Page 1

C+ SERIES

SELF CLEANING WATER FILTER

OPERATION & MAINTENANCE MANUAL

Page 2

CONTENTS

Filter Basics

1

Installation Requirements

Flush Line 2

Hydraulic Piston 3

Couplings 2

Hydraulic Connections 3

2

Filter Performance

Backwash Cycle 4

Normal Operation 3

3

Flow & Pressure Requirements

5

Maintenance & Spare Parts

Shutdown 6

Periodic Maintenance 6

Spare Parts 7

Particle Remover 7

Hydraulic Piston 8

Startup 5

5

Installation & Wiring

2x C+ Series Filters in Parallel 10

C+ Series Filter 9

9

Warranty

11

Page 3

Filter Basics

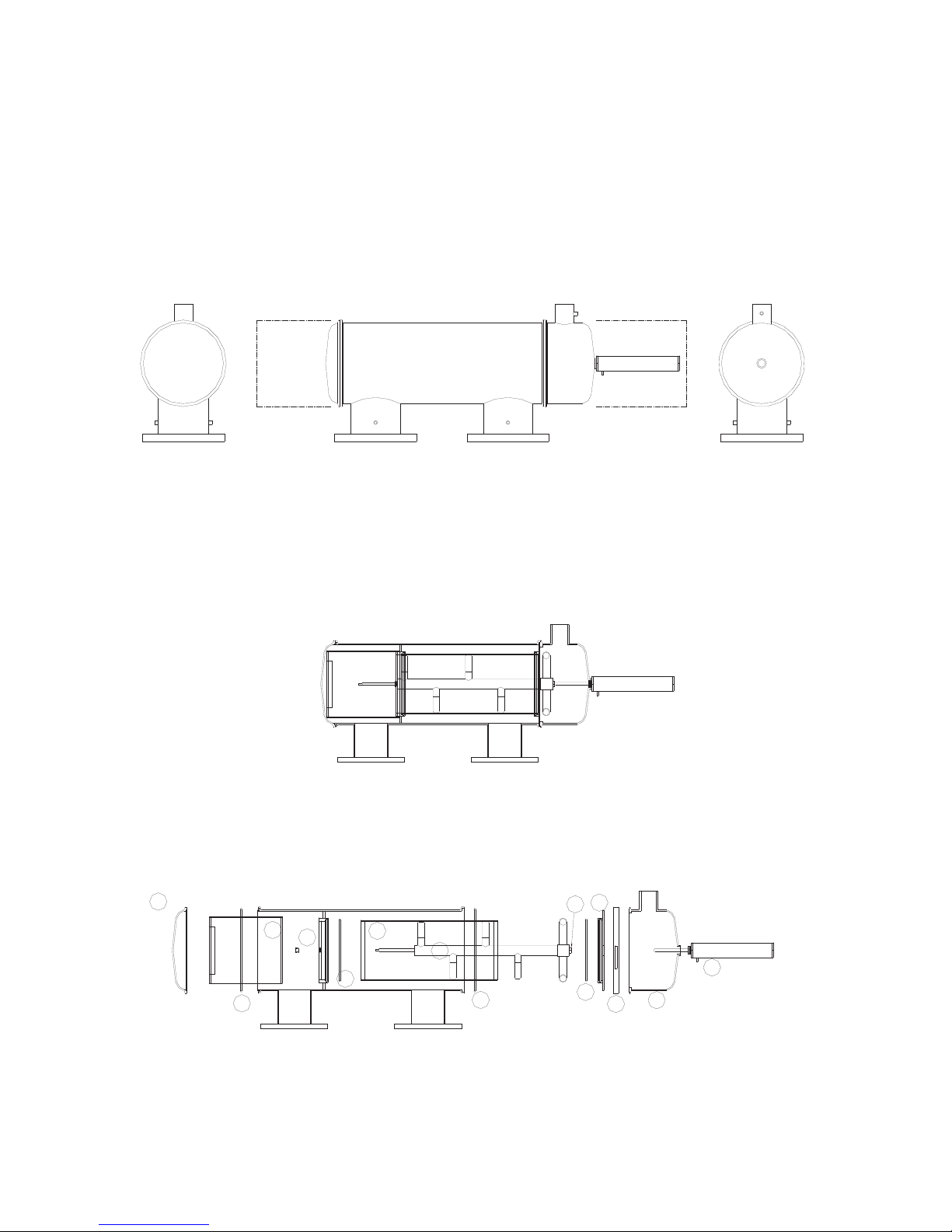

The Rain Bird C+ Series is a self cleaning screen water filter. The major components

include the Filter Housing (1), Coarse Screen Pre-Filter (11), Fine Screen Filter

Element (2), Particle Remover (3), Hydraulic Piston (8), and Backwash Valve

(12).

C+ SERIES FILTER - GENERAL LAYOUT

N3

SCREEN

SERVICE AREA

10 x 11.5

K3

SCREEN

SERVICE AREA

12 x 11.5

K1

N1

N1

INLET

N2

OUTLET

N3

FLUSH OUTLET

K1

HYD CONNECTION

K2

HYD CONNECTION

K3

HYD CONNECTION

K2

N2

C+ SERIES FILTER - ASSEMBLED VIEW

C+ SERIES FILTER - EXPLODED VIEW

1

11

4

5

1. FILTER HOUSING

2. FINE SCREEN

3. PARTICLE REMOVER

4. BUSHING

5. HOUSING SEAL

1

7

2

3

6

5

6

10

1

8

6. SCREEN O-RING

7. SPACER

8. HYDRAULIC PISTON

10. HOUSING CLAMP

11. COARSE SCREEN

1

Page 4

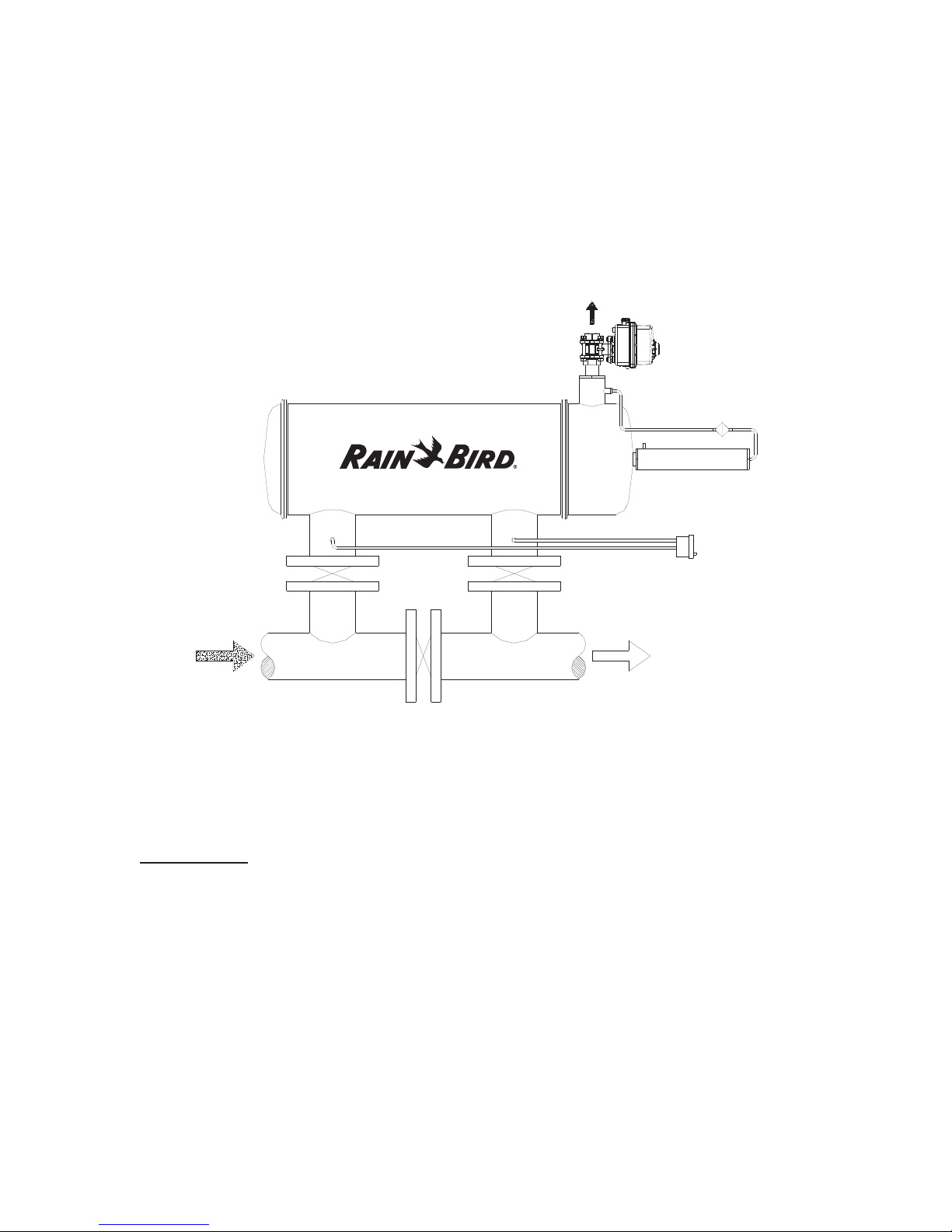

Installation Requirements

C+ Series filters may be mounted directly on the inlet (N1) and outlet (N2)

flanges, and positioned in any orientation. Isolation valves should be installed at

the inlet and outlet, and a bypass valve should be installed between the flanges.

This will allow the filter to be taken offline without disruption to water flow.

C+ SERIES FILTER - INSTALLATION LAYOUT

FLUSH

Filter

Differential

Pressure

Gauge

INLET

Isolation

Valve

Bypass

Valve

Isolation

Valve

OUTLET

There should be adequate clearance around the filter to allow for easy

maintenance access, including a minimum of 24” from the back (piston side). The

minimum clearance on the front (cover) depends on the model. There must be

enough room to remove the coarse screen and fine screen periodically.

FLUSH LINE

The piping for the flush valve must have no backpressure. It is strongly

recommended to use oversized piping to accommodate this requirement. For a

1” valve, 1.5” or 2” pipe must be used.

To minimize backpressure on the flush line, it is also important to avoid elevation

gain in the flush line. Even a small elevation gain can reduce the filter’s ability to

perform an effective backwash cycle. If flush water must be transported to higher

elevation, it is recommended to pipe the flush line to a storage tank first, and then

pump out to higher elevation.

2

Page 5

HYDRAULIC CONNECTIONS

Each flanged connection nozzle (N1 & N2) on the C+ filter has two ¼”

threaded couplings. One may be used to install a pressure gauge or other sensor

equipment. The other ¼” coupling will be used to connect hydraulic tubing from

the differential pressure switch to the filter. The high pressure line is fitted to the

inlet, and low pressure fitted to the outlet.

HYDRAULIC PISTON

The piston (8) is mounted on the flush end of the filter. ¼” tubing must be

installed from the fitting located on the back of the piston to the hydraulic

connection (K3) on the flush outlet (N3). A filter is installed on the hydraulic

tubing to protect the piston.

Filter Performance

NORMAL OPERATION

During normal operation of the filter, dirty water enters through the inlet and

passes through the coarse screen. Any abnormally large debris is caught here

and prevented from possibly damaging the fine screen or particle remover.

Water then travels down the center of the filter and is strained across the fine

screen. As water passes from inside the screen to outside, suspended particles

are trapped on the fine screen and continue to buildup, eventually creating a drop

in pressure at the outlet of the filter.

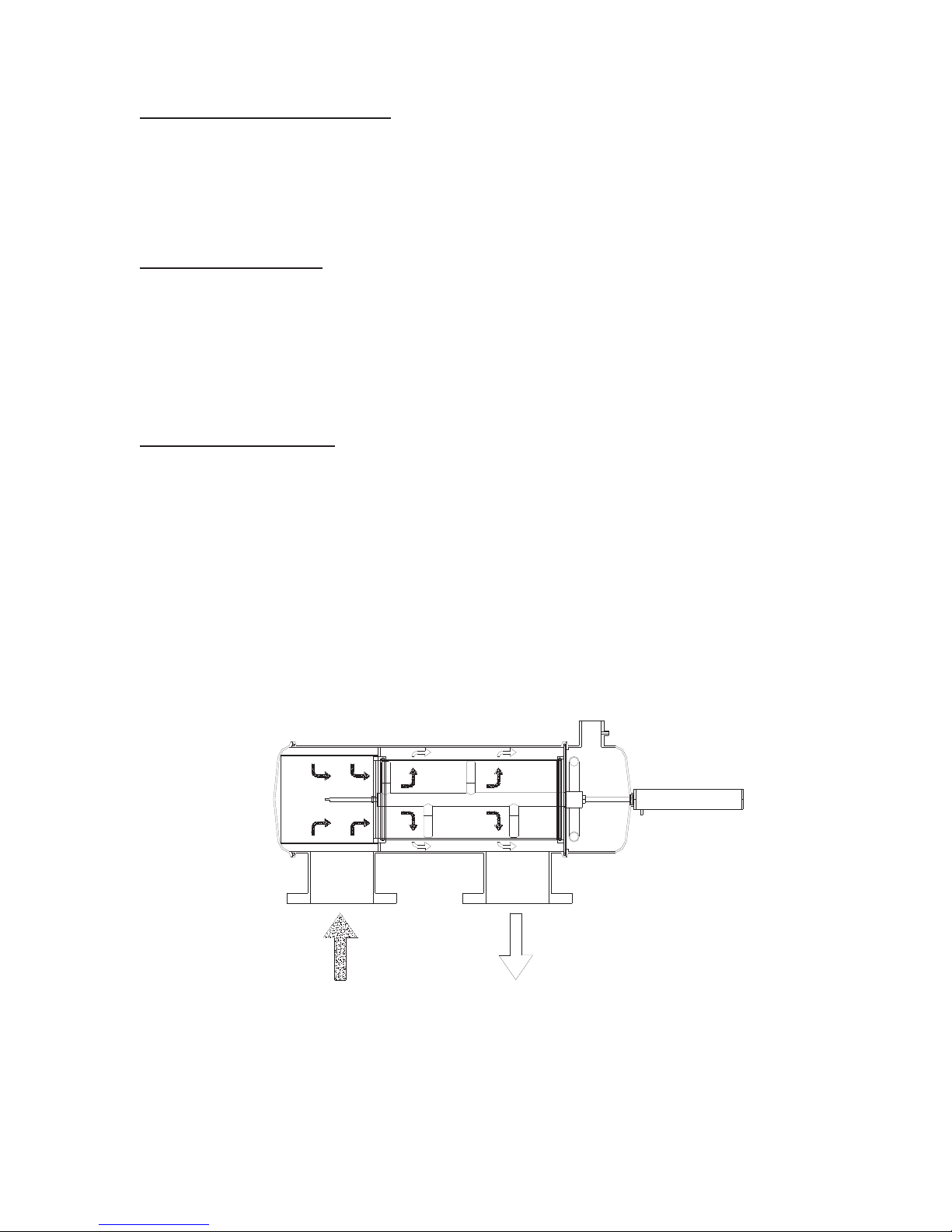

C+ SERIES FILTER - NORMAL OPERATION

This drop in outlet pressure is monitored by the differential pressure gauge,

which at seven PSID (pounds per square inch differential) sends a signal to the

controller to initiate a backwash cycle.

3

Page 6

BACKWASH CYCLE

The controller opens the flush valve, which causes a drop in pressure in the

hydraulic motor chamber. This creates a low pressure path inside the particle

remover, which acts as a vacuum at the end of the suction nozzles, removing the

built up debris from the inside of the fine screen.

C+ SERIES FILTER - BACKWASH CYCLE

FLUSH

INTERIOR OF FILTER

(HIGH PRESSURE)

HYDRAULIC MOTOR CHAMBER

(LOW PRESSURE)

Water flows through the suction nozzles, down the interior of the particle

remover, and out the hydraulic motor. The motor rotates the particle remover,

enabling each suction nozzle to cover a radial strip of screen. The pressure

difference between the interior of the filter and the hydraulic motor chamber

drives the particle remover toward the hydraulic piston.

The piston depressurizes during the backwash cycle, and expels the volume of

water from its chamber. This acts as a timer, gradually allowing the particle

remover to drive the piston rod into the piston, assuring that the suction nozzles

cover the entire surface of the fine screen. When the piston reaches the end of

its stroke, the backwash cycle is complete, and the flush valve closes. Pressure

inside the hydraulic motor chamber normalizes, and the piston pushes the

particle remover back to its original position.

After the piston and particle remover move back to their original positions, the

filter returns to normal operation. During the entire backwash cycle, the main flow

through the filter is never disrupted.

4

Page 7

Flow & Pressure Requirements

Rain Bird C+ Series filters have a minimum pressure requirement of 15 PSI. This

includes any pressure loss incurred during the backwash cycle. Therefore the

pump performance is a crucial component in determining whether the filter will

perform correctly.

Pump manufacturers will provide the performance data in the form of a pump

curve. This is a graph that plots pressure vs. flow rate. A pump is considered

adequate for an application if it can maintain a minimum of 15 PSI while pumping

the normal system flow AND the additional flow required during backwash. The

additional flow depends on the filter model and what valve is used.

C+ SERIES FILTERS

VALVE FLOW RATES

Valve Flow Rate

1" 40 gpm

1.5" 100 gpm

2" 220 gpm

Maintenance & Spare Parts

STARTUP

When pumping water through the Rain Bird C+ Series for the first time or after it

has been emptied, it is important to follow a correct sequence of valve actuation

in order to prevent damage to the filter components.

With both isolation valves closed and the bypass valve open, the correct

sequence is:

1. Slowly open the inlet isolation valve letting water flow into the filter. If

2. Close the bypass valve.

3. Open the outlet isolation valve.

If it is not possible to close the bypass valve momentarily before opening the

outlet valve, then both may be actuated simultaneously.

installed, bleed the air through a valve on the top of the filter body. Let the

entire filter fill with water before moving to the next step.

5

Page 8

SHUTDOWN

To remove the filter from operation, reverse the steps used for startup.

1. Close the outlet valve.

2. Open the bypass valve

3. Close the inlet valve, and slowly open the drain valve on the bottom of the

filter housing. There will be residual pressure in the tank still, so use

caution when draining.

If it is not possible to close the outlet valve momentarily before opening the

bypass, then both may be actuated simultaneously.

PERIODIC MAINTENANCE

Every six months to a year, or during scheduled down-time it is recommended to

open the filter and inspect the components. Access to the internal components is

through the front cover and hydraulic motor chamber.

Remove the piston from the back filter and drain the water from the hydraulic

motor chamber. Verify that the piston rod is moving smoothly in and out, and

inspect the piston tip for wear.

C+ SERIES FILTER - PERIODIC INSECTION

Remove the hydraulic motor from the rest of the particle remover by accessing it

through the piston-side cover.

Remove the screen and particle remover, using the piston-side cover for access.

Separate the two items and inspect them carefully. The screen mesh and

bushing should be inspected for wear, as well as the particle remover rod and

suction nozzles.

6

Page 9

SPARE PARTS

Spare parts for maintenance for two years include:

Screen O-rings (6)

Cover Seal (5)

Suction Nozzles (3.5)

Bushing (4)

Differential Pressure Gauge (18)

Piston Shaft Tip (8.9)

Piston Seal Kit (8K)

Mini-Filter (16)

Valve (p/n 12)

Fine Screen (2)

Particle Remover (3)

Spacer (7)

PARTICLE REMOVER - PART LIST

ITEM

Particle Remover

Rod

Counter-Nut

Casing

Rotating Sprinkler

Nozzles

Insert 3.6

PART NUMBER

3

3.1

3.2

3.3

3.4

3.5

3.1

3.2

3.3

3.6

3.4

7

Page 10

8-C+

8.01-C+

8.02-C+

8.03-C+

8.05-C+

8.08-C+

8.10-C+

8.11-C+

8.12-C+

8.14-C+

8.15-C+

8.06-C+

PART NUMBER

8.16-C+

ITEM

Shaft

Snap Ring

Head Ring

Shaft U-cup

Head O-ring

Hydraulic Piston

Piston Pin

Shaft O-Ring

8.16

Casing

Casing Cap

U-cup Holder

Casing U-cup

Piston Head

8.05

8.03

8.02

8.01

8.10

8.03

8.08

C+ SERIES PISTON

8.11

8.12

8.15

8

Page 11

F2-110/220

FLUSH

W R W

Valve Connections

Red-----------W(left)

Black-------W(right)

White---------------1

Filter

PD DWELL 1 2 ALARM

MANUAL

START/

ADVANCE

COUNTER

RESET

ALARM

RESET

POWER

OFF

ON

W R W 1C PDAM2

1

C

P

OFF

E

1/4

24

R

18

1/2

I

O

1

12

D

I

2

8

C

346

(HOURS)

BACKWASH

F

2

L

5

COUNT

180

U

150

10

S

H

15

120

20

90

60

30

45

(SEC)

D

0

W

2

90

E

75

5

L

L

10

60

50

15

203040

(SEC)

PDAM2

INLET

Isolation

Valve

Bypass

Valve

Isolation

Valve

OUTLET

Differential

Pressure

Gauge

9

Page 12

F2-110/220

OFF

ON

POWER

MANUAL

START/

ADVANCE

COUNTER

RESET

ALARM

RESET

Y

OR

PD DWELL 1 2 ALARM

Y 1

P

OFF

E

1/4

24

R

18

1/2

I

O

1

12

D

I

2

8

C

346

(HOURS)

BACKWASH

F

2

L

5

COUNT

180

U

150

10

S

H

15

120

20

90

304560

(SEC)

D

0

W

2

90

E

75

5

L

L

10

60

50

15

203040

(SEC)

PDAM2

C

INLET

Isolation

Valve

Bypass

Valve

FLUSH

Isolation

Valve

OUTLET

W R W 1

C

Valve Connections

Red-----------W(left)

Black-------W(right)

White---------------1

Filter

Differential

Pressure

Gauge

PDAM2

Valve

Isolation

Valve

Isolation

FLUSH

Filter

Valve Connections

Red-----------W(left)

Black-------W(right)

White---------------2

01

Page 13

WARRANTY

Rain Bird Corporation guarantees all self cleaning water filters, components, and

accessories free of defects for one year from the date of installation, or 18 months from

the date of original shipment. Rain Bird will replace any part found defective during the

warranty period, provided the equipment in question was handled, installed, and

operated in accordance with the operation and maintenance manual and sound

engineering practices. Rain Bird assumes no liability for incidental or consequential

damage resulting from the use of its products, services, or data. Liability is limited to

replacement or repair of products provide by Rain Bird , and no agent or sales

representative has authority to extend the warranty period without the express written

consent of Rain Bird . Shipping charges for returned equipment will be at the expense

of the purchaser, and all returned equipment must be sent to Rain Bird Corporation.

11

Page 14

Rain Bird Corporation

6991 E. Southpoint Road

Tucson, AZ 85756

Phone: (520) 741-6100

Fax: (520) 741-6522

Filter Support

1-877-648-9532 (U.S. and Canada)

lters@rainbird.com

Rain Bird Corporation

970 West Sierra Madre Avenue

Azusa, CA 91702

Phone: (626) 812-3400

Fax: (626) 812-3411

www.rainbird.com

Rain Bird International, Inc.

1000 West Sierra Madre

Azusa, CA 91702

Phone: (626) 963-9311

Fax: (626) 852-7343

® Registered Trademark of Rain Bird Corporation

© 2016 Rain Bird Corporation 11/16

Loading...

Loading...