Ransburg 76789, 77046 User Manual

SERVICE MANUAL

ARCHIVE

CP-99-01CP-99-01

CP-99-01

CP-99-01CP-99-01

MGS MULMGS MUL

MGS MUL

MGS MULMGS MUL

TI-GUN SOURCETI-GUN SOURCE

TI-GUN SOURCE

TI-GUN SOURCETI-GUN SOURCE

MODELS:MODELS:

MODELS:

MODELS:MODELS:

76789 MGS 2001 Low V76789 MGS 2001 Low V

76789 MGS 2001 Low V

76789 MGS 2001 Low V76789 MGS 2001 Low V

77046 MSG 2000C High V77046 MSG 2000C High V

77046 MSG 2000C High V

77046 MSG 2000C High V77046 MSG 2000C High V

oltage Control Unit for Cascade Gunsoltage Control Unit for Cascade Guns

oltage Control Unit for Cascade Guns

oltage Control Unit for Cascade Gunsoltage Control Unit for Cascade Guns

oltage Control Unit for Classic Gunsoltage Control Unit for Classic Guns

oltage Control Unit for Classic Guns

oltage Control Unit for Classic Gunsoltage Control Unit for Classic Guns

IMPORIMPOR

IMPOR

IMPORIMPOR

carefully read SAFETY PRECAUTIONS,carefully read SAFETY PRECAUTIONS,

carefully read SAFETY PRECAUTIONS,

carefully read SAFETY PRECAUTIONS,carefully read SAFETY PRECAUTIONS,

starting on page 1, and all instructions in thisstarting on page 1, and all instructions in this

starting on page 1, and all instructions in this

starting on page 1, and all instructions in thisstarting on page 1, and all instructions in this

manual. Keep this Service Manual for futuremanual. Keep this Service Manual for future

manual. Keep this Service Manual for future

manual. Keep this Service Manual for futuremanual. Keep this Service Manual for future

reference.reference.

reference.

reference.reference.

TT

ANTANT

T

ANT

TT

ANTANT

: Before using this equipment,: Before using this equipment,

: Before using this equipment,

: Before using this equipment,: Before using this equipment,

ARCHIVE

CONTENTSCONTENTS

ARCHIVE

CONTENTS

CONTENTSCONTENTS

SAFETY:SAFETY:

SAFETY:

SAFETY:SAFETY:

MGS Multi-Gun Source - Contents

PAGEPAGE

PAGE

PAGEPAGE

3-53-5

3-5

3-53-5

SAFETY PRECAUTIONS............................................................................................................

HAZARDS/SAFEGUARDS..........................................................................................................

INTRODUCTION:INTRODUCTION:

INTRODUCTION:

INTRODUCTION:INTRODUCTION:

GENERAL DESCRIPTION..........................................................................................................

SPECIFICATIONS.......................................................................................................................

PICTORIAL DESCRIPTION........................................................................................................

INSTALLATION:INSTALLATION:

INSTALLATION:

INSTALLATION:INSTALLATION:

LOCATION...................................................................................................................................

INPUT CONNECTIONS..............................................................................................................

EXTERNAL CONNECTIONS......................................................................................................

OPERATION:OPERATION:

OPERATION:

OPERATION:OPERATION:

PROCEDURES............................................................................................................................

MAINTENANCE AND TROUBLESHOOTING:MAINTENANCE AND TROUBLESHOOTING:

MAINTENANCE AND TROUBLESHOOTING:

MAINTENANCE AND TROUBLESHOOTING:MAINTENANCE AND TROUBLESHOOTING:

ROUTINE PREVENTIVE MAINTENANCE ................................................................................

GROUND TEST PROCEDURE..................................................................................................

CONTROL UNIT OUTPUT TEST...............................................................................................

KV OUTPUT TEST (MGS 2000C ONLY)....................................................................................

PC BOARD TEST JUMPERS.....................................................................................................

THEORY OF OPERATION.........................................................................................................

BENCH TESTING........................................................................................................................

TROUBLESHOOTING FLOW CHARTS....................................................................................

TROUBLESHOOTING DIAGRAM..............................................................................................

MGS UNIT BLOCK DIAGRAM....................................................................................................

3

4-5

6-86-8

6-8

6-86-8

6-7

7

8

9-139-13

9-13

9-139-13

9

10

10-13

14-1514-15

14-15

14-1514-15

14-15

16-2416-24

16-24

16-2416-24

16

16

17

17

18

19

19

20-23

23

24

SERVICE:SERVICE:

SERVICE:

SERVICE:SERVICE:

PARTS IDENTIFICATION:PARTS IDENTIFICATION:

PARTS IDENTIFICATION:

PARTS IDENTIFICATION:PARTS IDENTIFICATION:

ORDERING PROCEDURE.........................................................................................................

MGS 2001 PARTS LIST...............................................................................................................

MGS 2000C PART LIST...............................................................................................................

WARRANTIY POLICIES:WARRANTIY POLICIES:

WARRANTIY POLICIES:

WARRANTIY POLICIES:WARRANTIY POLICIES:

APPENDIX:APPENDIX:

APPENDIX:

APPENDIX:APPENDIX:

PAINT AND SOLVENT SPECIFICATIONS................................................................................

VISCOSITY CONVERSION........................................................................................................

VOLUMETRIC CONTENT OF HOSE OR TUBE.......................................................................

CP-99-01

25-2925-29

25-29

25-2925-29

30-3330-33

30-33

30-3330-33

30

30-31

32-33

3030

30

3030

31-3431-34

31-34

31-3431-34

31

32-33

34

ARCHIVE

CP-99-01

SAFETYSAFETY

ARCHIVE

SAFETY

SAFETYSAFETY

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

SAFETY PRECAUTIONS

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

Before operating, maintaining or servicing any

ITW Ransburg electrostatic coating system, read

and understand all of the technical and safety

literature for your ITW Ransburg products. This

manual contains information that is important for

you to know and understand. This information

relates to USER SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please pay particular attention to these

sections.

A WARNING! states information to alert youA WARNING! states information to alert you

A WARNING! states information to alert you

A WARNING! states information to alert youA WARNING! states information to alert you

to a situation that might cause serious injuryto a situation that might cause serious injury

to a situation that might cause serious injury

to a situation that might cause serious injuryto a situation that might cause serious injury

if instructions are not followed.if instructions are not followed.

if instructions are not followed.

if instructions are not followed.if instructions are not followed.

A CAUTION! states information that tellsA CAUTION! states information that tells

A CAUTION! states information that tells

A CAUTION! states information that tellsA CAUTION! states information that tells

how to prevent damage to equipment or howhow to prevent damage to equipment or how

how to prevent damage to equipment or how

how to prevent damage to equipment or howhow to prevent damage to equipment or how

to avoid a situation that might cause minorto avoid a situation that might cause minor

to avoid a situation that might cause minor

to avoid a situation that might cause minorto avoid a situation that might cause minor

injury.injury.

injury.

injury.injury.

A NOTE is information relevant to the pro-A NOTE is information relevant to the pro-

A NOTE is information relevant to the pro-

A NOTE is information relevant to the pro-A NOTE is information relevant to the procedure in progress.cedure in progress.

cedure in progress.

cedure in progress.cedure in progress.

While this manual lists standard specifications

and service procedures, some minor deviations

may be found between this literature and your

equipment. Differences in local codes and plant

requirements, material delivery requirements, etc.,

make such variations inevitable. Compare this

manual with your system installation drawings

and appropriate ITW Ransburg equipment manuals to reconcile such differences.

MGS Multi-Gun Source - Safety

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!

> The user

the Safety Section in this manual and the

ITW Ransburg safety literature therein identified.

> This manual

oughly understood by

operate, clean or maintain this equipment!

Special care should be taken to ensure that

WARNINGSWARNINGS

the

WARNINGS and safety requirements

WARNINGSWARNINGS

for operating and servicing the equipment

are followed. The user should be aware of

and adhere to

codes and ordinances as well as

SAFETY STANDARD, 1995 EDITION,SAFETY STANDARD, 1995 EDITION,

SAFETY STANDARD, 1995 EDITION,

SAFETY STANDARD, 1995 EDITION,SAFETY STANDARD, 1995 EDITION,

prior to installing, operating, and/or servicing this equipment.

> The hazards shown on the following page

may occur during the normal use of this

equipment. Please read the hazard chart

beginning on page 2.

MUST MUST

MUST read and be familiar with

MUST MUST

MUST MUST

MUST be read and thor-

MUST MUST

ALL ALL

ALL personnel who

ALL ALL

ALLALL

ALL local building and fire

ALLALL

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!

NFPA 33NFPA 33

NFPA 33

NFPA 33NFPA 33

Careful study and continued use of this manual will

provide a better understanding of the equipment

and process, resulting in more efficient operation,

longer trouble-free service and faster, easier troubleshooting. If you do not have the manuals and

safety literature for your Ransburg system, contact your local ITW Ransburg representative or

ITW Ransburg.

CP-99-01

11

1

11

MGS Multi-Gun Source - Safety

ARCHIVE

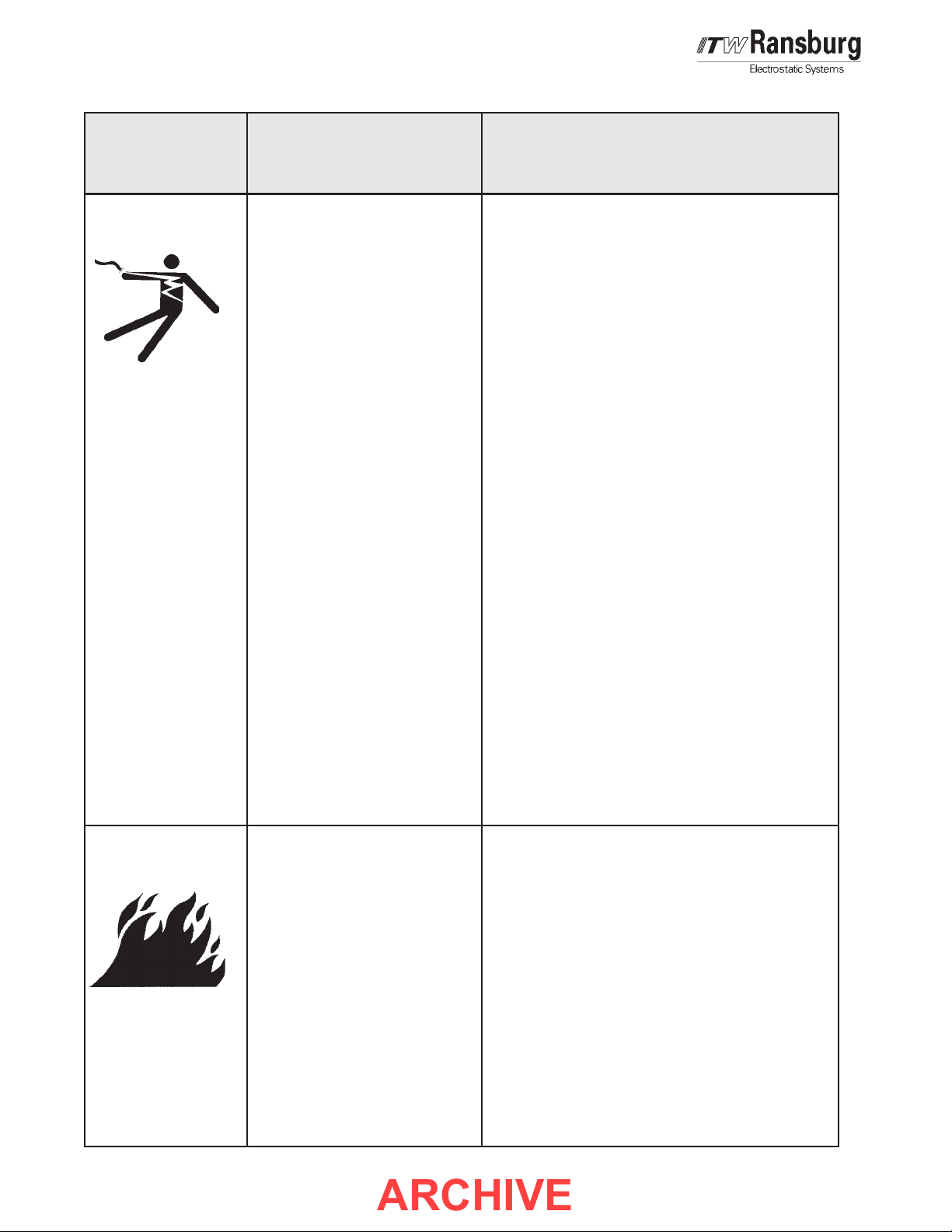

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells where hazards

may occur.

Spray AreaSpray Area

Spray Area

Spray AreaSpray Area

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

Electrostatic Arcing

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

Ensure the ground wire assembly is connected

from the MGS control unit ground stud to a true

earth ground.

Ensure that the MGS control unit is plugged in to

a properly grounded outlet.

Never operate the spray gun without properly

grounding the following.

A. Operators:

Operators must be grounded. Rubber

soled insulating shoes should

worn. Grounding leg straps may be

used.

Operators must remove from themselves

all metal objects that are not grounded.

B. Parts being sprayed. Resistance

between the part and a grounded

conveyor must not exceed 1 megohm.

NOTNOT

NOT be

NOTNOT

Spray AreaSpray Area

Spray Area

Spray AreaSpray Area

Fire

C. Every metal and conductive object in the

spray area. This includes the booth, part

hangers, fire extinguishers, conductive

flooring, etc. If shocks or sparks are

noticed at any point in the spray system,

immediatelyimmediately

immediately

immediatelyimmediately

unit and check the complete system for

proper grounding. Do not use the system

again until the problem has been

identified and corrected.

The MGS Control Unit (and High Voltage

Modules for MGS 2000C)

non-hazardousnon-hazardous

non-hazardous location.

non-hazardousnon-hazardous

Never alter or modify any electrical components of

the MGS control unit.

Always turn MGS control unit

cleaning, or working on spray system equipment.

Ensure that the MGS control unit is interlocked with

the ventilatin system, conveyor and atomization air

[See INSTALLATION section of this manual].[See INSTALLATION section of this manual].

[See INSTALLATION section of this manual].

[See INSTALLATION section of this manual].[See INSTALLATION section of this manual].

Fire entinguishing equipment must be present in

the spray area and tested periodically.

turn off the MGS control

MUST MUST

MUST be installed in a

MUST MUST

OFFOFF

OFF prior to flushing,

OFFOFF

22

2

22

Electrostatic arcing must be prevented (see above).

CP-99-01

MGS Multi-Gun Source - Safety

ARCHIVE

AREAAREA

AREA

AREAAREA

Tells where

hazards may occur.

General Use andGeneral Use and

General Use and

General Use andGeneral Use and

MaintenanceMaintenance

Maintenance

MaintenanceMaintenance

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

Improper operation or maintenance may create a hazard.

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

Read all instructions and safety precautions prior

to operating the MGS control unit.

Always turn power to the MGS control unit OFF,

unplug the electrical cord from its outlet, and

remove the front panel fuse, before opening the

MGS control unit cabinet door.

Comply with appropriate local, state, and national

codes governing ventilation, fire prevention, operation, maintenance and housekeeping of this

equipment. Refer to OSHA standard1910, NFPA33, 1995 edition and your insurance company requirements.

Operators must be given training in accordance

with the requirements of NFPA 33, Chapter 15.

The following notes apply to the MGS 2000CThe following notes apply to the MGS 2000C

The following notes apply to the MGS 2000C

The following notes apply to the MGS 2000CThe following notes apply to the MGS 2000C

only:only:

only:

only:only:

Whenever removing high voltage cables from

equipment, ground the contact end of the cable

by holding the cable such that the contact

touches earth ground for several seconds. Do

not touch the contact until it has been grounded.

This will reduce the possibility of residual charge

causing electrical shock.

The High Voltage Multiplier assembly contains

energy storage components that can cause serious shock injury, and therefore is not field repairable. Warranty will be voided if the High Voltage

Multiplier seal is broken. If the High Voltage Multiplier is defective contact your authorized ITW

Ransburg representative for exchange or repair.

The High Voltage Multiplier and high voltage

cable contain significant capacitance that will

store charge. Allow approximately 10 seconds

for this charge to bleed off before removing the

high voltage cable from the power supply or

spraygun.

CP-99-01

33

3

33

MGS Multi-Gun Source - Introduction

ARCHIVE

INTRODUCTIONINTRODUCTION

INTRODUCTION

INTRODUCTIONINTRODUCTION

GENERAL DESCRIPTIONGENERAL DESCRIPTION

GENERAL DESCRIPTION

GENERAL DESCRIPTIONGENERAL DESCRIPTION

The ITW Ransburg REA ProcessThe ITW Ransburg REA Process

The ITW Ransburg REA Process

The ITW Ransburg REA ProcessThe ITW Ransburg REA Process

The REA Process is an air atomized method for

applying coatings to objects electrostatically. The

REA system applies a high voltage DC charge to

the applicator nozzle electrode, creating an electrostatic field between the atomizer and the target

object. The target is electrically grounded through

its support which may be either stationary or

moving.

A regulated pressure fluid system delivers coating

material to the atomizer. At the atomizer, air is

applied which atomizes the coating material forming a spray mist which, under the influence of the

electrostatic field, becomes electrically charged.

The charged particles are attracted to and deposited on the target object. The forces between the

charged particles and the grounded target are

sufficient to turn most normal overspray around

and deposit it on the side and back surfaces of the

target. Therefore, a high percentage of the spray

is deposited on the target.

MGS 2001 Low VMGS 2001 Low V

MGS 2001 Low V

MGS 2001 Low VMGS 2001 Low V

Control UnitControl Unit

Control Unit

Control UnitControl Unit

The MGS 2001 is a multi-gun control unit which

may supply low voltage for up to 20 guns. The

circuitry is designed to lock out all other guns if one

gun is actuated with voltage.

The MGS 2001 unit converts standard AC line

voltage to a high frequency, low voltage signal

ranging from 0 to 10 Vrms. This signal is supplied

to the REA/REM spray gun where it is converted

to DC high voltage. The voltage/current characteristic is designed to optimize the charging process under varying load conditions and to limit the

operating current to a safe maximum value. In

addition to supplying low voltage output to the

spray gun, the MGS 2001 unit also provides

controls for AC power ON/OFF, high voltage

adjustment, a high voltage meter, a current meter,

a HIGH VOLTAGE indicator light, and a POWER

oltageoltage

oltage

oltageoltage

ON indicator light. Additionally, interlock connections for a conveyor, exhaust fan and high voltage

control are provided with all MGS units.

The MGS 2001 also includes an Independent Gun

Control (IGC) board. This board allows the voltage to each gun to be adjusted independently of

the other guns, if desired.

MGS 2000C High VMGS 2000C High V

MGS 2000C High V

MGS 2000C High VMGS 2000C High V

Control UnitControl Unit

Control Unit

Control UnitControl Unit

The MGS 2000C offers the same features as the

MGS 2001. Additionally, the MGS 2000C is

supplied with High Voltage Modules (one for each

gun) that convert the low voltage output of the

MGS control unit to high voltage. This allows the

MGS system to be used with non-cascade (classic)

guns.

Another difference between the MGS 2001 and

MGS 2000C is the use of reed switches in the

transformer, and air flow switches in the latter, to

trigger the high voltage. This results in a larger box

for the MGS 2000C, as the flow switches are

mounted inside the MGS enclosure, compared to

the MGS 2001 where the reed switches are located

in the gun.

NOTENOTE

NOTE

NOTENOTE

> Except where indicated, this manual

is applicable to all models of the MGS

unit.

oltageoltage

oltage

oltageoltage

44

4

44

CP-99-01

MGS Multi-Gun Source - Introduction

ARCHIVE

SPECIFICASPECIFICA

SPECIFICA

SPECIFICASPECIFICA

Electrical / PhysicalElectrical / Physical

Electrical / Physical

Electrical / PhysicalElectrical / Physical

Input: Input:

Input: Voltage: 85-264 VAC, Single Phase

Input: Input:

Current: 0.4/0.2 Amps AC

Frequency: 50/60 Hertz

Wattage: 40 Watts (Maximum)

Output Output

Output

Output Output

For MGS 2001:

Voltage: 0-10 VRMS

Current: 1 AMP RMS (Maximum)

For MGS 2000C:

Voltage: 0-rated kV of gun

Current: 175 µA (Maximum)

For MGS 2001:

Height: 20 inches

Width: 20 inches

Depth: 8.625 inches

Weight: 40 pounds

For MGS 2000C:

Height: 30 inches

Width: 24 inches

Depth: 9 inches

Weight: 90 pounds

TIONSTIONS

TIONS

TIONSTIONS

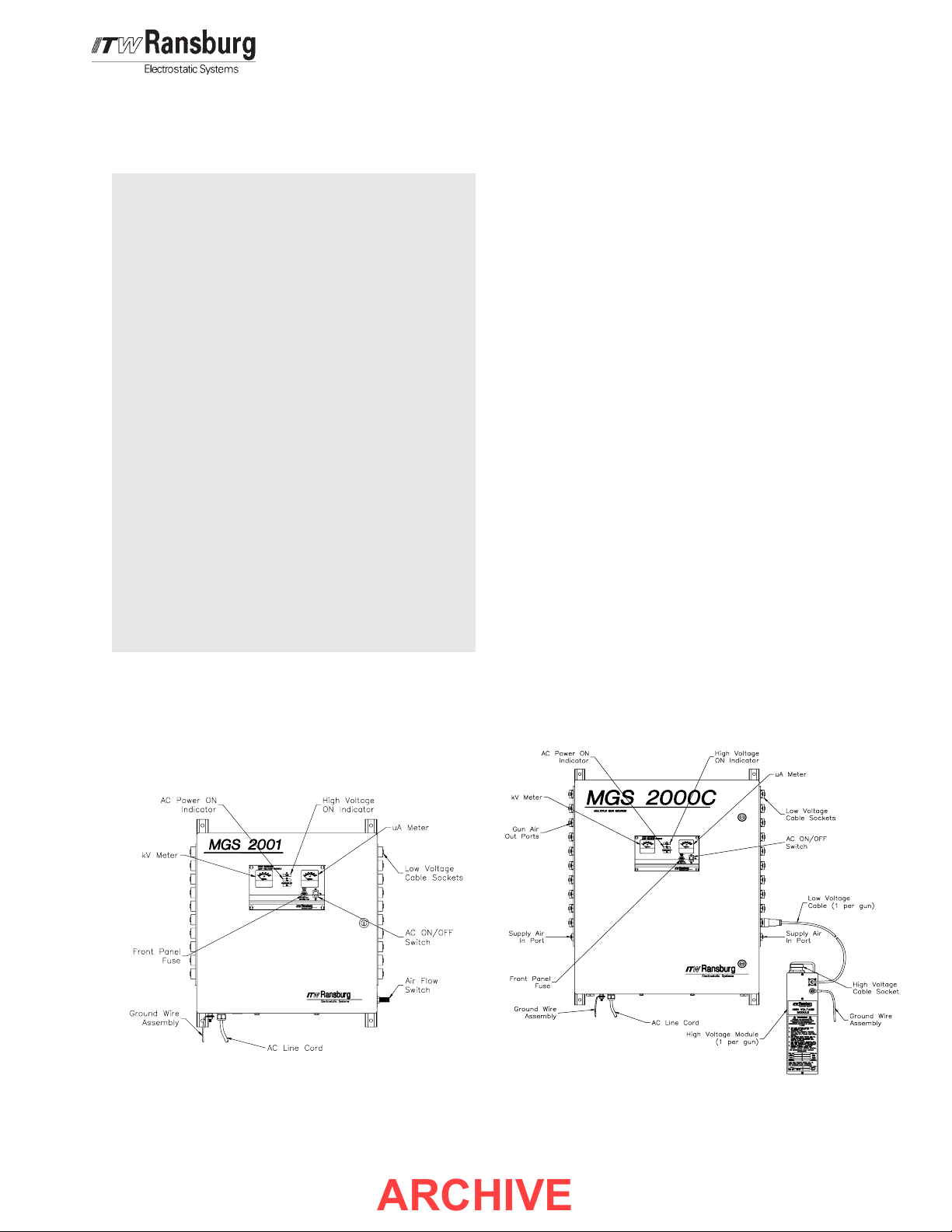

Figure 1a: MGS 2001 Low Voltage Control UnitFigure 1a: MGS 2001 Low Voltage Control Unit

Figure 1a: MGS 2001 Low Voltage Control Unit

Figure 1a: MGS 2001 Low Voltage Control UnitFigure 1a: MGS 2001 Low Voltage Control Unit

CP-99-01

FeaturesFeatures

Features

FeaturesFeatures

Figure 1b: MGS 2000C High Voltage Control UnitFigure 1b: MGS 2000C High Voltage Control Unit

Figure 1b: MGS 2000C High Voltage Control Unit

Figure 1b: MGS 2000C High Voltage Control UnitFigure 1b: MGS 2000C High Voltage Control Unit

FeaturesFeatures

Features

FeaturesFeatures

55

5

55

MGS Multi-Gun Source - Installation

ARCHIVE

INSTINST

INST

INSTINST

>>

>

The MGS control unit (and High Voltage

>>

Modules for MGS 2000C)

outside the hazardous area. (See National

Fire Protection Association Bulletin No. 33;

the Occupational Safety and Health Act of

1970, sections 1910.106 and 1910.107 and

ITW Ransburg Bulletin,

trostatic Coating System Safely.

>>

> The user

>>

the

SECTIONS SECTIONS

SECTIONS of this manual.

SECTIONS SECTIONS

> This manual

ly understood by

clean or maintain this equipment! Special care

should be taken to insure that the

INGSINGS

INGS and requirements for operating and

INGSINGS

servicing safely are followed. The user should

be aware of and adhere to

and fire codes and ordinances as well as

NFPA Standard 33 and The Occupational

Safety and Health Act of 1970 (OSHA) prior to

installing, operating and/or servicing this equipment.

ALLAALLA

ALLA

ALLAALLA

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!

MUSTMUST

MUST read and be familiar with

MUSTMUST

SAFETYSAFETY

SAFETY and

SAFETYSAFETY

MUSTMUST

MUST be read and thorough-

MUSTMUST

TIONTION

TION

TIONTION

MUSTMUST

MUST be located

MUSTMUST

Operating Your Elec-

))

)

))

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

SAFETY PRECAUTIONS

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

ALL ALL

ALL personnel who operate,

ALL ALL

WARN-WARN-

WARN-

WARN-WARN-

ALLALL

ALL local building

ALLALL

on the booth wall or where a convenient booth wall

penetration may be made.

C A U T I O NC A U T I O N

C A U T I O N

C A U T I O NC A U T I O N

!

DO NOTDO NOT

>

DO NOT locate the control unit (or high

DO NOTDO NOT

voltage modules for MGS 2000C) near or

adjacent to heat producing equipment such as

ovens, high wattage lamps, etc.

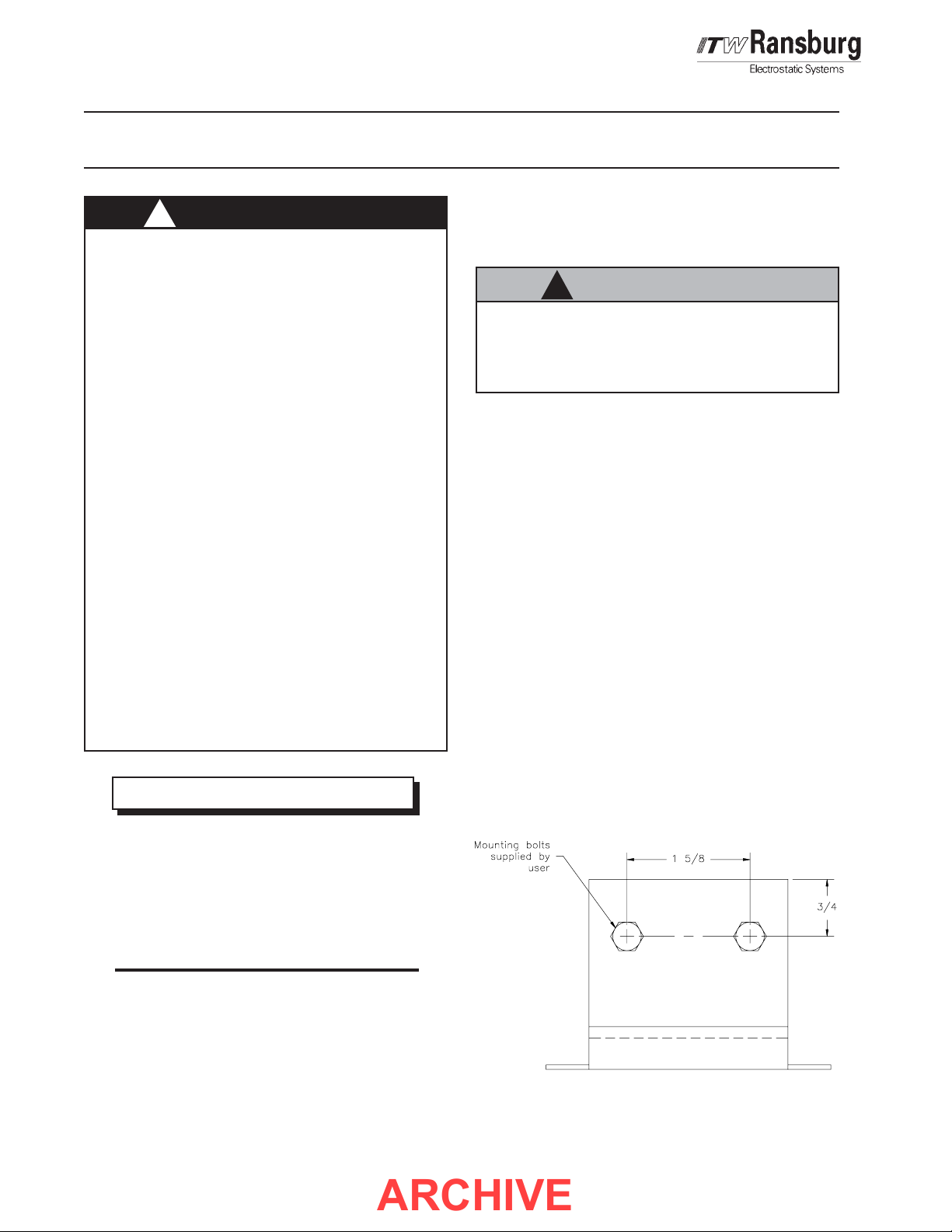

For MGS 2000CFor MGS 2000C

For MGS 2000C

For MGS 2000CFor MGS 2000C

The high voltage modules should be mounted in

an upright position ONLY. The mounting bracket

76086-00 (supplied) can be used to mount the

high voltage modules.

To mount the high voltage module, first install the

76086-00 brackets as shown in Figure 2a. Then,

lift the high voltage module so that it's handle can

be inserted into the bracket slot, as shown in

Figure 2b. Next, lower the bottom of the high

voltage module until the handle comes forward in

the slot and the back of the module rests against

the wall.

> As each installation is unique, this

information is intended to provide general

installation information for the MGS control unit. Consult your authorized ITW

Ransburg representative for specific directions pertaining to the installation of

your equipment.

LOCALOCA

LOCA

LOCALOCA

Install the MGS unit (and high voltage modules for

MGS 2000C) in a convenient area outside the

hazardous location, where it will be protected from

the possibility of environmental intrusion, such as

dust or moisture, and ambient temperatures do not

exceed 120° F. The control unit may be mounted

66

6

66

TIONTION

TION

TIONTION

NOTENOTE

NOTE

NOTENOTE

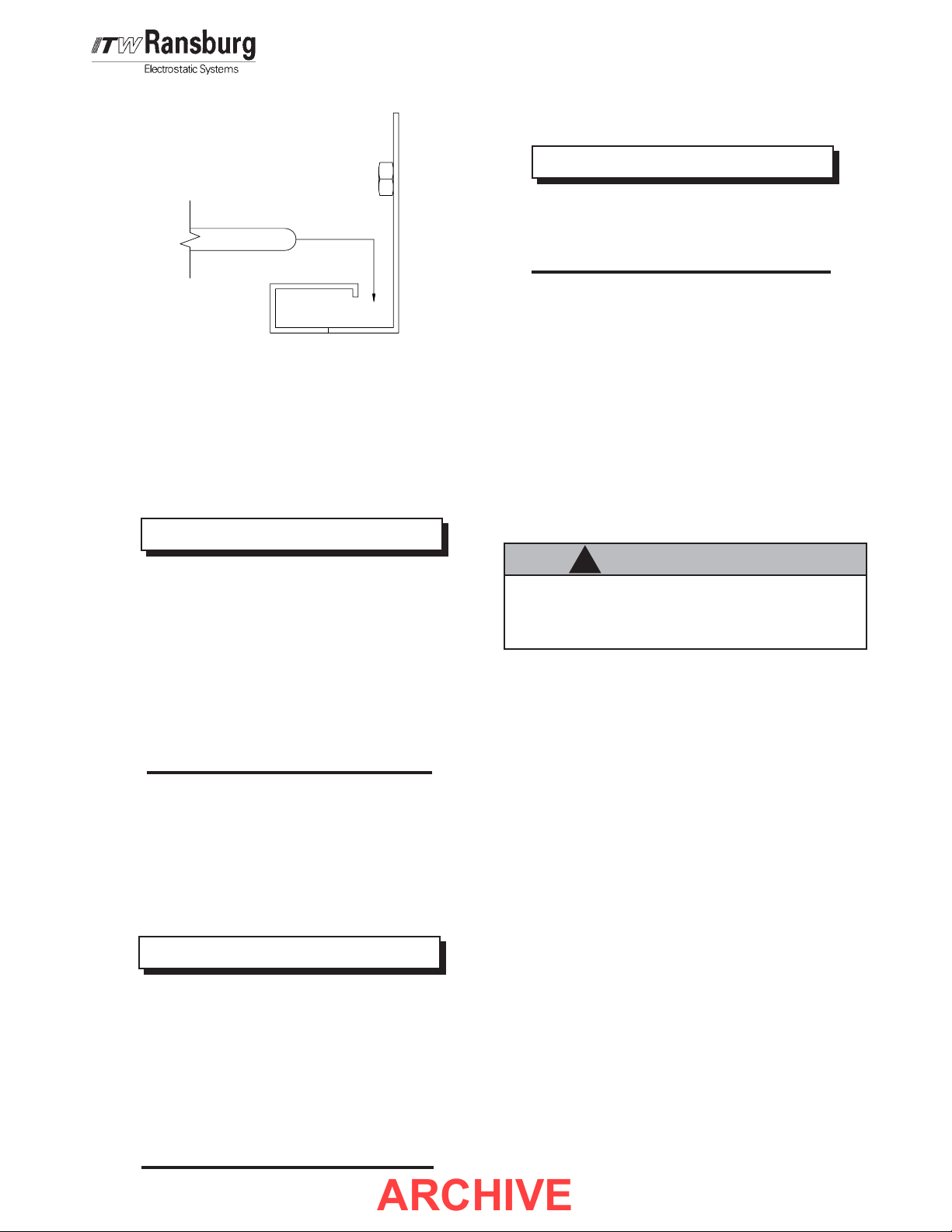

Figure 2a: High Voltage Module BracketFigure 2a: High Voltage Module Bracket

Figure 2a: High Voltage Module Bracket

Figure 2a: High Voltage Module BracketFigure 2a: High Voltage Module Bracket

Mounting for the MGS 2000C.Mounting for the MGS 2000C.

Mounting for the MGS 2000C.

Mounting for the MGS 2000C.Mounting for the MGS 2000C.

CP-99-01

Figure 2b: Inserting Handle Into Bracket Slot forFigure 2b: Inserting Handle Into Bracket Slot for

ARCHIVE

Figure 2b: Inserting Handle Into Bracket Slot for

Figure 2b: Inserting Handle Into Bracket Slot forFigure 2b: Inserting Handle Into Bracket Slot for

INPUT CONNECTIONSINPUT CONNECTIONS

INPUT CONNECTIONS

INPUT CONNECTIONSINPUT CONNECTIONS

Plug the AC line cord into a properly grounded

AC outlet.

MGS 2000C OnlyMGS 2000C Only

MGS 2000C Only

MGS 2000C OnlyMGS 2000C Only

MGS Multi-Gun Source - Installation

EXTERNAL CONNECTIONSEXTERNAL CONNECTIONS

EXTERNAL CONNECTIONS

EXTERNAL CONNECTIONSEXTERNAL CONNECTIONS

NOTENOTE

NOTE

NOTENOTE

> When connecting external wires to the

MGS unit, route the wiring through the

external wiring hole located on the bottom of the unit.

VV

oltage Outputoltage Output

V

oltage Output

VV

oltage Outputoltage Output

For MGS 2001 Low Voltage Control UnitFor MGS 2001 Low Voltage Control Unit

For MGS 2001 Low Voltage Control Unit

For MGS 2001 Low Voltage Control UnitFor MGS 2001 Low Voltage Control Unit

Connect low voltage cables to the low voltage

cable sockets located on the side panels of the

MGS cabinet.

line is individually numbered.

Connect the other end of the low voltage cable to

the handgun, using a wrench to tighten.

Hand tighten only. Hand tighten only.

Hand tighten only. Each voltage

Hand tighten only. Hand tighten only.

NOTENOTE

NOTE

NOTENOTE

> In general, conduit must be used for

approved AC installation, however, if national and local codes permit, the AC

power may be supplied via the factory

installed line cord. If conduit is utilized,

the control unit wiring MAY be routed

through an optional explosion proof

switch mounted on or near the spray

booth where it will be convenient to the

operator.

The MGS control unit accepts universal, single

phase input voltage between 85 and 264 VAC. As

such, there is no need to change any switch

settings when changing input from 115 to 230 VAC

or vice-a-versa.

NOTENOTE

NOTE

NOTENOTE

> MGS units shipped from the factory

for 115 VAC input will have a 72771-06,

1 amp front panel fuse installed. While

MGS units shipped from the factory for

230 VAC input will have a 72771-01, 0.5

amp front panel fuse installed. If the other

input is required, it is recommended that

the fuse be changed in order to keep the

same level of protection.

C A U T I O NC A U T I O N

C A U T I O N

C A U T I O NC A U T I O N

!

DO NOT DO NOT

>

DO NOT over tighten low voltage cable

DO NOT DO NOT

connection to handgun. Damage to plastic

parts may occur.

For MGS 2000C High Voltage ControlFor MGS 2000C High Voltage Control

For MGS 2000C High Voltage Control

For MGS 2000C High Voltage ControlFor MGS 2000C High Voltage Control

UnitUnit

Unit

UnitUnit

Connect low voltage cables to the low voltage

cable sockets located on the side panels of the

MGS cabinet.

voltage line is individually numbered.

Connect other end of low voltage cable to low

voltage cable connector on side of High Voltage

Module.

voltage cable from handgun to high voltage cable

socket located on top of the High Voltage Module.

Safety GroundSafety Ground

Safety Ground

Safety GroundSafety Ground

Crimp the appropriate connector onto the ground

wire assembly and install from the MGS unit

ground stud, located on the bottom panel, to a true

earth ground.

For MGS 2000C control units it is also necessary

to install a ground wire from each High Voltage

Module to earth ground. To do so, crimp the

Hand tighten only.Hand tighten only.

Hand tighten only. Each air and

Hand tighten only.Hand tighten only.

Hand tighten onlyHand tighten only

Hand tighten only. Connect high

Hand tighten onlyHand tighten only

CP-99-01

77

7

77

MGS Multi-Gun Source - Installation

ARCHIVE

appropriate connector onto the ground wire

assembly supplied with each High Voltage Module

and install from the High Voltage Module ground

stud to a true earth ground.

C A U T I O NC A U T I O N

C A U T I O N

C A U T I O NC A U T I O N

!

> The ground wire assembly MUST be

connected from the MGS unit ground stud

(and each high voltage module, for MGS

2000C) to a true earth ground.

InterlocksInterlocks

Interlocks

InterlocksInterlocks

As outlined in NFPA 33 and OSHA standardAs outlined in NFPA 33 and OSHA standard

As outlined in NFPA 33 and OSHA standard

As outlined in NFPA 33 and OSHA standardAs outlined in NFPA 33 and OSHA standard

1910, the AC power line must be series1910, the AC power line must be series

1910, the AC power line must be series

1910, the AC power line must be series1910, the AC power line must be series

interlocked with both the exhaust fan andinterlocked with both the exhaust fan and

interlocked with both the exhaust fan and

interlocked with both the exhaust fan andinterlocked with both the exhaust fan and

conveyor. conveyor.

conveyor. To interlock the MGS unit with the

conveyor. conveyor.

exhaust fan and conveyor perform the following:

1. Ensure the front panel fuse is removed, the

MGS unit is unplugged and the ON/OFF

switch is in the OFF position.

2. Open the MGS cabinet door.

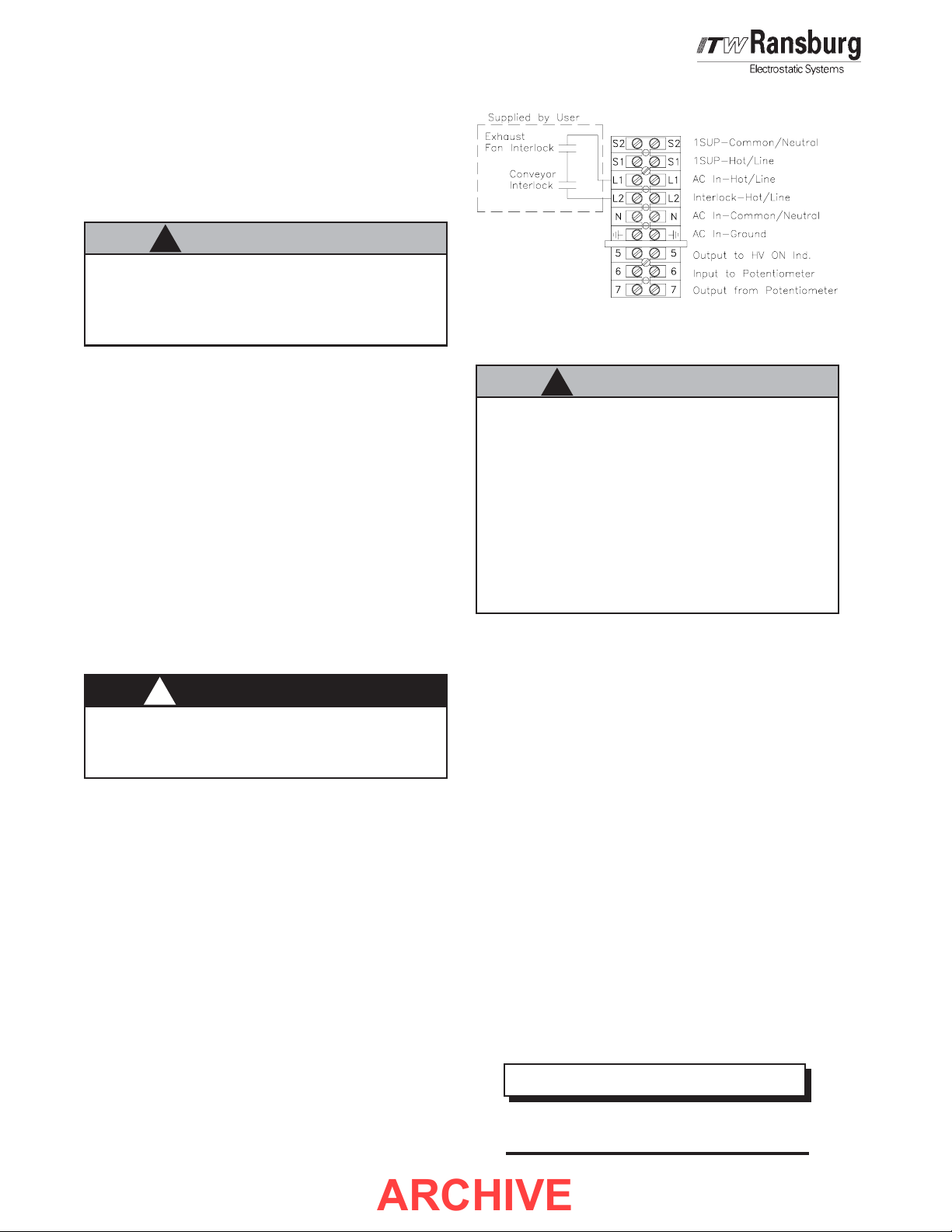

Figure 3: Terminal Block One (1TB)Figure 3: Terminal Block One (1TB)

Figure 3: Terminal Block One (1TB)

Figure 3: Terminal Block One (1TB)Figure 3: Terminal Block One (1TB)

C A U T I O NC A U T I O N

C A U T I O N

C A U T I O NC A U T I O N

!

> When highly conductive, solvent based

paints are used it is also recommended that the

high voltage control be series interlocked with

the atomization air. This prevents the possibility of a charged stream of fluid creating an arc,

and subsequent fire, as it approaches the floor

(or some other grounded object). Consult your

authorized ITW Ransburg representative for

information on interlocking the high voltage

with the atomization air.

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!

> Always double check that the control unit

is unplugged from its AC outlet before working

with any internal wiring.

3. Using a small blade screw driver, remove

the factory installed test jumper from 1TB-L1

to 1TB-L2 on the door-mounted control unit.

4. Route exhaust fan and conveyor interlock

(supplied by user) wiring through the external

wiring hole on the bottom of the MGS unit

and connect to 1TB-L1 and 1TB-L2 as

shown in Figure 3.

tacts should be rated for at least 1 tacts should be rated for at least 1

tacts should be rated for at least 1

tacts should be rated for at least 1 tacts should be rated for at least 1

Amp at 240 volts AC. Amp at 240 volts AC.

Amp at 240 volts AC. Leave ample wire

Amp at 240 volts AC. Amp at 240 volts AC.

to allow the door to close.

5. Secure the cabinet door, replace the front

panel fuse, and plug the MGS unit in.

The interlock con-The interlock con-

The interlock con-

The interlock con-The interlock con-

External Relay ContactsExternal Relay Contacts

External Relay Contacts

External Relay ContactsExternal Relay Contacts

A normally open contact that closes when high

voltage is energized is available at 6PL-6 and 6PL-

7. This contact is sometimes useful in configuring

the control of the spraygun system.

AirAir

Air

AirAir

For MGS 2001 Low Voltage Control UnitFor MGS 2001 Low Voltage Control Unit

For MGS 2001 Low Voltage Control Unit

For MGS 2001 Low Voltage Control UnitFor MGS 2001 Low Voltage Control Unit

1. Connect supply air to the IN port of the air flow

switch located on the lower right side of the

MGS cabinet.

2. Connect the OUT port of the air flow switch to

the manifold which feeds air to the individual

sprayguns. In multiple MGS applications, the

sprayguns for each MGS must be fed from an

air manifold supplied from the OUT port of that

MGS's air flow switch.

NOTENOTE

NOTE

NOTENOTE

> The supply air should be clean, filtered

air, suitable for painting.

88

8

88

CP-99-01

Loading...

Loading...