Page 1

KRYO 65

User Manual

Bedienungsanleitung

Mode d’emploi

Manuale d’uso

Manual de instrucciones

Manual do utilizador

Page 2

2

Page 3

Dear customer

First of all, we thank you for choosing RANCILIO.

We are confident that the product you have purchased will

meet all your expectations. The product you are about to use is

the outcome of extensive research and development. It is the

most efficient, user-friendly and well designed machine of its

kind.

This manual outlines the correct use and maintenance and will

help you to get the best results from your machine. We hope

you will find our explanations clear and we may continue to

earn your business in the future.

Verehrte Kundin, verehrter Kunde

Wir danken Ihnen, dass Sie sich für RANCILIO entschieden haben.

Wir sind überzeugt, dass das Produkt, das Sie erworben haben,

alle Ihre Erwartungen erfüllen wird. Dieses Produkt ist das

Ergebnis sorgfältiger Forschung und Entwicklung. Wir legen

besonderen Wert auf Leistungsfähigkeit, Benutzerfreundlichkeit

und Design.

Die Bedienungsanleitung wird Ihnen helfen Ihre Kaffeemaschine

ordnungsgemäss zu bedienen, zu verstehen und das beste

Ergebnis zu erzielen. Wir hoffen, unsere Erklärungen sind klar

und verständlich und wir dürfen Sie auch in Zukunft zu unseren

geschätzten Kunden zahlen.

Chère cliente, cher client

Tout d’abord merci d’avoir choisi RANCILIO.

Nous avons l’assurance que le produit que vous venez d’acheter

vous donnera entière satisfaction, tout comme tous nos autres

produits sont conçus pour le faire. Le produit que vous allez

utiliser est l’aboutissement de minutieux travaux de recherche et

d’essais. Nous garantit que l’équipement fourni offre une

fonctionnalité, une sécurité et une satisfaction maximales par

rapport aux produits actuellement sur le marché, à la fois en

termes de design et de performances.

Ce livret d’instructions qui explique comment utiliser et entretenir

correctement votre produit vous aidera à obtenir les meilleurs

résultats d’utilisation possibles. Nous espérons que nos

explications sont faciles à comprendre et que vous resterez l’un

de nos fidèles clients à l’avenir.

Gentile cliente

Grazie per averci accordato la Sua fiducia.

Siamo sicuri che il prodotto che Lei ha acquistato risponderà in

pieno alle Sue aspettative. Il prodotto che Lei si accinge ad

usare è il risultato di approfonditi studi e meticolose

sperimentazioni ed è quanto di più funzionale, sicuro ed

apprezzabile, anche sotto il profilo del design, si possa trovare

sul mercato.

Questo manuale per il corretto uso e manutenzione La aiuterà

a sfruttare al meglio la sua macchina. Sperando che trovi chiare

le nostre spiegazioni, ci auguriamo di poterLa sempre

annoverare tra i nostri clienti.

Estimado cliente

Ante todo, queremos agradecerle por haber elegido RANCILIO.

Estamos seguros de que el producto que ha adquirido cumplirá

con todas sus expectativas. El producto que está a punto de

utilizar es el resultado de extensas actividades de investigación y

desarrollo. Es la que ofrece el mejor rendimiento, es la más fácil

de usar y la mejor diseñada de su clase.

Este manual de instrucciones, en el que se explica la manera

correcta de utilizar y mantener su producto, le ayudara a obtener

los mejores resultados. Esperamos que nuestras explicaciones le

parezcan claras y fáciles de comprender y que siga siendo en el

futuro uno de nuestros fieles clientes.

Caro cliente

Em primeiro lugar, obrigado por seleccionar a RANCILIO.

Estamos confiantes de que o produto que adquiriu ira dar

resposta a todas as suas expectativas. O produto que esta

prestes a utilizar e o resultado de uma investigacao e

desenvolvimento extensivos. Trata-se da máquina mais

eficiente, facil de utilizar e bem concebida do seu genero.

Este manual descreve a utilizacao e manutencao correctas e ira

ajuda-lo a obter os melhores resultados da sua máquina.

Esperamos que considere as nossas explicacoes claras e que

possamos continuar a contar com a sua empresa no futuro.

3

Page 4

4

Page 5

ENGLISH

DEUTSCH

FRANCAIS

ITALIANO

ESPAGÑOL

PORTUGUES

1. DESCRIPTION ............................................................. 8

2. OPERATION ............................................................... 8

3. MAINTENANCE .......................................................... 8

4. TROUBLESHOOTING .................................................. 8

5. TECHNICAL DATA ...................................................... 9

6. INSTALLATION ........................................................... 9

7. FIRST START-UP ......................................................... 9

8. DECOMMISSIONING ............................................... 10

9. INFORMATION FOR SERVICE TECHNICIANS ............ 10

1. BESCHREIBUNG ....................................................... 12

2. FUNKTIONSWEISE ................................................... 12

3. REINIGUNG UND PFLEGE ........................................ 12

4. PROBLEME UND LÖSUNGEN ................................... 12

5. TECHNISCHE DATEN ................................................ 13

6. INSTALLATION ......................................................... 13

7. INBETRIEBNAHME ................................................... 13

8. AUSSERBETRIEBNAHME .......................................... 14

9. INFORMATION FÜR DEN KUNDENDIENST .............. 14

1. DESCRIPTION ........................................................... 16

2. FONCTIONNEMENT ................................................. 16

3. ENTRETIEN .............................................................. 16

4. INCONVÉNIENTS ET REMÈDES ................................ 16

5. CARACTÉRISTIQUES TECHNIQUES ........................... 17

6. INSTALLATION ......................................................... 17

7. MISE EN SERVICE ..................................................... 17

8. MISE HORS SERVICE ................................................ 18

9. INFORMATION POUR LE SERVICE D’ASSISTANCE ... 18

1. DESCRIZIONE ........................................................... 20

2. FUNZIONAMENTO ................................................... 20

3. MANUTENZIONE ..................................................... 20

4. INCONVENIENTI E RIMEDI ....................................... 20

5. DATI TECNICI ........................................................... 21

6. INSTALLAZIONE ....................................................... 21

7. MESSA IN SERVIZIO ................................................. 21

8. MESSA FUORI SERVIZIO ........................................... 22

9. INFORMAZIONE PER IL SERVIZIO ASSISTENZA ......... 22

1. DESCRIPCIÓN ........................................................... 24

2. FUNCIONAMIENTO ................................................. 24

3. MANTENIMIENTO ................................................... 24

4. PROBLEMAS Y SOLUCIONES .................................... 24

5. DATOS TÉCNICOS .................................................... 25

6. INSTALACIÓN ........................................................... 25

7. PUESTA EN MARCHA ............................................... 25

8. PUESTA FUERA DE SERVICIO ................................... 26

9. INFORMACIÓN PARA EL SERVICIO DE ASISTENCIA . 26

1. DESCRIÇÃO .............................................................. 28

2. FUNCIONAMENTO .................................................. 28

3. MANUTENÇÃO ........................................................ 28

4. PROBLEMAS E SOLUÇÕES ....................................... 28

5. DADOS TÉCNICOS .................................................... 29

6. INSTALAÇÃO ............................................................ 29

7. COLOCAR EM FUNCIONAMENTO ............................ 29

8. RETIRAR DE FUNCIONAMENTO ............................... 30

9. INFORMAÇÕES PARA O SERVIÇO DE ASSISTÊNCIA . 30

5

Page 6

6

Fig. 1

Page 7

Fig. 2

Fig. 3

Fig. 4

7

Page 8

ENGLISH

KRYO 65/ST KRYO 65/AT

Coffee doser grinder

1. DESCRIPTION

2. OPERATION

3. MAINTENANCE

3.1. Daily

3.2. Periodically or after intense use

4. TROUBLESHOOTING

4.1. Inspection that can be carried out by the user

KRYO 65/ST

Manual-switch operated coffee grinder

KRYO 65/AT

Automatic coffee grinder with optional manual-switch operation

Legend (Fig. 1)

1. Hopper lid

2. Bean hopper

3. Adjustment knob

4. Hopper locking slide

5. Doser lid

6. Doser

7. Tamper

8. Filter holder fork

9. Main switch

10. Grounds tray

11. Dosing lever

12. Doser adjustment knob

KRYO 65/ST

Grind coffee as needed by switching the main switch (Fig. 1 – 9)

KRYO 65/AT

Press the main switch (Fig. 1 – 9). The grinding will then take

place automatically.

You are advised to grind the amount of coffee required for your

immediate needs, since leaving ground coffee unused for too

long can result in loss of freshness and flavor.

Do not regrind coffee which has already been ground.

- Place the filter holder in the filter holder fork (Fig. 1 – 8), pull

the dosing lever (Fig. 1 – 11) firmly towards you and release,

repeating the action for each dose of coffee required.

- Level out the coffee contained in the filter, position the filter

holder under the tamper (Fig. 1 – 7) and raise gently to tamp

the coffee;

- Check that there are no coffee grounds on the rim of the

filter holder.

Maintenance operations should be carried out with the machine

turned off and cold, and with the plug removed from the power

source.

Do not use metallic or abrasive tools, such as steel wool, metal

brushes, needles, etc., or detergents (alcohol etc.), but simply a

damp cloth or sponge.

- Clean the housing and the grounds tray.

- Clean the filter holder fork area.

Empty the bean hopper, and clean it of oily residues left by the

coffee.

Waste materials used for processing or maintenance, if not

biodegradable or pollutant, should be placed in separate

containers and taken to suitable collection centers.

For any type of problem or difficulty not specified here, unplug the

machine, refrain from making attempts to repair or inspect the

machine yourself and contact an authorized service technician.

A) The machine does not turn on:

- Check that it is plugged in;

- Check that there is power being supply and that the

automatic circuit breaker or main switch is turned on;

- Check the condition of the plug and supply cable, and if they

are damaged have them replaced by a qualified technician.

B) Coffee is not ground:

- Check that there are coffee beans in the bean hopper;

- Check that the hopper locking slide is open (lever inwards)

C) Long grinding time

- Check the grind adjustment setting;

- Have the burrs replaced by qualified staff.

8

Page 9

D) Dose size varies:

5. TECHNICAL DATA

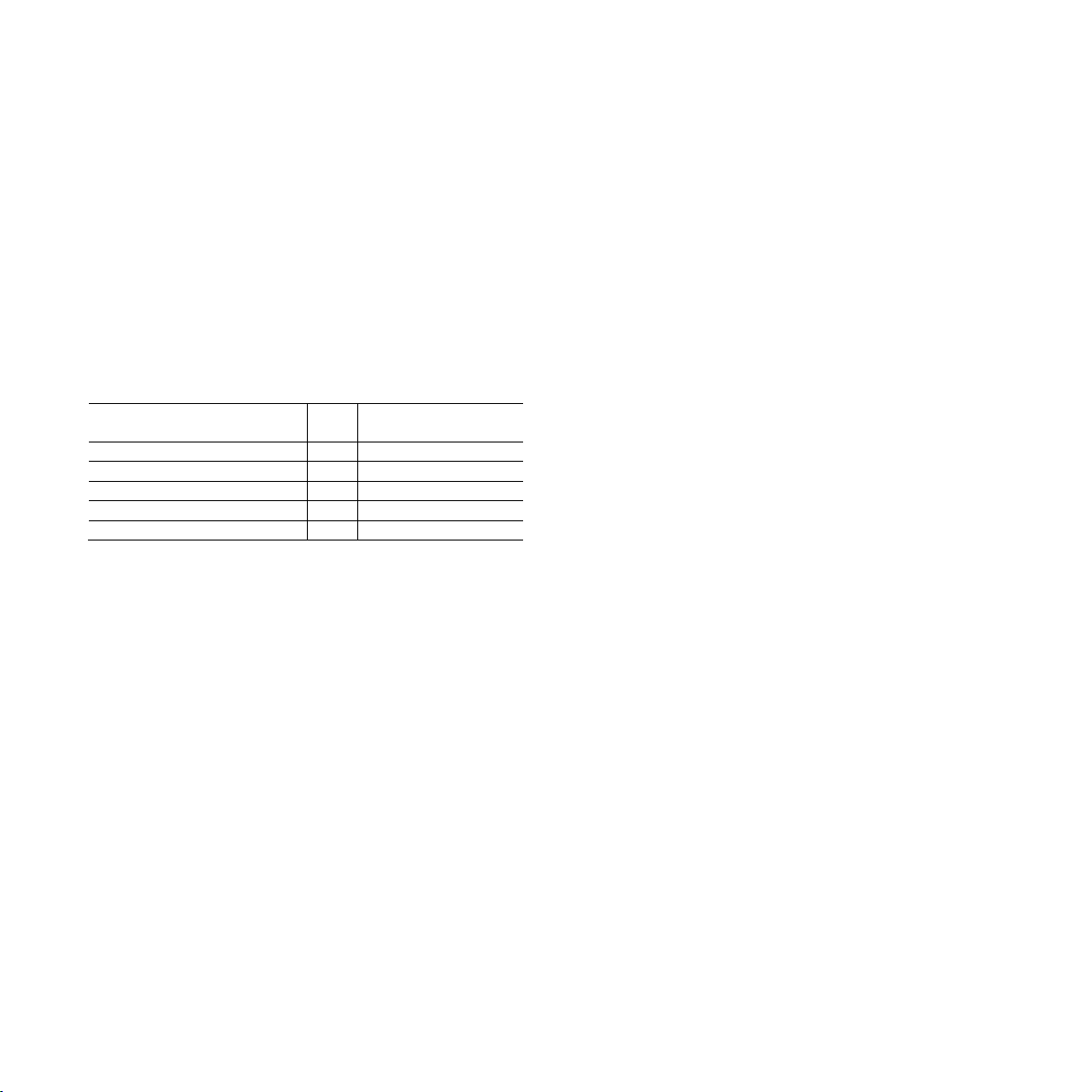

Versions KRYO 65/ST

KRYO 65/AT

Machine size

mm

L.220 - D.385 - H.575

Net weight of machine

kg

13

Production

kg/h

7-9

Bean hopper capacity

g

1300

Dose adjustment

g

5-10

6. INSTALLATION

6.1 Motor rotation

6.2. Burr calibration

7. FIRST START-UP

7.1. Description of commands

7.2. Grind setting

- Carefully clean the doser and the coffee dispenser outlet

- Check that the dosing lever can move freely and is not

obstructed in any way.

Identification details, specifications plate (Fig. 3)

1. Manufacturer

2. Model and version

3. Voltage

4. EC Conformity mark

5. Serial number

6. Pin

7. Total absorption

8. Motor power

9. - -

10. - -

11. Frequency

12. Conformity marks

13. Date of manufacture

Installation must be performed by a qualified technician.

The machine is delivered ready for installation according to the

data on the plate Fig. 3.

Check that the main power supply is compatible with the machine.

Check that the machine, the accessories, the supply cable and the

plug are intact, and in the event of damage, inform the retailer

promptly.

The machines have been designed and built for grinding coffee

beans for professional use.

Any other use is to be considered improper and thus dangerous.

To be carried out by a qualified technician.

For machines with 3-phase electrical supply, the correct rotation

of the motor should be checked.

- Start the grinder and check that grinding is performed

correctly. If this fails to occur, it means that the motor is

rotating in the wrong direction.

- Turn off the machine and the main power supply.

- Invert the two phase conductors, reassemble the machine

and try to perform the grinding operation again.

To be performed during installation and after burr replacement

The dosing grinders are tested with a random grind setting, and

will need to be readjusted. This operation should be carried out

with the bean hopper empty.

Hold down the adjustment unlock button (Fig. 2 – 1) and at the

same time slowly turn the adjustment knob (Fig. 2 – 3) counterclockwise until the burrs brush against each other (when they come

into contact, the sound of metallic friction can be heard), turn the

numbered ring (Fig. 2 – 2) so that the starting point 0 is frontal;

move the adjustment knob (Fig. 2 – 3) in the opposite direction

(clockwise), to position 10;

KRYO 65/ST

Main switch (Fig. 1 – 9) with two positions; when switched on, the

machine is on and coffee grinding begins.

KRYO 65/AT

Main switch (Fig. 1 – 9) with two positions; in position (I), the

machine is on and will automatically shut-off when the doser

has been filled.

The coffee grinder is tested by the manufacturer with a medium

grind setting. The setting depends on the type of coffee used.

Adjust the grind setting only when the appliance is not in

operation. Never adjust when in use.

9

Page 10

- Place a small quantity of coffee beans in the bean hopper

7.3. Adjusting the ground coffee dose

8. DECOMMISSIONING

8.1. Temporary

8.2. Final

9. INFORMATION FOR SERVICE TECHNICIANS

9.1. Replacement of burrs

and close the lid;

- Check that the hopper locking slide is open ((Fig. 1 – 4)

pushed in)

- Grind a small quantity of coffee:

- Position the filter holder on the filter holder fork (Fig. 1 – 8),

then pull the dosing lever (Fig. 1 – 11) to dispense a dose of

ground coffee (this operation should be performed after

adjusting the grind setting See 7.3);

- Brew some coffee, checking the dispensing time, which should

be between 25 and 30 seconds for perfectly ground coffee;

- Check the appearance of the coffee and its taste, considering

that excessively course grounds produce light coloured coffee

without a crema, while grounds that are too fine result in

strong, dark coffee without a crema.

- If the coffee does not respond to your desired requirements,

adjust grind fineness by pressing the ring block button (Fig. 2 – 1)

and turning the regulation knob (Fig. 2 – 3) counter-clockwise for

a finer grind or clockwise for a coarser grind.

- Repeat the operation until you have obtained the desired

quality of coffee.

If using the same kind of coffee, further grinding adjustments

are not normally necessary, whereas if you change type of

coffee, a preliminary check is required.

The doses can be adjusted as follows:

- Turn the knob below the doser (Fig. 1 – 12) counter-clockwise

to increase the dose.

- Close the hopper and grind the coffee beans remaining

between the burrs.

- Turn off the switch and unplug the appliance from the power

source;

- Remove the ground coffee and any coffee beans remaining in

the bean hopper.

- Perform cleaning and maintenance operations;

- Coil up the supply cable and attach it to the machine using

adhesive tape;

- Cover the machine and place it in a dry place, sheltered from

bad weather and to which you have exclusive access.

In addition to the operations of temporary decommissioning:

- Cut the power cable,

- Pack up the machine using cardboard or similar materials

and hand it over to specialized operators (authorized waste

disposal collectors or dealers in second-hand goods)

Although manufactured in tempered steel, the burrs are subject

to wear and tear.

Their lifespan is influenced by the amount of coffee ground, its

hardness and degree of roasting, as well as the quantity and

purity of the coffee beans.

Small stones and various impurities have a marked abrasive

action which significantly reduces the lifespan of the burrs.

When grinding time becomes noticeably longer or the grind

becomes irregular, the burrs should be replaced as follows:

- Pull the hopper locking slide (Fig. 1 – 4);

- Start the grinder to grind the coffee remaining between the

burrs;

- Once grinding has finished, turn off the machine and unplug

from the power source;

- Empty the bean hopper (Fig. 1 – 3);

- Remove the regulation knob (Fig. 1 – 3);

- Turn the upper burr-holder (Fig. 4 – 1) counter-clockwise until

the head emerges completely;

- Unscrew the screws (Fig. 4 – 2) and remove the burrs (Fig. 4 – 3)

from the burr-holder:

- Carefully clean the burr supports, the burr-holder thread and

its housing;

- Position the new burrs in their holders and block them firmly

in place;

- Reassemble the machine, performing the previous steps in

reverse.

- Calibrate the new burrs.

10

Page 11

Safety instructions

Specific safety instructions

• The appliance is not to be used by children or persons with

reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given

supervision or instruction.

• Children should not play with the machine, whether they are

supervised or unsupervised.

• Do not leave the packing elements (plastic bags, expanded

polystyrene, nails, cardboard, etc.) within the reach of children,

as these elements are potential sources of danger.

• Do not place heavy items on the packaging. Do not stack more

than three items of the same kind.

• Do not obstruct the suction and dispersion grilles. Do not cover

with cloths, etc.

• If the machine freezes, leave the machine in a place with a

minimum temperature of 20°C for at least 20 minutes before

switching it on.

• Keep the packed machine in a dry place, not exposed to

environmental elements and in conditions in which the

temperature does not go below 5°C.

• Never put any vessels filled with liquid on top of the machine.

• Improper installation can cause damage to people, animals

and things for which the manufacturer cannot be considered

responsible.

• Install the machine on a water repellent surface (laminate,

steel, ceramic, etc.) away from heat sources (oven, cooking

stove, fireplace, etc.) and in conditions in which the

temperature may not go below 5°C. KEEP WARM. Place on

even surface.

• Do not leave the machine exposed to environmental elements

or place them in damp rooms such as bathrooms.

• Switch off the appliance and disconnect from power supply before

changing accessories or approaching parts that move in use.

• Only use original spare parts in order to avoid compromising

the safety and proper functioning of the machine.

• In an emergency, such as fire, unusual noise, overheating, etc.,

take immediate action, disconnect the power.

• When in doubt, request a detailed diagram of the supplied

power from a qualified electrician.

• Adaptors, multiple sockets and/or extensions must not be used.

• Before connecting the equipment, check if the data on the

machine corresponds to your electrical power supply.

• The power supply must be provided with the following safety

devices: efficient grounding connection; section of conductors

suitable for absorption capacity; efficient grounding leakage

protection circuit breaker.

• If the power supply cable to the machine is damaged it must be

replaced by the manufacturer or his service personnel or an

authorized electrician in order to prevent any risks.

• The machine has to be connected to the fixed installation

using a UL listed grounding type plug of proper rating. Plug

shall be selected and installed only by qualified personnel. (For

US and Canada only).

• Installation and first start up must only be carried out by a

RANCILIO service technician or trained RANCILIO representative

with due regard to all local installation regulations.

• Leave enough free space around the machine to facilitate its

use and the performance of any maintenance operations.

• The machine must not be set up in areas where water tubes or

highpressure cleaners are in use!

• A qualified electrician must make all electrical connections.

• A power switch (mains switch) and / or an electrical socket

must be connected, and readily accessible, near the machine.

• The power switch must isolate the machine completely from

the power supply. The gap between the contacts must be at

least 3mm.

11

Page 12

DEUTSCH

KRYO 65/ST KRYO 65/AT

Kaffeemühle mit Dosierer

1. BESCHREIBUNG

2. FUNKTIONSWEISE

3. REINIGUNG UND PFLEGE

3.1. Tägliche Reinigung

3.2. Regelmässige Pflege und Reinigung nach

intensivem Gebrauch

4. PROBLEME UND LÖSUNGEN

4.1. Vom Bediener durchführbare Kontrollen

KRYO 65/ST

Kaffeemühle mit manueller Ein- und Ausschaltung

KRYO 65/AT

Automatische Kaffeemühle mit manueller Ein- und

Ausschaltmöglichkeit

Legende (Fig. 1)

1. Bohnenbehälterdeckel

2. Bohnenbehälter

3. Regler

4. Bohnenbehälterverschluss

5. Dosiererdeckel

6. Dosierer

7. Kaffeepresser

8. Siebträgeraufnahmegabel

9. Hauptschalter

10. Auffangschale

11. Dosierhebel

12. Einstellknopf für Dosiermenge

KRYO 65/ST

Kaffee nach Bedarf durch Betätigen des Hauptschalters (Fig. 1 -9)

mahlen.

KRYO 65/AT

Hauptschalter (Fig. 1 -9) betätigen; der Mahlvorgang wird

automatisch durchgeführt.

Es wird empfohlen, immer nur die für den sofortigen Bedarf

notwendige Menge zu vermahlen, da zu lange aufbewahrter

gemahlener Kaffee an Frische und Aroma verliert.

Bereits gemahlenen Kaffee nicht nochmals mahlen.

- Siebträger in die Aufnahmegabel (Fig. 1 - 8) einsetzen,

Dosierhebel (Fig. 1 -11) ein- oder mehrmals kräftig zu sich

ziehen und wieder loslassen, jedes Betätigen des

Dosierhebels entspricht einer Portion.

- Kaffee im Sieb glattstreichen, Siebträger unter den

Kaffeepresser (Fig. 1 -7) schieben und den Kaffee nicht allzu

kräftig festdrücken.

- Darauf achten, dass keine Kaffeereste auf dem Rand des

Siebträgers verbleiben.

Reinigungsarbeiten immer bei ausgeschaltetem, kaltem Gerät

vornehmen und den Netzstecker aus der Steckdose ziehen.

Keine metallischen oder scheuernden Hilfsmittel wie Stahlwolle,

Stahlbürsten, Nadeln etc. und auch keine aggressiven

Reinigungsmittel (Alkohol etc.) verwenden, sondern ein feuchtes

Tuch oder einen feuchten Schwamm.

- Mühlengehäuse und Auffangschale reinigen.

- Dosierbereich unter dem Dosierer reinigen.

Bohnenbehälter entleeren, fettige Kaffeerückstände entfernen.

Für Reinigung und Pflege verwendete Stoffe, die nicht biologisch

abbaubar bzw. umweltschädlich sind, in getrennten Behältern

an Abfallsammelstellen abgeben.

Bei allen anderen nicht spezifizierten Defekten oder Problemen

den Netzstecker ziehen, jedoch keine direkten Reparaturen oder

Kontrollen vornehmen, sondern den technischen Kundendienst

hinzuziehen.

A) Das Gerät lässt sich nicht einschalten:

- Prüfen, ob der Netzstecker eingesteckt ist.

- Prüfen, ob Netzstrom vorhanden, der FI-Schalter nicht

herausgesprungen und der Hauptschalter am Gerät

eingeschaltet ist.

- Netzstecker und Anschlusskabel auf Funktionstüchtigkeit

prüfen. Bei Beschädigungen vom Fachmann austauschen

lassen.

B) Die Mühle mahlt nicht:

- Prüfen, ob der Bohnenbehälter mit Kaffeebohnen gefüllt ist.

12

Page 13

- Prüfen, ob der Bohnenbehälterverschluss offen ist

5. TECHNISCHE DATEN

Versionen

KRYO 65/ST

KRYO 65/AT

Abmessungen

mm

L.220 - B.385 - H.575

Nettogewicht

kg

13

Leistung

kg/h

7-9

Fassungsvermögen Bohnenbehälter

g

1300

Einstellung der Dosierung

g

5-10

6. INSTALLATION

6.1 Motordrehrichtung

6.2. Kalibrierung der Mahlscheiben

7. INBETRIEBNAHME

7.1. Beschreibung der Bedienelemente

7.2. Mahlgradjustierung

(Verschluss nach innen).

C) Das Mahlen dauert zu lange:

- Mahlgradeinstellung kontrollieren.

- Mahlscheiben vom Fachmann austauschen lassen.

D) Die Dosierung ist ungleichmässig:

- Dosierer und Pulverauswurf sorgfältig reinigen.

- Prüfen, ob der Dosierhebel frei beweglich ist und sich

komplett verschieben lässt.

Kenndaten auf dem Typenschild (Fig. 3)

1. Hersteller

2. Modell und Version

3. Spannung

4. CE-Kennzeichnung

5. Seriennummer

6. Pin

7. Anschlussleistung

8. Motorleistung

9. - -

10. - -

11. Frequenz

12. Konformitätszeichen

13. Produktionsdatum

Die Installation muss von einem qualifizierten Techniker

vorgenommen werden.

Das Gerät wird installationsbereit gemäss den Kenndaten in Fig. 3

geliefert.

Sicherstellen, dass die Anschlussleitung dieselben Eigenschaften

wie das Gerät hat.

Mühle, Zubehörteile, Anschlusskabel und Stecker auf Schäden

prüfen und gegebenenfalls umgehend den Händler informieren.

Das Gerät wurde für das Mahlen von Kaffeebohnen im

professionellen Einsatz konzipiert und gebaut.

Jede andere Verwendung gilt als nicht bestimmungsgemäss und

ist gefährlich.

Darf nur durch qualifizierten Techniker vorgenommen werden.

Bei Geräten, die mit Dreiphasenwechselstrom betrieben werden,

muss die korrekte Motordrehrichtung kontrolliert werden.

- Mühle starten und prüfen, ob der Mahlvorgang korrekt läuft.

Ist dies nicht der Fall, bedeutet das, dass der Motor in die

falsche Richtung dreht.

- Gerät ausschalten und Netzstecker ziehen.

- Zwei Phasenleiter austauschen, alles wieder zusammenbauen

und einen weiteren Mahlversuch starten.

Bei der Installation und nach Mahlscheibenwechsel

Die Kaffeedosiermühle wird mit einer werkseitigen Mahlgradeinstellung ausgeliefert, eine Nachjustierung bei leerem

Bohnenbehälter ist erforderlich.

Den Verriegelungsknopf (Fig. 2 -1) gedrückt halten und gleichzeitig

den Regler (Fig. 2 -3) langsam gegen den Uhrzeigersinn drehen, bis

sich die Mahlscheiben berühren (dies ist an einem feinen

metallischen Klirrgeräusch erkennbar). Den nummerierten Ring

(Fig. 2 -2) in Nullstellung drehen und so einstellen, dass die 0 nach

vorne zeigt. Dann den Regler (Fig. 2 -3) in die Gegenrichtung (im

Uhrzeigersinn) in die Stellung 10 drehen.

KRYO 65/ST

Hauptschalter (Fig. 1 -9) mit zwei Stellungen. In Stellung (I) wird

die Stromzufuhr aktiviert und der Mahlvorgang gestartet.

KRYO 65/AT

Hauptschalter (Fig. 1 -9) mit zwei Stellungen. In Stellung (I) wird

die Stromzufuhr aktiviert. Der Mahlvorgang wird automatisch

durchgeführt

Die Kaffeemühle wird vom Hersteller mit einer mittleren

Mahlgradeinstellung ausgeliefert. Welcher Mahlgrad gewählt

wird, hängt von der verwendeten Kaffeesorte ab.

13

Page 14

Die Mahlgradjustierung nur bei stillstehender Mühle vornehmen,

7.3. Einstellung der Dosierung

8. AUSSERBETRIEBNAHME

8.1. Vorübergehend

8.2. Endgültig

9. INFORMATION FÜR DEN KUNDENDIENST

9.1. Mahlscheibenwechsel

niemals bei laufender Mühle!

- Eine kleine Menge Kaffeebohnen in den Bohnenbehälter

einfüllen und den Deckel schliessen.

- Prüfen, ob der Behälter offen ist (Bohnenbehälterverschluss

(Fig. 1 - 4) eingeschoben).

- Eine kleine Portion Kaffee mahlen:

- Siebträger in die Aufnahmegabel (Fig. 1 - 8) einsetzen und

Dosierhebel (Fig. 1 -11) betätigen, um die gemahlene Portion

Kaffee zu entnehmen (dies ist nach Einstellung der

Dosierung durchzuführen, siehe 7.3).

- Einen Kaffee zubereiten und dabei die Brühdauer

kontrollieren, die bei optimaler Mahlgradeinstellung

zwischen 25 und 30 Sekunden liegen soll.

- Kaffee auf Farbe und Geschmack prüfen. Ein zu grober

Mahlgrad ergibt hellen Kaffee ohne Crema, während ein zu

feiner Mahlgrad starken, dunklen Kaffee ohne Crema ergibt.

- Fällt der Kaffee nicht wunschgemäss aus, Mahlgrad durch

Drücken des Verriegelungsknopfs (Fig. 2 -1) und Drehen des

Reglers (Fig. 2 -3) gegen den Uhrzeigersinn für einen feineren

Mahlgrad bzw. im Uhrzeigersinn für einen gröberen Mahlgrad

einstellen.

- Vorgang so lange wiederholen, bis die gewünschte

Kaffeequalität erreicht ist.

Bei Verwendung derselben Kaffeesorte sind normalerweise

keine weiteren Mahlgradeinstellungen notwendig. Wenn jedoch

die Kaffeesorte gewechselt wird, muss eine neue

Mahlgradjustierung vorgenommen werden.

Zum Einstellen der Dosierung wie folgt vorgehen:

- Um die Menge zu erhöhen, den Knopf (Fig. 1 – 12) unter dem

Dosierer gegen den Uhrzeigersinn drehen.

- Bohnenbehälter schliessen und die zwischen den

Mahlscheiben verbliebenen Bohnen mahlen.

- Gerät abschalten und Netzstecker aus der Steckdose ziehen.

- Gemahlenen Kaffee und eventuell im Bohnenbehälter

verbliebene Bohnen entfernen.

- Reinigung durchführen.

- Stromkabel aufwickeln und mit Klebeband am Gerät fixieren.

- Gerät abdecken und an einem trockenen, witterungsgeschützten

und sicheren Ort aufbewahren.

Zusätzlich zur vorübergehenden Ausserbetriebnahme ist

Folgendes vorzunehmen:

- Anschlusskabel durchschneiden,

- Gerät mit Karton oder anderem Material verpacken und der

zuständigen Stelle übergeben (autorisierte Abfallentsorgung

oder Rücknahmestelle für Altgeräte).

Die Mahlscheiben sind zwar aus gehärtetem Stahl gefertigt,

nutzen sich aber mit der Zeit ab.

Ihre Lebensdauer ist von der gemahlenen Kaffeemenge, von

Härte und Röstgrad der Kaffeebohnen sowie von der Reinheit des

Mahlgutes abhängig.

Steinchen und andere Verunreinigungen haben eine stark

scheuernde Wirkung, die die Lebensdauer der Mahlscheiben

beträchtlich verkürzen kann.

Wenn der Mahlvorgang ungewöhnlich lange dauert oder das

Mahlergebnis unregelmässig ausfällt, sind die Mahlscheiben wie

folgt zu wechseln:

- Trichterverschlusshebel (Fig. 1 - 4) betätigen.

- Mühle starten, um die zwischen den Mahlscheiben

verbliebenen Bohnen zu mahlen.

- Nach Ende des Mahlvorgangs Gerät ausschalten und

Anschlusskabel abziehen.

- Bohnenbehälter (Fig. 1 -2) entleeren.

- Regler (Fig. 1 -3) entfernen.

- Oberen Mahlscheibenhalter (Fig. 4 - 1) gegen den Uhrzeigersinn

drehen, bis der Block komplett herausgefahren ist.

- Schrauben (Fig. 4 -2) lösen und Mahlschreiben (Fig. 4 -3) aus

der Halterung nehmen.

- Auflageflächen der Mahlscheiben sowie Gewinde und Sitz

des Mahlscheibenhalters sorgfältig reinigen.

- Die neuen Mahlscheiben in die entsprechenden Halterungen

einsetzen und fixieren.

- Alle Teile in umgekehrter Reihenfolge wieder montieren.

- Die neuen Mahlscheiben kalibrieren.

14

Page 15

Sicherheitshinweise

Spezifische Sicherheitshinweise

• Das Gerät darf nicht von Kindern oder Personen mit

eingeschränkten physischen, sensorischen oder geistigen

Fähigkeiten oder Mangel an Erfahrung und Wissen benutzt

werden, es sei denn, sie werden bei der Nutzung angeleitet oder

beaufsichtigt.

• Kinder müssen überwacht werden, damit sie nicht mit der

Maschine spielen.

• Verpackungselemente (Plastiksäcke, Schaumstoffe, Nagel,

Kartons, usw.) dürfen Kindern nicht zuganglich gemacht

werden, da sie eine potentielle Gefahrenquelle darstellen.

• Es dürfen nicht mehr als drei verpackte Maschinen desselben

Typs aufeinander gestapelt und keine schweren Gegenstände

auf den Kisten gelagert werden.

• Lüftungsgitter nicht verstopfen. Nicht mit Tüchern abdecken.

• Sollte die Maschine gefrieren, lassen Sie die Maschine an einem

Ort mit einer Temperatur von nicht unter 20°C mindestens 20

Minuten vor dem Einschalten stehen.

• Die verpackte Maschine muss an einem trockenen, vor

Witterungseinflüssen geschützten Ort gelagert werden. Die

Umgebungstemperatur darf nicht unter 5 °C fallen.

• Nie mit Flüssigkeiten gefüllte Gefässe auf das Gerat stellen.

• Nicht fachgerechte Installation kann zu Personen- und

Sachschäden führen, für die der Hersteller nicht verantwortlich

gemacht werden kann.

• Maschine auf einer wasserabweisenden Oberfläche (Laminat,

Stahl, Keramik, usw.) installieren. Nicht in der Nähe von

Wärmequellen (Ofen, Herd, Kamin, usw.) aufstellen. Die

Umgebungstemperatur darf nicht unter 5 °C fallen. MASCHINE

VOR FROST SCHUTZEN! Die Oberfläche muss eben sein.

• Maschine keinen Witterungseinflüssen aussetzen und nicht in

feuchten Raumen wie Badezimmern installieren.

• Schalten Sie das Gerat aus und trennen es von der Strom-

versorgung, bevor Sie Zubehör austauschen oder sich Teilen

nähern, die sich im Betrieb bewegen.

• Nur original Ersatzteile vom Hersteller verwenden, um den

störungsfreien Betrieb zu gewährleisten.

• Im Notfall, z.B. Feuer, merkwürdigen Geräuschen oder

Überhitzung, sofort den Netzstecker ziehen.

• Im Zweifelsfall die elektrische Anlage von einem Fachmann

überprüfen lassen.

• Die Verwendung von Adaptern, Mehrfachsteckdosen und / oder

Verlängerungskabeln ist nicht erlaubt.

• Vor dem Anschluss der Maschine überprüfen, ob die auf dem

Schild angegebenen Daten mit denen des Installationsorts

übereinstimmen.

• Die elektrische Netzversorgung muss den

Sicherheitsvorschriften entsprechen und folgende

Schutzeinrichtungen enthalten: Schutzerdung; ein dem

Leistungsbedarf angemessenen Kabeldurchmesser;

Leitungsschutzschalter.

• Sollte das Netzkabel beschädigt sein, muss es vom Hersteller,

durch seinen technischen Service oder von einer Fachperson

ersetzt werden, um jegliche Risiken zu vermeiden.

• Die Maschine darf nur unter Verwendung eines geerdeten

UL-Steckers in der richtigen Dimension an die Festinstallation

angeschlossen werden. Der Stecker darf nur von qualifiziertem

Personal ausgewählt und installiert werden. (nur für USA und

Kanada).

• Installation und Inbetriebnahme dürfen ausschliesslich von

einem RANCILIO Servicetechniker oder einem ausgebildeten

RANCILIO-Spezialisten unter Berücksichtigung aller lokalen

Installationsvorschriften durchgeführt werden.

• Zur einfacheren Bedienung und für Wartungsarbeiten

genügend Freiraum um die Maschine lassen.

• Die Maschine darf nicht in Raumen aufgestellt werden, in denen

mit Wasserschlauch oder Hochdruckreinigern gearbeitet wird!

• Der Elektroanschluss muss von einem zugelassenen Elektro-

Installateur vorgenommen werden.

• Ein elektrischer Schalter (Netzschalter) und / oder ein

Netzstecker muss leicht zuganglich installationsseitig

vorgeschaltet werden.

• Der elektrische Hauptschalter muss die Maschine wirksam und

allpolig vom Elektronetz trennen. Die Kontaktöffnung muss

dabei mindestens 3mm betragen.

15

Page 16

FRANCAIS

KRYO 65/ST KRYO 65/AT

Machine pour la mouture et le dosage du café

1. DESCRIPTION

2. FONCTIONNEMENT

3. ENTRETIEN

3.1. Quotidien

3.2. Périodique ou après usage intensif

4. INCONVÉNIENTS ET REMÈDES

4.1. Opérations de contrôle pouvant être effectuées par

l’utilisateur

KRYO 65/ST

Machine pour la mouture du café avec allumage et extinction en

mode manuel;

KRYO 65/AT

Machine pour la mouture du café fonctionnant en mode

automatique avec allumage et extinction possibles en mode manuel.

Légende (Fig. 1)

1. Couvercle de trémie

2. Trémie à grains

3. Poignée

4. Fermeture de trémie

5. Couvercle du doseur

6. Doseur

7. Presse-café

8. Fourche de référence

9. Interrupteur général

10. Bac de récupération de poudre

11. Levier doseur

12. Poignée dosage

KRYO 65/ST

Moudre le café en appuyant sur l’interrupteur général (Fig. 1 - 9)

KRYO 65/AT

Appuyer sur l’interrupteur général (Fig. 1 - 9), après quoi la

mouture est effectuée en mode automatique.

Il est recommandé de moudre la quantité de café nécessaire au

besoin immédiat car le café moulu laissé trop longtemps inutilisé

perd sa fraîcheur et son arôme.

Ne pas moudre une seconde fois le café déjà moulu.

- Placer le porte-filtre dans la fourche de référence (Fig. 1 - 8),

tirer vers soi par un mouvement ferme puis relâcher le levier

doseur(Fig. 1 - 11) une ou plusieurs fois selon les doses qui

doivent être extraites (chaque mouvement du levier correspond

à une dose).

- Niveler le café contenu dans le filtre, placer le porte-filtre

sous le presse-café (Fig. 1 - 7) et soulever en douceur pour

rendre le café compact ;

- Contrôler que le bord du porte-filtre est exempt de café moulu.

Pour effectuer les opérations d’entretien, la machine doit être

éteinte et froide et la prise d’alimentation débranchée.

Pour le nettoyage, ne pas utiliser d’outils métalliques ou abrasifs

de type tampon à récurer, brosses métalliques, aiguilles, etc., ni

de détergents, (alcool etc.). Utiliser plutôt un chiffon ou une

éponge humide.

- Nettoyer la structure et le bac de récupération de poudre.

- Nettoyer la zone de dosage placée sous le récipient de café.

Vider le récipient de café en grains, et le nettoyer de tous les

résidus huileux laissés par le café.

Les matériaux de rebut utilisés pour le travail ou l’entretien, s’ils

ne sont pas biodégradables ou polluants, doivent être entreposés

dans des conteneurs séparés et éliminés dans des centres de

recyclage spécialisés.

Pour tout autre type d’anomalie ou d’inconvénient non spécifié,

débrancher la prise de courant, s’abstenir d’intervenir

directement dans la réparation ou la vérification et s’adresser au

service technique d’assistance qualifié.

A) La machine ne s’allume pas :

- contrôler si la prise est branchée ;

- Contrôler le courant du réseau d’alimentation ainsi que le

branchement du disjoncteur ou de l’interrupteur général ;

- Contrôler l’état de la prise ou du câble d’alimentation, en cas

d’endommagement, les faire remplacer par du personnel

qualifié.

16

Page 17

B) La machine ne moud pas le café :

5. CARACTÉRISTIQUES TECHNIQUES

Versions KRYO 65/ST

KRYO 65/AT

Dimensions de la machine

mm

L.220 - P.385 - H.575

Poids net d e la machine

kg

13

Production

kg/h

7-9

Capacité du Trémie à grains

g

1300

Réglage des doses

g

5-10

6. INSTALLATION

6.1 Rotation du moteur

6.2. Réglage des meules

7. MISE EN SERVICE

7.1. Description des commandes

7.2. Réglage de la mouture

- Contrôler la présence de café en grains dans le récipient ;

- Contrôler l’ouverture du levier de fermeture de trémie (levier

vers l’intérieur)

C) Durée de mouture prolongée

- Contrôler le réglage de la mouture ;

- Faire remplacer les meules par du personnel qualifié.

D) Les doses ne sont pas uniformes :

- Nettoyer soigneusement le doseur et le bec de sortie du café

- Contrôler le parcours complet et libre du levier doseur.

Schéma d’identification des données de la plaque (Fig. 3)

1. Fabricant

2. Modèle et version

3. Tension

4. Marquage de conformité CE

5. Numéro de série

6. Pin

7. Absorption totale

8. Puissance moteur

9. - -

10. - -

11. Fréquence

12. Marques de conformité

13.

Date de fabrication

L’installation doit être effectuée par un technicien qualifié.

La machine est livrée prête à l’installation, conformément aux

données de la plaque, Fig. 3.

S’assurer que le réseau électrique possède les mêmes

caractéristiques que celles de la machine.

Contrôler l’intégrité de la machine, des accessoires, du câble

d’alimentation et de la prise, et en cas d’endommagements,

avertir immédiatement le revendeur.

Les machines ont été élaborées et construites pour la mouture du

café en grains à usage professionnel.

Tout autre usage est considéré comme impropre et donc dangereux.

À effectuer par le technicien qualifié.

Pour les machines à alimentation électrique triphasée, il est

nécessaire de contrôler la rotation correcte du moteur.

- Mettre en marche le moulin à café et contrôler que la

mouture est effectuée correctement. Si ce n’est pas le cas,

ceci signifie que le moteur tourne dans le sens contraire.

- Eteindre la machine et l’interrupteur général de réseau.

- Inverser les deux conducteurs de phase entre eux, remonter le

tout et tenter à nouveau de procéder à la mouture.

À effectuer en phase d’installation et après le remplacement

des meules

Les moulins-doseurs sont testés à l’aide d’un réglage de mouture

indicatif, pour lequel il est nécessaire de procéder à un nouveau

réglage à effectuer avec le récipient à trémie vide.

Maintenir le bouton ferme-embout pressé (Fig. 2 - 1) et

simultanément, tourner lentement la poignée (Fig. 2 - 3)dans le sens

des aiguilles d’une montre jusqu’à ce que les meules s’effleurent (le

contact est repérable à un léger bruit de frottement métallique),

tourner l'embout numéroté (Fig. 2 - 2) jusqu’à rejoindre le point de

remise à zéro, puis déplacer l'embout numéroté de manière à ce que

le 0 se trouve en position frontale ; puis déplacer la poignée (Fig. 2 - 3)

dans le sens inverse (des aiguilles d’une montre) en la portant jusqu’à

la position numérotée 10;

KRYO 65/ST

Interrupteur général (Fig. 1 – 9) à deux positions ; lorsqu’il est

appuyé, le raccordement électrique est effectué et la mouture du

café démarre.

KRYO 65/AT

Interrupteur général (Fig. 1 – 9) à deux positions; en position (I), le

raccordement électrique est effectué ;

Le moulin à café est testé par le constructeur via un réglage de

mouture intermédiaire. Puis, tout dépend donc du type de café

utilisé.

17

Page 18

7.3. Réglage de la dose de café moulu

8. MISE HORS SERVICE

8.1. Temporaire

8.2. Définitive

9. INFORMATION POUR LE SERVICE

D’ASSISTANCE

9.1. Remplacement des meules

Effectuer le réglage de la mouture uniquement lorsque l’appareil

est éteint, ne jamais procéder au réglage lorsque l’appareil est en

marche.

- Introduire une petite dose de café en grains dans le récipient

à trémie et fermer le couvercle ;

- Contrôler l’ouverture de la trémie (fermeture de trémie (Fig. 1 - 4)

vers l’intérieur) ;

- Procéder à la mouture d’une petite dose de café :

- Placer le porte-filtre sur la fourche de référence (Fig. 1 - 9),

puis actionner le levier doseur (Fig. 1 - 11) pour faire descendre

la dose de café moulu (cette opération doit être effectuée

après le réglage de la dose de café moulu, voir 7.3);

- Préparer un café en contrôlant le temps de distribution qui

doit être compris, pour une mouture optimale, entre 25 et 30

secondes ;

- Contrôler l’aspect du café et la saveur en considérant qu'une

mouture trop grosse produit un café clair et sans crème,

tandis qu’une mouture trop fine produit un café fort, foncé

et sans crème.

- Si le café ne satisfait pas aux attentes, régler la mouture en

appuyant sur le bouton (Fig. 2 - 1) et en tournant l’embout

(Fig. 2 - 3) dans le sens inverse des aiguilles d’une montre

pour une mouture plus fine ou dans le sens des aiguilles

d’une montre pour une mouture plus grosse.

- Répéter l’opération jusqu’à obtenir la quantité de café

désirée,

Si le même type de café est utilisé, aucun autre réglage de

mouture n’est normalement nécessaire, tandis qu’en cas de

changement de type de café, il est nécessaire de procéder à un

nouveau contrôle préliminaire.

Les doses peuvent être réglées comme suit :

- Actionner la poignée (Fig. 1 – 12) sous le doseur dans le sens

inverse des aiguilles d’une montre pour augmenter la dose.

- Fermer le récipient à trémie et moudre le café en grains

restant entre les meules ;

- Eteindre l’interrupteur et débrancher la prise d’alimentation

électrique ;

- Retirer le café moulu et l’éventuel café en grains resté dans le

récipient à trémie ;

- Effectuer les opérations de nettoyage et d'entretien ;

- Enrouler le câble électrique et le fixer sur la machine à l’aide

du ruban adhésif ;

- Couvrir la machine et la ranger dans un environnement sec, à

l’abri des intempéries et à l’accès exclusif.

En plus des opérations de mise hors service temporaire, il

convient de :

- Couper le câble d’alimentation,

- Emballer la machine avec le carton ou autre et la remettre à la

personne compétente (tri des déchets autorisé ou retrait usagé).

Les meules, bien qu’étant construites en acier trempé, sont

sujettes à l’usure.

Leur durée de vie est influencée par la quantité de café moulu,

par sa dureté et son niveau de torréfaction, ainsi que par la

quantité et la pureté des confections de café en grains.

Les petits cailloux et les impuretés diverses ont une forte

influence abrasive qui réduit de manière significative la durée de

vie des meules.

Quand le temps de mouture est prolongé de manière notable ou

quand la mouture devient irrégulière, il convient de procéder au

remplacement des meules en agissant comme suit :

- Tirer le levier de fermeture à trémie (Fig. 1 - 4) ;

- Mettre en marche le moulin-doseur pour moudre le café resté

entre les meules ;

- Une fois la mouture achevée, éteindre la machine et

débrancher la prise d’alimentation ;

- Vider le récipient à trémie (Fig. 1 - 2) ;

- Ôter la poignée de réglage (Fig. 1 - 3);

- Tourner le porte-meules supérieur (Fig. 4 - 1) dans le sens

inverse des aiguilles d’une montre jusqu’à la sortie complète

de la tête ;

- Dévisser les vis (Fig. 4 - 2) et démonter les meules (Fig. 4 - 3)

du support porte-meules :

- Nettoyer soigneusement les plans d’appui des meules, le

filetage du porte-meules et le siège ;

18

Page 19

- Placer les nouvelles meules dans leurs supports et les bloquer

Consignes de sécurité

Consignes de sécurité spécifique

fermement ;

- Remonter le tout en procédant dans l’ordre inverse.

- Procéder au réglage des nouvelles meules.

• Cet appareil n’est pas prévu pour être utilise par des enfants ou

des personnes dont les capacités physiques, sensorielles ou

mentales sont réduites, ou des personnes dénuées d’expérience

ou de connaissance, sauf si elles ont pu bénéficier d’une

surveillance ou d’instructions.

• Il convient de surveiller les enfants pour s’assurer qu’ils ne

jouent pas avec l’appareil.

• Tenir le matériel d’emballage (sacs en plastique, polystyrène

expansé, clous, cartons, etc.) hors de portée des enfants car il

constitue une source potentielle de danger.

• Ne pas poser d’objets lourds sur l’emballage. Ne pas empiler

plus de trois articles de même nature.

• Ne pas obstruer les grilles d’aspiration et de dispersion. Ne pas

recouvrir avec des chiffons, etc.

• Si la machine gelé, laisser la machine dans un lieu avec une

température égale ou supérieure à 20 °C pendant au moins 20

minutes avant de l’utiliser.

• Stocker la machine emballée dans un endroit sec, non expose

aux intempéries et ou la température ne descend pas audessous de 5°C.

• Ne jamais placer de récipients remplis de liquide sur la machine.

• Toute installation non réalisée dans les règles peut blesser des

personnes et animaux et endommager des biens. Dans ce cas,

le fabricant décline toute responsabilité.

• Installer la machine sur une surface hydrophobe (lamine, acier,

céramique, etc.) à l’ écart des sources de chaleur (four, plan de

cuisson, cheminée, etc.) et ou la température ne descend pas

au-dessous de 5°C. LA MACHINE CRAINT LE GEL. La surface

doit être plane.

• Ne pas exposer la machine aux intempéries ou la placer dans

une pièce humide comme la salle de bains.

• Eteindre l’appareil et le débrancher avant de remplacer des

accessoires ou d’approcher de pièces qui sont mobiles

lorsqu’elles sont utilisées.

• Utiliser exclusivement des pièces de rechange d’origine afin de

ne pas compromettre la sécurité et le bon fonctionnement de la

machine.

• En cas d’urgence, comme un incendie, bruit inhabituel,

surchauffe, etc., réagir immédiatement en coupant le courant.

• En cas de doute, se procurer un schéma électrique détaille

auprès d’un électricien qualifie.

• L’utilisation d’adaptateurs, multiprises et/ou rallonges est

interdite.

• Avant de brancher l’appareil, vérifier que les caractéristiques de

la machine correspondent à celles du réseau électrique.

• L’alimentation électrique doit comporter les dispositifs de

sécurité suivants: mise à la terre efficace, section des

conducteurs adaptée aux puissances, coupe-circuit de

protection efficace en cas de fuite de terre.

• Si le câble d’alimentation est endommage, il doit être remplace par

le fabricant, le service technique ou par une personne présentant

une qualification équivalente pour prévenir tout risque.

• La machine doit être raccordée à l’installation fixe à l’aide

d’une fiche UL mise à la terre uniquement et présentant les

bonnes caractéristiques. La fiche doit être sélectionnée et

installée exclusivement par des personnes qualifiées

(uniquement pour les Etats-Unis et le Canada).

• L’installation et la mise en service initiale de la machine doivent

être exécutée par un technicien spécialise RANCILO, en accord

avec toute législation en matière valable au lieu d’installation.

• Laisser suffisamment d’espace libre autour de la machine pour

faciliter son utilisation et l’exécution de toute opération de

maintenance.

• La machine ne doit pas être installée dans des locaux ou l’on

travaille au jet d’eau ou à la vapeur sous pression!

• Le branchement de la machine au réseau électrique doit être

effectue par un électricien qualifie et agrée.

• Il incombe au propriétaire de la machine de faire installer un

interrupteur électrique (interrupteur réseau) et / ou une prise

fixe facilement accessible.

• L’interrupteur doit séparer avec efficacité la machine du réseau sur

tous les pôles. L’ouverture du contact doit être d’au moins 3 mm.

19

Page 20

ITALIANO

KRYO 65/ST KRYO 65/AT

Macchina per la macinatura e dosatura di caffè

1. DESCRIZIONE

2. FUNZIONAMENTO

3. MANUTENZIONE

3.1. Giornaliera

3.2. Periodica o dopo l’uso intenso

4. INCONVENIENTI E RIMEDI

4.1. Operazioni di controllo eseguibili dall’utilizzatore

KRYO 65/ST

Macchina per la macinatura di caffè con accensione e

spegnimento in modo manuale;

KRYO 65/AT

Macchina per la macinatura di caffè funzionante in modo

automatico con possibile accensione e spegnimento in modo

manuale.

Legenda (Fig. 1)

1. Coperchio tramoggia

2. Tramoggia grani

3. Manopola di regolazione

4. Chiusura tramoggia

5. Coperchio dosatore

6. Dosatore

7. Pressino

8. Assieme forchetta

9. Interruttore generale

10. Scodellino raccolta polvere

11. Leva

12. Manopola di regolazione dose

KRYO 65/ST

Macinare il caffè all’occorrenza azionando l’interruttore generale

(Fig. 1 - 9)

KRYO 65/AT

Premere l’interruttore generale (Fig. 1 - 9) e dopo di che la

macinatura viene effettuata in modo automatico.

Si consiglia di macinare la quantità di caffè necessario al fabbisogno

imminente perché lasciare per troppo tempo inutilizzato il caffè

macinato significa perdita di freschezza e aroma.

Non macinare una seconda volta il caffè già macinato.

- Posizionare il portafiltro nella forchetta di riferimento (Fig. 1 - 8),

tirare a sé con un deciso movimento e successivo rilascio la leva

(Fig. 1 - 11) per una o più volte secondo le dosi che si vogliono

prelevare (ogni azione della leva corrisponde a una dose).

- Livellare il caffè contenuto nel filtro, posizionare il portafiltro

sotto il pressino (Fig. 1 - 7) e sollevare con moderazione per

imprimere compattezza al caffè;

- Controllare che sul bordo del portafiltro non rimanga caffè

macinato.

Le operazioni di manutenzione vanno effettuate a macchina spenta

e fredda e con la spina di alimentazione elettrica disinserita.

Per la pulizia non utilizzare strumenti metallici o abrasivi tipo

pagliette, spazzole metalliche, aghi, ecc., e detergenti, (alcool

ecc.) ma usare un panno o una spugna umidi.

- Pulire la carrozzeria e lo scodellino raccolta polvere.

- Pulire il dosatore posto sotto il contenitore di caffè.

Svuotare il contenitore del caffè in grani, pulirlo dai residui oleosi

lasciati dal caffè stesso.

I materiali di scarto usati per la lavorazione o manutenzione, se

non biodegradabili o inquinanti, vanno riposti in separati

contenitori e consegnati negli appositi centri di raccolta.

Per ogni altro tipo di anomalia o inconveniente non specificato,

staccare la spina di corrente, astenersi da interventi diretti di

riparazione o verifica e rivolgersi al servizio tecnico di assistenza

qualificato.

A) Non si accende la macchina:

- Controllare se è inserita la spina;

- Controllare che ci sia corrente in rete e il salvavita o

l’interruttore generale sia inserito;

- Controllare le condizioni della spina e del cavo di

alimentazione, se sono danneggiati farli sostituire da

personale qualificato.

B) Non macina caffè:

- Controllare che ci sia caffè in grani nel contenitore;

- Controllare che la leva di chiusura tramoggia sia aperta.

20

Page 21

C) Macinatura a tempi lunghi

5. DATI TECNICI

Versioni

KRYO 65/ST

KRYO 65/AT

Dimensione macchina

mm

L.220 - P.385 - H.575

Peso netto macchina

kg

13

Produzione

kg/h

7-9

Capacità Tramoggia grani

g

1300

Regolazione dosi

g

5-10

6. INSTALLAZIONE

6.1 Rotazione motore

6.2. Taratura delle macine

7. MESSA IN SERVIZIO

7.1. Descrizione comandi

7.2. Regolazione macinatura

- Controllare la regolazione di macinatura;

- Fare sostituire le macine da personale qualificato.

D) Le dosi non sono uniformi:

- Pulire accuratamente il serbatoio del caffè macinato e la

parte sottostante (bocca di uscita caffè)

- Controllare che la leva dosatrice percorra completamente e

liberamente il movimento.

Schema d’identificazione dati di targa (Fig. 3)

1. Produttore

2. Modello e versione

3. Tensione

4. Marchio CE di conformità

5. Numero di serie

6. Pin

7. Assorbimento totale

8. Potenza motore

9. - -

10. - -

11. Frequenza

12. Marchi di conformità

13. Data di produzione

L’installazione deve essere effettuata dal tecnico qualificato.

La macchina viene consegnata pronta per l’installazione secondo

i dati di targa – Fig. 3

Accertarsi che la linea elettrica abbia le stesse caratteristiche

della macchina.

Controllare l’integrità della macchina, degli accessori, del cavo di

alimentazione e della spina ed in caso di danni, avvertire con

tempestività il rivenditore.

Le macchine sono state progettate e costruite per la macinatura

di caffè in grani ad uso professionale.

Ogni altro uso è da considerarsi improprio e quindi pericoloso.

Ad opera del tecnico qualificato

Per le macchine con alimentazione elettrica trifase, è necessario

controllare la corretta rotazione del motore.

- Avviare il macinacaffè e controllare che venga effettuata

correttamente la macinatura. Se ciò non avviene significa

che il motore gira in senso contrario.

- Spegnere la macchina e l’interruttore generale di rete.

- Invertire fra loro due conduttori di fase, rimontare il tutto e

riprovare ad effettuare la macinatura.

Da effettuare in fase di installazione e dopo la sostituzione

delle macine

I macinadosatori vengono collaudati con una regolazione di

macinatura indicativa, per cui si rende necessario procedere ad una

nuova regolazione da effettuare con i contenitore a tramoggia vuoto.

Tenere premuto il pulsante ferma ghiera (Fig. 2 - 1) e

contemporaneamente ruotare lentamente in senso antiorario la

manopola (Fig. 2 - 3) fino a che le macine si sfiorino (il contatto si

avverte con un leggero suono di strofinamento metallico),ruotare

la ghiera numerata (Fig. 2 - 2) fino al raggiungimento del punto di

azzeramento, spostare quindi la ghiera numerata in modo che lo 0

sia in posizione frontale; spostare quindi la manopola (Fig. 2 - 3) in

senso opposto (orario) portandola alla posizione numerata 10;

KRYO 65/ST

Interruttore generale (Fig. 1 - 9) a due posizioni; premuto, si

inserisce il collegamento elettrico e inizia la macinatura caffè.

KRYO 65/AT

Interruttore generale (Fig. 1 - 9) a due posizioni; in posizione (I), si

inserisce il collegamento elettrico;

spegnerà automaticamente quando il dosatore sarà pieno.

Il macinacaffè viene collaudato dal costruttore con una regolazione

di macinatura intermedia. E’ quindi dipende dal tipo di caffè usato.

il macinacaffè è acceso e si

21

Page 22

Eseguire la regolazione della macinatura solo con l’apparecchio

7.3. Regolazione dose di caffè macinato

8. MESSA FUORI SERVIZIO

8.1. Temporanea

8.2. Definitiva

9. INFORMAZIONE PER IL SERVIZIO

ASSISTENZA

9.1. Sostituzione macine

fermo, non eseguire mai con l’apparecchio in funzione.

- Inserire nel contenitore tramoggia una piccola quantità di

caffè in grani e chiudere il coperchio;

- Controllare che la tramoggia sia aperta (leva (Fig. 1 - 4));

- Effettuare la macinatura di una piccola dose di caffè:

- Posizionare il portafiltro nella forchetta (Fig. 1 - 8), quindi

azionare la leva (Fig. 1 - 11) per far scendere la dose di caffè

macinato (questa operazione è da eseguire dopo la

regolazione della dose di macinato Vd. 7.3);

- Preparare un caffè controllando il tempo di erogazione che

deve essere, per una macinatura ottimale, fra i 25 e 30 secondi;

- Controllare l’aspetto del caffè e il sapore considerando che

una macinatura troppo grossa comporta caffè chiari e senza

crema, mentre una macinatura troppo fine comporta caffè

forti, scuri e senza crema.

- Se il caffè non risponde ai requisiti desiderati, regolare la

macinatura premendo il pulsante (Fig. 2 - 1) e ruotando la

manopola (Fig. 2 - 3) in senso anti-orario per macinatura più

fine o in senso orario per macinature più grosse.

- Ripetere l’operazione fino ad ottenere la quantità di caffè

desiderato,

Utilizzando lo stesso tipo di caffè non sono normalmente richieste

altre regolazioni di macinatura, mentre in caso di cambio di tipo di

caffè è necessario procedere ad una nuova preliminare di controllo.

Le dosi possono essere regolare intervenendo come segue:

- Agire sulla manopola (Fig. 1 – 12) sotto il dosatore in senso

antiorario per aumentare la dose.

- Chiudere il contenitore a tramoggia e macinare il caffè in

grani rimasto fra le macine;

- Spegnere l’interruttore e staccare la spina di alimentazione

elettrica;

- Togliere il caffè macinato e l’eventuale caffè in grani rimasto

nel contenitore a tramoggia;

- Effettuare le operazioni di pulizia e manutenzione;

- Avvolgere il cavo elettrico e fissarlo alla macchina con del

nastro adesivo;

- Coprire la macchina e riporla in un ambiente asciutto, al

riparo da intemperie e di esclusivo accesso.

Oltre alle operazioni della messa fuori servizio temporanea,

provvedere a:

- Tagliare il cavo di alimentazione,

- Imballare la macchina con cartone o altro e consegnarla al

personale preposto (smaltimento rifiuti autorizzato o ritiro

usato).

Le macine, pur essendo costruite in acciaio temperato, sono

soggette ad usura.

La loro durata è influenzata dalla quantità di caffè macinato,

dalla sua durezza e grado di tostatura, nonché dalla quantità e

purezza delle confezioni di caffè in grani.

Sassolini ed impurità varie hanno una forte azione abrasiva che

riduce notevolmente la vita delle macine.

Quando il tempo di macinatura si allunga notevolmente o la

macinatura diventa irregolare, occorre provvedere alla

sostituzione delle macine agendo nel seguente modo:

- Tirare la leva di chiusura tramoggia (Fig. 1 - 4);

- Avviare il macinadosatore per macinare il caffè rimasto fra le

macine;

- Terminata la macinatura, spegnere la macchina e staccare la

linea di alimentazione;

- Svuotare la tramoggia grani (Fig. 1 - 2);

- Togliere la manopola di regolazione (Fig. 1 - 3);

- Ruotare i porta macine superiore (Fig. 4 - 1) in senso

antiorario fino alla completa fuoriuscita della testata;

- Svitare le viti (Fig. 4 - 2) e smontare le macine (Fig. 4 – 3) dai

supporti porta macine:

- Pulire accuratamente i piani di appoggio delle macine, la

filettatura del porta macine e la sede;

- Posizionare le nuove macine nei rispettivi supporti e bloccarle

solidamente;

- Rimontare il tutto procedendo in senso inverso.

- Procedere alla taratura delle nuove macine.

22

Page 23

Istruzioni di sicurezza

Istruzioni di sicurezza specifiche

• L’apparecchio non deve essere usato da bambini o da persone

con capacità fisiche, sensoriali o mentali ridotte o privi di

esperienza e conoscenza dell’apparecchio, salvo che non siano

sorvegliati o che non siano stati opportunamente istruiti.

• Controllare che i bambini non giochino con l’apparecchio.

• Gli elementi d’imballaggio (sacchetti di plastica, polistirolo

espanso, chiodi, cartoni, ecc.) non devono essere lasciati alla

portata di bambini in quanto potenziali fonti di pericolo.

• Evitare di sovrapporre all’imballo colli pesanti di altro genere.

Non impilare più di tre pezzi dello stesso tipo.

• Non ostruire le griglie di aspirazione o di dissipazione. Non

coprire con panni o altro.

• In caso di congelamento, lasciare la macchina in un luogo con

temperatura minima di 20°C per almeno 20 minuti prima di

accenderla.

• La macchina imballata va immagazzinata in un luogo riparato

dalle intemperie, asciutto e privo di umidità. La temperatura

non deve essere inferiore a +5°C.

• Non appoggiare contenitori di liquidi sulla macchina.

• Un’errata installazione può causare danni a persone, animali e

cose per i quali il costruttore non può considerarsi responsabile.

• Posizionare la macchina su un piano idrorepellente (laminato,

acciaio, ceramica, ecc.) lontano da sorgenti di calore (forni, fornelli,

camini, ecc.) e in ambienti dove la temperatura non scenda sotto i

5°C. TEME IL GELO. Posizionare la macchina in piano.

• Non esporre la macchina ad intemperie né installarla in

ambienti ad elevata umidità come locali da bagno.

• Spegnere la macchina e scollegarla dalla rete prima di cambiare

accessori o avvicinarsi a parti in movimento durante l’uso normale.

• Utilizzare solo accessori e ricambi autorizzati dal produttore

per evitare di compromettere la sicurezza ed il corretto

funzionamento della macchina.

• In caso di emergenza, come principio d’incendio, rumorosità

anomala, surriscaldamento, ecc, intervenire immediatamente

staccando l’alimentazione elettrica.

• In caso di dubbio o di incertezza far controllare da personale

qualificato l’impianto di alimentazione elettrica.

• È vietato l’uso di adattatori, prese multiple e/o prolunghe.

• Prima di collegare la macchina accertarsi che i dati di targa

siano rispondenti a quelli della rete di distribuzione elettrica.

• L’impianto di alimentazione elettrica deve essere provvisto dei

seguenti dispositivi di sicurezza: efficace messa a terra; sezione

dei conduttori adatta alla potenza assorbita; dispositivo

salvavita efficiente.

• Se il cavo di alimentazione è danneggiato deve essere

sostituito dal costruttore o dal suo servizio assistenza tecnica o

da una persona qualificata, in modo da prevenire ogni rischio.

• La macchina deve essere connessa alla rete usando una spina

con contatto di terra approvata UL di portata adeguata. La

spina deve essere scelta e installata solo da personale

qualificato. (Solo per USA e Canada)

• Installazione e primo avvio devono essere effettuati da

personale RANCILIO o da un tecnico addestrato da RANCILIO

in completa osservanza delle regole di installazione locali.

• Lasciare degli spazi liberi attorno alla macchina al fine di

agevolare l’uso e le operazioni di manutenzione.

• Non istallare la macchina in luoghi dove vengono usati getti

d’acqua o macchine pulitrici ad alta pressione

• Le operazioni di allacciamento devono essere eseguite da

personale qualificato.

• L’ interruttore automatico differenziale o, nel caso di macchine

dotate di cavo con spina, la presa di corrente deve essere

situato in prossimità della macchina, in posizione facilmente

accessibile.

• Predisporre a monte del cavo di alimentazione un interruttore

automatico differenziale. I contatti devono avere una apertura

di almeno 3 mm.

23

Page 24

ESPAGÑOL

KRYO 65/ST KRYO 65/AT

Máquina para la molienda y dosificación de café

1. DESCRIPCIÓN

2. FUNCIONAMIENTO

3. MANTENIMIENTO

3.1. Diario

3.2. Periódico o después de un uso intenso

4. PROBLEMAS Y SOLUCIONES

4.1. Operaciones de control a ejecutar por el usuario

KRYO 65/ST

Máquina para la molienda de café con encendido y apagado en

modo manual.

KRYO 65/AT

Máquina para la molienda de café que funciona en modo

automático con la posibilidad de encendido y apagado en modo

manual.

Leyenda (Fig. 1)

1. Tapa de la tolva

2. Tolva de granos

3. Botón de regulación

4. Cierre de la tolva

5. Tapa del dosificador

6. Dosificador

7. Prensa café

8. Conjunto de horquilla

9. Interruptor

10. Cazoleta recoge polvo

11. Palanca

12. Botón de mando

KRYO 65/ST

Moler el café, en caso necesario, accionando el interruptor

general (Fig. 1 - 9).

KRYO 65/AT

Pulsar el interruptor general (Fig. 1 - 9) y después de que la

molienda se realice de modo automático.

Se aconseja moler la cantidad de café necesaria en el momento

de consumo puesto que, si se deja demasiado tiempo en pausa,

el café molido pierde su frescura y aroma.

No volver a moler el café ya molido.

- Colocar el portafiltros en la horquilla respectiva (Fig. 1 - 8),

tirar hacia sí con un movimiento seco y, a continuación,

soltar la palanca (Fig. 1 - 11) una o más veces, dependiendo de

las cantidades que se desean retirar (cada accionamiento de

la palanca corresponde a una dosis).

- nivelar el café contenido en el filtro, colocar el portafiltros

debajo del prensa café (Fig. 1 - 7) y levantar presionando

hasta obtener un café compacto;

- Eliminar posibles residuos de café molido en el borde del

portafiltros.

Las operaciones de mantenimiento se realizarán con la máquina

parada y fría y la clavija de la alimentación eléctrica

desconectada.

Para la limpieza no utilizar instrumentos metálicos o abrasivos,

como estropajos o cepillos metálicos, agujas, etc., ni detergentes

(alcohol, etc.), sino utilizar un paño o una esponja húmedos.

- Limpiar el cuerpo y el recoge polvo del café molido.

- Limpiar la zona dosificadora situada debajo del contenedor

de café.

Vaciar el contenedor del café en grano, limpiarlo de residuos

aceitosos dejados por el café mismo.

Los materiales de desecho utilizados para la elaboración y

mantenimiento, si no son biodegradables o están

contaminados, deberán depositarse en contenedores separados

y entregados en los centros de recogida de residuos apropiados.

Para cualquier otro tipo de anomalía o inconveniente no

especificado, desconectar la clavija de la corriente, abstenerse de

realizar reparaciones o verificaciones directamente y dirigirse al

servicio de asistencia técnica cualificado.

- A) La máquina no se enciende:

- Controlar si la clavija está conectada;

- controlar que haya corriente en la red y que el interruptor

diferencial o el interruptor general esté conectado;

24

Page 25

- controlar las condiciones de la clavija y del cable de

5. DATOS TÉCNICOS

Versiones KRYO 65/ST

KRYO 65/AT

Dimensiones de la máquina

mm

L.220 - P.385 - H.575

Peso neto de la máquina

kg

13

Producción

kg/h

7-9

Capacidad Tolva de granos

g

1300

Ajuste de las cantidades

g

5-10

6. INSTALACIÓN

6.1 Rotación del motor

6.2. Ajuste de las fresas

7. PUESTA EN MARCHA

7.1. Descripción de los mandos

alimentación; si están dañados, encargue su sustitución a

personal cualificado.

B) No muele café:

- Controlar que haya café en grano en la tolva;

- controlar que la palanca de cierre de la tolva esté abierta (la

palanca hacia adentro).

C) Molienda a intervalos largos:

- Controlar el ajuste de la molienda;

- encargar la sustitución de las fresas a personal cualificado.

D) Las cantidades no son uniformes:

- Limpiar cuidadosamente el depósito del café molido y la

parte inferior (la boca de salida del café);

- controlar que la palanca dosificadora recorra el movimiento

completa y libremente.

Esquema de identificación de los datos de la placa (Fig. 3)

1. Fabricante

2. Modelo y versión

3. Tensión

4. Marca de conformidad CE

5. Número de serie

6. Pin

7. Absorción total

8. Potencia del motor

9. - -

10. - -

11. Frecuencia

12. Marcas de conformidad

13. Fecha de fabricación

La instalación deberá ser efectuada por un técnico cualificado.

La máquina se entrega lista para su instalación según los datos

de la placa, fig. 1.

Comprobar que la línea eléctrica tenga las mismas características

que la máquina.

Controlar que la máquina, los accesorios, el cable de

alimentación y la clavija estén intactos y, en caso de daños,

avisar al distribuidor de inmediato.

Las máquinas han sido diseñadas y fabricadas para la molienda

de café en grano para uso profesional.

Toda otra utilización se considerará impropia y, por lo tanto,

peligrosa.

A realizar por un técnico cualificado.

Para las máquinas con alimentación eléctrica trifásica es

necesario controlar la rotación correcta del motor.

- Poner en marcha el molinillo de café y controlar que la

molienda se realice correctamente. Si esto no ocurre significa

que el motor está girando en sentido contrario.

- Apagar la máquina y el interruptor general de la red.

- Invertir dos conductores, volver a montar todo e intentar

moler de nuevo.

A efectuar en la fase de instalación y después de la sustitución

de las fresas

Los dosificadores de la molienda se comprueban con una regulación

indicativa de la molienda, por lo que resulta necesario proceder a un

nuevo ajuste a efectuarse con los contenedores tolvas vacías.

Mantener pulsado el botón cierra anillo (Fig. 2 - 1) y

simultáneamente girar lentamente el botón de mando (Fig. 2 - 3)

en el sentido contrario a las agujas del reloj hasta que las fresas

rocen (el contacto se advierte por un ligero sonido de fricción

metálico), girar el anillo numerado (Fig. 2 - 2) hasta alcanzar el

punto de puesta a cero, luego desplazar el anillo numerado de

modo que el 0 esté en posición frontal; luego desplazar el botón

de mando (Fig. 2 - 3) en el sentido opuesto (de las agujas del reloj)

llevándolo a la posición numerada 10.

KRYO 65/ST

Interruptor general (Fig. 1 - 9) y dos posiciones: pulsado, se

procede a la conexión eléctrica y se inicia la molienda del café.

25

Page 26

KRYO 65/AT

7.2. Ajuste de la molienda

7.3. Ajuste de la cantidad de café molido

8. PUESTA FUERA DE SERVICIO

8.1. Temporal

8.2. Definitiva

9. INFORMACIÓN PARA EL SERVICIO DE

ASISTENCIA

9.1. Sustitución de las fresas

Interruptor general (Fig. 1 - 9) con dos posiciones; en posición (I)

se procede a la conexión eléctrica.

El molinillo de café viene comprobado de fábrica con un ajuste de

molienda intermedia. Pero depende del tipo de café utilizado.

Efectuar el ajuste de la molienda solo cuando el aparato esté

cerrado, no efectuarlo jamás con el aparato en funcionamiento.

- Introducir en la tolva una pequeña cantidad de café en grano

y cerrar la tapa;

- controlar que la tolva esté abierta (la palanca (Fig. 1 - 4)

hacia adentro);

- efectuar la molienda de una pequeña cantidad de café;

- colocar el portafiltros sobre la horquilla (Fig. 1 - 8), a

continuación accionar la palanca (Fig. 1 - 11) para hacer

descender la cantidad de café molido (esta operación debe

realizarse después del ajuste de la cantidad a moler, véase 7.3);

- preparar un café controlando el tiempo de preparación que

deberá ser, para una molienda óptima, de entre 25 y 30

segundos;

- controlar el aspecto del café y el sabor, considerando que una

molienda demasiado gruesa da como resultado cafés claros y

sin crema, mientras que una molienda demasiado fina da

como resultado cafés fuertes, oscuros y sin crema.

- Si el café no cumple con los requisitos deseados, ajustar la

molienda pulsando el botón (Fig. 2 - 1) y girando el anillo