Page 1

1

R-VAN Adjustable Rotary Nozzle Installation Guide

Rain+Birdt

R-VAN Adjustable Rotary Nozzle

Installation Guide

Introduction

Rain Bird R-VAN Adjustable Rotary Nozzles provide

water eciency and design exibility. R-VAN Adjustable

Rotary Nozzles feature rotating stream technology which

uniformly delivers water at a low precipitation rate,

signicantly reducing runo and erosion. Retrotting

standard spray nozzles with R-VAN Adjustable Rotary

Nozzles can reduce ow by up to 60% and improve water

eciency by up to 30%. Nozzle spray pattern and distance

are easily adjusted by hand with no tools required.

Models

R-VAN1318

Black Rotary Deector

13’ to 18’ (4,0 to 5,5m) radius

45° to 270° arc

R-VAN1724

Yellow Rotary Deector

17’ to 24’ (5,2 to 7,3m) radius

45° to 270° arc

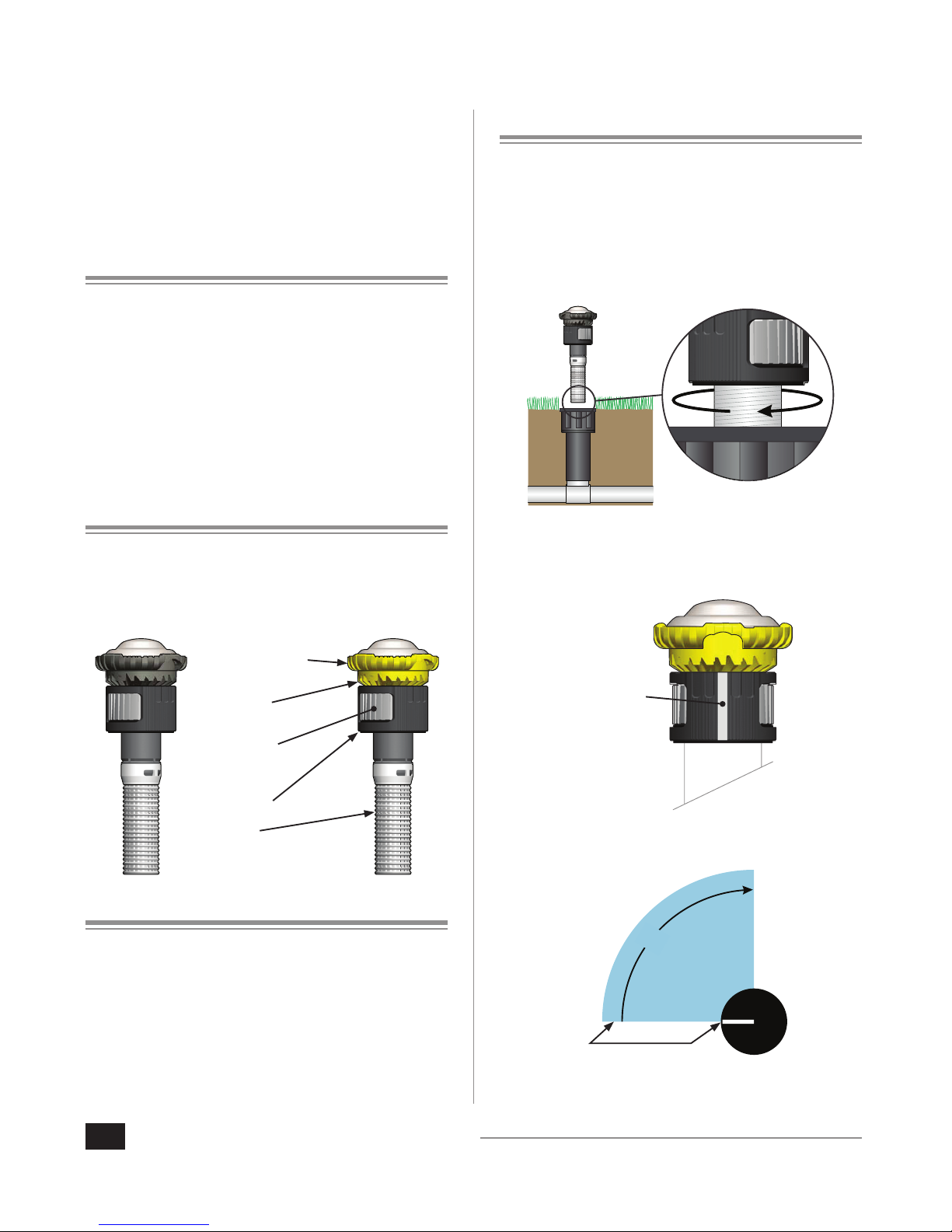

ARC

ADJUSTMENT

CAP

ROTARY

DEFLECTOR

FILTER

SCREEN

RADIUS

ADJUSTMENT

DIAL

COLLAR

Features

Adjust arc and radius without tools

Color coded for easy identication of R-VAN model

Low precipitation rate reduces run-o and erosion

Maintains ecient performance at high operating

pressures without misting or fogging

Compatible with all models of Rain Bird spray bodies in

addition to a wide variety of risers and adapters

Three year trade warranty

Installation

Install Nozzle

R-VAN Adjustable Rotary Nozzles can be used for a new

installation or to replace existing sprinkler nozzles.

1. Unscrew and remove the existing sprinkler nozzle (if

applicable) from the spray body.

2. Screw the nozzle onto the spray body until secure.

Identify the Left Edge

A grooved white mark located on the collar, just under the

rotary deector, represents the left edge of the arc.

LEFT EDGE

INDICATOR

1. Align the nozzle to the left most edge of desired

coverage area (arc).

ARC

ALIGN LEFT EDGE

INDICATOR WITH ARC

Page 2

2

R-VAN Adjustable Rotary Nozzle Installation Guide

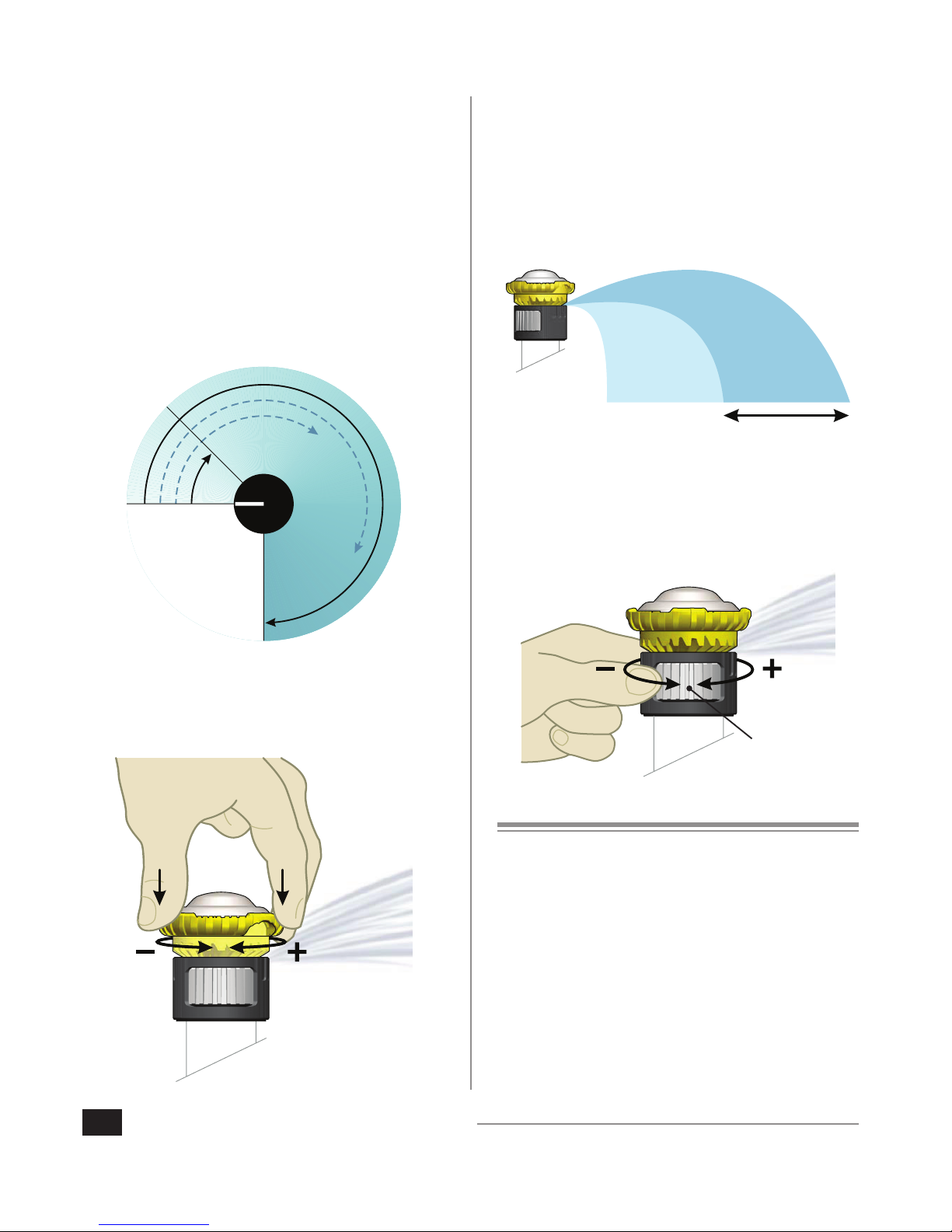

Radius Adjustment

Set the desired nozzle range, from 13’ to 18’ (4,0 to 5,5m)

for the R-VAN1318 (Black) or 17’ to 24’ (5,2 to 7,3m) for

the R-VAN1724 (Yellow). The factory default setting is the

maximum range for each model.

lb

NOTE: Water must be turned ON in order to set the

Radius Adjustment.

1. Turn the Radius Adjustment Dial counter-clockwise to

decrease the nozzle range.

2. Turn the Radius Adjustment Dial clockwise to increase

the nozzle range. A clicking sound will be heard when

range limits are reached.

TURN THE

RADIUS

ADJUSTMENT

DIAL

Re-program Controller

After installing R-VAN Adjustable Rotary Nozzles, the run

times for your watering schedule will need to be adjusted.

Refer to your controller's user manual for instuctions.

lb

NOTE: Adjust run times based on an application

rate of 0.6 in/hr. (14.7 mm/hr.). Run times for R-VAN

Adjustable Rotary Nozzles could be two to three

times as long as standard spray nozzles.

Initial Start Up

Apply water to the system. Verify proper operation of the

nozzles and check for leaks.

lb

NOTE: Nozzles may rotate at slightly dierent

speeds. These nozzles maintain uniformity and apply

water at the same rate, regardless of rotation speed.

Arc Adjustment

Set the desired nozzle coverage, from 45° to 270°.

lb

NOTE: Water must be turned ON in order to set the

Arc Adjustment.

270°

45°

1. Push down and turn the Arc Adjustment Cap counter-

clockwise to decrease the arc.

2. Push down and turn the Arc Adjustment Cap clockwise

to increase the arc.

PUSH DOWN

AND TURN

THE ARC

ADJUSTMENT

CAP

Page 3

3

R-VAN Adjustable Rotary Nozzle Installation Guide

Troubleshooting

The following table lists common problems and solutions

associated with nozzle operation.

Problem Cause Solution

Nozzle is not rotating

or watering.

Filter screen may be

clogged with debris.

Clean screen.

Water head pressure

may be too low.

Effective pressure range

for R-VAN nozzles is 138

to 379 KPa. Recommended

operating pressure is 310

KPa. Check system.

A small amount of fine

grit may be inside the

nozzle.

Cycle the system a few

times to flush.

Water path in the

rotary deflector may be

clogged with debris.

Visually inspect water paths

in the rotary deflector and

clean out any debris.

Nozzle operating

in a very sandy

environment.

Wait 2 to 4 minutes to see if

sand flushes out and nozzle

begins to rotate.

Gaps or distorted

streams in the water

spray pattern.

Nozzle operating

in a very sandy

environment.

Clean screen.

Range of water spray

from nozzles is less

than expected.

Water head pressure

may be low.

Ensure Radius Adjustment

Dial is fully open. Turn

clockwise until clicking

sound is heard. Check

system to ensure proper

pressure.

Nozzle Maintenance

debris causes degradation of performance.

1. Unscrew the rotary nozzle from the riser.

2. Remove the clogged screen.

3. Clean and replace the screen.

4. Screw the nozzle back onto

the riser.

NOTE: Rotary Nozzles may

be damaged by mowers or

other equipment. Check

the nozzles regularly to

ensure proper operation

and for safety.

Nozzle Spacing Options

This section describes the two most common sprinkler

layout designs for an irrigation zone, square spacing

and triangular spacing. Single row applications are not

recommended. Since the application rate of R-VAN

Adjustable Rotary Nozzles is much lower than standard

spray nozzles, mixing rotary and spray nozzles in the same

zone is not recommended.

NOTE: Square and triangular spacing is typically

based on 50% diameter of throw.

Square Spacing

Square spacing is a sprinkler layout where nozzles are

placed in a square pattern, with the same distance between

all nozzles. This is the best pattern for areas with 90° corners

areas that overlap, causing some over watering.

Triangular Spacing

Triangular spacing is a sprinkler layout where nozzles are

placed in a triangular grid, with the same distance between

all nozzles. This works best for irregularly shaped areas. More

surface area is watered with less overlap.

FILTER

SCREEN

D50004EO

Loading...

Loading...