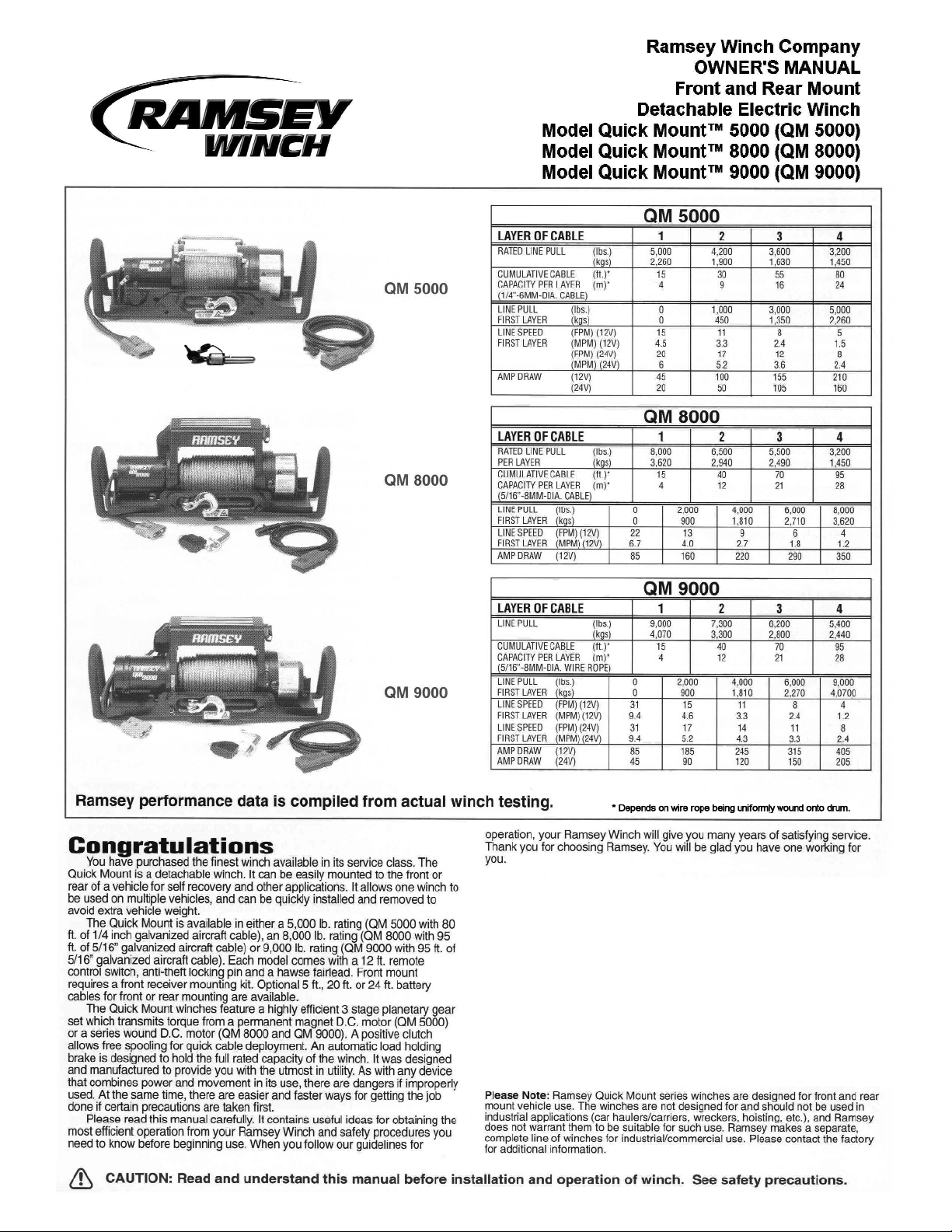

Page 1

Contents

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Front Cover

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Tips for Safe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Techniques of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Clutch Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Remote Control Switch Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Care and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Assembling Your Winch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Lubrication/Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Winch Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Back Cover

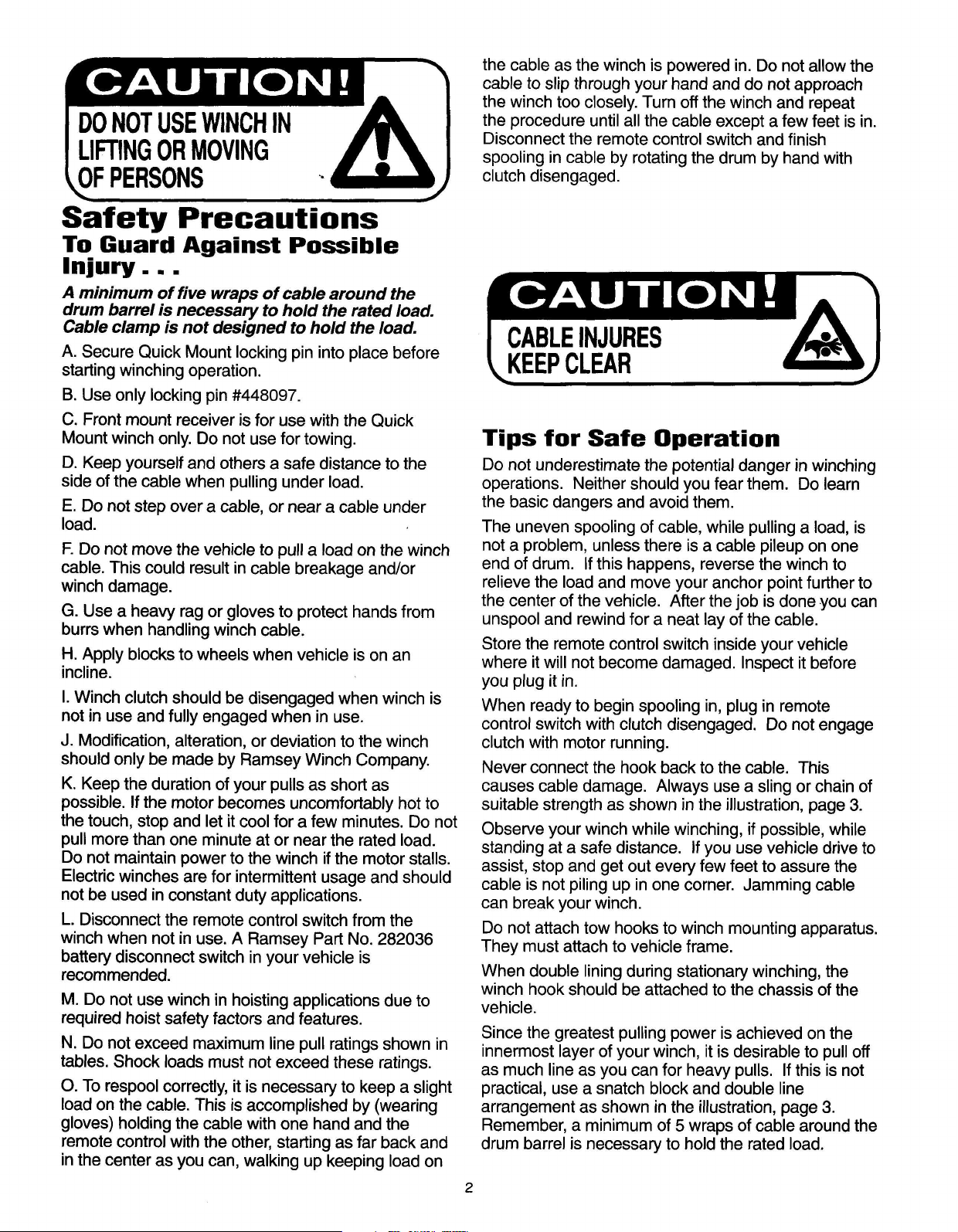

Page 2

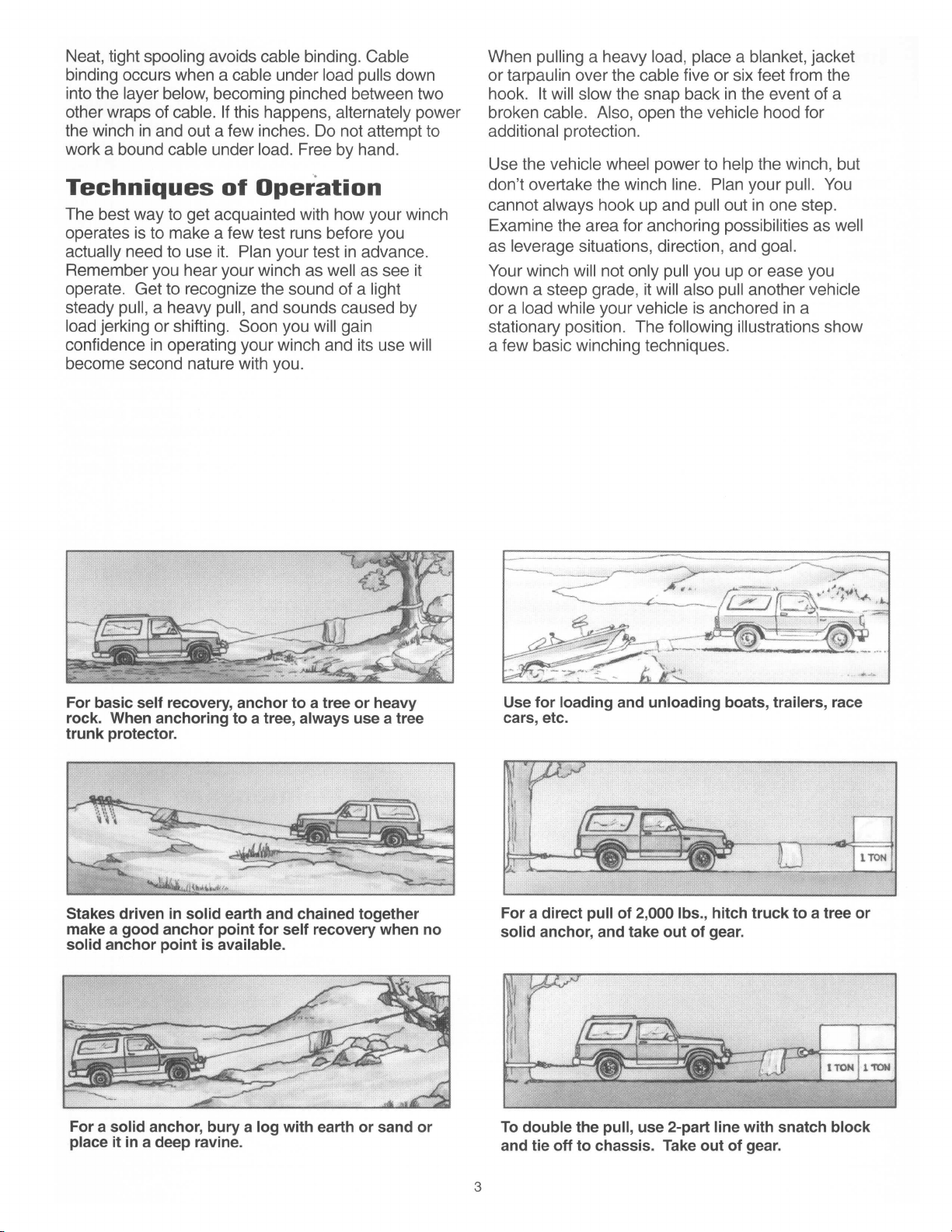

Page 3

Page 4

Installation

The Quick MountTMis solely and exclusively designed

for vehicle mounted, non-industrial applications. All

other applications will void warranty.

The Quick Mount

TM

must be front mounted with a

front receiver hitch available from Ramsey for selected vehicles. For rear mounting of the QM 5000, any

standard Class III rear receiver hitch may be used.

For rear mounting of the QM 8000 or QM 9000, a

SurePull Class III rear receiver or equivalent with a

5,000 lb. minimum weight carrying rating must be

used.

For normal self recovery work, your existing electrical

system is adequate. Your battery must be kept in

good condition. A fully charged battery and proper

connections are essential.

For front mounting, route quick connect battery power

lead through grille, leaving connector on outside and

connect red cable to positive(+) terminal and black

cable to negative(-) terminal of battery. Secure cable

under hood with cable ties.

For rear mounting connect battery power lead as

instructed above. Secure cables under vehicle away

from moving parts and exhaust system. Terminate

routing near the center of the vehicle at the rear. BE

SURE BATTERY CABLES ARE NOT DRAWN TAUT

ACROSS ANY SURFACES WHICH COULD POSSIBLY DAMAGE THEM.

Secure Quick Mount

TM

in the receiver with the

Ramsey locking pin. Connect quick disconnect from

Quick Mount

TM

winch to battery power lead. Plug

remote switch into receptacle on solenoid assembly.

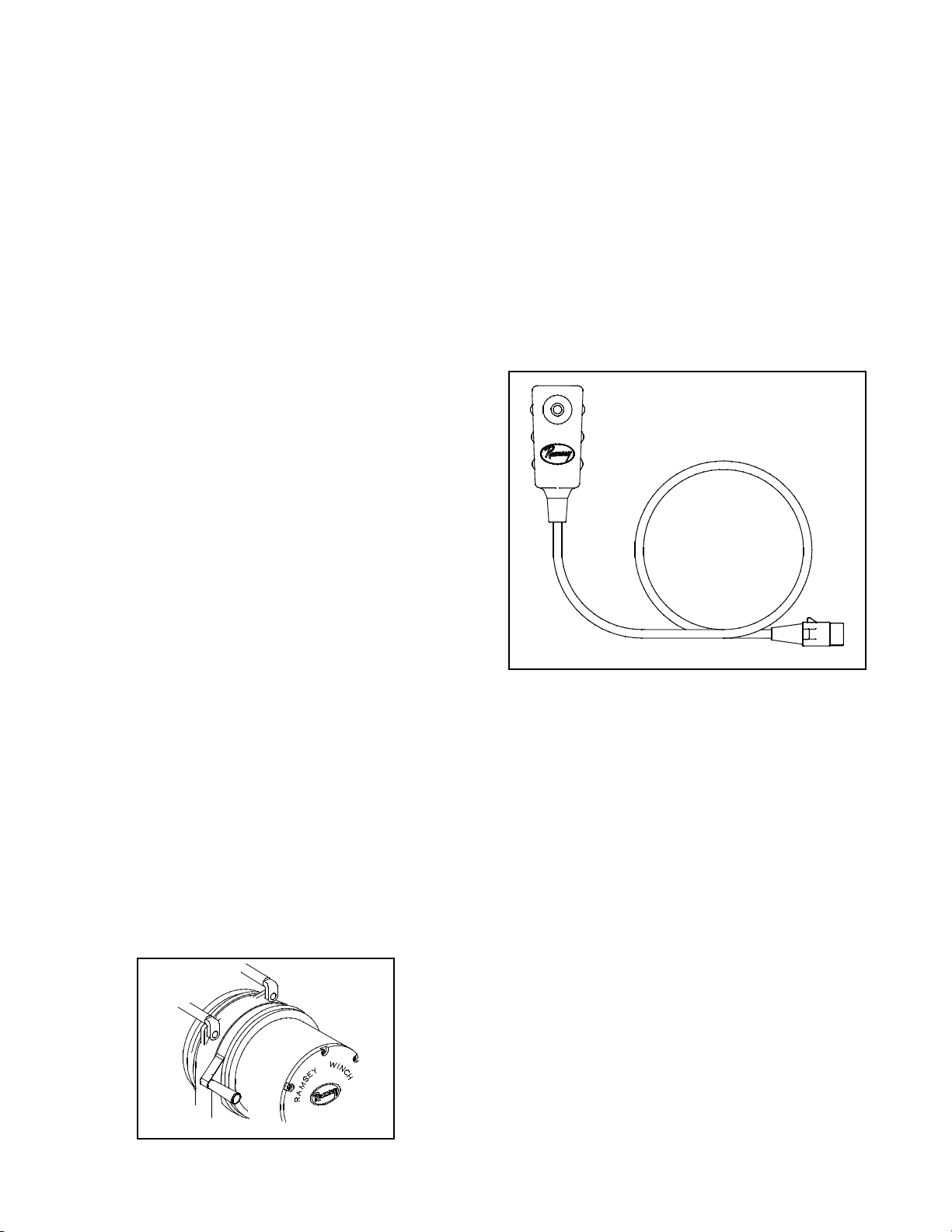

Clutch Operation

The winch clutch allows rapid unspooling of the cable

for hooking onto the load or anchor point. The clutch

is operated by the shifter lever located on the gear

housing end of the winch. Disengage the clutch,

(move the clutch shifter lever to the “OUT” position.)

Free spool some cable off the drum. Engage the

clutch, (move the clutch shifter lever to the “IN” position.)

Remote Control Switch Operation

The remote control switch is water proof and has

push button stations on either side. It is designed

this way to prevent quick winch reversals which lead

to premature solenoid failure. The switch is also

color coded to aid you in not having to guess at the

direction your winch willl run. Pushing both buttons

at the same time will not damage your winch in any

way. Make sure the motor has stopped fully before

reversing. Run the winch forward and reverse to

check connections. Snap appropriate plastic disc into

proper thumb button cavity on remote switch after

determining direction of rotation for winch drum.

DO NOT LEAVE SWITCH PLUGGED IN WHEN

WINCH IS NOT IN USE.

Care and Maintenance

Corrosion on electrical connections will reduce performance or may cause a short. Clean all connections, especially in remote control switch and receptacle. In salty environments use a silicone sealer to

protect from corrosion.

All moving parts in the winch are permanently lubricated with high temperature lithium grease at the

time of assembly. Under normal conditions, factory

lubrication will suffice.

Lubricate the cable periodically using light penetrating

oil. If the cable becomes worn or damaged it must

be replaced. Inspect for broken strands and replace

if necessary (see the next section for cable replacement instructions).

4

Page 5

Assembling your Winch

To assemble your QM winch to the quick mount

channel, attach handles to both ends of the quick

mount channel using (2) black 3/8” button head

screws for each handle as shown below. Tighten

to 20 ft-lbs. torque.

Once the handles are attached, lift the winch into

the quick mount channel. Feed the looped end

of the prewrapped cable through the fairlead.

Place a 3/8” nut and flatwasher in each of the

feet of the winch. Align the four mounting holes

in the channel with the feet of the winch. Place a

lockwasher on each 3/8” hex head bolt and

press a bolt through each mounting hole and

start it through a nut in the foot of the winch. Do

not tighten until all of the bolts have been started. Tighten evenly to 34 ft-lbs. torque.

Align the base of the clevis hook with the loop on

the end of the wire cable. Run the pin through

the clevis hook and the loop. Push the cotter pin

through the hole in the pin and bend the cotter

pin to lock.

5

20 ft-lbs.

torque

34 ft-lbs.

torque

Page 6

6

Page 7

26

6

27

29

15

19

29

4

41

19

28

27

36

5

39

35

43

14

12

20

2

44

26

34

16

8

41

10

21

37

25

16

45

18

42

22

20

30

44

17

32

33

3

40

11

31

1

44

13

7

9

23

24

46

47

7

Winch Parts List QM 5000™ (12 and 24 v)

Item

No.

Qty. Part No. Description

Item

No.

Qty. Part No. Description

1 1 247004 GEAR CARRIER ASS'Y-INPUT 24 2 414937 CAPSCREW 3/8-16NC X 3/4 BUTTON HD

2 1 247005 GEAR CARRIER ASS'Y-INTERMEDIATE 25 6 416273 SCREW #6-32NC X 3/8 LG. FIL. HD. F/B

3 1 247006 GEAR CARRIER ASS'Y-OUTPUT 26 4 418018 NUT ¼-20NC HX. REG.-ELASTIC STOP

4 1 278068 SOLENOID ASS'Y.-12V 27 6 418033 NUT 3/8-16NC HX. REG. F/B

1 278069 SOLENOID ASS'Y.-24V 28 4 418174 WASHER-FLAT 3/8 ID SAE F/B

5 1 251110 SWITCH ASS'Y. 29 6 418175 LOCKWASHER 3/8 ID MED. SECT. F/B

6 1 251150 FAIRLEAD 30 2 418515 SPACER-TIE BAR

7 1 251169 CABLE ASS'Y-1/4 DIA. X 80' 31 1 442207 GASKET-COVER

8 1 296285 BRAKE/SHAFT ASS'Y 32 1 444048 GEAR-OUTPUT SUN

9 1 299699 WINCH MOUNTING ASS'Y. 33 2 448061 TIE BAR

10 1 332143 DRUM-CABLE 34 1 448071 CABLE ANCHOR

11 1 334143 GEAR-RING 35 1 458131 MOTOR-END BEARING ASS'Y-12V

12 1 334145 GEAR-INTERMEDIATE SUN 1 458132 MOTOR-END BEARING ASS'Y-24V

13 1 334153 GEAR-INPUT SUN 36 1 470050 ROLL PIN 1/8 DIA. X 5/8 LG.

14 1 338249 END BEARING-GEAR HOUSING 37 1 470053 ROLL PIN 1/8 DIA. X 3/8 LG.

15 2 395294 QM HANDLE 38 NOT USED

16 2 412056 BUSHING-DRUM 39 1 477002 LOCKING RING

17 1 412061 BUSHING-SHAFT 40 1 477013 CAM RING

18 1 413018 COVER-GEAR HOUSING 41 2 477004 RING-HALF

19 6 414320 CAPSCREW 3/8-16NC X1-1/4LG.HX.HD. GR.5 F/B 42 1 479007 RETAINER-RING GEAR

20 4 414829 CAPSCREW 1/4-20NC X 1" LG. SOC. BUTT.HD. F/B 43 6 494077 SPRING

21 1 414830 CAPSCREW 1/4-20NC X 3/8 SOC BUTT. HD. 44 3 518020 THRUST WASHER

22 6 414861 CAPSCREW 1/4-20NC X 3/4 LG. FLATSOC.HD. NYLOK 45 1 518027 THRUST DISC

23 2 414900 CAPSCREW 3/8-16NC X 5/8 FLT 46 1 448097 LOCKING PIN

47 1 452005 SHIFTER HANDLE

QM 5000™

Page 8

8

Page 9

9

Page 10

18

GREEN

11

RED

RED

15

13

10

15

4

14

10

12

19

5

7

YELLOW

16

3

6

9

5

1

4

8

16

17

2

9

ITEM NO. QTY PART NO. DESCRIPTION

1 1 289090 WIRE ASS'Y-BLACK 10 GA X 3" LG

2 1 289091 WIRE ASS'Y-BLACK 16 GA X 1-1/2" LG

3 1 289092 WIRE ASS'Y-BLACK 6 GA X 3-1/2" LG

4 2 289095 WIRE ASS'Y-BLACK 6 GA X 6" LG

5 2 364002 STRAP-COPPER

6 1 408087 BRACKET-SOLENOID MOUNTING

7 1 413019 COVER-SOLENOID

8 4 416216 SCREW #10-24NC X 1/2" LG RD HD PLTD

9 2 416227 SCREW #10-24NC X 3/4" LG TRUSS HD BLACK

10 6 418004 NUT #10-24NC HEX REG PLTD

11 4 418140 WASHER #10 SAE FLAT PLTD

12 2 418141 LOCKWASHER #10 MED SECT

13 1 418165 WASHER 5/16 SHAKEPROOF EXT TEETH

14 1 430013 CONNECTOR FEMALE-MOLDED

15 2 440071 TERMINAL TAB

16 2 440110 SOLENOID-12V

2 440114 SOLENOID-24V

17 1 440111 STRAP-COPPER

18 1 440180 WIRE ASS'Y

19 1 482029 COVER-CONNECTOR

Solenoid Assembly Parts List QM 5000™

278068 12 Volt

278069 24 Volt

10

Page 11

11

Page 12

RAMSEY WINCH warrants each new RAMSEY WINCH to be free from defects in

material and workmanship for a period of one (1) year from date of purchase.

The obligation under this warranty, statutory or otherwise, is limited to the replacement

or repair at the Manufacturer's factory, or at a point designated by the Manufacturer, of

such part that shall appear to the Manufacturer, upon inspection of such part, to have

been defective in material or workmanship.

This warranty does not obligate RAMSEY WINCH to bear the cost of labor or transportation charges in connection with the replacement or repair of defective parts, nor

shall it apply to a product upon which repair or alterations have been made, unless

authorized by Manufacturer, or for equipment misused, neglected or which has not

been installed correctly.

RAMSEY WINCH shall in no event be liable for special or consequential damages.

RAMSEY WINCH makes no warranty in respect to accessories such as being subject

to the warranties of their respective manufacturers.

RAMSEY WINCH, whose policy is one of continuous improvement, reserves the right

to improve its products through changes in design or materials as it may deem desirable without being obligated to incorporate such changes in products of prior manufacture.

If field service at the request of the Buyer is rendered and the fault is found not to be

with RAMSEY WINCH's product, the Buyer shall pay the time and expense to the field

representative. Bills for service, labor or other expenses that have been incurred by

the Buyer without approval or authorization by RAMSEY WINCH will not be accepted.

See warranty card for details.

LIMITED WARRANTY

RAMSEY WINCH COMPANY

P.O. Box 581510 Tulsa, Oklahoma 74158-1510

Telephone: (918) 438-2760 FAX: (918) 438-6688

OM-912492-0107-H

Loading...

Loading...