Ransburg 76911 User Manual

SERVICE MANUAL

LN-9257-07.1

Replace LN-9257-07

April - 2013

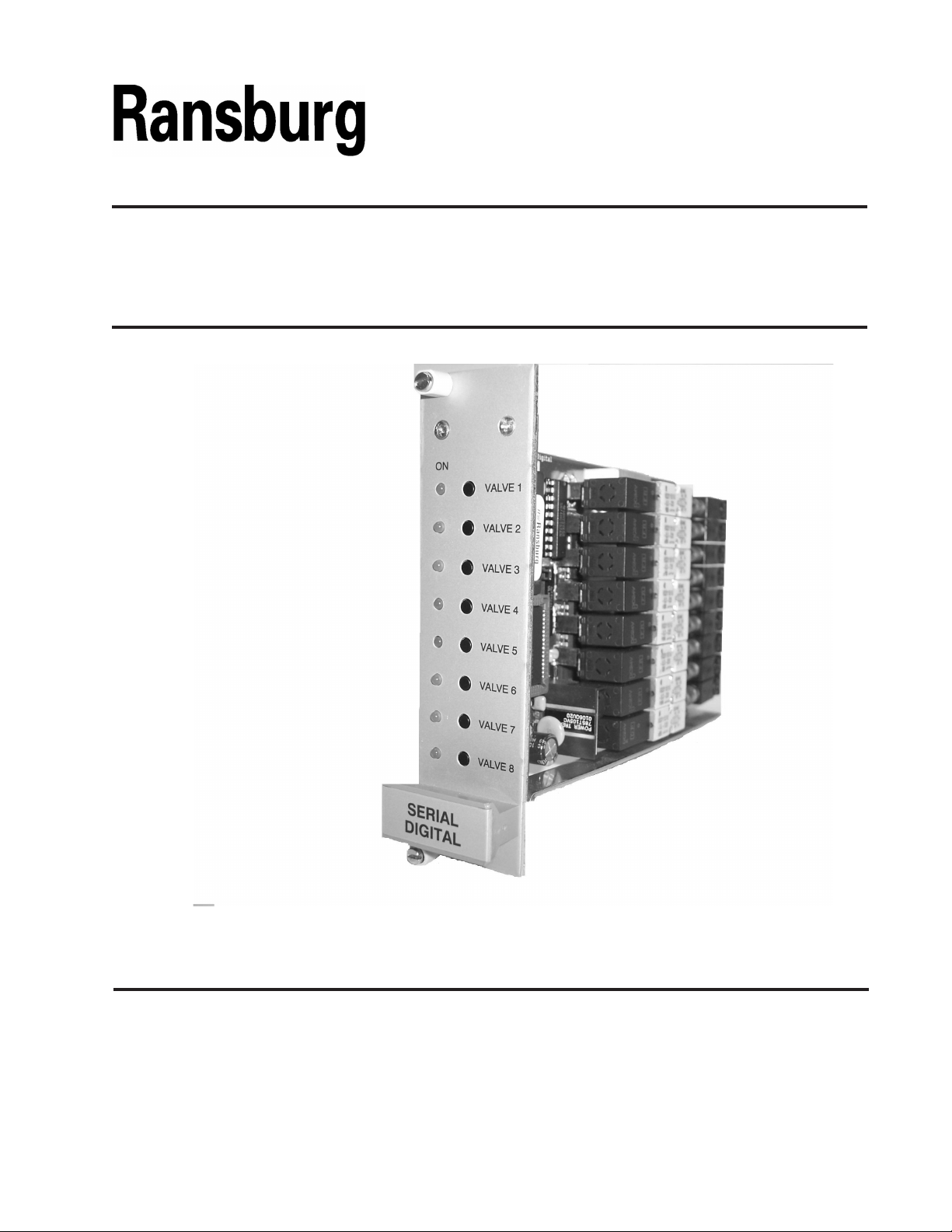

SERIAL DIGITAL MODULE

USER MANUAL

MODEL: 76911

IMPORTANT: Before using this equipment,

carefully read SAFETY PRECAUTIONS, starting

on page 1, and all instructions in this manual.

Keep this Service Manual for future reference.

Service Manual Price: $30.00 (U.S.)

LN-9257-07.1

Serial Digital Module - Contents

CONTENTS

SAFETY:

SAFETY PRECAUTIONS...........................................................................................................

HAZARDS / SAFEGUARDS.......................................................................................................

PAGE

1 - 4

1

2-4

INTRODUCTION:

GENERAL DESCRIPTION.........................................................................................................

SPECIFICATIONS.......................................................................................................................

MODES OF I/O..........................................................................................................................

SERIAL DIGITAL MODULE SETTINGS....................................................................................

INSTALLATION:

POWER.......................................................................................................................................

CONTROL SIGNALS..................................................................................................................

PNEUMATIC CONNECTIONS...................................................................................................

REMOTE I/O..............................................................................................................................

SERIAL DIGITAL MODULE INSTALLATION.............................................................................

WARRANTY POLICIES:

LIMITED WARRANTY.................................................................................................................

5-8

5

5

6

7

9-10

9

9

9

9

10

11

11

LN-9257-07.1

Serial Digital Module - Safety

SAFETY

SAFETY PRECAUTIONS

Before operating, maintaining or servicing any

Ransburg electrostatic coating system, read and

understand all of the technical and safety literature for your Ransburg products. This manual

contains information that is important for you to

know and understand. This information relates to

USER SAFETY and PREVENTING EQUIPMENT

PROBLEMS. To help you recognize this information, we use the following symbols. Please pay

particular attention to these sections.

A WARNING! states information to alert you

to a situation that might cause serious injury if

instructions are not followed.

A CAUTION! states information that tells how to

prevent damage to equipment or how to avoid a

situation that might cause minor injury.

A NOTE is information relevant to the procedure

in progress.

While this manual lists standard specifications and service procedures, some minor

deviations may be found between this literature and your equipment. Differences in local

codes and plant requirements, material delivery

requirements, etc., make such variations inevitable.

Compare this manual with your system installation

drawings and appropriate Ransburg equipment

manuals to reconcile such differences.

W A R N I N G

!

> The user MUST read and be familiar with

the Safety Section in this manual and the

Ransburg safety literature therein identied.

> This manual MUST be read and

thoroughly understood by ALL personnel who operate, clean or maintain this

equipment! Special care should be taken

to ensure that the WARNINGS and safety

requirements for operating and servicing the

equipment are followed. The user should

be aware of and adhere to ALL local build-

ing and re codes and ordinances as well

as NFPA-33 SAFETY STANDARD, prior to

installing, operating, and/or servicing this

equipment.

W A R N I N G

!

> The hazards shown on the following

page may occur during the normal use of

this equipment. Please read the hazard

chart beginning on page 2.

Careful study and continued use of this manual

will provide a better understanding of the equip-

ment and process, resulting in more efcient

operation, longer trouble-free service and faster,

easier troubleshooting. If you do not have the

manuals and safety literature for your Ransburg

system, contact your local Ransburg representative or Ransburg.

1

LN-9257-07.1

Serial Digital Module - Safety

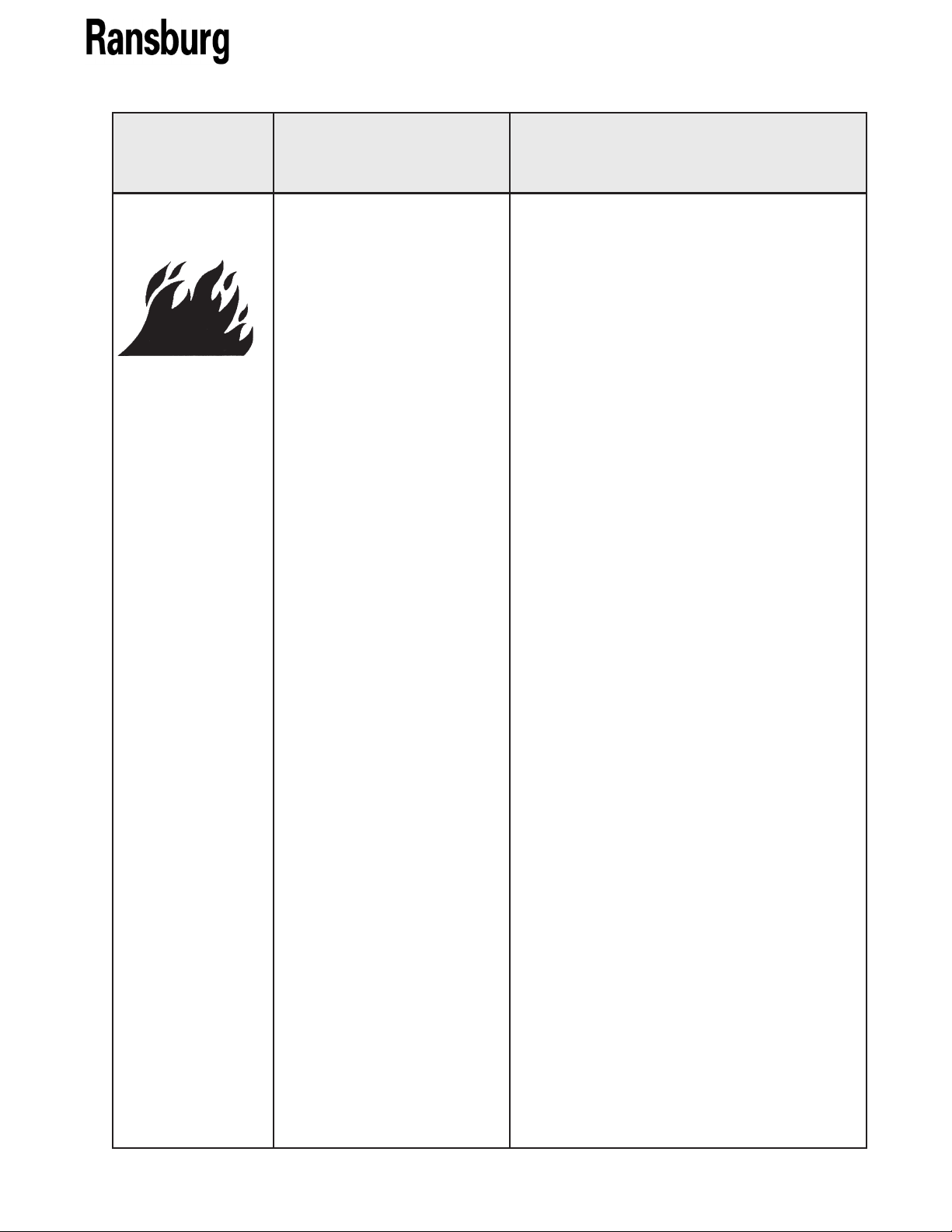

AREA

Tells where hazards

may occur.

Spray Area

HAZARD

Tells what the hazard is.

Fire Hazard

Improper or inadequate operation

and maintenance procedures will

cause a re hazard.

Protection against inadvertent

arcing that is capable of causing

re or explosion is lost if any safety interlocks are disabled during

operation. Frequent power supply shutdown indicates a problem

in the system requiring correction.

SAFEGUARDS

Tells how to avoid the hazard.

Fire extinguishing equipment must be present in

the spray area and tested periodically.

Spray areas must be kept clean to prevent the accumulation of combustible residues.

Smoking must never be allowed in the spray area.

The high voltage supplied to the atomizer must be

turned off prior to cleaning, ushing or maintenance.

When using solvents for cleaning:

Those used for equipment ushing should have

ash points equal to or higher than those of the

coating material.

Those used for general cleaning must have ash

points above 100oF (37.8oC).

Spray booth ventilation must be kept at the rates

required by NFPA-33, OSHA, and local codes. In

addition, ventilation must be maintained during

cleaning operations using ammable or combustible

solvents.

Electrostatic arcing must be prevented.

Test only in areas free of combustible material.

Testing may require high voltage to be on, but only

as instructed.

Non-factory replacement parts or unauthorized

equipment modications may cause re or injury.

If used, the key switch bypass is intended for use

only during set-up operations. Production should

never be done with safety interlocks disabled.

Never use equipment intended for use in waterborne installations to spray solvent based materials.

The paint process and equipment should be set up

and operated in accordance with NFPA-33, NEC,

and OSHA requirements.

LN-9257-07.1

2

Loading...

Loading...