Page 1

INSTALLATION INSTRUCTIONS

Y

QM FRONT RECEIVER KIT #295375

FOR 2005-7 FORD EXCURSION / SUPER-DUTY TRUCKS

Ramsey kits are designed for use with Ramsey Winches only.

Ramsey offers mounting kits and winches for various vehicles. In crash tests on a limited number

of automotive manufacturer's vehicles, winches/mounting kits, which have been properly

mounted, have not interfered with air bag operation.

The user/customer, or their installer, must verify that the mounting kit does not interfere with the

factory air bag sensors, which must not be relocated or modified in any way.

The user/customer should follow the vehicle manufacturer's recommendations and those of a

qualified mechanic to determine if the winch/mounting kit might interfere with the air bag

operation. The user/customer should then determine the suitability of a winch/mounting kit on a

particular vehicle.

PLEASE BE ADVISED THAT THE VEHICLE'S AIR BAG SYSTEM MAY NOT OPERATE

PROPERLY IF THE WINCH/MOUNTING KIT IS NOT MOUNTED IN COMPLIANCE WITH THE

VEHICLE MANUFACTURER'S RECOMMENDATIONS.

DO NOT ATTACH TOW HOOK TO ANY PART OF MOUNTING KIT UNLESS INSTRUCTED TO

DO SO.

DO NOT SUBSTITUTE ATTACHING HARDWARE ITEMS (BOLTS, NUTS, OR WASHERS).

READ AND UNDERSTAND WINCH OWNER'S MANUAL BEFORE INSTALLATION AND OPERATION OF WINCH.

SEE WARNING AND CAUTION.

Use or sales of kits for other winches or applications voids warranty.

NOTICE

WARNING

IMPORTANT NOTES!

1. RIGHT AND LEFT HAND DIRECTIONS AS IF SEATED BEHIND STEERING WHEEL.

2. ALL FASTENING HARDWARE MUST BE LOOSELY ASSEMBLED UNTIL DIRECTED TO TIGHTEN.

RAMSEY WINCH COMPAN

P.O. BOX 581510

TULSA, OKLAHOMA 74158

KI-913397-0307-B

Page 2

DO NOT TIGHTEN HARDWARE UNTIL INSTRUCTED!

STEP 1

Remove vehicle tow hooks. Discard existing hardware.

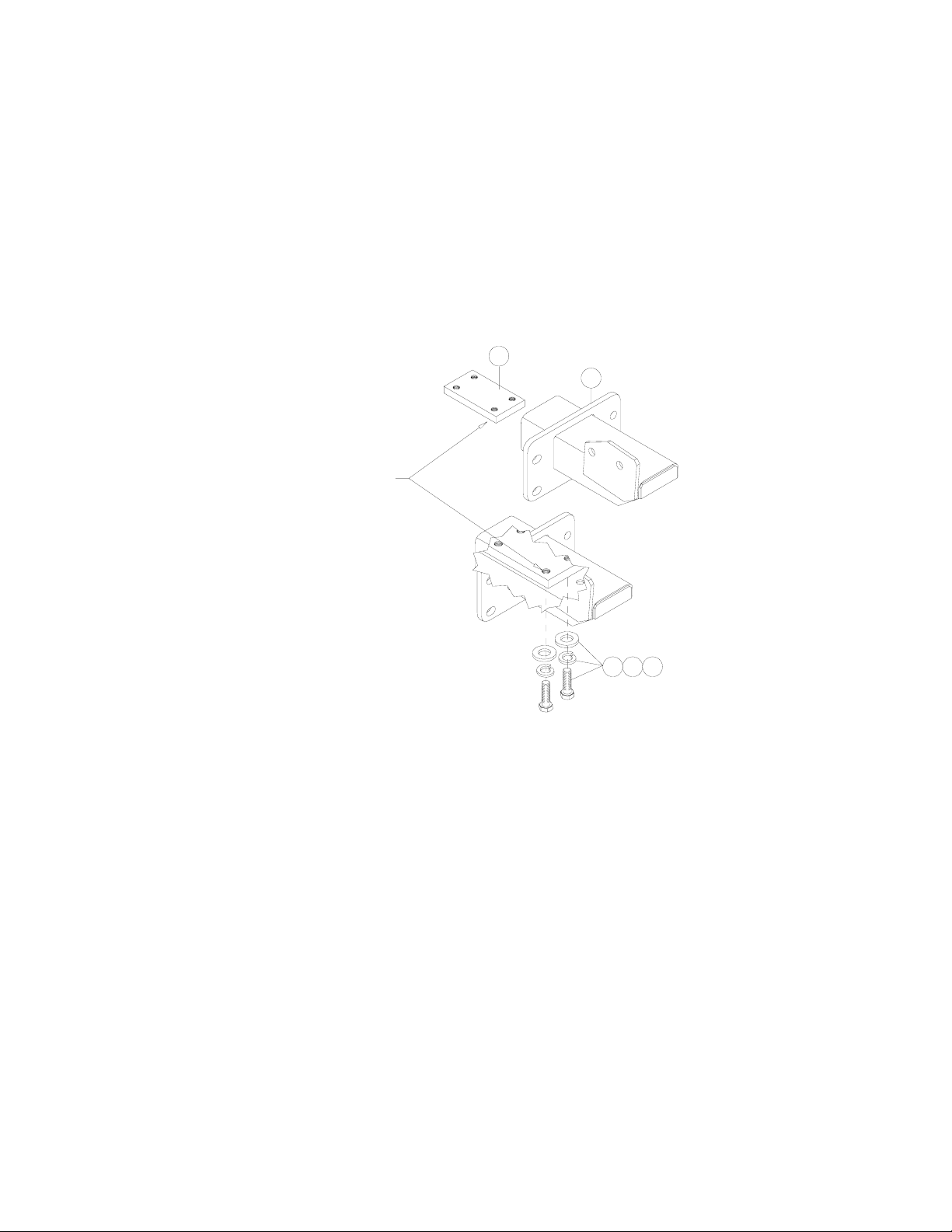

STEP 2

Insert nut plate #2 into R.H. mounting arm assembly as shown below. Attach nut plate to mounting

arm using (2) 1/2-13NC x 1.25” capscrews #9 through lockwashers #13 and flat washers #14 into

front nutserts in nut plate.

2

4

ALIGN NUT PLATE WITH THE

FOUR REAR HOLES IN

MOUNTING ARM ASSEMBLY.

SECURE WITH (2) CAPSCREWS

IN THIS LOCATION. REAR

CAPSCREWS ARE INSTALLED

IN A LATER STEP.

Repeat for L.H. bracket assembly #4.

91314

1

Page 3

STEP 3

Remove R.H. vehicle bumper bracket bolts (2 bolts) and discard.

Secure R.H. mounting arm #4 to vehicle frame using (2) 1/2-13NC x 1.75” capscrews #8, (2) nuts

#11, (2) lockwashers #12, (1) nutplate #3 and (2) flat washers #13 as shown below. These

capscrews go through the outside (slotted) holes on the mounting arm flanges.

HINT: To align holes between mounting arm flanges, bumper bracket, and frame, you may need to

raise or lower the bumper slightly.

Repeat for L.H. bracket assembly #5.

VEHICLE FRAME

REMOVE EXISTING

HARDWARE

VEHICLE FRAME

5

OUTSIDE MOUNTING

HOLES IN BRACKETS

ARE SLOTTED

11

3

INSTALLED IN A LATER STEP

13

4

8

14

2

Page 4

STEP 4

Hold receiver assembly #1 between R.H. & L.H. mounting arms #4 & #5. Make sure R.H. and L.H.

arms are installed so that slotted mounting holes on flanges are on the outside.

Insert (1) 1/2-13NC x 1.25” capscrew #9 through rear hole in R.H. bracket #4. Secure using (1)

lockwasher #12 and (1) nut #11. Repeat for L.H. bracket #4.

Next, insert (1) 1/2-13NC x 1.25” capscrew #9 through (1) lockwasher #12, front hole of R.H. bracket

#4, and into threaded nutsert in receiver.

Repeat for L.H. bracket #5.

Align and tighten all 1/2" hardware.

If necessary, license plate can be mounted to receiver using (2) 1/4-20 x .50” capscrews #6 with

lockwashers #11, as shown below.

Install receiver cover #15 as shown.

THROUGH HOLE

9

913

11

13

5

1

6

15

THREADED HOLE

4

LICENSE

PLATE

12

3

Page 5

STEP 5

Use (2) 1/2-13NC x 1.5” capscrews #7 with (2) lockwashers #13 and (2) flat washers #14 through

bottom of vehicle frame and into rear nutserts of nut plate attached to mounting arm assemblies #4 &

#5, each side. Tighten all hardware to full torque.

71314

4

STEP 6

Drill (2) 9/16 DIA. holes through bumper brackets, as shown below. Use mounting arm flanges #4 &

#5 as a template.

Install (2) 1/2-13NC x 1.75”. capscrews #8 with (2) flat washers #134 (2) lockwashers #13 and (2)

nuts #11, each side as shown below. Install vehicle tow hooks to inside of mounting arms #4 & #5

using M12 x 1.75 x 30mm capscrews #10. Tighten to full torque.

DRILL (2) 9/16" DIA. HOLES

THROUGH HOLES IN MOUNTING

ARM FLANGES AND INTO

VEHICLE BUMPER BRACKET.

VEHICLE TOW HOOKS

13

11

10

8

14

RECEIVER NOT SHOWN FOR CLARITY

REFER TO WINCH OWNER'S MANUAL FOR INSTALLATION INSTRUCTIONS AND ELECTRICAL CONNECTIONS

4

Page 6

PARTS LIST FOR KIT #295375

ITEM NO. QTY. PART NO. DESCRIPTION

1 1 299739 RECEIVER ASSEMBLY

2 2 350658 NUT PLATE (4 HOLES)

3 4 364165 NUT PLATE (2 HOLES)

4 1 408355 RH MOUNTING ARM ASSEMBLY

5 1 408356 LH MOUNTING ARM ASSEMBLY

6 2 414036 CAPSCREW 1/4-20NC X .5 LG HX HD GR5 BLK

7 4 414551 CAPSCREW 1/2-13NC X 1.5 LG HX HD GR5 BLK

8 8 414556 CAPSCREW 1/2-13NC X 1.75 LG HX HD GR5 BLK

9 8 414592 CAPSCREW 1/2-13NC X 1.25 LG HX HD GR5 BLK

10 6 415316 CAPSCREW M12 X 30mm LG GR8 Z/P

11 12 418072 HEX NUT 1/2-13NC BLK

12 2 418147 LOCKWASHER 1/4 BLK

13 26 418216 LOCKWASHER 1/2 BLK

14 16 418229 WASHER 1/2 USS BLK

15 1 472032 RECEIVER TUBE COVER

TORQUE VALUE CHART

TORQUE

SIZE FT./LB. NM

1/2-13 87 118

M12 39 54

5

Loading...

Loading...