Page 1

Tips on Installing

and Maintaining

Rain Bird

Residential Valves

Valves are an essential part of any

sprinkler system. They are the link between the "brains" of the system (the

timer) and the sprinkler heads to turn

the water on and off.

BBIRDIRD®RRAINAIN

Customer Support Center

6991 E. Southpoint Rd., Bldg. #1

Tucson, AZ 85706

1-800-RAIN-BIRD

1

Page 2

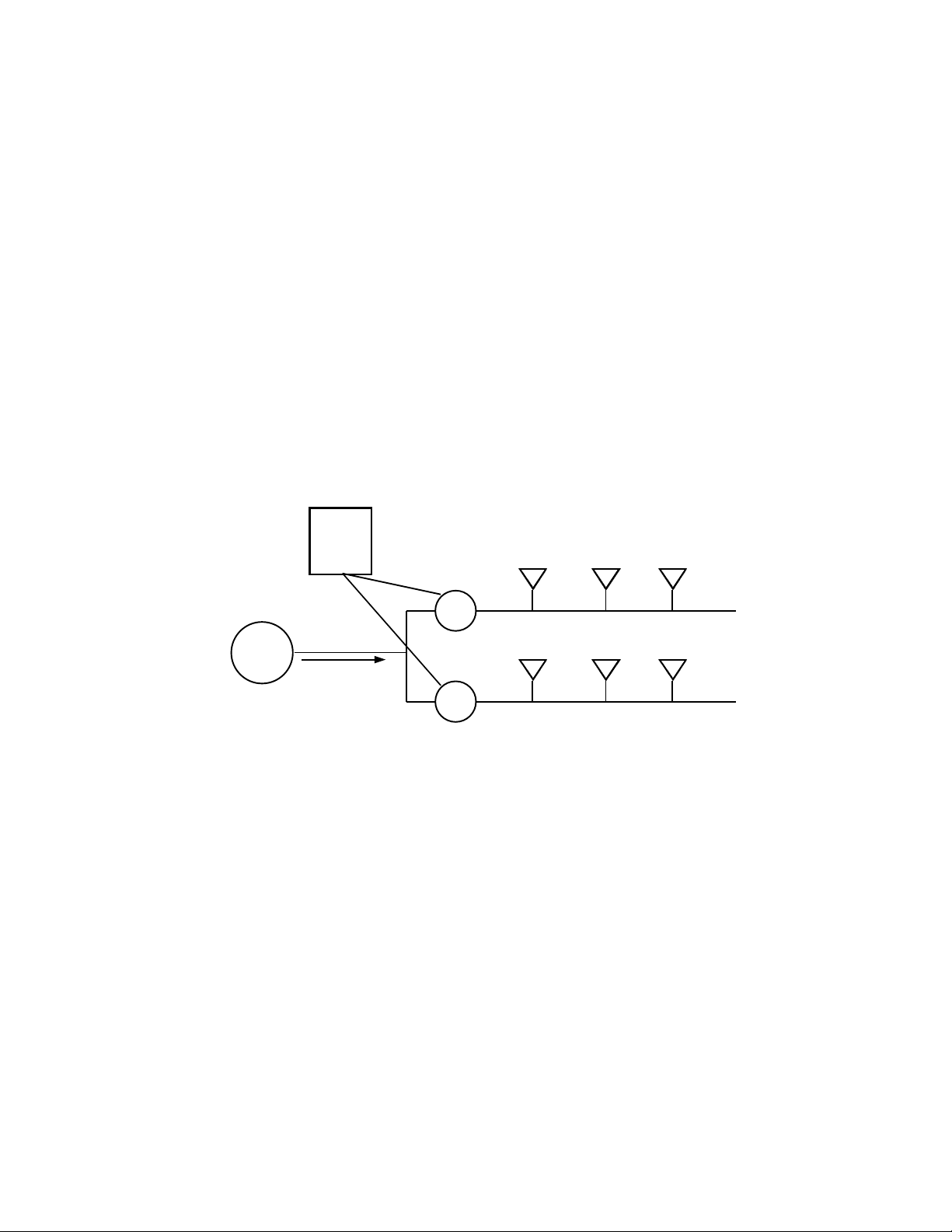

Valves are an essential part of any sprinkler system. They are the link between the

"brains" of the system (the timer) and the sprinkler heads, to turn the water on and off.

Most automatic sprinkler systems are set up with two types of valves. A brass "gate

valve" or "ball valve" is usually located right after the "tee" where the sprinkler system

cuts off from the main source of water to the house. This valve, referred to as the

"shutoff valve," is used to shut down the sprinkler system for repairs or winterizing

without shutting off the water to the entire house. It is recommended that all systems

be equipped with a shutoff valve installed in a box for easy access.

The second type of valve is the sprinkler "zone valve." Each zone valve is piped to a

set of sprinklers. When the valve is turned on, either by hand or in response to an

electronic signal from the timer, all the sprinklers piped to that particular valve go on.

In most cases, there are several valves located together (called a manifold), each con-

CONTROLLER

SPRINKLERS

VALVE

SHUT

OFF

INCOMING

VALVE

BASIC SYSTEM COMPONENTS

SPRINKLERS

Why are several valves needed? All systems are limited by a combination of the pressure of the water (psi) and the number of gallons per minute (gpm) available. Each

sprinkler uses a certain number of gallons per minute of water. This release of water

through the nozzle reduces water pressure to a certain degree while the system is

working. For maximum performance, each zone is controlled by one valve and is set

up with the proper amount of sprinklers so that the psi and gpm capacity of the system

is not exceeded. The purpose of this information is to address questions and problems

related to zone valves.

2

Page 3

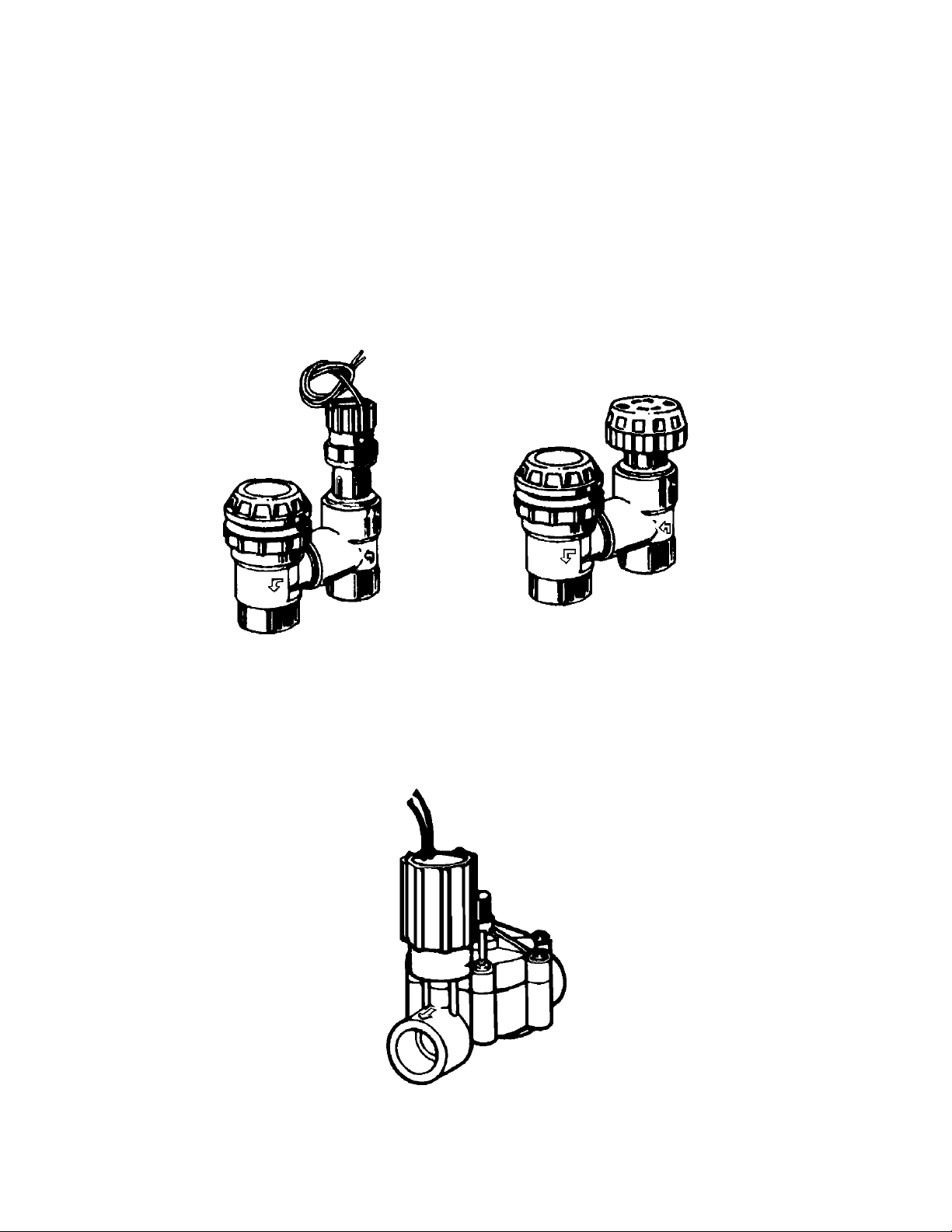

Types of Zone Valves

There are two basic types of zone valves commonly available. Anti-siphon valves

have a built-in backflow device to prevent possibly contaminated water from flowing

backward into the household supply. If approved by your local codes, these types of

valves provide inexpensive backflow protection. Anti-siphon valves must be installed

at least 6" above the highest sprinkler head on the line in order for the backflow device to work properly. Both automatic and manual versions are available.

APAS-100-P

APAS-075-P

PAS-100

PAS-075

The second type of valve is an "in-line" valve. It is installed below ground, preferably

in a valve box, for ease of maintenance. A separate backflow preventer is required for

backflow protection. In-line valves are automatic valves.

CP-075

CP-100

3

Page 4

Anti-Siphon Valves

Anti-siphon valves are an inexpensive choice and easy to install and maintain. The

built-in anti-siphon backflow device prevents potential contamination of household water supplies from fertilizers and other toxic chemicals which may enter the system.

Check your local codes for the types of backflow protection required in your area.

Electric models are simple to hook up to a timer for automatic watering. They are best

suited to plans where there is not more than a slight rise in elevation, and fairly clean

source water.

Caution: This valve is designed as a zone valve and as such may suffer severe damage if installed where constant pressure is placed on the outlet (sprinkler) side of the

valve. The manual version is not suitable for use in a continuous open position as a

main shutoff valve or as a means of inexpensive backflow prevention for an entire system; nor are the automatic models to be used as a master valve where other valves

will be installed downstream.

(Note: A master valve is an electric valve that is automatically activated to open and

allow the flow of water through, only when the zone valves downstream are activated.)

Automatic Anti-Siphon control

valves APAS-075-P/APAS-100-P

Install valves

at least 6”

above

the highest

sprinkler

PVC Pipe

Shutoff

To Sprinklers

Connecting pipe

from water source

Typical installation

using PVC pipe and

fittings

4

Page 5

In-Line Valves

In-line valves, installed below ground level, are suitable for sites with all types of elevation changes. Because of their protected location, in-line valves are less likely to be

tampered with by children or vandals, and less likely to incur freeze damage than

above ground models. In-line valves do not afford backflow protection.

In situations where the water is pumped from a lake, well, ditch, or other "dirty" water

source, sand and other debris should be filtered from the line through a filter with a

100 mesh screen. If water supply is also used as a drinking water source, a separate

backflow prevention device is required to prevent potential contamination should fertilizers or toxic chemicals in the water be siphoned backwards through the lines.

If your water is supplied by a municipal water system, check with your local Rain Bird

dealer or plumbing supplier for the type of backflow prevention device required in your

area. For specific information about backflow and the types of backflow prevention devices available, please call our toll-free number. 1-800-RAIN-BIRD, and request a

"Backflow Prevention Handbook."

In-line valves are installed below ground, protected by a valve box. An in-line valve is

also suitable for use as a master valve.

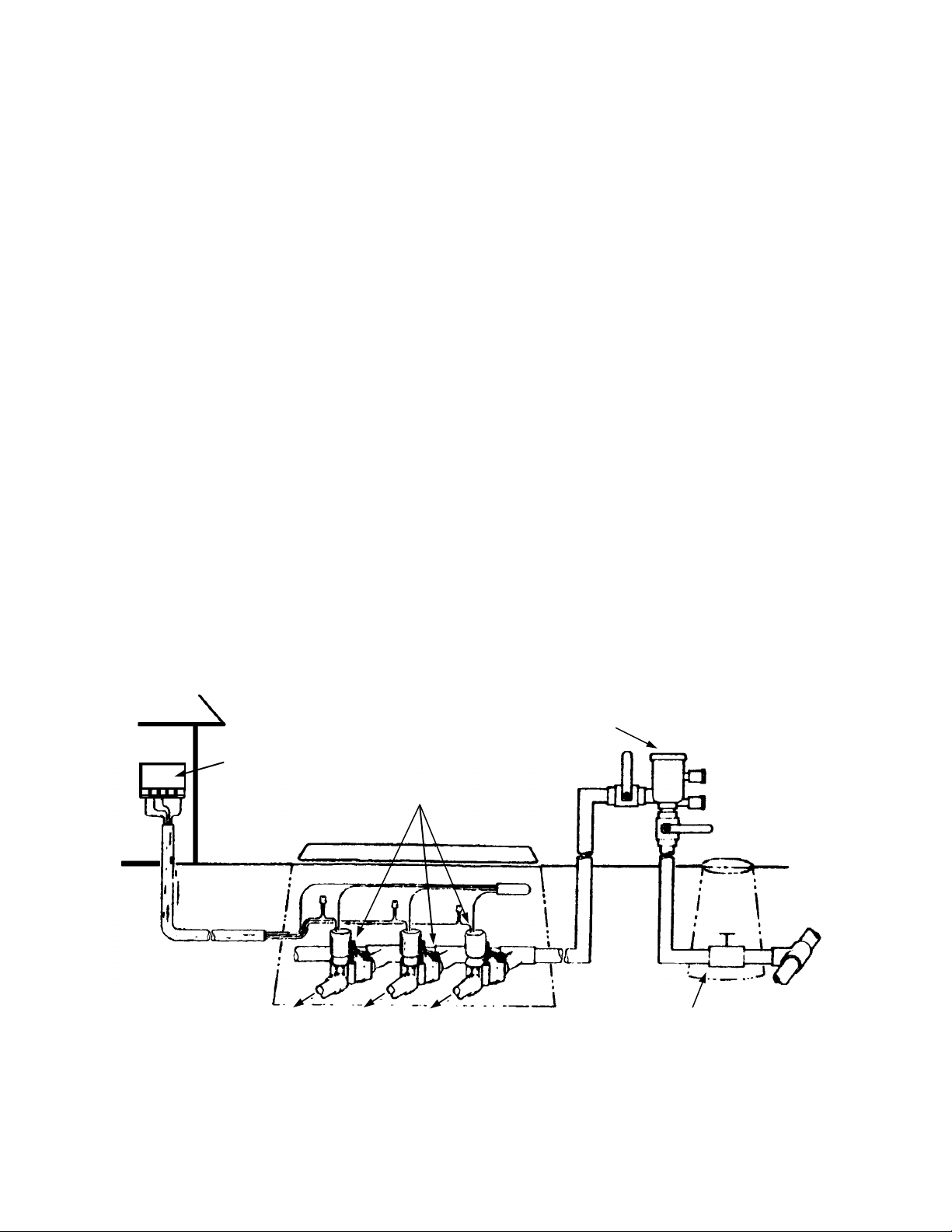

CONTROLLER

PVB VALVE

VALVES

Service

Line

from

Street

SHUTOFF

TO

SPRINKLERS

5

Page 6

Tips On New Installations

Tapping Into Your Water Source

Turn off the water at the meter. Cut into your household service line and install a brass

slip-type compression tee, after the meter. The cut can be done anywhere on the line,

depending on the layout of your system and the location of your first manifold. Unless

unregulated static pressure is over 80 psi, tap into the line before the household pressure regulator. In freezing climates, you will probably be tapping into your source inside a basement.

Next, install a gate or ball valve to act as your system shutoff valve. House the valve

in a valve box for easy access in below ground situations. Once this valve is installed

and tested, the valve at the meter may be left open for water usage inside the house.

In freezing climates, your next step will be to install a manual drain valve so that the

water can be drained from the pipes between the zone valves and the shut-off valve.

Install Schedule 40 PVC, thick-walled pipe up to the valves. In basement installations,

you will need to drill a hole through the wall to direct the pipe out to the valves. For

convenience in "blowing out" the system for winter, access to the line by means of a

tee with a capped 1" riser may be installed at this point.

If a backflow preventer is to be used, install it outside at the proper height.

Service to

House

FLUSH, FLUSH, FLUSH. . .Turn on the water at the shutoff valve and flush the pipes

free of dirt.

Meter in House

Compression

Tee

Shutoff

Valve

Shutoff

Valve

Water

Meter

Slope Downward

for Drainage

Shutoff

Valve

Drain

Cap

To

Control

Valves

Service

Line

from

Street

Service

Line to

House

To

Control

Valves

Meter in Yard

Compression

Shutoff

Valve

Tee

Water

Meter

Service

Line

from

Street

6

Page 7

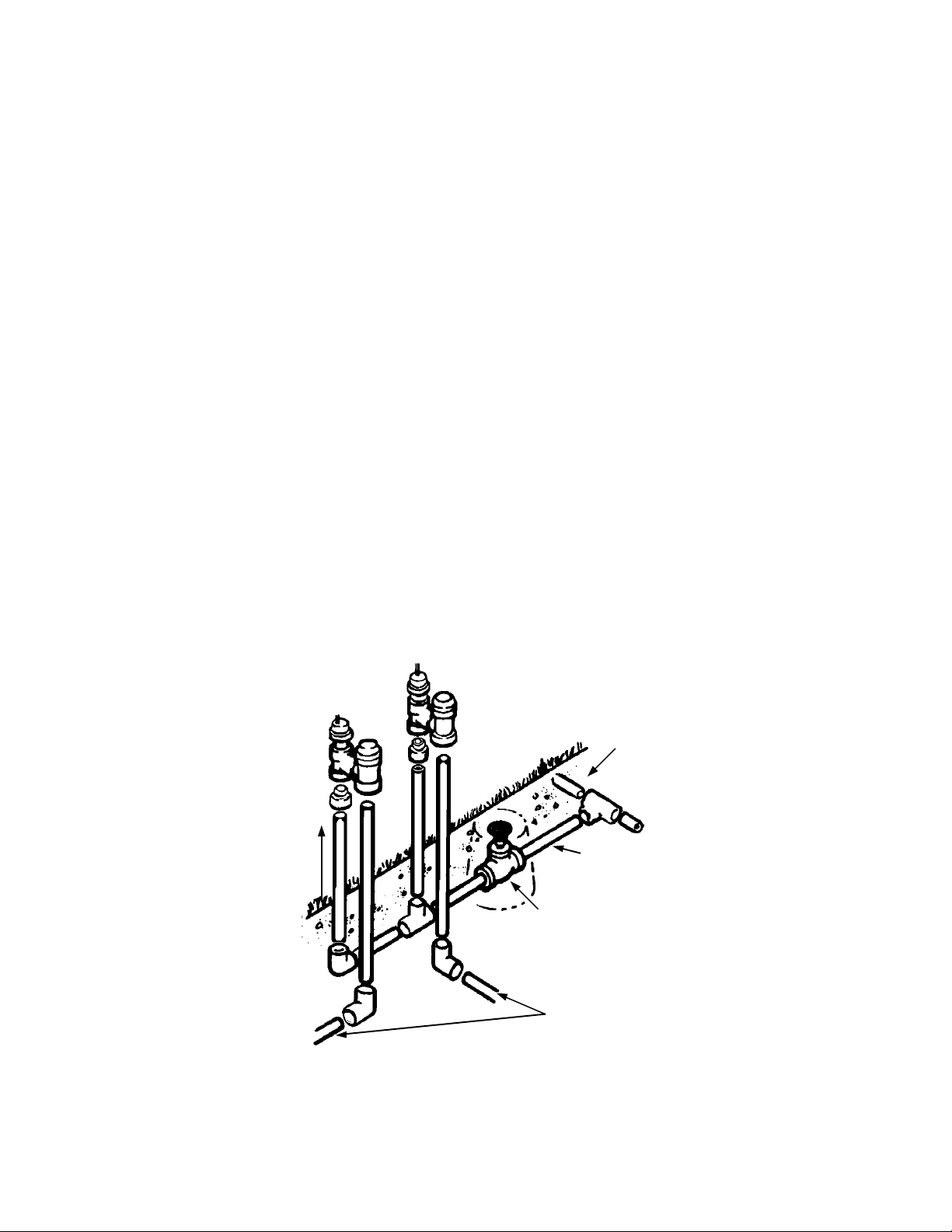

Installing the Manifold

If you are installing a new valve manifold, keep in mind that the location should be

easily accessible for maintenance. Locate the manifold where you are not likely to be

sprayed by the sprinklers when turning the system on manually. On larger systems,

separate manifolds may be required for the front and back yards. It is a good idea to

keep a plan showing where all in-ground valves and pipes have been installed.

Be sure to flush the line coming up to the manifold, before installing the valves. Test

and flush each line before sprinklers are attached. Most valves have a flush mode

which allows a little extra water through the valve to clean it out.

To Flush:

Turn Solenoid (Manual on/Off)

Hold Flow Control

Turn black SOLENOID counterclockwise (do not turn gray ring) until a small amount of water discharges

between SOLENOID and FLOW CONTROL ring.

Anti-Siphon Valves Grouped Above Ground

Connecting pipe and fittings to be

the same size as the largest control valve in the group

Connecting pipe

from water source

Install valves

at least 6”

the highest

sprinkler

Typical installation

using PVC pipe and

fittings

above

To Sprinklers

PVC Pipe

To backyard

control valves

7

Page 8

To Flush:

Solenoid

Bleed Knob

(Manual Bleed)

(Manual on/off)

Bonnet

Body

Turn bleed knob 1 full turn counterclockwise and allow water to spray out for 10-15 seconds; turn back

to clockwise position.

Automatic In-Line

control valves

CP-075 for 3/4” pipe

CP-100 for 1” pipe

PVC Pipe

To other

valves

To Sprinklers

Connecting pipe

from water source

Typical Installation

using PVC pipe

and fittings where no

backflow prevention is

required

Installing the Manifold (Continued)

Tip: Partially assembling the manifold ahead of time will make the job easier. Be sure

that the valve is installed horizontally according to the arrows printed on the body for

the direction of flow. Valve operation may be erratic and valve warranty is void if installed backward or in a vertical position. Call our toll-free Technical Services Hotline

for any questions on system installation: 1-800-RAIN-BIRD.

CAUTION: Do not use plumber's pipe dope on valve threads when installing. Chemicals in the pipe dope may react with the plastic in the valve body causing the valve to

weaken and crack at the threads. Three wraps of Teflon tape should be sufficient to

create a leak-proof seal.

How to Operate

Several models of Rain Bird 24 Volt valves are available for home use. Minimum current requirements for opening the smaller valves is .30 amps and for holding the valve

open is .19 amps. Larger valve models have slightly higher requirements. All Rain Bird

valves are designed to work with Rain Bird timers and other timers that have a power

output sufficient to activate the valve. Your Rain Bird valve offers some simple features you should be familiar with. Note: Some valves have only part of these features.

See the diagram above and on the previous page for information on flushing the

valves.

a. Flow control -

b. Manual bleed -

Regulates the amount of water passing through the valve. (Not

available on all models.)

Turns the valve on manually by "bleeding" water off of the diaphragm. External bleed models have a knob or screw to turn

and the water sprays out of the top of the valve. Internal bleed

models have a open/close knob or require a 1/4 turn of solenoid

and water bleeds off inside the valve.

c. Manual On/Off -

Turn solenoid 1/

ally.

turn counterclockwise to turn valve on manu-

4

8

Page 9

Troubleshooting

How the Valve Works

It is easier to troubleshoot valves if you know a little about how the valve works. When

an electrical impulse is transmitted to the solenoid (black cylinder with wires), an electromagnetic field causes a small metal plunger in the solenoid to move upward. When

the plunger moves upward, a small hole (port) in the valve is uncovered. Water in the

chamber above the closing mechanism (either diaphragm or piston) flows through the

port and out of the valve, relieving water pressure needed to hold the valve closed. At

this point, the pressure of the incoming flow of water is now greater than the pressure

in the chamber above the piston/diaphragm, and the force of the water pushing up underneath the piston/diaphragm opens the valve.

When the solenoid is de-energized, the plunger moves down, closing the small port.

Water flowing through a small hole in the closing mechanism refills the chamber

above the piston/ diaphragm and builds up pressure. The increased pressure forces

the piston/diaphragm downward, thus closing the valve. All valves have a range of

pressure and water flow that must be maintained in order to work properly.

Now that you have an idea of the way the valves work. you can see why sufficient

pressure and flow are important. If a problem does occur, it is also very important to

ensure that the small internal ports are not blocked by debris. Adequate flushing is the

key to success in a new installation.

Diaphragm

Moves UpValve Open

How a diaphragm valve opens and closes.

9

Diaphragm

Moves DownValve Closed

Page 10

TROUBLESHOOTING GUIDE

1. For any problem, check the

basics first.

SYMPTOM CAUSE DIAPHRAGM VALVE REMEDY

2. Valve won't turn on with

timer.

A. Is timer plugged in and properly programmed?

B. Is master shut off valve open?

C. Is flow control on valve in an "open" or "flow" position? Not all models have this feature. Check the instructions that came with your

valve, or see "How to Operate" section of this packet.

D. Are water pressure and flow rate adequate for your particular valve model? (Check the instructions that came with the valve or call us

toll free at 1-800-RAIN-BIRD for the requirements of your particular Rain Bird valve model.) If your pressure is too low,. Investigate these

causes:

• Pressure drain from washing machines, showers, etc. or broken pipe,

• Master shutoff valve not fully open,

• Blockage in main supply line; to repair, cut main line, flush line, and repair cut;

• Too many heads on line; redesign system layout to reduce the number of heads operating at once.

E. Is valve in "Manual Off" position? See "How to Operate" section of this packet.

F. If your system is supplied by a pump, is it working?

PISTON-TYPE VALVE REMEDY

A. Check the Basics as in No. 1

above.

(See Valve Disassembly Procedure A)

• If all basics check out, see if the valve will

work manually. On some models you will

need to turn the solenoid 1/4 turn counterclockwise. On other models, turn the screw

in the center of the bonnet (water should

spray out of the top of the valve temporarily). Check your valve operating instructions

or refer to section entitled "How to Operate," in this packet of information. If the

valve works manually, go on to step 2-B. If

the valve doesn't work, go on to step 2-D.

(See Valve Disassembly Procedure B)

• If all basics check out, see if the valve will work

manually by holding onto the gray flow control ring

and turning the solenoid 1/4 turn counter-clockwise.

If the valve works manually, go on to step 2-B. If the

valve doesn't work, go on to step 2-D.

B. No power between timer and

valves.

C. Solenoid burned out or clogged. • The solenoid should make a distinct

D. Valve opening mechanism dam-

aged or clogged with debris. Bleed

ports clogged.

• Check by pressing the "Manual Start"

button of the timer and advance to the

desired station. Attach a circuit tester

(voltmeter) to the common terminal and the

station terminal of the timer. If you do not

get a 24-27 volt reading, the problem is in

the timer.

• Check for shorted or broken wiring. Follow

directions as above, except attach voltmeter

to common wire and station wire nearest

valve. If you do not receive a 24-27 volt

reading, replace or repair wiring.

"click" when activated. If timer and wiring

check out, try unscrewing the solenoid and

swapping it with a nearby valve of the same

model. Using the "Manual Start" on your

timer, check the station again to see if the

borrowed solenoid activates the valve. If so.

replace solenoid. If not check 2-D.

• See if you can flush debris from the valve

by using the flush mode. If not, turn off the

water, disassemble, inspect and clean the

valve (See Valve Disassembly Procedure

A). Pay particular attention to cleaning the

small bleed ports underneath the solenoid

and on the surface of the diaphragm. Check

to see that the diaphragm is not torn damaged. Replace diaphragm if damaged. If

water is particularly dirty, install a 100 mesh

or finer filter before the valve to prevent

future grit build-up.

• See recommendations at left for diaphragm valve.

• See recommendations at left for diaphragm valve.

• See recommendations at left for diaphragm valve.

• Turn off the water. Remove the actuator and examine piston (See Valve Disassembly Procedure B).

Remove dirt and deposits. If removing and cleaning

the piston does not or help, replace with the PRK100 piston replacement kit. If the problem is continual, install a 150 mesh or finer filter before the valve

to prevent future grit build-up,

E. Valve installed backwards • Reinstall valve so that water flow is the

same direction as arrows embossed on

valve.

10

• See recommendations at left for diaphragm valve.

Page 11

TROUBLESHOOTING GUIDE

SYMPTOM CAUSE DIAPHRAGM VALVE REMEDY

3. Valve won't turn off with timer. A. When the valve won't turn off

4. Water leaks out at sprinkler

heads when station is off.

with the timer, the foremost goal is

to stop the flow of water. When this

is accomplished, check steps B

through D for trouble-shooting

procedure.

B. Solenoid burned out or plunger

clogged.

C. Valve closing mechanism stuck

in open position due to debris or

damage.

D. Damaged or misaligned parts

allow water to leak from valve.

E. Valve set in "Manual On" mode. • Depending on the model, you will need to

A. Closing mechanism dirty or

damaged and does not seat properly.

B. Valve not fully in "Manual Off"

mode.

C. Solenoid burned out or obstructed.

D. Low head drainage. • It is normal for water to temporarily con-

(See Valve Disassembly Procedure A)

• Put timer in auto/off (Rain Shutoff) mode. If

watering continues. . .

• Unplug timer. If this stops the watering, the

problem is probably in the timer. If watering

continues. . .

• Turn flow control knob (if there is one) to

lowest flow position. If this does not shut off

the flow completely. . .

• Turn off manual main shut off valve to

sprinkler system.

• Check solenoid as in 2-C. Check for dirt

impeding the movement of the plunger. To

do this, turn off the water and remove

power to the solenoid. Unscrew the

solenoid. Sometimes the plunger inside the

solenoid can become stuck in the upward

position due to dirt in the solenoid. Run water

into the solenoid to dislodge dirt. Push a

piece of wire into the small hole in the retainer at the bottom of the solenoid to see if

the plunger inside will move up and down

freely. If not. replace the solenoid.

• See Valve Disassembling Procedure A.

Check small ports for blockage by debris;

rinse and inspect diaphragm and diaphragm

seat for dirt or damage. Replace diaphragm

if damaged.

• Check valve body and bonnet for cracks.

Check integrity of seal between body and

bonnet and solenoid and bonnet. Repair or

replace parts as necessary to stop leak.

be sure the solenoid is tightened into the full

clockwise position ("Manual Off") or turn the

bleed screw or knob on top of the valve

clockwise to tighten. See section entitled

"How to Operate."

• See Valve Disassembly Procedure A.

Check small ports for blockage by debris;

rinse and inspect diaphragm and diaphragm

seat for dirt or damage. Replace diaphragm

or valve body if damaged.

• See 3-E above. • See 3-E above

• Turn off water. Remove solenoid. Check for

twisting or damage to solenoid O-ring. Check

solenoid plunger as in 3-B above. Rinse

bottom of solenoid and seating surface inside valve. Replace solenoid if damaged.

tinue to drain from the piping through the

lowest head on the line. The longer the piping, and the lower the slope of the pipe, the

longer this will take.

PISTON-TYPE VALVE REMEDY

(See Valve Disassembly Procedure B)

• See recommendations at left for diaphragm valve.

• See recommendations at left for diaphragm valve.

• Turn gray flow control ring on valve clockwise

until resistance is felt. This is the lowest flow position. If more than one valve is affected or if turning

the flow control does not shut off the flow completely...

• See recommendations at left for diaphragm valve.

• See recommendations at left for diaphragm valve.

• Remove piston and check for debris that may be

restricting movement (See Valve Disassembling

Procedure B). If piston is damaged replace with

PRK-100 piston replacement kit.

• Check for crack in actuator or bent o-rings. Replace actuator or o-rings to stop leak.

• Hold gray flow control ring and turn solenoid

clockwise until resistance is felt.

• See Valve Disassembly Procedure B. If thoroughly cleaning the piston and housing does not

help, replace piston with PRK-100 piston replacement kit.

• See recommendations at left for diaphragm valve.

• Same for all types of valves. See recommendations at left for diaphragm valve

11

Page 12

TROUBLESHOOTING GUIDE

SYMPTOM CAUSE DIAPHRAGM VALVE REMEDY

4. Water leaks out at sprinkler

head when station is off.

(Continued)

5. Valve won't turn off manually. A. Valve in "Manual On" mode.

6. Valve won't turn on manually. A. Flow control in closed position.

7. Water leaks out at valve. A. Leaking round pipe connections. • Tighten connections (use teflon tape only). • See recommendations at left for di-

- C. Leaking between bonnet and body. • Check that diaphragm washer is properly in

8. Valve slams on/off (water ham-

mer)

9. Water runs continuously when

valve is not activated; shuts off

when valve is activated.

D. Low head drainage. (Continued) Stop watering on the soggy zone for two days.

B. Valve closing mechanism stuck in

open position.

C. Solenoid energized

B. Valve opening mechanism blocked

by debris.

C. Valve in "Manual Off" mode.

B. Leaking around actuator assembly. • Not applicable. • Tighten actuator to body (See Valve Dis-

D. Leaking under anti-siphon cap.

(Anti-siphon models only).

A. Excessive water pressure. • Install pressure regulator on line before valves

B. Valve closing/opening mechanism

worn.

C. Air bubble in line • Shut off water at main shut off valve and drain

D. Valve too small for amount of flow. • Replace with larger valve • Not applicable

A. Valve installed backwards. • Reinstall valve according to arrows on valve

(See Valve Disassembly Procedure A)

Check the lowest head on the line.

If area is very wet or a small amount of water

drips from sprinkler, see 4-A and 4-B above. If

area around sprinkler has dried out somewhat,

the problem is probably due to drainage from

the piping.

• See 3-E above.

• See 3-C above.

• Stop power to valve.

• See I-C above.

• See 2-D above.

• See 2-A above.

place. Tighten bonnet screws.

• Not applicable. • Float under cap is not moving freely due

• Not applicable • Valves not installed 6" higher than highest

• Not applicable • Insufficient water pressure (See I-D)

• Not applicable • Vacuum breaker cap or valve body

to reduce pressure.

• Replace diaphragm with model number appropriate for your valve. Call our Technical Service

hotline for assistance in identifying valve or part

numbers. 1-800-RAIN-BIRD

the line to release air bubble. Slowly refill the

line.

depicting direction of flow.

PISTON-TYPE VALVE REMEDY

(See Valve Disassembly Procedure B)

• See 3-E above.

• See 3-C above.

• Stop power to valve

• Turn gray ring counterclockwise to increase flow.

• See 2-D above.

• See 2-A above.

aphragm valve.

assembly Procedure B) Be sure O-ring seal

is in place. Do not use pipe dope or teflon

tape or tighten with such force as to crack

plastic valve body.

• Not applicable.

to debris. Turn off water and unscrew cap.

Clean out area around float and replace

float and cap.

sprinkler head. Raise position of valve or

redesign system.

cracked. Replace as necessary.

• See recommendations at left for diaphragm valve.

• Replace piston with PRK-100 piston replacement kit.

• See recommendations at left for diaphragm valve.

• Not applicable.

12

Page 13

Disassembling the valve for cleaning or part replacement

— Disassembly Procedure A

To inspect the inside of the valve for cleaning or replacement of the diaphragm

use the following procedure:

1. Shut off the water at the master shut off valve.

2. Unscrew all bonnet screws. On some models, the bleed screw and/or flow control

knob will also need to be removed.

3. Remove bonnet assembly to expose the spring, diaphragm, and rubber gasket (if

any) and filter (if any). Remove and inspect the spring, diaphragm, and rubber gasket for wear or damage. Inspect the diaphragm for clog or a tear in the small hole

on its surface.

4. Inspect the valve body for dirt on the diaphragm seat.

5. Inspect the bonnet for dirt clogging the small bleed port near the solenoid.

6. Rinse dirt off if necessary, or use a wire to gently dislodge dirt from the bleed port.

7. Install new diaphragm if necessary. Do not forget to replace the spring. Some new

replacement diaphragms are an all-in-one design and do not have a separate rubber gasket to install. Be sure that the holes line up.

8. Press the bonnet firmly back in place. Replace the screws and tighten. Pressure

test the valve to assure that all of the screws are tight enough to prevent any water

leakage between the valve body and bonnet.

To replace the solenoid:

1. Unscrew the solenoid.

2. Check for debris clogging the small port where the solenoid seats.

3. Rinse off the solenoid to remove debris.

4. Check condition of solenoid O-ring.

5. Replace solenoid if necessary with part number applicable to your particular

model.

Model Solenoid P/N Diaphragm P/N

CP-075 or-100 208484 209391

EV-100 EV-100F 407200 407303

13

Page 14

CP-075

CP-100

VALVE PARTS

SOLENOID

BONNET SCREWS

BLEED PORT

BLEED SCREW

BONNET

DIAPHRAGM KIT

•Spring

•Diaphragm*

•Body Seal*

*May be combined as

BLEED PORT

one piece.

VALVE BODY

If you need further assistance, or other advice on installation,

contact our customer service team at 1-800-RAIN-BIRD.

CP-075-P

CP-100-P

EV-100

INSURE QUALITY - USE ONLY GENUINE RAIN BIRD PARTS

14

Page 15

Disassembling the valve for cleaning or part replacement

— Disassembly Procedure B

A removable actuator makes piston-type valves easy to access for maintenance.

Should you need to clean the valve or replace a part, the actuator is removable following these procedures:

1. Shut off the water at the master shut off valve.

2. Using a pair of adjustable pliers clamped in the area of the valve indicated in the

illustration (next page), unscrew the actuator counterclockwise.

3. To inspect the piston seals or replace the piston, gently pull piston from the bottom

to pull it out of valve.

4. To remove solenoid, hold gray flow ring and twist counter-clockwise to unscrew.

To reassemble the valve actuator assembly, screw it into the valve body in a clockwise direction until the actuator body contacts the valve body. Caution: Do no over

tighten as this may cause damage to the actuator. Do not use any pipe dope or tape

on the actuator threads. The bleed ports (holes) just above the threads can become

clogged and prevent operation.

Two types of Repair kits are available, the SRK-1 Solenoid Replacement Kit and the

PRK-100 Piston Replacement Kit.

Ref. Part Description Part No.

1 Solenoid Assembly (SRK-1) B40602

2 O-Ring

3 Piston Repair Kit (Santoprene) (PRK-100) B40642

4 Piston

5 Piston Spring

Piston Retainer

Piston Sleeve

6 Filter

7 Upper Bonnet O-Ring

8 Lower Bonnet O-Ring

9 Cap, Cover & Piston Assembly 210067

10 Cap & Cover Assembly 203661

11 Gasket

12 Piston Vacuum Breaker

13 Sealing Washer

14 Body

Please see the parts diagram on the next page.

15

Page 16

Parts and Repair Information

A variety of parts and parts assemblies are available for Rain Bird valves. If your local

Rain Bird dealer does not carry the part you need, ask if it can be ordered, or call our

toll free Technical Services hotline for dealer referral or factory direct ordering information. If you are unsure of the model you have or need help in identifying or finding a

part, the Technicians on our toll-free line are eager to assist you. A parts breakdown

on your particular model is available upon request.

If you have any questions about the information in this packet or about any Rain Bird

products, call us toll free for fast and knowledgeable service at: 1-800-RAIN-BIRD.

Customer Support Center: 6640 S. Bonney Ave., Tucson, AZ 85706

FAX: (520) 434-6289

In-Line Valves

(Discontinued)

AGV-075-P

AGV-100-P

PAS-100

Manual

Anti-Siphon

Valve

Anti-Siphon Valve

With Backflow Prevention

APAS-075-P

APAS-100-P

1

2

(Inside)

Actuator

(See inset)

Actuator AVA-100-P

Solenoid Replacement Kit

Use pliers

here to remove

Piston Replacement Kit

SRK-1

PRK-100

O-ring

Piston seal

(Inspect for

wear or

5

4

6

7

10

8

11

12

3

13

14

9

INSURE QUALITY - USE ONLY GENUINE RAIN BIRD PARTS

16

Loading...

Loading...