Rain Bird PT5002 User Manual

Industrial Flow Computer

PT5002 Flow Monitor

User Manual

Industrial Flow Computer, PT5002 Flow Monitor

CONTENTS

Scope of This Manual � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

Unpacking and Inspection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

Safety Considerations� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

Terminology and Symbols� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

Safety Instructions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Safety Rules and Precautionary Measures � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Description � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

Functions and Features � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

Flow Meter Input � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

Digital Inputs � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

Relay Control Outputs � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

Power Supply� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

Conguring the Unit � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

Display Information� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

Installing the PT5002 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

Mounting Options� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

Installation Overview � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

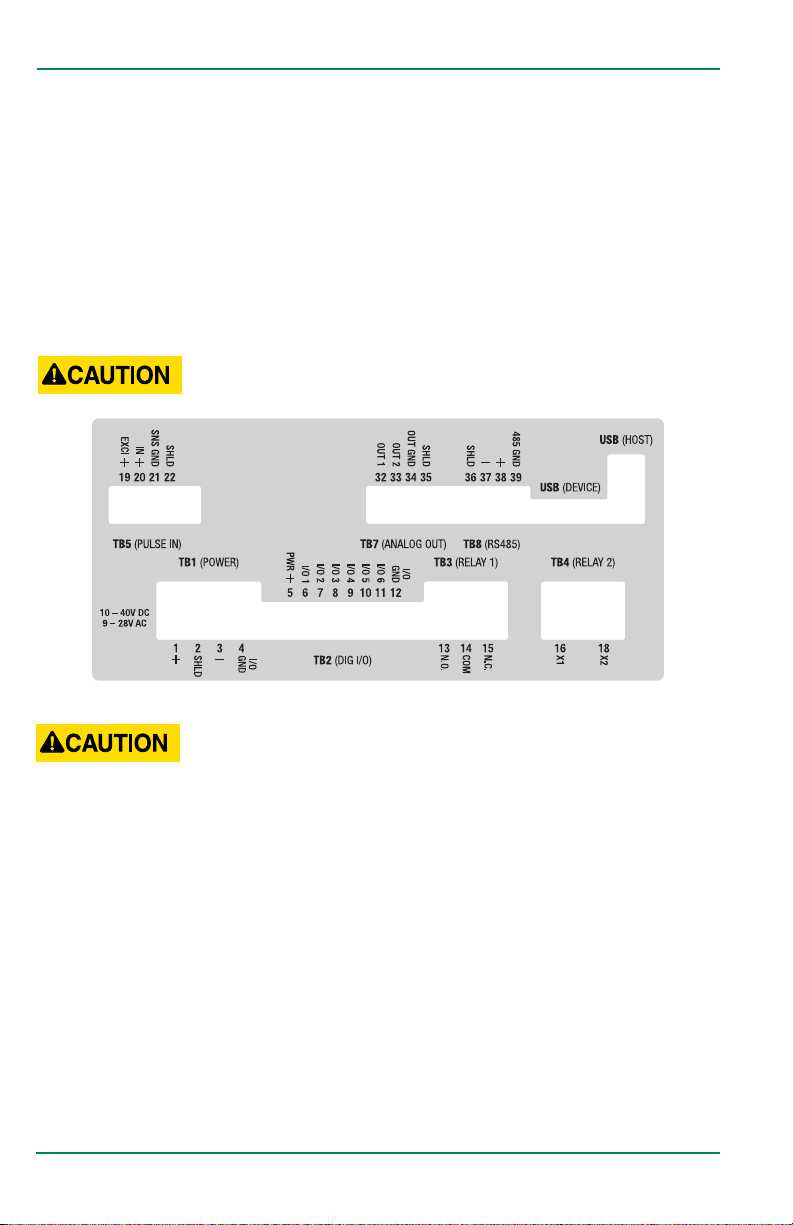

Wiring the PT5002 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

Terminal Connector Descriptions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

Operator Interface� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

Keypad and Soft Keys � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

Scrolling � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

Control Panel Keys � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

Icon Functionality � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

Numeric Editing � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

Alpha-Numeric Editing� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

Selection/Enumeration Editing � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

Conrmation Screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

Navigating the Menus � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

Menu Structure � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

Info/Sensor Data � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 28

System Information � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 29

Basic Setup � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 30

Display � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 30

Resets � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 30

Passcode Setup � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 31

Page 2 June 2020

User Manual

Units � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 32

Advanced Setup � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 34

Conguring a Flow Meter � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 34

Conguring Outputs � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 35

Conguring Digital I/O � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 38

Conguring BACnet Communications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 39

BACnet Map � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 39

Troubleshooting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 40

Specications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 42

Standards and Certications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 45

Agency Approval/Standards � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 45

EMI/EMC Compliance� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 45

Enclosure Protection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 45

APPENDIX A � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 46

For Rain Bird Tee Type Flow Sensors and Anemometer� � � � � � � � � � � � � � � � � � � � 46

APPENDIX B � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 47

For Rain Bird Insert Type Flow Sensors� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 47

Rain Bird’s Professional Customer Satisfaction Policy � � � � � � � � � � � � � � � � � � � � � � � � 52

June 2020

Page 3

Scope of This Manual

SCOPE OF THIS MANUAL

This manual describes how to install and program the PT5002�

MPORTANTI

Read this manual carefully before attempting any installation or operation.

Keep the manual in an accessible location for future reference.

UNPACKING AND INSPECTION

Upon opening the shipping container, visually inspect the product and applicable

accessories for any physical damage such as scratches, loose or broken parts, or

any other sign of damage that may have occurred during shipment�

OTE: N If damage is found, request an inspection by the carrier’s agent within

48 hours of delivery and file a claim with the carrier� A claim for equipment damage

in transit is the sole responsibility of the purchaser�

SAFETY CONSIDERATIONS

Terminology and Symbols

Indicates a hazardous situation, which, if not avoided, will result in death or

serious personal injury�

WARNING

• Operating temperature is 32…130° F (0…55° C) with a maximum humidity

of 85% non-condensing� Always select a mounting location with proper

ventilation and environmental protection�

• Maximum operating altitude: 2000 meters (6561 feet)

• Pollution Degree 2: Only non-conductive pollution occurs except that

occasionally a temporary conductivity caused by condensation is to

be expected

• Over-Voltage Rating: CAT II

Indicates a hazardous situation, which, if not avoided, could result in death or

serious personal injury�

Indicates a hazardous situation, which, if not avoided, could result in minor or

moderate personal injury or damage to property�

Please consult the user manual in all cases where this symbol is used in order

to find out the nature of potential hazards, and any actions which have to be

taken to avoid them�

This symbol signifies that the PT5002 may be powered by a DC power supply�

Acceptable DC input voltage range is: 10…40V DC�

This symbol signifies that the PT5002 may be powered by an AC power

supply� Acceptable AC input voltage range is:

9…28V AC RMS (50…60 Hz)�

Page 4 June 2020

Safety Considerations

Safety Instructions

WARNING

• LIFE SUPPORT APPLICATIONS: THE PT5002 IS NOT DESIGNED FOR USE IN LIFE

SUPPORT APPLIANCES, DEVICES, OR SYSTEMS WHERE MALFUNCTION OF

THE PRODUCT CAN REASONABLY BE EXPECTED TO RESULT IN A PERSONAL

INJURY. CUSTOMERS USING OR SELLING THESE PRODUCTS FOR USE IN SUCH

APPLICATIONS DO SO AT THEIR OWN RISK AND AGREE TO FULLY INDEMNIFY

THE MANUFACTURER AND SUPPLIER FOR ANY DAMAGES RESULTING FROM

SUCH IMPROPER USE OR SALE.

• ELECTROSTATIC DISCHARGE INFLICTS IRREPARABLE DAMAGE TO

ELECTRONICS. BEFORE INSTALLING OR OPENING THE UNIT, INSTALLERS

MUST DISCHARGE THEMSELVES BY TOUCHING A WELL-GROUNDED OBJECT.

• THIS UNIT MUST BE INSTALLED IN ACCORDANCE WITH THE EMC

(ELECTROMAGNETIC COMPATIBILITY) GUIDELINES.

Safety Rules and Precautionary Measures

The manufacturer accepts no responsibility whatsoever if the following safety

rules and precaution instructions and the procedures as described in this manual

are not followed�

• Modifications of the PT5002 implemented without preceding written consent

from the manufacturer will result in the immediate termination of product

liability and warranty period�

• Installation, use, maintenance, and servicing of this equipment must be carried

out by authorized technicians�

• Check the mains voltage and information on the manufacturer’s nameplate

before installing the unit�

• Check all connections, settings and technical specifications of the various

peripheral devices with the PT5002 supplied�

• Never open the enclosure�

• Never touch the electronic components (ESD sensitivity)�

• Never expose the system to heavier conditions than allowed according to the

casing classification (see manufacturer’s nameplate)�

• If the operator detects errors or dangers, or disagrees with the safety

precautions taken, then inform the owner or the principal responsible�

• Adhere to the local labor and safety laws and regulations�

Page 5 June 2020

Description

DESCRIPTION

The PT5002 is a microprocessor-driven device that is designed for flow and wind

speed monitoring� This manual was written for firmware version 1�3�3�683

Functions and Features

This product is designed with a focus on:

• Large display for easy viewing

• Ease-of-use with softkeys and a full numeric keypad

• Ruggedness for its application with a robust enclosure, keypad and

mechanical relays

• Info/Sensor Data Screen—view raw and calculated data, both to and from the

unit, including flow data and output statuses

• User-friendly installation with quality plug-and-play terminals

• A wide range of outputs and functions for a broad fulfillment in

many applications

• User defined relay triggers for flow rates and totals

Flow Meter Input

The PT5002 accepts a passive or active signal output� The input circuit supports

low and high frequency (0�5…3500 Hz) flow meters� A 12V DC exitation terminal is

available for flow meter sensors that require power�

Digital Inputs

The PT5002 control inputs allow the following functions:

• Unlatch Relays

• Reset Totalizers

• Unlatch Relays and Reset Totalizers

Relay Control Outputs

The PT5002 has two independent relay outputs, a mechanical Form C switch and

a solid state form A switch� All control functions are always available by dedicated

relay outputs� Unneeded outputs may be left disconnected or disabled within the

firmware�

Relays in general, can be used for alarm indication or as a totalizing output�

Form-C

• Can be powered directly from mains circuits rated up to 240V�

• Must be powered through circuits that are insulated from mains by at least

basic insulation�

• Connected sources of power need to be limited to 240V AC and fused at 5A

or less�

• Not suitable for connection to external circuits that are insulated from mains by

at least double insulation (SELV)�

Page 6 June 2020

Installing the PT5002

Form A

• Located on TB4 and recommended to use, if configured as a high-rate,

totalizing output�

• Relay energizes (contact closes) with a minimum input current of 3 mA through

the input LED�

• The relay turns off (contact opens) with an input voltage of 0�8V or less�

Power Supply

The power supply used must be isolated from mains by double or reinforced

insulation (for instance, SELV power supply)�

The PT5002 operates on 10…40V DC or 9…28V AC supplied by any suitable

source that also meets the requirement listed above� A pre-wired wall wart power

supply is included with the device, as well as several adapters for different kinds of

power outlets�

A power supply not sourced from the factory must be capable of supplying a

minimum of 8 Watts�

Conguring the Unit

The PT5002 is designed for many types of applications� See “Advanced Setup” on

page34 for instructions on configuring your

PT5002 to your specific requirements�

All information is stored in EEPROM memory and will not be lost in the event of

power failure�

Display Information

The PT5002 has a large transflective LCD with a bright LED backlight that displays

symbols and digits for measuring units, status information and keyword messages�

See “Units” on page32�

INSTALLING THE PT5002

MOUNTING, ELECTRICAL INSTALLATION, STARTUP AND MAINTENANCE OF THIS

INSTRUMENT MAY ONLY BE CARRIED OUT BY TRAINED PERSONNEL AUTHORIZED BY

THE OPERATOR OF THE FACILITY. PERSONNEL MUST READ AND UNDERSTAND THIS

OPERATING MANUAL BEFORE CARRYING OUT ITS INSTRUCTIONS.

THE PT5002 MAY ONLY BE OPERATED BY PERSONNEL WHO ARE AUTHORIZED AND

TRAINED BY THE OPERATOR OF THE FACILITY. OBSERVE ALL INSTRUCTIONS IN THIS

MANUAL.

OBEY ALL SAFETY PRECAUTIONS IN “SAFETY CONSIDERATIONS” ON PAGE4.

Page 7 June 2020

Installing the PT5002

Mounting Options

The PT5002 can be mounted on a wall, shelf or instrumentation panel� Wall-mount

units are shipped in a NEMA 4X enclosure, ready to mount�

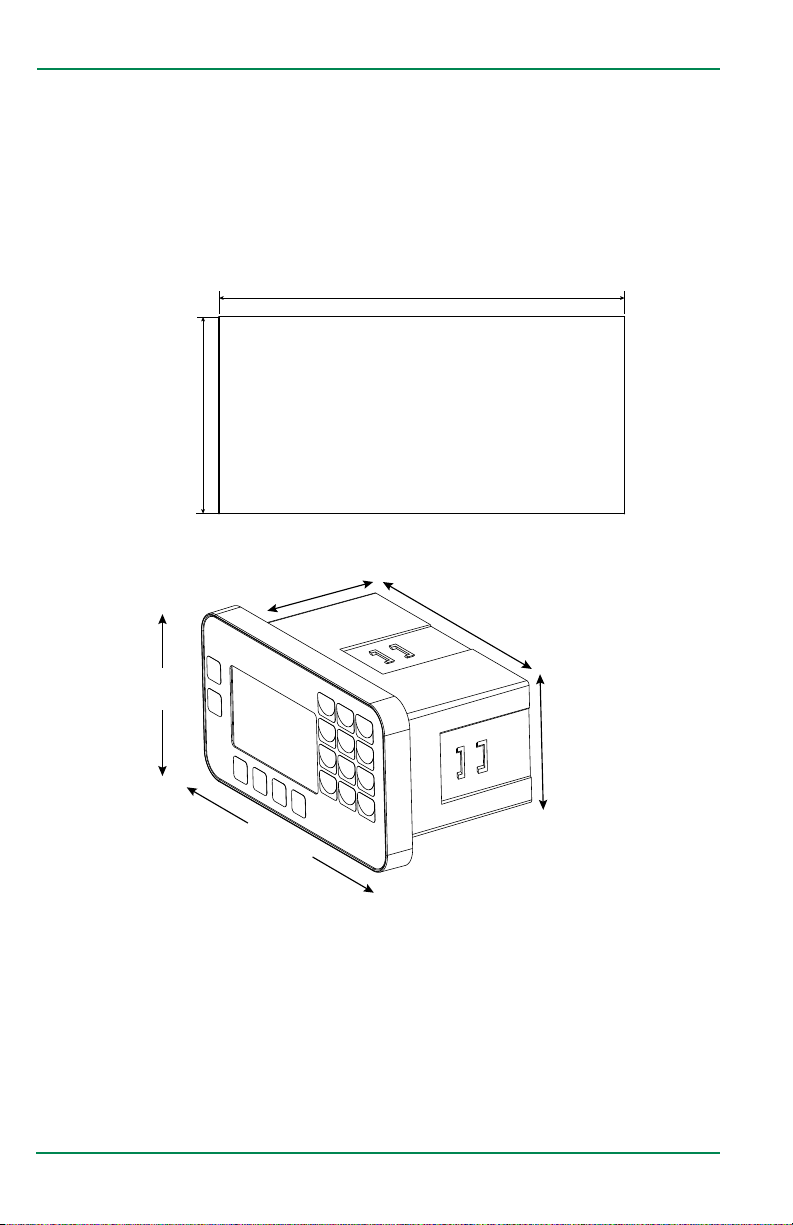

Panel-Mount Installations

OTE: N Mounting clips can accommodate a maximum panel thickness of 1�5 in� (38�1 mm)�

5.40 in.

(137.16 mm)

2.65 in.

(67.31 mm)

Figure 1: Panel cutout

3.07 in.

(78.00 mm)

Panel Cutout

5.38 in.

(136.65 mm)

3.50 in.

(89.00 mm)

2.54 in.

(64.52 mm)

6.22 in.

(158.00 mm)

Figure 2: Mounting dimensions

To install:

1� Measure and cut a mounting hole to the dimensions shown in Figure 1�

2� Verify that the gasket is secure inside the mounting bezel�

3� Insert the unit through the panel cutout�

4� Secure the unit to the panel with the provided mounting clips (see page 9).

Page 8 June 2020

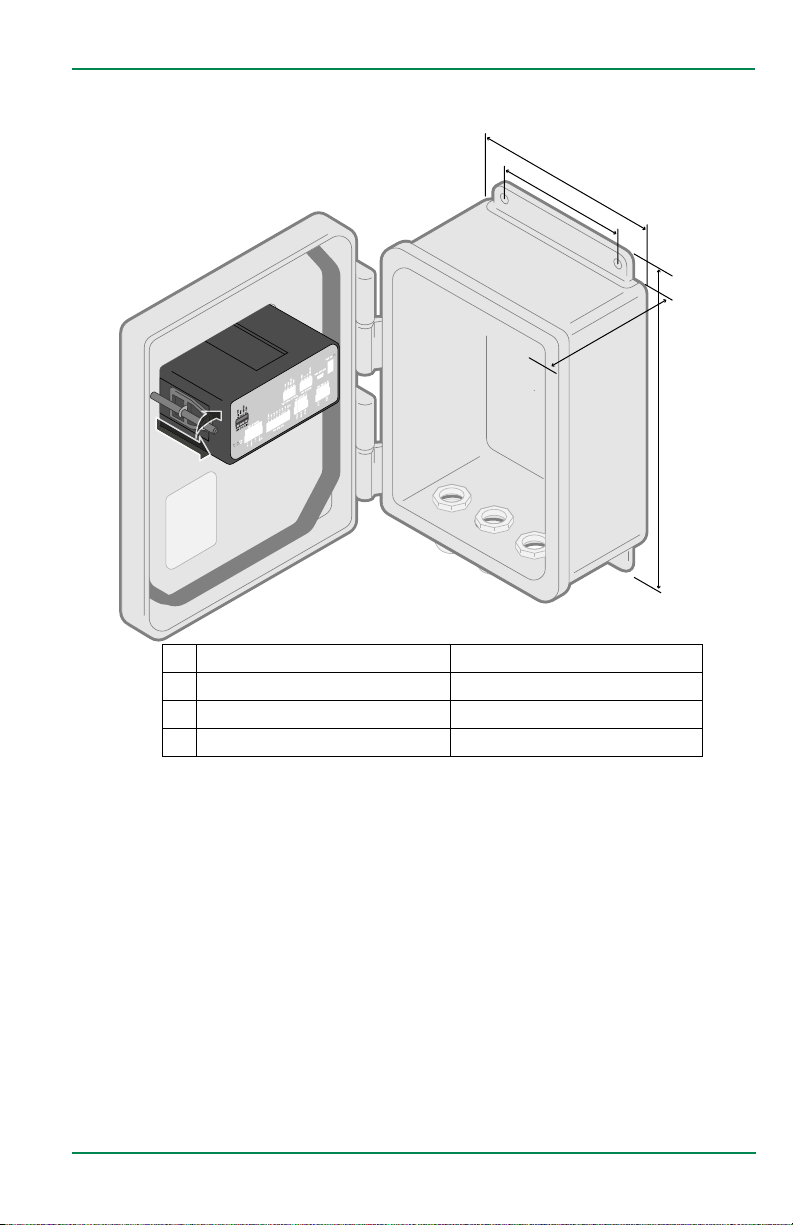

NEMA Installation

Installing the PT5002

A�

B�

C�

D�

A. Width 9�38 in� (238�25 mm)

B. Distance between mounting holes 6�00 in� (152�40 mm)

C. Total depth 4�88 in� (123�95 mm)

D. Height 9�65 in� (245�11 mm)

Wall-Mount Installations

To install the PT5002 cabinet on a wall, secure the enclosure to the wall with four

mounting screws (customer-supplied)�

MOUNTING THE PT5002

When mounting the PT5002 to a Panel, or to the NEMA enclosure, place the

PT5002 through the cabinet's front panel, and hold against the outer surface�

Slide the mounting hardware firmly into the shallow undercut on the left and

right sides of the monitor, pulling away from the panel surface� Firmly tighten the

screw clockwise, to compress the rubber seal against the outer surface� Do not

overtighten�

Page 9 June 2020

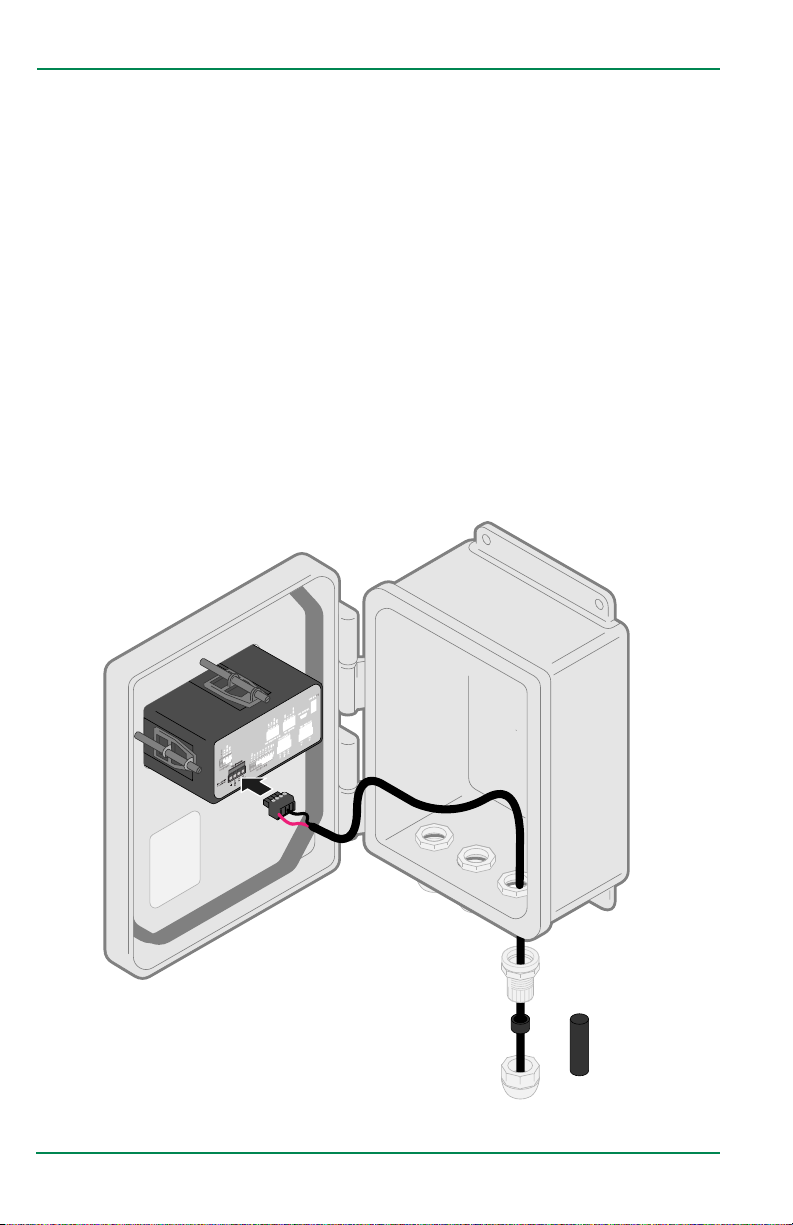

Installing the PT5002

Installation Materials

1� Wire Strippers

2� Wire Cutters

3� Thin blade screwdriver

4� PE-39 #19 AWG Wire (for

Anemometer Instillation)

Wiring Instructions

1� Remove compression nut

2� Remove Rubber bushing and

rubber plug

3� Discard Rubber Plug

4� Thread the wire through the

compression nut, rubber bushing

and housing

5� Install connector (see wiring

instructions p. 16 – 21)

5� 10 AWG Wire

6� #18 AWG Wire

7� Wire Nuts

6� Snap connector into back panel

7� Press rubber bushing into

housing seat

8� Tighten compression nut

until sealed

Connector

Rubber Bushing

Compression Nut

Page 10 June 2020

Rubber Plug

Installation Overview

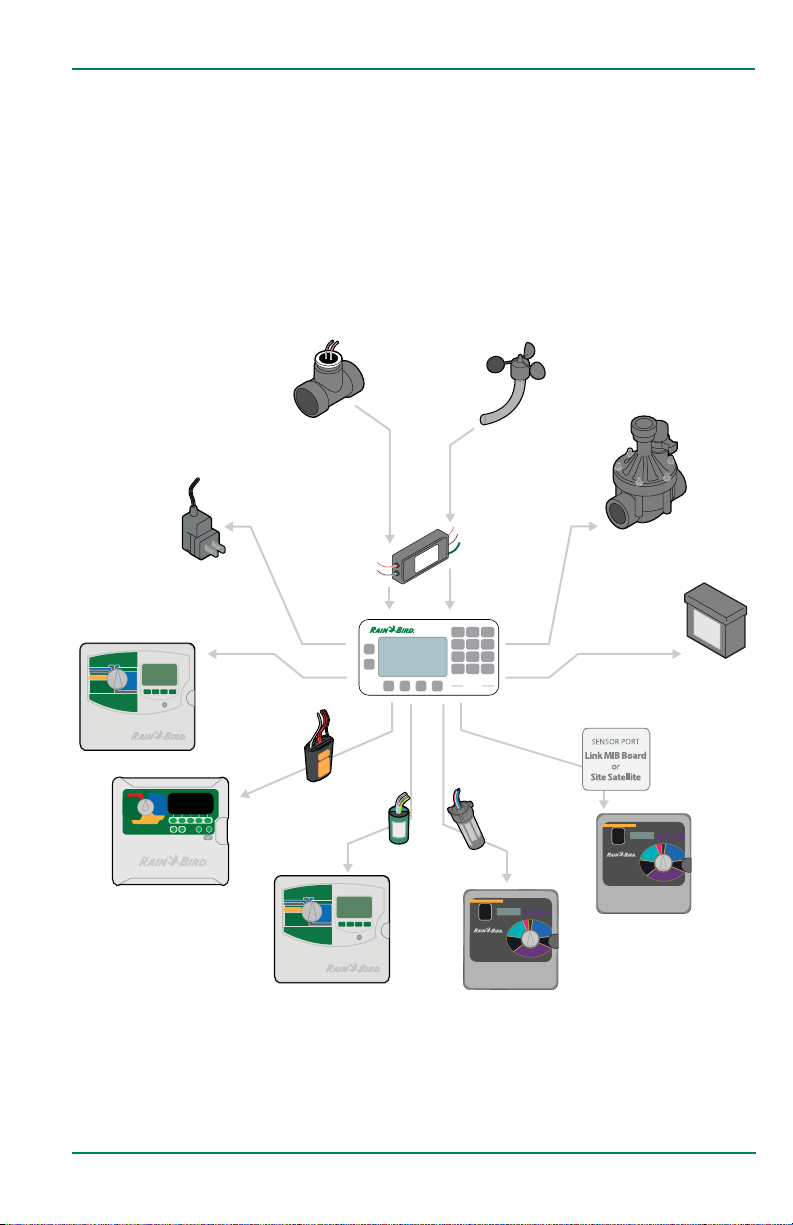

INSTALLATION OVERVIEW

The PT5002 scales the flow sensor or Anemometer wind sensor output for input

into Maxicom and SiteControl Satellite Controller Systems� It can also be used

with the Anemometer wind sensor for high wind shutdown for ESP-LX Controllers�

When connecting to Flow Sensors or Anemometers, a surge kit may be required to

protect the components� When connecting to various controllers, a decoder may

be required� Please check the following pages in this manual as well as the Tech

Specs for each controller on the Rain Bird website www�rainbird�com�

Transformer

Power

ESP-LXME/ LXMEF

ESP-LXIVM

Flow Sensor

Sensor

Input

LXIVMSEN

Surge

Protection

FSSURGEKIT

Sensor

Decoder

SD210TURF

Anemometer

PT5002

Pulse

Decoder

DECPULLR

Control a Valve

Control a Pump

Start Relay

Maxicom or SiteControl

ESP-SAT Link Satellite

and Maxicom ESP-SITE

ESP-LXD

Maxicom or SiteControl

ESP-SAT Two-Wire

Satellite

Satellite

• PT5002 required for Anemometer use with LXD, LXIVM, and LXME/F

• PT5002 not required for Flow Sensing with LXD, LXIVM, and LXME/F

Page 11 June 2020

Installation Overview

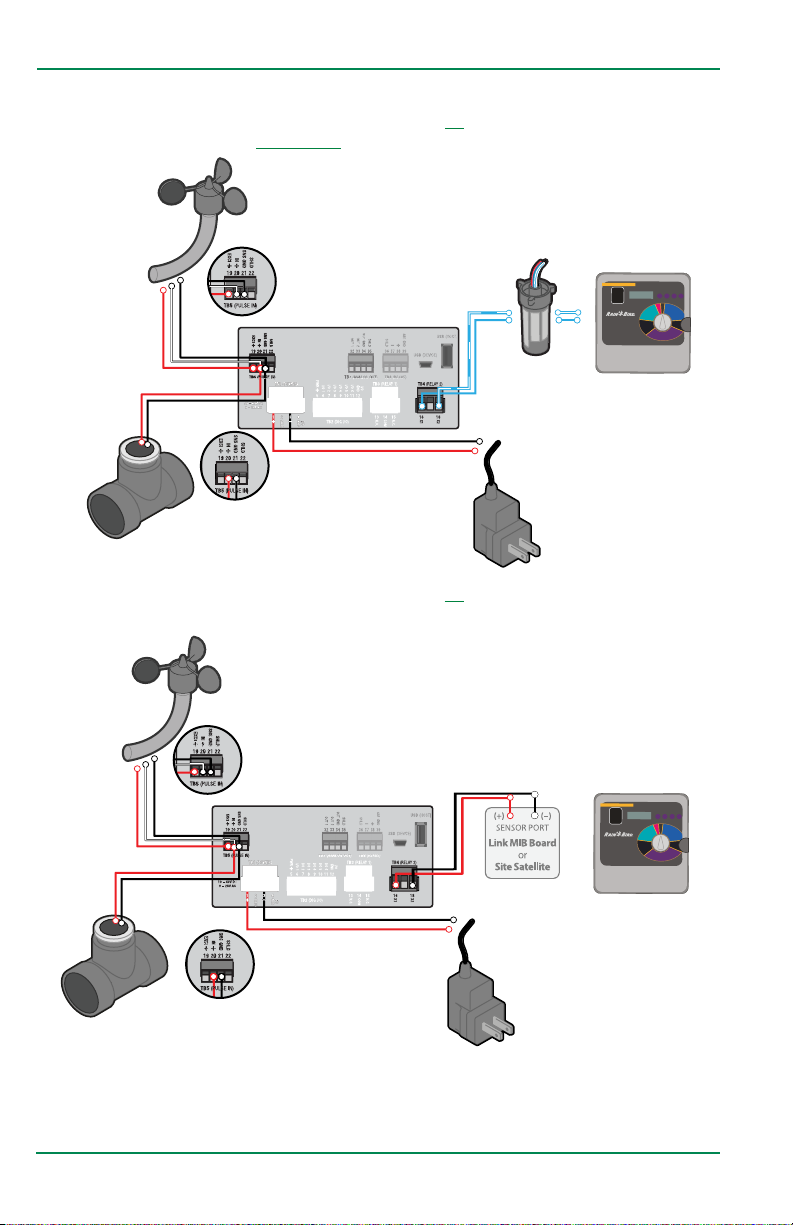

PT5002 T

erminal Connections for Flow Sensor or Anemometer for Maxicom

and SiteControl ESP-SAT Two-Wire Satellite Systems

Anemometer

or

Flow Sensor

Decoder

(DECPULLR)

Power Supply

Maxicom and

SiteControl ESP-

SAT Two-Wire

Satellite Systems

PT5002 Terminal Connections for Flow Sensor or Anemometer for Maxicom

and SiteControl ESP-SAT Link Satellites and Maxicom ESP-SITE Satellite

Systems

Anemometer

or

Flow Sensor

Maxicom and

SiteControl ESP-SAT

Link Satellite and

Maxicom ESP-SITE

Satellite Systems

Power Supply

Page 12 June 2020

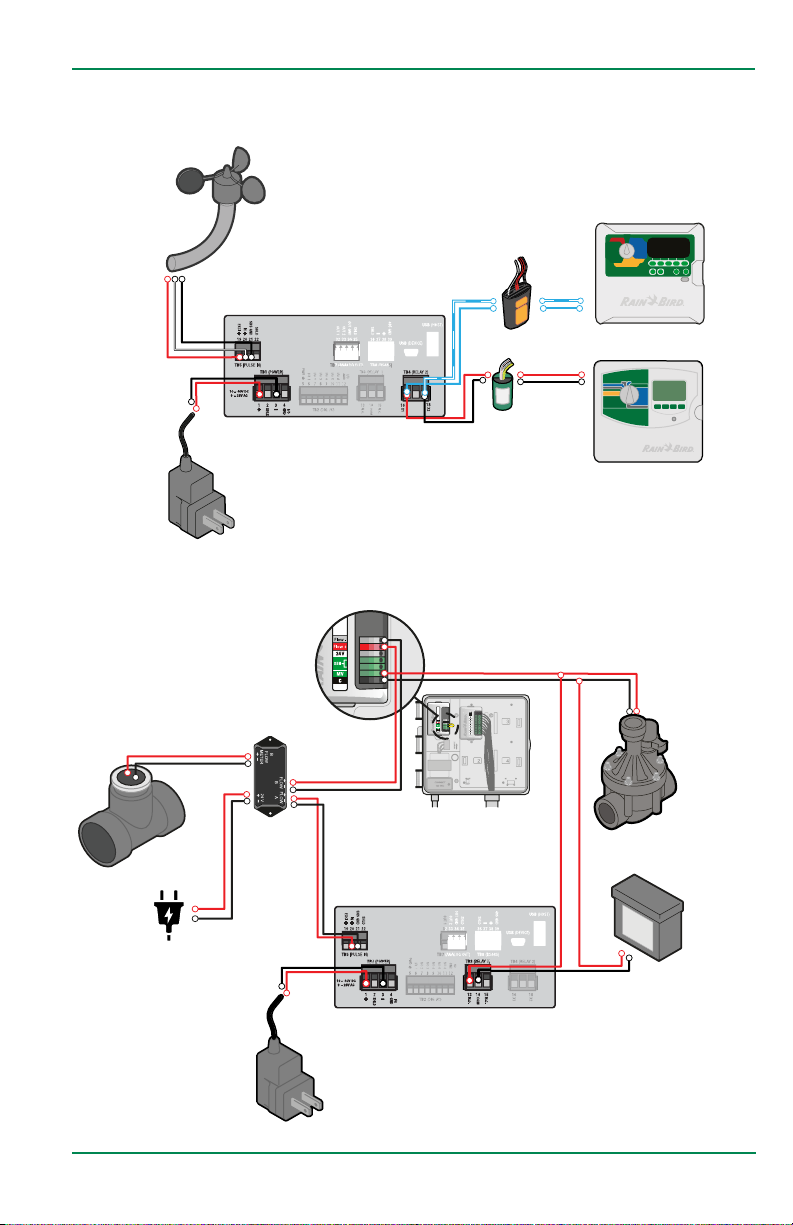

Installation Overview

PT5002 T

erminal Connections for Anemometer for 2-Wire Sensor LXD or

LXIVM Controllers

ESP-LXIVM

OR

ESP-LXD

Anemometer

Power Supply

Sensor Input

LXIVMSEN

Sensor Decoder

SD210TURF

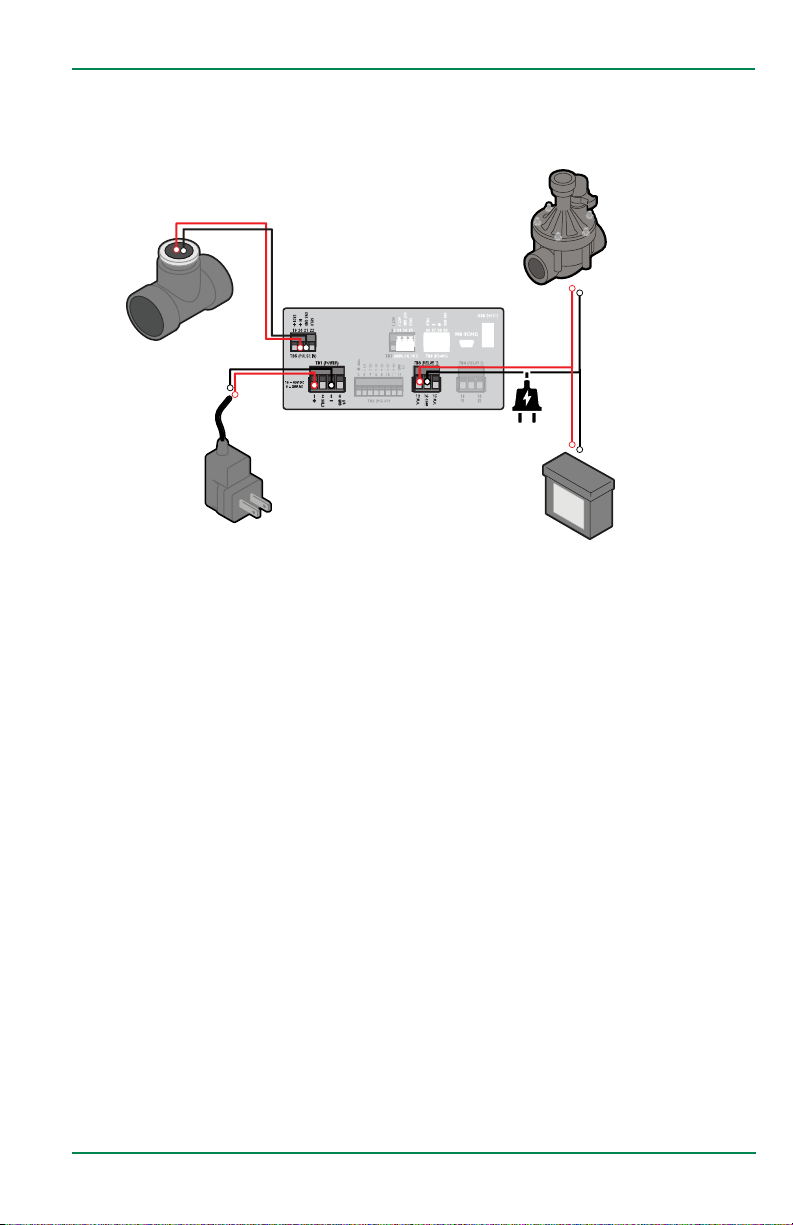

ESP-LXMEF with 1 Flow Sensor, 1 Master Valve, and a Pump Start Relay

controlled by a PT5002 Flow Monitor used to control a Booster Pump

ESP-LXME

FSMLXME Flow

Smart Module

Master Valve

Flow Sensor

Power Supply

CST Isoflow

Sharing Relay

PSR Universal

Pump Start

Relay

Power Supply

Page 13 June 2020

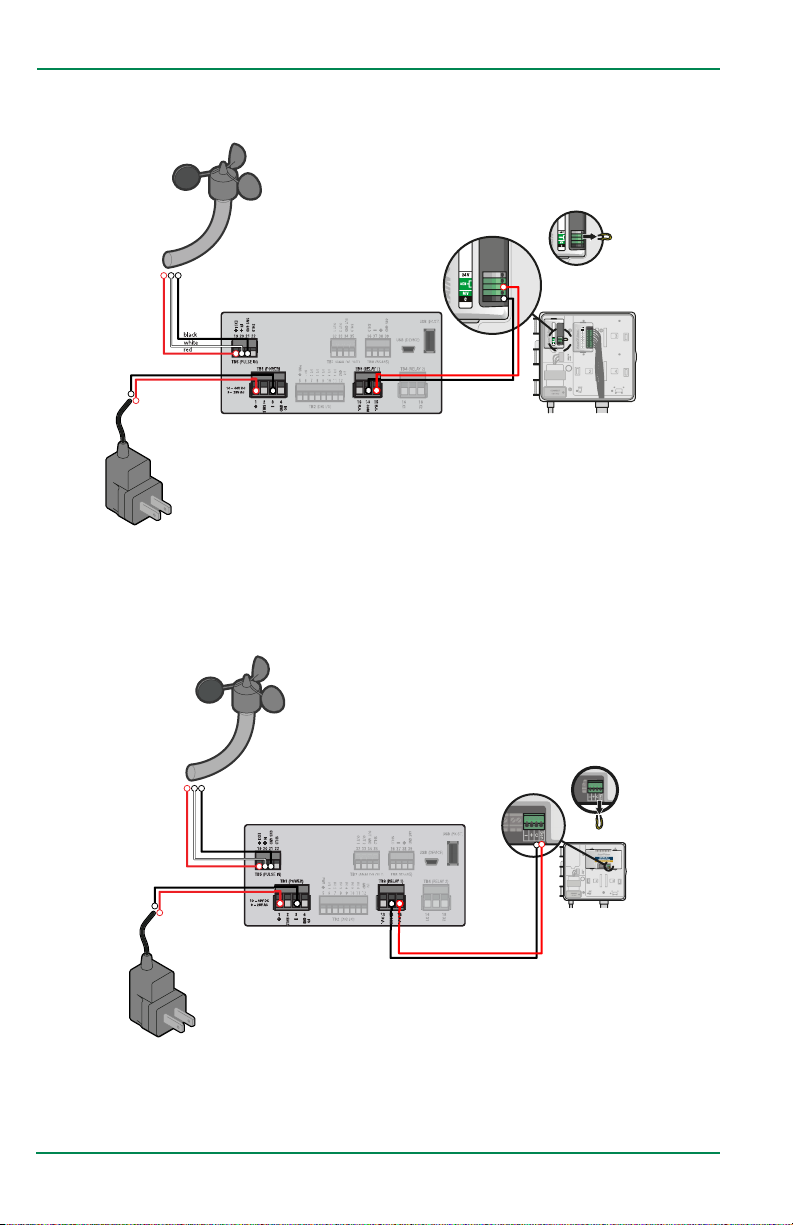

Installation Overview

ANEMOMETER Wiring to PT5002 Relay & ESP-LXME/-LXMEF Controller

Anemometer

ESP-LXME/F

Controller

Weather Sensor

Input

Power Supply

Anemeometer to PT5002 Relay & ESP-LXD or ESP-LXIVM Controller

Anemometer

ESP-LXD or

ESP-LXIVM/P

Controller Local

Weather Sensor

Input

Power Supply

Page 14 June 2020

Installation Overview

PT5002 Controlling a Master Valve or Pump Start Relay at a Preset Flow Rate

Master Valve

Flow Sensor

Power Supply

24VAC Power

Supply

PSR Universal

Pump Start

Relay

Page 15 June 2020

Wiring the PT5002

WIRING THE PT5002

At installation, be sure to comply with the following requirements:

• Disconnect power to the unit before attempting any connection or service to

the unit�

• Avoid using machine power service for AC power� When possible, use a

dedicated circuit or a lighting circuit�

• Observe all local electrical codes�

• The unit must be wired with wires and/or cables with a minimum temperature

rating of 167° F (75° C)�

TO PREVENT ACCIDENTS, DO NOT APPLY POWER UNTIL ALL OTHER

CONNECTIONS HAVE BEEN COMPLETED.

Figure 3: One sensor input, analog output

THE PT5002 IS MICROPROCESSOR CONTROLLED. IT IS VERY IMPORTANT THAT THE

POWER SUPPLY BE FREE OF ELECTRICAL NOISE. AVOID USING POWER LINES THAT

FEED HEAVY LOAD ELECTRICAL DEVICES SUCH AS PUMPS AND MOTORS.

Page 16 June 2020

Loading...

Loading...