Page 1

INPUT

1-2-3

AUTO-GAIN

MIC ENGAGE

PHONO

LINE

1

PHONO

+12

LINE

R

-12

GAIN

L

PAN

2 3

PHONO

-12 +12 -12 +12

GAIN

LR LR

PAN

LINE

GAIN

PAN

LEFT RIGHT

+10

+7

+4

+2

0

-2

-4

-7

-10

-20

MAINCUE

DRY

2

2

486

MIC

HI

LOW

MIC

486

AUX IN

EQ

OFF

HIGH

1 00

OL

+12-12

+12-12

DRY

OFF +6

MID

OFF +6

LOW

WET

CUE

1 00

EQ

+6

WET

AB

POST

WET

EQ

DRY WET

OFF +6

HIGH

OFF +6

MID

OFF +6 OFF +6

LOW

DRY

A B

CUE

AB

POST

CUE

OFF +6

OFF +6

CUE

HIGH

MID

LOW

SPLIT CUE

CUE MASTER

AB

POST

2

2

2

2

CUE

2

1 10

65

7 4

9

3

8

RETURNAUX

10

0

SEND RETURN LOW HIGH

FlexFX

4

3

2

65

1 10

7 4

3

8

9

CD1 TRIGGER

1

A

OFF

02

4 6 8 10

2

1 10

B

65

7

8

9

CD2 TRIGGER

3B

486

MAIN

486

BOOTH

486

AUX OUT

486

LEVEL

PHONES

EQ

+12

8

4

0

-4

-8

-12

OFF

1 00

1 00

1 00

1 00

10 8

A

6420

Page 2

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION

IMPORTANT SAFETY INSTRUCTIONS

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with a dry cloth.

7. Do not block any ventilation openings. Install in accordance with manufacturer’s instructions.

8. Do not install near any heat sources such as radiators, registers, stoves, or other apparatus (including ampliers) that produce heat.

9. Do not defeat the safety purpose of the polarized or grounding-type plug. A polarized plug has two blades with one wider than the other. A grounding-type plug has two blades and a third grounding prong. e wide blade or third prong is provided for your safety. If the provided plug does not

t into your outlet, consult an electrician for replacement of the obsolete outlet.

10. Protect the power cord and plug from being walked on or pinched particularly at plugs, convenience receptacles, and the point where it exits from

the apparatus.

11. Only use attachments and accessories specied by Rane.

12. Use only with the cart, stand, tripod, bracket, or table specied by the manufacturer, or sold with the apparatus. When a cart is used, use caution

when moving the cart/apparatus combination to avoid injury from tip-over.

13. Unplug this apparatus during lightning storms or when unused for long periods of time.

14. Refer all servicing to qualied service personnel. Servicing is required when the apparatus has been damaged in any way, such as power supply

cord or plug is damaged, liquid has been spilled or objects have fallen into the apparatus, the apparatus has been exposed to rain or moisture, does

not operate normally, or has been dropped.

15. e plug on the power cord is the AC mains disconnect device and must remain readily operable. To completely disconnect this apparatus from

the AC mains, disconnect the power supply cord plug from the AC receptacle.

16. is apparatus shall be connected to a mains socket outlet with a protective earthing connection.

17. When permanently connected, an all-pole mains switch with a contact separation of at least 3 mm in each pole shall be incorporated in the electrical installation of the building.

18. If rackmounting, provide adequate ventilation. Equipment may be located above or below this apparatus, but some equipment (like large power

ampliers) may cause an unacceptable amount of hum or may generate too much heat and degrade the performance of this apparatus.

19. is apparatus may be installed in an industry standard equipment rack. Use screws through all mounting holes to provide the best support.

WARNING: To reduce the risk of re or electric shock, do not expose this apparatus to rain or moisture. Apparatus shall not be exposed to dripping

or splashing and no objects lled with liquids, such as vases, shall be placed on the apparatus.

NOTE: is equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. ese

limits are designed to provide reasonable protection against harmful interference in a residential installation. is equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment o and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit dierent from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

CAU TIO N: Changes or modications not expressly approved by Rane Corporation could void the user's authority to operate the equipment.

is Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

WARNING

To reduce the risk of electrical shock, do not open the unit. No user

serviceable parts inside. Refer servicing to qualied service personnel.

e symbols shown below are internationally accepted symbols that warn

of potential hazards with electrical products.

is symbol indicates that a dangerous voltage

constituting a risk of electric shock is present within

this unit.

is symbol indicates that there are important

operating and maintenance instructions in the

literature accompanying this unit.

Page 3

OPERATORS MANUAL

0

10

10 8

02

6420

46810

-12

-4

-8

8

4

0

+12

L

-12

OFF

100

+12-12

2

486

R

+6

-20

-10

-4

-7

-2

+12

+10

+2

0

+4

+7

OFF +6

OFF +6

+12-12

OFF +6 OFF +6

OFF +6

OFF +6

OFF +6

OFF +6

LR LR

-12 +12 -12 +12

100

2

486

100

2

486

100

2

486

100

2

486

100

2

486

1

23

OL

CD1 TRIGGER

FlexFX

1

OFF

A

AUX IN

DRY

LOW

WET

DRY

CUE

CUE

RETURNAUX

A

B

CD2 TRIGGER

OFF

3B

DRY

POST

AB

WET

POST

AB

WET

CUE

AB

CUE

LEVEL

PHONES

EQ

AB

POST

DRY WET

SPLIT CUE

AUX OUT

CUE MASTER

CUE

SEND RETURN LOW HIGH

HI

MIC

MIC

MIC ENGAGE

AUTO-GAIN

INPUT

1-2-3

EQ

LINE

PHONO

LINE

PHONO

LINE

PHONO

LOW

MID

HIGH

PAN

EQ

EQ

BOOTH

MAIN

GAIN

LOW

MID

HIGH

PAN

GAIN

LOW

MID

HIGH

PAN

GAIN

LEFT RIGHT

MAINCUE

4

2

3

9

110

8

65

74

2

3

9

110

8

65

74

2

3

9

110

8

65

7

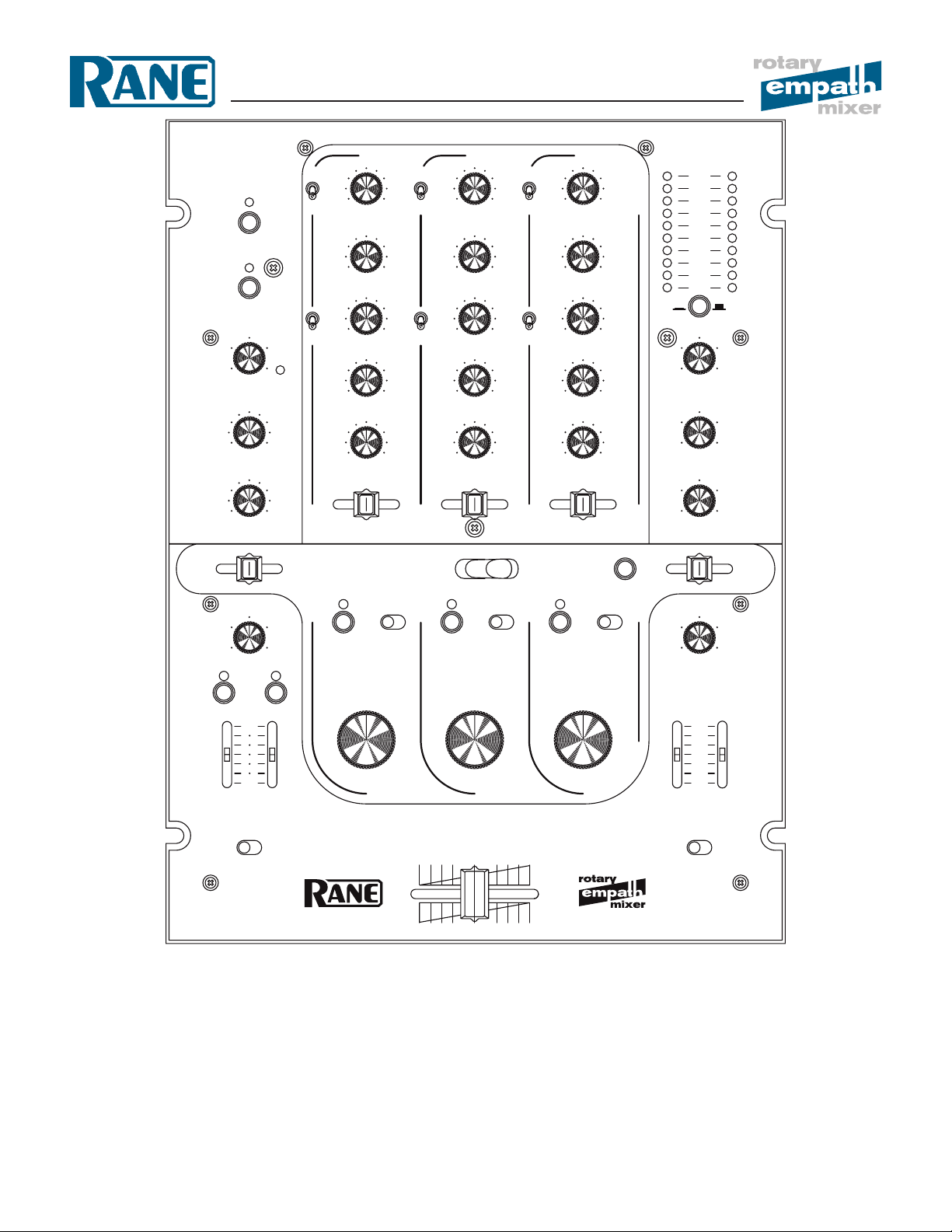

ROTARY EMPATH

DJ MIXER

Introduction

e Empath 10" format mixer oers big-board features and

studio quality sound. e mixer is feature packed, yet easy and

intuitive to use. How did we pull it o? We asked the master

— Grandmaster Flash is responsible for many of the important

features and control locations, even the name. “Empath” implies

WEAR PARTS: is product contains the following wear parts subject to the ninety (90) day warranty period described on page

Warranty-1: Penny & Giles Fader Assembly (Crossfader).

understanding, insight and feeling. When you use the mixer,

you’ll get it. e Empath mixer is designed for professional applications: large club, broadcast, competition, remix, live sound.

e Empath oers a combination of features, compact size and

quality presently unavailable at any price.

Manual-1

Page 4

-20

-10

-4

-7

-2

+10

+2

0

+4

+7

CUE

AB

CUE

SPLIT CUE

“in”

Any Cue

“in”

CUE MASTER

CUE

AUTO-GAIN

“in”

INPUT

1-2-3

Gain

Before

AGC

LEFT

Gain

After

AGC

RIGHT

MAINCUE

“in”

AUDIO PRECISION AMPL (dBr) vs AMPL (dBr)

INPUT LEVEL

23 MAY 102 13:01:49

ON

OFF

-24

-21

-18

-15

-12

-9

-6

-3

0

3

6

9

12

-24 -21 -18 -15 -12 -9 -6 -3 03 6912

O

U

T

P

U

T

L

E

V

E

L

AUDIO PRECISION AMPL (dBr) vs AMPL (dBr) 23 MAY 102 13:01:49

-24

-21

-18

-15

-12

-9

-6

-3

0

3

6

9

12

-24 -21 -18 -15 -12 -9 -6 -3 036912

O

U

T

P

U

T

L

E

V

E

L

INPUT LEVEL

Gain is

increased

Gain is

held below

Threshold

Gain is

decreased

-16 dB Threshold

Target

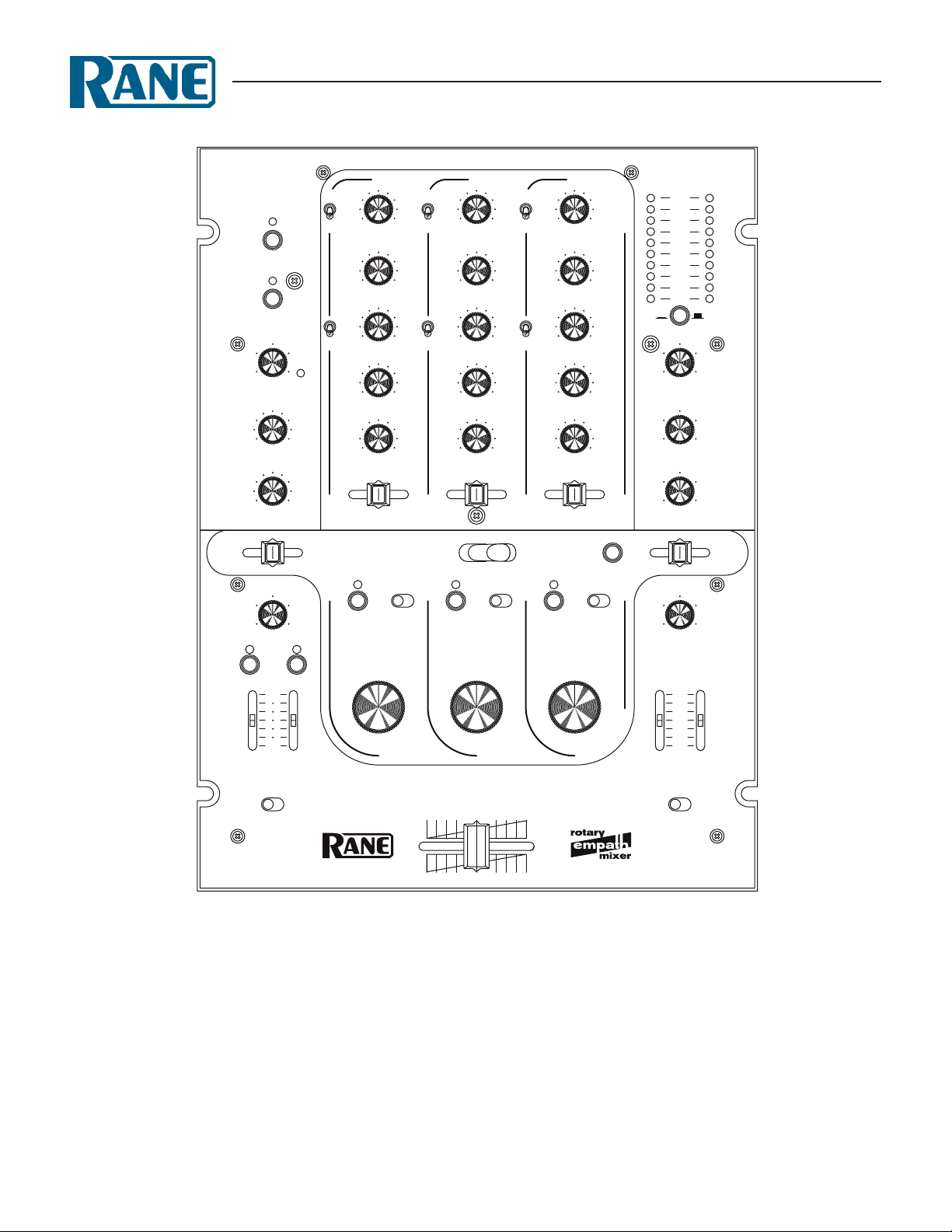

3 fully equipped stereo input channels

1 / 2 / 3

AB

• One Phono and one Line Input for each channel.

° Be sure to connect each turntable ground to the Phono GND terminal.

° PHONO/LINE source switch selects the Input for each channel.

• ±12 dB input GAIN trims adjust for +0 dB on the CUE Meter.

• Left/Right, constant-level PAN controls:

° e loudness stays the same in the room as you Pan left to right.

• 3-band, full-cut tone controls:

° +6 dB boost to full-cut (o).

° 2nd-order Linkwitz-Riley lter topology.

° Low-Mid crosspoint is 300 Hz.

° Mid-High crosspoint is 4 kHz.

• EQ engage switch allows “transform” EQ eects.

• DRY/WET Pan controls:

° Use to split signal between DRY (no eect) and WET (FlexFx loop).

° See FlexFx Loop section for details.

• A-POST-B Crossfader assignment

° Input channels are assignable to A-side, B-side or Post-Crossfader.

° See Advanced Cue Selection section for automatic “Flash-Cue” operation.

Auto-Gain Switch

• Monitors channel-1, -2, and -3 input signals and automatically adjusts the input gain.

° Level is monitored at the Cue point: After PHONO/LINE source selection

After GAIN trim

After EQ

Before the channel Fader

• Enable by setting the Input 1-2-3 Auto-Gain switch to the “in” position.

° Green indicator will light.

° Auto-Gain is engaged for all three channels or none.

• Target Level: 0 dBu = No gain change.

• reshold: –16 dBu

° Minimum level required for Auto-Gain operation.

° If the signal is below –16 dB, the gain holds indenitely.

• Ratio = 3:1

° 3 dB increase or decrease in input level results in 1 dB increase/decrease in output level.

• Turns the gain down at a rate of 32 dB per second.

• Turns the gain up at a rate of 5.33 dB per second.

• Auto-Gain increase or decrease is monitored by the Cue meter system:

° Set A-CUE-B switch to CUE position.

° Select the desired Cue source.

° Set SPLIT CUE switch to “in” position.

° Set CUE/MASTER Pan to center position.

° Set meter CUE/MAIN source switch “in” to CUE.

° Level before Auto-Gain is shown on the left meter.

° Level after Auto-Gain is shown on the right meter.

• Set the Input GAIN trim so that normal input levels result in 0 dB on the meter with or without Auto-Gain engaged.

Automatic Gain Control

(input level increasing)

Manual-2

PHONO

LINE

-12

+12

GAIN

L

PAN

EQ

OFFR+6

HIGH

OFF +6

MID

OFF +6

LOW

DRY

Automatic Gain Control

WET

POST

(input level decreasing)

Page 5

-12

-4

-8

8

4

0

+12

AUX IN

CUE

CUE

RETURNAUX

POST

AB

POST

AB

CUE

AB

CUE

LEVEL

PHONES

EQ

AB

POST

SPLIT CUE CUE MASTER

CUE

LOW HIGH

100

2

486

100

2

486

Penny & Giles Crossfader

SLOW FAST

1

CONTOUR

CROSSFADER

3

SLOW FAST SLOW FAST

-12

-4

-8

8

4

0

+12

-20

-10

-4

-7

-2

+10

+2

0

+4

+7

OFF +6 OFF +6

OFF +6

OFF +6

OFF +6

OFF +6

LR LR

-12 +12 -12 +12

100

2

486

100

2

486

100

2

486

100

2

486

23

CD2 TRIGGER

OFF

3B

DRY

POST

AB

WET

CUE

AB

CUE

LEVEL

PHONES

EQ

AB

POST

DRY WET

SPLIT CUE

AUX OUT

CUE MASTER

CUE

LINE

PHONO

LINE

PHONO

EQ

EQ

BOOTH

MAIN

LOW

MID

HIGH

PAN

GAIN

LOW

MID

HIGH

PAN

GAIN

LEFT RIGHT

MAINCUE

9

8

74

2

3

9

110

8

65

74

2

3

9

110

8

65

7

• Most respected, highest quality analog faders available:

° Very high performance, long life and low maintenance.

° Excellent Feel.

° Rated for 2 million cycles.

° Two kinds of fader caps are provided with each mixer for dierent preferences:

° soft rubber cap for smooth mixing.

° hard plastic cap for fast mixing.

• is crossfader meets the requirements of the most demanding turntablist.

• Caution!

° Do not disrespect your Penny & Giles crossfader.

° Precision parts deserve proper care.

° Read and follow care instructions:

° Do not spray any lubricant or cleaner in the crossfader;

e resistive element is cleaned with warm water and lint free cloth.

° Do not spray lubricant on the slide mechanism —

Apply a drop of silicone lubricant directly on rod.

° When in doubt, give Rane a call: 425-355-6000.

° Failure to follow these simple instructions may aect the performance of the pot and will void the warranty.

° See the service and replacement instructions on page Manual-7.

• CONTOUR controls are provided for Input-1 and Input-3 controls.

° Allows any fader response from SLOW smooth fade to FAST cut.

• CONTOUR control provided for the Crossfader.

° Allows any response from SLOW smooth blend to FAST cut.

Advanced Cue selection

• ree position switch allows automatic “Flash-Cue” or individual Cue selection:

° Set switch to “A” to Cue all channels assigned to the A-side of the Crossfader.

° Set switch to “B” to Cue all channels assigned to the B-side of the Crossfader.

° Set switch to center position for manual Cue selection using individual Cue switches.

• Individual Cue switches with green indicators are provided for:

° Input channel-1

° Input channel-2

° Input channel-3

° AUX Input

° FlexFX RETURN

Headphone Monitor

• Headphone monitor source is decided by two controls:

SPLIT CUE switch

CUE / MASTER pan control.

• SPLIT CUE switch “OUT”:

CUE / MASTER control pans between stereo Cue selection and stereo Master mix.

• SPLIT CUE switch “IN”:

• Headphone LEVEL control determines the loudness.

• Two-band Headphone EQ:

Maximum boost: 12 dB

Maximum cut: -12 dB

Center frequency: 1 kHz.

•

⅛" (3.5 mm) and ¼" jacks provided.

CUE / MASTER control pans between:

mono-Cue in the left channel

and mono-Master in the right channel.

A

02

10 8

46810

6420

B

Manual-3

Page 6

Mic Input

• Balanced ¼" TRS input (Tip (+), Ring (–), Sleeve (ground)

• Accepts unbalanced ¼" TS (Tip-Sleeve) plugs.

• Mic Engage switch turns the Mic on and o without changing the Mic level.

° Green indicator lights when engaged.

• MIC level control range is O to +50 dB

• Overload Indicator:

° Lights 3 dB before clipping.

° Monitors the signal level before and after the HI and LOW tone controls.

° If it lights, turn the MIC level down and/or reduce the tone control boost.

• 2-band tone control:

° Maximum boost: 12 dB.

° Maximum cut: -12 dB.

° Center frequency: 1 kHz.

• FlexFX eects loop:

° WET (eect), DRY (no eect) pan control.

° Process mic with any combination of input channels.

° See FlexFX Eects Loop section for details.

AUX Input and Output

• AUX Input:

° Unbalanced RCA jack.

° AUX CUE signal is sent to the cue circuit before the AUX IN level control.

° AUX IN level control range is O to +10 dB.

° AUX input sums to the Master mix after the Crossfader and FlexFX loop.

• AUX Output:

° Unbalanced RCA jack.

° AUX OUT control range is O to +0 dB

° Source is the Master mix:

Program 1, 2, 3 (pre- or post-eects)

plus the Mic (pre- or post-eects)

plus the AUX Input.

DRY

INPUT

1-2-3

AUTO-GAIN

MIC ENGAGE

486

2

MIC

LOW

MIC

486

2

AUX IN

CUE

AUX

100

OL

+12-12

HI

+12-12

WET

100

Booth Output

• Balanced ¼" TRS output

• Level control range is O to +6 dB

• Source is the Master mix:

Program 1, 2, 3 (pre- or post-eects)

plus the Mic (pre- or post-eects)

plus the AUX Input.

Main Output

• Balanced XLR output.

• Level control range is O to +6 dB.

• Source is the Master mix:

Program 1, 2, 3 (pre- or post-eects)

plus the Mic (pre- or post-eects)

plus the AUX Input.

Manual-4

LEFT RIGHT

+10

+7

+4

+2

0

-2

-4

-7

-10

-20

MAINCUE

486

2

100

MAIN

486

2

100

BOOTH

486

2

100

AUX OUT

Page 7

0

10

FlexFX

DRY

Inputs 1, 2, 3 and MIC

WET

CUE

RETURN

SEND RETURN

Level Meters

• Level Meters have two modes of operation:

° Stereo Main output

° Cue Monitor.

• Meter mode switch set to MAIN “out”:

° Meter displays the level at the Main output, after the Main output LEVEL control.

• Meter mode switch set to CUE “in”:

° Meter displays whatever is selected by the Cue and Headphone monitoring circuit.

° is is the same signal heard in the headphones.

° Monitor any combination of the ve individual Cue signals

-or- A-side auto-cue

-or- B-side auto-cue.

° Split Cue metering is the same as split cue monitoring in the headphones:

Mono-Cue in the left, Mono-Master in the right.

LEFT RIGHT

+10

+7

+4

+2

0

-2

-4

-7

-10

-20

MAINCUE

FlexFX Effects Loop

• Allows the addition of an external stereo eects processor.

• Individual DRY/WET pan controls for channels 1, 2, 3 and MIC.

• Use DRY/WET pan controls simultaneously in any combination.

• SEND level control:

° O to +0 dB.

° Set SEND to prevent overloading the eects processor.

° Many eects devices can't tolerate the high signal levels possible with the Empath.

• Unbalanced ¼" Tip/Sleeve SEND jacks.

• Unbalanced ¼" Tip/Sleeve RETURN jacks.

• FlexFX RETURN CUE

° FlexFX RETURN CUE is before the RETURN level control.

° Allows Cuing eects before bringing into mix:

Set FlexFX RETURN to minimum.

Adjust desired DRY/WET pan control to send signal to the eects processor.

Set A-CUE-B switch to center CUE position.

Engage FlexFX RETURN CUE “in”.

Monitor the eect in the headphones.

Bring the eect into the master mix by increasing FlexFX RETURN Level

• Important reminders when using the FlexFX Return Cue:

° e FlexFX Loop is after the channel Fader and Crossfader.

You will hear nothing in the Return Cue if the signal is turned down by the Crossfader

° For a signal to reach the FlexFX Loop:

One or more of the four DRY/WET pan controls must be set for some WET.

e Send Level must be turned up.

° To send DRY (no eect) signal to the Master mix while you Cue the WET signal:

Set the DRY/WET pan control in the middle.

If you set it to WET with the FlexFX RETURN down, you will lose the signal in the Master mix.

If you set it to DRY, nothing is sent to the FlexFX Loop.

° Setting any DRY/WET Pan control to its center position sends an equal signal to the Master mix and the FlexFX Loop.

• RETURN level control:

° O to +6 dB

° Use in combination with the DRY/WET pan controls to determine how much eect is in the Master mix.

° Increases the signal level of low voltage eects processors to the higher levels possible with the Empath.

You will hear nothing in the Return Cue if the signal is turned down by the channel Fader.

Manual-5

Page 8

CUE

AB

POST

CUE

AB

POST

AB

POSTCUE

3

2

110

46810

6420

65

7 4

9

3

8

2

110

B

CD1 TRIGGER

1

OFF

65

110

7 4

8

9

02

10 8

A

4

3

2

A

CD Triggers

• e Empath mixer provides two CD triggers:

CD1 TRIGGER switch determines trigger source

°

1 —› Input Fader 1 is the source

OFF —› No trigger

A —› A-side Crossfader is the source

CD2 TRIGGER switch determines trigger source

°

3 —› Input Fader 3 is the source

OFF —› No trigger

B —› B-side Crossfader is the source

• Standard CD trigger format

⅛" (3.5 mm) mini TRS jacks

°

Start pulse on Tip.

°

° Stop pulse on Ring/Sleeve.

° Normally high – Active low.

° Pulse width is 20 ms.

° Start threshold is at –65 dB of control attenuation.

° Stop threshold is at –75 dB of control attenuation.

• CD triggers may be used with some external eects processors and drum machines

° See manufacturers specications for details.

65

7

8

9

CD2 TRIGGER

3B

OFF

Internal switching power supply

• Plug in virtually anywhere

• IEC inlet with power switch

• Universal internal switching power supply

• 100 to 240 VAC ±10%

• 50/60 Hz, 20 watts

• US 120 volt cord provided

Note: e internal fuse F1 should be replaced only by qualied service personnel with the same type and rating:

(Wickman, type TR5, #372-1100-000, 250 volt, 1.0 amp, time delay).

Manual-6

Page 9

Service Instructions for the Penny & Giles X3000 Series Crossfader

Introduction

is section describes how to service the Penny & Giles PGFX3000 Series crossfader. Servicing is limited to cleaning, re-lubrication

and replacement of some components, such as the slider and track assembly. Periodic maintenance of these parts provides a smooth

operating feel and extends the life of the unit. Cleaning of the unit is necessary if it is used in dirty or dusty environments or if contaminants have reached inside. e fader must be removed from the panel before servicing.

Spare Part

Description Penny & Giles Part No. Rane Part Number

PGFX3000 D460621 12206 (shown right)

Instructions

1. Remove the two screws from the end of the fader where the

wires exit, and pull away the end block. Withdraw the dust

cover and damping washer. Taking great care remove the

slider assembly, ensuring the wiper contacts are not damaged

as this aects operation. Cleaning of the slider assembly is

possible by gently wiping the wiper contacts and slider bear-

ings using a tissue or cotton bud. If the slider bearings are

excessively worn, as seen by excessive slider rocking, a replace-

ment assembly should be tted.

2. Clean the guide rod, using a tissue or cloth, removing all

traces of dirt or contamination.

3. Remove the track by carefully withdrawing from the unit and

placing face up on the desk. It may be cleaned with a lint free

cloth, rubbing rmly along the track so no debris remains.

If necessary, the track can be washed in warm water, wiped

gently and then dried thoroughly using a dry cloth. When

dry, wipe with a lint free cloth and check for marks along the

track. (Note: Lint-free clothes are recommended to avoid dust

or bers from being deposited). If the track appears worn, or

if cleaning does not improve operation, replacement may be

necessary.

4. Examine the centre channel of the fader body and if dirty,

clean using cotton buds.

5. Re-assemble and lubricate the fader as follows:

a) Hold the fader body so the end block is to your right, as

shown below (the label may be on either side).

a) Insert the slider assembly onto the guide rod and into the

fader body, with the contacts facing away from you.

b) Insert the track into the back of the fader body with the

track contacts facing you (to meet the slider contacts).

c) Lubricate the guide rod by placing one small drop of silicon

oil, using a cocktail stick, either side of the slider assembly.

Move the slider from end to end in order to disperse the oil

evenly. Carefully wipe away any excess oil using a tissue or

cloth.

e) Insert the dust cover and damping washer. Hold in place

while securing the remaining end block. Be sure track wires

exit the bottom of the fader body and are not pinched.

6. Once assembled, move the slider from end to end and ensure

operation is smooth.

Manual-7Manual-7

Page 10

Empath Rotary Fader

Replacement

e main channel faders in the Rotary

Empath are sealed to prevent contamination. Cleaning is not possible, they must be

replaced if damaged. e pot is Rane part

#15422, and may be ordered from the Rane

factory within the U.S.A., or your distributor

outside the U.S.A. Follow these directions:

1. Required Tools: #1 Philips screwdriver,

small wrench.

2. Disconnect the power.

3. Remove knobs from controls covered by

the lower Lexan faceplate.

4. Remove the four screws attaching the

Lexan faceplate.

5. Remove the Lexan faceplate as seen here.

6. e three rotary pots are mounted on a

separate plate. Remove the six screws hold-

ing the fader mounting plate.

7. Lift the plate out of the chassis and rotate

it up as in the photo below.

8. Carefully disconnect the ribbon connector

from the fader assembly.

9. Use a small wrench to remove the nut

holding the fader to the plate.

10. Insert the new fader where the old one

was. Fasten the nut so the ribbon connector aims to the left as in the photo below.

Attach the ribbon connector.

11. To reassemble, reverse the disassembly

procedure.

12. Problems? Contact Rane Corporation

customer service at 425-355-6000.

©Rane Corporation 10802 47th Ave. W., Mukilteo WA 98275-5000 USA TEL 425-355-6000 FAX 425-347-7757 WEB www.rane.com

Manual-8

All features & specications subject to change without notice. 111031

Loading...

Loading...