Page 1

Customer Support Center

6991 E. Southpoint Rd., Bldg. #1

BBIRDIRD®RRAINAIN

Tucson, AZ 85706 1-800-RAIN-BIRD

IMPACT SPRINKLER TROUBLESHOOTING GUIDE

USE AND OPERATION

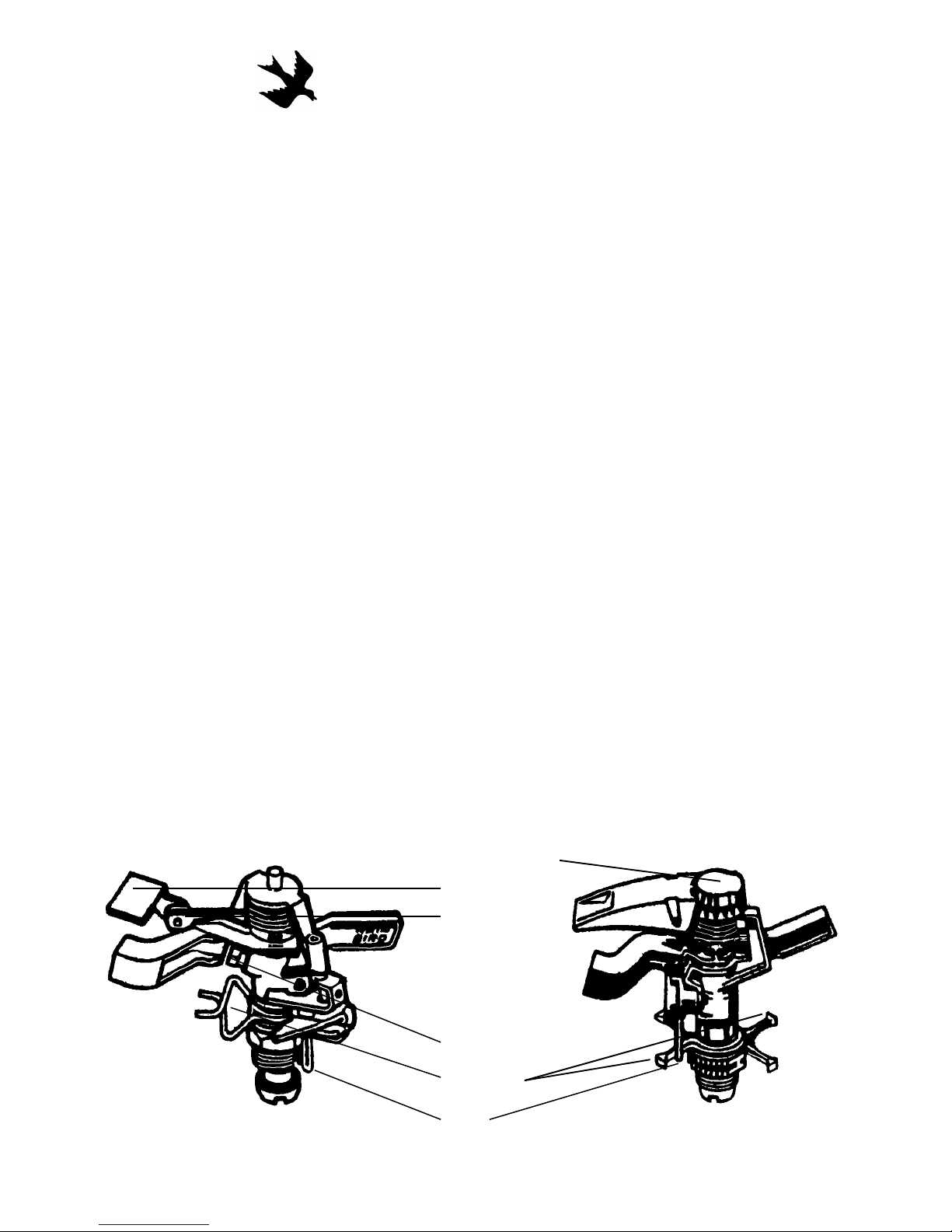

The diagrams below depict typical Rain Bird sprinklers with all available controls. Your particular

model may have only some of these features.

Diffuser screw:

Distance

control flap:

Distance

control dial:

Arc Adjusters

(Trip collar):

Breaks up the stream of water for more close-in watering. Shortens distance of the stream (throw) up to 25% of total throw. Screw clockwise

into the stream to produce misting and shorten throw. Turn counterclockwise until totally out of stream for maximum distance (unadjusted throw).

Reduces length of the stream and redistributes water. Tilt downward into

stream to deflect water. May be used in conjunction with diffuser screw

for maximum throw reduction.

Some plastic models have a dial on top marked for minimum and maximum distance. Turning the dial will cause modification of the stream of

water and distance of throw as indicated on the dial. This feature serves

the same purpose as the distance control flap found on other models.

Used to adjust degree of arc sprinkler will rotate. Position one arc adjuster for each side of the desired arc. Several types of arc adjusters are

available depending on the model of your sprinkler. Generally, plastic

models move by just a push of the thumb. To adjust the metal models,

pinch the ends of each metal adjuster together before sliding into position.

Trip Pin:

Used to determine part or full circle operation. Flip or bend the trip pin

upward so it does not hit the trip collar for full circle operation. Pin should

be downward for part circle operation (then slide arc adjusters into position to set degree of arc).

25PJDA P5-PJ

Diffuser Control Dial

Diffuser Control Flap

Diffuser Screw

Nozzle

Arc Adjusters

Trip Pin

1

Page 2

IMPACT SPRINKLER TROUBLESHOOTING

Through many years of experience, we have found that conditions which most often interfere with

the proper operation of impact sprinklers are the use of any lubricants (other than water), low water

pressure, foreign materials in the irrigation water, and excessive damage or wear to sprinkler parts.

Any one or a combination of these factors can cause the sprinkler to stop rotating completely or rotate to one side and fail to return.

If your sprinkler stops working:

DON'T....Spray it with lubricant!

DON'T....Drill out the nozzle!

DO..........Disassemble and clean the unit thoroughly.

DO..........Check for sources of reduction in water pressure.

Impact Sprinkler Troubleshooting Guide

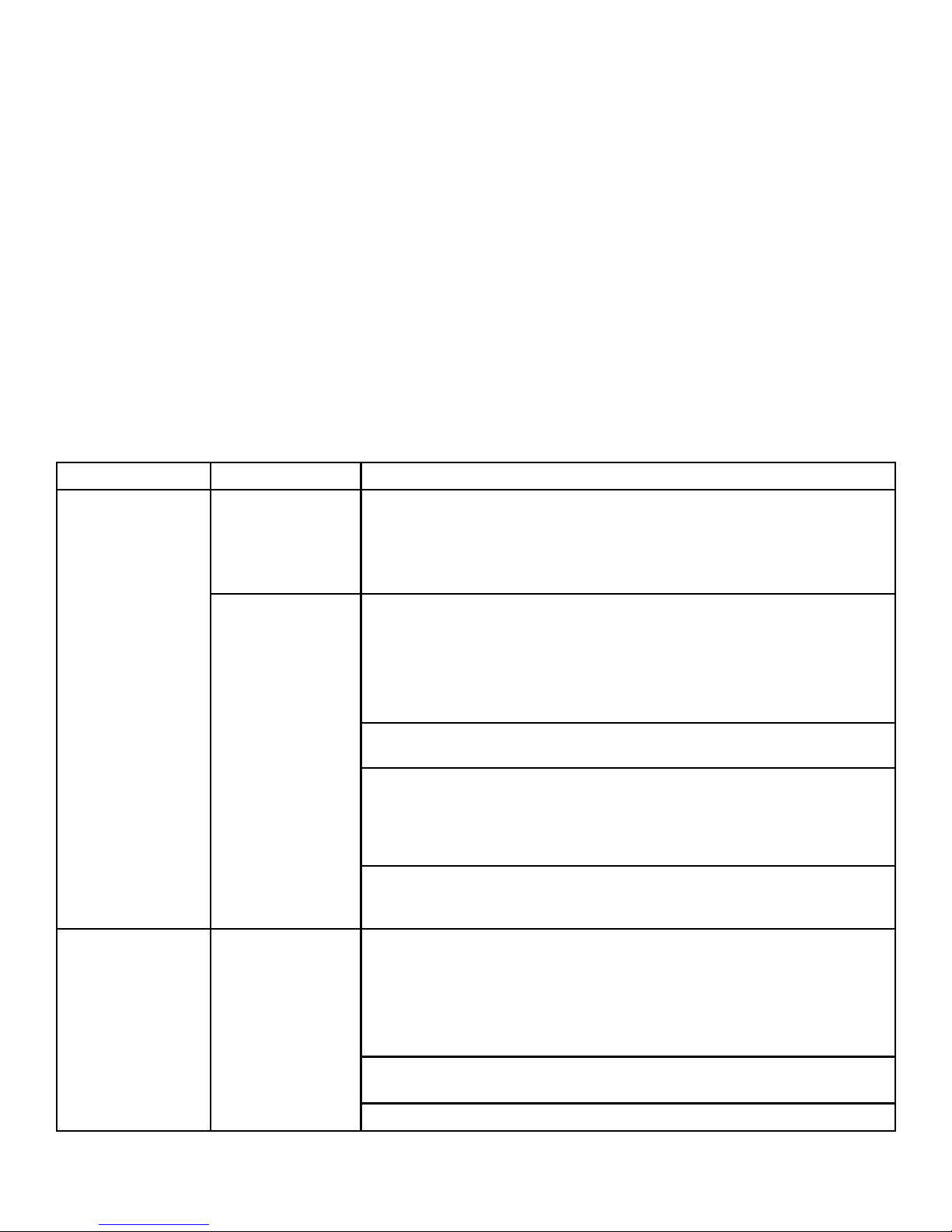

Problem Cause Remedy

A. Sprinkler does not

rotate back and forth.

A. Sprinkler does not

rotate back and forth.

1. Insufficient

water pressure. Re-

quirements vary

from model to

model.

Most popular models need at least 25

psi at the last sprinkler head, and

should have an unadjusted throw of at

least 36'.

2. Debris in nozzle

or other parts of

sprinkler.

Build up of water

deposits causing

friction.

a. Remove sprinkler head and attach pressure gauge to riser. Check operating pressure with line running. If pressure is low. check for breaks in the line

or water running elsewhere which could drain pressure.

b. Pop-up Models: Check for water coming out around the guide seal below

the sprinkler head. This is a pressure activated seal. if pressure is insufficient, water will leak around this seal causing the unit to stall and pop up

only part way. If the unit is new or others on the line have same problem, it

is probably related to pressure. If the unit is older, clean or replace the

guide nut seal if necessary.

c. Try switching with another sprinkler closer to water source. If it works,

then pressure could be the problem.

d. If the sprinkler stopped working within a month or two of installation, the

system may not have been designed to accommodate the normal operating

pressure of the type of sprinklers installed. If metal sprinklers are being

used, try switching to plastic. If plastic sprinklers are being used, try a lower

gallonage variety.

e. If measures above do not provide enough pressure boost, system may

have to be rerouted to include less sprinkler heads per line.

a. Remove sprinkler and check for debris in nozzle, swivel bearing, and

inlet. Sometimes, a wire pushed gently into the nozzle will loosen debris so

it can be rinsed out. Do not drill or alter nozzles as this may permanently

hinder the sprinkler performance.

Metal models only: If sand is caught in vane inside of nozzle, it will need to

be removed. Loosen nozzle with wrench and unscrew.

b. Thoroughly wash sprinkler to remove dirt and oil. A vinegar and water

solution will help remove water deposits.

c. Replace bearing washers if oil has been used on the sprinkler.

2

Page 3

Impact Sprinkler Troubleshooting Guide Continued

Problem Cause Remedy

3. Worn or

damaged parts.

a. If arm or body of sprinkler is bent or damaged, replace sprinkler or part if

available.

b. Arm spring tension may need increasing. Metal models: Unhook spring

from arm with needle-nosed pliers. Bend slightly to shorten and re-hook.

Plastic Models: Unhook spring from arm with needle-nosed pliers, re-hook to

next adjoining protrusion on arm.

c. Replace bearing washers if less than 2/3 of original thickness, if mineral

deposits are a problem, or if oil based products have been used.

B. Sprinkler

rotates to one side

and stops.

1. Check points for

non-rotation in Section A, 1-3.

2. Excessive

water pressure. Just

as each sprinkler

has a lower pressure

limit for proper operation, there is also

an upper limit. For

most sprinklers the

limit is 80 psi at the

head. The optimum

operating pressure

is around 50 psi.

Pressure that is too

high will, at the

worst, cause the

sprinkler to stall, and

at the least, cause

the premature wear

of the sprinkler

parts. If the sprinkler

rotates or reverses

very fast, this a forewarning of excessive pressure.

a. Put more heads on your line or try making adjustments in the flow at the

valve. In some cases, installing a pressure regulator ahead of your main

shutoff valve is a good idea and will protect your entire system.

3

Page 4

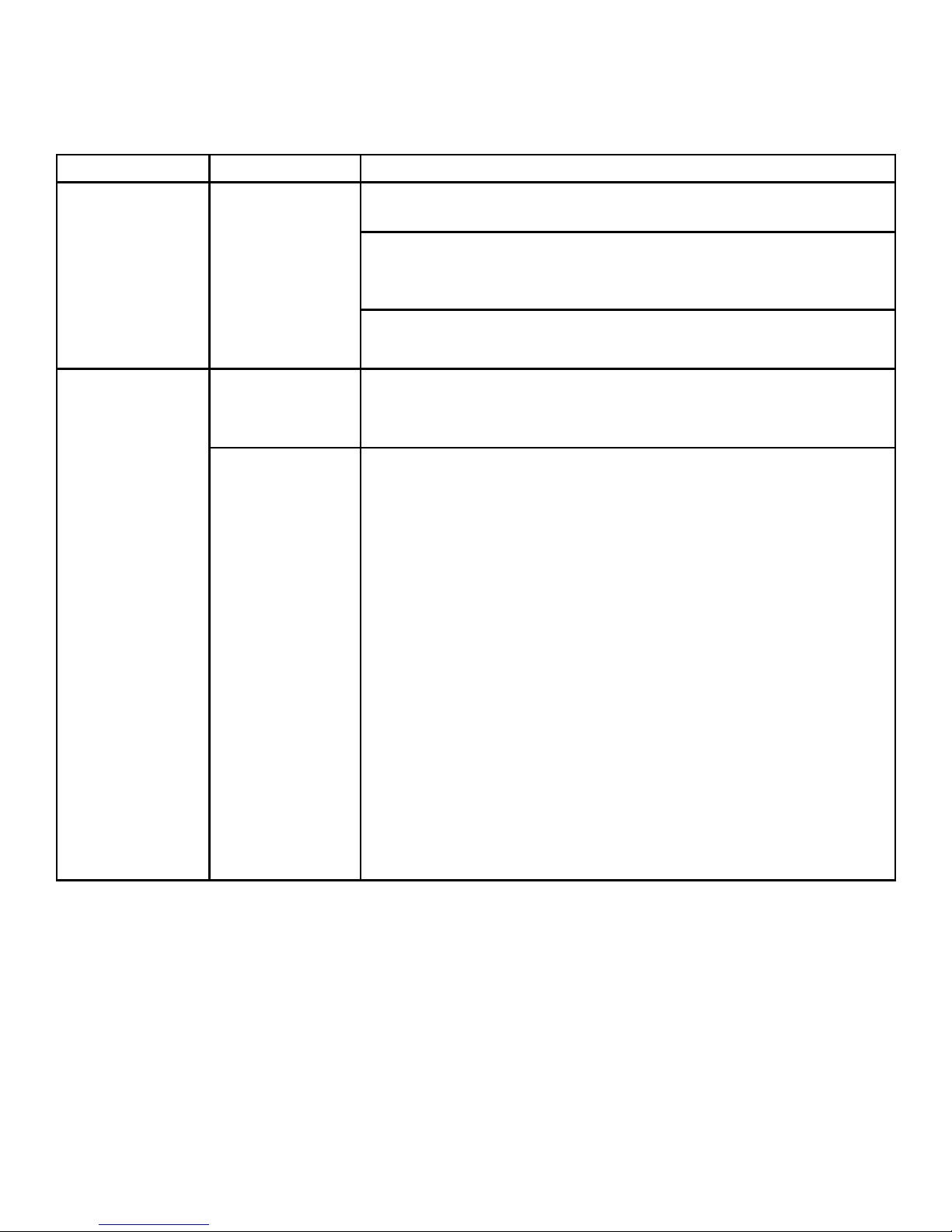

Impact Sprinkler Troubleshooting Guide Continued

Problem Cause Remedy

B. Sprinkler

rotates to one

side and stops.

3. Trip spring broken or

other trip mechanism

parts damaged.

a. Metal models: Replace with trip assembly repair kit for your model.

b. Plastic models: Only trip spring is replaceable. Call our toll free hotline

for replacement springs. 1-800-RAIN-BIRD

4. Trip collar missing. a. Metal models: Replace with repair kit for your specific model.

b. Plastic models: Call our toll free hotline for replacement plastic arc ad-

justers. 1-800-RAIN-BIRD

5. Trip pin missing or not

in downward position.

a. Call our toll free hotline for replacement trip pins for most models. 1800-RAIN-BIRD

C. Special problems with Pop Up

sprinklers in

cases (rotors).

6. Pop-up models:

debris in case.

1. Unit will not pop up or

down.

2. Case fills up with wa-

ter.

a. Check for debris or water in case which could restrict movement of

sprinkler head.

a. Check for insufficient water pressure to fully pop up unit or seal internal

assembly.

b. Remove dirt or debris from case which may be obstructing pop up/down

action.

c. Check that internal assembly is properly screwed into case.

d. Rock or debris trapped in retract spring or spring is damaged.

e. Remove internal assembly from case using wrench available for your

model. Disassemble, inspect for damage or foreign materials, clean and

reassemble.

a. Check as in Section C-1 a and c above. If water is coming out around

seal. there may be dirt lodged between the seal and pop up shaft preventing sealing, or seal may need replacing.

b. Internal assembly may not be properly screwed into case.

c. Case installed too low without sufficient gravel drainage below sprinkler.

Try enlarging the drain holes with a screwdriver.

d. Dense, clay soil may not allow swift drainage of sprinkler even with

gravel drainage area.

D. Water continues to leak out of

sprinkler when

system is turned

1. This is not a problem

with the sprinkler, but

rather with one of the two

points at right.

off.

a. Water continues to drain out of the lowest sprinkler head on the line for

a period of time when system is shut off. The less the angle of slope and

the longer the length of pipe, the longer it takes for all the water to drain.

Consult your local Rain Bird contractor about sprinklers which contain a

built-in check valve to prevent water in the pipe from draining out of the

sprinkler head.

b. Valve controlling sprinkler line is not shutting off all the way and allowing water to continue seeping through. If water continues to leak from the

sprinkler head when area has not been watered within the last day, a faulty

valve is most likely the cause.

4

Page 5

IMPACT SPRINKLER DISASSEMBLY 15111A

Cover Assembly

Internal Assembly:

1511A/B

(Metal Sprinkler)

Case

Diffuser Screw

Nozzle Vane

Nozzle

Head

Assembly

Swivel Bearing

Assembly

Arm Spring

Trip Collar

Drain Holes

Body

Trip

Pin

Trip

Mechanism

Bearing

Washers

Arm

Trip

Spring

Guide Seal

Guide Nut

Retract Spring

Guide Sleeve

Assembly

Pop-up Shaft

Inlet Screens

Inlet

5

Page 6

POP UP UNITS IN A CASE

For Metal or Plastic sprinklers, remove unit from case using special Rain Bird wrench for your unit.

Wrenches are available where Rain Bird underground sprinklers arc sold. Sprinkler portion of unit is

detachable from pop-up stem using a 1/2" hex wrench with a 6" extension.

To remove and replace cover on top of sprinkler:

Metal models - Unscrew cover retainer screw and remove damaged cover. Replace cover and

screw.

Plastic models - Pry out the center button with a screwdriver and, using needle-nosed pliers, carefully pinch together the retaining bracket on top of the sprinkler.

Remove old cover. Snap on new cover and replace center button.

Cover

Case

42064 Wrench

n For LG-3, and MG-4 Sprinklers

n AG-5, 2045-A

Wrench

Sleeve

41045 Wrench

n For 15111A Sprinkler

Sleeve

Screen

6

Page 7

DISASSEMBLY OF METAL SPRINKLER HEAD

To replace the trip collar and bearing washers, lock the body of sprinkler in a vise, making sure the

sprinkler arm is not touching the vise. Insert a file into nipple slot (figure A) or use a bearing wrench.

Rotate file counterclockwise to unscrew nipple. Clean nipple in a solvent if necessary, to remove corrosion and dirt before installing washer.

To replace the arm or arm spring, you will need to disassemble the top portion of the sprinkler.

Grasp the pin at the top of the sprinkler with a pair of large diagonals or side cutting pliers and pry

out (See Figure B). Take note of the way the arm spring is held in place. Use a pair of needle-nosed

pliers to remove the spring.

To replace trip assembly, grasp trip shaft (See Figure C) with a pair of pliers and remove. Attach the

"E" ring to the end of the new trip shaft that does not have vertical grooves. Install the lower trip

and the upper trip on the trip shaft. Insert the bent end of the new trip spring into the small hole in

the upper trip, and slip the other end of the spring into the small "U" notch in the lower trip. Insert

new trip shaft into the sprinkler (Figure C). Gently tap in until there is a small clearance between the

trips. When finished, the lower trips should "click" when pushed back and forth.

Bearing

Assembly

Slot

File

How to replace friction collars and

bearing washer

Figure A

Trip Spring

Upper Trip

Casting

Fulcrum Pin

Pry Down

Removing the fulcrum pin

Figure B

Make bend such that

spring will pivot freely

and cut off excess.

Changing the Trip Mechanism

Trip

Shaft

Trip Washers

“E” Ring

Flat Collars:

Install the round wire spacer

onto the bearing, then install

the new friction collars.

7

Round Collars:

Discard the round wire

spacer, then install the new

friction collars.

Installing Trip Collars

Figure D

Page 8

DISASSEMBLY OF PLASTIC SPRINKLER HEAD

Most components of plastic sprinkler heads are not detachable for cleaning or replacement. It is,

however, possible to install a new trip spring using a needle-nosed pliers or plastic arc adjusters

without damaging the sprinkler. On pop-up models, the cap can be replaced. Call our toll free hotline for availability of parts for your particular model. 1-800-RAIN-BIRD

PARTS AND REPAIR SERVICES

A variety of parts and parts assemblies are available for Rain Bird metal and plastic sprinklers. If

your local Rain Bird dealer does not carry the part you need, ask if it can be ordered, or call our toll

free Technical Services hotline at 1-800-RAIN-BIRD for dealer referral or factory direct ordering information. If you are unsure of the model you have or need help in identifying or finding a part, the

Technicians on our toll-free line are eager to assist you. A parts breakdown on your particular

model is available upon request. In addition, the Rain Bird Parts Service Center offers a repair service on many of our metal sprinklers for a nominal fee; please see our website at www.rainbird.com.

If you have any questions about the items addressed in this pamphlet or any Rain Bird products,

IMPACT SPRINKLER PARTS

4

5

3

12

13

6

7

17

18

19

20

11

Maxi-Paw Mini-Paw

AG-5 LG-3

2045-A MG-4

Please see parts number chart on the next page.

8

9

10

10

16

15

1

2

21

8

Page 9

BBIRDIRD®RRAINAIN

MASTER PARTS LIST

PART CIRCLE ROTOR

Date: 2/95

Page: 1 of 1

MINI-PAW / MAXI-PAW / MAXI-PAW SAM

Ref. Part Description Mini-Paw Maxi-Paw Maxi-Paw-SAM

CASES

1 Case Assembly 205175-01 207281-01 207281-01

2 Plug 208320 208320 208320

COVER ASSEMBLIES

3 Cover Kit 206973 208001 208001

4 Dust Cap (A) (204423-07) (204423-12) (204423-12)

5 Cover, Snap On (A) (204422-01) (207301) (207301)

NOZZLES (B)

6 Low Angle Nozzle — 115902 115902

6 Standard Nozzle — 206592 206592

7 Vane — 202141 202141

INTERNAL ASSEMBLY (B) 206678 206644 206637

8 Head Assembly (B) (A) (206776) 206638 206638

Diffuser Screw 203933 203933 203933

Trip Spring 207740 207740 207740

Bearing Hood (Black) (C) (202965) (C) (202965) (C) (202965)

9 Upthrust Spring (C) (203871) (C) (203871) (C) (203871)

10 Bearing Washer (Blue) (C) (206071) (C) (206071) (C) (206071)

11 Pop-Up Sleeve Assembly 202415 202415 204400

12 Guide Nut 204555 204555 204555

13 O-Ring Seal 202011 202011 202011

14 Retract Spring (202012) (202012) (204398)

15 Guide SIeeve 203171 203171 203171

16 Friction Collars (2) 203148 203148 203148

17 Buna N Washer (Black) (C) (203363) (C) (203363) (C) (203363)

18 Wearing Washer (White) (C) (204374) (C) (204374) (C) (204374)

19 Brg Backup Washer (Gray) (C) (0(202138) (C) (202138) (C) (202138)

20 Body Retainer (C) (202007) (C) (202007) (C) (202007)

21 Inlet Screen (Standard) 202076 202076 —

21 SAM Screen/Seal Assembly — — 205396

MINI-PAW WRENCH 42064

Catalog No.: 401

(A) Included in Body Cover Assembly # 206974. (Specify nozzle size.)

(B) Specify nozzle size when ordering.

(C) Included in Bearing Washer Kit # 202190.

NOTE: Part numbers enclosed in brackets ( ) are not available individually, but may be sold in assem-

blies or kits.

INSURE QUALITY - USE ONLY GENUINE RAIN BIRD PARTS

© COPYRIGHT 1991 RAIN BIRD SPRINKLER MFG. CORP.

9

Loading...

Loading...