacting with aluminum can become violent and lead to an

equipment explosion.

Certain material may be harmful

if inhaled, or if there is contact

with the skin.

Aluminum is widely used in other spray application

equipment - such as material pumps, regulators,

triggering valves, etc. Halogenated hydrocarbon

solvents must never be used with aluminum

equipment during spraying, flushing, or cleaning.

Read the label or data sheet for the material you

intend to spray. If in doubt as to whether or not a

coating or cleaning material is compatible, contact

your material supplier. Any other type of solvent

may be used with aluminum equipment.

Follow the requirements of the Material Safety

Data Sheet supplied by coating material manufacturer.

Adequate exhaust must be provided to keep the

air free of accumulations of toxic materials.

Use a mask or respirator whenever there is a

chance of inhaling sprayed materials. The mask

must be compatible with the material being

sprayed and its concentration. Equipment must

be as prescribed by an industrial hygienist or

safety expert, and be NIOSH approved.

LN-9237-00.1

33

3

33

Aerobell M Rotary Atomizer - Safety

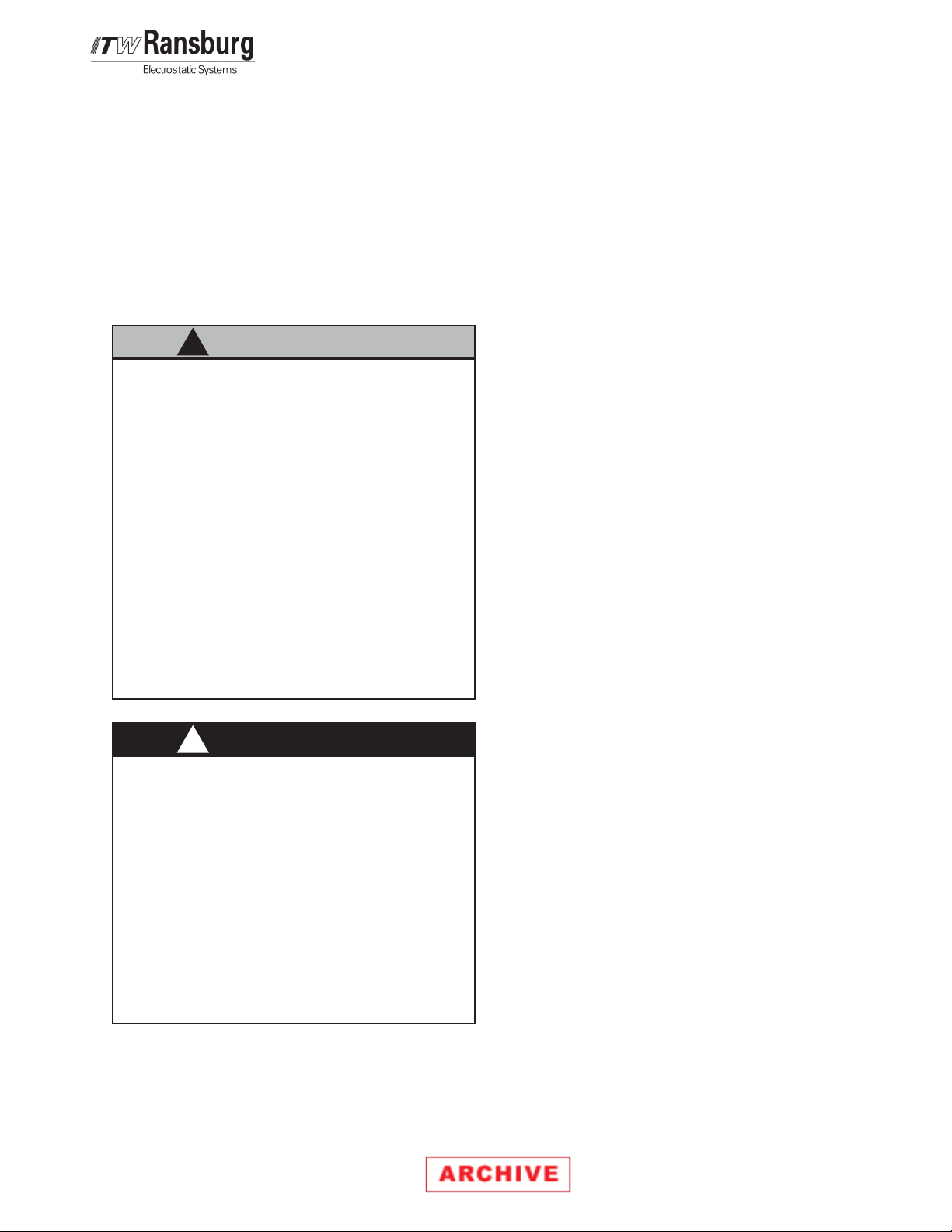

AREAAREA

AREA

AREAAREA

Tells where

hazards may

occur.

Spray Area /Spray Area /

Spray Area /

Spray Area /Spray Area /

High VoltageHigh Voltage

High Voltage

High VoltageHigh Voltage

EquipmentEquipment

Equipment

EquipmentEquipment

Personnel Safety /Personnel Safety /

Personnel Safety /

Personnel Safety /Personnel Safety /

Mechanical HazardsMechanical Hazards

Mechanical Hazards

Mechanical HazardsMechanical Hazards

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

There is a high voltage device

that can induce an electrical

charge on ungrounded objects

which is capable of igniting coating materials.

Inadequate grounding will cause

a spark hazard. A spark can

ignite many coating materials

and cause a fire or explosion.

The bell atomizer can rotate at

speeds up to 55,000 rpm. At

these speeds, the edge of the

applicator can easily cut into

skin. Loose articles can also be

caught by the rotating bell.

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

Parts being sprayed must be supported on conveyors

or hangers and be grounded. The resistance between

the part and ground must not exceed 1 megohm.

All electrically conductive objects in the spray area,

with the exception of those objects required by the

process to be at high voltage, must be grounded.

Any person working in the spray area must be

grounded.

Unless specifically approved for use in hazardous

locations, the power supply and other electrical

control equipment must not be used in Class 1,

Division 1 or 2 locations.

Personnel must stay clear of the bell whenever it

is rotating.

Before touching the bell, the turbine air must be

shut off.

If the bell has been rotating, allow at least two

minutes for it to come to a complete stop before

touching it.

44

4

44

LN-9237-00.1

NOTES:NOTES:

NOTES:

NOTES:NOTES:

Aerobell M Rotary Atomizer - Safety

LN-9237-00.1

55

5

55

Aerobell M Rotary Atomizer - Introduction

INTRODUCTIONINTRODUCTION

INTRODUCTION

INTRODUCTIONINTRODUCTION

FEAFEA

FEA

FEAFEA

Features which make the Aerobell® M Rotary

Atomizer advantageous for use in electrostatic

applications include:

• Proven long life turbine motor capable of

• 30mm, 57mm, and 70mm diameter bell as-

• Fast color changes are achieved using center

• Bell wash is quick and efficient. Solvent usage

TURESTURES

TURES

TURESTURES

speeds up to 55k rpm at minimal air consumption. See "Specifications" in the "Introduction" section of this manual for bell cup

speed ratings.

semblies available for application flexibility.

feed fluid delivery, integral brake air, high flow

regulator and the fluid valves which provide for

simultaneous paint push out while solvent

washes the feed tube and bell cup.

is controlled at the feed tube with an internally

mounted solvent valve.

spray angles for better paint coverage in difficult areas of the product.

• Turbine air exhausts behind bell, keeping paint

and solvent contamination out of atomizer interior and keeping back of bell clean.

• Speed readout (or control) uses reliable magnetic pickup for fiber-optic transmission of rotational speed data.

GENERAL DESCRIPTIONGENERAL DESCRIPTION

GENERAL DESCRIPTION

GENERAL DESCRIPTIONGENERAL DESCRIPTION

Bell AssemblyBell Assembly

Bell Assembly

Bell AssemblyBell Assembly

Metallic bell cups are available in both aluminum and titanium. Three different bell cup sizes

are available: 30mm, 57mm, and 70mm. Each

bell cup size has a matching front shroud and

shaping air ring.

• Less waste to the spray booth, with the dump

valve located internally next to the feed tube.

• More precise fluid regulation, with an (optional)

internal regulator.

• Easy to install and maintain. Hosing and connections are easily accessible at either the

rear of the assembly or by sliding back the

protective rear cover.

• Quick removal of the turbine assembly for offline repair.

• Annular shaping air passage design providing

excellent pattern control at minimal air consumption.

• Aerodynamic design for ease of cleaning external surfaces.

• Assembly can be swiveled to provide oblique

66

6

66

Air TAir T

urbine Assemblyurbine Assembly

Air T

urbine Assembly

Air TAir T

urbine Assemblyurbine Assembly

The air bearing turbine assembly with bell cup is

mounted to the air manifold assembly with four

socket head cap screws. The front resistor tube

is also attached to the air turbine assembly and

provides the high voltage connection to the motor shaft and bell.

Air and Fluid Manifold AssemblyAir and Fluid Manifold Assembly

Air and Fluid Manifold Assembly

Air and Fluid Manifold AssemblyAir and Fluid Manifold Assembly

This unit mounts onto the insulator support rod

assembly with a swivel post. The fluid valve

manifold block is mounted directly onto the back

side, connecting with fluid passages internal to

the manifold. Tube connections for valve control lines protrude through the rear shroud plate.

The fluid feed tube is screwed into the rear of

this manifold block and the air turbine assembly

mounts to the front with four socket head

screws.

LN-9237-00.1

Aerobell M Rotary Atomizer - Introduction

Insulator Support Rod AssemblyInsulator Support Rod Assembly

Insulator Support Rod Assembly

Insulator Support Rod AssemblyInsulator Support Rod Assembly

The air and fluid manifold assembly mount onto

the insulator support rod assembly, which in

turn is attached to the reciprocator or support

stand.

Rear Shroud AssemblyRear Shroud Assembly

Rear Shroud Assembly

Rear Shroud AssemblyRear Shroud Assembly

The rear shroud assembly consists of a rear

bulkhead which provides a passageway for fluid

and air tubes, mounting rods to connect the rear

bulkhead to the air and fluid manifold assembly,

a fluid regulator mounted onto the outside surface of the rear bulkhead, and a resistor module

nested between the rear bulkhead and air manifold assembly.

Resistor ModuleResistor Module

Resistor Module

Resistor ModuleResistor Module

The module encapsulates the high voltage resistors necessary for control of the electrostatic

charge being fed to the bell through the high

voltage cable.

High VHigh V

High V

High VHigh V

The SSW-1064, high voltage cable, is used to

connect the power supply to the resistor module

inside the atomizer assembly.

Speed Monitor/ControlSpeed Monitor/Control

Speed Monitor/Control

Speed Monitor/ControlSpeed Monitor/Control

The Aerobell M rotary atomizer is designed to

operate with the ITW Ransburg PulseTrackTM or

Atomizer Module for speed monitoring and/or

speed control.

oltage Cablesoltage Cables

oltage Cables

oltage Cablesoltage Cables

Power Supply andPower Supply and

Power Supply and

Power Supply andPower Supply and

Junction TJunction T

Junction T

Junction TJunction T

The Aerobell M System operates with a variety

of high voltage power supplies. The power supplies operate at output voltages of up to 100,000

volts DC. Also available is a junction tank which

is used to distribute high voltage to multiple

Aerobell M assemblies from a single power supply.

> The high voltage equipment that is

used in this application creates a hazard

for personnel. The high voltage power

supply is not approved for use inside of

the spray booth, as defined in NFPA 33.

This high voltage power supply can

produce sparks which are capable of

igniting coating material.

ankank

ank

ankank

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

LN-9237-00.1

77

7

77

Aerobell M Rotary Atomizer - Introduction

SPECIFICASPECIFICA

SPECIFICA

SPECIFICASPECIFICA

ElectricalElectrical

Electrical

ElectricalElectrical

Power SupplyPower Supply

Power Supply LECU5003 / LEPS5001

Power SupplyPower Supply

Type:Type:

Type: (Voltage Master

Type:Type:

TIONSTIONS

TIONS

TIONSTIONS

TM

)

MechanicalMechanical

Mechanical

MechanicalMechanical

Length:Length:

Length:

Length:Length:

30mm Bell Cup:30mm Bell Cup:

30mm Bell Cup: 16.55 inches (420mm)

30mm Bell Cup:30mm Bell Cup:

57mm Bell Cup:57mm Bell Cup:

57mm Bell Cup: 16.37 inches (416mm)

57mm Bell Cup:57mm Bell Cup:

70mm Bell Cup:70mm Bell Cup:

70mm Bell Cup: 16.75 inches (425mm)

70mm Bell Cup:70mm Bell Cup:

Diameter:Diameter:

Diameter: 5.6 inches (142mm)

Diameter:Diameter:

76045 / LEPS5002

(MicroPakTM)

Charging Method:Charging Method:

Charging Method: Direct

Charging Method:Charging Method:

Output Voltage:Output Voltage:

Output Voltage: 30-100 kV Variable

Output Voltage:Output Voltage:

Output Current:Output Current:

Output Current: 125 μA (Short Circuit)

Output Current:Output Current:

Turbine SpeedTurbine Speed

Turbine Speed

Turbine SpeedTurbine Speed

Control:Control:

Control: PulseTrack or Eurocard

Control:Control:

Atomizer Module

Paint Resistance:*Paint Resistance:*

Paint Resistance:* .1 MΩ to

Paint Resistance:*Paint Resistance:*

**

*(Use Model No. 76652, Test Equipment)

**

Part Sprayability:Part Sprayability:

Part Sprayability: Determine sprayability of

Part Sprayability:Part Sprayability:

part to be coated using

76652, Test Equipment

(see TE-98-01).

∞

Approximate Weight:Approximate Weight:

Approximate Weight: 10.3 lbs. (4.7 kg)

Approximate Weight:Approximate Weight:

Turbine Type:Turbine Type:

Turbine Type: Air Bearing Impulse Drive

Turbine Type:Turbine Type:

Turbine Air Supply:Turbine Air Supply:

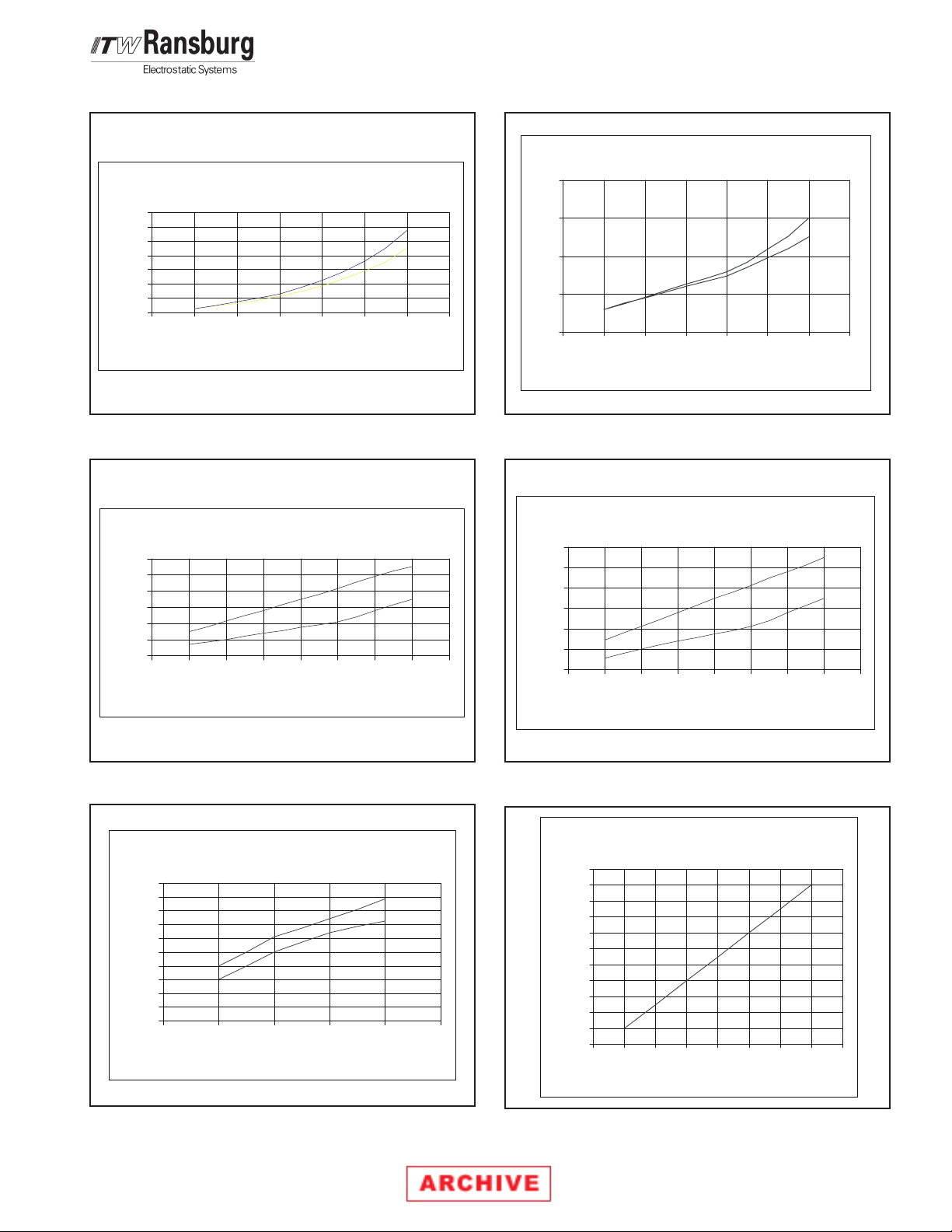

Turbine Air Supply: Variable (See Figures 1-4)

Turbine Air Supply:Turbine Air Supply:

At 30,000 rpmAt 30,000 rpm

At 30,000 rpm 23 psig (158 kPa)

At 30,000 rpmAt 30,000 rpm

(Nominal):(Nominal):

(Nominal): 7.7 scfm (220 slpm)

(Nominal):(Nominal):

Maximum TurbineMaximum Turbine

Maximum Turbine

Maximum TurbineMaximum Turbine

Speed:Speed:

Speed: Continuous (Intermittent)

Speed:Speed:

30mm Bell Cup:30mm Bell Cup:

30mm Bell Cup: 40,000 rpm (55,000 rpm)

30mm Bell Cup:30mm Bell Cup:

57mm Bell Cup:57mm Bell Cup:

57mm Bell Cup: 40,000 rpm (55,000 rpm)

57mm Bell Cup:57mm Bell Cup:

70mm Bell Cup:70mm Bell Cup:

70mm Bell Cup: 30,000 rpm (40,000 rpm)

70mm Bell Cup:70mm Bell Cup:

Bearing Air Supply:Bearing Air Supply:

Bearing Air Supply: (See Figure 6)

Bearing Air Supply:Bearing Air Supply:

(Nominal)(Nominal)

(Nominal) 90 psig (±10 psi)

(Nominal)(Nominal)

(621 kPa ±69 kPa)

2.1 scfm (60 slpm)

Shaping Air Supply:Shaping Air Supply:

Shaping Air Supply: Variable (See Figure 5)

Shaping Air Supply:Shaping Air Supply:

Nominal)Nominal)

(

Nominal) 5-15 psig (34-103 kPa)

Nominal)Nominal)

4.7-9.8 scfm (134-280 slpm)

Brake Air Supply:Brake Air Supply:

Brake Air Supply:

Brake Air Supply:Brake Air Supply:

(Nominal)(Nominal)

(Nominal)

(Nominal)(Nominal)

60 psig (414 kPa)

Maximum FluidMaximum Fluid

Maximum Fluid

Maximum FluidMaximum Fluid

Pressure Supply:Pressure Supply:

Pressure Supply: 100 psig (689 kPa)

Pressure Supply:Pressure Supply:

Fluid Flow Rate:Fluid Flow Rate:

Fluid Flow Rate: 25-500 cc/minute

Fluid Flow Rate:Fluid Flow Rate:

Usable Spray PatternUsable Spray Pattern

Usable Spray Pattern

Usable Spray PatternUsable Spray Pattern

Diameter:Diameter:

Diameter: 15-30 inches (381-762 mm)

Diameter:Diameter:

Bell Cup CleaningBell Cup Cleaning

Bell Cup Cleaning

Bell Cup CleaningBell Cup Cleaning

Time:Time:

Time: Approximately 2-3 seconds

Time:Time:

Color Change Time:Color Change Time:

Color Change Time: Dependent on system

Color Change Time:Color Change Time:

configuration, fluid

pressure, fluid viscosity,

fluid line lengths, etc.

Speed Readout:Speed Readout:

Speed Readout: Magnetic pickup,

Speed Readout:Speed Readout:

unidirectional fiber-optic

transmission

Atomizer ReplacementAtomizer Replacement

Atomizer Replacement

Atomizer ReplacementAtomizer Replacement

Time:Time:

Time: Less than 2 minutes

Time:Time:

Bell Cup ReplacementBell Cup Replacement

Bell Cup Replacement

Bell Cup ReplacementBell Cup Replacement

Time:Time:

Time: Less than 2 minutes

Time:Time:

88

8

88

LN-9237-00.1

Turbine Speed vs. Pr essur e

Aerobell M Rotary Atomizer - Introduction

Turbine Speed vs. Flow

20

70

60

PSI

50

40

30

20

10

57mm57mm

57mm

57mm57mm

BellBell

Bell

BellBell

30mm30mm

30mm

30mm30mm

BellBell

Bell

BellBell

0

0 10203040506070

Thousands RPM

Figure 1: Turbine Speed vs. PressureFigure 1: Turbine Speed vs. Pressure

Figure 1: Turbine Speed vs. Pressure

Figure 1: Turbine Speed vs. PressureFigure 1: Turbine Speed vs. Pressure

57mm Bell/Loaded vs. Unloaded

60

50

40

30

PSI

20

10

0

15 20 25 30 35 40 45 50 55

Load 600 cc/minLoad 600 cc/min

Load 600 cc/min

Load 600 cc/minLoad 600 cc/min

WaterWater

Water

WaterWater

Thousands RPM

UnloadedUnloaded

Unloaded

UnloadedUnloaded

15

57mm57mm

57mm

57mm57mm

BellBell

Bell

10

SCFM

5

0

0 10203040506070

Thousands RPM

Figure 2: Turbine Speed vs. FlowFigure 2: Turbine Speed vs. Flow

Figure 2: Turbine Speed vs. Flow

Figure 2: Turbine Speed vs. FlowFigure 2: Turbine Speed vs. Flow

BellBell

30mm30mm

30mm

30mm30mm

BellBell

Bell

BellBell

57mm Bell/Loaded vs. Unloaded

16

14

12

10

SCFM

8

6

4

15 20 25 30 35 40 45 50 55

Load 600 cc/minLoad 600 cc/min

Load 600 cc/min

Load 600 cc/minLoad 600 cc/min

WaterWater

Water

WaterWater

Thousands RPM

UnloadedUnloaded

Unloaded

UnloadedUnloaded

LN-9237-00.1

Figure 3: 57mm Bell / Loaded vs. UnloadedFigure 3: 57mm Bell / Loaded vs. Unloaded

Figure 3: 57mm Bell / Loaded vs. Unloaded

Figure 3: 57mm Bell / Loaded vs. UnloadedFigure 3: 57mm Bell / Loaded vs. Unloaded

Shaping Air Flow

20

18

16

14

12

10

SCFM

8

6

4

2

0

0 5 10 15 20 25

30mm30mm

30mm

30mm30mm

BellBell

Bell

BellBell

Figure 5: Shaping Air FlowFigure 5: Shaping Air Flow

Figure 5: Shaping Air Flow

Figure 5: Shaping Air FlowFigure 5: Shaping Air Flow

57mm57mm

57mm

57mm57mm

BellBell

Bell

BellBell

Pressure (PSI)

Figure 4: 57mm Bell / Loaded vs. UnloadedFigure 4: 57mm Bell / Loaded vs. Unloaded

Figure 4: 57mm Bell / Loaded vs. Unloaded

Figure 4: 57mm Bell / Loaded vs. UnloadedFigure 4: 57mm Bell / Loaded vs. Unloaded

Bearing Air Flow

2.6

2.5

2.4

2.3

2.2

2.1

2

SCFM

1.9

1.8

1.7

1.6

1.5

55 60 65 70 75 80 85 90 95

Pressure (PSI)

Figure 6: Bearing Air FlowFigure 6: Bearing Air Flow

Figure 6: Bearing Air Flow

Figure 6: Bearing Air FlowFigure 6: Bearing Air Flow

99

9

99

Aerobell M Rotary Atomizer - Installation

INSTINST

INST

INSTINST

AIR FILAIR FIL

AIR FIL

AIR FILAIR FIL

The following air filter installation guidelines are

essential for optimum performance.

1. Use only recommended pre-filters and

2. Mount the bearing air filter as close as

3. Do not use Teflon tape, pipe dope, or

4. If air heaters are used in the system (to

ALLAALLA

ALLA

ALLAALLA

TER INSTTER INST

TER INST

TER INSTTER INST

bearing air filters as shown in Figure 8.

Additional system air filtration (i.e., refrigerated air dryer) may also be used if desired.

possible to the Aerobell M. (Do not

mount further than 30 feet away.)

other thread sealant downstream of the

bearing air filter. Loose flakes of teflon

tape or other sealant can break loose

and plug the very fine air holes in the

turbine air bearings.

minimize the effect of excessively humid

conditions), and the heated air will exceed 120

after all filters to prevent damage to the

filter media.

o

TIONTION

TION

TIONTION

ALLAALLA

ALLA

ALLAALLA

F, the heaters must be located

TIONTION

TION

TIONTION

AIR PRESSUREAIR PRESSURE

AIR PRESSURE

AIR PRESSUREAIR PRESSURE

REQUIREMENTSREQUIREMENTS

REQUIREMENTS

REQUIREMENTSREQUIREMENTS

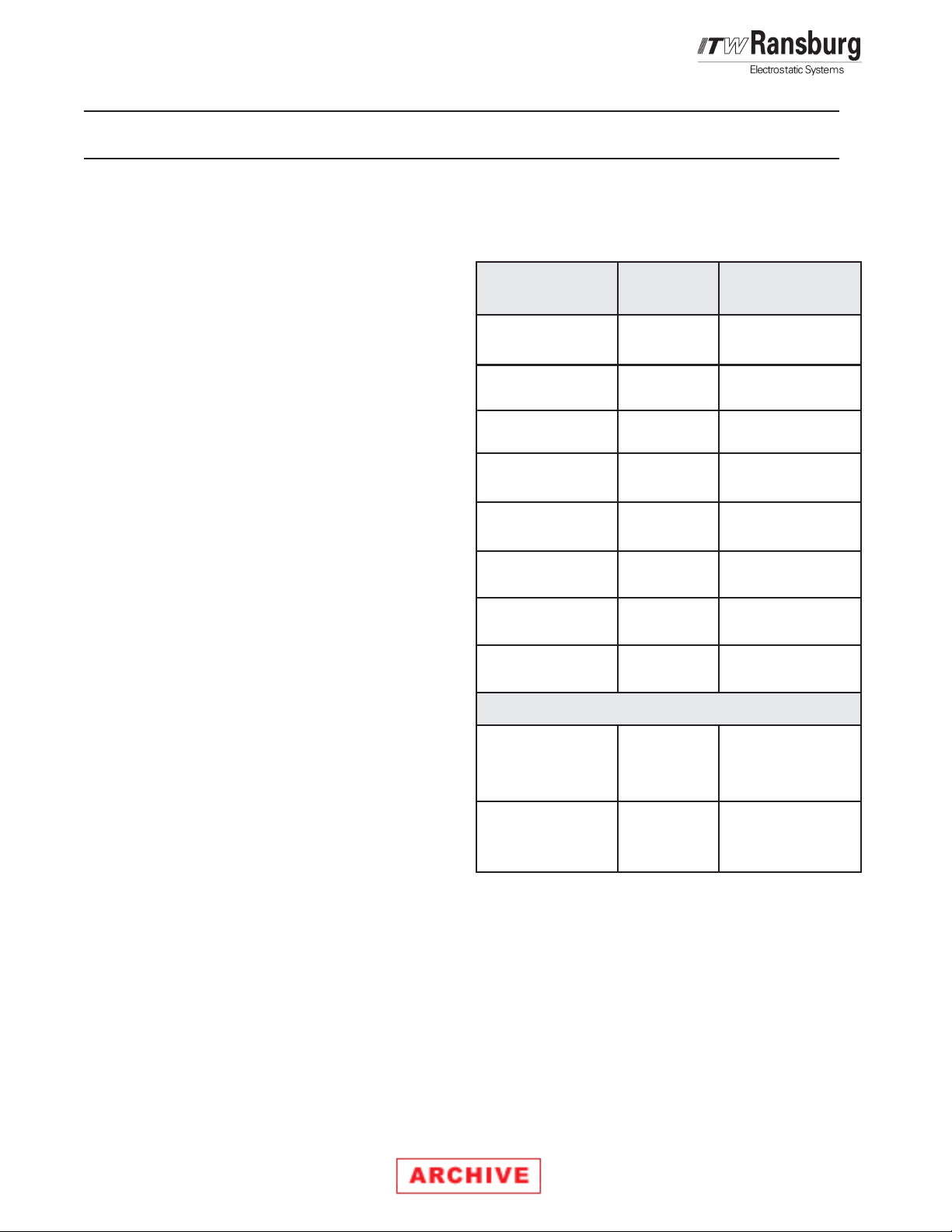

Tube SizeTube Size

Tube Size

Tube SizeTube Size

Bearing Air

Supply (B.A)

Bearing Air

Return (B.A)

Turbine Air (T.A)

Shaping Air (S.A)

Brake Air (BRK)

(if used)

Trigger Valve

Control (TV)

Dump Valve

Control (DV)

Solvent Valve

Control (SV)

Paint Fluid Regulator (Optional):Paint Fluid Regulator (Optional):

Paint Fluid Regulator (Optional):

Paint Fluid Regulator (Optional):Paint Fluid Regulator (Optional):

High Flow

Signal Air (High)

Low Flow

Signal Air (Low)

Figure 7: Air Tubing ConnectionsFigure 7: Air Tubing Connections

Figure 7: Air Tubing Connections

Figure 7: Air Tubing ConnectionsFigure 7: Air Tubing Connections

1/4" O.D.

1/4" O.D.

1/2" O.D.

3/8" O.D.

3/8" O.D.

1/4" O.D.

1/4" O.D.

1/4" O.D.

1/4" O.D.

1/4" O.D.

Air PressureAir Pressure

Air Pressure

Air PressureAir Pressure

RequirementsRequirements

Requirements

RequirementsRequirements

90 psi ±10

(621kPa ± 69kPa)

80 psi ±10

(551kPa ± 69kPa)

Variable

Variable

60 psi ±10

(413kPa ± 69kPa)

80 psi ±10

(551kPa ± 69kPa)

80 psi ±10

(551kPa ± 69kPa)

80 psi ±10

(551kPa ± 69kPa)

Variable

70 psi max.

(482 kPa)

Variable

80 psi max.

(551 kPa)

1010

10

1010

LN-9237-00.1

Aerobell M Rotary Atomizer - Installation

AIR FILAIR FIL

AIR FIL

AIR FILAIR FIL

REQUIREMENTSREQUIREMENTS

REQUIREMENTS

REQUIREMENTSREQUIREMENTS

ITW RansburgITW Ransburg

ITW Ransburg

ITW RansburgITW Ransburg

Filter Model No.Filter Model No.

Filter Model No.

Filter Model No.Filter Model No.

HAF-503

RPM-417

RPM-418

TRATRA

TRA

TRATRA

!!

!

!!

TIONTION

TION

TIONTION

Description / SpecificationsDescription / Specifications

Description / Specifications

Description / SpecificationsDescription / Specifications

Pre-filter, removes coarse amounts of oil, moisture &

dirt. Used upstream of RPM-417 pre-filter (used in

systems with poor air quality).

Pre-filter, coalescing type, 136 scfm, 98.5% efficiency

particulate removal .3 to .6 micron, max. aerosol passed

1.0 micron, max. solid passed .4 micron (dependent

upon scfm requirement per applicator, one RPM-417

can be used with up to three Aerobell M assemblies).

Bearing air filter, coalescing type, 19 scfm, 99.995%

efficiency particulate removal .3 to .6 micron, max.

aerosol passed .6 micron, max. solid passed .2 micron

(one per applicator).

C A U T I O NC A U T I O N

C A U T I O N

C A U T I O NC A U T I O N

Figure 8: Recommended Air FiltrationFigure 8: Recommended Air Filtration

Figure 8: Recommended Air Filtration

Figure 8: Recommended Air FiltrationFigure 8: Recommended Air Filtration

ReplacementReplacement

Replacement

ReplacementReplacement

Element Part No.Element Part No.

Element Part No.

Element Part No.Element Part No.

HAF-15 Element, One

RPM-32 Elements,

Carton of 4

RPM-33 Elements,

Carton of 8

> Air must be properly filtered to ensure

extended turbine life and to prevent

contamination of the paint finish. Air

which is not adequately filtered will foul

the turbine air bearings and cause turbine

failure. The correct type of filters must be

used in an Aerobell M system. The filter

elements must be replaced on a regular

schedule to assure clean air.

It is the user’s responsibility to en-It is the user’s responsibility to en-

>

It is the user’s responsibility to en-

It is the user’s responsibility to en-It is the user’s responsibility to en-

sure clean air at all times. Turbine failuresure clean air at all times. Turbine failure

sure clean air at all times. Turbine failure

sure clean air at all times. Turbine failuresure clean air at all times. Turbine failure

resulting from contaminated air will notresulting from contaminated air will not

resulting from contaminated air will not

resulting from contaminated air will notresulting from contaminated air will not

be covered under warranty.be covered under warranty.

be covered under warranty. Figure 8

be covered under warranty.be covered under warranty.

shows the pre-filter and bearing air filter(s)

which are recommended for use in

Aerobell M systems. If other filters are

incorporated in the system, the filters to

be used must have filtering capacities

equal or better than those shown in Figure

8.

LN-9237-00.1

> The user must ensure the bearing air

supply is not inadvertently turned off while

the Aerobell M air motor is turning. This

will cause air bearing failure.

1111

11

1111

Aerobell M Rotary Atomizer - Installation

MOUNTINGMOUNTING

MOUNTING

MOUNTINGMOUNTING

The Aerobell M incorporates its own insulator

mounting rod. The diameter at the rear is 1.9

inches, for mounting to a reciprocator, stationary

stand, or other means of support. The atomizer

assembly is mounted to this horizontal rod by a

3/4 inch insulating post, inserted into a swivel

clamp and secured by four plastic bolts. The

arrangement allows positioning of the front of

the turbine. Normally, the insulator support rod

is positioned perpendicular to the conveyor

path, with the swivel providing for left or right

adjustment of the atomizer assembly. The

swivel clamp plate can be inverted to provide a

locking mechanism to hold the applicator in line

with the insulator support rod.

FLUID CONNECTIONSFLUID CONNECTIONS

FLUID CONNECTIONS

FLUID CONNECTIONSFLUID CONNECTIONS

The paint supply to the Aerobell M is connected

at the rear of the atomizer assembly to the

regulator. Solvent and dump line connections

enter the housing and are connected to the

appropriate valves. Ports are labeled with blue

lettering.

ELECTRICALELECTRICAL

ELECTRICAL

ELECTRICALELECTRICAL

CONNECTIONSCONNECTIONS

CONNECTIONS

CONNECTIONSCONNECTIONS

Electrical connections to the Aerobell M atomizer assembly consist of only the high voltage

cable. This cable plugs into the resistor module

fitting, located at the rear of the assembly, which

protrudes through an opening in the rear bulkhead. After inserting the cable entirely into the

tube and feeling the banana plug make contact

on the inside, tighten the cable compression

fitting nut around the high voltage cable with an

appropriate wrench. Reinstall the connector

cover with plastic screw.

SPEED MONITSPEED MONIT

SPEED MONIT

SPEED MONITSPEED MONIT

CONNECTIONSCONNECTIONS

CONNECTIONS

CONNECTIONSCONNECTIONS

A fiber-optic cable assembly connects the

speed signal output of the rotary atomizer

assembly to the Pulsetrak Speed Monitor/

Control System or Fotronics Atomizer Module.

OROR

OR

OROR

FixedFixed

Fixed

FixedFixed

AtomizerAtomizer

Atomizer

AtomizerAtomizer

Paint Line

(P.IN)

Solvent Line

(SOL)

Dump Line

(DUMP)

Figure 9: Fluid Tubing Connection RequirementsFigure 9: Fluid Tubing Connection Requirements

Figure 9: Fluid Tubing Connection Requirements

Figure 9: Fluid Tubing Connection RequirementsFigure 9: Fluid Tubing Connection Requirements

> The normal fluid flow range is 25-500

cc/minute. The maximum flow rate must

not exceed 500 cc/minute to avoid solvent

or paint from flooding into the internal

portion of the air bearing motor assembly

or front shroud.

.156", .170", or .188" I.D.

PFA, Teflon

.125" I.D.

PFA, Teflon

.250" I.D.

PFA, Teflon

C A U T I O NC A U T I O N

C A U T I O N

C A U T I O NC A U T I O N

!!

!

!!

(nominal/max.)

(207-413 kPa)

PressurePressure

Pressure

PressurePressure

100 psig

(689 kPa)

30-60 psig

Variable

1212

12

1212

LN-9237-00.1

Aerobell M Rotary Atomizer - Installation

INTERLOCKSINTERLOCKS

INTERLOCKS

INTERLOCKSINTERLOCKS

The following system interlocks are required to

prevent equipment damage:

1. Bearing air should remain on at all times

and should be shut off only by turning off

the main air to the pneumatic control

cabinet.

C A U T I O NC A U T I O N

C A U T I O N

C A U T I O NC A U T I O N

!!

!

!!

> When the turbine air is turned off, the

turbine will continue to operate or “coast

down” for about two minutes. Provisions

should be made to assure that the operator waits at least three minutes, after

shutting off the turbine air, before shutting

off the main air supply.

> The bell assembly must be removed

when making flow checks. If the paint is

turned on when the bell is mounted on the

motor shaft and not rotating, paint will

enter the shaft and possibly damage the

air bearing. Normally pneumatic interlocks will not allow the paint to trigger on

when the turbine air is off.

3. Two interconnected bearing air ports are

provided, one for supply air and the

other to be used as a return signal for

measuring bearing air pressure at the

atomizer. If bearing air falls below 60 psi

at the atomizer, the turbine air should be

automatically interlocked to shut off.

4. High voltage must be interlocked with

the solvent valve pilot signal to prevent

solvent flow while high voltage is energized.

5. Turbine air and brake air must be interlocked to prevent both from being used

simultaneously.

2. It should not be possible for the coating

LN-9237-00.1

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

> The high voltage and/or coating

material must never be turned on unless

the bell cup is mounted on the motor shaft

and the turbine is rotating.

> Pneumatic input to the turbine air inlet

must be controlled to prevent the turbine

from exceeding the maximum rated

intermittent speed of 55,000 rpm for

30mm and 57mm bell cups and 40,000

rpm for 70mm bell cups. (See "Specifications" in the "Introduction" section.)

material to be sprayed unless the turbine

is spinning.

1313

13

1313

Aerobell M Rotary Atomizer - Operation

OPERAOPERA

OPERA

OPERAOPERA

!!

!

!!

> Operators must be fully trained in safe

operation of electrostatic equipment.

Operators must read all instructions and

safety precautions prior to using this

equipment (See NFPA 33, Chapter 16).

As with any spray finishing system, operation of

the Aerobell M involves properly setting the operating parameters to obtain the best finish

quality for the coating material being sprayed,

while maintaining correct operation and reliability of the equipment used. Adjustments to operating parameters, which cover spraying, cleaning and on/off control, include:

• Coating Materials

• Fluid Flow Rate Control

• Fluid Valve Control

• Turbine Speed

• Bearing Air Adjustment

• Shaping Air

• Brake Air

• Electrostatic Voltage

• Target Distance

COACOA

COA

COACOA

The Aerobell M can be used with a full range of

coating material conductivities. However, with

coatings having very high conductivities, such

as waterborne paints, it may be necessary to

isolate paint supply from ground.

TING MATING MA

TING MA

TING MATING MA

TIONTION

TION

TIONTION

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

TERIALSTERIALS

TERIALS

TERIALSTERIALS

FLUID FLOW RAFLUID FLOW RA

FLUID FLOW RA

FLUID FLOW RAFLUID FLOW RA

CONTROLCONTROL

CONTROL

CONTROLCONTROL

Fluid flow is controlled by an internally mounted

dual diaphragm fluid regulator. Reference the

LREG5001, DR-1

Manual# LN-9221-00 (latest version) for

detailed information.

The regulator features two independently controllable flow pressure ranges from the fluid

output port. The high flow range port accommodates higher fluid deliveries thereby providing

increased film build capabilities and minimal

color change times. The low flow range provides precise fluid delivery control. There are

seven low range models available (1:1, 1:2, 1:3,

1:4, 1:6, 1:8, and 1:10) which can be selected

based on the required fluid flow rate.

Separate pilot signals modulate each of the

regulator’s two diaphragms to control the

amount of paint being delivered from the regulator to the atomizer bell cup. These pilot signals

can be controlled manually or automatically with

closed loop flow control system.

Because of the regulator’s dual range capabilities, it provides the user flexibility of selecting

either the high flow range or the low flow range.

Different coating material viscosities and quick

color change requirements may necessitate the

use of both ranges. If color change time is not a

factor or if material viscosity remains relatively

constant, either port may be used depending on

flow rate requirements.

TM

Plastic Fluid Regulator,

TETE

TE

TETE

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

> Electrical discharge of a high electrical

capacitance fluid/paint system can cause

fire or explosion with some materials. If

arcing occurs when a specific coating

materials is used, turn the system off and

verify that the fluid is nonflammable. In

these conditions the system is capable of

releasing sufficient electrical and thermal

energy to cause ignition of specific hazardous material in air.

1414

14

1414

The high flow port characteristics are similar to

those found in most commercially available, air

operated fluid regulators. Fluid regulation from

the high flow port is therefore comparable in total flow capacity, although consistency of flow is

improved considerably when using a regulator.

All regulators, regardless of ratio designation,

have the high flow port.

The low flow (i.e. 1:2, 1:4, etc.) port provides a

lower, more precise flow response curve. Fluid

output, as a result, is less likely to be affected

by pilot signal errors. An increase in the ratio

LN-9237-00.1

Loading...

Loading...